热膨胀系数表(英语版)

- 格式:doc

- 大小:99.50 KB

- 文档页数:2

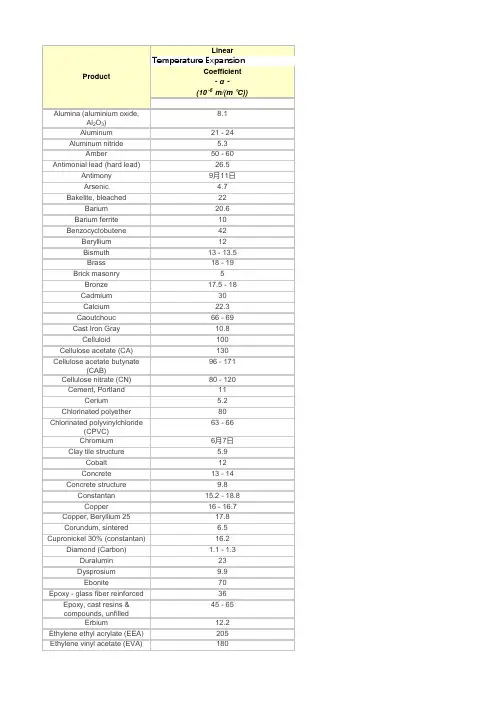

常见高分子热膨胀系数CTE熱膨脹係數Coefficient of thermal expansion(CTE)Product Linear Temperature Expansion Coefficient- α-(10-6 m/m K)(10-6 in/in oF)ABS(Acrylonitrilebutadienestyrene)thermoplastic73.841ABS -glassfiber-reinforced30.417 Acetal106.559.2 Acetal - glassfiber-reinforced39.422 Acrylic, sheet, 8145Acrylic, extruded234130Alumina 5.4 3.0Aluminum22.212.3Antimony10.4 5.8Arsenic 4.7 2.6Barium20.611.4Beryllium11.5 6.4Bismuth137.3Brass18.710.4Brick masonry 5.5 3.1Bronze18.010.0Cadmium3016.8Calcium22.312.4Carbon - diamond 1.20.67Cast Iron Gray10.8 6.0Cellulose acetate13072.2 (CA)Cellulose acetate80 - 95 butynate (CAB)Cellulose nitrate 10055.6Cement10.0 6.0Cerium 5.2 2.9 Chlorinated66.637 polyvinylchloride(CPVC)Chromium 6.2 3.4Clay tile5.9 3.3 structureCobalt12 6.7 Concrete14.58.0Concrete9.8 5.5 structureConstantan18.810.4 Copper16.69.3Copper, Beryllium17.89.9 25Corundum,6.5 3.6 sinteredCupronickel 30%16.29 Diamond 1.10.6Dysprosium9.9 5.5 Ebonite76.642.8 Epoxy, castingsresins &5531 compounds,unfilledErbium12.2 6.8Ethylene ethyl205113.9 acrylate (EEA)Ethylene vinyl180100 acetate (EVA)Europium3519.4Fluoroethylene13575 propylene (FEP)Gadolinium95Germanium 6.1 3.4Glass, hard 5.9 3.3Glass, Pyrex 4.0 2.2Glass, plate9.0 5.0Gold14.28.2Granite7.9 4.4Graphite, pure7.9 4.4 Hafnium 5.9 3.3Hard alloy K206 3.3 Hastelloy C11.3 6.3 Holmium11.2 6.2Ice5128.3 Inconel12.67.0 Indium3318.3 Invar 1.50.8 Iridium 6.4 3.6 Iron, pure12.0 6.7 Iron, cast10.4 5.9 Iron, forged11.3 6.3 Lanthanum12.1 6.7Lead28.015.1 Limestone8 4.4 Lithium4625.6 Lutetium9.9 5.5 Magnesium2514 Manganese2212.3 Marble 5.5 - 14.1 3.1 - 7.9Masonry 4.7 - 9.0 2.6 - 5.0Mica3 1.7Molybdenum5 2.8Monel13.57.5Mortar7.3 - 13.5 4.1-7.5Neodymium9.6 5.3Nickel13.07.2Niobium7 3.9 (Columbium)Nylon, general7240 purposeNylon, Type 11,molding and10055.6 extrudingcompoundNylon, Type 12,molding and80.544.7 extrudingcompoundNylon, Type 6,8547.2castNylon, Type 6/6,8044.4 molding compoundOsmium5 2.8Palladium11.8 6.6Phenolic resin8044.4 without fillersPlaster16.49.2Platinum9.0 5.0Plutonium5430.2Polyallomer91.550.8Polyamide (PA)11061.1Polybutylene (PB)72Polycarbonate70.239 (PC)Polycarbonate -21.512 glassfiber-reinforcedPolyester123.569Polyester - glass2514 fiber-reinforcedPolyethylene (PE)200111Polyethylene (PE)60 - High MolecularWeightPolyethylene59.433 terephthalate(PET)Polyphenylene -glass35.820 fiber-reinforcedPolypropylene90.550.3 (PP), unfilledPolypropylene -glass3218 fiber-reinforcedPolystyrene (PS)7038.9Polysulfone (PSO)55.831Polyurethane57.632 (PUR), rigidPorcelain 3.6 2.0Potassium8346.4Polyvinyl 50.428chloride (PVC)Polyvinylidene127.871fluoride (PVDF)Porcelain 4.5 2.5 Potassium8346.1 Praseodymium 6.7 3.7 Promethium11 6.1Quartz0.77 - 1.40.43 - 0.79 Rhenium 6.7 3.7 Rhodium8 4.5 Rubber, hard7742.8 Ruthenium9.1 5.1 Samarium12.77.1 Sandstone11.6 6.5 Scandium10.2 5.7 Selenium 3.8 2.1Silicon 5.1 2.8Silver19.510.7Slate10.4 5.8Sodium7039.1Solder 50 - 5024.013.4Steatite8.5 4.7Steel13.07.3Steel Stainless17.39.6 Austenitic (304)Steel Stainless14.48.0 Austenitic (310)Steel Stainless16.08.9 Austenitic (316)Steel Stainless9.9 5.5 Ferritic (410)Strontium22.512.5Tantalum 6.5 3.6Tellurium36.920.5Terbium10.3 5.7Terne11.6 6.5Thallium29.916.6Thorium12 6.7Thulium13.37.4Tin23.413.0Titanium8.6 4.8Tungsten 4.3 2.4Uranium13.97.7 Vanadium8 4.5Vinyl Ester16 - 228.7 - 12 Wood, fir 3.7 2.1Wood, oak parallel4.9 2.7to grainWood, oak across5.4 3.0to grainWood, pine5 2.8 Ytterbium26.314.6Yttrium10.6 5.9Zinc29.716.5 Zirconium 5.7 3.2一些液體的體積熱膨脹係數γ物質γ in 10-3/K 20 °C 酒精 (乙醇) 1.10丙酮 1.43汽油 1.06苯 1.23氯仿 (三氯甲烷) 1.28果酸 1.07乙醚 1.62乙酸乙酯 1.38甘油 (Propantriol)0.49甲醇 1.10Mineralol (Hydraulikol)0.70石蠟0.76煤油0.96水銀0.18松節油 1.00四氯化碳 1.22甲苯 1.12水0.21參考資料1. /designation/te.htm2. /zh-tw/熱膨脹係數。

热膨胀系数英文The thermal coefficient of expansion, also known as the thermal expansion coefficient, is a measure of the change in volume (or length, if the material is constrained) of a material in response to a change in temperature. It is defined as the fractional change in volume (or length) per unit change in temperature, usually expressed in units of parts per million per degree Celsius (ppm/°C) or per degree Fahrenheit (ppm/°F). The thermal coefficient of expansion varies widely among different materials and can be influenced by factors such as crystal structure, composition, and processing history. For example, materials with a higher coefficient of expansion tend to expand more when heated and contract more when cooled than materials with a lower coefficient of expansion. This property is important for a variety of applications, such as in the construction of buildings and bridges, where thermal expansion and contraction can cause significant stress on materials over time. Factors such as humidity, pressure, and material purity can also affect the coefficient of expansion. Therefore, it is important to carefully consider the thermal properties of a material before choosing it for a particular application or engineering design.热膨胀系数,也称热膨胀系数或线膨胀系数,是一种测量材料在温度变化时体积(或长度,如果材料受到约束)变化的指标。

