葡萄酒酿造科学英文资料:WINE202_Protein Stabilisation_Bin

- 格式:pptx

- 大小:2.02 MB

- 文档页数:21

葡萄酒英语作文Wine is a popular alcoholic beverage made from fermented grapes. It has been enjoyed by people around the world for centuries and is often associated with celebrations and social gatherings. In this essay, we will explore thehistory of wine, its production process, different types of wine, and the health benefits associated with moderate wine consumption.The history of wine dates back thousands of years, with evidence of winemaking dating as far back as 6000 BC in the region of Georgia. The ancient Greeks and Romans alsoplayed a significant role in the development of wine culture, with the Romans spreading viticulture throughout Europe. Wine has been an integral part of many cultures and religions, often used in rituals and ceremonies.The production of wine involves several key steps, including harvesting the grapes, crushing and pressing them to extract the juice, fermenting the juice with yeast to convert sugars into alcohol, and aging the wine in barrelsor tanks. The quality of the grapes, the winemaking process,and the aging conditions all contribute to the final flavor and aroma of the wine.There are several different types of wine, categorizedby the grape variety used, the region where the grapes are grown, and the winemaking techniques employed. The main categories of wine include red wine, white wine, rosé wine, and sparkling wine. Each type of wine has its own unique characteristics and flavors, making it suitable fordifferent occasions and food pairings.Moderate wine consumption has been associated withseveral health benefits, including a reduced risk of heart disease, stroke, and certain types of cancer. The antioxidants and polyphenols found in wine, particularlyred wine, are believed to have protective effects on the cardiovascular system and may help lower inflammation inthe body. However, it is important to note that excessive alcohol consumption can have serious negative healtheffects and should be avoided.In conclusion, wine is a versatile and culturally significant beverage that has been enjoyed by people around the world for centuries. Its rich history, diverseproduction methods, and health benefits make it a popular choice for many consumers. Whether enjoyed with a meal oras a standalone drink, wine continues to hold a special place in the hearts of many.葡萄酒是一种由葡萄发酵而成的受欢迎的酒精饮料。

英语介绍葡萄酒作文下载温馨提示:该文档是我店铺精心编制而成,希望大家下载以后,能够帮助大家解决实际的问题。

文档下载后可定制随意修改,请根据实际需要进行相应的调整和使用,谢谢!并且,本店铺为大家提供各种各样类型的实用资料,如教育随笔、日记赏析、句子摘抄、古诗大全、经典美文、话题作文、工作总结、词语解析、文案摘录、其他资料等等,如想了解不同资料格式和写法,敬请关注!Download tips: This document is carefully compiled by theeditor. I hope that after you download them,they can help yousolve practical problems. The document can be customized andmodified after downloading,please adjust and use it according toactual needs, thank you!In addition, our shop provides you with various types ofpractical materials,such as educational essays, diaryappreciation,sentence excerpts,ancient poems,classic articles,topic composition,work summary,word parsing,copyexcerpts,other materials and so on,want to know different data formats andwriting methods,please pay attention!Wine, a heavenly elixir that has been enjoyed by humans for centuries. Its rich history and diverse flavors make it a beloved beverage all around the world. From the lush vineyards of France to the sun-kissed hills of Italy, wine has become a symbol of sophistication and pleasure.The process of making wine is a delicate art. Grapesare carefully harvested and crushed to extract their juices. These juices are then fermented, allowing the naturalsugars to transform into alcohol. The length offermentation and the type of yeast used can greatlyinfluence the taste and aroma of the final product.There are countless varieties of wine, each with its own unique characteristics. Red wines, such as Cabernet Sauvignon and Merlot, are known for their bold flavors and deep colors. White wines, like Chardonnay and Sauvignon Blanc, tend to be lighter and crisper. Rosé wines, with their pink hues, offer a refreshing and fruity alternative.Sparkling wines, such as Champagne and Prosecco, add a touch of celebration to any occasion.Wine is not just a beverage, but an experience. The act of swirling the glass, taking in its aromas, and savoring its flavors is a ritual that wine enthusiasts cherish. Each sip tells a story, revealing the terroir of the vineyard and the skill of the winemaker. It is a journey for the senses, transporting us to distant lands and evoking emotions that only wine can inspire.Beyond its sensory pleasures, wine also holds a special place in cultural traditions. It is a symbol of communion and celebration, often shared among friends and family during festive gatherings. Wine tastings and vineyard tours offer a glimpse into the world of winemaking, allowing us to appreciate the craftsmanship and dedication that goes into every bottle.In recent years, the popularity of wine has soared, with more and more people discovering its allure. Wine bars and shops have become trendy destinations, offering a wideselection of wines from around the world. Wine tourism has also gained momentum, with travelers seeking out vineyards and wineries as part of their vacation experiences.Whether you are a connoisseur or a casual drinker, wine has something to offer everyone. Its complexity and diversity make it a never-ending journey of exploration. So raise your glass, and toast to the magic of wine, a drink that brings joy and pleasure to all who indulge. Cheers!。

