美国联邦法规 16 CFR 1500.86 列为禁止供儿童使用的玩具和其他物品的豁免

- 格式:docx

- 大小:23.48 KB

- 文档页数:10

美国联邦法规 16 CFR 1500.52 供18个月以上至36个月以下儿童使用的玩具和其他物品正常使用和滥用的模拟试验方法原文出处:作者:编辑: [2009-02-25][打印文章] [关闭窗口]Title 16: Commercial PracticesPART 1500—HAZARDOUS SUBSTANCES AND ARTICLES; ADMINISTRATION AND ENFORCEMENTREGULATIONS§ 1500.52 Test methods for simulating use and abuse of toys and other articles intended for use by children over 18 but not over 36 months of age. (a) Application.The test methods described in this section, shall be used to simulate the normal and reasonably foreseeable use, damage, or abuse of toys and other articles intended for use by children over 18 but not over 36 months of age in conjunction with §1500.18.(b) Impact test—(1) Application.Except as provided in paragraph (b)(4) of this section, toys having a weight of less than 4.0 pounds ±0.01 pound (1.8 kilograms) shall be subject to this test.(2) Impact medium.The impact medium shall consist of a1/8-inch (0.3-centimeter) nominal thickness of type IV vinyl-composition tile, composition 1—asbestos free, as specified by paragraphs 1.2 and 3.1.4 of Interim Amendment-1(YD), dated November 14, 1979, to the Federal Specification entitled Tile, Floor: Asphalt, Rubber, Vinyl, Vinyl-Asbestos, SS-T-312B, dated October 10, 19741[1][1], over at least a 2.5-inch (6.4-centimeter) thickness of concrete. The impact area shall be at least 3 square feet (0.3 square meter). The Commission recognizes that this specified impact medium is the equivalent of, and will yield the same impact test results as, a surface covered with vinyl-asbestos tile meeting the requirements of Federal Specification SS-T-312A.(3) Testing procedure.Except as provided in paragraph (b)(4) (i) and (ii) of this section, the toy shall be dropped four times from a height of 3 feet ±0.5 inch[1] See footnote 1 to §1500.51.(0.92 meter) onto the impact medium described in paragraph (b)(2) of this section. The toy shall be dropped in random orientation. After each drop, the test sample shall be allowed to come to rest and shall be examined and evaluated before continuing.(4) Large and bulky toys.(i) A toy that has a projected base area of 400 or more square inches (2,560 or more square centimeters) shall be tested for impact in accordance with paragraph (b)(4)(iii) of this section. The base area for toys with permanently attached legs shall be measured by calculating the area enclosed by straight lines connecting the outermost edge of each leg of the perimeter. (ii) A toy that has a volume of more than 3 cubic feet (0.085 cubic meter), calculated by the major dimensions without regard to minor appendages, shall be tested for impact in accordance with paragraph (b)(4)(iii) of this section. (iii) The toys described in paragraph (b)(4) (i) and (ii) of this section shall be tested for impact by tipping them over three times by pushing the samples slowly past their centers of balance onto the impact medium described in paragraph (b)(2) of this section.(c) Bite test—(1) Application.A toy (or component or any accessible portion thereof) that has an external dimension of 1.25 inches ±0.05 inch (3.18 centimeters) or less and a design configuration that would permit a child to insert a portion into the mouth in any orientation up to a biting thickness of 1.25 inches ±0.05 inches (3.18 centimeters), for a penetration of at least 0.25 inch (0.635 centimeter), shall be subject to this test.(2) Test equipment—(i) Contact mechanism.The contact mechanism shall be two metal strips or plates each measuring 0.25 inch ±0.002 inch (0.635 centimeter) high and each having a contact edge radius of 0.020 inch ±0.002 inch (0.05 centimeter) for at least a 150-degree cross-sectional arc. A suggested contact mechanism appears in figure 1 of §1500.51.(ii) Loading device.The loading device shall be a scale or force gauge having an accuracy of ±0.5 pound (±225 grams).(3) Testing procedure.The test article shall be placed in the contact mechanism in any reasonable position for a penetration of 0.25 to 0.5 inch (0.64 to 1.27 centimeters), which position utilizes less than 180 degrees of the arc of thecontact mechanism, and a test load increasing to 50 pounds ±0.5 pound (22.74 kilograms) shall be evenly applied within 5 seconds. This load shall be maintained for an additional 10 seconds.(d) Flexure test—(1) Application.This test shall be applied to each component of a toy containing metal wire(s), or other metal material(s), for stiffening or for retention of form if the component can be bent through a 60-degree arc by a maximum force of 15 pounds ±0.5 pound (6.80 kilograms) applied perpendicularly to the major axis of the component at a point 2 inches ±0.05 inch (5 centimeters) from the intersection of the component with the main body of the toy or at the end of the component if the component is less than 2 inches ±0.05 inch (5 centimeters) long.(2) Testing procedure.The toy shall be secured in a vise equipped with vise shields that are fabricated from 13-gauge cold-rolled steel or other similar material and that have a 0.375-inch (0.95-centimeter) inside radius. The component shall then be bent through a 60-degree arc by a force applied at a point on the component 2 inches ±0.05 inch (5 centimeters) from the intersection of the component with the main body of the toy or applied at the end of the component if the component is less than 2 inches (5 centimeters) long. The component shall then be bent in the reverse direction through a 120-degree arc. This process shall be repeated for 30 cycles at a rate of one cycle per two seconds with a 60-second rest period occurring after each 10 cycles. Two 120-degree arc bends shall constitute one cycle.(e) Torque test—(1) Application—(i) General.A toy with a projection, part, or assembly that a child can grasp with at least the thumb and forefinger or the teeth shall be subject to this test.(ii) Toys with rotating components.Projections, parts, or assemblies that are rigidly mounted on an accessible rod or shaft designed to rotate along with the projections, parts, or assemblies shall be tested with the rod or shaft clamped to prevent rotation.(2) Test equipment—(i) Loading device.The loading device shall be a torque gauge, torque wrench, or other appropriate device having an accuracy of ±0.2 inch-pound (±0.23 kilogram-centimeter).(ii) Clamp.The clamp shall be capable of holding the test component firmly andtransmitting a torsional force.(3) Testing procedure.With the toy rigidly fastened in any reasonable test position, the clamp is fastened to the test object or component. A torque of 3 inch-pounds ±0.2 inch-pound (3.46 kilogram-centimeters) shall be applied evenly within a period of 5 seconds in a clockwise direction until a rotation of 180 degrees from the original position has been attained or 3 inch-pounds ±0.2 inch-pound (3.46 kilogram-centimeters) exceeded. The torque or maximum rotation shall be maintained for an additional 10 seconds. The torque shall then be removed and the test component permitted to return to a relaxed condition. This procedure shall then be repeated in a counterclockwise direction.(f) Tension test—(1) Application—(i) General.Any projection of a toy that the child can grasp with at least the thumb and forefinger or the teeth shall be subject to this test. This test is to be conducted on the same toy that has been subjected to the torque test described in paragraph (e) of this section. (ii) Stuffed toys and beanbags.A stuffed toy or beanbag constructed of pliable materials having seams (such as fabrics) shall have the seams subjected to 15 pounds ±0.5 pound (6.80 kilograms) of force applied in any direction.(2) Test equipment—(i) Clamps.One clamp capable of applying a tension load to the test component is required. A second clamp suitable for applying a tension load perpendicularly to the major axis of the test component is also required. (ii) Loading device.The loading device is to be a self-indicating gauge or other appropriate means having an accuracy of ±0.5 pound (±255 grams).(3) Testing procedure.With the test sample fastened in a convenient position, an appropriate clamp shall be attached to the test object or component. A 15-pound ±0.5 pound (6.80-kilogram) direct force shall be evenly applied, within a period of 5 seconds, parallel to the major axis of the test component and maintained for an additional 10 seconds. The tension clamp shall then be removed and a second clamp appropriate for pulling at 90 degrees shall be attached to the test object or component. A 15-pound ±0.5 pound (6.80-kilogram) tensile force shall be evenly applied, within a period of 5 seconds, perpendicularly to the major axis of the test component and maintained for an additional 10 seconds.(g) Compression test—(1) Application.Any area on the surface of a toy that isaccessible to a child and inaccessible to flat-surface contact during the impact test shall be subject to this test.(2) Test apparatus.The loading device shall be a rigid metal disc 1.125 inches ±0.015 inch (2.86 centimeters) in diameter and 0.375 inch (0.95 centimeter) in thickness. The perimeter of the disc shall be rounded to a radius of1/32inch (0.08 centimeter) to eliminate irregular edges. The disc shall be attached to an appropriate compression scale having an accurancy of ±0.5 pound (±225 grams).(3) Testing procedure.The disc shall be positioned so that the contact surface is parallel to the surface under test. A direct force of 25 pounds ±0.5 pound (11.4 kilograms) shall be evenly applied within 5 seconds through the disc. This load shall be maintained for an additional 10 seconds. During the test the toy is to rest on a flat, hard surface in any convenient position.[40 FR 1485, Jan. 7, 1975; 40 FR 6210, Feb. 10, 1975; 40 FR 16192, Apr. 10, 1975; as amended at 56 FR 10, Jan. 2, 1991]。

美国联邦法规第16部分(CPSC 16CFR)要求2007-09-20美国联邦法规与玩具有关的内容如下:1、1303部分:关于含铅油漆和某些含有铅油漆消费品的禁令条款1) 在1303部分,消费品产品安全委员会根据消费品安全条例(CPSA)15U.S.C.2057,2058第8.9章公布,供消费者使用的油漆和类似的涂层材料含铅或铅化合物(以金属铅计)不得超过总的不挥发油漆重量或干漆层重量的0.06%,否则则为危险品,禁止使用。

下列消费品被宣布为禁止使用的危险品。

a) 用于儿童使用的,含有“含铅油漆”的玩具和其它制品;b) 供消费者使用的,含有“含铅油漆”的家俱制品。

2) 本禁令适用于(a)段所述的1978年2月27日后制造的产品,这些产品称为“消费品”,该术语已在SPSA第3(a)(1)中作了定义。

法规包括上文述及的习惯为销售、使用、消费或家庭内外,学校、娱乐场等供消费者观赏的产品和分发的消费品。

摩托车、轮船所用的油漆,不包括在本禁令的范围内,因为它们超出了“消费品”的定义。

除了直接销售给消费者的产品外,本禁令还适用于售后被消费者使用的产品,如用于住宅、学校、医院、公园、运动场、公共建筑或其它消费者可能直接接触油漆表面的区域。

3) 根据(1)发现儿童触及的油漆、涂层含铅量超过0.06%,则有铅中毒的极大的危险。

2、1500部分:对危险物质和危险品管理及执行的法规:2.1 1500.44 鉴别极易燃或易燃固体物质的方法1) 样品制备a) 颗粒、粉未和糊状的样品:把样品放入一个平底的矩形金属舟中,舟的尺寸为152.4mm ×25.4mm,深6.35mm。

b) 硬质或软质固体:测量样品尺寸,用金属环形架,夹子、环或其它装置,将样品固定,使其长轴水平放置,使样品最大表面积自然暴露。

2) 步骤:把制备好的样品置于无气流处,该处能在每次试验后进行通风和清洁。

试验时,样品温度应保持在20℃~30℃之间。

世界各国地区玩具安全标准法规玩具作为儿童生活中不可或缺的一部分,必须经过严格的安全检测和遵守相应的法规标准。

各国地区都有相应的玩具安全标准法规,旨在保障儿童的安全和健康。

本文将介绍几个主要国家和地区的玩具安全标准法规。

一、美国玩具安全标准法规美国对玩具安全有严格的法规标准。

美国消费品安全委员会(CPSC)负责制定和监管美国的消费品安全标准,其中包括玩具安全标准。

根据美国联邦法典第16章第1501节,玩具必须符合ASTMF963标准,该标准涵盖了玩具的材质、尺寸、可玩性、耐久性和标识要求等方面。

此外,美国也规定玩具不能含有对儿童有害的物质,如铅、可溶性重金属等。

根据《美国消费者产品安全改革法》(CPSIA),所有进口或销售于美国市场的玩具必须经过第三方实验室的认证,以确保符合相关的安全标准。

二、欧盟玩具安全标准法规欧盟对玩具的安全标准由欧盟委员会制定和监管。

欧盟玩具安全指令(2009/48/EC)规定了欧盟内销售的所有玩具必须符合特定的安全要求。

根据该指令,玩具必须进行风险评估,并满足关于物质和机械性能等方面的要求。

同时,该指令还限制了一些有害物质的使用,如铅、镉等。

欧盟还规定了关于噪音、电磁兼容性和纸张/包装材料的安全要求,以确保儿童在玩乐过程中不受伤害。

三、中国玩具安全标准法规中国国家标准化管理委员会制定了一系列的玩具安全标准,其中最主要的是《GB 6675-2014 儿童玩具安全》和《GB 19865-2005 儿童纸制品及纸板玩具安全》。

