FCCA验厂要求

- 格式:docx

- 大小:14.90 KB

- 文档页数:2

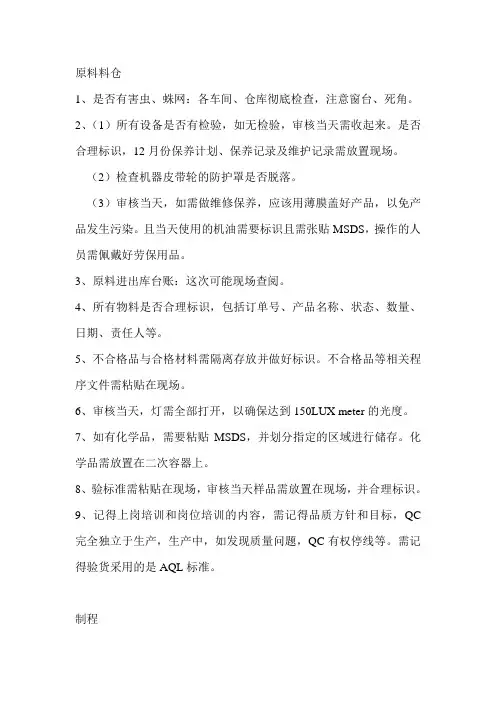

原料料仓1、是否有害虫、蛛网:各车间、仓库彻底检查,注意窗台、死角。

2、(1)所有设备是否有检验,如无检验,审核当天需收起来。

是否合理标识,12月份保养计划、保养记录及维护记录需放置现场。

(2)检查机器皮带轮的防护罩是否脱落。

(3)审核当天,如需做维修保养,应该用薄膜盖好产品,以免产品发生污染。

且当天使用的机油需要标识且需张贴MSDS,操作的人员需佩戴好劳保用品。

3、原料进出库台账:这次可能现场查阅。

4、所有物料是否合理标识,包括订单号、产品名称、状态、数量、日期、责任人等。

5、不合格品与合格材料需隔离存放并做好标识。

不合格品等相关程序文件需粘贴在现场。

6、审核当天,灯需全部打开,以确保达到150LUX meter的光度。

7、如有化学品,需要粘贴MSDS,并划分指定的区域进行储存。

化学品需放置在二次容器上。

8、验标准需粘贴在现场,审核当天样品需放置在现场,并合理标识。

9、记得上岗培训和岗位培训的内容,需记得品质方针和目标,QC 完全独立于生产,生产中,如发现质量问题,QC有权停线等。

需记得验货采用的是AQL标准。

制程1、是否有害虫、蛛网:各车间、仓库彻底检查,注意窗台、死角。

2、各车间检查利器是否绑定在工位上。

3、如用到化学品,需粘贴MSDS。

4、审核当天,现场需有首件样品,样品需有主管签名,有订单号,批号、日期等,以保证可追溯。

5、各车间需检查现场是否粘贴作业指导书,审核当天工序上需有IPQC。

6、包装部需有作业指导,审核当天包装车间需有工作台,包装好的产品需正确摆放,不能直接放在地上,需放在卡板上。

灯需全部打开,以确保达到150LUX meter的光度。

7、机器维修人员需有上岗培训。

8、IPQC是不属于生产部门管理,不帮忙生产,是独立于质检部。

工厂的检验标准是AQL标准。

9、公司质量方针:质量第一,信誉第一10、公司质量目标:1、成品外观以此检验合格率达98%。

2、产品交付合格率达100%。

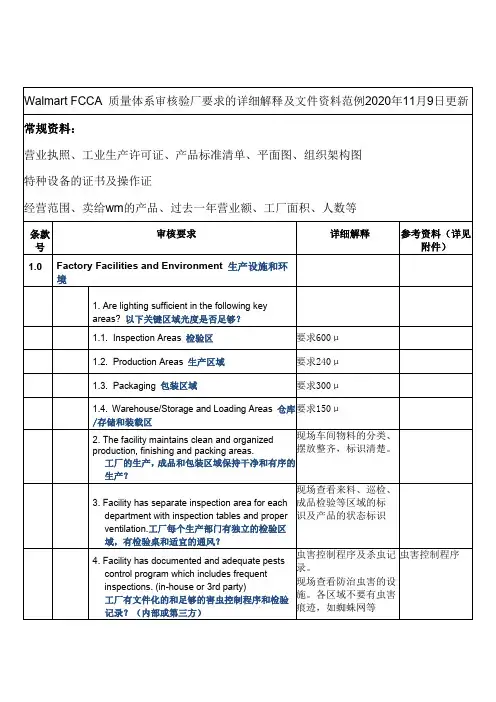

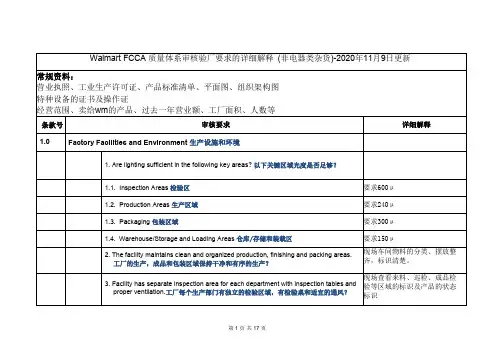

Walmart FCCA质量体系审核验厂要求的详细解释及文件资料范例2020年11月9日更新常规资料:营业执照、工业生产许可证、产品标准清单、平面图、组织架构图特种设备的证书及操作证经营范围、卖给wm的产品、过去一年营业额、工厂面积、人数等条款号审核要求详细解释参考资料(详见附件)1.0Factory Facilities and Environment生产设施和环境1.Are lighting sufficient in the following keyareas?以下关键区域光度是否足够?1.1.Inspection Areas检验区要求600μ1.2.Production Areas生产区域要求240μ1.3.Packaging包装区域要求300μ1.4.Warehouse/Storage and Loading Areas仓库/存储和装载区要求150μ2.The facility maintains clean and organized production,finishing and packing areas.工厂的生产,成品和包装区域保持干净和有序的生产?现场车间物料的分类、摆放整齐,标识清楚。

3.Facility has separate inspection area for eachdepartment with inspection tables and proper ventilation.工厂每个生产部门有独立的检验区域,有检验桌和适宜的通风?现场查看来料、巡检、成品检验等区域的标识及产品的状态标识4.Facility has documented and adequate pestscontrol program which includes frequentinspections.(in-house or3rd party)工厂有文件化的和足够的害虫控制程序和检验记录?(内部或第三方)虫害控制程序及杀虫记录。

更新日期:2020.1.6第1页共9页Walmart 沃尔玛FCCA 验厂标准清单条款对应的文件记录及现场巡视要求FCCA 生产能力评估清单书面程序记录现场巡视备注1.0工厂设施和环境1.在生产,修理,加工,检验,包装及装载的区域是否有足够的照明?►现场查看车间照明度:Wal-Mart的最低要求,生产区、成品区240lux,检测区域600lux,包装区域360lux,原料仓150lux2.工厂是否保持清洁,在生产,加工和包装区域是否有秩序?►现场车间物料的摆放整齐,标识清楚。

3.工厂是否有单独的检验区与检验台并且通风良好?►现场查看来料、巡检、成品检验等区域的标识及产品的状态标识4.工厂是否有害虫/霉菌和湿度的控制程序文件?是否有经常巡查(公司内部或第三方检查)?►灭虫/灭鼠控制程序►防潮/防霉菌控制程序►虫害/灭鼠巡查记录5.在审核其间有没有发现窗户破损及房顶漏水可能导致产品污染。

玻璃破碎控制程序玻璃破碎巡查记录►现场查看窗户玻璃有无破损6.工厂是否实行严格的利器控制程序,以防止剪刀、小刀、刀片、碎玻璃及针等混入产品中。

Critical 严重►利器控制程序\利器、断针►利器收发记录、利器、断针►现场查看利器的管理1.1机器校准和维护1.工厂是否有书面的文件系统和程序计划安排设备的清洁及维修。

►生产设施控制程序►机器设备保养记录2.工厂的机器和设备是否清洁及运行良好。

►现场查看3.机器、设备和工具是否有最近的维护/校准日期及计划日期的标识。

►检测设备控制程序►检测设备清单►检测设备校准计划►校准报告►现场看检测设备的校准标识4.需要维修机器、设备和工具是否有维修标识以避免意外使用。

►“LTT”挂牌5.工厂是否有适当,整洁的存储区域储存关键模具(比如:注射模具),并且放在有标识的架子上。

►现场查看(NA)6.工厂有适当的机器、工具、零部件和设备的库存文件,并保持更新。

►机器设备清单7.工厂是否拥有一定技术水平的保养团队和设备可以执行必要的机器维修和校准的工作维修部职务描述2.0质量管理体系1.工厂是否建立起符合他们产品和生产流程的质量管理体系。