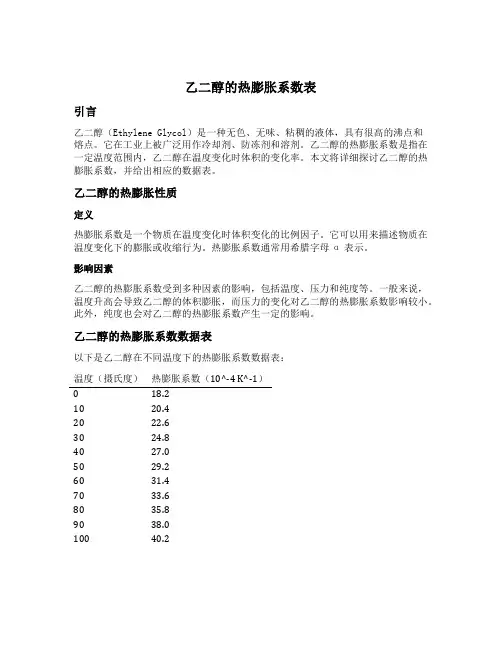

乙二醇的热膨胀系数表引言乙二醇(Ethylene Glycol)是一种无色、无味、粘稠的液体,具有很高的沸点和熔点。

它在工业上被广泛用作冷却剂、防冻剂和溶剂。

乙二醇的热膨胀系数是指在一定温度范围内,乙二醇在温度变化时体积的变化率。

本文将详细探讨乙二醇的热膨胀系数,并给出相应的数据表。

乙二醇的热膨胀性质定义热膨胀系数是一个物质在温度变化时体积变化的比例因子。

它可以用来描述物质在温度变化下的膨胀或收缩行为。

热膨胀系数通常用希腊字母α表示。

影响因素乙二醇的热膨胀系数受到多种因素的影响,包括温度、压力和纯度等。

一般来说,温度升高会导致乙二醇的体积膨胀,而压力的变化对乙二醇的热膨胀系数影响较小。

此外,纯度也会对乙二醇的热膨胀系数产生一定的影响。

乙二醇的热膨胀系数数据表以下是乙二醇在不同温度下的热膨胀系数数据表:温度(摄氏度)热膨胀系数(10^-4 K^-1)0 18.210 20.420 22.630 24.840 27.050 29.260 31.470 33.680 35.890 38.0100 40.2乙二醇的热膨胀系数的应用乙二醇的热膨胀系数在工业和科学研究中具有重要的应用价值。