《GB 6675-2014》指定了儿童玩具的安全性能要求,包括尺寸、结构、机械性能、可燃性、饭菜相容性和有害物质等方面。

该标准对于生产、进口和销售的玩具都有严格的要求。

此外,中国还制定了《GB 19865-2005》标准,该标准规定了儿童纸制品和纸板玩具的安全要求,包括儿童纸制品的可打印性、材料要求、可溶性物质和印刷油墨等方面的要求。

四、日本玩具安全标准法规日本国家标准化组织制定了《ST 2002玩具安全》和《ST 2014玩具标识》等一系列玩具安全标准。

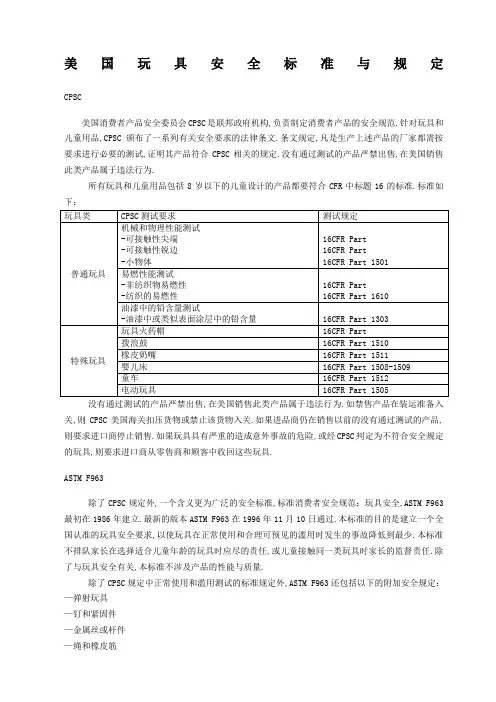

美国玩具安全标准与规定CPSC美国消费者产品安全委员会CPSC是联邦政府机构,负责制定消费者产品的安全规范.针对玩具和儿童用品,CPSC颁布了一系列有关安全要求的法律条文.条文规定,凡是生产上述产品的厂家都需按要求进行必要的测试,证明其产品符合CPSC相关的规定.没有通过测试的产品严禁出售,在美国销售此类产品属于违法行为.所有玩具和儿童用品包括8岁以下的儿童设计的产品都要符合CFR中标题16的标准.标准如下:没有通过测试的产品严禁出售,在美国销售此类产品属于违法行为.如禁售产品在装运准备入关,则CPSC美国海关扣压货物或禁止该货物入关.如果进品商仍在销售以前的没有通过测试的产品,则要求进口商停止销售.如果玩具具有严重的造成意外事故的危险,或经CPSC判定为不符合安全规定的玩具,则要求进口商从零售商和顾客中收回这些玩具.ASTM F963除了CPSC规定外,一个含义更为广泛的安全标准,标准消费者安全规范:玩具安全,ASTM F963最初在1986年建立.最新的版本ASTM F963在1996年11月10日通过.本标准的目的是建立一个全国认准的玩具安全要求,以使玩具在正常使用和合理可预见的滥用时发生的事故降低到最少.本标准不排队家长在选择适合儿童年龄的玩具时应尽的责任,或儿童接触同一类玩具时家长的监督责任.除了与玩具安全有关,本标准不涉及产品的性能与质量.除了CPSC规定中正常使用和滥用测试的标准规定外,ASTM F963还包括以下的附加安全规定:—弹射玩具—钉和紧固件—金属丝或杆件—绳和橡皮筋—包装薄膜—轮、轮胎和轴—折叠装置和铰链—机械装置的孔间隙和可触及性—稳定性和超载要求—封闭的空间—模拟的保护装置—挤压玩具—出牙器和出牙玩具—代连接在童床或游戏围栏上的玩具—玩具柜—电池驱动玩具—学前玩偶—球物理性能方面的安全规定:1、包装薄膜弹性塑料薄膜和弹性塑料膜—薄膜额定厚度必须为毫米以上;—实际厚度不得少于毫米.2、玩具上的绳和橡皮筋绳—一根细长的、柔软的材料,包括单纤维丝,纺织和搓捻的绳,粗绳,塑料纺织袋,丝带,及那些通常被称谓线的纤维状材料.供18个月以下的儿童使用的玩具不包括拖拉玩具上含有或系有绳或橡皮筋,在松弛状态和承受51B的重荷时测量,其最大长度必须小于12英寸.如果绳/橡皮筋盘或多段绳/橡皮筋或缠结或形成环状而与玩具的任何部位连接,包括在绳/橡皮筋末端的珠子或其它附着件,在51B的重力作用下,环的周长必须小于14英寸.本标准适用于滥用试验前后.3、学前玩偶被定义为头端是圆的、球形或半球形,颈是细的,而跟颈相连的是一个无任何附属结构的简单圆柱形:总长度不超过英寸.不能穿过附加测试器内径是的空腔.4、球被定义为由纤维束,毛线束,或线束粘在一起的,并且中间被牢固的绑或固定,外形成刷状,形成圆球形或半圆球形的由填充材料制成的小物体.5、脉冲在距玩具表面25厘米的任何位置测量时,玩具不能产生瞬间声级超过138分贝的脉冲噪音.电池驱动玩具的基本要求在ASTM F963-96a中总共有十一条来说明使用电池驱动玩具时潜在的危险如遇热过度,渗漏和爆炸等.1、包装电池盖或电池盖附近要标有永久性清晰易懂的电池极性和电压标志.2、最高可允许额定电压任何二个可接触电接点之间的最高可允许直流额定电压约为24V.3、防止一次性电池的充电这适用于电池可以放错和充电器可以对装有一次性电池的玩具充电的情况.4、电池的可触及性对于供3岁以下的儿童使用的玩具,在滥用测试或前或后,所有电池在不使用工具和情况下,都不能可触及.5、小电池的可触及性所有玩具中的电池如果能完全进入小零件测试筒,在滥用测试或前或后,所有电池在不使用工具和情况下,都不能可触及.6、不同电池的分开使用在任何单一的电路内不能将不同型号或容量的电池混用.7、表面温度测试在正常使用期间和合理可预见滥用后,电池表面温度不得超过71度,包括安装马达的情况下.8、短路测试在正常使用期间和合理可预见滥用后,不得出现可影响温度测试的短路现象.9、电短路接触除了在终羰的接触表面外,电气电路不能与电池的任何部分形成电接触.10、密封产品假使电池产生的气体量足以形成燃烧危险,密封产品的设计必须使电池产生的气体被吸收或泄出.11、操作说明使用一只以上电池的玩具需注明:1新、旧电池不可混用;2碱性电池、普通电池和充电电池不可混用.毒性1、重金属测试油漆和类似的表面涂层材料中重金属含量标准要符合最新的欧洲标准和规定.细节请参照附录IV.2、铅、镉测试用来或可能盛放食品的玩具的部件,如陶瓷茶具必须符合FDCA中402a2c和FDA产品合格方针导则中的有关要求.3、聚氯乙烯中的邻苯二甲酸二脂测试橡皮奶嘴、拔浪鼓和出牙器等PVC原料产品中含量不得超过固体物质含量的3%.4、亚硝铵含量测试橡皮奶嘴要求进行亚硝铵含量测试.5、填充材料的清洁度测试填充玩具的松散填充料不能有来自昆虫、鸟、啮齿类动物或其它动物寄生虫侵扰的不良材料,也不能有在良好操作规范中可能产生的污物,如碎片和金属屑.确定不良材料的测试方法见“法定分析化学家协会的法定分析方法”的第16章.另外,无论是天然还是合成的纤维填充材料都应满足“宾夕法尼亚洲填充玩具的容许量规定”的相关要求.6、微生物测试在ASTM中,清洁度包括另一个含义.尤其要注意含有液体、凝胶等玩具化妆品和玩具,因为他们为细菌生长提供了一个良好的环境.可注水的玩具要做所有的大肠茵测试.含有液体、凝胶和粉末等的玩具化妆品和玩具要求做微生限量测试USP〈62〉和抗微生物防腐剂的有效性测试USP〈51〉.安全标识要求某些玩具,以及在某些情况下它们的包装,要求加上安全标识来表明潜在的危险和使用说明.下列产品和玩具的包装必须按照规定的格式和措辞.—童床和游戏围栏玩具—活动玩具—滚轴滑冰鞋和玩具滑析—模拟的保护装置格式是:1、安全标记要全部大写并集中在第一行;2、警告标记可以在左侧或中间;3、“危险”或其它字样应继续写下去.而且,信号词“小心”或“警告”的所有字母都必须为高度不小于1/8英寸的大写字母.有关危险的声明和其它规定的声明必须用大写或小写字母,其中大写字母的高度不得小于1/16英寸.用在包装上的这类标识必须标在包装的一个主要展示面上,并且与它们出现在其上的背景成鲜明对比.所有的安全标识必须显眼和易读,必须与其它说明或图案明显分开.例如:系在童床和游戏围栏上的活动玩具在通过热印、丝网印刷,或类似的染色过程,将安全标识印到玩具本身上时,在滥用试验前或后,标签依然清晰易读.当安全标识以粘贴方式贴到玩具上时,该标签必须牢固地粘贴在玩具上,标签的任何边缘都不能翘起.在经过滥用试验前或后,标签依然清晰易读.美国小零件危险警告标签规定美国总统克林顿在1994年6月16日就已签发了儿童安全保护法案H.R965.消费者安全委员会于1995年2月27日颁布了修正案,并且于1995年8月28日最终生效,以对在美国生产或进入美国的产品作出规定.1995年8月28日后,制造商还有六个月时间以使他们的产品符合该规定.此法案包括:(a ) 如小球为三岁以下的儿童使用时,该球直径小于或等于”,则禁止出售. (b ) 在某些儿童使用的玩具、游戏机上的窒息危险警告标语应包括:1小物体至少三岁但小于六岁儿童使用的玩具和游戏机,若该玩具或游戏机 中包含小物体,则应有发下的警告声明:警告:窒息危险——小物体不适用于三岁以下儿童使用.2汽球,标识应写明:8岁以下 的儿童产生窒息危险,需成年人监护.将未充气的气球远离儿童.破裂的气球立即丢弃.3小球三岁或以上儿童使用的小球,标识应写明:窒息危险——此玩具是小球,不适用于三岁以下儿童使用. 岁儿童使用并含有小球的玩具或游戏机,标识 应写明:3岁以下儿童使用4弹子三岁或以上儿童使用的弹子,标识应写明:窒息危险——此玩具是弹子,不适用于三岁以下儿童使用. 岁儿童使用并含有弹子的玩具或游戏机,标识 应写明: 警告:窒息危险——玩具含有弹子 不适用于3岁以下儿童使用(c ) 以上标签要用英语写而且要清晰易读在以下地方: —在产品包装的主要展示面;—任何说明材料如说明书等要随附该产品;—如果该产品出售时无包装,在集装箱或售货机上,当出售产品时,警告标签则必须要被展示. (d ) 如果产品没有以上的规定标签,则被认为是冒牌的危险产品. (e ) 字符类型随主要展示面而定:。