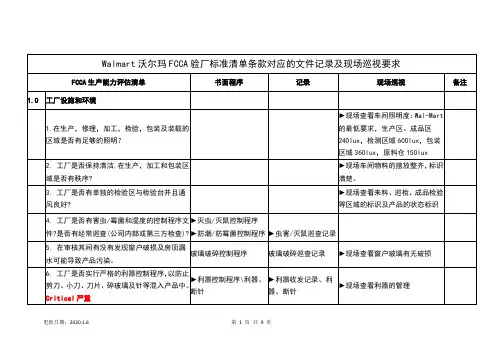

WM-FCCA相关部门基本要求品管部1、QC和主管要熟悉工厂质量方针和质量目标(全厂的和本部门的)。

及质量目标达成状况。

2、有与生产部管理参加解决质量问题的会议记录3、有产品产前会议记录(产前会议中有没有审查及确认严重的质量问题和安全问题并记录采取的改进行动)4、生产现场要有首件样品(根据客户签样和产品规格表来制定),首件报告及检验指导书5、授权当产品质量不符合规格时是有权停止生产的QC名单(有授权者签署)6、每个生产过程须要有IPQC巡查,及要有巡检记录7、 QC检验要求按照AQL抽样检验标准或按照工业标准检查,有记录8、最终产品要有实施100%功能性检查,有记录9、针对质量问题要有纠正措施和根本原因分析方法,有记录(现场返工及检验记录,供应商不良处理记录,10、包装检验作业指引,挂现场11、所有量规和测试设备是有效校准,有清单12、有相关测试工作指引13、内部实验室测试人员须接受培训执行测试工作14、有最终检验程序,最终检验QC要有工作指导书15、QC 要根据AQL抽样检验标准或行业标准来实施最终检验,有检验报告16、退货的产品在客户最终检验前要有得到适当纠正,有记录17、有只有在客户同意情况下才能出货的控制程序,请查找相关程序文件(请查找)18、货仓和生产车间的产品和物料有检验状态标识,要有正确物料检验标识,半成品检验标识,来料检验标识,成品检验标识19、有有效玩具安规。

20、有关键工序标识及相关的作业及检验指引。

21、实行严格的利器控制程序(系绳于工作台上),要有利器收发记录。

当天收发一定要按实际做。

22、准备相关ISO程序文件和三级作业指引文件。

23、本部门有相关培训记录。

24、现有所有QC报表25、成品仓成品检验标识及相应的检验报告。

生产部1、实行严格的利器控制程序(系绳于工作台上),要有利器收发记录。

当天收发一定要按实际做。

2、设备状态标识3、设备清洁和保养记录4、盛装化学品的容器警示标识和二次容器及相应的MSDS张贴5、合格物料和不合格物料标识,合格产品(半成品或成品等)标识及不合格产品(半成品或成品等)标识,要分隔存放且有合格和不合格区域状态标识。

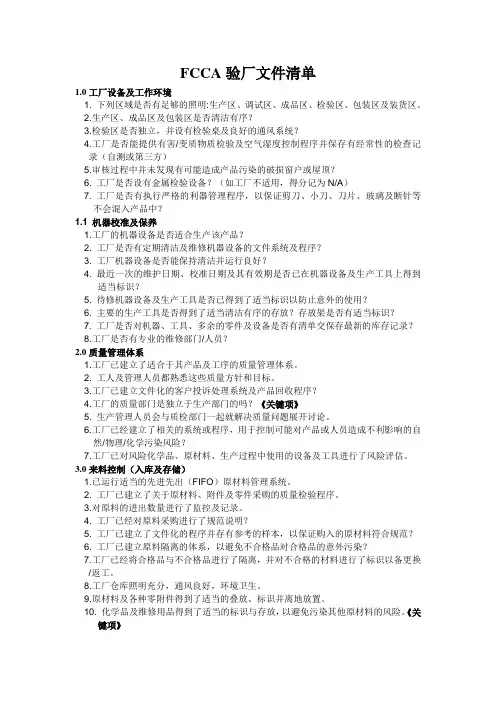

FCCA验厂文件清单1.0工厂设备及工作环境1. 下列区域是否有足够的照明:生产区、调试区、成品区、检验区、包装区及装货区。

2.生产区、成品区及包装区是否清洁有序?3.检验区是否独立,并设有检验桌及良好的通风系统?4.工厂是否能提供有害/变质物质检验及空气湿度控制程序并保存有经常性的检查记录(自测或第三方)5.审核过程中并未发现有可能造成产品污染的破损窗户或屋顶?6. 工厂是否设有金属检验设备?(如工厂不适用,得分记为N/A)7. 工厂是否有执行严格的利器管理程序,以保证剪刀、小刀、刀片、玻璃及断针等不会混入产品中?1.1 机器校准及保养1.工厂的机器设备是否适合生产该产品?2. 工厂是否有定期清洁及维修机器设备的文件系统及程序?3. 工厂机器设备是否能保持清洁并运行良好?4. 最近一次的维护日期、校准日期及其有效期是否已在机器设备及生产工具上得到适当标识?5. 待修机器设备及生产工具是否已得到了适当标识以防止意外的使用?6. 主要的生产工具是否得到了适当清洁有序的存放?存放架是否有适当标识?7. 工厂是否对机器、工具、多余的零件及设备是否有清单交保存最新的库存记录?8.工厂是否有专业的维修部门/人员?2.0质量管理体系1.工厂已建立了适合于其产品及工序的质量管理体系。

2. 工人及管理人员都熟悉这些质量方针和目标。

3.工厂已建立文件化的客户投诉处理系统及产品回收程序?4.工厂的质量部门是独立于生产部门的吗?《关键项》5. 生产管理人员会与质检部门一起就解决质量问题展开讨论。

6.工厂已经建立了相关的系统或程序,用于控制可能对产品或人员造成不利影响的自然/物理/化学污染风险?7.工厂已对风险化学品、原材料、生产过程中使用的设备及工具进行了风险评估。

3.0来料控制(入库及存储)1.已运行适当的先进先出(FIFO)原材料管理系统。

2. 工厂已建立了关于原材料、附件及零件采购的质量检验程序。

3.对原料的进出数量进行了监控及记录。

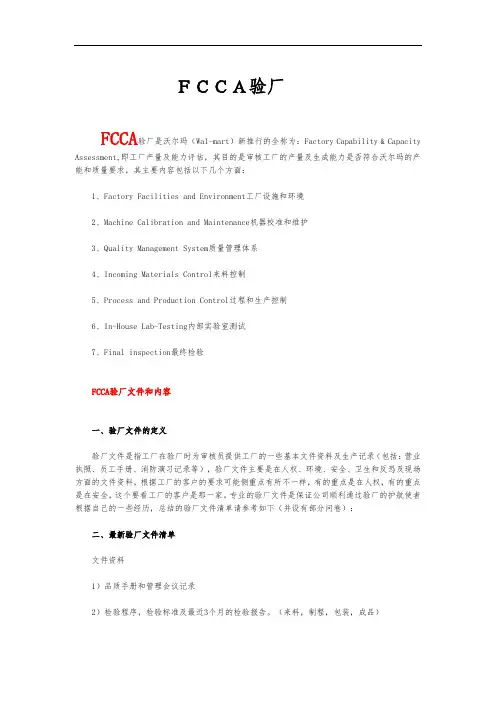

FCCA验厂FCCA验厂是沃尔玛(Wal-mart)新推行的全称为:Factory Capability & Capacity Assessment,即工厂产量及能力评估,其目的是审核工厂的产量及生成能力是否符合沃尔玛的产能和质量要求,其主要内容包括以下几个方面:1、Factory Facilities and Environment工厂设施和环境2、Machine Calibration and Maintenance机器校准和维护3、Quality Management System质量管理体系4、Incoming Materials Control来料控制5、Process and Production Control过程和生产控制6、In-House Lab-Testing内部实验室测试7、Final inspection最终检验FCCA验厂文件和内容一、验厂文件的定义验厂文件是指工厂在验厂时为审核员提供工厂的一些基本文件资料及生产记录(包括:营业执照、员工手册、消防演习记录等),验厂文件主要是在人权、环境、安全、卫生和反恐及现场方面的文件资料,根据工厂的客户的要求可能侧重点有所不一样,有的重点是在人权,有的重点是在安全,这个要看工厂的客户是那一家。

