PFS矩形流量计

- 格式:pdf

- 大小:700.33 KB

- 文档页数:8

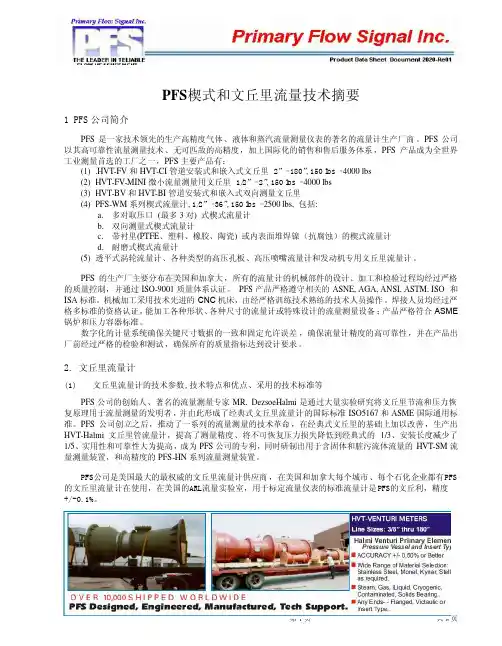

PFS楔式和文丘里流量技术摘要1 PFS公司简介PFS、液体和蒸汽流量测量仪表的著名的流量计生产厂商。

PFS公司、无可匹敌的高精度,加上国际化的销售和售后服务体系,PFS产品成为全世界,PFS:(1).HVT-FV和HVT-CI管道安装式和嵌入式文丘里2”– 180”, 150 lbs– 4000 lbs(2)HVT-FV-MINI微小流量测量用文丘里1/2”– 2”, 150 lbs– 4000 lbs(3)HVT-BV和HVT-BI管道安装式和嵌入式双向测量文丘里(4)PFS-WM系列楔式流量计, 1/2”– 36”, 150 lbs– 2500 lbs,包括:a.多对取压口(最多3对)式楔式流量计b.双向测量式楔式流量计c.带衬里(PTFE塑料、橡胶、陶瓷)(抗腐蚀)的楔式流量计d.耐磨式楔式流量计(5)、各种类型的高压孔板、高压喷嘴流量计和发动机专用文丘里流量计。

PFS,所有的流量计的机械部件、加工和检验过程均经过严格,并通过ISO-9001。

PFS产品严格遵守相关的ASNE, AGA, ANSI, ASTM, ISO和ISA。

机械加工采用技术先进的CNC,由经严格训练技术熟练的技术人员操作。

焊接人员均经过严,能加工各种形状、各种尺寸的流量计或特殊设计的流量测量设备;产品严格符合ASME。

,确保流量计精度的高可靠性,并在产品出,确保所有的质量指标达到设计要求。

2.文丘里流量计(1)文丘里流量计的技术参数,、采用的技术标准等PFS、著名的流量测量专家MR. DezsoeHalmi是通过大量实验研究将文丘里节流和压力恢,并由此形成了经典式文丘里流量计的国际标准ISO5167和ASME国际通用标。

PFS,推动了一系列的流量测量的技术革命,在经典式文丘里的基础上加以改善,生产出HVT-Halmi,提高了测量精度、将不可恢复压力损失降低到经典式的1/3安装长度减少了1/5实用性和可靠性大为提高,成为PFS,同时研制出用于含固体和脏污流体流量的HVT-SM流,和高精度的PFS-HN。

