ASTME505中文版

- 格式:docx

- 大小:7.51 KB

- 文档页数:1

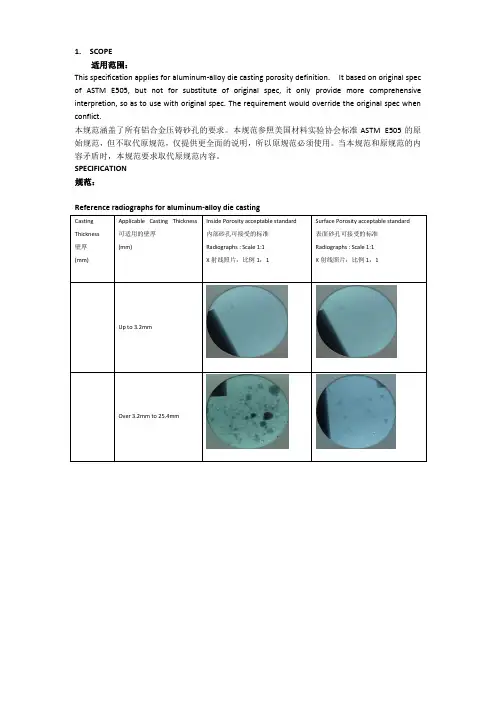

1.SCOPE适用范围:This specification applies for aluminum-alloy die casting porosity definition. It based on original spec of ASTM E505, but not for substitute of original spec, it only provide more comprehensive interpretion, so as to use with original spec. The requirement would override the original spec when conflict.本规范涵盖了所有铝合金压铸砂孔的要求。

本规范参照美国材料实验协会标准ASTM E505的原始规范,但不取代原规范,仅提供更全面的说明,所以原规范必须使用。

当本规范和原规范的内容矛盾时,本规范要求取代原规范内容。

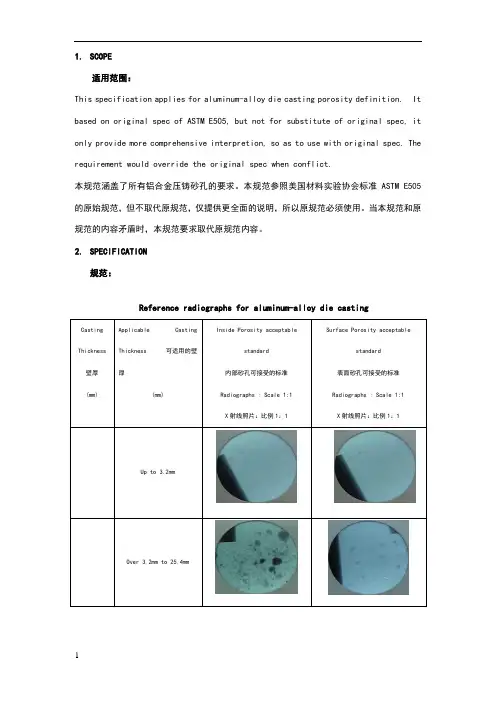

2.SPECIFICATION规范:Reference radiographs for aluminum-alloy die castingCasting Thickness壁厚(mm)Applicable CastingThickness 可适用的壁厚(mm)Inside Porosity acceptablestandard内部砂孔可接受的标准Radiographs : Scale 1:1X射线照片:比例1:1Surface Porosity acceptablestandard表面砂孔可接受的标准Radiographs : Scale 1:1X射线照片:比例1:1 Up to 3.2mmOver 3.2mm to 25.4mm3.POROSITY LEVELLevel 11级Radiographs : Scale 1:1 X射线照片:比例1:1Level 22级Radiographs : Scale 1:1X射线照片:比例1:1Level 33级Radiographs : Scale 1:1X射线照片:比例1:1Level 44级Radiographs : Scale 1:1X射线照片:比例1:1~0.70mm 3个/10cm2 ~1. 0mm 1个/10cm2~1.0mm 5个/10cm2~1.5mm 1个/10cm2~1.5mm 10个/10cm2~4.0mm 1个/10cm2~4.0mm 15个/10cm2~10mm 1个/10cm24.REMARK备注:Unless special explanation, void with size of ≦0.5mm will not be considered as porosity, and this apply to inside and on the surface porosity of aluminum-alloy die casting!如果没有特别说明,0.50mm及以下的气孔不作为砂孔的评估控制范围内,此要求适用于铝合金压铸件的内部和加工表面!5.REFERENCE参考文献:ASTM E505 Reference radiographs for Inspection of Aluminum and MagnesiumDie Castings铝合金及镁合金压铸件X射线检查规范ASTM B85 Standard Specification for aluminum-alloy die castings压铸铝合金的标准规范GB/T 13822-92 Test specimens for non ferrous die casting alloys压铸有色合金的检测试样。

气孔标准

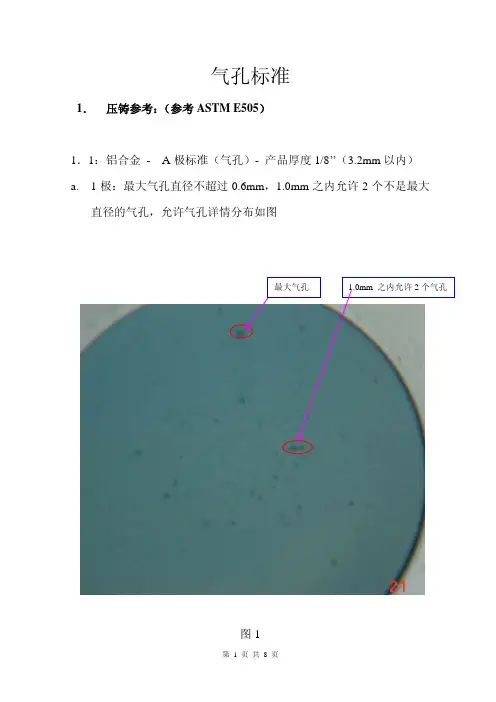

1. 压铸参考:(参考ASTM E505)

1.1:铝合金 - A 极标准(气孔)- 产品厚度1/8’’(3.2mm 以内) a. 1极:最大气孔直径不超过0.6mm ,1.0mm 之内允许2个不是最大

直径的气孔,允许气孔详情分布如图

图

1

直径的气孔,2.0之内允许3个不是最大气孔,允许气孔详情分布如图2:

图2

直径的气孔,气孔可以较密集,但气孔须较小,允许气孔分布详情如图3

d.4极,最大气孔外径为2.5×5,不允许这样的大气孔连续出现。

气孔

密集,最大气孔周围允许小气孔。

如图4

1.2:铝合金 - A 极标准(气孔)- 产品厚度5/8’’(15.9mm 以内) a. 1极:最大气孔直径不超过1.0mm ,3.5mm 之内允许2个不是最大直径的气孔,气孔不能连续分布,详情分布如图5

图5

径的气孔,气孔不能连续分布,详情分布如图6

图6

的气孔,气孔不能连续分布,详情分布如图7

图7

径的气孔,气孔不能连续分布,详情分布如图8

图8。

PURPOSE目的The purpose of this material standard is to provide a comprehensive hot forged steel specification that will allow a cost-effective end product to be produced. Any supplier suggestions to improve product cost will always be evaluated. This standard is intended to supplement any and all requirements currently specified on the applicable engineering detail drawing. All references to steel and properties apply to the finished forged product unless otherwise noted.这种材料标准的目的是提供一种全面的热锻造钢的规范,将允许生产具有成本效益的最终产品。

供应商提出的,以提高产品的性价比的任何建议会一直进行评估。

该标准旨在补充任何及所有要求,目前适用的工程详图规定。

除非另有说明,钢和属性的所有引用适用于锻造品。

RESPONSIBILITY责任The Director of Engineering is responsible to assure that this specification accurately reflects the up-to-date material standard. The Director of Purchasing is responsible to assure that the appropriate specification is forwarded to the vendor concerned. Plant managers are responsible to assure that the specification is followed at the local level.工程总监负责确保本规范准确地反映最新的材料标准。

ASTME155铝镁铸件检验⽤标准参考射线底⽚图谱使⽤和定量ASTM E155是什么?1.本参考射线底⽚⽤于说明可能在铝合⾦铸件和镁合⾦铸件中存在缺陷的类型和程度。

图谱中所⽰的铸件厚度为1.4英⼨(约6.35mm)和3.4英⼨(约19.1mm)。

参考底⽚仅作为本⽂件中的辅助⽂件,需单独从ASTM购买。

2.参考底⽚不适⽤于数字成像时在铝合⾦铸件和镁合⾦铸件中出现的不连续类型和严重程度。

(注:铝合⾦铸件数字成像时参考ASTM E2422,镁合⾦铸件数字成像时参考ASTM E2869)3.对于其它材料厚度,在没其他的适⽤⽂件存在时,采购商和制造商之间达成协议,则可使⽤本⽂件4.X射线底⽚在制作的过程中可能有轻微的变化,变化可能包括底⽚或者使⽤化学药品处理的变化、模具或印刷或纸板的变化。