美国的儿童玩具安全标准每个国家都有关于儿童玩具的安全标准,美国当然也不例外。

美国的儿童玩具安全标准是什么?这也是很多家长并不太了解的领域,如果使用复处理过的材料,必须将其精制以使其危险物含量符合1.3.1的要求。

易燃性玩具中使用的非纺织品(不包括纸)材料不能是易燃的,上述易燃定义按照联邦有害物质条例(FHSA)16CFR1500.3(C)(6)(VI)的规定。

为达到试验目的,玩具中使用的任何纺织物应符合16CFR 1610 的要求。

玩具易燃性的测试规程,即对16CFR1500.44 的说明,在附录A5中。

毒性有毒物质---玩具或用于玩具的材料必须符合FHSA以及根据FHSA所颁布的有关规定。

16 CFR 1500.85中列出了不属FHSA规定的某些种类的玩具。

上述有关规定对有毒、腐蚀性的、刺激性的、敏化的、产生压力的、放射性的、易燃的和可燃性物质规定了限量。

应注意的是,有些州对有毒物质的规定可能比联邦规定更严格。

食品的制造和包装--- 与玩具一起出售的食品的制造与包装都必须符合关于人类仪器制造、加工、包装和贮存的卫生操作条例21 CFR110。

非直接仪器添加剂---供与食品接触的玩具部件,如玩具炊具必须符合食品,药物和化妆品条例(FDCA)的有关要求。

特别是21 CFR 110。

供与食品接触的玩具部件的标签--- 由供与食品接触的部件组成的玩具,如玩具炊具和玩具餐具,必须根据2.8 的要求贴上标签。

陶瓷中铅镉含量---用来或可能盛放食品的陶瓷玩具部件,例如:陶瓷茶具必须符合FDCA中402(2)(C)和FDA产品合格方针导则中的有关要求。

化妆品---玩具化妆品必须符合FDCA中代码为21CER的有关要求。

其中适用于化妆品的规定见21CFR700-740。

以化妆品中色素的有关规定见21 CFR中73,74,81和82。

另外,所有玩具化妆品必须符合本标准和FHSA条例的所有要求,但不包括16 CFR 1500.81和50.3(b)(ii)。

国外玩具企业安全标准简介欧美发达国家对于儿童教育及日常生活都给予高度的重视,对于平时玩耍的玩具都有极高的要求。

所以,欧美比较成熟的玩具行业对于他们的产品在满足玩具法规要求基础上,根据自身产品的特定,制定一系列的行业标准要求,这些要求不仅增强了产品的安全性能,而且对产品质量也有极高的要求,也就是说,很多欧美玩具企业的行业标准是安全性能和高质量要求的集合体。

对于我国玩具业的发展有极高借鉴。

提高中国玩具自身品牌,以及玩具企业的转型极好的参考价值。

欧美从事玩具生产或销售的企业按主营的业务不同可分为三类:零售企业,主要业务是日用品的零售,商品种类中包含玩具,典型的企业如Wal-mart,家乐福,Target等。

玩具企业,主要业务为玩具的设计,制造和销售,典型的企业有Mattel,乐高,Harsbo 等。

快餐行业,主要业务是经营快餐,但会赠送玩具以吸引儿童就餐,典型的企业如McDonald, KFC等。

由于这些企业自身特点以及其产品所面对客户群体有相同处也有区别,所以他们对产品的要求就有所区别。

下面就这些玩具企业的行业标准作一些简述,以供参考。

一、国外玩具企业对儿童产品质量控制的特点国外玩具企业的行业标准与法规要求主要区别表现在以下方面:1、测试方法滥用测试方法相似,只是要求的限值/量不同,或者测试的次数不同,或者强度不同。

区别在于:(1)扭力测试:这项测试,一般按照玩具标准执行测试基本就可以满足所预期的考察要求了,但有些企业要求更严,扭力值达到1Nm. 常常要求乘骑玩具上的活动部件连接处等的螺母在1Nm的作用力下,不可以被旋下。

(2)拉力测试:产品不同,这个方面的要求也有所不同,通常主要表现在拉力值要求比玩具标准上的大,拉力的测试方向要求更严。

(3)跌落测试:通常这部分测试,按照玩具标准测试基本可以满足要求,有些企业会增加一些要求:在标准要求的高度,执行更多的测试,这个主要表现在木制玩具和一些塑胶产品上;或者提供跌落测试的高度来评估产品的安全性能。

欧美玩具用纺织品燃烧性能技术法规与标准解读_REACH法规纺织品PCP限量欧美玩具用纺织品燃烧性能技术法规与标准解读_REACH法规纺织品PCP限量本文主要介绍了美国、加拿大、欧盟等发达国家和地区玩具标准中关于玩具用纺织品燃烧性能的技术法规和标准要求。

The regulations and standards of flammability of textiles for toys in United States, Canada and European Union and other developed countries were explained in this paper.如今,玩具中大量用到了纺织品,比如毛绒玩偶、布制娃娃、玩具风筝、戏偶和玩具帐篷等。

因为纺织品是易引发火灾的材料,所以玩具用纺织品的燃烧性能越来越受到人们的重视。

欧美发达国家对玩具用纺织品的阻燃性能都提出了要求,并制定了相关的技术法规和标准。

并且,这些发达国家往往以维护人身安全为由将玩具用纺织品的阻燃性能要求作为限制玩具产品进口的一种技术性手段。

1美国玩具用纺织品燃烧性能技术法规1.1ASTM F963《玩具安全》的燃烧性能要求ASTM F963是一部美国玩具产品的强制性标准,由美国商务部国家标准局主持制定,版ASTM F963�08于2021年12月1日正式生效。

ASTM F963 � 08针对所有的固体玩具(包括纺织品组成的固体玩具,如毛绒玩偶、玩具帐篷等),其规定玩具中使用的材料不能是易燃的。

关于易燃性的定义,按照美国联邦有害物质条例(FHSA)16CFR 1500.3(C)(6)(VI)的规定,玩具整体易燃性必须符合燃烧速度小于0.1 in/s的要求。

关于玩具整体易燃性的测试方法,标准的程序包括:样品制备和实验步骤。

把制备好的样品置于无气流处,该处能在每次试验后进行通风和清洁。

试验时,样品温度应保持在20 ~30 ℃之间。

美國玩具安全標準一、安全要求:1、安全要求1.1 材料品質-玩具中以用新的或復處理過的材料製成。

假如使用復處理過的材料,必須將其精製以使其危險物含量符合1.3.1的要求。

1.2 易燃性-玩具中使用的非紡織品(不包括紙)材料不能是易燃的,上述易燃定義按照聯邦有害物質條例(FHSA)16CFR 1500.3(C)(6)(VI)的規定。