专业的验厂文件是保证公司顺利通过验厂的护航使者根据自己的一些经历,总结的验厂文件清单请参考如下(并设有部分问卷):二、最新验厂文件清单文件资料1)品质手册和管理会议记录2)检验程序,检验标准及最近3个月的检验报告。

(来料,制程,包装,成品)3)主要机器设备清单(请准备中英文复印件各一份)4)机器设备保养计划和记录5)机器保养人员的专业证书6)产品规格书7)原料的来料和发料记录8)员工培训计划及培训记录9)产前会议程序及记录和质量会议记录10)供应商管理程序,记录,采购单及物料规格单11)实验室操作手册及测试报告12)缺陷统计报告及出货记录13)工厂组织架构图(请准备复印件一份)14)工厂营业执照(请准备复印件一份)15)当前的品质水准记录16)出货及时率的统计记录17)ISO证书及最近一次的审查报告(如有,请准备正本及复印件一份) 18)纠正预防措施的记录现场布设1)安全通道线2)安全出口、应急灯、火警铃3)化学药品摆放4)仓库特殊要点5)饮水区划分6)意见箱的设立及程序文件三、反恐重点C-TPAT证书保安制度装柜作业程序货柜检查程序及纪录封柜纪录封条管理程序则人权是随机抽查的FCCA验厂审核项目一、童工CL/未成年工U L二、非志愿劳工IL三、胁迫与骚扰CH四、不歧视DI五、最低工资WM六、加班工资OW七、加班时间OT八、社会保险SB九、福利OB十、监测与守法十一、卫生与安全HS&DO十二、宿舍DO十三、环保PE十四、分包Sub十五、其它要求OLFCCA质量验厂文件资料清单1. 营业执照 ;2. 质量体系认证证书 ;3. 组织架构图 ;4. 质量手册 ;5. 程序文件;6. 质量体系内审计划;7. 质量体系内审记录:1)内审员资格证书;2)首末次会议 ;3)检查表 ;4)不符合项报告;5)内审报告8. 质量体系管理评审计划9. 质量体系管理评审记录: 1)管理评审会议记录;2)管理评审报告;3)决议事项的跟进记录10. 主要生产设备清单;11. 设备保养计划 ;12. 设备保养记录;13. 仪器清单 ;14. 仪器校准计划 ;15. 仪器校准记录:1)外校报告 ;2)内校人员资格证书3)内校规程;4)内校报告16. 年度培训计划17. 培训记录 :1)签到表;2)测试卷18. 品管人员岗前资质认定资料(培训及测试记录;19. 新产品设计开发资料 :1)产品规格书;2) BOM表(BOM);3)安规认证证书;4)样品检测报告5)试产记录 ;6)试产评估报告 ;7)作业指导书 ;8)检验标准 ;9) FMEA分析资料 ;10)产品质量控制计划(QC工程图。

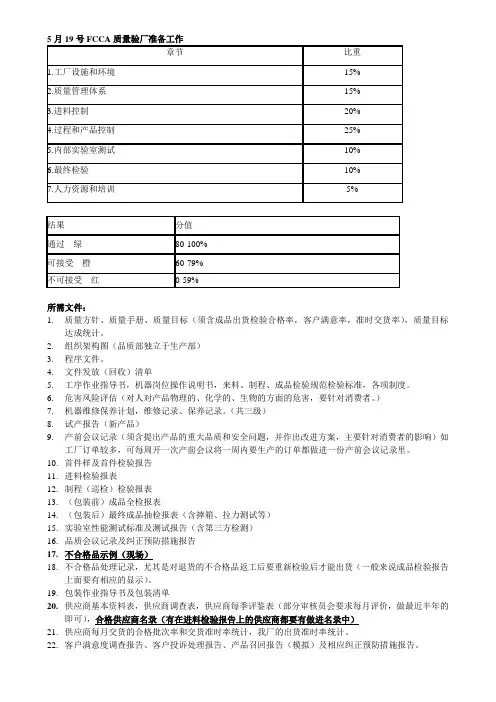

所需文件:1.质量方针、质量手册、质量目标(须含成品出货检验合格率,客户满意率,准时交货率),质量目标达成统计。

2.组织架构图(品质部独立于生产部)3.程序文件。

4.文件发放(回收)清单5.工序作业指导书,机器岗位操作说明书,来料、制程、成品检验规范检验标准,各项制度。

6.危害风险评估(对人对产品物理的、化学的、生物的方面的危害,要针对消费者。

)7.机器维修保养计划,维修记录、保养记录。

(共三级)8.试产报告(新产品)9.产前会议记录(须含提出产品的重大品质和安全问题,并作出改进方案,主要针对消费者的影响)如工厂订单较多,可每周开一次产前会议将一周内要生产的订单都做进一份产前会议记录里。

10.首件样及首件检验报告11.进料检验报表12.制程(巡检)检验报表13.(包装前)成品全检报表14.(包装后)最终成品抽检报表(含摔箱、拉力测试等)15.实验室性能测试标准及测试报告(含第三方检测)16.品质会议记录及纠正预防措施报告17.不合格品示例(现场)18.不合格品处理记录,尤其是对退货的不合格品返工后要重新检验后才能出货(一般来说成品检验报告上面要有相应的显示)。

19.包装作业指导书及包装清单20.供应商基本资料表,供应商调查表,供应商每季评鉴表(部分审核员会要求每月评价,做最近半年的即可),合格供应商名录(有在进料检验报告上的供应商都要有做进名录中)21.供应商每月交货的合格批次率和交货准时率统计,我厂的出货准时率统计。

22.客户满意度调查报告、客户投诉处理报告、产品召回报告(模拟)及相应纠正预防措施报告。

23.员工年度培训计划,员工培训记录及考核表(含新员工岗前培训、机修人员电工的培训、品质部人员的培训、技术员的培训、机器操作人员的培训等)24.温湿度记录(当月的贴温湿度计旁边,温湿度计不能是水银的,要指针式的)。

25.虫害霉变巡查记录(最近三个月的,每天巡查)26.杀虫灭鼠记录,最近三个月每月一次。

FCCA质量验厂最新审核要求内容及评分标准评分标准质量体系工厂未设有金属检验设备。

工厂有备用电力设备但运行状况并不佳工厂的机器设备并不适合工厂机器设备比较陈旧且能发现机油渗漏的迹象是的,工厂可以提供机器、工具、多余的零件及设备清单及工厂可以提供机器、工具、多余的零件及设备清单,但无最新的库存记录工厂有专业的维修队伍,且有工厂的维修队伍未能达到要求,缺乏专业性且装备不足及工序的质量方针及程序,该工厂已建立了适合于其产品及工序的质量方针及程序,但内容难以理解且仅存放于办公室,未能在各部门得到充分沟通工厂已设立系统化的客户投诉程序及产品召回计划,但并无任何记录显示其有被有效执行是的,工厂的质量部门是独立工厂的质量部门并未独立于生产部料、生产过程中使用的设备及工厂已对风险化学品、原材料、生产过程中使用的设备及工具进行了风险评估相关记录但并未能得到持续执行工厂并未执行理系统工厂未对原料采购进行了规范说明工厂已建立原料隔离的体系,工厂未建立原料隔离的体系,以避免不合格品对合格品的意外污染是的,工厂有专门进行产品开发的车间;产品开发人员都得到了完善的培训;文件化的产是的,工厂无专门进行产品开发的车间产品开发人员未得到完善的培训不完整或无文件化的产品开发记录及参考样本工厂产品开发部门仅以客是的,工厂产品开发部门在包装设计及测试方面均不符合产业标准及/在产品生产的各个阶段都操作性也不强工厂并无建立任何文件化的生产程序在产品生产的各个阶段都操作性也不强工厂并无建立任何文件化的质量检验程序工厂在投产前并未召开产前会议录受检的产品存在较小的质量问题,需要改进是的,工厂有利用不合格品来工厂只提供了不合格品作为参考,但对其缺陷未有任何成文的讲述是的,产品质量未能达以要求时,质量控制部门可以要求停产品质量未能达以要求时,质量控制部门无权要求停产善措施都有记录,改善措施责任人、改善措施及完成期限都工厂有运用改善措施及根本原因分析方法,但未明确定义改善措施责任人、改善措施及完成期限,可能会影响到改善措施的有效进行是的,工厂已建立保证包装正工厂有建立指导方针,但未有明确定义是的,包装区有足够的空间保证包装工序的正常运行,包装包装区有足够的空间保证包装工序的正常运行,但不够干净、有序是的,工厂对出货的准时性进工厂未对出货的准时性进行了跟踪及记录是的,工厂已建立文件化的供应商评估程序,且留有相关记工厂已建立文件化的供应商评估程序,但未留有相关记录是的,工厂对其供应商的可靠性(表现)进行了跟踪、评估工厂未对其供应商的可靠性评估及记录是的,所有的测试仪器都进行部份测试仪器都进行了有效的校准是的,工厂可获得相关的行业. 工厂只能获得部份行业标准测试手册作为测试依据是的,内部测试人员已得到了只有部份内部测试人员得到了适当的培训在客户进行最终产品检验前,工厂会先纠正其不适当的最终产品不当的检验并没有更正,也无任何记录证明会在客户进行最终产品检验前会作出更正工厂未保留任何客户出货通知文件或记录,工厂也出现过不遵照客户程序出货的例子。