但⽆需过分担⼼底⽚图谱的品质,图谱监制⼩组都参考了原版的固定模型进⾏整理满⾜验收要求。

5.以英⼨作为标准单位,括号内为转换单位。

本标准的主旨不是⽤来阐述所有的安全相关点,如果⽤,只是与其使⽤相关联。

建⽴合适的安全和健康规则并在使⽤前确定规则的适⽤性,这些是本标准使⽤者需要承担的责任。

共两卷卷,信息如下:卷1:该套射线照⽚包含了13张覆盖了铝合⾦铸件中的缺陷中的照⽚和10张覆盖了镁合⾦铸件的缺陷中的照⽚。

每张照⽚都固定于85英⼨宽11英⼨长(216imm宽279mm长)的纸板框架中,并且每张照⽚图解说明在约2英⼨宽2英⼨长(51lmmm宽51mm长),⾯积内的缺陷的8个严重级别。

这些纸框含在10.5英⼨宽11.5英⼨长的套具内。

卷2:该套射线参考底⽚包含4张覆盖了镁合⾦铸件中缺陷的照⽚,每张照⽚都置于8.5英⼨宽11.5英⼨长(216mm宽279mm长)的纸板框架中,且每张照⽚的图解说明缺陷的8个严重级别(除了离散缺陷以外,这⾥对每种缺陷只给出了以⼀种例⼦)。

