沃尔沃-牵引车品牌、型号及配置

- 格式:pdf

- 大小:132.29 KB

- 文档页数:4

豪沃7系列336牵引车模型作者:来源:《专用汽车》2015年第06期摘要:豪沃作为中国重汽的拳头产品,标志着中国重汽产品从此走上了自己的创新之旅。

在经历了企业重组和产品更新换代凤凰涅槃的痛苦之后,全新的豪沃7系列诞生让中国重汽成为国内重型汽车的领军企业,也让中国重汽成为国际知名品牌。

2001年伴随着我国加入世界贸易组织(WTO),中国重汽重组成功。

整个汽车业面临着巨大的机遇的同时,更面临着严峻的挑战,国外重卡和国内重卡群雄突起,中国重汽的市场份额岌岌可危。

刚刚重组成功的中国重汽适时推出了斯太尔王,这让中国重汽暂时渡过了最困难的时期,但中国重汽更急需推出新款高端车型来与国内外车厂同台竞争,而这个机会终于来到。

2003年,中国重汽与国际重卡巨头沃尔沃就组建中国华沃卡车有限公司达成协议。

作为礼物,沃尔沃送给了中国重汽一套重型卡车驾驶室模具和全套技术资料,这为中国重汽开发新款车型奠定了坚实的技术基础。

2004年10月,豪沃(HOWO)系列重型汽车举行下线仪式,该系列为中国重汽的发展序列代号“7”,习惯上大家都称其为“豪沃7系列”。

这是中国重汽依托已经成熟的斯太尔技术,再加上与沃尔沃进行全方位的技术交流与合作,历经三年时间精心打造出的成果。

置于绝地而后生,凤凰涅槃般的痛苦换来了中国重汽崭新的风貌。

2005年,在豪沃推向市场的当年就达到产销过万台的水平,这让中国重汽重新成为国内重型汽车的领军企业。

豪沃完美地体现了当时国内的最高技术水平,而且部分已经接近和达到国际先进水平。

时至今日,豪沃系列重型汽车仍然是中国重汽的主力产品,并远销到国外,使中国重汽成为国际知名的汽车品牌。

作为中国重汽的合作模型厂家,深圳市圣然精品有限公司(以下简称深圳圣然公司)是在相继推出斯太尔、斯太尔王模型之后,再次如约推出了1:24比例的豪沃336牵引车合金模型(如图1),这让我们可以近距离地领略到中国重汽这款经典车型的魅力。

模型赏析豪沃336牵引车模型不再是斯太尔模型的延续,深圳圣然公司针对前两款重型汽车模型设计中的一系列问题,在这款模型上做了许多改进,再加上应用了新技术及新工艺,使它成为重型牵引车经典模型之一。