為達到試驗目的,玩具中使用的任何紡織物應符合16CFR 1610 的要求。

玩具易燃性的測試規程,即對16CFR 1500.44 的說明,在附錄A5中。

1.3 毒性1.3. 1 有毒物質---玩具或用於玩具的材料必須符合FHSA以及根據FHSA所頒布的有關規定。

16 CFR 1500.85 中列出了不屬FHSA規定的某些種類的玩具。

上述有關規定對有毒、腐蝕性的、刺激性的、敏化的、產生壓力的、放射性的、易燃的和可燃性物質規定了限量。

5.2 為測定有毒物質含量的參考方法。

應注意的是,有些州對有毒物質的規定可能比聯邦規定更嚴格。

1.3.2 食品的製造和包裝--- 與玩具一起出售的食品的製造與包裝都必須符合關於人類儀器製造、加工、包裝和貯存的衛生操作條例 21 CFR 110。

1.3.3 非直截了当儀器添加劑---供與食品接觸的玩具部件,如玩具炊具必須符合食品,藥物和化粧品條例(FDCA)的有關要求。

特別是21 CFR 110。

1.3.3.1 供與食品接觸的玩具部件的標簽--- 由供與食品接觸的部件組成的玩具,如玩具炊具和玩具食具,必鬚根據2.8 的要求貼上標簽。

1.3.3.2 陶瓷中鉛鎘含量---用來或可能盛放食品的陶瓷玩具部件,例如:陶瓷茶具必須符合FDCA中402 (2)(C)和FDA產品合格方針導則中的有關要求。

1.3.4 化粧品---玩具化粧品必須符合 FDCA 中代碼為21CER的有關要求。

其中適用於化粧品的規定見21CFR700-740。

以化粧品中色素的有關規定見21 CFR中73,74,81和82。

美国联邦法规 16 CFR 1501 识别供3岁以下儿童使用.含可引起窒息,吸入或咽下危险小部件的玩具和其它物品的方法原文出处:作者:编辑: [2009-02-25][打印文章] [关闭窗口]PART 1501—METHOD FOR IDENTIFYING TOYS AND OTHER ARTICLES INTENDED FOR USEBY CHILDREN UNDER 3 YEARS OF AGE WHICH PRESENT CHOKING, ASPIRATION, ORINGESTION HAZARDS BECAUSE OF SMALL PARTSSec.1501.1 Purpose.1501.2 Scope.1501.3 Exemptions.1501.4 Size requirements and test procedure.1501.5 Enforcement procedure.AUTHORITY: Secs. 2(f)(1)(D), (q)(1)(A), (s), 3(e)(1), and 10; 74 Stat. 372,374, 375 as amended; 80 Stat. 1304–05, 83 Stat. 187–89 (15 U.S.C. 1261,1262, 1269).SOURCE: 44 FR 34903, June 15, 1979, unless otherwise noted.§ 1501.1 Purpose.Section 1500.18(a)(9) of this chapter classifies as a banned hazardoussubstance any toy or other article intended for use by children under 3years of age that presents a choking, aspiration, or ingestion hazardbecause of small parts. This part 1501 describes certain articles that aresubject to §1500.18(a)(9); lists certain articles that are specificallyexempted; and provides a test method for determining whether an article ishazardous to children under 3 because it, or one of its components that canbe detached or broken off during normal or reasonable foreseeable use, istoo small.§ 1501.2 Scope.(a) This regulation (§1500.18(a)(9) and the criteria described in §1501.4below) applies to all toys and other articles intended for use by childrenunder 3 years (36 months) of age that are introduced into interstatecommerce after the effective date. Such articles include, but are not tolimited to: squeeze toys; teethers; crib exercisers; crib gyms; crib mobiles; other toys or articles intended to be affixed to a crib, stroller, playpen, or baby carriage; pull and push toys; pounding toys; blocks and stacking sets; bathtub, wading pool and sand toys; rocking, spring, andstick horses and other figures; chime and musical balls and carousels;jacks-in-the-box; stuffed, plush, and flocked animals and other figures; preschool toys, games and puzzles intended for use by children under 3; riding toys intended for use by children under 3; infant and juvenile furniture articles which are intended for use by children under 3 such as cribs, playpens, baby bouncers and walkers, strollers and carriages; dolls which are intended for use by children under 3 such as baby dolls, rag dolls, and bean bag dolls; toy cars, trucks, and other vehicles intended for use by children under 3. In addition, such articles include any other toys or articles which are intended, marketed or labeled to be entrusted to or used by children under 3 years of age.(b) In determining which toys and other articles are intended for use by children under 3 years (36 months) of age, for purposes of this regulation, the following factors are relevant: the manufacturer's stated intent (such as on a label) if it is a reasonable one; the advertising, promotion, and marketing of the article; and whether the article is commonly recognized as being intended for children under 3.(c) This regulation does not apply to toys or articles which are solely intended for use by children 3 years of age or older. In addition, it does not apply to all articles to which children under 3 years of age might have access simply because of presence in a household. Certain articles which are specifically exempted from this regulation are listed in §1501.3 below.§ 1501.3 Exemptions.The following articles are exempt from this regulation (§§1500.18(a)(9) and 1501.4 below):(a) Balloons;(b) Books and other articles made of paper;(c) Writing materials such as crayons, chalk, pencils, and pens;(d) Children's clothing and accessories, such as shoe lace holders and buttons;(e) Grooming, feeding, and hygiene products, such as diaper pins and clips, barrettes, toothbrushes, drinking glasses, dishes and eating utensils;(f) Phonograph records;(g) Modeling clay and similar products;(h) Fingerpaints, watercolors, and other paint sets;(i) Rattles (as defined at 16 CFR 1510.2); and(j) Pacifiers (as defined at 16 CFR 1511.2(a)).§ 1501.4 Size requirements and test procedure.(a) No toy or other children's article subject to §1500.18(a)(9) and tothis part 1501 shall be small enough to fit entirely within a cylinder with the dimensions shown in Figure 1, when tested in accordance with the procedure in paragraph (b) of this section. In testing to ensure compliance with this regulation, the dimensions of the Commission's test cylinder will be no greater than those shown in Figure 1. (In addition, for compliance purposes, the English dimensions shall be used. The metric approximations are included only for convenience.)(b)(1) Place the article, without compressing it, into the cylinder. If the article fits entirely within the cylinder, in any orientation, it fails to comply with the test procedure. (Test any detached components of the article the same way.)(2) If the article does not fit entirely within the cylinder, subject it to the appropriate “use and abuse” tests of 16 CFR 1500.51 and 1500.52 (excluding the bite tests of §§1500.51(c) and 1500.52(c)). Any components or pieces (excluding paper, fabric, yarn, fuzz, elastic, and string) whichhave become detached from the article as a result of the use and abuse testing shall be placed into the cylinder, one at a time. If any such components or pieces fit entirely within the cylinder, in any orientation and without being compressed, the article fails to comply with the test procedure.§ 1501.5 Enforcement procedure.The Commission will enforce this regulation, unless it determines that an emergency situation exists, only in accordance with Chapter 2, Guide 2.05—Letter of Advice/Notices of Noncompliance of the CPSC Enforcement Policy and Procedural Guides, issued in January 1990 and available from the Office of the Secretary, Consumer Product Safety Commission, Washington, DC 20207. Under the procedure described in this chapter, firms must be informed by letter that they or their products may be the subject of enforcement action and must be provided ten days within which to submit evidence and arguments that the products are not violative or are not covered by the regulation, prior to the initiation of enforcement action by the Commission or by its delegated staff member. The function of approving such enforcement actionsis currently delegated by the Commission to the Assistant Executive Director for Compliance and Enforcement (copies of the existing delegation documents are also available from the CPSC's Office of the Secretary).[56 FR 46986, Sept. 17, 1991]。

美国联邦法规 16 CFR 1500.48 供8岁以下儿童使用的玩具或类似品中尖点的测定的技术要求原文出处:作者:编辑: [2009-02-25][打印文章] [关闭窗口]§ 1500.48 Technical requirements for determining a sharp point in toys and other articles intended for use by children under 8 years of age.(a) Objective. The sharp point test prescribed by paragraph (d) of this section will be used by the Commission in making a preliminary determination that points on toys and other articles intended for use by children under 8 years of age, and such points exposed in normal use or as a result of reasonably foreseeable damage or abuse of such toys and articles, present a potential risk of injury by puncture or laceration under section 2(s) of the Federal Hazardous Substances Act (15 U.S.C. 1261(s)). The Commission will further evaluate points that are identified as presenting a potential risk of puncture or laceration injury to determine the need for individual product regulatory action.(b) Scope—(1) General. The sharp point test of paragraph (d) of this section is applicable to toys or other articles that are introduced into interstate commerce on or after December 22, 1978. The sharp point test shall be applied to any accessible portion of the test sample before and after subjecting the test sample to the use and abuse tests of §§1500.51, 1500.52, and 1500.53 (excluding the bite test-paragraph (c) of each section).(2) Exemptions. (i) Toys and other children's articles that are the subject of any of the following regulations are exempt from this §1500.48: The regulations for bicycles, non-full-size baby cribs, and full-size baby cribs (parts 1508, 1509, and 1512, of this chapter).(ii) Toys that by reason of their functional purpose necessarily present the hazard of sharp points and that do not have any nonfunctional sharp points are exempt from this §1500.48: Provided, Each toy is identified by a conspicuous, legible, and visible label at the time of any sale, as having functional sharp points. An example of such toys is a toy sewing machine with a needle.(iii) Articles, besides toys, intended for use by children that by reason of their functional purpose necessarily present the hazard of sharp points and that do not have any nonfunctional sharp points are exempt from this §1500.48. An example of such articles is a ball-point pen.(c) Accessibility—(1) General. Any point that is accessible either before or after these tests of §1500.51, §1500.52, and §1500.53 (excluding the bite test—paragraph(c) of each section) are performed shall be subject to the sharp point test of paragraph(d) of this section.(2) Accessible points.(i) An accessible point for a toy or article intended for children3 years of age or less is one that can be contacted by any portion forward of the collar of the accessibility probe designated as probe A in figure 2 of this section.(ii) An accessible point for a toy or article intended for children over 3 years up to 8 years of age is one that can be contacted by any portion forward of the collar of the accessibility probe designated as probe B in figure 2 of this section.(iii) An accessible point for a toy or article intended for children of ages spanning both age groups is one that can be contacted by any portion forward of the collar of either probe A or B, as shown in figure 2 of this section.(3) Insertion depth for accessibility. (i) For any hole, recess, or opening having a minor dimension (The minor dimension of an opening is the diameter of the largest sphere that will pass through the opening.) smaller than the collar diameter of the appropriate probe, the total insertion depth for accessibility shall be up to the collar on the appropriate probe. Each probe joint may be rotated up to 90 degrees to simulate knuckle movement.(ii) For any hole, recess, or opening having a minor dimension larger than the collar diameter of probe A but less than 7.36 inches (186.9 millimeters), when probe A is used, or a minor dimension larger than the collar diameter of probe B but less than 9.00 inches (228.6 millimeters), when probe B is used, the total insertion depth for accessibilityshall be determined by inserting the appropriate probe with the extension shown in figure 2 in any direction up to two and one-quarter times the minor dimension of the probe, recess, or opening, measured from any point in the plane of the opening. Each probe joint may be rotated up to 90 degrees to simulate knuckle movement.(iii) For any hole, recess, or opening having a minor dimension of 7.36 inches (186.9 millimeters) or larger when probe A is used, or a minor di-mension of 9.00 inches (228.6 millimeters), or larger when probe B is used, the total insertion depth for accessibility is unrestricted unless other holes, recesses, or openings within the original hole, recess, or opening are encountered with dimensions specified in paragraph (c)(3) (i) or (ii) of this section. In such instances, the appropriate paragraphs (c)(3) (i) or (ii) of this section shall be followed. If both probes are to be used, a minor dimen-sion that is 7.36 inches (186.9 millimeters or larger shall determine unrestricted access.(4) Inaccessible points. Points shall be considered inaccessible without testing witha probe if they lie adjacent to a surface of the test sample and any gap between the point and the adjacent surface does not exceed 0.020 inch (0.50 millimeter) either before or after the tests of §§1500.51, 1500.52, and 1500.53 (excluding the bite test—paragraph (c) of each section) are performed.(d) Sharp point test method—(1) Principle of operation. The principle of operation of the sharp point tester shown in figure 1 of this section is as follows (Detailed engineering drawings for a suggested sharp point tester are available from the Commission's Office of the Secretary.): A rectangular opening measuring 0.040 inch (1.02 millimeters) wide by 0.045 inch (1.15 millimeters) long in the end of the slotted cap establishes two reference dimensions. Depth of penetration of the point being tested determines sharpness. If the point being tested can contact a sensing head that is recessed a distance of 0.015 inch (0.38 millimeter) below the end cap and can move the sensing head a further 0.005 inch (0.12 millimeter) against a 0.5-pound (2.2-newton) force of a return spring, the point shall be identified as sharp. A sharp point tester of the general configuration shown in figure 1 of this section or one yielding equivalent results shall identify a sharp point. In conducting tests to determine the presence of sharp points, the Commission will use the sharp point tester shown in figure 1 of this section and the accessibility probes designated as A or B in figure 2 of this section.(2) Procedure. (i) The sample to be tested shall be held in such a manner that it does not move during the test.(ii) Part of the test sample may need to be removed to allow the sharp point testing device to test a point that is accessible by the criteria of paragraph (c) of this section. Such dismantling of the test sample could affect the rigidity of the point in question. The sharp point test shall be performed with the point supported so that its stiffness approximates but is not greater than the point stiffness in the assembled sample.(iii) Using the general configuration shown in figure 1 of this section, the adjustment and operation of the sharp point tester is as follows: Hold the sharp point tester and loosen the lock ring by rotating it so that it moves towards the indicator lamp assembly a sufficient distance to expose the calibration reference marks on the barrel. Rotate the gaging can clockwise until the indicator lamp lights. Rotate the cap counterclockwise until an equivalent of five divisions (the distance between the short lines on the cap) have passed the calibration reference mark. Lock the gaging cap in this position by rotating the lock ring until it fits firmly against the cap. Insert the point into the gaging slot in all directions in which it was accessible by the criteria of paragraph (c) of this section, and apply a force of 1.00 pound (4.45 newtons). A glowing light identifies the point as sharp.(iv) The test instruments used by the Commission in its tests for compliance with this regulation shall have gaging slot opening dimensions no greater than 0.040 inch by 0.045 inch and shall have the sensing head recessed a depth of no less than 0.015 inch. The force applied by the Commission when inserting a point into the gaging slot shall be no more than 1.00 pound.(e) For the purpose of conformance with the technical requirements prescribed by this §1500.48, the English figures shall be used. The metric approximations are provided in parentheses for convenience and information only.。