葡萄酒的制作方法1.破碎。

将成熟的红葡萄用清水冲洗干净后,除去果梗及青粒、霉粒、破粒等,放入经过消毒容器里,用手挤碎或捣碎,但操作前须将手、容器等先用高锰酸钾水洗一次,再用清水冲洗,擦干,然后再去操作,以防止杂菌污染。

将葡萄捏碎,皮,籽,汁一并放进发酵桶内盖好,一次可做10斤新鲜葡萄。

2.发酵。

发酵是将葡萄皮汁中的糖分经酵母的作用产生酒精和二氧化碳,红葡萄酒的前发酵过程是皮汁籽混在一起的,因为葡萄皮上的白霜存在有酵母,所以自制葡萄酒在发酵时可以不另外加入酵母。

发酵的温度最好在25——30℃,一般可以达到不超过32℃。

当皮汁装入容器后,一般经过一天即可开始发酵。

液面开始是平静,这时已有微弱的二氧化碳气泡产生,表示酵母已开始繁殖,经过2~3天有大量二氧化碳放出,皮渣上浮结成一层帽盖,口尝果汁,甜味渐减,酒味渐增。

发酵时每天应将上浮的葡萄皮用漏勺压到汁内1——2次,这样做一方面防止葡萄皮生霉,变酸,同时可将皮上的色素和单宁溶解在酒液中,且排出CO2,使酵母得到氧气,发酵更旺盛。

发酵第三天,此时可以进行加糖,一般10斤葡萄加2——3斤糖,分两次加,第一次加一半,糖加进去后搅动一下,盖好继续发酵。

171克可提升一度酒,发酵至第7——8天二氧化碳放出至微弱而接近平静,酒精味很浓、糖分减少至1%以下,汁液开始清晰,即为发酵结束,进行压榨过滤,将皮汁分离。

3.压榨过滤的方法;是用洁净的布袋或纱布,进行挤压或扭压,除掉渣和籽,清理干净发酵桶擦干水,将过滤好的葡萄酒放进桶内,也可以放在其它的溶器内,比如玻璃瓶,陶瓷,不锈钢等溶器。

加入白糖进行二次发酵,发酵至15天,用一根管子用虹吸法将上面清亮的酒吸出,洗理干净下面的沉淀物。

再将葡萄酒放在阴凉避光的地方存放15——20天,用虹吸法再倒一次溶器。

4.存放的方法;将第三次倒过的葡萄酒,10斤酒放5片维生素C片,起抗氧化的作用。

用玻璃瓶装放在阴凉避光的地方存放。

这样的葡萄酒每天喝一杯,对心血管,抗衰老,都有一定的作用。

红酒酿造过程英语介绍作文The Process of Making Red Wine。

Red wine is a popular alcoholic beverage made from the fermentation of dark-colored grapes. The process of making red wine is a complex and intricate one, involving several key steps that are essential for creating the perfect blend of flavors and aromas. In this article, we will take a closer look at the process of making red wine, from grape selection to bottling.Grape Selection and Harvesting。