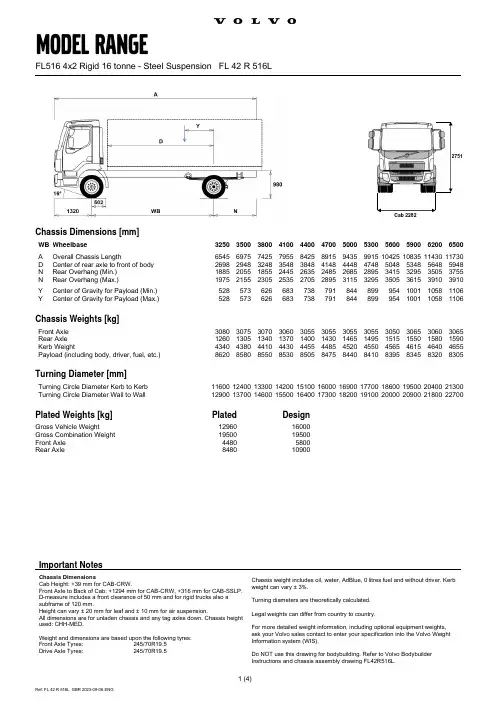

Important NotesChassis DimensionsCab Height: +39 mm for CAB-CRW.Front Axle to Back of Cab: +1294 mm for CAB-CRW, +316 mm for CAB-SSLP. D-measure includes a front clearance of 50 mm and for rigid trucks also a subframe of 120 mm.Height can vary ± 20 mm for leaf and ± 10 mm for air suspension.All dimensions are for unladen chassis and any tag axles down. Chassis height used: CHH-MED.Weight and dimensions are based upon the following tyres:Chassis weight includes oil, water, AdBlue, 0 litres fuel and without driver. Kerb weight can vary ± 3%.Turning diameters are theoretically calculated.Legal weights can differ from country to country.For more detailed weight information, including optional equipment weights, ask your Volvo sales contact to enter your specification into the Volvo WeightChassis Dimensions [mm]WB Wheelbase3250 3500 3800 4100 4400 4700 5000 5300 5600 5900 6200 6500A Overall Chassis Length6545 6975 7425 7955 8425 8915 9435 9915 10425 10835 11430 11730 D Center of rear axle to front of body 2698 2948 3248 3548 3848 4148 4448 4748 5048 5348 5648 5948 N Rear Overhang (Min.) 1885 2055 1855 2445 2635 2485 2685 2895 3415 3295 3505 3755 NRear Overhang (Max.)19752155230525352705289531153295 3505 3615 3910 3910Y Center of Gravity for Payload (Min.) 528 573 626 683 738 791 844 899 954 1001 1058 1106 Y Center of Gravity for Payload (Max.) 528 573 626 683 738 791 844 899 954 1001 1058 1106Chassis Weights [kg]Front Axle 3080 3075 3070 3060 3055 3055 3055 3055 3050 3065 3060 3065 Rear Axle 1260 1305 1340 1370 1400 1430 1465 1495 1515 1550 1580 1590 Kerb Weight4340 4380 4410 4430 4455 4485 4520 4550 4565 4615 4640 4655 Payload (including body, driver, fuel, etc.) 8620 8580 8550 8530 8505 8475 8440 8410 8395 8345 8320 8305Turning Diameter [mm]Turning Circle Diameter Kerb to Kerb 11600 12400 13300 14200 15100 16000 16900 1770018600 19500 20400 21300 Turning Circle Diameter Wall to Wall12900 13700 1460015500 16400 17300 18200 19100 20000 20900 21800 22700Plated Weights [kg]PlatedDesignGross Vehicle Weight12960 16000 Gross Combination Weight 19500 19500 Front Axle 4480 5800 Rear Axle 8480 10900■ Standard Equipment □ Optional EquipmentFor more detailed information about cab and powertrain equipment, please refer to separate specification sheets.For all possible options and combinations of options please consult your Volvo sales contact who can create a specification to match your requirements using the Volvo Sales Support system (VSS).■ UNIFORM Transport Adaption - Basic platform vehicleCORE COMPONENTS □ CHH-HIGH Chassis height - High - for loading heights check the uniqueBEP chassis drawing attached to this quote■ CHH-MED Chassis height - Medium - for loading heights check the uniqueBEP chassis drawing attached to this quote■ RAD-L80 Rear suspension - 80mm parabolic rear springs □ CAB-CRW Cab - Four-door, six seat crewcabDesigned and built to Swedish impact and ECE R29 regulations□ CAB-DAY Cab - Day, with steel safety cage design.Designed and built to Swedish impact and ECE R29 regulations□ CAB-SSLP Cab - Comfort with additional storage space or optional fold upbunk behind the driver - with steel safety cage design. Designed and built to Swedish impact and ECE R29 regulations.■ EU6SCR Emission level - Euro VI step E ■ D5K210 Engine - D5K210 four-cylinder 5.1 litre developing 210hp at2200rpm.Peak torque 800Nm at 1100-1700rpm.□ D5K240 Engine - D5K240 four-cylinder 5.1 litre developing 240hp at2200rpm.Peak torque 900Nm at 1100-1600rpm.□ ATO1056 Gearbox - Automated 6-speed I-sync overdrive - if the truck isbuilt from week 47 an 8 speed ZF powerline automatic.□ ATO8006 Gearbox - Automated 6-speed I-sync overdrive - if the truck isbuilt from week 47 an 8 speed ZF powerline automatic.■ STO8006 Gearbox - Manual 6-speed overdrive □ ZTO1006 Gearbox - Manual 6-speed overdrive ■ EBR-EPG Engine brake type - Exhaust brake controlled by steeringcolumn switch■ RSS1125A Drive axle - RS1125A single reduction with differential lockDesign GCW 25tonne□ RSS1132A Drive axle - RS1132A single reduction with differential lockDesign GCW 32tonnePackages □ DRIVEFL Cab Package - Drive □ VISIFL Visibility package □ AIRFLOW Airflow Package□ AUDIODAB Audio System - Digital DAB AM/FM Radio with Bluetooth -without CD player■ AUDIOPD Audio - Preparation for DAB radio including amplifier and aerial CHASSIS ■ FST-PAR Front suspension - Parabolic front springs with shockabsorbers and anti-roll bar□ FST-PAR3 Front suspension - Parabolic front springs with shockabsorbers and anti-roll bar■ FAL5.8 Front axle design capacity - 5.8 tonne □ FAL6.3 Front axle design capacity - 6.3 tonne ■ RAL10.9 Rear axle design capacity - 10.9 tonne ■ RSTAB1 Rear anti-roll bar - Normal stiffness □ EBS-MED Brake package - EBS medium including traction control & hillhold■ EBS-STD Brake package - EBS standard package without tractioncontrol - Without■ RST-PAR1 Rear suspension - Parabolic springs□ RST-PAR3 Rear suspension - Stiffer parabolic rear springs□ RST-PAR4 Rear suspension - Asymmetric parabolic rear springsFor short rear overhang■ FST7070 Chassis frame thickness - 7 mm web and flange □ FST8080 Chassis frame thickness - 8 mm web and flange■ 2BATT170 Battery Capacity - 2 x 170 Ah on the left-hand side□ ADR2ADR Adaptation - For transportation of dangerous goods on the road - Note does NOT include safe loading pass package if required this is quoted separately■ R215P Right fuel tank - 215-litre plastic Min volume 80l Max volume 430l ■ UL-FUEL Left fuel tank - Without Min volume 80l Max volume 215l □ ADTP-L Adblue tank position - Chassis mounted on the left-hand side ■ ADTP-R Adblue tank position - Chassis mounted on the right-hand side □ WHC-FIX1 Wheel chock - One fixed design □ WHC-FIX2 Wheel chocks - Two fixed design□ TOWMBRH Tow member - High mounted in centre of frame - Check theGCW in the "Truck Use" section of this specification□ C-RO40AG Drawbar coupling - Rockinger 400 G145■ TOWF-NO1 Front towing device - One pin in bumper □ TOWF-NO2 Front towing device - Two pins in bumper□ TOWR-ONE Light trailer coupling - Pintle type hitch attached to rear crossmember for an unbraked trailer□ TREL15 Trailer electrical connection - Single 15 pin - ADR certified □ TBC-EC Trailer brakes with EC palm coupling connectors □ RUP-FIX2 Rear underrun protection - Fixed EC approved □ RFEND-T Rear mud wings - Temporary on drive axle for transportdelivery only□ 2024GSR GSR2 Safety Package - includes moving off information, cyclistand pedestrian side sensors, reverse camera, driver alert support, tyre pressure monitoring, intelligent speed assist, alcohol lock preparation interface, emergency brake lights and automatic headlight switchingWHEELS & TYRES □ RT-AL Wheels - Howmet Alcoa brushed aluminium rims - standardholes for long stud fixing□ RT-ALDP Wheels - Howmet Alcoa Dura-Bright aluminium rims - standardholes for long stud fixing■ RT-STEEL Wheels - Steel rims □ SPWT-F Spare wheel & tyre - Spare with front tyre pattern □ SWCP-LF Spare wheel carrier on left side of chassis ahead of rear axle □ SWCP-R Spare wheel carrier rear mounted below frame. □ SWCP-T Spare wheel supplied temporarily strapped to chassis □ SWCP-TP Spare wheel carrier tranport mounted on frame (spare wheelcarrier not included)□ JACK-10T 10 tonne bottle jack □ JACK-8T 8 tonne bottle jack□ GAUGE-TP Tyre pressure gaugeDRIVELINE EQUIPMENT ■ CS39A-O Clutch - Single plate 395mm (16") □ RET-TPT Retarder for automatic gearbox □ TC-HWO Transmission oil cooler - water to oil■ 1COMP500 Air compressor - Single cylinder 360 cc - 500 litres per minute □ AIRIN-FR Air intake - Under the front grille - Left-hand drive only ■ AIRIN-HI Air intake - Mounted behind cab on the left-hand side □ AIRIN-RL Air intake - Chassis mounted behind cab on the left-hand side ■ ACL1ST Air filter - Single element □ ACL1ST-S Air filter - two-stage element ■ 24AL110B Alternator capacity - 110 amp □ 24AL130B Alternator capacity - 130 amp■ Standard Equipment □ Optional EquipmentFor more detailed information about cab and powertrain equipment, please refer to separate specification sheets.For all possible options and combinations of options please consult your Volvo sales contact who can create a specification to match your requirements using the Volvo Sales Support system (VSS). ■ CCV-OXOpen crankcase ventilation with oil separator and a maintenance free gas centrifuge□ EST-AID Engine starting aid -Preheating element in the air inlet manifold □ PTER-100 Engine power-take-off - Rear-mounted with DIN100/ISO7646flange□ PTER-DIN Engine power-take-off - Rear-mounted with DIN5462 (female)splined shaft for a close-coupled pump□ PTER1400 Engine power-take-off - Rear-mounted with SAE 1410 flange □ PR-HF4S Live-drive PTO for Allison gearbox output 400Nm for flangeconnectionmounted on the side of the torque convertor□ PR-HF4SH Live-drive high speed PTO for Allison gearbox output 400Nmfor hydraulic pump connectionmounted on the side of the torque convertor□ PR-HF6S Live-drive PTO for Allison gearbox output 600Nm for flangeconnectionmounted on the side of the torque convertor□ PR-HP4S Live-drive PTO for Allison gearbox output 400Nm for hydraulicpump connectionmounted on the side of the torque convertor□ PR-HP4SH Live-drive high speed PTO for Allison gearbox output 400Nmfor hydraulic pump connectionmounted on the side of the torque convertor□ PR-HP6S Live-drive PTO for Allison gearbox output 600Nm for hydraulicpump connectionmounted on the side of the torque convertor□ PTR-FH1 Rear PTO Gearbox S81 flange DIN connection □ PTR-FH2 Rear PTO Gearbox S84 flange DIN connection □ PTR-FH5 Rear PTO Gearbox S88 flange DIN connection □ PTR-PH1 Rear PTO Gearbox S81 pump DIN connection □ PTR-PH2 Rear PTO Gearbox S84 pump DIN connection □ PTR-PH4 Rear PTO Gearbox S88 pump DIN connection □ PTR-PK Electrical and solenoid prep kit for gearbox PTO □ PTR-ZF2 Rear Power Take Off flange DIN connection □ PTR-ZF3 Rear Power Take Off Gearbox pump DIN connection □ PTR-ZF4 Rear PTO Gearbox 320Nm flange connection □ PTR-ZF5 Rear PTO Gearbox 320Nm pump connection □ PTR-ZF6 Rear PTO Gearbox 320Nm flange connection □ HPG-F101 Gearbox mounted hydraulic pump F1-101, fixed displacement,single flow.□ HPG-F41 Gearbox mounted hydraulic pump F1-41, fixed displacement,single flow.□ HPG-F51 Gearbox mounted hydraulic pump F1-51, fixed displacement,single flow.□ HPG-F61 Gearbox mounted hydraulic pump F1-61, fixed displacement,single flow.□ HPG-F81 Gearbox mounted hydraulic pump F1-81, fixed displacement,single flow.□ ETC Electronic throttle control - dash mounted switch for PTOspeed controlCAB INTERIOR □ STWPOS-L Steering wheel position - LEFT-HAND DRIVE ■ STWPOS-R Steering wheel position - RIGHT-HAND DRIVE ■ TAS-DIG4 Smart tachograph - Continental VDO 4.1 version 2 - legaldemand from 21/08/2023CAB EXTERIOR □ SUNV-B Exterior sun visor - Smoked grey ■ SUNV-PK Exterior sun visor preparation kit only □ AD-SIDES Cab side deflector - Short extension panels□ BEACON-P Roof beacons - switch and wiring preparation only□ BEACONA2 Roof-mounted beacons - Two LED amber beacons mounteddirect on roofSUPERSTRUCTURE PREPARATIONS □ FBA-BTF Lower front body attachments - For torsionally flexible -platform body□ FBA-BTSF Lower front body attachments - For torsionally semi-flexiblebody - box or curtainsider□ TAILPREP Taillift preparation kit - cab switch and warning in driver displayDELIVERY SERVICES □ TGW-4G Telematics gateway - GSM/GPRS/4G modem, WLAN ■ WVTA EC Whole Vehicle Type Approved - First stage chassis cab■ Standard Equipment □ Optional EquipmentFor more detailed information about cab and powertrain equipment, please refer to separate specification sheets.For all possible options and combinations of options please consult your Volvo sales contact who can create a specification to match your requirements using the Volvo Sales Support system (VSS).。