参考射线照⽚E505包含了适⽤厚度在1英⼨(25mm)以下的铝压铸件和铁铸件的参考射线照⽚。

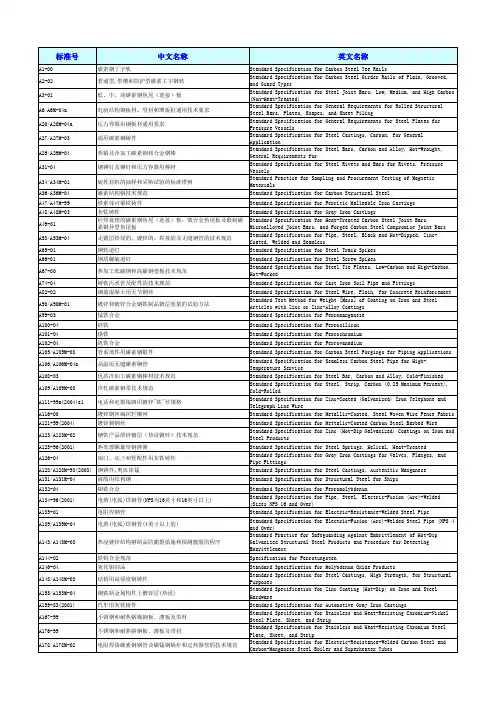

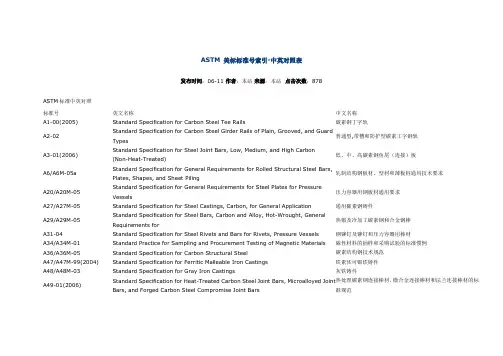

ASTM 美标标准号索引-中英对照表发布时间:06-11 作者:本站来源:本站点击次数:878ASTM标准中英对照标准号英文名称中文名称A1-00(2005) Standard Specification for Carbon Steel Tee Rails 碳素钢丁字轨A2-02 Standard Specification for Carbon Steel Girder Rails of Plain, Grooved, and GuardTypes普通型,带槽和防护型碳素工字钢轨A3-01(2006) Standard Specification for Steel Joint Bars, Low, Medium, and High Carbon(Non-Heat-Treated)低、中、高碳素钢鱼尾(连接)板A6/A6M-05a Standard Specification for General Requirements for Rolled Structural Steel Bars,Plates, Shapes, and Sheet Piling轧制结构钢板材、型材和薄板桩通用技术要求A20/A20M-05 Standard Specification for General Requirements for Steel Plates for PressureVessels压力容器用钢板材通用要求A27/A27M-05 Standard Specification for Steel Castings, Carbon, for General Application 通用碳素钢铸件A29/A29M-05 Standard Specification for Steel Bars, Carbon and Alloy, Hot-Wrought, GeneralRequirements for热锻及冷加工碳素钢和合金钢棒A31-04 Standard Specification for Steel Rivets and Bars for Rivets, Pressure Vessels 钢铆钉及铆钉和压力容器用棒材A34/A34M-01 Standard Practice for Sampling and Procurement Testing of Magnetic Materials 磁性材料的抽样和采购试验的标准惯例A36/A36M-05 Standard Specification for Carbon Structural Steel 碳素结构钢技术规范A47/A47M-99(2004) Standard Specification for Ferritic Malleable Iron Castings 铁素体可锻铁铸件A48/A48M-03 Standard Specification for Gray Iron Castings 灰铁铸件A49-01(2006) Standard Specification for Heat-Treated Carbon Steel Joint Bars, Microalloyed JointBars, and Forged Carbon Steel Compromise Joint Bars热处理碳素钢连接棒材,微合金连接棒材和法兰连接棒材的标准规范A53/A53M-06 Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Weldedand Seamless无镀层热浸的、镀锌的、焊接的及无缝钢管的技术规范A65-01 Standard Specification for Steel Track Spikes 钢轨道钉A66-01 Standard Specification for Steel Screw Spikes 钢质螺旋道钉A67-00(2005) Standard Specification for Steel Tie Plates, Low-Carbon and High-CarbonHot-Worked热加工低碳钢和高碳钢垫板技术规范A74-06 Standard Specification for Cast Iron Soil Pipe and Fittings 铸铁污水管及配件的技术规范A82/A82M-05a Standard Specification for Steel Wire, Plain, for Concrete Reinforcement 钢筋混凝土用无节钢丝A90/A90M-01 Standard Test Method for Weight [Mass] of Coating on Iron and Steel Articles withZinc or Zinc-Alloy Coatings镀锌和镀锌合金钢铁制品镀层重量的试验方法A99-03 Standard Specification for Ferromanganese 锰铁合金A100-04 Standard Specification for Ferrosilicon 硅铁A101-04 Standard Specification for Ferrochromium 铬铁A102-04 Standard Specification for Ferrovanadium 钒铁合金A105/A105M-05 Standard Specification for Carbon Steel Forgings for Piping Applications 管系部件用碳素钢锻件A106/A106M-06 Standard Specification for Seamless Carbon Steel Pipe for High-TemperatureService高温用无缝碳素钢管A108-03e1 Standard Specification for Steel Bar, Carbon and Alloy, Cold-Finished 优质冷加工碳素钢棒材技术规范A109/A109M-03 Standard Specification for Steel, Strip, Carbon (0.25 Maximum Percent),Cold-Rolled冷轧碳素钢带技术规范A111-99a(2004)e1 Standard Specification for Zinc-Coated (Galvanized) Iron Telephone and TelegraphLine Wire电话和电报线路用镀锌"铁"丝规格A116-05 Standard Specification for Metallic-Coated, Steel Woven Wire Fence Fabric 镀锌钢丝编织栏栅网A121-99(2004) Standard Specification for Metallic-Coated Carbon Steel Barbed Wire 镀锌刺钢丝A123/A123M-02 Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and SteelProducts钢铁产品的锌镀层(热浸镀锌)技术规范A125-96(2001) Standard Specification for Steel Springs, Helical, Heat-Treated 热处理螺旋形钢弹簧A126-04 Standard Specification for Gray Iron Castings for Valves, Flanges, and Pipe Fittings 阀门、法兰和管配件用灰铁铸件A128/A128M-93(2003) Standard Specification for Steel Castings, Austenitic Manganese 钢铸件,奥氏体锰A131/A131M-04ae1 Standard Specification for Structural Steel for Ships 海船用结构钢A132-04 Standard Specification for Ferromolybdenum 钼铁合金A134-96(2005) Standard Specification for Pipe, Steel, Electric-Fusion (Arc)-Welded (Sizes NPS 16and Over)电熔(电弧)焊钢管(NPS为16英寸和16英寸以上)A135/A135M-06 Standard Specification for Electric-Resistance-Welded Steel Pipe 电阻焊钢管A139/A139M-04 Standard Specification for Electric-Fusion (Arc)-Welded Steel Pipe (NPS 4 and Over) 电熔(电弧)焊钢管(4英寸以上的)A143/A143M-03 Standard Practice for Safeguarding Against Embrittlement of Hot-Dip GalvanizedStructural Steel Products and Procedure for Detecting Embrittlement热浸镀锌结构钢制品防脆裂措施和探测脆裂的程序A144-04 Specification for Ferrotungsten 铁钨合金规范A146-04 Standard Specification for Molybdenum Oxide Products 氧化钼制品A148/A148M-05 Standard Specification for Steel Castings, High Strength, for Structural Purposes 结构用高强度钢铸件A153/A153M-05 Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware 钢铁制金属构件上镀锌层(热浸) A159-83(2001) Standard Specification for Automotive Gray Iron Castings 汽车用灰铁铸件A167-99(2004) Standard Specification for Stainless and Heat-Resisting Chromium-Nickel SteelPlate, Sheet, and Strip不锈钢和耐热铬镍钢板、薄板及带材A176-99(2004) Standard Specification for Stainless and Heat-Resisting Chromium Steel Plate,Sheet, and Strip不锈钢和耐热铬钢板、薄板及带材A178/A178M-02 Standard Specification for Electric-Resistance-Welded Carbon Steel andCarbon-Manganese Steel Boiler and Superheater Tubes电阻焊接碳素钢钢管及碳锰钢锅炉和过热器管的技术规范A179/A179M-90a(2005) Standard Specification for Seamless Cold-Drawn Low-Carbon Steel Heat-Exchangerand Condenser Tubes热交换器和冷凝器用无缝冷拉低碳钢管A181/A181M-01 Standard Specification for Carbon Steel Forgings, for General-Purpose Piping 普通锻制碳素钢管的规格A182/A182M-05a Standard Specification for Forged or Rolled Alloy-Steel Pipe Flanges, ForgedFittings, and Valves and Parts for High-Temperature Service高温设备用锻制或轧制的合金钢管法兰、锻制管件、阀门及零件A183-03 Standard Specification for Carbon Steel Track Bolts and Nuts 钢轨用碳素钢螺栓和螺母A184/A184M-06 Standard Specification for Fabricated Deformed Steel Bar Mats for ConcreteReinforcement混凝土加筋用变形钢筋编织网A185/A185M-06e1 Standard Specification for Steel Welded Wire Reinforcement, Plain, for Concrete 钢筋混凝土用焊接钢丝结构A192/A192M-02 Standard Specification for Seamless Carbon Steel Boiler Tubes for High-PressureService高压用无缝碳素钢锅炉管A193/A193M-06a Standard Specification for Alloy-Steel and Stainless Steel Bolting Materials for HighTemperature or High Pressure Service and Other Special Purpose Applications高温或高压设备和其他特殊用途用合金钢和不锈钢螺栓材料A194/A194M-06a Standard Specification for Carbon and Alloy Steel Nuts for Bolts for High Pressure orHigh Temperature Service, or Both高温和高压设备用碳素钢与合金钢螺栓和螺母的规格A197/A197M-00(2006) Standard Specification for Cupola Malleable Iron 化铁炉用可锻铸铁A203/A203M-97(2003) Standard Specification for Pressure Vessel Plates, Alloy Steel, Nickel 压力容器用镍合金钢板A204/A204M-03 Standard Specification for Pressure Vessel Plates, Alloy Steel, Molybdenum 压力容器用钼合金钢板A209/A209M-03 Standard Specification for Seamless Carbon-Molybdenum Alloy-Steel Boiler andSuperheater Tubes锅炉和过热器用无缝碳钼合金钢管A210/A210M-02 Standard Specification for Seamless Medium-Carbon Steel Boiler and SuperheaterTubes锅炉和过热器用无缝碳钼合金钢管A213/A213M-06ae1 Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler,Superheater, and Heat-Exchanger Tubes无缝铁素体和奥氏体合金钢锅炉、过热器和换热器管A214/A214M-96(2005) Standard Specification for Electric-Resistance-Welded Carbon SteelHeat-Exchanger and Condenser Tubes热交换器与冷凝器用电阻焊接碳素钢管A216/A216M-04 Standard Specification for Steel Castings, Carbon, Suitable for Fusion Welding, forHigh-Temperature Service高温下使用的适合于熔焊的碳素钢铸件规格A217/A217M-04 Standard Specification for Steel Castings, Martensitic Stainless and Alloy, for 适合高温受压零件用合金钢和马氏体不锈钢铸件Pressure-Containing Parts, Suitable for High-Temperature ServiceA220/A220M-99(2004) Standard Specification for Pearlitic Malleable Iron 珠光体可锻铁A225/A225M-03 Standard Specification for Pressure Vessel Plates, Alloy Steel,Manganese-Vanadium-Nickel压力容器用锰矾镍合金钢板A227/A227M-06 Standard Specification for Steel Wire, Cold-Drawn for Mechanical Springs 机械弹簧用冷拉钢丝A228/A228M-02 Standard Specification for Steel Wire, Music Spring Quality 乐器用优质弹簧钢丝A229/A229M-99(2005) Standard Specification for Steel Wire, Oil-Tempered for Mechanical Springs 机械弹簧用油回火的钢丝A230/A230M-05 Standard Specification for Steel Wire, Oil-Tempered Carbon Valve Spring Quality 阀门用油回火优质碳素钢弹簧丝A231/A231M-04 Standard Specification for Chromium-Vanadium Alloy Steel Spring Wire 铬钒合金钢弹簧丝A232/A232M-05 Standard Specification for Chromium-Vanadium Alloy Steel Valve Spring QualityWire阀门用优质铬钒合金钢弹簧丝A234/A234M-06 Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steelfor Moderate and High Temperature Service中温与高温下使用的锻制碳素钢及合金钢管配件A239-95(2004) Standard Practice for Locating the Thinnest Spot in a Zinc (Galvanized) Coating onIron or Steel Articles用普力斯试验法(硫酸铜浸蚀)确定铁或钢制品上镀锌层最薄点的测试方法A240/A240M-06b Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate,Sheet, and Strip for Pressure Vessels and for General Applications压力容器用耐热铬及铬镍不锈钢板、薄板及带材A242/A242M-04e1 Standard Specification for High-Strength Low-Alloy Structural Steel 高强度低合金结构钢A247-67(1998)e1 Standard Test Method for Evaluating the Microstructure of Graphite in Iron Castings 铁铸件中石墨显微结构评定试验方法A249/A249M-04a Standard Specification for Welded Austenitic Steel Boiler, Superheater,Heat-Exchanger, and