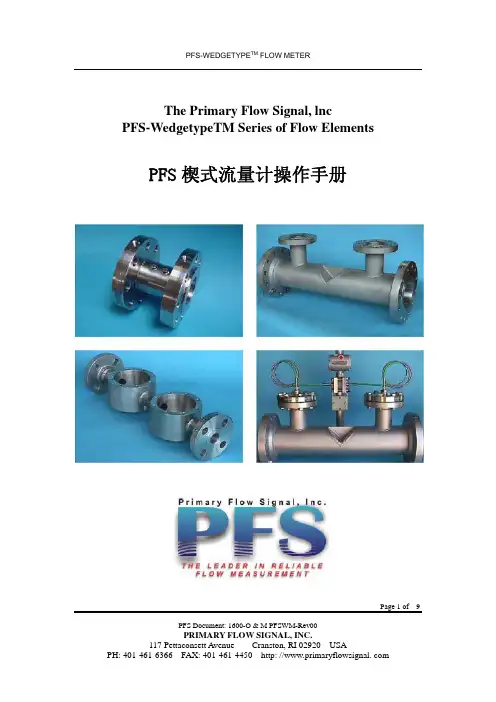

The Primary Flow Signal, lncPFS-WedgetypeTM Series of Flow Elements PFS楔式流量计操作手册Page 1 of 9 PFS Document: 1600-O & M PFSWM-Rev00PRIMARY FLOW SIGNAL, INC.A.安装概述Page 2 of 9PFS Document: 1600-O & M PFSWM-Rev00PRIMARY FLOW SIGNAL, INC.流量计水平安装,取压口方位距竖直中心线45°~90°角为 一般情况下的推荐安装方式(见图9)。

压的变化,进而影响变送器的测量精度。

注意以下几点:z 适当的给变送器放空z 调节变送器的零点来补偿由于引压管的高度差引起的液体压头差,避免其影响测量结果(这一影响在竖直安装PFS-Wedgetype 楔式流量计时非常明显)。

流量计前后直管段要求流量计的精度受上下游配管引起的流动状态干扰,消除这种干扰的标准做法是加上适当长度的上下游的直管段。

这种直管段的内径与截流元件出入口直径相一致。

注意: 当流量计用于高精度场合或者流体实验室流量系数标定时,采用加入适当型式的上下游直管段(也称为整流管)会得到对所测量流体在所需流量范围之内的最佳精度。

这种整流管为可选附件,额外收费。

表9:典型直管段要求上游干扰因素首选最小要求半开闸阀 10D 5D 10D 3D 同心扩径接头 10D 5D 5D 3D 同心缩颈接头 10D 5D 5D 3D 1个弯头 10D 5D 5D 3D 同平面2个弯头 10D 5D 5D 3D 异面2个弯头 10D5D10D3D表9给出了消除这些干扰因素影响的推荐直管段要求。