沃尔沃牵引车操作说明书1、同时按住LR后视镜可以在电路接通的任何状态下收起左右后视镜,再次同时按则打开;2、可以设置将座椅、后视镜等位置信息存入钥匙。

这样夫妻就可以用不同的钥匙自动导入不同的存储数据(如座位位置)。

此功能很实用。

而且注意座椅的三个存储位置也存储后视镜的角度的;3、钥匙是可以在启动发动机后拔下来的。

此时进入地库为了停车方便就可以按钥匙上的照明键;4、启动发动机的状态下按下启动按钮第一次会提示不在P档,第二次会熄火;5、CD插槽可以播放DVD而不只是CD;6、按左档杆的侧面的按钮可以显示汽车的故障等信息;7、如灯光在大灯档位,熄火后可自动关闭大灯,如在示廓灯档位(中间档),熄火不会关闭。

故需要注意不要放在示廓灯位锁车离开。

8、仪表盘显示屏是根据自动感应光线明暗自动调节的,也可以在左侧旋钮手动调节;9、在第三档灯光(近光)状态下,短促向怀里拉方向盘下左拉杆为闪远光,用于警示前车;略长(超过半秒种)拉动拉杆为由近光切换到远光,适用于高速夜间行车或光线严重不足的道路行车;10、短按启动键可接通屏幕、多媒体、车窗等电路,不发动发动机长按启动键可接通全部电路。

接通电路的情况下15分钟电路会出于保护自动关闭。

11、隐藏的储物小空间:中控台后面的三角空间可以放些卡等物品,驾驶位正前方下边缘有小口袋12、有原装GPS的可以注意GPS上有指南针,也可设置显示附近的医院和加油站。