The first step in making red wine is the careful selection and harvesting of the grapes. The quality of the grapes is crucial to the final product, as the flavor and aroma of the wine are largely determined by the type and quality of the grapes used. Grapes are typically harvested in the early fall, when they have reached their peak ripeness. The grapes are then carefully hand-picked andsorted to ensure that only the best quality fruit is usedfor the wine-making process.Crushing and Destemming。

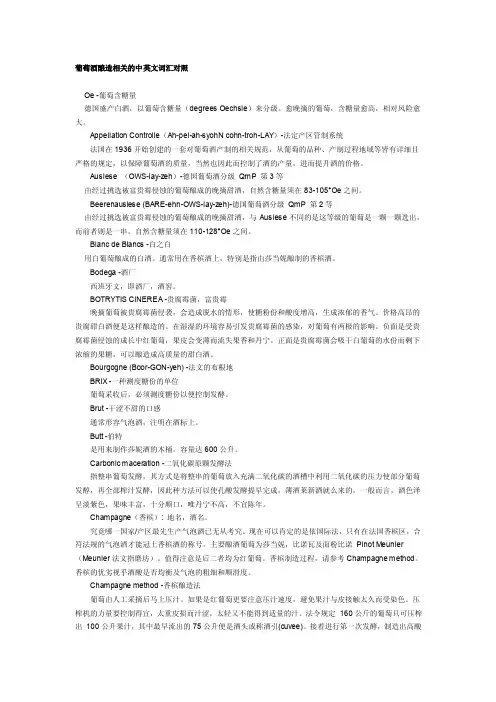

葡萄酒酿造相关的中英文词汇对照Oe -葡萄含糖量德国盛产白酒,以葡萄含糖量(degrees Oechsle)来分级。

愈晚摘的葡萄,含糖量愈高,相对风险愈大。

Appellation Controlle(Ah-pel-ah-syohN cohn-troh-LAY)-法定产区管制系统法国在1936开始创建的一套对葡萄酒产制的相关规范,从葡萄的品种、产制过程地域等皆有详细且严格的规定,以保障葡萄酒的质量,当然也因此而控制了酒的产量,进而提升酒的价格。

Auslese (OWS-lay-zeh)-德国葡萄酒分级QmP 第3等由经过挑选被富贵霉侵蚀的葡萄酿成的晚摘甜酒,自然含糖量须在83-105°Oe之间。

Beerenauslese (BARE-ehn-OWS-lay-zeh)-德国葡萄酒分级QmP 第2等由经过挑选被富贵霉侵蚀的葡萄酿成的晚摘甜酒,与Auslese不同的是这等级的葡萄是一颗一颗选出,而前者则是一串。