以下是乙二醇热膨胀系数的几个应用示例:1. 冷却剂和防冻剂的设计乙二醇常被用作冷却剂和防冻剂,其热膨胀系数的了解对于设计冷却系统和防冻液的配方非常重要。

通过了解乙二醇在不同温度下的热膨胀系数,可以有效控制冷却剂和防冻剂在温度变化时的体积变化,从而确保系统的正常运行。

2. 温度测量乙二醇的热膨胀系数可以用于温度测量。

通过测量乙二醇在温度变化下的体积变化,可以计算出温度的变化量。

这在某些实验和工业应用中非常有用,特别是在需要测量高温或低温的情况下。

3. 材料工程乙二醇的热膨胀系数对于材料工程非常重要。

在设计和制造材料时,需要考虑材料在温度变化下的膨胀或收缩行为,以确保材料的稳定性和可靠性。

通过了解乙二醇的热膨胀系数,可以更好地选择和设计材料,以满足特定的工程需求。

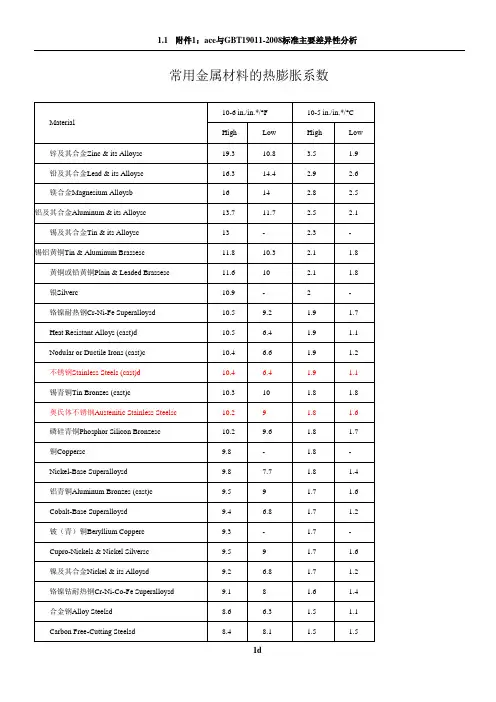

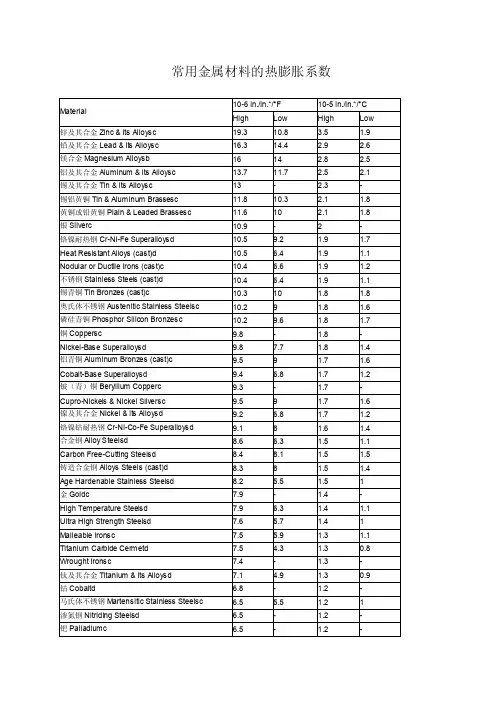

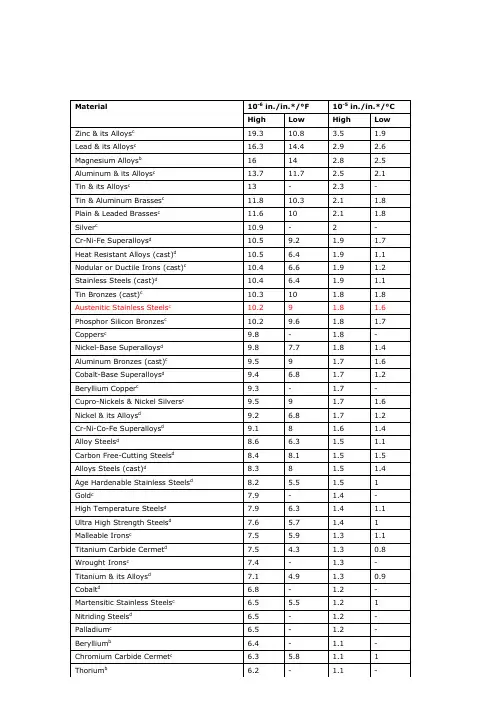

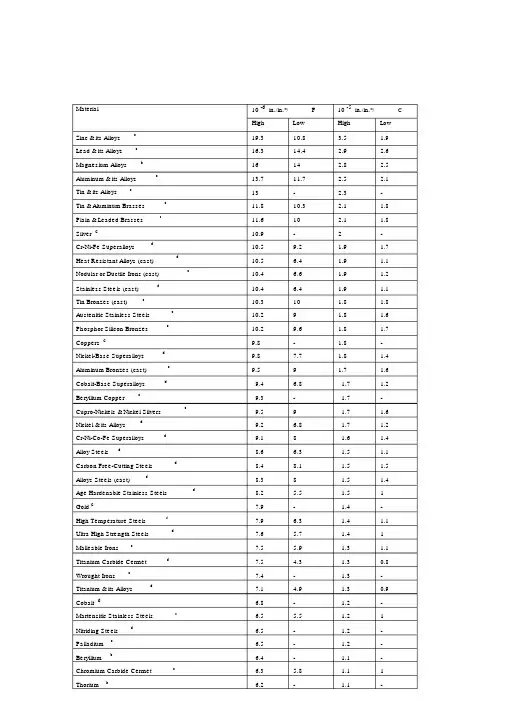

Material10 -6 in./in.*/°F10 -5 in./in.*/°CHigh Low High Low Zinc & its Alloys cLead & its Alloys cMagnesium Alloys bAluminum & its Alloys cTin & its Alloys cTin & Aluminum Brasses Plain & Leaded Brasses c Silver cCr-Ni-Fe Superalloys d Heat Resistant Alloys (cast) Nodular or Ductile Irons (cast) Stainless Steels (cast)d Tin Bronzes (cast)c Austenitic Stainless Steels Phosphor Silicon Bronzes Coppers cNickel-Base Superalloys Aluminum Bronzes (cast)cdcccdc19.310.8 3.5 1.916.314.4 2.9 2.61614 2.8 2.513.711.7 2.5 2.113- 2.3-11.810.3 2.1 1.811.610 2.1 1.810.9-2-10.59.2 1.9 1.710.5 6.4 1.9 1.110.4 6.6 1.9 1.210.4 6.4 1.9 1.110.310 1.8 1.810.29 1.8 1.610.29.6 1.8 1.79.8- 1.8-9.87.7 1.8 1.49.59 1.7 1.6Cobalt-Base Superalloys d Beryllium Copper cCupro-Nickels & Nickel Silvers Nickel & its Alloys dCr-Ni-Co-Fe Superalloys d Alloy Steels dCarbon Free-Cutting Steels Alloys Steels (cast)dAge