13、中控台悬浮式储物箱底下的胶皮垫子可以打开,下面有个按钮,可以在汽车未通电状态(如停车时被水泡了)强制从P挡到空挡上。

14、拔出钥匙壳里的钥匙,可以单独机械锁闭副驾前的储物箱。

锁闭储物箱的同时后备箱被机械锁闭。

在交4S维修时可用此功能,无需清理车上物品。

15、长按开锁键可以在任何状态降下四个车窗,反之锁车键升起。

然后长按升窗,升到顶后继续按5秒以上。

同样可以用此方法从已设置一键升降。

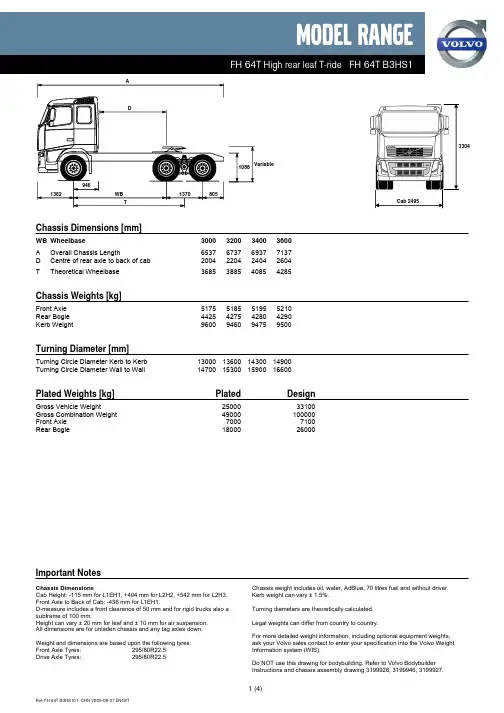

Important NotesChassis DimensionsCab Height: -115 mm for L1EH1, +404 mm for L2H2, +542 mm for L2H3. Front Axle to Back of Cab: -436 mm for L1EH1.D-measure includes a front clearance of 50 mm and for rigid trucks also a subframe of 100 mm.Height can vary ± 20 mm for leaf and ± 10 mm for air suspension.All dimensions are for unladen chassis and any tag axles down.Weight and dimensions are based upon the following tyres: Chassis weight includes oil, water, AdBlue, 70 litres fuel and without driver. Kerb weight can vary ± 1.5%.Turning diameters are theoretically calculated.Legal weights can differ from country to country.For more detailed weight information, including optional equipment weights, ask your Volvo sales contact to enter your specification into the Volvo WeightChassis Dimensions [mm]WB Wheelbase 3000320034003600A Overall Chassis Length 6537673769377137D Centre of rear axle to back of cab 2004220424042604T TheoreticalWheelbase 3685388540854285Chassis Weights [kg]Front Axle 5175518551955210Rear Bogie 4425427542804290Kerb Weight 9600946094759500Turning Diameter [mm]Turning Circle Diameter Kerb to Kerb 13000136001430014900Turning Circle Diameter Wall to Wall 14700153001590016600Plated Weights [kg] Plated DesignGross Vehicle Weight 2500033100Gross Combination Weight 49000100000Front Axle 70007100Rear Bogie 1800026000Cab 2495■ Standard Equipment □ Optional EquipmentFor more detailed information about cab and powertrain equipment, please refer to separate specification sheets.For all possible options and combinations of options please consult your Volvo sales contact who can create a specification to match your requirements using the Volvo Sales Support system (VSS). Core components□ L1EH1 Day cab ■ L2H1 Sleeper cab □ L2H2 Sleeper cab with high roof, Globetrotter □ L2H3 Sleeper cab with extra high roof (+140 mm), Globetrotter XL(FH) / LXL (FM) cabs ■ EU3 Euro 3 Engine emission level.■ D13A400 Diesel engine, 13 litre, 400 hp, 2000 Nm. □ D13A440 Diesel engine, 13 litre, 440 hp, 2200 Nm. □ D13A480 Diesel engine, 13 litre, 480 hp, 2400 Nm. □ D13A520 Diesel engine, 13 litre, 520 hp, 2500 Nm.□ D13C420 Diesel engine, 13 litre Euro 5 SCR, 420 hp, 2100 Nm □ D13C460 Diesel engine, 13 litre Euro 5 SCR, 460 hp, 2300 Nm □ D13C500 Diesel engine, 13 litre Euro 5 SCR, 500 hp, 2500 Nm □ D13C540 Diesel engine, 13 litre Euro 5 SCR, 540 hp, 2600 Nm■ EBR-EPG Engine brake, exhaust pressure governor□ EBR-EPGC Engine brake, exhaust pressure governor for I-shift□ EBR-VEB Engine brake, Volvo Engine Brake (incl. exhaust pressure governor)□ EBR-VEB+ Engine compression brake, Volvo Engine Brake+ (VEB+), incl. Exhaust Pressure Governor (EPG).□ EBR-VGT Engine brake, Variable Geometry Turbo□ AT2412C I-Shift, 12 speed, 2400 Nm, max. permitted GCW 44000 kg, fully automated electronically controlled gearshift and clutch, without clutch pedal.□ AT2412D I-Shift, 12 speed, 2400 Nm, max. permitted GCW 44000 kg, fully automated electronically controlled gearshift and clutch, without clutch pedal.□ AT2512CI-shift, 12 speed, 2500 Nm, max. permitted GCW 100000 kg and fully automated electronically controlled gearshift and clutch, without clutch pedal.(Only combinations with T-FLAT and rear axle ratios higher than or equal to 3.61 give GCW 100000 kg, others 80000 kg.) □ AT2612D I-Shift, 12 speed, 2600 Nm, max. permitted GCW 60000 kg, fully automated electronically controlled gearshift and clutch, without clutch pedal.□ ATO2512CI-shift overdrive, 12 speed, 2500 Nm, max. permitted GCW 60000 kg, for use with hub reduction axles. Fully automated electronically controlled gearshift and clutch, without clutch pedal.□ ATO2612DI-shift overdrive, 12 speed, 2600 Nm, max. permitted GCW 60000 kg, for use with hub reduction axles. Fully automated electronically controlled gearshift and clutch, without clutch pedal.□ PT2606 Powertronic 6-speed automatic gearbox, 2600 Nm ■ VT2214B Manual split range gearbox 2400 Nm, 14 speed □ VT2514B Manual split range gearbox 2500 Nm, 14 speed □ VT2814B Manual split range gearbox 2800 Nm, 14 speed□ VTO2214B Manual split range gearbox 2400 Nm with overdrive, 14 speed □ VTO2514B Manual split range gearbox 2500 Nm with overdrive, 14 speed □ VTO2814B Manual split range gearbox 2800 Nm with overdrive, 14 speed □ TP-BAS City gear changing software□ TP-DICON Distribution and Construction optimized gear changing software□ TP-FUEC Fuel optimized gear changing software □ TP-HDHeavy Duty gear changing software□ AMSO-AUT Manual gear shift in automatic mode, (I-Shift). □ AMSO-BAS Basic gear shifting (I-Shift). □ AVO-BAS Basic vocational I-shift software (not for version C)□ AVO-ENH Enhanced vocational I-shift software, construction & timber adapted (not for version C)□ CD40B-O Double disc clutch, diameter 400 mm □ CS43B-O Single disc clutch, diameter 430 mm■ CS43B-OR Single disc clutch, diameter 430 mm, reinforced; version B ■ FAL7.1 Front axle load 7.1 tonnes □ FAL7.5 Front axle load 7.5 tonnes □ FAL8.0 Front axle load 8.0 tonnes □ FAL8.5 Front axle load 8.5 tonnes □ FAL9.0 Front axle load 9.0 tonnes□ FST-MULFront leaf suspension, conventional spring■ FST-PAR Front leaf suspension, parabolic spring □ FST-PAR3 Front leaf suspension, stiff parabolic spring □ FSTAB Front stabilizer, normal stiffness■ FSTAB2 Front stabilizer, medium high stiffness □ FSTAB3 Front stabilizer, stiff■ RADD-TR1 Rear leaf suspension (6x4/8x4), T-ride narrow, 75 mm wide leafs□ RADD-TR2 Rear leaf suspension (6x4/6x6/8x4), T-ride wide, 90 mm wide leafs.■ RT2610HV Rear tandem axle, hub reduction, 3 planet gear, bogie load 26 tonnes, GCW 100 tonnes□ RT3210HV Rear tandem axle, hub reduction, bogie load 32 tonnes, GCW 100 tonnes□ RTS2370A Rear single reduction tandem, bogie load 23 tonnes, GCW 70 tonnes□ RAL23 Bogie load 23 tonnes ■ RAL26 Bogie load 26 tonnes □ RAL32 Bogie load 32 tonnes□ RST-MUL Rear leaf suspension, conventional spring ■ RST-PAR1 Rear leaf suspension, parabolic spring □ RALIM15First rear drive axle load limiter, 15.0 tonnesPackages■ AUDBAS Audio basic□ AUDMED+Audio medium plusTruck use□ ADR2 ADR adaptation, transportation of dangerous goods, 2 switches.□ PSCOOL Power steering cooler. ■ STWPOS-LLeft hand driveChassis■ BRAKE-ZV Volvo Z-cam brakes□ AUXPARK Auxiliary parking brake (2 extra parking brake chambers) ■ ABS-WHL ABS, Anti-lock brake system ■ FRAME88 Frame section thickness 8 mm■ FIL-TXEB Inner liner from transmission member to bogie end. ■ FRAMEHIG Frame rail section height, 300 mm ■ BBOX-L Battery box on left hand side ■ 2BATT170 Batteries 2x170 Ah □ 2BATT225Batteries 2x225 Ah□ BAMAFREE Maintenance free batteries ■ R405A71 Right aluminium 710 mm D-shaped fuel tank, 405 litres volume.Usable volume is 97% of stated volume. Min volume 150lMax volume 810l ■ UL-FUEL Without left fuel tank Min volume 160l Max volume 450l ■ FCAP-L Lockable fuel tank cap■ ESH-LEFT Muffler horizontal, left exhaust outlet □ ESH-REAR Muffler horizontal, rear exhaust outlet □ ESH-RIGH Muffler horizontal, right exhaust outlet□ ESH-VERT Muffler horizontal, vertical exhaust outlet on right hand side □ ESV-VERT Muffler vertical, vertical exhaust outlet on right hand side □ SWCP-BC Spare wheel carrier, behind cab■ SWCP-LB Spare wheel carrier, on left hand side partly under battery box □ SWCP-LF Spare wheel carrier, on left hand side in front of rear axle □ SWCP-T Plastic strips strapped to the chassis used as a temporary spare wheel carrier.