对特别复杂的安装条件,请与PFS 的代表联系以得到进一步的安装指导。

安装与连接为到达楔式流量计的最好测量性能,安装时请遵照以下方针:初步检查所有PFS公司的流量计装运时其螺纹,取压口连接面等部件均带有防护物。

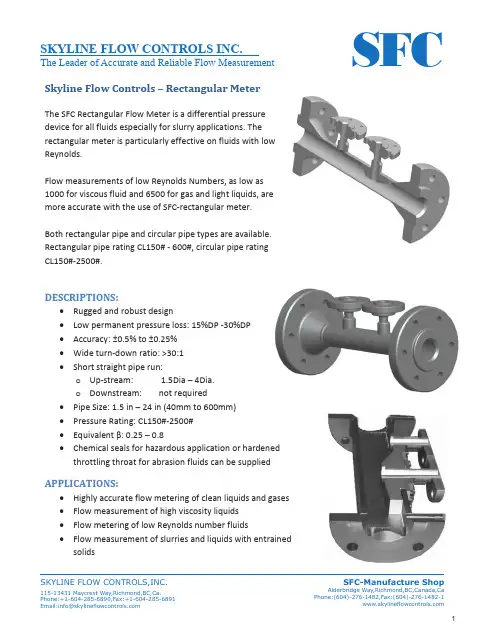

SKYLINE FLOW CONTROLS,INC.SFC-Manufacture Shop SFCSKYLINE FLOW CONTROLS INC. The Leader of Accurate and Reliable Flow MeasurementThe Leader of Accurate and Reliable Flow MeasurementSKYLINE FLOW CONTROLS, INC.SFC-ABCO SHOPPipe Size: 1.5 in – 24 in (40mm to 600mm) Chemical seals for hazardous application or hardened throttling throat for abrasion fluids can be suppliedHighly accurate flow metering of clean liquids and gasesSFCSKYLINE FLOW CONTROLS INC.The Leader of Accurate and Reliable Flow MeasurementSKYLINE FLOW CONTROLS,INC.SFC-Manufacture ShopSKYLINE FLOW CONTROLS, INC.SFC-ABCO SHOPADVANTAGES:•Proven flow metering technology•Rugged design - will withstand slurries and entrained solids •Flow measurement with No moving parts•Negligible wear and erosion therefore requires less maintenance and inspection •Low permanent pressure drop resulting in Energy savings •High accuracy and good repeatability TECHNICAL SPECIFICATIONS:The rectangular type flow meter is a differential device for use on all liquids and gases. It is generally applied to liquids with entrained air, liquids with entrained particulates, and liquids with high viscosity. The SFC rectangular meter is highly suitable for abrasive or fibrous slurry. Fluids with low Reynolds numbers can be addressed as well with a degree of accuracy where the discharge coefficient is stable through the application range. There are three models of rectangular meters: SFC-RRF, SFC-RCF, and SFC-RVF (see below table).ModelsDescriptionSizeRatingOperating TemperatureSFC-RRFUse square or rectangular pipe with specially designed rectangular flow constriction to accurately measure the flow rate.2” x 2” to 16” x 16” CL 150# to CL 600# -1800C to 8000C SFC-RCFUse circular pipe with specially designed rectangular flow constriction to accurately measure the flow rate.2” to 16” CL 150# to CL 2500# -1800C to 8000C SFC-RVFUse circular pipe with special cylindrical flow constriction with excellent measuring accuracy1.5” to 24”CL 150# to CL 2500#-1800C to 8000CSKYLINE FLOW CONTROLS,INC.SFC-Manufacture ShopSFCSKYLINE FLOW CONTROLS INC.The Leader of Accurate and Reliable Flow MeasurementRectangular Meters combines both the advantage of venturi and wedge meters with higher accuracy and reliability. The lower head loss characteristics is inherited from its venturi like design. Similar to the wedge meter, it has the ability to measure high viscous and particulate laden flows. SFC rectangular flow meter is a reliable metering method with high accuracy, low permanent head loss, and wide application range.When your application requirement dictates the use of rectangular type flow meters, SFC can provide expert technical assistance for a fully customized design.The operating principal of the SFC rectangular meter is analogous to that of other differential producing flow meters such as orifice plates or venturi meters. The pressure difference measured across a flow constriction, or in this case a sloping "rectangular restricting piece" is related to the velocity of the flow passing through the narrowest cross section.Pressure taps are located upstream from the rectangular constriction (rectangular throttling element) as well as on the throat of the rectangular piece. The constriction creates a pressure drop between the upstream tap and throat tap which is related to the velocity in the pipe line, and thus the volumetric flow rate can be obtained.The opening height of the rectangular throat can be customized according to the amount of differential pressure required to meet within specified pressure loss.SFCSKYLINE FLOW CONTROLS INC.The Leader of Accurate and Reliable Flow MeasurementSKYLINE FLOW CONTROLS,INC.SFC-Manufacture ShopLine Size INCHDimension LLDimension FDimension T Dimension L150 300 600 150 300 600 150 300 600 150 300 600 1.5 20.86 21.37 22.00 9.00 9.00 9.00 8.0 8.0 8.0 7.0 7.0 7.0 2.0 21.50 22.00 22.75 9.00 9.00 9.00 8.0 8.0 8.0 8.0 8.0 8.0 3.0 24.50 25.25 26.00 9.00 9.00 9.00 6.5 6.5 6.5 10.0 10.0 10.0 4.0 35.50 36.25 38.00 9.00 9.00 9.00 4.93 4.93 4.93 12.0 12.0 12.0 6.0 40.50 41.25 43.25 9.00 9.00 9.00 4.93 4.93 4.93 16.0 16.0 16.0 8.0 43.00 43.75 48.00 10.25 10.25 10.25 4.93 4.93 4.93 20.0 20.0 20.0 10.0 45.00 46.25 