Factory Prequalification Process – Type A SuppliersBackgroundFactory Prequalification (initial audits) will be required prior to order commitment for new factories of Type A Suppliers that control and manage their business overseas. The cost of all prequalification audits will be borne by the supplier. The Factory Prequalification process consists of the following:• Factory Capability & Capacity Audit (FCCA)FCCA will be conducted for all new factories of type A suppliers by a designated third party audit firm. FCCA is also applicable to all existing non-food “A” suppliers’ factories.Audits will be carried out by either Bureau Veritas (BV), Intertek or SGS, at the supplier’s cost. The FCCA audit fee for new and existing factories is USD 400~450 (for factories located within 100km from the designated third party audit firm’s nearest office) in People’s Republic of China only. If the distance exceeds 100km, additional traveling cost will be incurred. For factories located in other countries the audit fee may vary depending on the factory location.Important Notice: All Wal-Mart Direct Import Suppliers are responsible to schedule the audit date as early as possible and promptly pay the audit company in advance of the audit. All arrangements must be made directly with the audit company and not through Wal-Mart commercial or QA.Note: unnecessary delays due to scheduling requested FCCA audits will not be tolerated• Ethical Standards (ES) AuditES audits will be conducted for all new factories of type A suppliers by third party audit firms at a cost of $1200 - $1600 per audit depending on the location of the factory.•Audits in Far East, South East Asia, & Americas: US$1200 per audit•Audits in Middle East / Africa / Europe: US$1600 per auditFactory Prequalification (initial audits) will be required prior to order commitment for new factoriesPurposeThe purpose of FCCA includes:•Pre-qualify a new factory prior to building business relationship.•Reduce turnover of new factories•To provide Audit result & information to merchandising team prior to selecting a qualified factory before order commitmentObjectivesThe objectives of FCCA are as follow:•Identify a factory’s production capability, capacity and quality control system.•Develop global factory base and establish long-term relationships.•Increase first time lab test pass rates and inspection acceptance rates•Reduce quality claim.Structure of FCCA standardsThe Quality System Audit covers seven (7) sectionsSection Weighting1. Factory Facility and Environment 15 %2. Quality Management System 15%3. Incoming Materials Control 20%4. Process and Production Control 25%5. In-house Lab Testing 10%6. Final Inspection 10%7. People Resources & Training 5%Key points of FCCA•Third party – Bureau Veritas (BV) has been designated to perform the Audit•Audit standards – BV will use WM GP FCCA format•FCCA Audit will be conducted at supplier’s cost of US$ 850 per audit•An existing factory under inactive status, FCCA will not be required for a period of 18 months. After 18 months, they need to do Factory Prequalification includes both ES and FCCA if they want to be reactivated• Audit ResultResult RatingPass80-100% w/o critical point rating 0Acceptable 60-79% with Corrective Actions, without critical point rating 0Unacceptable0-59%Based on the initial audit and result, a follow-up audit may be required• All new factories must achieve an FCCA rating no less than 60% with at least one score on critical check points•No order will be placed to new factories with rating under 60% or zero score on any critical check points.•Re-application for FCCA Audit will depend on correction of all non-compliances. CAP will be reviewed by BV and approved by Corp QA.Third Party Audit FirmsEthical StandardsITS (Intertek Testing Services)Intertek Testing Services is a Wal-Mart approved 3rd party audit firm to conduct ES and SCS audits.Primary Contact Information for the audit firm:• Divya Arora (divya.arora@ location: India) – Phone: 918-0402-13802• Toni Bellacosa (toni.bellacosa@ location: USA) - Phone: 973-924-2514AGC Group LLC – AccordiaAGC Group Services is a Wal-Mart approved 3rd party audit firm to conduct ES audits only in the Americas region.Primary Contact Information for the audit firm:• Tamara Lamberson (tlamerson@ Location: USA) - Phone: 716-635-0566 • Richard Ingrao (ringrao@ Location: USA) - Phone: 716-635-0566FCCABV (Bureau Veritas)Bureau Veritas is a Wal-Mart approved 3rd party audit firm that will conduct FCCA audits. Please coordinate with BV for corresponding fee that must be paid prior to audit process.BV Primary Contact Information:Ada LiuCustomer Service Officer,Consumer Product Services - Inspection, Audit and AssessmentBureau Veritas Hong Kong LimitedShenzhen OfficeRoom 707, Tianan Hi-Tech Plaza Tower B, Tianan Cyber Park,Futian District, Shenzhen City, P/C 518040Tel: 86-755-83437146, Fax: 86-755-83433077 / 78E-mail: ada.liu@DefinitionsSupplier Types• Supplier Type A (OVERSEAS SUPPLIER): Supplier controls and manages the business overseas with GP oversight. The prequalification program is applicable only to all Type A supplier’s new factories at this time.• Supplier Type B (DOMESTIC SUPPLIER): Supplier controls and manages the business domestically with Buyer oversight.• Supplier Type C (LEADING BRAND NAME SUPPLIER): Supplier owns the product and the label, which is well-recognized within the product category.Existing SupplierSupplier that has an existing and active vendor agreement and supplier/vendor ID for Retail Link along with user id and password set up to access Retail LinkNew SupplierSupplier that does not have an existing and active vendor agreement and supplier/vendor ID for Retail LinkExisting FactoryA factory that is active in the Retail Link system today.New FactoryA factory that may exist in Retail Link, has a valid factory id, Inactive but never had an ES audit conducted and/or the factory does not exist in Retail LinkFCCA involves the following four different scenarios•Existing Supplier – New Factory•Existing Supplier – Existing Factory•New Supplier – New Factory•New Supplier – Existing FactorySection A – Existing Supplier New Factory RequestOverviewStep 1 – Supplier submits factory request via Retail LinkStep 2 – ES verifies if factory is new or existing. If factory is new, then ES will approve factory ID with IOR = prequalification GP and notify supplier and concerned GP Sourcing / Merchandising team, and send FCCA and ES audit request to BV and ITSStep 3 – 3rd party sends supplier package to supplierStep 4 – Supplier pays 3rd party for both FCCA & ESStep 5 – ES informs GP sourcing / merchandising teams and supplier with the FCCA results Step 6 – If factory passes both the FCCA & ES the audits, ES will change IOR for the factory to Wal-MartStep 1 - How suppliers submit New Factory ID request on Retail Link (For Prequalification Audit)1) From the Retail Link Homepage, click on Site MapFromRetail Link homepage,click on “Site Map”.2) The different applications maybe sorted by “category”. (Accounting, Admin, etc…) To easily find the Supplier Classification information, click on “Alphabetical” and sort all the applications by alphabets.2)Select “Alphabetical” to sortthe applications in alphabetical3) Within the Alphabetical view, click on the letter “E” and go to the “E” section.3)Within the Alphabetical view,click on the letter “E” and go tothe “E” section4) Within the “E” section, look for the “Ethical Standards” link and click on it.5) Within Ethical Standards, click on “Supplier Queue”6) Within Supplier Queue , first select the appropriate HOST Vendor Number , then click on Request New Factory7) After clicking the “Request New Factory ”, first fill out the Factory Information section, both in English and in the respective local language.a. Upon selecting the “country”, choose the city from the drop down box in the local language columnb. Ensure the Importer of Record (IOR) is selected as “Prequalification GP”8) Fill out the Supplier Information section9) Enter the Factory Contact Information sectionEnter any additional commentshere, and the press “SubmitRequest” when finished.10) Enter any additional comments regarding the factory in the “Comments” area11) Hit the “Submit Request” button when finished.Step 2 – ES verifies if factory is new or existing. If factory is new, then ESwill approve factory ID with IOR = prequalification GP and notify supplierand concerned GP Sourcing / Merchandising team, and send FCCA and ES audit request to BV and ITS.How Ethical Standards team confirms suppliers and notify for 3rd party inspection•After verifying the information from suppliers, the regional ES coordinator will inform the supplier to proceed and will provide them with 3rd party audit firm’s information and payment details.o The e-mail to supplier and concerned GP Sourcing / Merchandising team will look like:o The e-mail to 3rd party and concerned GP Sourcing / Merchandising team will look like:Step 3 – 3rd party sends supplier package to supplierHow Suppliers prepare for FCCAFor FCCA, suppliers should receive one of the following documents from 3rd party. After completing the questionnaire, supplier should return the questionnaire to the 3rd party.A sample section of the Pre-audit questionnaire – HardlinesWal-Mart Factory Pre-Audit Questionnaire(Hardline)Wal-Mart Dept.No: __________ Date: (mm/dd/yy)Wal-Mart Merchandiser Name & email: ___________________________________________ Contact InformationFactory Name (in Local Language):Country:Year Established:Type of Ownership: □ Single Ownership □ Partnership □ Private Incorporation□ Public Traded Company □ Belong to Group (Multinational) □ Others•FCCA Pre-audit Questionnaire - SoftlinesA sample section of the Pre-audit questionnaire – Softline•FCCA Pre-audit Questionnaire - Home TextileA sample section of the Pre-audit questionnaire – Home TextileFactory Pre-Audit Questionnaire(Home Textile)Wal-Mart Dept.No.Date :__________________(mm/dd/yy)Wal-Mart Merchandiser Name & email address: ______________________________ Contact InformationFactory Name (in Local Language):Country:Year Established:Type of Ownership: □ Single Ownership □ Partnership □ Private Incorporation□ Public Traded Company □ Belong to Group (Multinational) □ OthersProduction Area (sq meter):Warehouse Area (sq meter):Total Employees Working for Factory:Total No. of Employees Dormitories can Accommodate:Category Produced:□ Beddings (Sheets, BIAB, Mattress pads etc.) □ Towels □ Seasonal □ Curtains □ Kitchen items □Throws, Rugs □ Others: Please specifyStep 4 – Supplier pays 3rd party for both FCCA & ES •Supplier makes payment to designated third parties and schedules ES Audit and FCCA o Third parties conduct ES Audit and FCCA.ES requirements may be found at Retail Link => Site Map =>GP Ethical Standards Documentation.FCCA requirements may be found at Retail Link => Site Map =>Wal-Mart Import Supplier Summit 2008Upon completion of ES Audit and FCCA, the third party will send findings to GP for final auditStep 5 – ES informs GP sourcing / merchandising teams and supplier with FCCA resultsUpon completion of Audit the ES coordinator will send a notice of approval/disapproval to the supplier and the concerned GP Sourcing / Merchandising team. The notice will include copies of the ES audit and FCCA reports•Sample of FCCA approved e-mail to supplier and concerned GP Sourcing / Merchandising team•Sample of FCCA disapproved e-mail to supplier and concerned GP Sourcing / Merchandising teamStep 6 – If factory passes both the FCCA & ES audits, ES change factory ID to IOR = Wal-MartSection B – Existing Supplier Existing FactoryOverviewStep 1 – Supplier submits factory request via Retail LinkStep 2 – ES verifies if factory is new or existing. If factory exists, then ES would notify supplier and concerned GP Sourcing / Merchandising team. If GP sourcing / merchandising team confirms the factory needs FCCA, ES send FCCA request to 3rd party (BV only)Step 3 – 3rd party sends supplier package to supplierStep 4 – Supplier pays 3rd party for FCCA onlyStep 5 – ES informs GP sourcing / merchandising teams and supplier with the FCCA results Step 6 – If factory passes both the FCCA & ES audits, ES keep the factory active in Retail LinkStep 1 - How suppliers submit New Factory ID request on Retail Link (For Prequalification Audit)1)From the Retail Link Homepage, click on Site MapFromRetail Link homepage,click on “Site Map”.2) The different applications maybe sorted by “category”. (Accounting, Admin, etc…) To easily find the Supplier Classification information, click on “Alphabetical” and sort all the applications by alphabets.2)Select “Alphabetical” to sortthe applications in alphabetical3)Within the Alphabetical view, click on the letter “E” and go to the “E” section.3)Within the Alphabetical view,click on the letter “E” and go tothe “E” section4) Within the “E” section, look for the “Ethical Standards” link and click on it.5)Within Ethical Standards, click on “Supplier Queue”6) Within Supplier Queue , first select the appropriate HOST Vendor Number , then click on Request New Factory7) After clicking the “Request New Factory ”, first fill out the Factory Information section, both in English and in the respective local language.a. Upon selecting the “country”, choose the city from the drop down box in the local language columnb. Ensure the Importer of Record (IOR) is selected as “Prequalification GP”8) Fill out the Supplier Information section9) Enter the Factory Contact Information sectionEnter any additional commentshere, and the press “SubmitRequest” when finished.10) Enter any additional comments regarding the factory in the “Comments” area11) Hit the “Submit Request” button when finished.Step 2 – ES verifies if factory is new or existing and confirm with Sourcing / Merchandising. If factory exists, then ES would notify supplier and concerned GP Sourcing / Merchandising team. If GP sourcing / merchandising team confirms the factory needs FCCA, ES will send FCCA request to 3rd party (BV only)How Ethical Standards team confirms suppliers and notify for 3rd party inspection•After verifying the information from suppliers, the regional ES coordinator will inform the supplier and concerned GP Sourcing / Merchandising team to proceed and will provide them with 3rd party audit firm’s information and payment .o The e-mail to supplier and concerned GP Sourcing / Merchandising team will look like:o The e-mail to 3rd party and concerned GP Sourcing / Merchandising team will look like:Step 3 – 3rd party sends supplier package to supplierHow Suppliers prepare for FCCAFor FCCA, suppliers should receive one of the following documents from 3rd party. Aftercompleting the questionnaire, supplier should return the questionnaire to the 3rd party.A sample section of the Pre-audit questionnaire – HardlinesWal-Mart Factory Pre-Audit Questionnaire(Hardline)Wal-Mart Dept.No: __________ Date: (mm/dd/yy)Wal-Mart Merchandiser Name & email: ___________________________________________ Contact InformationFactory Name (in Local Language):Country:Year Established:Type of Ownership: □ Single Ownership □ Partnership □ Private Incorporation□ Public Traded Company □ Belong to Group (Multinational) □ OthersProduction Area (sq meter):•FCCA Pre-audit Questionnaire - Softlineso A sample section of the Pre-audit questionnaire – Softline•FCCA Pre-audit Questionnaire - Home TextileA sample section of the Pre-audit questionnaire – Home TextileFactory Pre-Audit Questionnaire(Home Textile)Wal-Mart Dept.No.Date :__________________(mm/dd/yy)Wal-Mart Merchandiser Name & email address: ______________________________ Contact InformationFactory Name (in Local Language):Country:Year Established:Type of Ownership: □ Single Ownership □ Partnership □ Private Incorporation□ Public Traded Company □ Belong to Group (Multinational) □ OthersProduction Area (sq meter):Warehouse Area (sq meter):Total Employees Working for Factory:Total No. of Employees Dormitories can Accommodate:Category Produced:□ Beddings (Sheets, BIAB, Mattress pads etc.) □ Towels □ Seasonal □ Curtains □ Kitchen items □Throws, Rugs □ Others: Please specifyExport Rate in percentage:Step 4 – Supplier pays 3rd party for FCCA only •Supplier makes payment to designated third parties and schedules FCCAo Third parties conduct FCCA. FCCA requirements may be found at Retail Link => Site Map => Wal-Mart Import Supplier Summit 2008Upon completion of FCCA, the third party will send findings to GP for auditStep 5 – ES informs GP Sourcing / Merchandising team and supplier with FCCA resultsUpon completion of Audit the ES coordinator will send a notice of approval/disapproval to the supplier and the sourcing team. The notice will include copies of the ES audit and FCCA reports•Sample of FCCA approved e-mail to supplier concerned GP Sourcing / Merchandising team•Sample of FCCA disapproved e-mail to supplier and concerned GP Sourcing / Merchandising teamStep 6 – If factory passes both the FCCA & ES audits, ES keep the factory active in Retail LinkSection C – New Supplier New FactoryOverviewStep 1 - How suppliers submit New Factory ID request using New Factory Prequalification Form Step 2 – ES verifies if factory is new or existing. If factory is new, then ES will send FCCA and ES audit request to BV and ITSStep 3 – 3rd party sends supplier package to supplierStep 4 – Supplier pays 3rd party for both FCCA & ESStep 5 – ES informs GP sourcing / merchandising teams and supplier with the FCCA results Step 6 – If factory passes both the FCCA & ES audits, ES assign factory ID after supplier signed supplier agreement and got supplier IDStep 1 - How suppliers submit New Factory ID request using New Factory Prequalification FormNew Suppliers – Supplier obtains the New Factory Request form from the local GP Office and submits it to the ES coordinator by email. A sample section of the request form is enclosed below:New Supplier/New Factory Prequalification Form: ES & FCCATo request Wal-Mart to audit a factory in order to be pre qualified for Wal-Mart production, please fill in the following information. All information for factory and supplier is required; agent information, if applicable. Please write or type legibly. Note this form is only for new suppliers without Retail Link access and supplier ID. Existing suppliers should request using Ethical Standards on Retail Link.SUPPLIER INFORMATION: (Supplier Classification: ______)In Chinese (中文): In English (英文)供应商名称:Supplier Name:地址:Address:負責人: Contact Person:(In Credit Country)Contact Person:(In ProductionCountry)Telephone No.:辦事處電話(Tel):傳真號碼 (Fax): Fax No.:Step 2 – ES verifies if factory is new or existing. If factory is new, then ES will send FCCA and ES audit request to BV and ITSHow Ethical Standards team confirms suppliers and notify for 3rd party inspection•After verifying the information from suppliers, the regional ES coordinator will inform the supplier to proceed and will provide them with 3rd party audit firm’s information andpayment details.o The e-mail to supplier and concerned GP Sourcing / Merchandising team will look like:o The e-mail to 3rd party and concerned GP Sourcing / Merchandising team will look like:Step 3 – 3rd party sends supplier package to supplierHow Suppliers prepare for FCCAFor FCCA, suppliers should receive one of the following documents from 3rd party. Aftercompleting the questionnaire, supplier should return the questionnaire to the 3rd party.A sample section of the Pre-audit questionnaire – HardlinesWal-Mart Factory Pre-Audit Questionnaire(Hardline)Wal-Mart Dept.No: __________ Date: (mm/dd/yy)Wal-Mart Merchandiser Name & email: ___________________________________________ Contact InformationFactory Name (in Local Language):Country:Year Established:Type of Ownership: □ Single Ownership □ Partnership □ Private Incorporation□ Public Traded Company □ Belong to Group (Multinational) □ Others•FCCA Pre-audit Questionnaire - SoftlinesA sample section of the Pre-audit questionnaire – Softline•FCCA Pre-audit Questionnaire - Home TextileA sample section of the Pre-audit questionnaire – Home TextileFactory Pre-Audit Questionnaire(Home Textile)Wal-Mart Dept.No.Date :__________________(mm/dd/yy)Wal-Mart Merchandiser Name & email address: ______________________________ Contact InformationFactory Name (in Local Language):Country:Year Established:Type of Ownership: □ Single Ownership □ Partnership □ Private Incorporation□ Public Traded Company □ Belong to Group (Multinational) □ OthersProduction Area (sq meter):Warehouse Area (sq meter):Total Employees Working for Factory:Total No. of Employees Dormitories can Accommodate:Category Produced:□Step 4 – Supplier pays 3rd party for both FCCA & ES •Supplier makes payment to designated third parties and schedules ES Audit and FCCA o Third parties conduct ES Audit and FCCA.Upon completion of ES Audit and FCCA, the third party will send findings to GP for AuditStep 5 – ES informs GP sourcing / merchandising teams and supplier with FCCA resultsUpon completion of Audit the ES coordinator will send a notice of approval/disapproval to the supplier and the sourcing / merchandising team. The notice will include copies of the ES audit and FCCA reports•Sample of FCCA approved e-mail to supplier and concerned GP Sourcing / Merchandising team•Sample of FCCA disapproved e-mail to supplier and concerned GP Sourcing / Merchandising teamStep 6 – If factory passes both the FCCA & ES audits, ES assign factory ID after supplier signed supplier agreement and got supplier IDSection D – New Supplier Existing FactoryOverviewStep 1 - How suppliers submit New Factory ID request using New Factory Prequalification Form Step 2 – ES verifies if factory is new or existing and confirm with Sourcing / Merchandising. If factory exists, then ES would notify supplier and concerned GP Sourcing / Merchandising team. If GP sourcing / merchandising team confirms the factory needs FCCA, ES send FCCA request to 3rd party (BV only).Step 3 – 3rd party sends supplier package to supplierStep 4 – Supplier pays 3rd party for FCCA onlyStep 5 – ES informs GP sourcing / merchandising teams and supplier with the prequalification resultsStep 6 – If factory passes both the FCCA & ES audits, ES keep the factory active in Retail LinkStep 1 - How suppliers submit New Factory ID request using New Factory Prequalification FormNew Suppliers – Supplier obtains the New Factory Request form from the local GP Office and submits it to the ES coordinator by email. A sample section of the request form is enclosed below:New Supplier/New Factory Prequalification Form: ES & FCCATo request Wal-Mart to audit a factory in order to be pre qualified for Wal-Mart production, please fill in the following information. All information for factory and supplier is required; agent information, if applicable. Please write or type legibly. Note this form is only for new suppliers without Retail Link access and supplier ID. Existing suppliers should request using Ethical Standards on Retail Link.SUPPLIER INFORMATION: (Supplier Classification: ______)In Chinese (中文): In English (英文)供应商名称:Supplier Name:地址:Address:負責人: Contact Person:(In Credit Country)Contact Person:(In ProductionCountry)Telephone No.:辦事處電話(Tel):傳真號碼 (Fax): Fax No.:Step 2 – ES verifies if factory is new or existing and confirm with Sourcing / Merchandising. If factory exists, then ES would notify supplier and concerned GP Sourcing / Merchandising team. If GP sourcing / merchandising team confirms the factory needs FCCA, ES send FCCA request to 3rd party (BV only)How Ethical Standards team confirms suppliers and notify for 3rd party inspection•After verifying the information from suppliers, the regional ES coordinator will inform the supplier and concerned GP Sourcing / Merchandising team to proceed and will provide them with 3rd party audit firm’s information and payment.o The e-mail to supplier and concerned GP Sourcing / Merchandising team will look like:。