□ SWCP-TPSpare wheel carrier transport mounted on top of frame■ Standard Equipment □ Optional EquipmentFor more detailed information about cab and powertrain equipment, please refer to separate specification sheets.For all possible options and combinations of options please consult your Volvo sales contact who can create a specification to match your requirements using the Volvo Sales Support system (VSS). □ WHC-TRP2 Two foldable wheel chocks delivered loose in cab □ WHCHOCK2 Two foldable wheel chocks □ TB-L80 Toolbox 800 mm, left side □ TB-R80 Toolbox 800 mm, right side □ SUP-BAS Standard side underrun protection □ CHAIN-SSnow chains□ TOWR-ONE One rear towing device ■ RFEND-BRear fenders, basic (3 piece fender with anti-spray function)Rims and Tyres□ WL-AL Aluminium rims□ WL-ALDP Dura-Bright aluminium rims, front-drive□ WL-ALDPD Dura-Bright aluminium rims, dual holes, front-drive □ WL-ALDU Aluminium rims, dual holes □ WL-ALP Polished aluminium rims□ WL-ALPDU Polished aluminium rims, dual holes ■ WL-ST Steel rims□ SPWT-D Spare wheel&tyre equal to drive wheel ■ SPWT-F Spare wheel and tyre equal to front wheel □ WCAPWheel capsPowertrain equipment■ 1COMP530 Single cylinder air compressor 318 cc □ 2COM1080 Dual cylinder air compressor 704 cc □ 2COMP900 Dual cylinder air compressor 636 cc ■ AIRIN-HI High air intake □ AIRIN-LO Low air intake□ ACL1ST-S Air cleaner with additional filter element□ 24AL120B Alternator 120 Ampere □ 24AL150B Alternator 150 Ampere■ 24ALT-HB Alternator 80 Ampere (D13/16) / 90 Ampere (D9/D11) □ 24ALT-XB Alternator 110 Ampere□ CCV-C Closed crankcase ventilation.□ CCV-OX Crank case ventilation for cold markets □ COOLC40 Cooling capacity 40°C, ATB ■ COOLC48 Cooling capacity 48º C, ATB□ TC-HWO Oil cooler for hydraulic transmissions – water/oil□ TC-MAOH2Oil cooler/mechanical transmission, air/oil, extra high performance■ TC-MWO Oil cooler for mechanical transmissions, basic performance,without retarder – water/oil□ TC-MWOH2 Oil cooler/mechanical transmission, water/oil, highperformance □ TRAP-HDSteel gearbox range housing, heavy duty. □ FUEQ-EH Fuel line electric heater■ AF-E Auxiliary fuel filter, electrically heated ■ EST-AID Engine start pre heating element□ PTER-DIN Power Take Off / splined shaft groove (female) DIN5462. □ PTER1400 Rear engine mounted power-take-off with flange SAE 1410 □ HPE-F101 Hydraulic pump F1-101, fixed displacement, single flow, rear engine mounted.□ HPE-F41 Hydraulic pump F1-41, fixed displacement, single flow, rear engine mounted.□ HPE-F51 Hydraulic pump F1-51, fixed displacement, single flow, rear engine mounted.□ HPE-F61 Hydraulic pump F1-61, fixed displacement, single flow, rear engine mounted.□ HPE-F81 Hydraulic pump F1-81, fixed displacement, single flow, rear engine mounted.□ HPE-T53 Hydraulic pump F2-53/53, fixed displacement, double flow, rear engine mounted.□ HPE-T70Hydraulic pump F2-70/35, fixed displacement, double flow, rear engine mounted.□ HPE-V120 Hydraulic pump VP1-120, variable displacement, single flow, rear engine mounted.□ HPE-V45 Hydraulic pump VP1-45, variable displacement, single flow, rear engine mounted.□ HPE-V75 Hydraulic pump VP1-75, variable displacement, single flow, rear engine mounted.□ PTPT-D DIN connection PTO, Powertronic □ PTPT-F Flange connection PTO, Powertronic□ PTR-D DIN connection PTO, low speed, manual gearbox □ PTR-DH DIN connection PTO, high speed, manual gearbox □ PTR-DM DIN connection PTO, medium speed, manual gearbox □ PTR-F PTO, 1 rear flange connection□ PTR-FH Flange connection PTO, high speed, manual gearbox □ PTR-FL Flange connection PTO, low speed, manual gearbox □ PTRD-D Power take-off with 1 front DIN connection + 1 rear DIN connection, manual gearbox□ PTRD-D1 Power take-off with 1 front DIN connection + 1 rear flange connection, manual gearbox□ PTRD-D2 Power take-off with 1 front DIN connection and 2 rear flange connections, manual gearbox□ PTRD-F Power take-off with 1 rear flange connection, manual gearbox □ APF-BAS Basic I-shift PTO functions□ APF-ENH Enhanced I-shift PTO functions□ HPG-F101 Hydraulic pump F1-101, fixed displacement, single flow, gearbox mounted.□ HPG-F41 Hydraulic pump F1-41, fixed displacement, single flow, gearbox mounted.□ HPG-F51 Hydraulic pump F1-51, fixed displacement, single flow, gearbox mounted.□ HPG-F61 Hydraulic pump F1-61, fixed displacement, single flow, gearbox mounted.□ HPG-F81 Hydraulic pump F1-81, fixed displacement, single flow, gearbox mounted.□ HPG-V120Hydraulic pump VP1-120, variable displacement, single flow, gearbox mounted.Cab exterior■ BUMP-S Front steel bumper.□ BUMP-SC Front steel bumper, construction applications. □ GUARD-EH Guard plate for cooling pipes and oil sump □ CABS-FUA Full air cab suspension■ CABS-MEC Mechanical cab suspension□ CABS-REA Cab suspension, rear air and front mechanical □ AD-ROOF Roof air deflector□ AD-ROOFB Roof air deflector with light box □ AD-SIDEL Long cab side air deflector □ AD-SIDES Short cab side air deflector. □ LADDERLadder back of cabSuperstructure preparations□ 5WM-ISHD 5th wheel ISO mounting, heavy duty, 16 mm mounting plate ■ 5WM-ISOHFifth wheel ISO mounting, high Z-profiles (t=8 mm) for 10 mm ISO saddle.Z-profile height above frame = 80 mm. Total height above frame 90 mm. ■ 5WH150 Fifth wheel leg-height 150 mm □ 5WH185 Fifth wheel leg-height 185 mm □ 5WH190 Fifth wheel leg-height 190 mm□ 5WT-GF George Fischer SK-S 36.20 V cast fifth wheel□ 5WT-GFHD Georg Fischer SK-HD 38.36 cast heavy duty fifth wheel ■ 5WT-JOJost cast fixed fifth wheel.Type JSK 37C for 5WM-ISOL/5WM-ISOM/5WM-ISOH, LUB-CENT.Type JSK 37E for 5WM-LPRO, LUB-CENT.Type JSK 42K for all fifth wheel mountings with ULUBCENT. □ 5WT-JOHDJost JSK 38C cast heavy duty fifth wheel■ RAMP-LOW Ramp sliding member, low height□ RAMP-MED Ramp sliding member, medium height ■ RDECKRear deck, basic□ RDECK-M Rear deck, medium□ WL-TA1A Working lamp trailer arch, 1 lamp amber■ WL-TA1W Working lamp trailer arch, 1 lamp white■ TBC-EC European Community trailer brake connection□ TRCON145 Trailer cable connection 14-pin connector for ADR vehicles(ADR).□ TRCON147 Trailer cable connection 14-pin connector without ADR(UADR).□ TRCONKOR Trailer cable connections for Korea□ TTRCON15 Trailer cable connections for ADR□ TTRCON7 Trailer cable connections, UADR■ TTRCON77 Trailer cable, two connections, UADR■ TRBR-HCF Hand controlled trailer brake, full pressure□ TRBR-HCR Hand controlled trailer brake, reduced pressure□ TAILPREP Taillift preparation kit■ Standard Equipment □ Optional EquipmentFor more detailed information about cab and powertrain equipment, please refer to separate specification sheets.For all possible options and combinations of options please consult your Volvo sales contact who can create a specification to match your requirements using the Volvo Sales Support system (VSS).。