自然含糖量须在110-128°Oe之间。

Blanc de Blancs -白之白用白葡萄酿成的白酒。

通常用在香槟酒上,特别是指由莎当妮酿制的香槟酒。

Bodega -酒厂西班牙文,即酒厂,酒窖。

BOTRYTIS CINEREA -贵腐霉菌,富贵霉晚摘葡萄被贵腐霉菌侵袭,会造成脱水的情形,使糖粉份和酸度增高,生成浓郁的香气。

价格高昂的贵腐甜白酒便是这样酿造的。

在湿湿的环境容易引发贵腐霉菌的感染,对葡萄有两极的影响。

负面是受贵腐霉菌侵蚀的成长中红葡萄,果皮会变薄而流失果香和丹宁。

正面是贵腐霉菌会吸干白葡萄的水份而剩下浓缩的果糖,可以酿造成高质量的甜白酒。

Bourgogne (Boor-GON-yeh) -法文的布根地BRIX -一种测度糖份的单位葡萄采收后,必须测度糖份以便控制发酵。

Brut -干涩不甜的口感通常形容气泡酒,注明在酒标上。

Butt -伯特是用来制作莎妮酒的木桶。

容量达600公升。

制作葡萄酒英语作文Wine production, an art as old as time, involves a meticulous process that transforms humble grapes into exquisite elixirs. The journey of crafting wine begins in the vineyard, where grapevines are carefully tended to produce the best quality fruit. Factors like soil composition, climate, and topographyall play a crucial role in determining the characteristics of the grapes and, ultimately, the wine.Harvest season marks a significant milestone in the winemaking process. Grapes are handpicked or harvested by machines, depending on the vineyard's size and practices. The timing of the harvest is crucial, as it significantly impacts the wine's acidity, sweetness, and overall flavor profile.Once the grapes are harvested, they undergo the process of crushing and pressing. This step extracts the juice from the grapes, which is essential for fermentation. The juice, along with the skins and seeds, is transferred to fermentation tanks. Yeast is added to initiate the fermentation process, where sugars in the grape juice are converted into alcohol.Fermentation can take anywhere from a few days to several weeks, depending on the type of wine being produced. Red wines are fermented with the grape skins, which give them their color and tannins, while white wines are typically fermented without the skins.After fermentation is complete, the wine is transferred to barrels or tanks for aging. Aging is a critical stage in winemaking, as it allows the wine to develop its complex flavors and aromas. The type of container used for aging, such as oak barrels or stainless steel tanks, can also influence the wine's taste.Once the wine has aged to perfection, it undergoes a process called fining and filtering to clarify and stabilize it. This step helps remove any remaining solids or impurities, ensuring the wine is clear and free of any offflavors.Finally, the wine is bottled and labeled, ready to be enjoyed by wine enthusiasts around the world. From the vineyard to the cellar, the process of making wine is a labor of love that requires skill, patience, and a deep understanding of the grapes and the winemaking process.In conclusion, the art of winemaking is a harmonious blend of science, nature, and craftsmanship. Each bottle of wine tells a story of the land it came from, the hands that crafted it, and the traditions that have been passed down through generations. So, raise a glass to the winemakers who turn simple grapes into liquid poetry, creating a magical experience with each sip. Cheers to the timeless art of making wine.。