Walmart FCCA质量体系审核验厂要求的详细解释(非电器类杂货)-2020年11月9日更新常规资料:营业执照、工业生产许可证、产品标准清单、平面图、组织架构图特种设备的证书及操作证经营范围、卖给wm的产品、过去一年营业额、工厂面积、人数等条款号审核要求详细解释1.0Factory Facilities and Environment生产设施和环境1.Are lighting sufficient in the following key areas?以下关键区域光度是否足够?1.1.Inspection Areas检验区要求600μ1.2.Production Areas生产区域要求240μ1.3.Packaging包装区域要求300μ1.4.Warehouse/Storage and Loading Areas仓库/存储和装载区要求150μ2.The facility maintains clean and organized production,finishing and packing areas.工厂的生产,成品和包装区域保持干净和有序的生产?现场车间物料的分类、摆放整齐,标识清楚。

3.Facility has separate inspection area for each department with inspection tables andproper ventilation.工厂每个生产部门有独立的检验区域,有检验桌和适宜的通风?现场查看来料、巡检、成品检验等区域的标识及产品的状态标识4.Facility has documented and adequate pests control program which includesfrequent inspections.(in-house or3rd party)工厂有文件化的和足够的害虫控制程序和检验记录?(内部或第三方)虫害控制程序及杀虫记录。