VOLVO TRUCK [瑞典]沃尔沃集团是世界上最大的商用运输产品供应商之一。

产品遍布世界140多个国家。

始创于1927年,总部瑞典哥德堡。

制造卡车、客车、建筑机械、应用于船舶和工业用途的动力系统、航空发动机及航空发动机部件。

产品范围还包括客户定制的金融、租赁、保险和维修总体解决方案,以及基于IT技术的运输信息和管理的整体解决方案。

公司核心价值观:质量,安全,环保。

通过2001年收购法国雷诺(Renault)公司的卡车业务,使得集团获得了另外两个强大的品牌:法国雷诺(Renault)和美国马克(Mack)卡车。

在市场上,互为补充,在其核心价值观的引导下,沃尔沃集团不断发展和壮大。

经营范围主要由八个商业领域组成,分别是:沃尔沃卡车,雷诺(Renault)卡车,马克(Mack)卡车,沃尔沃客车,沃尔沃建筑设备,沃尔沃遍达公司,沃尔沃航空航天公司以及金融服务。

SCANIA [瑞典]斯堪尼亚公司成立于1891年。

业务遍及欧洲、拉美、亚洲、非洲和澳大利亚。

全球拥有29,100名雇员。

在欧洲、拉丁美洲均设有生产厂。

斯堪尼亚是其所在领域内最赢利的公司之一。

产品销往世界各地100多个国家,且95%以上的产品销往瑞典以外的国家和地区。

与竞争对手不同,斯堪尼亚已经将公司资源系统地集中于重型卡车领域。

今天,斯堪尼亚已成为世界最大的重型卡车和巴士制造商之一。

斯堪尼亚凭借技术领先的模块化组合系统成为重型卡车行业赢利能力最强的公司。

即使在卡车市场价格日益下跌的日子里,斯堪尼亚仍然保持很强的赢利能力。

最近70多年来,斯堪尼亚公司每年都保持赢利状态。

1969年,斯堪尼亚-VABIS与萨伯(SAAB)合并成立萨伯-斯堪尼亚有限公司。

1995年5月,斯堪尼亚再次成为一家独立的公司。

RENAULT TRUCK[法国]世界十大汽车公司之一,法国第二大汽车公司。

与世界上许多汽车公司的创始人一样,雷诺汽车公司的创始人路易.雷诺也是一个对机械充满兴趣的人。

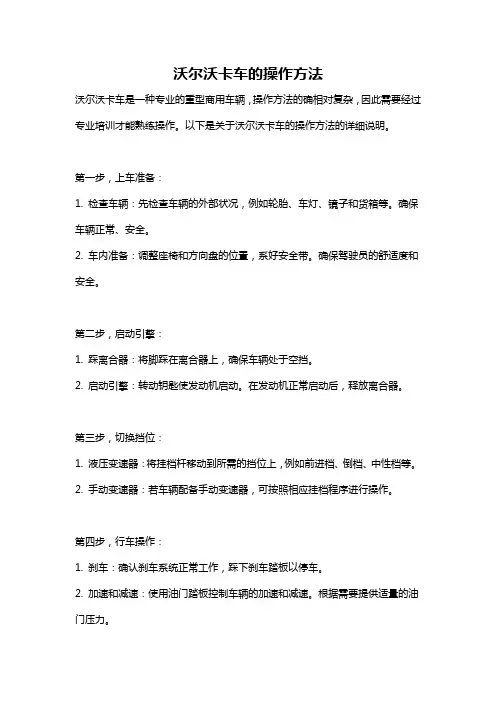

沃尔沃卡车的操作方法沃尔沃卡车是一种专业的重型商用车辆,操作方法的确相对复杂,因此需要经过专业培训才能熟练操作。

以下是关于沃尔沃卡车的操作方法的详细说明。

第一步,上车准备:1. 检查车辆:先检查车辆的外部状况,例如轮胎、车灯、镜子和货箱等。

确保车辆正常、安全。

2. 车内准备:调整座椅和方向盘的位置,系好安全带。

确保驾驶员的舒适度和安全。

第二步,启动引擎:1. 踩离合器:将脚踩在离合器上,确保车辆处于空挡。

2. 启动引擎:转动钥匙使发动机启动。

在发动机正常启动后,释放离合器。

第三步,切换挡位:1. 液压变速器:将挂档杆移动到所需的挡位上,例如前进档、倒档、中性档等。

2. 手动变速器:若车辆配备手动变速器,可按照相应挂档程序进行操作。

第四步,行车操作:1. 刹车:确认刹车系统正常工作,踩下刹车踏板以停车。

2. 加速和减速:使用油门踏板控制车辆的加速和减速。

根据需要提供适量的油门压力。

3. 转向:使用方向盘将车辆转向所需的方向。

手轻而准确地转动方向盘,在路口或弯道前提前转向。

4. 换挡:根据行驶状况和需要,及时按照挂档序列切换挡位。

注意避免急剧换挡,以免对车辆造成损害。

5. 安全距离:保持与前车的安全距离,减少碰撞的风险。

6. 加载和卸载:根据需要进行货物的装载和卸载,确保货物的稳定和安全。

第五步,停车操作:1. 停车:在需要停车的时候,先放慢车速,找到合适的停车空间。

踩下刹车踏板,将车辆完全停稳。

2. 挂空挡:将挂档杆移动到空挡上,拉起手刹。

第六步,熄火:1. 关闭其他设备:例如车灯、空调等。

2. 关闭引擎:将车辆走完一段时间后,将挂档杆移回空挡,转动钥匙将引擎熄火。

拔下钥匙,关闭电器设备。

此外,为了确保驾驶的安全和有效,还需要注意以下几点:1. 遵守交通规则:必须严格遵守道路交通规则和信号,以确保自身和他人的安全。

2. 注意车辆限制:了解并遵守车辆的载重和尺寸限制,确保在合适的道路上行驶。

3. 常规检查:在每次驾驶前,应检查刹车、转向、轮胎和车灯等重要设备的正常工作。

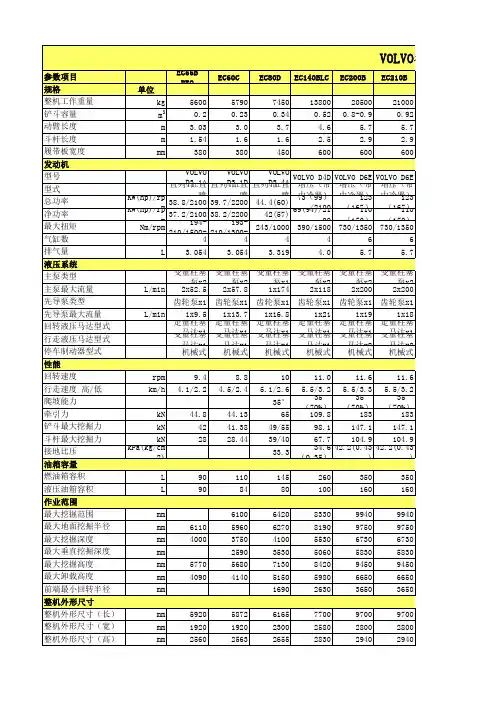

牵引车规格参数

牵引车是一种用于拖拉货物的大型车辆,其规格参数对于保证车辆的安全运行和承载能力非常重要。

以下是牵引车的一些主要规格参数:

1. 车辆重量:牵引车的重量通常在10-30吨之间,具体取决于车型和配置。

2. 发动机功率:牵引车需要具备足够的动力来拖拉重负荷,其发动机功率通常在250-600马力之间。

3. 轴距:牵引车的轴距越长,其稳定性越好,通常在3000-4000毫米之间。

4. 传动方式:牵引车的传动方式分为前驱、后驱和四驱,其中后驱和四驱的承载能力更大。

5. 制动系统:牵引车需要具备强大的制动系统来保证安全运行,其中包括气制动和液压制动两种。

6. 轮胎规格:牵引车的轮胎通常使用大型胎面宽度,以提供更好的牵引力和承载能力。

7. 车身长度:牵引车的车身长度通常在6-12米之间,具体取决于车型和配置。

以上是牵引车的一些主要规格参数,购买时需要根据具体用途和需求进行选择。

- 1 -。

牵引车参数欧曼310W 4*2H= H2=1370 L1=2150 L2=1700 R=2100欧曼330w 4*2(BJ4171SKFJA-14)H=1370 H2=1170 L1=1900 L2=1700 R=1950,2100欧曼380kw6*4H= H2=1380 L1=2500 L2=1800 R=2200欧曼6 336w6*4H=1180 H2=1400 L1=2650 L2=1900 R=2300前置距1100(后桥中⾄座中)欧曼6-336w6*2H= H2=1410 L1=2850 L2=1700 R=欧曼6-380ps6*2H1= H2=1380 L1=2800 L2=1800 R=2200欧曼9 290kw 4*2H= H2=1380 L1=1950 L2=1700 R=2100欧曼9 270kw6*4H= H2=1380 L1=2100 L2=1600 R=2000欧曼9-336w6*2H= H2=1410 L1=2750 L2=1750 R=2150欧曼9-340CL 6*4H= H2=1420 L1=2500 L2=1850 R=2230欧曼9-375W6*4H= H2=1420 L1=2600 L2=1900R=2350欧曼牵引车数据车型欧曼9神⾈280A6*2H= H2=1400 L1=2500 L2=1600-1800 R=2100欧曼9神⾈290kw6*4H= H2=1380 L1=2100 L2=1600 R=2000欧曼9神⾈290w6*2H= H2=1400 L1=2800 L2=1800 R=2190欧曼9神⾈340kw6*4H= H2=1410 L1=2400 L2=1800 R=2300欧曼9神⾈360ps4*2H= H2=1400 L1=2050 L2=1750 R=2100欧曼9神⾈中悬浮270kw H= H2=1380 L1=2100 L2=1600 R=2000欧曼神⾈9 4*2H= H2=1380 L1=2100 L2=1700 R=2000欧曼神⾈O2 4*2H= H2=1420 L1=2100 L2=1700 R=2000欧曼雄狮230 4*2H= H2=1300 L1=2200 L2=1400 R=2100欧曼雄狮260 4*2H= H2=1370 L1=2100 L2=1300 R=欧曼雄狮280H=1350 H2= L1=1900 L2=1700 R=2100雄狮310kw 4*2H= H2=1370 L1=1900 L2=1700 R=2150BJ4251SMF 6*4H=1200 H2=1420 L1=2200 L2= R=2200(2150)BJ4253SMF 6*4H=1200 H2=1420 L1=2200 L2= R=2200(2150)BJ4183H=1200 H2= L1=2100 L2= R=1800BJ4258H=1120 H2= L1=2100 L2= R=1950 前置距700(后桥中⾄座中)BJ4251SNF.JB 6*2H= H2=1320 L1=2900 L2= R=1900BJ4253SNFKB-1 6*2H=1200 H2=1350 L1=2600 L2= R=1900 BJ4251SNF.JB-1 6*2H= H2=1320 L1=2600 L2= R=1900BJ4253SMFJB 6*2H= H2=1280 L1= L2= R=1900BJ42578MFJBSSNF6*4H= H2=1370 L1= L2= R=新型轻型双驱(5.6系)H= H2=1320 L1= L2= R=新型轻型双转向(9系)H= H2=1300 L1= L2= R=陕汽牵引车陕汽奥龙平头 4*2H=1360 H2= L1=2100 L2=1700 R=2100陕汽奥龙ps280 4*2H=1360 H2= L1=2100 L2=1700 R=2100陕汽奥龙280 4*2H= H2=1380 L1=1800 L2=1700 R=2000陕汽奥龙320 4*2H= H2=1360 L1=1800 L2=1700 R=2100陕汽奥龙280kw6*4H= H2=1385 L1= L2=1850 R=2200 R=陕汽奥龙380kw6*4H= H2=1400 L1=2700 L2=1700 R=2200陕汽德龙320kw6*4F2000H= H2=1420 L1=2350 L2=1850 R=2200,2300陕汽奥龙380ps 6*4H= H2=1420 L1=2400 L2=1850 R=2200陕汽奥龙330ps 6*4H= H2=1400 L1=2450 L2=1850 R=2200陕汽德龙420ps 6*4H= H2=1420 L1=2300 L2=1900 R=陕汽奥龙270ps6*2H= H2=1420 L1=2800 L2=1950 R=2200陕汽奥龙290ps4204wevb 6*2H= H2=1440 L1=2750 L2=1900 R=2250车型数据陕汽德御290kw6*2H= H2=1410 L1=2300 L2=1850 R=2100陕汽奥龙330ps6*2H= H2=1440 L1=2750 L2=1900 R=2270陕汽德龙6*2(sx4204 7M2791)H= 1110(1200) H2=1340 L1=2400 L2=R=奥龙中浮桥 6*2H= 1170 H2= L1=2600 L2=1700 R=2100前置距750(后桥中⾄座中)德龙双驱 6*4H= 1200 H2= L1=2350 L2=1800 R=2250前置距950(后桥中⾄座中)陕汽奥龙6*2(sx4204 TM2791)H=1245H2=1485此车应为客户特殊要求L1=26000 L2=R=2100前置距800(后桥中⾄座中)德龙单驱4*2(sx4185NM351)H= 1180 H2=1420 L1=2150 L2=1700 R=2100前置距600(后桥中⾄座中)德龙双转向6*2H= H2=1370 L1=1800 L2= R=1900前置距750(后桥中⾄座中)奥龙双驱6*4H= H2=1400 L1=2370 L2= R=2170陕汽燃⽓双驱6*4sx4255N12384T H= H2=1310 L1=1900(2400-500)L2= R=2200德龙F3000-6*4(轻量化)H= H2=1375 L1=2650 L2= R=2100陕汽燃⽓双转向6*4sx4255N12384T H=1060 H2=1280 L1=1550 L2= R=1900(最⼩)前置距750(后桥中⾄座中)陕汽双驱M3000轻量化H=1060 H2=1310 L1=0 L2= R=陕汽重卡奥龙平头270中悬浮H= H2=1400 L1=2500 L2=1900 R=2200解放尖头299kw 4*2H= H2=1270 L1=1500 L2=1100 R=1500解放尖头单驱195KW260 CA4172F2KIA H= H2=1350 L1=1600 L2=1650 R=2100解放尖头柳州 4*2H= H2=1380 L1= L2= R=2200解放悍威280kw 4*2H= H2=1380 L1=1950 L2=1400 R=1900解放300 4*2H= H2=1420 L1=1800 L2=1550 R=2100解放奥威310kw 4*2H= H2=1360 L1=2000 L2=1550 R=2100解放尖头柳州300kw4*2H= H2=1400 L1=1500 L2=1400 R=2100解放尖头260ps4*2H=1350 H2= L1=2100 L2=1640 R=2000解放尖顶310ps4*2H1=1145 H2= L1=1700 L2=1600 R=2100解放平头230ps4*2H1=1060 H2= L1=1750 L2=1300 R=解放悍威双驱3206*4H= H2=1310 L1=2200 L2=1800 R=2300解放奥威350kw6*4H= H2=1400 L1=2100 L2=1700 R=2200J6390ps6*4(CA4250P66K2TIAE)H= H2=1320 L1=2450 L2=1950R=2350(最⼩)前置距1250(后桥中⾄座中)新⼤威380kw6*4H=1100 H2=1320 L1= L2= R=解放奥威310kw 6*4H= H2=1360 L1=2500 L2=1750 R=2200解放平头310kw 6*4H= H2=1360 L1=2350 L2=1900 R=2200解放尖头280 6*4H= H2=1350 L1=1800 L2=1600 R=2200解放J6 350PS6*4H= H2=1300 L1=2800 L2=1900 R=解放平头280kw6*4H= H2=1360 L1= L2= R=2200解放奥威330ps6*4H= H2=1400 L1=2500 L2=1750 R=2200解放380kw6*4H1=1200 H2=1410 L1=2700 L2=1600 R=2200解放奥威尖顶J5 6*4H= H2=1350 L1=2400 L2=1900 R=解放新⼤威310ps6*2H= H2=1360 L1=2300 L2=1650 R=2070解放奥威280kw6*2H=1120 H2=1360 L1=2300 L2=1650 R=2100解放尖顶280kw6*2H= H2=1360 L1=2300 L2=1650 R=2100解放悍威310kw6*2H1= H2=1370 L1=2400 L2=1700 R=2200解放尖头柳特260ps6*2H= H2=1340 L1=1515 L2=985 R=2100解放尖头293ps6*2H1=1080 H2= L1=2600 L2=1450 R=1900解放奥威310ps6*2H= H2=1400 L1=2300 L2=1800 R=2200解放新⼤威290ps6*2H= H2=1350 L1=2350 L2=1650 R=2100解放尖顶280kw 6*2H= H2=1370 L1=2500 L2=1600 R=2000解放平头280kw6*2H= H2=1400 L1=2500 L2=1600 R=2100解放尖头280kw6*2H1=1335 H2= L1=1800 L2=730 R=1500-1700解放平头280kw中悬浮H=1130 H2=1360 L1=2300 L2=1650 R=2100青岛解放双驱CA258P2K6*4新⼤威双驱H=1110 H2=1300 L1=1960 L2=1870 R=2250(最⼩)前置距1040(后桥中⾄座中)青岛解放双驱CA253P7K271 6*4H=1110 H2= L1= L2= R=CA4226(6*2)H=1130 H2= L1= L2= R=解放双驱CA250P2K1 6*4H=1100 H2= L1=1900 L2= R=2100柳特尖头CA4283H=1060 H2=1280 L1=1800 L2= R=1700解放J6双驱H=1100 H2=1310 L1=2300 L2= R=2350解放奥威单驱H=1100 H2= L1=1800 L2= R=新⼤威双转向6*2H=1090 H2= L1=2200 L2= R=1900前置距600(后桥中⾄座中)CA4250P21K22TIE 6*4H=1100 H2= L1=2200 L2=1900 R=2250(最⼩)前置距1100(后桥中⾄座中)奥威双驱CA4254H=1100 H2= L1=2450 L2=1910 R=2250(最⼩)前置距1050(后桥中⾄座中)解放奥威6*2H=1120 H2= L1=2450 L2=1700 R=2100(最⼩)前置距700(后桥中⾄座中)CA4252P21K(J5-310)6*4H=1040 H2=1280 L1= L2= R= 此车或许改装过J6双转向6*2H= H2=1320 L1=2800 L2= R=2100(最⼩) CA4256PIK2TI悍威新型6*4H=1110 H2= L1=2500 L2= R=2200 J6(420)CA4250P66K24TIAEX 6*4H=1070(1140) H2=1280(1350) L1= L2= R=J5双驱(4252P21K211A2E)H=1100 H2= L1=2100 L2= R=2200(最⼩)前置距1040CA252K2R5T3E(尖头6*2)H=1103 H2= L1=1500 L2= R=2100(最⼩)前置距1040CA4257P2K2(6*4l⽼款)H= H2=1320 L1= L2= R=(最⼩)前置距1040豪沃336kwZZ483Z36 4*2H= H2=1320 L1=1950 L2=1500 R=2200豪沃290kw 4*2H= H2=1350,1320 L1=1800 L2=1600 R=2100斯太尔平顶,尖顶双卧280ps4*2H= H2=1370 L1=1850 L2=1700 R=2100HOKA290PS.ZZ4183H= H2=1330 L1=2150 L2=1500 R=斯太尔王280ps 4*2H= H2=1370 L1=2000 L2=1650 R=2100斯太尔280ps 4*2H= H2=1400 L1=1850 L2=1700 R=2100豪运265kw360ps 4*2H= H2=1380 L1=2050 L2=1700 R=2100斯太尔王310w尖顶双卧 6*4H= H2=1400 L1=2400 L2=1800R=2200重汽牵引车车型数据豪沃336kwT1100 6*4H= H2=1380 L1=2450 L2=1850 R=2350豪沃371kwZZ4257S3241V 4*2H= H2=1380,1400 L1=2500 L2=1900 R=2350斯太尔310kw6*4H= H2=1400 L1=2400 L2=1000 R=2200斯太尔330kw6*4H= H2=1420 L1= L2= R=2200斯太尔350kw6*4H= H2=1420 L1=2300 L2=1700 R=2250⾦王⼦平顶2906*4H= H2=1380 L1=2500 L2=1800 R=豪沃A7340ps6*4H= H2=1410 L1=2450 L2=1850 R=斯太尔王336ps6*4H= H2=1420 L1=2250 L2=1800 R=2250豪沃360zz425 6*4H= H2=1400 L1=2500 L2=1850 R=2250豪沃360ps 6*4H= H2=1380 L1=1850 L2=1950 R=2350豪沃290ps 6*4H= H2=1370 L1=2350 L2=1850 R=2250豪运371kw 6*4H= H2=1410 L1=2300 L2=1750 R=2150斯太尔霸王266kw6*4H= H2=1380 L1=2300 L2= R=2200斯太尔⾦王⼦290ps6*4H= H2=1430 L1=2500 L2=1800 R=2200豪沃⾼顶375ps6*4H= H2=1360 L1=2550 L2=1850 R= HOKA375ps6*4H= H2=1360 L1=2550 L2=1850 R=沃尔沃480ps6*4H= H2=1420 L1=2300 L2=1800 R=豪沃A7340ps6*4H= H2=1410 L1=2400 L2=1800 R=豪沃336PS6*4H= H2=1360 L1=2500 L2=1800 R=豪运336kw6*2H= H2=1350 L1=2300 L2=1900 R=2250豪运300ps6*2H= H2=1350 L1=2400 L2=2000 R=豪沃290kw6*2H= H2=1370 L1=2450 L2=1750 R=2100豪沃336kw6*2H= H2=1370 L1=2500 L2=1700 R=2000豪沃后背油箱290ps6*2H= H2=1380 L1=1850 L2=1850 R=2100豪骏平头290kw6*2H=1420 H2= L1=2700 L2=1850 R=2100豪骏平头266kw6*2H= H2= 1420 L1=2600 L2=1850 R=2100豪沃290kw中悬浮H= H2=1330 L1=2500 L2=1600 R=2100豪沃290kw后悬浮H= H2=1420 L1=2100 L2=2000 R=2400豪沃266后悬浮H= H2=1420 L1=2200 L2=2150 R=2550斯太尔王330kw后悬浮H= H2=1380 L1=2400 L2=2050 R=2300斯太尔王336kw后悬浮H= H2=1380 L1=2300 L2=2100 R=2500斯太尔后悬浮4*2H= H2= L1=1700 L2= R=2500红岩新⼤康6*4H=1150 H2=1400 L1= L2= R=豪泺6*2(后部带油箱)336ZZ4257N25C7A H=1180 H2= L1=1850 L2=1750 R=2100豪泺6*2(后部带油箱)336ZZ4257N25C7C H=1140 H2= L1=1600 L2=1750 R=2100ZZ4257MZ5C7A(豪沃6*2)H=1150 H2= L1=2550 L2=1650 R=2100前置距650(后桥中⾄座中)ZZ4257S3241V(豪沃双驱)H=1220 H2= L1=2500 L2=1830 R=2250(最⼩)前置距980红岩新⼤康(290)6*2CQ4253FRWG253H= H2=1330 L1=1407 L2= R=1973(最⼩)前置距810豪沃后浮轮H=1180 H2= L1=2000 L2= R=2650(最⼩)豪沃双驱H= H2=1380 L1=2400 L2= R=2200(最⼩)豪沃单驱欧Ⅲ4*2H= H2=1300豪沃A7340ps6*2H= H2=1320 L1= L2= R=)豪卡6*2H= H2=1400 L1=2040 L2= R=1950)豪卡H7(375)ZZ4253 6*4H=1090 H2=1390 L1=2500 L2= R=2200(最⼩)前置距1000凌野280kw 4*2H= H2=1390 L1=2100 L2=1470 R=1800,2000东风康明斯240H= H2=1320 L1=1700 L2=1350 R=2100东风尖头龙卡290kw6*4H= H2=1410 L1=2300 L2=1800 R=2300东风龙卡尖头290美式 6*4H=1110 H2=1330 L1=1800 L2=1800 R=2100(最⼩)前置距900东风龙卡尖头280美式 6*4H=1 H2=1330 L1=1750 L2=1800 R=2200平头天龙375kw6*4H= H2=1390 L1=2600 L2=1700 R=2100,2200东风尖顶单卧330kw6*4H1=1100 H2=1350 L1=2100 L2=1800 R=2250东风霸龙ps6*4H= H2=1400 L1=2450 L2=1700 R=2200东风天龙300ps6*2H1=1200 H2=1420 L1=2600 L2=1800 R=2200东风龙卡尖头290ps6*2H= H2=1320 L1=1550 L2=1450 R=1915东风280w尖顶单卧6*2H1=1130 H2=1390 L1=1700 L2=1550 R=2000东风尖顶4221-405 6*2H= H2=1370 L1=2300 L2=2000 R=2100东风霸龙290ps6*2H= H2=1370 L1=2900 L2=1750 R=2000东风天龙双卧340 6*2H= H2=1420 L1=2600 L2=1800 R=2200东风天龙310ps6*2H= H2=1410 L1=2800 L2=1550 R=2100(最⼩)前置距450东风⼤康4*2H= H2=1330 L1=1700 L2= R=1700EQ4240ASZ7尖头6*2H=1160 H2= L1=1300 L2= R=2000(最⼩)前置距650平头EQ4250W H= H2= L1=2400 L2= R=东风双转向EQ4251(6*2)蓝东风H=1120 H2= L1=2300 L2= R=2400车备注H=车架⾼。