Condenser Tubes锅炉、过热器、换热器和冷凝器用焊接奥氏体钢管A250/A250M-05 Standard Specification for Electric-Resistance-Welded Ferritic Alloy-Steel Boiler andSuperheater Tubes锅炉和过热器用电阻焊铁素体合金钢管A252-98(2002) Standard Specification for Welded and Seamless Steel Pipe Piles 焊接钢和无缝钢管桩A254-97(2002) Standard Specification for Copper-Brazed Steel Tubing 铜焊钢管规格A255-02e1 Standard Test Methods for Determining Hardenability of Steel 测定钢淬透性用末端淬火试验的标准试验方法A262-02ae3 Standard Practices for Detecting Susceptibility to Intergranular Attack in AusteniticStainless Steels奥氏体不锈钢晶间浸蚀敏感性的检测A263-03 Standard Specification for Stainless Chromium Steel-Clad Plate 耐腐蚀铬钢包覆板材,薄板材及带材技术规范A264-03 Specification for Stainless Chromium-Nickel Steel-Clad Plate 包覆的不锈铬镍钢板,薄板及带材规格A265-03 Standard Specification for Nickel and Nickel-Base Alloy-Clad Steel Plate 镍和镍基合金包覆钢板规格A266/A266M-03a Standard Specification for Carbon Steel Forgings for Pressure Vessel Components 压力容器部件用碳素钢锻件规格A268/A268M-05a Standard Specification for Seamless and Welded Ferritic and Martensitic StainlessSteel Tubing for General Service一般设备用无缝和焊接铁素体与马氏体不锈钢管A269-04 Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubingfor General Service一般设备用无缝和焊接奥氏体不锈钢管A270-03a Standard Specification for Seamless and Welded Austenitic Stainless Steel SanitaryTubing卫生设施用无缝钢和焊接奥氏体不锈钢管A275/A275M-06 Standard Test Method for Magnetic Particle Examination of Steel Forgings 钢锻件的磁粉检查试验方法A276-06 Standard Specification for Stainless Steel Bars and Shapes 不锈钢棒材和型材A278/A278M-01 Standard Specification for Gray Iron Castings for Pressure-Containing Parts forTemperatures Up to 650°F (350°C)适用于650F容压部件用灰铸铁件的技术规范A283/A283M-03 Standard Specification for Low and Intermediate Tensile Strength Carbon SteelPlates低和中等抗拉强度碳素钢板A285/A285M-03 Standard Specification for Pressure Vessel Plates, Carbon Steel, Low- andIntermediate-Tensile Strength压力容器用低和中等抗拉强度的碳素钢板A288-91(2003) Standard Specification for Carbon and Alloy Steel Forgings for Magnetic RetainingRings for Turbine Generators涡轮发电机磁性定位环用碳素钢和合金钢锻件A289/A289M-97(2003) Standard Specification for Alloy Steel Forgings for Nonmagnetic Retaining Rings forGenerators发电机非磁性定位环用合金钢锻件的技术规范A290/A290M-05 Standard Specification for Carbon and Alloy Steel Forgings for Rings for ReductionGears减速器环用碳素钢和合金钢锻件A291/A291M-05 Standard Specification for Steel Forgings, Carbon and Alloy, for Pinions, Gears andShafts for Reduction Gears减速器小齿轮、齿轮和心轴用碳素钢和合金钢锻件A295/A295M-05 Standard Specification for High-Carbon Anti-Friction Bearing Steel 高碳耐磨轴承钢技术规范A297/A297M-97(2003) Standard Specification for Steel Castings, Iron-Chromium andIron-Chromium-Nickel, Heat Resistant, for General Application一般用耐热铬铁与镍铬铁合金钢铸件规格A299/A299M-04 Standard Specification for Pressure Vessel Plates, Carbon Steel, Manganese-Silicon 压力容器用锰硅碳钢板A302/A302M-03 Standard Specification for Pressure Vessel Plates, Alloy Steel,Manganese-Molybdenum and Manganese-Molybdenum-Nickel压力容器用锰钼和锰钼镍合金钢板A304-05e2 Standard Specification for Carbon and Alloy Steel Bars Subject to End-QuenchHardenability Requirements有末端淬火淬透性要求的合金钢棒材的技术规范A307-04 Standard Specification for Carbon Steel Bolts and Studs, 60 000 PSI TensileStrength抗拉强度为60000psi的碳素钢螺栓和螺柱的技术规范A308/A308M-03 Standard Specification for Steel Sheet, Terne (Lead-Tin Alloy) Coated by theHot-Dip Process经热浸处理镀有铅锡合金的薄板材的技术规范A309-01 Standard Test Method for Weight and Composition of Coating on Terne Sheet by theTriple-Spot Test用三点试验法测定长镀锌薄钢板镀层的重量成分的试验方法A311/A311M-04 Standard Specification for Cold-Drawn, Stress-Relieved Carbon Steel Bars Subjectto Mechanical Property Requirements有机械性能要求的消除应力的冷拉碳素钢棒A312/A312M-06 Standard Specification for Seamless, Welded, and Heavily Cold Worked AusteniticStainless Steel Pipes无缝和焊接奥氏体不锈钢管A313/A313M-03 Standard Specification for Stainless Steel Spring Wire 不锈钢弹簧丝技术规范A314-97(2002) Standard Specification for Stainless Steel Billets and Bars for Forging 锻造用不锈及耐热钢坯及钢棒规格A319-71(2001) Standard Specification for Gray Iron Castings for Elevated Temperatures forNon-Pressure Containing Parts高温无压部件用灰铁铸件A320/A320M-05a Standard Specification for Alloy-Steel and Stainless Steel Bolting Materials forLow-Temperature Service低温用合金钢螺栓材料规格A321-90(2001) Standard Specification for Steel Bars, Carbon, Quenched and Tempered 经淬火和回火的碳素钢棒A322-06 Standard Specification for Steel Bars, Alloy, Standard Grades 合金钢棒材.级别A323-05 Standard Specification for Ferroboron 硼铁规格A324-73(2004) Standard Specification for Ferrotitanium 钛铁合金A325M-05 Standard Specification for Structural Bolts, Steel, Heat Treated 830 MPa MinimumTensile Strength [Metric]经热处理最小抗拉强度为830Mpa的热处理钢结构螺栓A325-06 Standard Specification for Structural Bolts, Steel, Heat Treated, 120/105 ksiMinimum Tensile Strength经热处理最小抗拉强度为120/106ksi的热处理钢结构螺栓A327-91(2006) Standard Test Methods for Impact Testing of Cast Irons 铸铁冲击试验方法A327M-91(2006) Standard Test Methods for Impact Testing of Cast Irons (Metric) 铸铁冲击试验方法(米制) A328/A328M-05 Standard Specification for Steel Sheet Piling 薄钢板桩A333/A333M-05 Standard Specification for Seamless and Welded Steel Pipe for Low-TemperatureService低温用无缝与焊接钢管规格A334/A334M-04a Standard Specification for Seamless and Welded Carbon and Alloy-Steel Tubes forLow-Temperature Service低温设备用无缝与焊接碳素和合金钢管A335/A335M-06 Standard Specification for Seamless Ferritic Alloy-Steel Pipe for High-TemperatureService高温用无缝铁素体合金钢管A336/A336M-06 Standard Specification for Alloy Steel Forgings for Pressure and High-TemperatureParts压力与高温部件用合金钢锻件规格A338-84(2004) Standard Specification for Malleable Iron Flanges, Pipe Fittings, and Valve Parts forRailroad, Marine, and Other Heavy Duty Service at Temperatures Up to 650°F(345°C)铁路,船舶和其他重型装备在温度达到650华氏度(345摄氏度)时使用的可锻铸铁法兰,管件和阀门零件A340-03a Standard Terminology of Symbols and Definitions Relating to Magnetic Testing 有关磁性试验用符号和定义的术语A341/A341M-00(2005) Standard Test Method for Direct Current Magnetic Properties of Materials Using D-CPermeameters and the Ballistic Test Methods用直流磁导计和冲击试验法测定材料的直流磁性能的试验方法A342/A342M-04 Standard Test Methods for Permeability of Feebly Magnetic Materials 磁铁材料导磁率的试验方法A343/A343M-03 Standard Test Method for Alternating-Current Magnetic Properties of Materials atPower Frequencies Using Wattmeter-Ammeter-Voltmeter Method and 25-cmEpstein Test Frame在电力频率下用瓦特计-安培计-伏特计法(100-1000赫兹)和25 厘米艾普斯亭(EPSTEIN) 机架测定材料的交流电磁性能的试验方法A345-04 Standard Specification for Flat-Rolled Electrical Steels for Magnetic Applications 磁设备用平轧电炉钢A348/A348M-05 Standard Test Method for Alternating Current Magnetic Properties of Materials Usingthe Wattmeter-Ammeter-Voltmeter Method, 100 to 10 000 Hz and 25-cm EpsteinFrame用瓦特计--安培计--伏特计法(100-10000赫兹)和25厘米艾普斯亭框测定材料的交流磁性能的试验方法A350/A350M-04a Standard Specification for Carbon and Low-Alloy Steel Forgings, Requiring NotchToughness Testing for Piping Components要求进行缺口韧性试验的管道部件用碳素钢与低合金钢锻件技术规范A351/A351M-06 Standard Specification for Castings, Austenitic, for Pressure-Containing Parts 容压零件用奥氏体及奥氏体铁素体铸铁的技术规范A352/A352M-06 Standard Specification for Steel Castings, Ferritic and Martensitic, forPressure-Containing Parts, Suitable for Low-Temperature Service低温受压零件用铁素体和马氏体钢铸件规格A353/A353M-04 Standard Specification for Pressure Vessel Plates, Alloy Steel, 9 Percent Nickel,Double-Normalized and Tempered压力容器用经二次正火及回火处理的含9%镍的合金钢板A354-04 Standard Specification for Quenched and Tempered Alloy Steel Bolts, Studs, andOther Externally Threaded Fasteners淬火与回火合金钢螺栓,双头螺栓及其他外螺纹紧固件规格A355-89(2006) Standard Specification for Steel Bars, Alloys, for Nitriding 渗氮用合金钢棒A356/A356M-05 Standard Specification for Steel Castings, Carbon, Low Alloy, and Stainless Steel,Heavy-Walled for Steam Turbines蒸汽轮机用厚壁碳素钢、低合金钢和不锈钢铸件A358/A358M-05 Standard Specification for Electric-Fusion-Welded Austenitic Chromium-NickelStainless Steel Pipe for High-Temperature Service and General Applications高温用电熔焊奥氏体铬镍合金钢管A363-03 Standard Specification for Zinc-Coated (Galvanized) Steel Overhead Ground WireStrand地面架空线用镀锌钢丝绳A367-60(2005) Standard Test Methods of Chill Testing of Cast Iron 铸铁的激冷试验方法A368-95a(2004) Standard Specification for Stainless Steel Wire Strand 不锈钢和耐热钢丝绳的标准A369/A369M-02 Standard Specification for Carbon and Ferritic Alloy Steel Forged and Bored Pipe for 高温用锻制和镗孔碳素钢管和铁素体合金钢管High-Temperature ServiceA370-05 Standard Test Methods and Definitions for Mechanical Testing of Steel Products 钢制品机械测试的标准试验方法和定义A372/A372M-03 Standard Specification for Carbon and Alloy Steel Forgings for Thin-Walled PressureVessels薄壁压力容器用碳素钢及合金钢锻件A376/A376M-06 Standard Specification for Seamless Austenitic Steel Pipe for High-TemperatureCentral-Station Service高温中心站用无缝奥氏钢管A377-03 Standard Index of Specifications for Ductile-Iron Pressure Pipe 球墨铸铁压力管规范索引A380-06 Standard Practice for Cleaning, Descaling, and Passivation of Stainless Steel Parts,Equipment, and Systems不锈钢零件、设备和系统的清洗和除垢A381-96(2005) Standard Specification for Metal-Arc-Welded Steel Pipe for Use With High-PressureTransmission