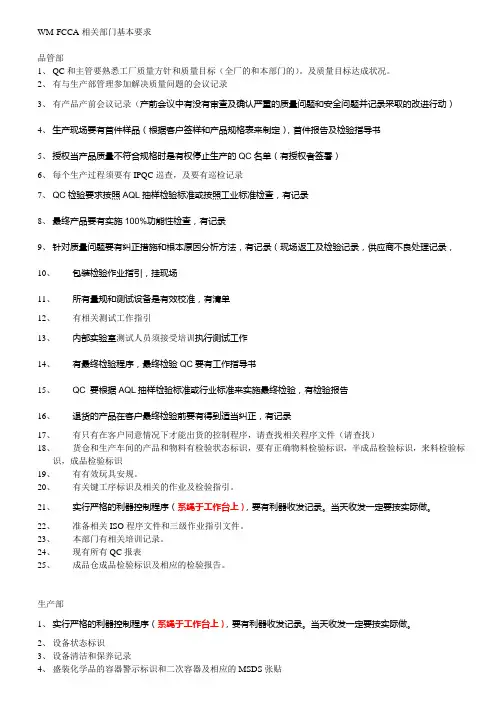

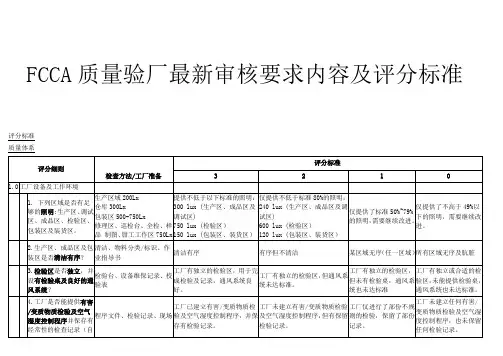

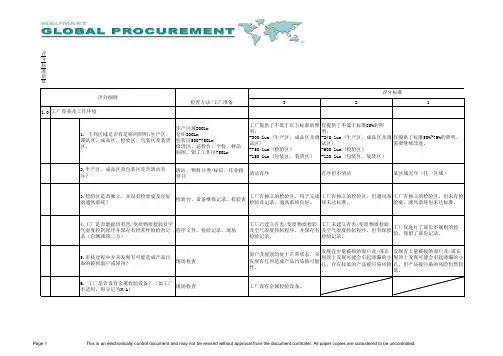

评分标准质量体系检查方法/工厂准备3211.0生产区域200Lx 仓库300Lx包装区500-750Lx修理区、巡检台、全检、样品制图、钳工工作区750Lx 工厂提供了不低于以下标准的照明:-300 lux (生产区、成品区及调试区)-750 lux (检验区)-150 lux (包装区、装货区)仅提供了不低于标准80%的照明:-240 lux (生产区、成品区及调试区)-600 lux (检验区)-120 lux (包装区、装货区)仅提供了标准50%~79%的照明,需要继续改进。

清洁、物料分类/标识、作业指导书清洁有序有序但不清洁某区域无序(任一区域)检验台、设备维保记录、校验表工厂有独立的检验区,用于完成检验及记录,通风系统良好。

工厂有独立的检验区,但通风系统未达标准。

工厂有独立的检验区,但未有检验桌,通风系统也未达标准。

程序文件、检验记录、现场工厂已建立有害/变质物质检验及空气湿度控制程序,并保存有检验记录。

工厂未建立有害/变质物质检验及空气湿度控制程序,但有保留检验记录。

工厂仅进行了部份不规则的检验,保留了部份记录。

现场检查窗户及屋顶均处于正常状态,未发现有任何造成产品污染的可能性。

发现有少量破损的窗户及/或在屋顶上发现可能会引起渗漏的小孔,存在较低的产品被污染风险。

发现有大量破损的窗户及/或在屋顶上发现可能会引起渗漏的小孔,但产品被污染的风险仍然较低。

现场检查工厂设有金属检验设备。

关键项发放记录、用绳绑住现场使用的工厂设有并严格执行了利器管理程序,以避免利器与产品混在一起。

目前有保留与利器管理程序相对应记录文件。

工厂已建立了文件化的利器管理程序,但未能提供完整的记录。

工厂已建立了文件化的利器管理程序,但未能提供相对应的记录。

工厂设备及工作环境评分标准1. 下列区域是否有足够的照明:生产区、调试区、成品区、检验区、包装区及装货区。

3.检验区是否独立,并设有检验桌及良好的通风系统?2.生产区、成品区及包装区是否清洁有序?评分细则4.工厂是否能提供有害/变质物质检验及空气湿度控制程序并保存有经常性的检查记录(自测或第三方)5.审核过程中并未发现有可能造成产品污染的破损窗户或屋顶?6. 工厂是否设有金属检验设备?(如工厂不适用,得分记为N/A)7. 工厂是否有执行严格的利器管理程序,以保证剪刀、小刀、刀片、玻璃及断针等不会混入产品中?。

Walmart沃尔玛FCCA质量技术验厂标准审核条款清单对应的文件记录及现场要求更新日期:2020.08.18常规文件资料:营业执照、工业生产许可证、产品标准清单平面图、组织架构图特种设备的证书及操作证经营范围、卖给wm的产品、过去一年营业额、工厂面积、人数等FCCA生产能力评估清单书面程序记录现场巡视备注1.0工厂设施和环境1.在生产,修理,加工,检验,包装及装载的区域是否有足够的照明?►现场查看车间照明度:Wal-Mart的最低要求,生产区、成品区240lux,检测区域(IQC/FQC/OQC)600lux,包装区域360lux,原料仓150lux2.工厂是否保持清洁,在生产,加工和包装区域是否有秩序?►现场车间物料的分类、摆放整齐,标识清楚。

3.工厂是否有单独的检验区与检验台并且通风良好?►现场查看来料、巡检、成品检验等区域的标识及产品的状态标识4.工厂是否有害虫/霉菌和湿度的控制程序文件?是否有经常巡查(公司内部或第三方检查)?►灭虫/灭鼠控制程序►防潮/防霉菌控制程序►虫害/灭鼠巡查记录现场查看防治虫害的设施。

各区域不要有虫害痕迹,如蜘蛛网等5.在审核其间有没有发现窗户破损及房顶漏水可能导致产品污染。

玻璃破碎控制程序玻璃破碎巡查记录►现场查看窗户玻璃有无破损6.工厂是否实行严格的利器控制程序,以防止剪刀、小刀、刀片、碎玻►利器控制程序\利器、断针►利器收发记录、利器、断针►现场查看利器的管理璃及针等混入产品中。

Critical严重1.1机器校准和维护1.工厂是否有书面的文件系统和程序计划安排设备的清洁及维修。

►生产设施控制程序►机器设备保养记录►现场查看2.工厂的机器和设备是否清洁及运行良好。

►现场查看,设备的运行状态要做好标识如(运行、待机、停机、维修等)3.机器、设备和工具是否有最近的维护/校准日期及计划日期的标识。

►检测设备控制程序►检测设备清单►检测设备校准计划►校准报告►现场看检测设备的校准标识4.需要维修机器、设备和工具是否有维修标识以避免意外使用。

质量

1.公司质量方针:诚信服务,增强顾客满意;持续改进,造就一流

产品

2.公司质量目标:产品一次交验合格率98%,商检合格率100%,顾

客满意率大于95%。

3.QC完全独立于生产,生产中,如发现质量问题,QC有权停线。

4.工厂有顾客投诉体系及产品召回程序。

5.工厂实施物料先进先出(FIFO)体系

6.所有计量设备已及时校验。

7.现场的原材料、半成品、成品、合格品、不合格品、待处理品均

要有标识卡,保证其可追溯性。

8.工厂在生产前必须进行产前会议。

9.工厂有进行“试生产”,根据产品规格明细检讨产品质量,并记录

在生产前的纠正行动。

10.工厂QC根据客户签样和产品规格表来制定首件样品。

11.每一个操作过程都有QC执行巡检

12.工厂QC检验是按照AQL抽样检验标准(2.5、4.0)

13.员工上班时间不可佩戴珠宝首饰。

14.刀片、剪刀有严格的收发控制,现场的刀片、剪刀必须绑好。

FCCA验厂标准要求2012(精选)第一篇:FCCA验厂标准要求2012(精选)FCCA验厂标准要求目前Wal-Mart验厂新增项目FCCA,所有Wal-Mart供应商都要通过FCCA的审核,FCCA的结果以打分的形式,60分以上为合格,FCCA即为Wal-Mart对工厂的质量体系要求,FCCA验厂标准:Factory Quality System工厂的质量体系1.0 Factory Facilities and Environment工厂设施和环境1.0.1 There is sufficient lighting on: Production, revising, finishing, inspection, packing and loading areas? 足够的照明上:生产,返工,加工,检验,包装及装载的区域?1.0.2 The facility maintains clean and organized production, finishing and packing areas.工厂保持清洁和有组织的生产,加工和包装领域。

1.0.3 Facility has separate inspection area with inspection table and proper ventilation.工厂有单独的检验区与检验台并且适当的通风设备。

1.0.4 Facility has documented pests/mildew and moisture control program, which includes frequent inspections.(In-house or 3rd party)工厂已记录害虫/霉菌和湿度的控制程序,其中包括经常巡查。