Hardenable Stainless Steels Gold cHigh Temperature Steels d Ultra High Strength Steelscddd9.4 6.8 1.7 1.29.3- 1.7-9.59 1.7 1.69.2 6.8 1.7 1.29.18 1.6 1.48.6 6.3 1.5 1.18.48.1 1.5 1.58.38 1.5 1.48.2 5.5 1.517.9- 1.4-7.9 6.3 1.4 1.17.6 5.7 1.41Malleable Irons cTitanium Carbide Cermet d Wrought Irons cTitanium & its Alloys dCobalt dMartensitic Stainless Steels c Nitriding Steels dPalladium cBeryllium bChromium Carbide Cermet c Thorium b 7.5 5.9 1.3 1.1 7.5 4.3 1.30.8 7.4- 1.3-7.1 4.9 1.30.9 6.8- 1.2-6.5 5.5 1.21 6.5- 1.2-6.5- 1.2-6.4- 1.1-6.3 5.8 1.11 6.2- 1.1-Ferritic Stainless Steels c Gray Irons (cast)cBeryllium Carbide dLow Expansion Nickel Alloys c Beryllia & Thoria eAlumina Cermets d Molybdenum Disilicide c Ruthenium bPlatinum cVanadium bRhodium bTantalum Carbide dBoron Nitride dColumbium & its AlloysTitanium Carbide dSteatite cTungsten Carbide Cermet c Iridium bAlumina Ceramics cZirconium Carbide dOsmium and Tantalum b Zirconium & its Alloys b Hafnium bZirconia eMolybdenum & its AlloysSilicon Carbide eTungsten bElectrical Ceramics cZircon cBoron Carbide eCarbon and Graphite c 6 5.8 1.116- 1.1-5.8-1-5.5 1.510.3 5.3-0.9-5.2 4.70.90.8 5.1-0.9-5.1-0.9-4.9-0.9-4.8-0.9-4.6-0.8-4.6-0.8-4.3-0.8-4.1 3.80.70.68 4.1-0.7-4 3.30.70.6 3.9 2.50.70.4 3.8-0.7-3.7 3.10.70.6 3.7-0.7-3.6-0.6-3.6 3.10.60.55 3.4-0.6-3.1-0.6-3.1 2.70.60.5 2.4 2.20.40.39 2.2-0.4-2-0.4-1.8 1.30.30.2 1.7-0.3-1.5 1.30.30.2。