美国联邦法规第16部分(CPSC 16 CFR)要求(2007-09-20)美国联邦法规与玩具有关的内容如下:1、1303部分:关于含铅油漆和某些含有铅油漆消费品的禁令条款1) 在1303部分,消费品产品安全委员会根据消费品安全条例(CPSA)15U.S.C.2057,2058第8.9章公布,供消费者使用的油漆和类似的涂层材料含铅或铅化合物(以金属铅计)不得超过总的不挥发油漆重量或干漆层重量的0.06%,否则则为危险品,禁止使用。

下列消费品被宣布为禁止使用的危险品。

a) 用于儿童使用的,含有“含铅油漆”的玩具和其它制品;b) 供消费者使用的,含有“含铅油漆”的家俱制品。

2) 本禁令适用于(a)段所述的1978年2月27日后制造的产品,这些产品称为“消费品”,该术语已在SPSA第3(a)(1)中作了定义。

法规包括上文述及的习惯为销售、使用、消费或家庭内外,学校、娱乐场等供消费者观赏的产品和分发的消费品。

摩托车、轮船所用的油漆,不包括在本禁令的范围内,因为它们超出了“消费品”的定义。

除了直接销售给消费者的产品外,本禁令还适用于售后被消费者使用的产品,如用于住宅、学校、医院、公园、运动场、公共建筑或其它消费者可能直接接触油漆表面的区域。

3) 根据(1)发现儿童触及的油漆、涂层含铅量超过0.06%,则有铅中毒的极大的危险。

2、1500部分:对危险物质和危险品管理及执行的法规:2.1 1500.44 鉴别极易燃或易燃固体物质的方法1) 样品制备a) 颗粒、粉未和糊状的样品:把样品放入一个平底的矩形金属舟中,舟的尺寸为152.4mm×25.4mm,深6.35mm。

b) 硬质或软质固体:测量样品尺寸,用金属环形架,夹子、环或其它装置,将样品固定,使其长轴水平放置,使样品最大表面积自然暴露。

2) 步骤:把制备好的样品置于无气流处,该处能在每次试验后进行通风和清洁。

试验时,样品温度应保持在20℃~30℃之间。

美国联邦法规 16 CFR 1501 识别供3岁以下儿童使用.含可引起窒息,吸入或咽下危险小部件的玩具和其它物品的方法原文出处:作者:编辑: [2009-02-25][打印文章] [关闭窗口]PART 1501—METHOD FOR IDENTIFYING TOYS AND OTHER ARTICLES INTENDED FOR USE BYCHILDREN UNDER 3 YEARS OF AGE WHICH PRESENT CHOKING, ASPIRATION, OR INGESTIONHAZARDS BECAUSE OF SMALL PARTSSec.1501.1 Purpose.1501.2 Scope.1501.3 Exemptions.1501.4 Size requirements and test procedure.1501.5 Enforcement procedure.AUTHORITY: Secs. 2(f)(1)(D), (q)(1)(A), (s), 3(e)(1), and 10; 74 Stat. 372, 374,375 as amended; 80 Stat. 1304–05, 83 Stat. 187–89 (15 U.S.C. 1261, 1262, 1269). SOURCE: 44 FR 34903, June 15, 1979, unless otherwise noted.§ 1501.1 Purpose.Section 1500.18(a)(9) of this chapter classifies as a banned hazardous substanceany toy or other article intended for use by children under 3 years of age thatpresents a choking, aspiration, or ingestion hazard because of small parts. Thispart 1501 describes certain articles that are subject to §1500.18(a)(9); listscertain articles that are specifically exempted; and provides a test method fordetermining whether an article is hazardous to children under 3 because it, orone of its components that can be detached or broken off during normal orreasonable foreseeable use, is too small.§ 1501.2 Scope.(a) This regulation (§1500.18(a)(9) and the criteria described in §1501.4below) applies to all toys and other articles intended for use by children under3 years (36 months) of age that are introduced into interstate commerce afterthe effective date. Such articles include, but are not to limited to: squeezetoys; teethers; crib exercisers; crib gyms; crib mobiles; other toys or articlesintended to be affixed to a crib, stroller, playpen, or baby carriage; pull andpush toys; pounding toys; blocks and stacking sets; bathtub, wading pool and sand toys; rocking, spring, and stick horses and other figures; chime and musical balls and carousels; jacks-in-the-box; stuffed, plush, and flocked animals and other figures; preschool toys, games and puzzles intended for use by children under 3; riding toys intended for use by children under 3; infant and juvenile furniture articles which are intended for use by children under 3 such as cribs, playpens, baby bouncers and walkers, strollers and carriages; dolls which are intended for use by children under 3 such as baby dolls, rag dolls, and bean bag dolls; toy cars, trucks, and other vehicles intended for use by children under 3. In addition, such articles include any other toys or articles which are intended, marketed or labeled to be entrusted to or used by children under 3 years of age.(b) In determining which toys and other articles are intended for use by children under 3 years (36 months) of age, for purposes of this regulation, the following factors are relevant: the manufacturer's stated intent (such as on a label) if it is a reasonable one; the advertising, promotion, and marketing of the article; and whether the article is commonly recognized as being intended for children under 3.(c) This regulation does not apply to toys or articles which are solely intended for use by children 3 years of age or older. In addition, it does not apply to all articles to which children under 3 years of age might have access simply because of presence in a household. Certain articles which are specifically exempted from this regulation are listed in §1501.3 below.§ 1501.3 Exemptions.The following articles are exempt from this regulation (§§1500.18(a)(9) and 1501.4 below):(a) Balloons;(b) Books and other articles made of paper;(c) Writing materials such as crayons, chalk, pencils, and pens;(d) Children's clothing and accessories, such as shoe lace holders and buttons;(e) Grooming, feeding, and hygiene products, such as diaper pins and clips, barrettes, toothbrushes, drinking glasses, dishes and eating utensils;(f) Phonograph records;(g) Modeling clay and similar products;(h) Fingerpaints, watercolors, and other paint sets;(i) Rattles (as defined at 16 CFR 1510.2); and(j) Pacifiers (as defined at 16 CFR 1511.2(a)).§ 1501.4 Size requirements and test procedure.(a) No toy or other children's article subject to §1500.18(a)(9) and to this part 1501 shall be small enough to fit entirely within a cylinder with the dimensions shown in Figure 1, when tested in accordance with the procedure in paragraph (b) of this section. In testing to ensure compliance with this regulation, the dimensions of the Commission's test cylinder will be no greater than those shown in Figure 1. (In addition, for compliance purposes, the English dimensions shall be used. The metric approximations are included only for convenience.)(b)(1) Place the article, without compressing it, into the cylinder. If the article fits entirely within the cylinder, in any orientation, it fails to comply with the test procedure. (Test any detached components of the article the same way.)(2) If the article does not fit entirely within the cylinder, subject it to the appropriate “use and abuse” tests of 16 CFR 1500.51 and 1500.52 (excluding the bite tests of §§1500.51(c) and 1500.52(c)). Any components or pieces (excluding paper, fabric, yarn, fuzz, elastic, and string) which have become detached from the article as a result of the use and abuse testing shall be placed into the cylinder, one at a time. If any such components or pieces fit entirely within the cylinder, in any orientation and without being compressed, the article fails to comply with the test procedure.§ 1501.5 Enforcement procedure.The Commission will enforce this regulation, unless it determines that an emergency situation exists, only in accordance with Chapter 2, Guide 2.05—Letter of Advice/Notices of Noncompliance of the CPSC Enforcement Policy and Procedural Guides, issued in January 1990 and available from the Office of the Secretary, Consumer Product Safety Commission, Washington, DC 20207. Under the procedure described in this chapter, firms must be informed by letter that they or theirproducts may be the subject of enforcement action and must be provided ten days within which to submit evidence and arguments that the products are not violative or are not covered by the regulation, prior to the initiation of enforcement action by the Commission or by its delegated staff member. The function of approving such enforcement actions is currently delegated by the Commission to the Assistant Executive Director for Compliance and Enforcement (copies of the existing delegation documents are also available from the CPSC's Office of the Secretary).[56 FR 46986, Sept. 17, 1991]。