(在公司内部或第三方)1.0.5 No broken windows or leaking roofs that may result to product con*****ination was observed duringaudit.没有打破窗户或屋顶漏水,可能导致产品污染的观察审核期间。

FCCA Quality System Audit Outline质量体系审核纲要(非电器类杂货)1.0 Factory Facilities and Environment 生产设施和环境1. Are lighting sufficient in the following key areas? 以下关键区域光度是否足够?1.1. Inspection Areas 检验区1.2. Production Areas 生产区域1.3. Packaging 包装区域1.4. Warehouse/Storage and Loading Areas 仓库/存储和装载区2. The facility maintains clean and organized production, finishing and packing areas.工厂的生产,成品和包装区域保持干净和有序的生产?3. Facility has separate inspection area for each department with inspection tables andproper ventilation.工厂每个生产部门有独立的检验区域,有检验桌和适宜的通风?4. Facility has documented and adequate pests control program which includesfrequent inspections. (in-house or 3rd party)工厂有文件化的和足够的害虫控制程序和检验记录?(内部或第三方)5. Facility has documented moisture control program which includes frequentinspections. [Mandatory for factories producing products with solid wood &composite wood parts]工厂有文件化的湿度控制程序及检验记录?[此项为对于生产实木及复合木制品的工厂的强制要求]6. Are storage conditions appropriate and adequate for raw material, WIP, finishedproducts to avoid deterioration of quality or safety? Especially for sensitivematerials/components. For example, for IC storage. Does factory have goodenvironmental control on temperature, humidity, etc.原料,半成品,成品的存储条件是否适宜和充足以避免其质量或安全的降级退化。

WM工厂生产能力评估(FCCA)----验厂要求

工厂质量体系

1.0 工厂的设备和环境

1.0.1在生产,修整,成品,检验,包装和装载等车间的照明充足。

1.0.2在生产,成品和包装车间,工具设备要保持干净整齐,

1.0.3工具设备等有单独的校验区域,配备校验工作台,并有适当的通风条件

1.0.4要有书面的对设备工具的有害物/发霉和潮湿的管理计划,和经常进行检查的纪录。

1.0.5不能发现有窗户破损和屋漏等情况。

1.0.6必须有检针器

1.0.7工厂必须严格执行尖锐物管理程序,防止剪刀,刀子,刀片,碎玻璃和断针等混在产品里面。

(非常重要!)

1.0.8工厂有备用的电力供应设备:发电机等。

1.1 机器的校准和维护

1.1.1工厂的机器和设备适与生产沃尔玛的产品。

1.1.2工厂有定期清洁和修理机器设备的书面制度和程序

1.1.3工厂的机器设备清洁,运行状况良好。

1.1.4在机器,设备和工具上用标签标明上一次维护/校准的日期和时间表

1.1.5需要修理的机器,设备和工具等需要使用标签标明,以避免误用。

1.1.6工厂有适当,整洁的存放区域存放需修理的工具,将其摆放在有标签标明的架子上。

1.1.7工厂有机器,工具,备件和设备的相关文件和最新的详细目录。

1.1.8工厂拥有具有一定的技术水准和设备的维修组,以对机器进行必要的维修和校准。

2.0 质量管理体系

2.0.1工厂已经建立起适合他们产品和程序的质量管理体系

2.0.2.工人和检查员熟悉该质量政策和目标

2.0.3工厂有书面的客户反馈体系和书面的召回程序。

2.0.4工厂的质检人员和生产活动是相分离的。

(非常重要!)

2.0.5生产管理人员和质检小组一起工作并讨论解决质量问题。

2.0.6工厂要有适当的制度和程序控制物理上的,化学上的和生物学上的玷污和污染,以避免损坏产品,危及工作人员的健康。

2.0.7工厂要对化学品,原料和设备和工具的使用进行风险评估,确认其是否具有风险。

3.0 来料控制

3.0.1熟练的执行原料先进先出制度。

3.0.2工厂有对进厂的各种原辅料进行质量检查的程序

3.0.3原料的进出受到监控并有书面纪录。

3.0.

4.工厂有所购原料的详细资料。

3.0.5.工厂有书面的程序和参考样品,以确保购入的原材料符合规格和说明。

3.0.6工厂要有对原料的隔离制度,以避免被不合格品意外玷污。

(非常重要!!)

3.0.7.工厂需要将质量合格的产品同不合格的产品隔离,识别并替换不一致的产品或原料。

3.0.8工具设备的存放区域必须有充足的照明,良好的通风条件和干净整洁的环境。

3.0.9将原辅料适当的堆叠,用标签标明以进行辨别,并且必须离开地面(不能直接堆在地上)

3.0.10化学品和维护机器的物质必须清楚的标明并适当的进行存放,以避免玷污其他产品。

(非常重要!!)3.0.11 和染色有关的原辅料,例如面料,真皮,合成PU/PVC, 必须按批号存放。

4.0 工艺和生产控制

4.0.1工厂是否有为产品开发部门提供单独的工作区域? (产品开发是新产品设计,创造和营销的努力行为)4.0.2工厂在产品的设计和开发过程中是否每天学习并且应用产品安全装置;评估图案样式,模具和样品?

4.0.3产品开发是否包含包装设计和符合工业标准的测试?

4.0.4工厂是否每天安排时间集体研究产品,并根据消费者的利益开发更简便易用的产品?

4.0.5在每一个操作阶段上,工厂都要有书面的生产程序。

4.0.6在每一个操作阶段上,工厂都要有书面的质量管理程序。

4.0.7在生产开始之前,工厂是否开产前会?

4.0.8在产前会上,生产和质量检查员是是否出席?

4.0.9(非常重要!!)在产前会上,质量和安全标准的回顾,确认,和提高是否有书面的纪录?

4.0.10 在正式投产之前,工厂是否进行“试生产“—根据详细资料回顾产品的质量,并记录正确行为和结果?

4.0.11 现在生产的产品的质量是否可以接受?(检查3件或4件已经生产出来的产品)

4.0.12 正在生产的产品是否进行了厂内的测试?(要求提供测试报告副本)

4.0.13 质检人员是否根据确认样和相关详细资料核对初样?

4.0.14 是否有充足的样品,如初样,参考样和工作指示书等给工人适当的指导?

4.0.15 工厂是否使用有缺陷的/不合格的样品作为常见缺陷的展示样品?

4.0.16 (非常重要)如果产品的质量不符合要求,质检员是否有权利停止生产?

4.0.17 每个工艺流程都要在流水线上通过质检员的检验。

4.0.18 工厂是否使用统计学工艺管理?

4.0.19 工厂的质检员根据AQL标准或者根据其他工业标准进行检验。

4.0.20 工厂是否对最终产品进行100% 的功能性检查?

4.0.21 工厂行为是否正确?是否使用根本原因分析方法?(举例说明)

4.0.22 工厂是否在适当的位置张贴指导方针,以确保产品包装正确?

4.0.23 包装车间是否有足够的空间来进行包装?车间是否整洁?

4.0.24 包装好的纸箱存放在封闭的区域,不会受到阳光的暴晒或者受到天气潮湿的影响。

4.0.25 工厂是否追踪并留存及时装船的纪录?

4.1 供应商和转包商

4.1.1工厂是否有选择和确认供应商的书面记录?

4.1.2工厂是否追踪,评价并书面纪录原料供应商的可靠性(表现)?

4.1.3工厂是否已经建立有书面纪录的质量程序?

工厂是否评价和监督次一级转包商的质量情况和可靠性?

5.0 厂内产品测试

5.0.1工厂是否有厂内的实验室测试?并且购置了适当的设备?

5.0.2所有的测量和测试仪器的刻度有效。

.

5.0.3不同工业标准的测试指南可以作为参考。

.

5.0.4厂内的实验室技术员要经过适当的培训才能进行产品测试。

6.0 最终验货

6.0.1工厂的检验员是否进行最终验货并且进行书面记录?

6.0.2所有带有箱单和箱唛的确认样或参考样都可以为工厂的检验员提供参考。

6.0.3如果厂内验货有问题,则必须在客户进行最终验货之前进行改正。

6.0.4只有得到客户的允许,工厂才能出运货物。

7.0 人力资源和训练

7.0.1工厂需要持续地对所有的员工进行在职培训,并作书面纪录。

如果要雇用已经有技能的工人,则要经过雇用前的测试。

(非常重要!!)

7.0.2.工厂还要对电力/机械工程师,机械工,检验员,和实验室技术人员进行专业的培训,并作书面纪录。

7.0.3必须保留新工人和所有的固定工人的考勤等表现纪录。