Systems高压输送用金属弧焊钢管A384/A384M-02 Standard Practice for Safeguarding Against Warpage and Distortion During Hot-DipGalvanizing of Steel Assemblies防止钢组件热浸镀锌时翘曲和扭曲用安全保护A385-05 Standard Practice for Providing High-Quality Zinc Coatings (Hot-Dip) 提供高质量镀锌覆层(热浸)A387/A387M-06 Standard Specification for Pressure Vessel Plates, Alloy Steel,Chromium-Molybdenum压力容器用铬钼合金钢板A388/A388M-05 Standard Practice for Ultrasonic Examination of Heavy Steel Forgings 重型钢锻件超声波检测A389/A389M-03 Standard Specification for Steel Castings, Alloy, Specially Heat-Treated, forPressure-Containing Parts, Suitable for High-Temperature Service适合高温受压部件用经特殊热处理的合金钢铸件规格A390-06 Standard Specification for Zinc-Coated (Galvanized) Steel Poultry Fence Fabric(Hexagonal and Straight Line)饲养家禽用镀锌钢丝栏栅网(六角形和直线形)A391/A391M-01 Standard Specification for Grade 80 Alloy Steel Chain 80号合金钢链条A392-03 Standard Specification for Zinc-Coated Steel Chain-Link Fence Fabric 镀锌钢丝链环栏栅网A394-05 Standard Specification for Steel Transmission Tower Bolts, Zinc-Coated and Bare 传动塔架用镀锌和裸露钢螺栓A395/A395M-99(2004) Standard Specification for Ferritic Ductile Iron Pressure-Retaining Castings for Useat Elevated Temperatures高温用铁素体球墨铸铁受压铸件A400-69(2006) Standard Practice for Steel Bars, Selection Guide, Composition, and MechanicalProperties钢棒的成分及机械性能选择指南A401/A401M-03 Standard Specification for Steel Wire, Chromium-Silicon Alloy 铬硅合金钢丝A403/A403M-06 Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings 锻制奥氏体不锈钢管配件A407-93(2004) Standard Specification for Steel Wire, Cold-Drawn, for Coiled-Type Springs 盘簧用冷拉钢丝A409/A409M-01(2005) Standard Specification for Welded Large Diameter Austenitic Steel Pipe forCorrosive or High-Temperature Service腐蚀场所或高温下使用的焊接大口径奥氏体钢管A411-03 Standard Specification for Zinc-Coated (Galvanized) Low-Carbon Steel Armor Wire 镀锌低碳钢铠装线A413/A413M-01 Standard Specification for Carbon Steel Chain 碳素钢链A414/A414M-06 Standard Specification for Steel, Sheet, Carbon, for Pressure Vessels 压力容器用碳素薄钢板A416/A416M-06 Standard Specification for Steel Strand, Uncoated Seven-Wire for PrestressedConcrete预应力混凝土用无涂层七股钢铰线A417-93(2004) Standard Specification for Steel Wire, Cold-Drawn, for Zig-Zag, Square-Formed,and Sinuous-Type Upholstery Spring Units之字形、方形、正弦形家具用弹簧元件用冷拔钢丝A418/A418M-05 Standard Test Method for Ultrasonic Examination of Turbine and Generator SteelRotor Forgings涡轮机及发电机钢转子锻件的超声波检查方法A420/A420M-06 Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steelfor Low-Temperature Service低温下用锻制碳素钢和合金钢管配件A421/A421M-05 Standard Specification for Uncoated Stress-Relieved Steel Wire for PrestressedConcrete预应力混凝土用无涂层消除应力钢丝的技术规范A423/A423M-95(2004) Standard Specification for Seamless and Electric-Welded Low-Alloy Steel Tubes 无缝和电焊低合金钢管A424-06 Standard Specification for Steel, Sheet, for Porcelain Enameling 搪瓷用钢薄板A426/A426M-05 Standard Specification for Centrifugally Cast Ferritic Alloy Steel Pipe forHigh-Temperature Service高温用离心铸造的铁素体合金钢管A427-02 Standard Specification for Wrought Alloy Steel Rolls for Cold and Hot Reduction 冷轧和热轧用锻制合金钢辊A428/A428M-01 Standard Test Method for Weight [Mass] of Coating on Aluminum-Coated Iron or 钢铁制品上铝覆层重量的测试方法Steel ArticlesA434-06 Standard Specification for Steel Bars, Alloy, Hot-Wrought or Cold-Finished,Quenched and Tempered热轧与冷精轧经回火及淬火的合金钢棒A435/A435M-90(2001) Standard Specification for Straight-Beam Ultrasonic Examination of Steel Plates 钢板的直射束纵向超声波检验A436-84(2001) Standard Specification for Austenitic Gray Iron Castings 奥氏体灰口铁铸件A437/A437M-06 Standard Specification for Alloy-Steel Turbine-Type Bolting Material Specially HeatTreated for High-Temperature Service高温用经特殊处理的涡轮型合金钢螺栓材料A439-83(2004) Standard Specification for Austenitic Ductile Iron Castings 奥氏体可锻铸铁铸件A447/A447M-93(2003) Standard Specification for Steel Castings, Chromium-Nickel-Iron Alloy (25-12Class), for High-Temperature Service高温用镍铬铁合金钢铸件(25-12级)A449-04b Specification for Hex Cap Screws, Bolts, and Studs, Steel, Heat Treated,120/105/90 ksi Minimum Tensile Strength, General Use经淬火和回火的钢螺栓和螺柱A450/A450M-04a Standard Specification for General Requirements for Carbon, Ferritic Alloy, andAustenitic Alloy Steel Tubes碳素钢管、铁素体合金钢管及奥氏体合金钢管A451/A451M-02 Standard Specification for Centrifugally Cast Austenitic Steel Pipe forHigh-Temperature Service高温用离心铸造的奥氏体钢管A453/A453M-04 Standard Specification for High-Temperature Bolting Materials, with ExpansionCoefficients Comparable to Austenitic Stainless Steels具有同奥氏体钢相类似的膨胀系数、屈服强度为50-120Ksi(345-827MPa)的耐高温螺栓材料A455/A455M-03 Standard Specification for Pressure Vessel Plates, Carbon Steel, High-StrengthManganese压力容器用高强度碳锰钢板A456/A456M-99(2003) Standard Specification for Magnetic Particle Examination of Large CrankshaftForgings大型曲轴锻件的磁粉检查A459-97(2003) Standard Specification for Zinc-Coated Flat Steel Armoring Tape 镀锌平轧扁钢铠装带A460-94(2004)e1 Standard Specification for Copper-Clad Steel Wire Strand 包铜钢丝绳标准A463/A463M-05 Standard Specification for Steel Sheet, Aluminum-Coated, by the Hot-Dip Process 热浸镀铝薄钢板A466/A466M-01 Standard Specification for Weldless Chain 非焊接碳素钢链A467/A467M-01(2006) Standard Specification for Machine and Coil Chain 机器链和盘旋链A469/A469M-06 Standard Specification for Vacuum-Treated Steel Forgings for Generator Rotors 用于发电机转子的真空处理钢锻件A470/A470M-05 Standard Specification for Vacuum-Treated Carbon and Alloy Steel Forgings forTurbine Rotors and Shafts涡轮机转子和轴用经真空处理的碳素钢和合金锻件A471-06 Standard Specification for Vacuum-Treated Alloy Steel Forgings for Turbine RotorDisks and Wheels涡轮转子转盘和转轮用真空处理合金钢锻件技术规范A472/A472M-05 Standard Test Method for Heat Stability of Steam Turbine Shafts and Rotor Forgings 蒸汽涡轮机轴及转子锻件的热稳定性的试验方法A473-01 Standard Specification for Stainless Steel Forgings 不锈和耐热钢锻件A474-03 Standard Specification for Aluminum-Coated Steel Wire Strand 包铝钢丝绳标准A475-03 Standard Specification for Zinc-Coated Steel Wire Strand 镀锌钢丝绳A476/A476M-00(2005) Standard Specification for Ductile Iron Castings for Paper Mill Dryer Rolls 造纸厂干燥辊用球墨可锻铸铁件A478-97(2002) Standard Specification for Chromium-Nickel Stainless Steel Weaving and KnittingWire铬镍不锈钢和耐热钢制编织钢丝A479/A479M-06a Standard Specification for Stainless Steel Bars and Shapes for Use in Boilers andOther Pressure Vessels锅炉及压力容器用不锈钢和耐热钢棒与型材A480/A480M-06a Standard Specification for General Requirements for Flat-Rolled Stainless andHeat-Resisting Steel Plate, Sheet, and Strip扁平轧制耐热不锈钢厚板材、薄板材和带材通用要求A481-05 Standard Specification for Chromium Metal 金属铬A482-05 Standard Specification for Ferrochrome-Silicon 铬铁硅A483-04 Standard Specification for Silicomanganese 硅锰合金A484/A484M-06a Standard Specification for General Requirements for Stainless Steel Bars, Billets,and Forgings不锈及耐热锻钢棒,钢坯及锻件的规格A485-03 Standard Specification for High Hardenability Antifriction Bearing Steel 高淬透性耐磨轴承钢的技术规范A487/A487M-93(2003) Standard Specification for Steel Castings Suitable for Pressure Service 受压钢铸件A488/A488M-04 Standard Practice for Steel Castings, Welding, Qualifications of Procedures andPersonnel钢铸件焊接规程和工作人员的合格鉴定A489-04 Standard Specification for Carbon Steel Lifting Eyes 碳素钢吊耳A490M-04a Standard Specification for High-Strength Steel Bolts, Classes 10.9 and 10.9.3, forStructural Steel Joints [Metric]最小拉伸强度为150千磅/平方英寸热处理钢结构螺栓A490-06 Standard Specification for Structural Bolts, Alloy Steel, Heat Treated, 150 ksiMinimum Tensile Strength最小拉伸强度为150千磅/平方英寸热处理钢结构螺栓A491-03 Standard Specification for Aluminum-Coated Steel Chain-Link Fence Fabric 镀铝钢链环栏栅结构A492-95(2004) Standard Specification for Stainless Steel Rope Wire 耐热不锈钢丝绳A493-95(2004) Standard Specification for Stainless Steel Wire and Wire Rods for Cold Heading andCold Forging冷镦和冷锻不锈钢和耐热钢丝A494/A494M-05 Standard Specification for Castings, Nickel and Nickel Alloy 镍和镍合金铸件A495-06 Standard Specification for Calcium-Silicon Alloys 硅钙合金钢技术规范A496/A496M-05 Standard Specification for Steel Wire, Deformed, for Concrete Reinforcement 钢筋混凝土用变形钢丝A497/A497M-06e1 Standard Specification for Steel Welded Wire Reinforcement, Deformed, forConcrete钢筋混凝土用焊接变形钢丝网A498-04 Standard Specification for Seamless and Welded Carbon Steel Heat-ExchangerTubes with Integral Fins无缝与焊接碳素钢,铁素体钢与奥氏体钢制有整体散热片的换热器钢管A499-89(2002) Standard Specification for Steel Bars and Shapes, Carbon Rolled from T Rails 轧制丁字钢轨用的碳素钢棒材及型材的技术规范A500-03a Standard Specification for Cold-Formed Welded and Seamless Carbon SteelStructural Tubing in Rounds and Shapes圆形与异型焊接与无缝碳素钢结构管A501-01(2005) Standard Specification for Hot-Formed Welded and Seamless Carbon SteelStructural Tubing热成型焊接与无缝碳素钢结构管A502-03 Standard Specification for Rivets, Steel, Structural 结构钢铆钉规范A503/A503M-01(2006) Standard Specification for Ultrasonic Examination of Forged Crankshafts 锻制大型曲轴的超声波检验A504/A504M-04e1 Standard Specification for Wrought Carbon Steel Wheels 锻制碳素钢轮A505-00(2005) Standard Specification for Steel, Sheet and Strip, Alloy, Hot-Rolled and Cold-Rolled,General Requirements for热轧和冷轧合金钢薄板和带材。