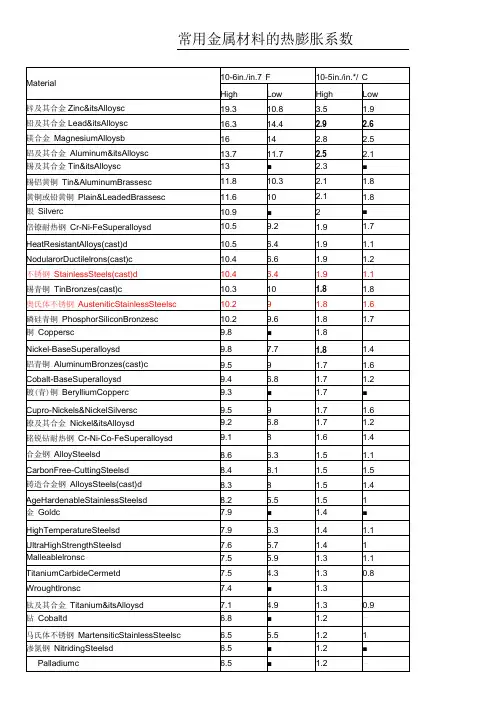

常用金属材料的热膨胀系数Material 10-6 in./in.*/ F °10-5 in./in.*/ C °High Low High Low锌及其合金 Zinc & its Alloysc19.310.8 3.5 1.9铅及其合金 Lead & its Alloysc16.314.4 2.9 2.6镁合金 Magnesium Alloysb1614 2.8 2.5铝及其合金 Aluminum & its Alloysc13.711.7 2.5 2.1锡及其合金 Tin & its Alloysc13- 2.3-锡铝黄铜 Tin & Aluminum Brassesc11.810.3 2.1 1.8黄铜或铅黄铜 Plain & Leaded Brassesc11.610 2.1 1.8银 Silverc10.9-2-铬镍耐热钢 Cr-Ni-Fe Superalloysd10.59.2 1.9 1.7 Heat Resistant Alloys (cast)d10.5 6.4 1.9 1.1 Nodular or Ductile Irons (cast)c10.4 6.6 1.9 1.2不锈钢 Stainless Steels (cast)d10.4 6.4 1.9 1.1锡青铜 Tin Bronzes (cast)c10.310 1.8 1.8奥氏体不锈钢 Austenitic Stainless Steelsc10.29 1.8 1.6磷硅青铜 Phosphor Silicon Bronzesc10.29.6 1.8 1.7铜 Coppersc9.8- 1.8-Nickel-Base Superalloysd9.87.7 1.8 1.4铝青铜 Aluminum Bronzes (cast)c9.59 1.7 1.6 Cobalt-Base Superalloysd9.4 6.8 1.7 1.2铍(青)铜 Beryllium Copperc9.3- 1.7-Cupro-Nickels & Nickel Silversc9.59 1.7 1.6镍及其合金 Nickel & its Alloysd9.2 6.8 1.7 1.2铬镍钴耐热钢 Cr-Ni-Co-Fe Superalloysd9.18 1.6 1.4合金钢 Alloy Steelsd8.6 6.3 1.5 1.1 Carbon Free-Cutting Steelsd8.48.1 1.5 1.5铸造合金钢 Alloys Steels (cast)d8.38 1.5 1.4 Age Hardenable Stainless Steelsd8.2 5.5 1.51金 Goldc7.9- 1.4-High Temperature Steelsd7.9 6.3 1.4 1.1 Ultra High Strength Steelsd7.6 5.7 1.41 Malleable Ironsc7.5 5.9 1.3 1.1 Titanium Carbide Cermetd7.5 4.3 1.30.8 Wrought Ironsc7.4- 1.3-钛及其合金 Titanium & its Alloysd7.1 4.9 1.30.9钴 Cobaltd 6.8- 1.2-马氏体不锈钢 Martensitic Stainless Steelsc 6.5 5.5 1.21渗氮钢 Nitriding Steelsd 6.5- 1.2-钯 Palladiumc 6.5- 1.2-铍 Berylliumb 6.4- 1.1-Chromium Carbide Cermetc 6.3 5.8 1.11钍 Thoriumb 6.2- 1.1-铁素体不锈钢 Ferritic Stainless Steelsc6 5.8 1.11 Gray Irons (cast)c6- 1.1-Beryllium Carbided 5.8-1-Low Expansion Nickel Alloysc 5.5 1.510.3 Beryllia & Thoriae 5.3-0.9-Alumina Cermetsd 5.2 4.70.90.8 Molybdenum Disilicidec 5.1-0.9-Rutheniumb 5.1-0.9-Platinumc 4.9-0.9-Vanadiumb 4.8-0.9-Rhodiumb 4.6-0.8-Tantalum Carbided 4.6-0.8-Boron Nitrided 4.3-0.8-铌及其合金 Columbium & its Alloys 4.1 3.80.70.68 Titanium Carbided 4.1-0.7-Steatitec4 3.30.70.6 Tungsten Carbide Cermetc 3.9 2.50.70.4铱 Iridiumb 3.8-0.7-Alumina Ceramicsc 3.7 3.10.70.6 Zirconium Carbided 3.7-0.7-Osmium and Tantalumb 3.6-0.6-锆及其合金 Zirconium & its Alloysb 3.6 3.10.60.55 Hafniumb 3.4-0.6-Zirconiae 3.1-0.6-钼及其合金 Molybdenum & its Alloys 3.1 2.70.60.5 Silicon Carbidee 2.4 2.20.40.39钨 Tungstenb 2.2-0.4-Electrical Ceramicsc2-0.4-Zirconc 1.8 1.30.30.2 Boron Carbidee 1.7-0.3-Carbon and Graphitec 1.5 1.30.30.2。