49.50 12.00 12.00 12.00 4.93 4.93 4.93 24.0 24.0 24.0 12.0 49.00 50.00 53.50 14.00 14.00 14.00 4.93 4.93 4.93 28.0 28.0 28.0 14.0 56.00 59.25 59.50 16.00 16.00 16.00 4.93 4.93 4.93 32.0 32.0 32.0 16.0 62.00 63.50 66.50 18.00 18.00 18.00 4.93 4.93 4.93 36.0 36.0 36.0 18.0 69.00 70.50 73.00 20.00 20.00 20.00 4.93 4.93 4.93 40.0 40.0 40.0 20.0 75.35 76.75 79.50 22.00 22.00 22.00 4.93 4.93 4.93 44.0 44.0 44.0 24.088.5089.7593.0026.0026.0026.004.934.934.9352.052.052.0Transmitter connection: 1/2”NPTF or 2” flangesPressure rating: CL 150# to CL 2500#Material: Stainless 316, 304, 321, 347, CS, Hastelloy C or Monel, other material are available on requestProcess connection: BW, Flanges 150lbs to 2500lbsSFC SKYLINE FLOW CONTROLS INC.The Leader of Accurate and Reliable Flow MeasurementInstallation: Rectangular meter is dependent on orientation and upstream pipe runIntegrated Mass Flow TransmitterSFC offers an Integrated Mass Flow Metering System. This fully integrated, highly accurate, wide flow ranged rectangular flow meter is a single unit that includes the flow primary, instrument manifold, and secondary instrumentation with pressure and temperature compensation.Directly mounted on the primary flow element is the Instrument manifold, the secondary instrumentation (DP Cell), and thermo-well with a temperature probe. It is fully assembled and calibrated to your application and installation requirements.This technology is useful in numerous applications such as, oil & gas, coal gas, LNG, methane, CO2 injection flow, etc.The rectangular meter is capable of accurate measurements in low Reynolds Numbers application (as low as 5000). It has a linear discharge coefficient throughout the entire flow range with standard accuracy of +/-0.50% and calibrated accuracy of +/-0.25% or better.Output: 4-20mA dc/HART, Loop poweredExplosion proof: EEx dIICT5, EEx iaIICT5InstallationsThe SFC rectangular meter does not require specific installation requirements as it is relatively forgiving and will operate properly under most conditions. Nevertheless, to achieve the best results, the recommended installation guidance below should be observed and incorporated.The adverse effects arising from improper installation can include plugged impulse lines or tap holes, entrapped air/gas in the taps or impulse lines, and introduction of a minor hydrostatic head effect (in a vertically orientated installation) or discharge coefficient shift.The horizontal orientation of the meter, is preferred and typical for most installations and operations. Straight pipe-run requirementLike most flow meters, straight or unrestricted pipe-run upstream and downstream of the flow element is preferred, and will produce better results and accuracy.SKYLINE FLOW CONTROLS,INC.SFC-Manufacture ShopSFCSKYLINE FLOW CONTROLS INC. The Leader of Accurate and Reliable Flow Measurement SKYLINE FLOW CONTROLS,INC.SFC-Manufacture Shop pipeline systems for petroleum, wastewater treatment,petrochemical, pharmaceutical, chemical, food and The Leader of Accurate and Reliable Flow MeasurementS1.405 1199 1251.320 1306 2131.308 673 -1171.380 956 -1371.404 492 -2331.401 730 -182(-) 800 161.133 617 2061.1538 667 1971.240 1142 3151.335 3206 705SKYLINE FLOW CONTROLS,INC.SFC-Manufacture Shop SFCSKYLINE FLOW CONTROLS INC. The Leader of Accurate and Reliable Flow MeasurementThe Leader of Accurate and Reliable Flow MeasurementSKYLINE FLOW CONTROLS, INC.SFC-ABCO SHOPSFCSKYLINE FLOW CONTROLS INC. The Leader of Accurate and Reliable Flow MeasurementSKYLINE FLOW CONTROLS,INC.SFC-Manufacture ShopThe Leader of Accurate and Reliable Flow MeasurementSPipe Size: 1.5 in – 24 in (40mm to 600mm) The Leader of Accurate and Reliable Flow Measurement 115 -13431 Maycrest Way , Richmond , BC V6X 2A4, Ca. Alderbridge Way, Richmond, BC, Canada, V6X 2A4Phone: (604)-276-1482, Fax: (604)-276-1482-1A515-65A516,65,70A350-LF2A352-LCB A352-LC2A203-D A350-LF3A352-LC 3A353A522A352-LC8A204-B A182-F1A217WC1A387-12A182-F12--A387-11A182-F11A217WC6A387-22A182-F22A217WC9A387-5A182-F5A217WC5--A182-F7----A182-F9A217WC12A182-F91A217WC12AA182-F92A240-Type304A182-F304A351CF8A240-Type304H A182-F304HA240-Type304L A182-F304L A351CF3A240-Type309S ----A240-Type310S A182-F310A351CK20A240-Type316A 182-F316A351CF8MA240-Type316H182-F316H--A240-Type316L A182-F316L A351CF3M A240-Type321A182-F321A351CF10A240-Type321H A182-F321H --。