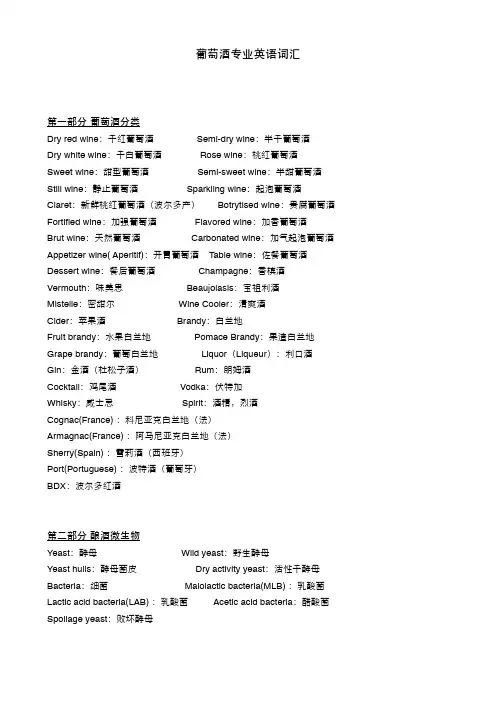

英文浅谈葡萄酒扩充知识:Wine Varieties葡萄酒种类:(By wine making process按工艺分)SPARKLING WINE气泡葡萄酒Champagne香槟Cava加瓦Other Sparkling wines其他气泡酒STILL WINE静态葡萄酒Red 红葡萄酒White白葡萄酒Rose桃红葡萄酒FORTIFIED WINE加强葡萄酒Port / Sherry钵酒/雪利酒Wine Varieties 葡萄酒种类:( By service sequence按用餐顺序分)Beginning of the meal 餐前Sugar 糖份 Alcohol 酒精Low 低 Aperitif (Drysherry/Champagne/Light dry White) Low 低餐前开胃酒(干性雪利/香槟/清淡干白葡萄酒)Table Wine ( Red, White, Rose… )佐餐酒(红/白/玫瑰红)Dessert Wine ( Botrytis, Ice wine,Port, Late Harvest…)甜酒(贵腐甜白,冰酒,钵酒,迟采半甜…)High 高 Digestive ( Brandy, Liquors, Grappa… ) High 高消化酒(白兰地,利口酒,果渣酒…)End of the meal 餐后Most Common Wine Varietals 主要葡萄品种8,000 grape varieties known in the world世界上目前已知的葡萄品种有8000种1,000 grape varieties used for wine around the world世界上大约有1000种葡萄被制成葡萄酒200 traditionally used in Italy意大利大约使用200种葡萄100 traditionally used in France法国大约使用100种葡萄50 traditionally used in Spain西班牙大约使用50种葡萄Grape variety, a major factor in the taste of a wine不同的葡萄品种,是影响葡萄酒品尝的主要因素White varietals 白葡萄品种Chardonnay/莎当妮Sauvignon Blanc/白苏维翁Riesling/雷司令Gewuztraminer /格乌兹塔米内Pinot Grigio/灰皮诺Viognier/维奥妮Red varietals 红葡萄品种Cabernet Sauvignon/卡本尼苏维翁Merlot/梅洛Cabernet Franc卡本尼弗朗Shiraz (Syrah)/设拉子Pinot Noir/黑皮诺Sangiovese/桑吉奥维谢Nebbiolo /内比奥罗Zinfandel/仙芬黛Tempranillo/泰普妮洛土壤沙质土 sand ( 质淡,葡萄成熟醇化速度较快)白垩土 chalk ( 多样化,高贵品种)砾石 gravel ( 品质佳,质地出色)黏土 clay ( 坚实,浓厚)最重要的一个因素是土壤的排水性最差的土壤最有利于葡萄树的生长,“葡萄树生长最好的地方是什么都不能长的地方”。

制作精美的葡萄酒英语作文Making Exquisite Wine。

Wine has been a popular drink for centuries and making exquisite wine is an art form. The process of making wine involves many steps, from planting the grapes to bottling the finished product. In this essay, we will explore the process of making exquisite wine and the factors that contribute to its quality.The first step in making wine is to select the grapes. The type of grape used will determine the flavor and aroma of the wine. Grapes that are grown in the right climate and soil conditions will produce the best wine. Once the grapes have been selected, they are harvested and sorted to remove any damaged or unripe grapes.The next step is to crush the grapes. This can be done by hand or by machine. The juice is then separated from the skins and seeds. The juice is then fermented with yeast,which converts the sugar in the juice into alcohol. This process can take anywhere from a few days to a few weeks.After fermentation, the wine is transferred to barrels or tanks for aging. The type of barrel used will alsoaffect the flavor of the wine. Oak barrels are commonly used because they add a unique flavor to the wine. The wine is aged for several months or even years, depending on the type of wine being made.Once the wine has been aged, it is bottled and labeled. The label will include information such as the type of grape used, the vintage, and the alcohol content. The wine is then ready to be enjoyed.The quality of wine is determined by several factors. The type of grape used, the climate and soil conditions, and the aging process all contribute to the quality of the wine. The skill and experience of the winemaker are also important factors. A skilled winemaker can create a wine that is balanced and complex.In conclusion, making exquisite wine is a complex process that requires skill, patience, and attention to detail. The quality of the wine is determined by several factors, including the type of grape used, the climate and soil conditions, and the aging process. A skilled winemaker can create a wine that is both delicious and unique.。