热膨胀系数(Thermal Expansion Coefficient)1. 介绍热膨胀系数,又称为热膨胀系数、线膨胀系数或体膨胀系数,是描述物质在温度变化下体积或长度变化的比例关系的物理量。

它反映了物质对温度变化的敏感程度,是材料工程、建筑工程、电子设备等领域中重要的参数之一。

2. 定义热膨胀系数(α)可以定义为单位温度变化时单位长度或单位体积的长度或体积变化。

它通常用公式表示:α = ΔL / (L * ΔT)其中,ΔL是长度(或体积)的变化量,L是初始长度(或体积),ΔT是温度的变化量。

3. 物理原理根据热力学和分子动理论,当物体受到加热时,其内部分子会以更高的平均能量振动。

这种振动会导致物质结构发生微小的扩张,从而引起尺寸上的变化。

相反地,当物体冷却时,分子振动减弱,导致收缩。

热膨胀系数的大小取决于物质的化学成分、结晶结构和温度变化范围。

不同材料具有不同的热膨胀系数,因此在工程设计和材料选择时,热膨胀系数是一个重要的考虑因素。

4. 应用4.1 材料工程在材料工程中,了解材料的热膨胀系数对于设计和制造过程至关重要。

例如,在高温环境下使用的合金必须具有较低的热膨胀系数,以避免由于温度变化而导致的尺寸变化问题。

另一方面,在某些应用中,如密封件或连接器中,需要考虑到材料之间的匹配热膨胀系数以确保性能和可靠性。

4.2 建筑工程在建筑工程中,热膨胀系数对于建筑结构设计和施工也是至关重要的。

例如,在铁路轨道设计中,需要考虑到轨道材料与环境温度变化之间的匹配程度,以减少由于温度变化引起的轨道长度变化。

同样,在混凝土结构中,了解混凝土和钢筋的热膨胀系数可以帮助设计人员预测结构在温度变化下的变形情况。

4.3 电子设备在电子设备中,热膨胀系数对于电子元件和半导体材料的可靠性和封装技术至关重要。

由于电子元件在运行过程中会产生热量,因此材料的热膨胀系数必须与其他组件相匹配,以避免因温度变化引起的应力和失效问题。

此外,在半导体制造过程中,了解材料的热膨胀系数可以帮助控制工艺参数,以确保产品质量和性能。