Georg Fischer的Signet 2552金属电磁流量计采用全不锈钢结构。

PVDF末端和FKM O形圈是唯一的其他接液材料。

2552可快速安装到标准的1¼英寸或1½英寸管道出口中,并可调节以适合DN50至DN2550(2至102英寸)的管道。

两种传感器长度提供了最大的灵活性,以适应各种硬件配置,包括用于hot-tap安装的球阀。

当配备为频率输出时,2552可与任何Signet流量仪表兼容,而S³L数字输出则可与Signet 8900多参数流量控制器实现多通道兼容。

选择盲4-20mA电流输出,可直接与数据采集器,PLC或遥测系统连接。

主要功能包括空管检测,LED辅助故障排除和双向量程(4-20mA型号)。

Signet 3-0252配置工具可用于自定义2552中的每个功能,因此可以根据用户的应用要求进行调整。

*3-2552.090*3-2552.090 Rev. 8 10/19Signet 2552 电磁流量计中文操作说明书目录3-2552-33-2552-2质保信息 .................................................................................................................2产品注册 .................................................................................................................2安全信息 .................................................................................................................2环境建议 .................................................................................................................2产品规格 ............................................................................................................2-3尺寸 .........................................................................................................................4概况 .........................................................................................................................4位置选择 .................................................................................................................4安装的一般要求 ....................................................................................................4安装于竖直管道 ....................................................................................................5安装于水平管道 ....................................................................................................5传感器调节 .............................................................................................................5接地 .........................................................................................................................5安装准备 .................................................................................................................6H-尺寸 ....................................................................................................................6安装电磁流量计 ...............................................................................................7-8频率输出接线 .........................................................................................................9数字(S³L)输出接线 ...................................................................................9-104-20mA回路输出接线 ......................................................................................10校准数据 .......................................................................................................11-12技术支持 ..............................................................................................................13故障排除 ..............................................................................................................14维护 ......................................................................................................................14选择传感器 ..........................................................................................................15订货信息 .. (16)2Signet 2552 电磁流量计该设备符合FCC规则的第15部分。

![矩形截面管均速管流量计[实用新型专利]](https://uimg.taocdn.com/6f4235ea0740be1e640e9a2e.webp)

专利名称:矩形截面管均速管流量计专利类型:实用新型专利

发明人:吴国纷,王关松

申请号:CN90207365.6

申请日:19900623

公开号:CN2076668U

公开日:

19910508

专利内容由知识产权出版社提供

摘要:本实用新型涉及一种用于矩形截面管道流量测 量的均速管流量计。

根据矩形截面管道内流速分布 的特点,它采用了特殊的总压孔布置方案。

通过检测 杆的不同组合方式,它可以适用于各种截面形状和尺 寸的矩形管道。

它具有结构简单、造价低廉、装卸维 修方便、操作容易、精度高,复现性好以及使用寿命长 等特点,因而适用范围很广,它不仅能在低压、高温等 条件下工作,且特别适用于废气、烟气、空气等介质的 测量,本实用新型可在环保、冶金、化工、采矿、电站、 高层建筑等领域内广泛应用。