astm-e505标准三级管控一、引言本文件规定了金属材料焊接质量控制中实施ASTM-E505标准的三级管控方法。

通过实施三级管控,确保焊接质量符合规定要求,从而保障工程安全和性能。

二、三级管控内容1. 一级管控:制定合理的焊接工艺规程,明确焊接材料、设备等要求,确保其符合ASTM-E505标准。

同时,对焊接过程进行全面监控,确保操作规范和参数准确。

2. 二级管控:对焊接过程中的温度、速度、压力等参数进行实时监控,确保焊接质量稳定。

同时,对焊接后的试样进行取样检测,并分析焊接缺陷的原因,采取相应措施予以解决。

3. 三级管控:对焊接成品进行全面检测,包括外观、无损检测、力学性能等方面,确保焊接成品符合设计要求和客户标准。

同时,对检测结果进行分析和总结,及时发现和解决问题,确保焊接质量持续提高。

三、实施要点1. 建立完善的监控系统,确保焊接过程中的参数和温度、速度等指标符合要求。

2. 定期对焊接设备和材料进行检查和更换,确保其性能稳定。

3. 定期对焊接人员进行培训和考核,提高其技能水平和质量意识。

4. 建立完善的档案管理制度,对焊接过程和结果进行记录和保存,以便后续查阅和分析。

四、总结实施ASTM-E505标准的三级管控是保证金属材料焊接质量的关键措施。

通过严格执行三级管控制度,加强监督和检查,可以有效地提高焊接质量,确保工程安全和性能。

五、附录本文件的附录提供了常用的焊接材料、设备等表格和图片,供实际操作人员参考。

同时,也提供了相关的图示和说明,以帮助理解和执行本文件。

此外,本文件还列出了其他相关信息,如无损检测方法和相关标准等。

这些信息对于实施ASTM-E505标准的三级管控具有重要的参考价值。

astm e505 标准好的,以下是一篇完整的《astm e505 标准》的文档,不含敏感信息:一、标准概述ASTM E505标准是建筑材料燃烧性能评估的重要标准,旨在保障火灾发生时人们的生命安全和财产安全。

该标准提供了建筑材料在火灾中的燃烧特性和安全性的评估方法,根据建筑材料的燃烧性能将其分为不同的等级。

二、建筑材料分类根据ASTM E505标准,建筑材料被分为A级、B级、C级等不同等级,反映了材料在火灾中的燃烧特性和蔓延速度。

这些等级是根据建筑材料在模拟火灾条件下的燃烧性能测试结果而确定的。

三、测试方法ASTM E505标准规定了测试建筑材料燃烧性能的方法和程序,包括样品准备、测试设备、测试过程和结果评估等。

测试过程通常包括点燃建筑材料、观察其燃烧情况、测量燃烧蔓延速度、评估烟雾产生和毒性等指标。

测试结果将用于确定建筑材料的燃烧性能等级,并为建筑设计和使用提供参考。

四、安全要求根据ASTM E505标准,为了确保建筑物的安全,建筑设计应考虑逃生和灭火措施。

建筑物的构造应能够阻止火势蔓延,并为人员提供足够的时间和空间进行逃生。

此外,建筑物内的消防设施也应得到充分的维护和检查。

五、实施与监督ASTM E505标准规定了各方的责任和义务,包括测试机构、生产厂家、销售商和使用者等。

测试机构应按照标准要求进行测试,并出具报告。

生产厂家应确保其产品符合标准要求,并承担相应的质量责任。

销售商和使用者也应了解标准要求,并在购买和使用过程中注意安全。

六、参考文献本标准引用了以下文献:1. ASTM E162 建筑材料分类和标记标准2. ASTM E84 建筑制品及材料燃烧性能试验方法标准3. 其他相关标准和规范以上参考文献提供了本标准的背景和依据,确保标准的科学性和准确性。

七、附录附录A:建筑材料燃烧性能等级表附录B:测试设备和材料清单附录C:测试过程和结果记录表附录A提供了常见建筑材料的燃烧性能等级,方便使用者查阅。

1.SCOPE适用范围:This specification applies for aluminum-alloy die casting porosity definition. It based on original spec of ASTM E505, but not for substitute of original spec, it only provide more comprehensive interpretion, so as to use with original spec. The requirement would override the original spec when conflict.本规范涵盖了所有铝合金压铸砂孔的要求。

本规范参照美国材料实验协会标准ASTM E505的原始规范,但不取代原规范,仅提供更全面的说明,所以原规范必须使用。

当本规范和原规范的内容矛盾时,本规范要求取代原规范内容。

SPECIFICATION规范:Casting Thickness 壁厚(mm)Applicable Casting Thickness可适用的壁厚(mm)Inside Porosity acceptable standard内部砂孔可接受的标准Radiographs : Scale 1:1X射线照片:比例1:1Surface Porosity acceptable standard表面砂孔可接受的标准Radiographs : Scale 1:1X射线照片:比例1:1Up to 3.2mmOver 3.2mm to 25.4mmLevel 11级Radiographs : Scale 1:1X射线照片:比例1:1Level 22级Radiographs : Scale 1:1X射线照片:比例1:1Level 33级Radiographs : Scale 1:1X射线照片:比例1:1Level 44级Radiographs : Scale 1:1X射线照片:比例1:1~0.70mm 3个/10cm2~1. 0mm 1个/10cm2~1.0mm 5个/10cm2~1.5mm 1个/10cm2~1.5mm 10个/10cm2~4.0mm 1个/10cm2~4.0mm 15个/10cm2~10mm 1个/10cm2REMARK备注:Unless special explanation, void with size of ≦0.5mm will not be considered as porosity, and this apply to inside and on the surface porosity of aluminum-alloy die casting!如果没有特别说明,0.50mm及以下的气孔不作为砂孔的评估控制范围内,此要求适用于铝合金压铸件的内部和加工表面!REFERENCE参考文献:ASTM E505 Reference radiographs for Inspection of Aluminum and Magnesium Die Castings铝合金及镁合金压铸件X射线检查规范ASTM B85 Standard Specification for aluminum-alloy die castings压铸铝合金的标准规范GB/T 13822-92 Test specimens for non ferrous die casting alloys压铸有色合金的检测试样。