美国联邦法规 16 CFR 1500.18 严禁供儿童使用的玩具或其它物品原文出处:作者:编辑: [2009-02-24][打印文章] [关闭窗口]§ 1500.18 Banned toys and other banned articles intended for use by children.(a) Toys and other articles presenting mechanical hazards. Under the authority of sections 2(f)(1)(D) and 24 of the act and pursuant to the provisions of section 3(e) of the act, the Commission has determined that the following types of toys or other articles intended for use by children present a mechanical hazard within the meaning of section 2(s) of the act because in normal use, or when subjected to reasonably foreseeable damage or abuse, the design or manufacture presents an unreasonable risk of personal injury or illness:(1) Any toy rattle containing, either internally or externally, rigid wires, sharp protrusions, or loose small objects that have the potential for causing lacerations, puncture wound injury, aspiration, ingestion, or other injury. (But see §1500.86(a)(1)).(2) Any toy having noisemaking components or attachments capable of being dislodged by the operating features of the toy or capable of being deliberately removed by a child, which toy has the potential for causing laceration, puncture wound injury, aspiration, ingestion, or other injury.(3) Any doll, stuffed animal, or other similar toy having internal or external components that have the potential for causing laceration, puncture wound injury, or other similar injury. (But see §1500.86(a)(2)); (See also §§1500.48 and 1500.49).(4) Lawn darts and other similar sharp-pointed toys usually intended for outdoor use and having the potential for causing puncture wound injury.(5) Caps (paper or plastic) intended for use with toy guns and toy guns notintended for use with caps if such caps when so used or such toy guns produce impulse-type sound at a peak pressure level at or above 138 decibels, referred to 0.0002 dyne per square centimeter, when measured in an anechoic chamber at a distance of 25 centimeters (or the distance at which the sound source ordinarily would be from the ear of the child using it if such distance is less than 25 centimeters) in any direction from the source of the sound. This paragraph is an interim regulation pending further investigation to determine whether prevention of damage to the hearing of children requires revision hereof.(6) Any article known as a “baby-bouncer,”“walker-jumper,” or “baby-walker”and any other similar article (referred to in this paragraph as “article(s)”) which is intended to support very young children while sitting walking, bouncing, jumping, and/or reclining, and which because of its design has any exposed parts capable of causing amputation, crushing, lacerations, fractures, hematomas, bruises, or other injuries to fingers, toes, or other parts of the anatomy of young children. Included among, but not limited to, the design features of such articles which classify the articles as banned hazardous substances are:(i) The areas about the point on each side of the article where the frame components are joined together to form an “X” shape capable of producing a scissoring, shearing, or pinching effect.(ii) Other areas where two or more parts are joined in such a manner as to permit a rotational movement capable of exerting a scissoring, shearing, or pinching effect.(iii) Exposed coil springs which may expand sufficiently to allow an infant's finger, toe, or any other part of the anatomy to be inserted, in whole or in part, and injured by being caught between the coils of the spring or between the spring and another part of the article.(iv) Holes in plates or tubes which provide the possibility of insertion, in whole or in part, of a finger, toe, or any part of the anatomy that could then be injured by the movement of another part of the article.(v) Design and construction that permits accidental collapse while in use. (But see §1500.86(a)(4)).(7) Toys usually known as clacker balls and consisting of two balls of plastic or another material connected by a length of line or cord or similar connector (referred to as “cord” in §1500.86(a)(5)), intended to be operated in a rhythmic manner by an upward and downward motion of the hand so that the two balls will meet forcefully at the top and bottom of two semicircles thus causing a “clacking” sound, which toys present a mechanical hazard because their design or manufacture presents an unreasonable risk of personal injury from fracture, fragmentations, or disassembly of the toy and from propulsion of the toy or its part(s). (But see §1500.86(a)(5).) This does not include products that are constructed so that the connecting members consist of plastic rods integrally molded to the balls and are mounted on a pivot so that movement of the balls is essentially limited to a single plane.(8) Any pacifier that does not meet the requirements of 16 CFR part 1511 and that is introduced into interstate commerce after February 26, 1978.(9) Any toy or other article intended for use by children under 3 years of age which presents a choking, aspiration, or ingestion hazard because of small parts as determined by part 1501 of this chapter and which is introduced into interstate commerce after January 1, 1980. For purposes of this regulation, introduction into interstate commerce is defined as follows: A toy or children's article manufactured outside the United States is introduced into interstate commerce when it is first brought within a U.S. port of entry. A toy or children's article manufactured in the United States is introduced into interstate commerce (1) at the time of its first interstate sale, or (2) at the time of its first intrastate sale if one or more of its components and/or raw materials were received interstate, whichever occurs earlier. Part 1501 defines the term “toy or other article intended for use by children under 3,” as used in this regulation, and exempts certain products from banning under this regulation.(10)–(11) [Reserved](12) Any bicycle as defined in §1512.2(a) of this chapter (except a bicycle that is a “track bicycle” or a “one-of-a-kind bicycle” as defined in §1512.2 (d) and (e) of this chapter) that is introduced into interstate commerce on or after May 11, 1976, and that does not comply with the requirements of part 1512 of this chapter, except for §§1512.5(c)(3), 1512.9(a), 1512.18(e) and 1512.18(f) which become effective November 13, 1976.(13) Any full-size baby crib (as defined in §1508.1(a) of this chapter) that is introduced into interstate commerce on or after February 1, 1974, and that does not comply with the requirements of §§1508.2 through 1508.10 of this chapter; and any full size baby crib (as defined in §1508.1(a) of this chapter) that is manufactured on or after April 27, 1983, and that does not comply with §§1508.2 through 1508.11 of this chapter.(14) Any non-full-size baby crib (as defined in §1509.2 of this chapter) that is introduced into interstate commerce after August 9, 1976, and that does not comply with the requirements of §§1509.3 through 1509.12 of this chapter; and any non-full size baby crib (as defined in §1509.2 of this chapter) that is manufactured on or after April 27, 1983, and that does not comply with §§1509.3 through 1509.13 of this chapter.(15) Any rattle (as defined in §1510.2 of this chapter) that is introduced into interstate commerce on or after August 21, 1978, and that does not comply with the requirements of part 1510 of this chapter. For purposes of the regulation, introduction into interstate commerce is defined as follows: A rattle manufactured outside the United States is introduced into interstate commerce when it is first brought within a U.S. port of entry. A rattle manufactured in the United States is introduced into interstate commerce (a) at the time of its first interstate sale, or (b) at the time of its first intrastate sale if one or more of its components and/or raw materials were received interstate.(16) (i) Any article known as an “infant cushion” or “infant pillow,” andany other similar article, which has all of the following characteristics (But see §1500.86(a)(9)):(A) Has a flexible fabric covering. The term fabric includes those materials covered by the definition of “fabric” in section 2(f) of the Flammable Fabrics Act, 15 U.S.C. 1191(f).(B) Is loosely filled with a granular material, including but not limited to, polystyrene beads or pellets.(C) Is easily flattened.(D) Is capable of conforming to the body or face of an infant.(E) Is intended or promoted for use by children under one year of age.(ii) Findings —(A) General. In order to issue a rule under section 2(q)(1) of the Federal Hazardous Substance Act (FHSA), 15 U.S.C. 1261(q)(1), classifying a substance or article as a banned hazardous substance, the FHSA requires the Commission to make certain findings and to include these findings in the regulation. These findings are discussed in paragraphs (a)(16)(ii) (B) through (D) of this section.(B) Voluntary standard. No findings concerning compliance with or adequacy of a voluntary standard are necessary since no voluntary standard addressing infant cushions has been adopted or implemented.(C) Relationship of benefits to costs.The Commission estimates that the removal of infant cushions from the market will result in total annual benefits of approximately five million dollars. The potential costs to businesses are expected to be offset by production of other products, and the potential costs to consumers are likely to be offset by the availability of substitutes for a comparable price.(D) Least burdensome requirement.The Commission considered labeling and a design or performance standard as alternatives to the ban. The Commission does not believe that any form of labeling would have a significant effect in preventing the hazard associated with infant cushions. The Commission also concluded that no feasible standard exists that would address the hazard. Thus, the Commission determined that a ban of infant cushions is the least burdensome alternative that would prevent or adequately reduce the risk of injury.(17) Any ball intended for children under three years of age that, under the influence of its own weight, passes, in any orientation, entirely through a circular hole with a diameter of 1.75 inches (44.4 mm.) in a rigidtemplate1/4inches (6 mm.) thick. In testing to evaluate compliance with this paragraph, the diameter of opening in the Commission's test template shall be no greater than 1.75 inches (44.4 mm.).(i) For the purposes of this paragraph, the term “ball” includes any spherical, ovoid, or ellipsoidal object that is designed or intended to be thrown, hit, kicked, rolled, dropped, or bounced. The term “ball” includes any spherical, ovoid, or ellipsoidal object that is attached to a toy or article by means of a string, elastic cord, or similar tether. The term “ball” also includes any multi-sided object formed by connecting planes into a generally spherical, ovoid, or ellipsoidal shape that is designated or intended to be used as a ball, and any novelty item of a generally spherical, ovoid, or ellipsoidal shape that is designated or intended to be used as a ball.(ii) The term “ball” does not include dice, or balls permanently enclosed inside pinball machines, mazes, or similar outer containers. A ball is permanently enclosed if, when tested in accordance with 16 CFR 1500.52, the ball is not removed from the outer container.(iii) In determining whether such a ball is intended for use by children under three years of age, the criteria specified in 16 CFR 1501.2(b) and the enforcement procedure established by 16 CFR 1501.5 shall apply.(18)(i) Any bunk bed (as defined in §1513.2(c) of this chapter) that does not comply with the requirements of part 1513 of this chapter.(ii)Findings.In order to issue a rule under Section 3(e) of the Federal Hazardous Substances Act (FHSA), 15 U.S.C. 1262(e), classifying a toy or other article intended for use by children as a hazardous substance on the basis that it presents a mechanical hazard (as defined in Section 2(s) of the FHSA), the FHSA requires the Commission to make the following findings and to include these findings in the regulation: Bunk beds present a mechanical hazard; Where a voluntary standard has been adopted and implemented by the affected industry, that compliance with such voluntary standard is not likely to result in the elimination or adequate reduction of the risk of injury, or it is unlikely that there will be substantial compliance with such voluntary standard; The benefits expected from the rule bear a reasonable relationship to its costs; and The rule imposes the least burdensome requirement that prevents or adequately reduces the risk of injury for which the rule is being promulgated. These findings are made in the appendix to Part 1513.(19)(i) Dive sticks, and other similar articles, that are used in swimming pools or other water environments for such activities as underwater retrieval games or swimming instruction, and which, when placed in the water, submerge and rest at the bottom of the pool. This includes products that are pre-weighted to sink to the bottom and products that are designed to allow the user to adjust the weight. Dive sticks and similar articles that come to rest underwater at an angle greater than 45 degrees from vertical when measured under the test at §1500.86(a)(7) and dive sticks and similar articles that maintain a compressive force of less than 5-lbf under the test at §1500.86(a)(8) are exempt from this banning rule. Articles that have a continuous circular shape, such as dive rings and dive disks are also exempt.(ii)(A) Findings. In order for the Commission to issue a rule under section 2(q)(1) of the FHSA classifying a substance or article as a banned hazardous substance, the Commission must make certain findings and include these findings in the regulation. 15 U.S.C. 1262(i)(2). These findings are discussed in paragraphs (a)(18)(ii)(B) through (D) of this section.(B) Voluntary standard. No findings concerning compliance with and adequacy of a voluntary standard are necessary because no relevant voluntary standard addressing the risk of injury posed by dive sticks has been adopted and implemented.(C) Relationship of benefits to costs. The Commission estimates the potential benefits of removing hazardous dive sticks from the market to be 2 to 4 cents per dive stick. With the availability of substitutes and the expected low cost of modifying dive sticks to conform to the rule, the Commission anticipates that necessary changes will be minimal. The Commission estimates that the costs of the rule will be no more than 2 to 4 cents per dive stick. Thus, the Commission finds that there is a reasonable relationship between the expected benefits of the rule and its costs.(D) Least burdensome requirement. The Commission considered pursuing voluntary recalls, following a voluntary standard, requiring labeling or changing the scope of the rule. A banning rule would be more effective than case-by-case recalls because the impalement hazard affects all dive sticks, not a specific brand or model. Awaiting recalls would allow these hazardous items on the market until the Commission obtained recalls. No applicable voluntary standard exists, and compliance may be low if one did. Although labeling could help reduce the risk of injuries from dive sticks, it would be less effective than a banning rule. It may be difficult for a label to convey the necessary information at the time of use. Modifying the scope so that the rule would only apply to pre-weighted dive sticks would continue to permit hazardous items because the unweighted dive sticks can easily be weighted to stand vertically at the bottom of the water. Thus, the Commission finds that a ban of dive sticks with the hazardous characteristics it has identified is the least burdensome alternative that would adequately reduce the risk of injury.(b) Electrically operated toys and other electrical operated children's articles presenting electrical, thermal, and/or certain mechanical hazards. Under the authority of section 2(f)(1)(D) of the act and pursuant to provisions of section3(e) of the act, the Commission has determined that the following types of electrically operated toys or other electrically operated articles intended for use by children present electrical, thermal, and/or certain mechanical hazards within the meaning of section 2 (r), (s), and/or (t) of the act because in normal use or when subjected to reasonably foreseeable damage or abuse, the design or manufacture may cause personal injury or illness by electric shock and/or presents an unreasonable risk of personal injury or illness because of heat as from heated parts, substances, or surfaces, or because of certain mechanical hazards.(1) Any electrically operated toy or other electrically operated article intended for use by children (as defined in §1505.1(a)(1)) that is introduced into interstate commerce and which does not comply with the requirements of part 1505 of this chapter.Note: Paragraph (b)(1) was originally promulgated as 21 CFR 191.9a(b)(1) with an effective date of September 3, 1973 (38 FR 6138).(2) [Reserved](c) Toys and other articles (not electrically operated) presenting electric hazards. Under the authority of section 2(f)(1)(D) of the act and pursuant to provisions of section 3(e) of the act, the Commission has determined that the following types of toys or other articles intended for use by children (not electrically operated) present an electrical hazard within the meaning of section 2(r) of the act.(1) Any kite 10 inches or greater in any dimension constructed of aluminized polyester film or any kite having a tail or other component consisting of a piece of aluminized polyester film 10 inches or greater in any dimension presents an electrical hazard and is a banned hazardous substance because its design (specifically its size and electrical conductivity) presents a risk of personal injury from electric shock due to its ability to conduct electricity and to become entangled in or otherwise contact high voltage electric power lines.(2) [Reserved](15 U.S.C. 1261 (f)(1)(D), (g)(1)(A), (r); 15 U.S.C. 1262(e)(1); 15 U.S.C. 2079(a))[38 FR 27012, Sept. 27, 1973, as amended at 38 FR 30105, Nov. 1, 1973; 38 FR 32132, Nov. 21, 1973; 41 FR 4144, Jan. 28, 1976; 41 FR 6240, Feb. 12, 1976; 42 FR 36823, July 18, 1977; 42 FR 61594, Dec. 6, 1977; 43 FR 22005, May 23, 1978; 44 FR 34903, June 15, 1979; 44 FR 55819, Sept. 28, 1979; 48 FR 16, Jan. 3, 1983; 48 FR 57268, Dec. 29, 1983; 53 FR 46839, Nov. 18, 1988; 57 FR 27915, June 23, 1992; 59 FR 9076, Feb. 25, 1994; 60 FR 10752, Feb. 27, 1995; 64 FR 71907, Dec. 22, 1999; 66 FR 13650, Mar. 7, 2001; 73 FR 77495, Dec. 19, 2008]。