申请人:上海机械学院

地址:200093 上海市军工路516号

国籍:CN

代理机构:机械电子工业部上海专利事务所

更多信息请下载全文后查看。

SFC矩形流量计样本中文1.测量原理SFC矩形流量计采用了迈阿密大学教授John Stock在1976年提出的原理,也称为浦沅定理。

根据浦沅定理,流体通过矩形截面的速度与流量呈正比关系。

因此,通过测量流体通过矩形截面的速度,可以计算出流量。

2.结构与特点-测量范围广:SFC矩形流量计可以用于测量液体和气体的流量,适用于各种工业领域。

-精度高:由于浦沅定理的准确性,SFC矩形流量计具有较高的测量精度。

-构造简单:SFC矩形流量计结构简单,易于安装和维护。

-耐腐蚀性好:SFC矩形流量计通常采用不锈钢等耐腐蚀材料制造,具有良好的耐腐蚀性能。

3.工作原理-流体进入矩形截面后,通过压力差传感器测量进口和出口之间的压力差。

-压力差与流体通过矩形截面的速度成正比,根据浦沅定理计算流量。

-测量结果通过显示屏或输出信号显示给操作人员或其他设备。

4.应用领域-石油化工:石油、化工等流体的流量测量。

-食品饮料:食品、饮料等液体的流量测量。

-环保监测:废水、废气等的流量测量。

-能源领域:天然气、煤气等气体的流量测量。

5.型号与规格-测量范围:根据具体应用需求,测量范围可以选择不同的范围。

-精度等级:精度等级通常为0.5级或1.0级,根据不同应用场景选择。

-压力等级:根据实际压力条件,选择适当的压力等级。

-材料:可选不锈钢、铜、铝等材质,根据流体特性选择。

总结:SFC矩形流量计是一种用于测量液体和气体流量的仪器,采用浦沅定理进行测量。

它具有广泛的应用范围、高精度的测量结果、结构简单易于维护和良好的耐腐蚀性能等特点。

在不同的工业领域中,SFC矩形流量计都发挥着重要的作用,为生产运作提供准确的流量数据。

【楔形流量计】楔形流量计四个常见问题1.楔形流量计的测量原理楔形流量计是一种新型流量计,其检测件是一个v字形楔块(又称楔形节流件),它的圆滑顶角朝下,这样有利于含悬浮颗粒的液体或粘稠液体顺当通过,不会在节流件上游侧产生滞流。

因此特别适合在石油、化工等行业中用于体积流量和质量流量的测量。

楔形流量计的测量原理:流体通过楔形流量计时,由于楔块的节流作用,在其上、下游侧产生了一个与流量值成平方关系的差压,将此差压从楔块两侧取压口引出,送至差压变送器变化为电信号输出,再经经专用智能流量计算仪运算后,即可获知流量值。

美国的pfs楔形流量计的。

是目前国内使用的测量精度可以的一种,由于它的楔高比是依据固定测量范围、固定量程压差、变楔比(实际是变流量、变流动状态)的计算方法,该方法是基于大量的流量试验,对不同的流动状态拟合修正而进展起来的,其原理与孔板节流元件的计算是仿佛的,计算精度在整个量程范围内都比较高,并可以保证最大/最小流量测量比为10比1、在不标定的情况下可以达到1.0~2.0%,标定精度达到0.5%。