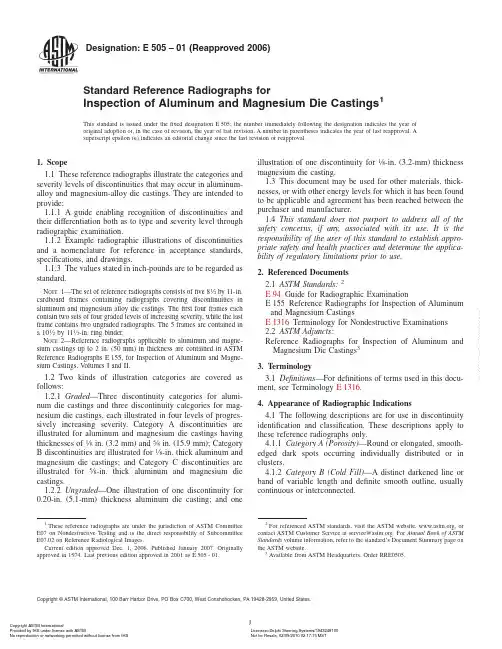

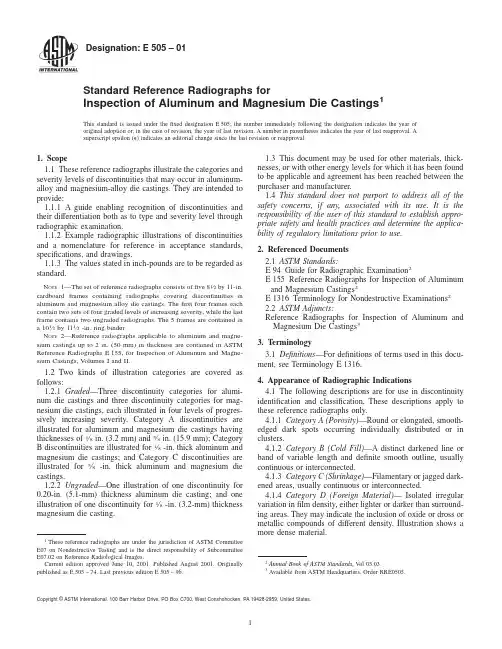

Designation:E505–01Standard Reference Radiographs forInspection of Aluminum and Magnesium Die Castings1This standard is issued under thefixed designation E505;the number immediately following the designation indicates the year of original adoption or,in the case of revision,the year of last revision.A number in parentheses indicates the year of last reapproval.A superscript epsilon(e)indicates an editorial change since the last revision or reapproval.1.Scope1.1These reference radiographs illustrate the categories and severity levels of discontinuities that may occur in aluminum-alloy and magnesium-alloy die castings.They are intended to provide:1.1.1A guide enabling recognition of discontinuities and their differentiation both as to type and severity level through radiographic examination.1.1.2Example radiographic illustrations of discontinuities and a nomenclature for reference in acceptance standards, specifications,and drawings.1.1.3The values stated in inch-pounds are to be regarded as standard.N OTE1—The set of reference radiographs consists offive81⁄2by11-in. cardboard frames containing radiographs covering discontinuities in aluminum and magnesium alloy die castings.Thefirst four frames each contain two sets of four graded levels of increasing severity,while the last frame contains two ungraded radiographs.The5frames are contained in a101⁄2by111⁄2-in.ring binder.N OTE2—Reference radiographs applicable to aluminum and magne-sium castings up to2in.(50mm)in thickness are contained in ASTM Reference Radiographs E155,for Inspection of Aluminum and Magne-sium Castings,V olumes I and II.1.2Two kinds of illustration categories are covered as follows:1.2.1Graded—Three discontinuity categories for alumi-num die castings and three discontinuity categories for mag-nesium die castings,each illustrated in four levels of progres-sively increasing severity.Category A discontinuities are illustrated for aluminum and magnesium die castings having thicknesses of1⁄8in.(3.2mm)and5⁄8in.(15.9mm);Category B discontinuities are illustrated for1⁄8-in.thick aluminum and magnesium die castings;and Category C discontinuities are illustrated for5⁄8-in.thick aluminum and magnesium die castings.1.2.2Ungraded—One illustration of one discontinuity for 0.20-in.(5.1-mm)thickness aluminum die casting;and one illustration of one discontinuity for1⁄8-in.(3.2-mm)thickness magnesium die casting.1.3This document may be used for other materials,thick-nesses,or with other energy levels for which it has been found to be applicable and agreement has been reached between the purchaser and manufacturer.1.4This standard does not purport to address all of the safety concerns,if any,associated with its use.It is the responsibility of the user of this standard to establish appro-priate safety and health practices and determine the applica-bility of regulatory limitations prior to use.2.Referenced Documents2.1ASTM Standards:E94Guide for Radiographic Examination2E155Reference Radiographs for Inspection of Aluminum and Magnesium Castings2E1316Terminology for Nondestructive Examinations2 2.2ASTM Adjuncts:Reference Radiographs for Inspection of Aluminum and Magnesium Die Castings33.Terminology3.1Definitions—For definitions of terms used in this docu-ment,see Terminology E1316.4.Appearance of Radiographic Indications4.1The following descriptions are for use in discontinuity identification and classification.These descriptions apply to these reference radiographs only.4.1.1Category A(Porosity)—Round or elongated,smooth-edged dark spots occurring individually distributed or in clusters.4.1.2Category B(Cold Fill)—A distinct darkened line or band of variable length and definite smooth outline,usually continuous or interconnected.4.1.3Category C(Shrinkage)—Filamentary or jagged dark-ened areas,usually continuous or interconnected.4.1.4Category D(Foreign Material)—Isolated irregular variation infilm density,either lighter or darker than surround-ing areas.They may indicate the inclusion of oxide or dross or metallic compounds of different density.Illustration shows a more dense material.1These reference radiographs are under the jurisdiction of ASTM Committee E07on Nondestructive Testing and is the direct responsibility of Subcommittee E07.02on Reference Radiological Images.Current edition approved June10,2001.Published August2001.Originally published as E505–st previous edition E505–96.2Annual Book of ASTM Standards,V ol03.03.3Available from ASTM Headquarters.Order RRE0505. 1Copyright©ASTM International,100Barr Harbor Drive,PO Box C700,West Conshohocken,PA19428-2959,United States.5.Significance and Use5.1These radiographs are so designed that acceptance standards,which may be developed for particular require-ments,can be specified in terms of these radiographs.The radiographs are of castings that were produced under condi-tions designed to produce the discontinuities.These reference radiographs are intended to be used for casting thickness ranges in accordance with Table1.5.2The radiographic illustrations listed in Table1illustrate three types of discontinuities in four severity levels.Two ungraded illustrations have been included to establish the radiographic appearance of foreign material.5.3These reference radiographs were produced in accor-dance with Guide E94.All of the references are original radiographs.5.4Film Deterioration—Radiographicfilms are subject to wear and tear from handling and use.The extent to which the image deteriorates over time is a function of storage condi-tions,care in handling and amount of use.Reference radio-graphfilms are no exception and may exhibit a loss in image quality over time.The radiographs should therefore be peri-odically examined for signs of wear and tear,including scratches,abrasions,stains,and so forth.Any reference radio-graphs which show signs of excessive wear and tear which could influence the interpretation and use of the radiographs should be replaced.6.Basis for Application6.1These reference radiographs may be applied as accep-tance standards tailored to the end use of the product.Appli-cation of these reference radiographs as acceptance standards should be based on the intended use of the product and the following considerations(see Note3):6.1.1Unless otherwise specified,discontinuities of equal or lesser severity than that in the specified reference radiograph are acceptable in any specified unit area of the casting.The size of the unit area should be specified in the acceptance criteria. Discontinuities more severe than those in the specified refer-ence radiograph shall be considered rejectable.6.1.2Any combination or portion of these reference radio-graphs may be used as is relevant to the particular application. Different grades or acceptance limits may be specified for each discontinuity type.Further,different grades may be specified for various regions or zones of the component.6.1.3Special consideration may be required where more than one discontinuity type is present in the same area.Any modification of the acceptance criteria required on the basis of multiple discontinuity types must be specified.6.1.4Where the reference radiograph contains multiple discontinuities,as in that case of gas holes,acceptance may be based upon the aggregate area of the discontinuities,the maximum discontinuity size in the reference radiograph,the spacing between discontinuities,or a combination of these or other criteria,or both.6.1.5As a minimum the acceptance criteria should contain information addressing;zoning of the part(if applicable), acceptance severity level for each discontinuity type,and the specific area to which the reference radiographs are to be applied.N OTE3—Caution should be exercised in specifying the acceptance criteria to be met in the casting.Casting design coupled with foundry practice should be considered.It is advisable to consult with the manufacturer or foundry before establishing the acceptance criteria to ensure the desired quality level can be achieved.7.Keywords7.1aluminum;die castings;discontinuities;magnesium; reference radiographs;X-rayTABLE1Reference Radiographs for Aluminum and Magnesium Die CastingsDiscontinuityPlate Thickness,in.(mm)Applicable CastingThickness,in.(mm) Aluminum Die CastingsCategory A(Porosity)1⁄8(3.2)up to3⁄8(9.5),incl Category A(Porosity)5⁄8(15.9)over3⁄8to1(9.5to25.4),inclCategory B(Coldfill)1⁄8(3.2)up to3⁄8(9.5),incl Category C(Shrinkage)5⁄8(15.9)over3⁄8to1(9.5to25.4),inclCategory D(Foreignmaterial)0.200(5.08)up to1(25.4),inclMagnesium Die CastingsCategory A(Porosity)1⁄8(3.2)up to3⁄8(9.5),incl Category A(Porosity)5⁄8(15.9)over3⁄8to1(9.5to25.4),inclCategory B(Coldfill)1⁄8(3.2)up to3⁄8(9.5),incl Category C(Shrinkage)5⁄8(15.9)over3⁄8to1(9.5to25.4),inclCategory D(Foreign material)1⁄8(3.2)up to1(25.4),inclASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned in this ers of this standard are expressly advised that determination of the validity of any such patent rights,and the risk of infringement of such rights,are entirely their own responsibility.This standard is subject to revision at any time by the responsible technical committee and must be reviewed everyfive years and if not revised,either reapproved or withdrawn.Your comments are invited either for revision of this standard or for additional standards and should be addressed to ASTM International Headquarters.Your comments will receive careful consideration at a meeting of the responsible technical committee,which you may attend.If you feel that your comments have not received a fair hearing you should make your views known to the ASTM Committee on Standards,at the address shown below.This standard is copyrighted by ASTM International,100Barr Harbor Drive,PO Box C700,West Conshohocken,PA19428-2959, United States.Individual reprints(single or multiple copies)of this standard may be obtained by contacting ASTM at the above address or at610-832-9585(phone),610-832-9555(fax),or service@(e-mail);or through the ASTM website ().。