volvo 740参数Volvo 740是一款豪华轿车,以其卓越的性能和卓越的品质而备受关注。

以下是一份详细的参数说明,帮助您了解这款车型的各个方面。

一、车身尺寸Volvo 740的车身尺寸为长**5070毫米**、宽**1873毫米**、高**1445毫米**。

这款车型提供了宽敞的车内空间,适合多人口家庭使用。

二、发动机参数Volvo 740搭载了一台直列六缸发动机,型号为B6发动机,最大功率为**210马力**,最大扭矩为**320牛·米**。

这款发动机具有出色的燃油经济性和低排放性能,同时提供了充足的动力储备,适合在城市和高速公路上行驶。

三、变速箱与驱动方式Volvo 740采用了一款六速自动变速箱,提供了顺畅的换挡体验。

驱动方式为前置前驱,适合在城市和高速公路上行驶。

此外,这款车型还配备了四驱系统,可以在复杂的路况下提供更好的牵引力和稳定性。

四、悬挂系统Volvo 740采用了前麦弗逊式独立悬挂和后多连杆式独立悬挂,提供了出色的操控性和舒适性。

这款车型还配备了自适应悬挂系统,可以根据路况和驾驶模式自动调整悬挂的硬度,以满足不同的驾驶需求。

五、安全性配置Volvo 740配备了多项安全配置,包括盲点监测、主动刹车、自动紧急制动、车道偏离预警等。

这些配置可以大大提高驾驶安全性,减少交通事故的发生。

六、其他配置Volvo 740提供了丰富的舒适性和便利性配置,包括电动座椅、座椅加热/通风、自动空调、导航系统等。

此外,这款车型还配备了智能互联功能,可以通过手机应用程序远程控制车辆。

七、油耗表现在城市和高速公路行驶条件下,Volvo 740的油耗表现较为理想,百公里综合油耗在**8升左右**。

这得益于其高效的燃油经济性和优化的动力分配系统。

综上所述,Volvo 740是一款性能和品质卓越的豪华轿车,具有宽敞的车内空间、出色的操控性和舒适性、丰富的安全配置和便利性配置以及良好的油耗表现。

如果您正在寻找一款豪华轿车,Volvo 740是一个值得考虑的选择。