固定楔比的楔形流量计是实行内插法貌似计算,误差比较大。

在某个固定点上可以达到所说的精度,流量偏离该点后,就会产生很大的误差。

2.楔形流量计的优点是怎样的呢?楔形流量计的优点是怎样的呢?楔式流量计水平管道测液体,取压口zui佳位置0°—180°,差压变送器垂直安装在三阀组的垂直端面上。

水平管道测量气体时,取压口zui佳位置270°,变压变送器水平安装在三阀组顶水平面上。

垂直管道测液体,差压变送器安装在垂直管道低端取压口一侧,且垂直安装在低于取压口的三阀组板垂直端面。

流体必需自下而上垂直管道测气体,差压变送器安装在垂直管道取压口一侧,且水平安装在高于取压口的三阀组板水平面上。

对流体流向没有要求。

原则:气体测量中导压管路、三阀组管路和差压变送器正负压侧容室不能有液体液体。

液体测量中,导压管路、三阀组管路和差压变送器正负压侧容室不能有气体积存。

楔形流量计结构和原理流量计是一种用于测量流体流量的仪器。

在工业生产中,流量计广泛应用于石油、化工、食品、医药等领域。

楔形流量计是一种常见的流量计,具有结构简单、使用方便、精度高等特点,被广泛应用于各种流量测量场合。

一、楔形流量计的结构楔形流量计主要由测量管、楔形件、传感器、显示部分等组成。

测量管是流量计的主体部分,用来引导流体流动。

楔形件是流量计的核心部件,其结构如图1所示:图1 楔形流量计楔形件结构示意图楔形件主要由楔形板和楔形角度组成。

楔形板与测量管内壁呈一定的角度,使流体流过楔形板时发生偏转,形成压力差,压力差与流量成正比。

楔形角度是指楔形板与水流方向的夹角,通常为20度或30度。

传感器是用来检测楔形件所产生的压力差的。

传感器一般采用压电传感器或电阻式传感器。

压电传感器的原理是当压力作用于传感器上时,会产生电荷,产生的电荷与压力成正比。

电阻式传感器的原理是当压力作用于传感器上时,传感器内部的电阻值发生变化,变化的电阻值与压力成正比。

显示部分是用来显示流量大小的。

显示部分一般采用数字式显示器或指针式指示器。

数字式显示器可以直接显示流量大小,精度高,易于读取;指针式指示器则需要进行校准,精度相对较低。

二、楔形流量计的工作原理楔形流量计的工作原理是利用楔形板与水流的相互作用,测量流体的流量。

当流体流过楔形板时,会发生偏转,形成压力差。

压力差与流量成正比,通过传感器检测压力差,再经过计算,即可得到流量大小。

楔形流量计的流量计算公式如下:Q=k×C×A×(2gΔP)1/2其中,Q为流量,k为流量系数,C为修正系数,A为测量截面积,ΔP为楔形件两侧的压力差,g为重力加速度。

流量系数k是楔形流量计的重要参数,它与楔形角度、楔形板的长度和宽度、流体的密度和粘度等因素有关。

修正系数C是用来修正流体在管道中流动时的影响因素的,如流体的雷诺数、流体的黏度、管道的壁面粗糙度等。

三、楔形流量计的优缺点楔形流量计具有以下优点:1. 结构简单,操作方便,易于维护。

利用micro-PIV测量矩形微管道内流量

张永胜;王金华

【期刊名称】《实验流体力学》

【年(卷),期】2011(025)002

【摘要】利用微观粒子图像测速技术(micro-PIV)测量了矩形微管道内低雷诺数下速度矢量场,并以此为基础计算微管道内流体体积流量.微管道水力直径为83μm,横截面深宽比为0.155,长度为17mm.实验中获得雷诺数分别为47、127和215三工况下管道中心水平截面内速度分布.与理论速度剖面比较,管道中心的测量速度值吻合很好,偏差控制在±2%以内.利用中心速度值结合层流解析解计算微管道内平均流速和体积流量.经过误差分析得到该方法测量误差约为3.3%.实验结果表明,利用micro-PIV技术完全可以实现微通道流量的高精度测量.

【总页数】4页(P92-95)

【作者】张永胜;王金华

【作者单位】北京长城计量测试技术研究所,北京100095;北京长城计量测试技术研究所,北京100095

【正文语种】中文

【中图分类】O353.5

【相关文献】

1.利用Micro-PIV测量微管道内流量的研究 [J], 张永胜;刘彦军;王金华

2.利用Micro-PIV进行微管道内流量测量 [J], 张永胜;刘彦军;王金华

3.矩形微管道内流量测量 [J], 张永胜;王金华;刘彦军

4.矩形微管道内电势分布的数值模拟 [J], 张鹏;左春柽;周德义

5.激光自混合测量矩形管道流速分布及流量 [J], 鲁岸立;刘建国;桂华侨;孙悟;程寅;余同柱

因版权原因,仅展示原文概要,查看原文内容请购买。

匀速管流量计原理The principle of a constant velocity tube flowmeter is a key concept in the field of fluid mechanics. It is crucial in accurately measuring the flow rate of various fluids in industries such as oil and gas, chemical processing, and water treatment.匀速管流量计的原理是流体力学领域的关键概念。