美国联邦法规 16 CFR 1500.51 供18个月以下儿童使用的玩具和其他物品正常使用和滥用模拟试验方法原文出处:作者:编辑: [2009-02-25][打印文章] [关闭窗口]Title 16: Commercial PracticesPART 1500—HAZARDOUS SUBSTANCES AND ARTICLES; ADMINISTRATION AND ENFORCEMENTREGULATIONS§ 1500.51 Test methods for simulating use and abuse of toys and other articles intended for use by children 18 months of age or less.(a) Application.The test methods described in this section shall be used to simulate the normal and reasonably foreseeable use, damage, or abuse of toys and other articles intended for use by children 18 months of age or less in conjunction with §1500.18.(b) Impact test—(1) Application.Except as provided in paragraph (b)(4) of this section, toys having a weight of less than 3.0 pounds ±0.01 pound (1.4 kilograms) shall be subject to this test.(2) Impact medium.The impact medium shall consist of a1/8-inch (0.3-centimeter) nominal thickness of type IV vinyl-composition tile, composition 1—asbestos free, as specified by paragraphs 1.2 and 3.1.4 of Interim Amendment-1(YD), dated November 14, 1979, to the Federal Specification entitled Tile, Floor: Asphalt, Rubber, Vinyl, Vinyl-Asbestos, SS-T-312B, dated October 10, 1974,1over at least a 2.5-inch (6.4-centimeter) thickness of concrete. The impact area shall be at least 3 square feet (0.3 square meter). The Commission recognizes that this specified impact medium is the equivalent of, and will yield the same impact test results as, a surface covered with vinyl-asbestos tile meeting the requirements of Federal Specification SS-T-312A.1These documents may be ordered from the General Services Administration, Specifications Unit, Room 6654, 7th and D Streets, S.W., Washington, DC 20407. The price of the specification and amendment is $1.00.(3) Testing procedure.Except as provided in paragraphs (b)(4) (i) and (ii) of this section, the toy shall be dropped 10 times from a height of 4.5 feet ±0.5 inch (1.37 meters) onto the impact medium described in paragraph (b)(2) of this section. The toyshall be dropped in random orientation. After each drop, the test sample shall be allowed to come to rest and shall be examined and evaluated before continuing.(4) Large and bulky toys.(i) A toy that has a projected base area of 400 or more square inches (2,560 or more square centimeters), shall be tested for impact in accordance with paragraph (b)(4)(iii) of this section. The base area for toys with permanently attached legs shall be measured by calculating the area enclosed by straight lines connecting the outermost edge of each leg of the perimeter.(ii) A toy that has a volume of more than 3 cubic feet (0.085 cubic meter), calculated by the major dimensions without regard to minor appendages, shall be tested for impact in accordance with paragraph (b)(4)(iii) of this section.(iii) The toys described in paragraph (b)(4)(i) and (ii) of this section shall be tested for impact by tipping them over three times by pushing the samples slowly past their centers of balance onto the impact medium described in paragraph (b)(2) of this section.(c) Bite test—(1) Application.A toy (or component or any accessible portion thereof) that has an external dimension of 1.25 inches ±0.05 inch (3.18 centimeters) or less and a design configuration that would permit a child to insert a portion into the mouth in any orientation up to a biting thickness of 1.25 inches ±0.05 inch (3.18 centimeters), for a penetration of at least 0.25 inch (0.635 centimeter), shall be subject to this test.(2) Test equipment—(i) Contact mechanism.The contact mechanism shall be two metal strips or plates each measuring 0.25 inch ±0.002 inch (0.635 centimeter) high and each having a contact edge radius of 0.020 inch ±0.002 inch (0.05 centimeter), for at least a 150-degree cross-sectional arc. A suggested contact mechanism appears in figure 1 of this section.(ii) Loading device.The loading device shall be a scale or force gauge having an accuracy of ±0.5 pound (±225 grams).(3) Testing procedure.The test article shall be placed in the contact mechanism in any reasonable position for a penetration of 0.25 to 0.5 inch (0.64 to 1.27 centimeters), which position utilizes less than 180 degrees of the arc of the contact mechanism, and a test load increasing to 25 pounds ±0.5 pound (11.35 kilograms) shall be evenly applied within 5 seconds. This load shall be maintained for an additional 10 seconds.(d) Flexure test—(1) Application.This test shall be applied to each component of a toycontaining metal wire(s), or other metal material(s), for stiffening or for retention of form if the component can be bent through a 60-degree arc by a maximum force of 10 pounds ±0.5 pound (4.55 kilograms), applied perpendicularly to the major axis of the component at a point 2 inches (5 centimeters) from the intersection of the component with the main body of the toy or at the end of the component if the component is less than 2 inches ±0.05 inch (5 centimeters) long.(2) Testing procedure.The toy shall be secured in a vise equipped with vise shields that are fabricated from 13-gauge cold-rolled steel or other similar material and that have a 0.375-inch (0.95-centimeter) inside radius. The component shall then be bent through a 60-degree arc by a force applied at a point on the component 2 inches ±0.05 inch (5 centimeters) from the intersection of the component with the main body of the toy or applied at the end of the component if the component is less than 2 inches (5 centimeters) long. The component shall then be bent in the reverse direction through a 120-degree arc. This process shall be repeated for 30 cycles at a rate of one cycle per two seconds with a 60-second rest period occurring after each 10 cycles. Two 120-degree arc bends shall constitute one cycle.(e) Torque test—(1) Application—(i) General.A toy with a projection, part, or assembly that a child can grasp with at least the thumb and forefinger or the teeth shall be subject to this test.(ii) Toys with rotating components.Projections, parts, or assemblies that are rigidly mounted on an accessible rod or shaft designed to rotate along with the projections, parts, or assemblies shall be tested with the rod or shaft clamped to prevent rotation.(2) Test equipment—(i) Loading device.The loading device shall be a torque gauge, torque wrench, or other appropriate device having an accuracy of ±0.2 inch-pound (±0.23 kilogram-centimeter).(ii) Clamp.The clamp shall be capable of holding the test component firmly and transmitting a torsional force.(3) Testing procedure.With the toy rigidly fastened in any reasonable test position, the clamp is fastened to the test object or component. A torque of 2 inch-pounds ±0.2 inch-pound (2.30 kilogram-centimeters) shall be applied evenly within a period of 5 seconds in a clockwise direction until a rotation of 180 degrees from the original position has been attained or 2 inch-pounds (2.30 kilogram-centimeters) exceeded. The torque or maximum rotation shall be maintained for an additional 10 seconds. The torqueshall then be removed and the test component permitted to return to a relaxed condition. This procedure shall then be repeated in a counterclockwise direction.(f) Tension test—(1) Application—(i) General.Any projection of a toy that the child can grasp with at least the thumb and forefinger or the teeth shall be subject to this test. This test is to be conducted on the same toy that has been subjected to the torque test described in paragraph (e) of this section.(ii) Stuffed toys and beanbags.A stuffed toy or beanbag constructed of pliable materials having seams (such as fabrics) shall have the seams subjected to 10 pounds ±0.5 pound (4.55 kilograms) of force applied in any direction.(2) Test equipment—(i) Clamps.One clamp capable of applying a tension load to the test component is required. A second clamp suitable for applying a tension load perpendicularly to the major axis of the test component is also required.(ii) Loading device.The loading device is to be a self-indicating gauge or other appropriate means having an accuracy of ±0.5 pound (±225 grams).(3) Testing procedure.With the test sample fastened in a convenient position, an appropriate clamp shall be attached to the test object or component. A 10-pound ±0.5 pound (4.55–kilogram) direct force shall be evenly applied, within a period of 5 seconds, parallel to the major axis of the test component and maintained for an additional 10 seconds. The tension clamp shall then be removed and a second clamp appropriate for pulling at 90 degrees shall be attached to the test object or component. A 10-pound ±0.5 pound (4.55-kilogram) tensile force shall be evenly applied, within a period of 5 seconds, perpendicularly to the major axis of the test component and maintained for an additional 10 seconds.(g) Compression test—(1) Application.Any area on the surface of a toy that is accessible to a child and inaccessible to flat-surface contact during the impact test shall be subject to this test.(2) Test apparatus.The loading device shall be a rigid metal disc 1.125 inches ±0.015 inch (2.86 centimeters) in diameter and 0.375 inch (0.95 centimeter) in thickness. The perimeter of the disc shall be rounded to a radius of1/32inch (0.08 centimeter) to eliminate irregular edges. The disc shall be attached to an appropriate compression scale having an accuracy of ±0.5 pound (±225 grams).(3) Testing procedure.The disc shall be positioned so that the contact surface isparallel to the surface under test. A direct force of 20 pounds ±0.5 pound (9.1 kilograms) shall be evenly applied within 5 seconds through the disc. This load shall be maintained for an additional 10 seconds. During the test the toy is to rest on a flat, hard surface in any convenient position.[40 FR 1484, Jan. 7, 1975; 40 FR 6210, Feb. 10, 1975; 40 FR 16192, Apr. 10, 1975; 40 FR 17746, Apr. 22, 1975; as amended at 55 FR 52040, Dec. 19, 1990; 56 FR 9, Jan. 2, 1991;56 FR 558, Jan. 7, 1991]。