astm e505 标准-回复ASTM E505 标准是一个关于光学粗糙度测量的国际标准。

它提供了一种统一的方法来评估光学表面的粗糙度,并确保不同实验室和制造商之间的结果具有可比性和一致性。

本文将逐步回答有关ASTM E505标准的各个方面。

引言:ASTM E505标准是由美国材料和试验协会(ASTM International)制定的一项标准。

它提供了一种测量光学粗糙度的方法,用于评估光学元件的质量和性能。

这个标准是由ASTM E42委员会负责制定,并由全球各个实验室和制造商广泛采用和遵守。

第一步:标准背景和目的ASTM E505标准的主要目的是提供一种在实验室和制造环境中测量光学元件表面粗糙度的统一方法。

该标准的制定旨在确保在不同的实验室和制造商之间获得可比性和一致性的结果。

它帮助用户准确评估光学元件的表面质量,从而对光学系统的整体性能进行合理的预测和优化。

第二步:应用范围和适用对象ASTM E505标准适用于各种光学元件的表面粗糙度测量,包括镜片、透镜、反射镜、棱镜等。

这个标准适用于任何表面材料,无论是光学玻璃、塑料还是金属等。

它还适用于不同的光谱范围,从紫外到红外。

第三步:测量装置和方法ASTM E505标准提供了一种标准的装置和方法,用于测量光学元件表面的粗糙度。

它要求使用一台适应性强、精度高的光学仪器,如原子力显微镜(AFM)或干涉仪。

测量过程中需要进行多次重复测量,并计算得出平均值和标准偏差。

该标准还提供了测量条件的建议,包括环境温度、湿度和光照强度等。

第四步:数据处理和结果评估ASTM E505标准规定了如何处理测量数据以及如何评估光学元件表面的粗糙度。

测量数据应按照标准的要求进行处理,例如计算平均值、标准偏差和相关参数。

结果评估时,可以使用各种统计方法和图表来表示和比较不同样品之间的粗糙度水平。

第五步:结果报告和数据共享ASTM E505标准要求对测量结果进行记录和报告,包括测量条件、仪器的规格、测量数据和处理结果等。

astm-e505标准三级管控ASTM E505标准是由美国材料和试验协会(ASTM International)制定的一项测试方法标准,主要用于测量和描述非金属薄片制品的表面平整度。

该标准包含了三个不同级别的管控,通过分别检测和分类表面平整度的不同级别,可以确定和控制产品的质量。

ASTM E505标准的三级管控是指根据标准将被测试样品的表面平整度分为三个级别,从而对产品质量进行评估和管控。

三个级别分别是A 级、B级和C级,每个级别都有相应的指标和要求。

在ASTM E505标准中,A级是指最高标准的表面质量,要求非常严格,用于要求非常高的应用,如光学和电子设备。

B级是指中等标准的表面质量,要求适中,用于大多数一般应用。

C级是指相对较低的表面质量,适用于对表面质量要求不高的一般应用。

根据ASTM E505标准的要求,进行表面平整度测试需要使用光学测量设备,如激光扫描仪或显微镜。

测试过程包括扫描或观察被测样品表面,并测量表面的凸起或凹陷程度。

根据测量结果,可以将样品分为不同的级别。

通过进行ASTM E505标准的三级管控,可以确保产品的表面质量符合特定的要求,并能够满足用户的需求。

对于高精度应用,选择A级的产品可以保证表面质量的最佳性能。

对于一般应用,选择B级的产品可以满足大多数需求。

对于表面质量要求不高的应用,选择C级的产品能够节省成本并满足基本要求。

ASTM E505标准的三级管控对于制造商和用户来说都非常重要。

对制造商来说,可以根据不同的应用需求进行产品的分级和分类,以便提供符合用户需求的产品。

对用户来说,可以根据产品的级别选择最适合自己需求的产品,确保获得满意的产品质量。

总之,ASTM E505标准的三级管控是一种用于评估和管控非金属薄片制品表面平整度的方法。

通过将产品分为A级、B级和C级,可以根据不同应用需求选择最适合的产品,以确保产品表面质量的符合要求。

这种标准对于制造商和用户来说都非常重要,能够提高产品质量并满足用户需求。

astm-e505标准三级管控ASTM-E505标准是针对金属和陶瓷材料的表面粗糙度的测量方法,属于表面分析和测量技术领域。

该标准将表面粗糙度划分为三个级别:一级、二级和三级。

这三个级别分别对应不同的应用要求和测量精度。

在进行表面粗糙度检测时,根据需求可选择不同的级别进行测试和评估。

一级管控是最高级别,对于要求非常高的应用场景,如光学镜面、信号处理器等,一级管控要求材料表面非常光滑,没有明显的缺陷。

一级管控的测量结果一般以RMS(均方根)值或Ra(平均粗糙度)值进行表示,其测量结果要求非常精确,对测量设备的要求也相当高。

二级管控是中级别,适用于一些一般要求的应用场景。

材料表面在二级管控下,可以有一些细微的缺陷和粗糙度。

测量结果一般以RMS 值或Ra值进行表示,对于表面缺陷的度量也有相应的要求。

二级管控的精度相对较低,对测量设备的要求也相对较低。

三级管控是最低级别,适用于一些粗糙度要求不高的应用场景。

材料表面在三级管控下,可以有较大的缺陷和粗糙度。

测量结果一般以RMS值或Ra值进行表示,对于表面缺陷的度量也有相应的要求。

三级管控的精度相对较低,对测量设备的要求也相对较低。

ASTM-E505标准通过对不同级别的管控,为金属和陶瓷材料的表面粗糙度提供了统一的测量准则,方便了工程设计和制造过程的控制。

厂商可以根据应用需求选择适当的级别进行测试和管控,从而保证产品的质量和性能。

在进行表面粗糙度测试时,需要使用专用的测量仪器,如表面粗糙度仪、激光扫描仪等。

测试前,需要对仪器进行校准,确保其测量结果的准确性和可靠性。

测试过程中,将测量仪器轻轻地放置在材料表面,仪器将通过测量探针或激光扫描来获取表面的粗糙度信息,最后通过计算得到RMS值或Ra值。

ASTM-E505标准的应用范围广泛,涉及到许多行业,如航空航天、汽车制造、电子工业等。

这些行业对于金属和陶瓷材料表面的粗糙度要求严格,需要通过精确的测量和管控来确保产品质量。

ASTME505中⽂版

压铸件质量标准

1.范围

1.1 本《⽓孔和铸件质量要求》标准适⽤于压铸件。

1.2 所有的线性尺⼨单位为英⼨

2.定义

砂眼——铸件中由夹带⽓体引起的表⾯缺陷。

冷隔——由于⾦属的凝固速率不同,有时在压铸过程中产⽣的凝固⾦属的重叠。

内部缩孔——铸件冷凝期间的⼀种情况,铸件内部体积收缩⽽形成空隙但铸件的外形尺⼨没有减⼩。

穿透性缺陷——铸件中有⼀个闭环孔或通孔,其孔径⼤于0.005(0.127㎜)但不属于设计部分。

注:本标准中所指的“穿透性缺陷”均参照以上的定义。

3.分类

4.铸件⽓孔及铸件质量的⼀般要求

不加⼯表⾯

不允许有可见的内部缩孔和砂眼

若供应商和客户许可,允许有微⼩的可见的冷隔

若⽆附加说明,不允许有不完整的零件特征

⽓孔密度应符合⽓孔等级Ⅰ

加⼯表⾯

不允许有可见的内部缩孔、冷隔和砂眼

不完整的零部件特征是不允许的

穿透性缺陷不应⼤于零件特征或壁厚的50℅。

一. 标准图谱

1.A类图中标样厚度1/8 inch (3.2mm)共分为4个等级

2.A类图中标样厚度5/8 inch (15.9mm)共分为4个等级

3.B类图中标样厚度1/8 inch (3.2mm)共分为4个等级

4.C类图中标样厚度5/8 inch (15.9mm)共分为4个等级

5.D类图中标样厚度1/8 inch (3.2mm)共分为1个等级

压铸企业可联系我,我们需要构造起周边的压铸环境,相互学习,相互提升,甚至我们应该集体考虑产品价格问题,不要任凭国外的企业打压产品价格,其实他们购买的中国产品+运费还远远低于他们国内的购买价格。

如果他们大肆压价,又要求我们PPM<=50,我们将彻底成为国外的机器,干得又好又便宜。

低利润长时间运行,会导致没有足够的资金进行技术革新,提高我们的生产技术,永远处于劣势……

对于外国企业我们有付出,就要有更高的回报,从而我们需要壮大自己,改变自己,真正能过以后我们为我们的国家贡献点什么…….我们是把祖国的资源卖给他们,需要我们深思!

先不多说,搞铝合金和镁合金压铸的,有空联系我

fultureliu@。

压铸件质量标准

1. 范围

1.1本《气孔和铸件质量要求》标准适用于压铸件。

1.2所有的线性尺寸单位为英寸

2. 定义

砂眼一一铸件中由夹带气体引起的表面缺陷。

冷隔 -- 由于金属的凝固速率不同,有时在压铸过程中产生的凝固金属的重叠。

内部缩孔一一铸件冷凝期间的一种情况,铸件内部体积收缩而形成空隙但铸件的外形尺寸没有减小。

穿透性缺陷一一铸件中有一个闭环孔或通孔,其孔径大于0.005(0.127伽)但不属于设计部分。

注:本标准中所指的“穿透性缺陷”均参照以上的定义3.分类

3.1表格1规定了本标准中所有的气孔等级

4.1不加工表面

不允许有可见的内部缩孔和砂眼

若供应商和客户许可,允许有微小的可见的冷隔若无附加说明,不允许有不完整的零件特征

气孔密度应符合气孔等级I

4.2加工表面

不允许有可见的内部缩孔、冷隔和砂眼

不完整的零部件特征是不允许的

穿透性缺陷不应大于零件特征或壁厚的50 %。