在石油和天然气、化工加工和水处理等行业,精确测量各种流体的流量至关重要。

This type of flowmeter operates based on the principle of a constriction in the flow path causing the fluid velocity to increase, which is then measured to determine the flow rate.这种流量计基于流道中的收缩原理运行,收缩会导致流体速度增加,然后通过测量速度来确定流量。

The constant velocity tube flowmeter consists of a pipe with a uniform diameter that contains a constriction, such as a sharp-edged orifice or a venturi tube, which causes the fluid velocity to increase at the point of constriction.匀速管流量计由一个直径均匀的管道组成,其中包含一个收缩部分,比如一个带有锐利边缘的节流装置或一个文丘里管,这会导致流体在收缩点的速度增加。

H-15U V irtually No Pressure LossU No Moving PartsU A NSI 150# Flanges or Tri-Clover Sanitary MountU RS485 StandardU S uitable for Pipes Up to 305 mm (12")U High AccuracyU 4 to 20 mA and Frequency Outputs StandardU N IST 3-Point Calibration Included SPECIFICATIONS Flange Sizes: 150# ANSI: 19 to 305 mm (³⁄₄ to 12") Sanitary Tri-Clamp: 13 to 305 mm (¹⁄₂ to 12")Maximum Pressure: 145 psi Minimum Conductivity: 20 µS Electrode Material: Hastelloy C4 (standard), tantalum (TGE optional)Environmental Temperature: -5 to 55°C (23 to 131°F)Sensor Lining: PTFE Electronics Housing: Local or remote (optional)ElEctRomagnEtic FlowmEtERFMG600 SeriesLiquid Temperature: 0 to 50°C (32 to 122°F) STD, 0 to 150°C (32 to 302°F) with remote electronics Empty Pipe Alarm: Available on 2" and larger sizes (-EPD option)Accuracy: ±0.5% from 5 to 100% Qs, ±1% from 1 to 5% Qs Range: 0.1 to 10 m/s (0.328 to 32.81 fps)Outputs: Adjustable from 0.1 to 1000 gallons/pulse Current: 4 to 20 mA with galvanic isolation Frequency: 0 to 1000 Hz with galvanic isolation Communications: RS485Power: 24 Vdc, 115/230 Vac switchable (optional)Consumption: 15 VA Protection: IP67Storage Temperature and Humidity: -10 to 70°C (14 to 158°F) at maximum;relative humidity 70%FMG606, 51 mm (2") meter with 150# flanges shownsmaller than actual size.The FMG600 Series electromagnetic flowmeters are designed for measurement of conductive liquids. With no moving parts and a PTFE lining, they can handle applications involving wastewater, pulp, food, and slurries. Standard outputs include analog, frequency, and RS485 communications. Optional sanitary tri-clamp mounting allows use of the FMG600 flowmeters in applications not previously open to magmeters. Local- and remote- display models are available.H-16HA Nominal size D d Flanged Sensor DimensionsWeights of the sensors are approximate.FMG605 shownsmaller than actual size.FMG601-S shown smaller than actual size.HFor units with switchable 115/230 Vac power, add “-VAC” to the model number and consult sales for cost.For empty pipe detection on units 2” and larger, add “-EPD” to the model number, for additional cost.For units with a batching option, add “-B” to the model number, for additional cost.For units with tantalum electrodes, add “-TE” to the model number, for additional cost.If a third tantalum grounding electrode is needed, add “-TGE” to the model number, for additional cost.If a third hastelloy grounding electrode is needed, add “-HGE” to the model number, for additional cost.For a 4-point NIST calibration, add “-NIST4” to the model number, for additional cost.For a 10-point NIST calibration, add “-NIST10” to the model number, for additional cost.Comes complete with operator’s manual and 3-point NIST calibration certificate.Ordering Examples: FMG606-R-EPD, 2", 150# flange mount magmeter with remote electronics and empty pipe detection.FMG605-NIST4, 150# flange mount magmeter with optional 4-point NIST calibration.H-17。