美国玩具安全标准标准消费者安全规范:玩具安全ASTM F963-96a本标准以固定代号F963发布.紧跟代号的数字表示启用的年份或最新修改的年份;括号中的数字表示最近复批的年份,右上角的符号(e)表示最新修改或复批后的版本变动. 序言本标准的目的建立一个全国认可的玩具安全要求.虽然本标准不排除家长在选择适合儿童年龄的玩具时应尽的责任,或不同年龄的儿童接触同一种玩具时家长的监督责任,但是它的运用可将其涉及的玩具在正常使用和合理可预见的滥用时发生的事故降低到最少.本标准起初是作为一种非强制性的产品标准在商务部国家标准局主持下制定的,于1976年出版(PS72-76).目前的版本是用来更新安全要求,在参考了下面要求后使本标准包括这些要求的内容:已出版的强制性联邦要求,有关的非强制性标准,涉及潜在危险的一些新要求及基于制造商使用原标准的经验所进行的技术修改.此外,在适当的地方更新测试标准以便更多地反映当前美国儿童的人体测量数据.1 范围1.1 本标准涉及了公众可能不易认识到的及玩具在正常使用中或合理可预见的滥用后可能遇到的危险.本标准并不意味着能包括某一特定玩具的所有可想到的危险.除了与产品安全有关,本标准不涉及产品的性能与质量.除标准要求指出的玩具的功能性危害以及玩具适当年龄组之外,本标准对玩具中作为功能作用显示的固有及公认的危险部分不作要求.例如:尖端是针的功能所必须的.对于购买玩具缝纫机的顾客来说,缝纫针的固有危险是人人皆知的,并且这种危险是作为一种常识性教育传授给使用者的.1.2 另外,尽管一个坐骑玩具存在与其使用有关的固有危险(例如,摔倒在人行道上),但通过采用本标准与其结构有关的可能危险(锐利边缘,暴露的机构等)将减少.1.3 本标准包括14岁以下各年龄组的儿童玩具的要求与测试方法,本标准对不同年龄组儿童制定适用的不同要求.这些年龄组反映了危险性质和预期儿童应付这些危险智力或/和体力.1.4 标准不包括下列项目:自行车三轮车小弹弓,尖头标枪游乐场设备无火药枪风筝成品主要不是作游戏用的业余消遣品,艺术品,成品主要不是作游戏用的模型物品不具玩耍价值的腊笔、油漆、粉笔和类似的艺术材料,(原料或成品),然而所有艺术材料除外,它们不论是否玩具的一部分,必须符合LHAMA 4.31.1至4.31.3条.体育用品、野营用品、体育设备、乐器及家具;然而,上述的玩具仿制品应包括在本标准内(玩具仿制品与这些用品之间通常有明显的界线,这上公认的.例如:乐器或体育用品和其他玩具仿制品之间的界线.决定该项目是不是玩具仿制品取决于制造商或批发商的意图,以及正常使用和合理可预见的滥用.)动力驱动的飞机、火箭、船只及陆地车辆模型,但其玩具仿制品包括在本标准内.1.5 玩具年龄标示和玩具包装的一般准则规定在附录A1中.1.6 有关包装运输的情况规定在附录A2中,附录A3中的表为标准适用于不同玩具种类要求指南.1.7 标准包括以下几个部分:标题章节范围 1参考文献 2术语 3安全要求 4材料质量 4.1易燃性 4.2毒性 4.3电/热能 4.4脉冲噪音 4.5小物件 4.6可接触边缘 4.7可接触尖端 4.8突起 4.9钉和紧固件 4.10金属丝和杆件 4.11包装薄膜 4.12绳和橡皮筋 4.13轮,轮胎和轴 4.14折叠装置和铰链 4.15机械装置的孔,间隙和可触及性 4.16稳定性和超载要求 4.17封闭的空间 4.18模拟保护装置 4.19弹射玩具 4.20摇铃 4.21橡皮奶咀 4.22挤压玩具 4.23出牙器和出牙玩具 4.24 供连接在童床或游戏围栏 4.25 上的玩具玩具柜 4.26 电池驱动玩具 4.27 漂浮玩具 4.28 婴儿推车和童车玩具 4.29 填充玩具和豆袋类玩具 4.30 艺术材料 4.31 玩具枪标记 4.32 汽球 4.33 弹子 4.34 球 4.35 学前玩偶 4.36 丝球 4.37 安全标识要求 5使用说明 6制造商的标志7测试方法8概述8.1 有毒物含量的测试8.2 溶解可溶性物质的方法8.3 清洁度和防腐性能的试验8.4 正常使用试验8.5 滥用试验8.6 冲击试验8.7 部件移取的扭力试验8.8 部件移取的拉力试验8.9 压缩试验8.10 轮胎移取试验和咬接式8.11 轮轴组合的移取试验挠曲试验8.12 口动式玩具的试验8.13 玩具箱盖和关闭件的试验8.14 弹射玩具8.15 乘骑玩具的稳定性试验8.16 识别9年龄分组准则附录A1包装和运输附录A2玩具种类的要求指南附录A3系在童床或游戏围栏上附录A4的玩具的设计准则玩具的易燃性测试程序附录A51.8 用in-lb单位表示的数值为标准数值.括号里的数值仅作参考.1.9 下述预防声明仅涉及本标准章节8中的测试方法部分:本标准并非意味针对所有与其使用有关的安全问题.使用本标准有责任建立合适的安全及健康的操作程序,并在使用前决定受控限量的适用性.2 参考文献2.1 ASTM 标准:D374 固态电绝体的厚度测试方法D642 确定装动容器、零部件及单位负载的抗压力的测试方法D775 载物箱的跌落试验D880 装运容器的倾斜冲击试验D999 装运容器的震动试验D1193 水试剂的标准要求D2240 橡胶性质的测试方法—硬度测定D3421 氯乙烯塑料中的混合增塑剂的萃取和分析方法D4236 对造成慢性健康危害的艺术材料的标示方法F1313 橡皮奶嘴上奶头中易挥发的n-亚硝胺含量规定2.2 ANSI标准Z315.1 三轮脚踏车的安全要求C18.1 干电池和电池的美国国家标准—要求2.3 联邦标准15 CFR 1150 仿真玩具枪和仿制玩具枪的标志16 CFR 1303 含铅油漆和某些含铅油漆消费品的禁令16 CFR 1500 危险物品条例规则,包括以下部分:1500.14(b)(8) 有害艺术材料的标示1500.18 禁用的玩具和其他供儿童使用禁用物品1500.3(c)(6)(VI) “易燃固体”的定义1500.19 贴错标识的玩具与其它供儿童使用的禁用物品测定极易燃和易燃固体的方法1500.47 测定玩具火药帽产生的声级的方法1500.48 测定供8岁以下儿童使用的玩具和其分物品中锐利尖端的技术要求1500.49 测定供8岁以下儿童使用的玩具和其它物品中金属或玻璃锐利边缘的技术要求1500.50-53 供儿童使用的玩具和其他物品的摸拟使用和滥用测试方法1500.83 小包装袋,小危害及特别情况的豁免归类为禁用的危险物品的豁免归类为禁用的玩具或其他供儿童使用的禁用物品的豁免16CFR 1501 识别供3岁以下儿童使用,含可引起窒息,吸入或咽下危险小部件的玩具和其它物品的方法16CFR 1505 供儿童使用的电动玩具或其他电动物品的要求16CFR 1510 摇铃的要求16CFR 1511 橡皮奶嘴的要求16CFR 1610 服装纺织品的易燃性标准21CFR 110 制造、处理、包装或贮存人类食物的现行良好操作规范21CFR 170-189 供人类食用的食物49 CFR 173.000,109C 级炸药的定义SS-T-312B 天然沥青、橡胶、乙烯、石棉乙烯的片材、板材3 术语3.1 本标准指定用语的定义3.1.1 可触性---能被在16CFR 1500.48及16CFR 1500.49规定的探头接触的任何玩具部分.探头的使用方法见16CFR 1500.48(C).可触性探头的说明见图1.3.1.1.1 论述---为两个年龄组的儿童提供了两个尺寸不同的探头.3.1.1.2 艺术材料---任何由制造商或重新包装商出售或提供的,适合于在制作任何媒介的视觉艺术或图画艺术作品的任何阶段使用的物品.该定义包括艺术品组成部件在内的物品,例如:油漆、油画布、墨水、蜡笔、粉笔、焊料、铜焊条、焊剂、纸、粘土、石头、线、布及照相胶片,还包括与最终艺术品制作紧密相关的物品,例如:刷子、清扫刷、溶剂、陶瓷炉、丝网印刷、模具、模具制造材料及摄影用的显影剂.3.1.3 球---指设计成或打算用作掷、击、踢、滚、跌、反弹的任何球形、卵形或椭圆形物件.术语“球”包括任何通过绳、橡皮筋或类似绳拴系到玩具或物品上的球形、卵形、椭圆形物件.术语“球”还包括设计成或打算用作球的,由多个面连接成一个圆球卵形或椭圆形的多边物体. 术语“球”不包括永久性密封于弹子机、迷宫和类似外部容器内的骰子或球.如果根据16CFR 1500.53测试时,球不能从外部容器取走,则属于永久密封.3.1.4 毛刺---由于材料切割或最后加工得不平整而使玩具或零部件的边缘或结合处出现的粗糙部分.3.1.5 绳索---一根细长的,柔软的材料包括单纤维丝,编织和捻搓的绳,粗绳、塑料纺织带,丝带及那些通常被称为线的纤维状材料.3.1.6 卷曲边缘---邻近边的薄片部分被卷成弧形并与底片形成小于90°角的边,如图2所示.3.1.7 发射装置---释放并推进一个弹射物的无生命系统.3.1.8 危险边缘---在玩具的正常使用和合理可预见的滥用时能产生不合理伤害的危险的可接触边缘.供8岁以下儿童使用的玩具金属和玻璃边缘如不能通过16CFR 1500.49规定的锐边试验,则被定义为潜在的危险边缘.非金属和玻璃的其他边缘在通常使用条件下经接触为锐利时,被定义为潜是的危险边缘.3.1.9 弹性---在以不低于20in.(510mm)/min.的测试速度拉长至少10%后,能立即完全地回复到原来尺寸和形状的材料.3.1.10 斜薄边---材料在剪切或切割过程中产生的斜薄边(或厚度由中间向一边逐渐减少).3.1.11 溢料---在模具合箱的啮合部分溢出的过剩材料.3.1.12 折叠机构---由绞链、转轴、折叠或滑动部件组装的机构,在使用时能产生压、挤或切割动作.3.1.13 危险---在正常使用时或由于合理可预见的滥用产生不合理的伤害或致病危险的任何玩具特性.3.1.14 折叠边缘---邻近边的薄片部分往薄片主体方向折叠大约180°,并与主体薄片平行而形成的边.如图3所示.3.1.15 铰链线间隙---玩具的固定部分和沿转轴线或邻近转轴线的活动部分之间的距离.见图4的尺寸A.3.1.16 脉冲噪音---噪音水平变动的最大间隔大于1秒钟的噪音.3.1.17 搭接---一条边与一平行表面部分重迭形成的搭接,但在整个重迭长度上并非所有的点都机械地结合在一起.如图5所示.3.1.18 乳胶汽球---由设计来可充注空气或气体的乳胶袋组成的任何玩具或装饰品.该术语不包括用于水上活动的可充气的儿童玩具,例如筏、水袖、泳圈或其它类似物件.3.1.19 弹子---由硬性材料构成的球体,例如:玻璃、玛瑙、大理石、或塑胶,用于各种儿童游戏中,一般做为玩物或标记,术语“弹子”不包括永久地封于玩具或游戏机内的弹子.弹子根据16CFR 1500.53测试,如不能从玩具或游戏机内取出,则属于永久封闭.3.1.20 正常使用---按照玩具附有的说明进行使用的方式,由传统与习惯所决定的使用方式,或看到玩具后即明白的使用方式.3.1.21 儿童化妆品---供14岁以下儿童使用和将他们作为销售对象的物品,用于擦,洒或喷在身上.进入人体或以其他方式附着在身上,以达到清洁,美化,改善或增加魅力或改变形象的目的.3.1.22 危险利尖---在正常使用或合理可预见的滥用过程中产生的不合理伤害的可触性利尖.供8岁以下儿童使用的玩具上的尖端如果不能通过16CFR 1500.48中规定的利尖试验,则被认为是潜在的危险.3.1.23 丝球---中心被夹住或固定和系住并整理成球形的一段或一束纤维、纱线或线条,也包括由填充材料做成的球形附件.3.1.24 主要展示面---指零售包装或容器、箱或自动售货机的展示面,即设计成最主要的展示,显示或呈现给意欲购买的顾客观看或检查的侧面或表面.3.1.25 弹射物---由在使用者控制下控制能贮存和释放能量的发射机构所发射的物体。