红酒酿造过程英语作文Title: The Process of Wine Making。

Wine making, also known as vinification, is a fascinating process that involves a series of carefully orchestrated steps to transform grapes into the delightful beverage we all know and love. From grape harvesting to bottling, each stage plays a crucial role in shaping the final product. Let's delve into the intricate process of wine making.1. Grape Harvesting: The journey of wine making begins with the careful selection and harvesting of grapes. Grapes are typically harvested by hand to ensure that only the ripest and highest quality fruit is chosen. This process often occurs in the early hours of the morning to take advantage of cooler temperatures and preserve the grapes' freshness.2. Sorting and Crushing: Once harvested, the grapesundergo a meticulous sorting process to remove any unwanted debris or underripe grapes. After sorting, the grapes are gently crushed to release their juices. Traditionally, this was done by foot stomping, but modern wineries use mechanical presses to crush the grapes efficiently while minimizing damage to the skins.3. Fermentation: The crushed grapes, now known as "must," are transferred to fermentation vessels. During fermentation, yeast converts the sugars in the grape juice into alcohol and carbon dioxide. This process can take anywhere from several days to several weeks, depending on various factors such as grape variety, temperature, and desired wine style.4. Pressing: Once fermentation is complete, the wine undergoes pressing to separate the liquid from the solid grape skins, seeds, and stems. The resulting liquid is known as "free-run wine," which is often of higher quality and is kept separate from the pressed wine.5. Aging: After pressing, the wine is transferred tobarrels or tanks for aging. Aging allows the wine todevelop complex flavors and aromas as it interacts with oxygen and compounds present in the wood or container. The duration of aging varies depending on the type of winebeing produced and the winemaker's preferences.6. Blending (optional): In some cases, winemakers may choose to blend wines from different batches or grape varieties to achieve the desired flavor profile. Blending requires skill and precision to balance acidity, tannins, and other characteristics to create a harmonious final product.7. Filtration and Clarification: Before bottling, the wine may undergo filtration to remove any remaining solidsor impurities and clarification to improve its visual clarity. This step helps ensure that the wine is stable and free from any unwanted sediment.8. Bottling: The final stage of the wine making process involves bottling the wine for distribution and consumption. Bottles are typically filled, corked, labeled, and packagedwith care to maintain the wine's quality and integrity.In conclusion, wine making is a labor-intensive yet rewarding process that requires skill, patience, and attention to detail. From grape to glass, each step contributes to the creation of a unique and distinctive wine that reflects the terroir and craftsmanship of the winemaker. Cheers to the art and science of wine making!。

Chapter6CProteinsElizabeth Joy Waters and Christopher Bruce ColbyContents6C.1Introduction (213)6C.2The Origin of Wine Proteins (214)6C.3Characterization of Wine Proteins (215)6C.3.1Size (215)6C.3.2Isoelectric Point (215)6C.3.3Stability (215)6C.3.4Levels in White Wines (216)6C.4Effect of Growing and Harvesting Conditions on Subsequent Wine Protein Levels (216)6C.4.1Fungal Infection (217)6C.4.2Water Stress (218)6C.4.3Mechanical Harvesting (218)6C.5Haze Formation in Wine (219)6C.6Bentonite Fining (220)6C.6.1The Sensory Impact of Bentonite Fining (222)6C.7Improving Bentonite Efficiency (223)6C.7.1Predictive Assays for Heat Stability (223)6C.7.2Selecting an Appropriate Bentonite Type (224)6C.7.3In-Line Dosing of Bentonite (224)6C.8Summary (225)References (226)6C.1IntroductionGrape and wine proteins have been of interest to winemakers for many years.This interest is primarily due to the ability of these proteins to aggregate together in finished white wines and form unattractive hazes and sediments.Proteins are signif-icant in wine because they are a nuisance!Endogenous wine proteins,of course,also have other roles in wine and have been examined for their impact on the aroma andE.J.Waters(B)The Australian Wine Research Institute,PO Box197,Glen Osmond,SA5064,Australiae-mail:Elizabeth.Waters@.au213 M.V.Moreno-Arribas,M.C.Polo(eds.),Wine Chemistry and Biochemistry,DOI10.1007/978-0-387-74118-59,C⃝Springer Science+Business Media,LLC2009214 E.J.Waters and C.B.Colby taste of wines(Jones et al.2008;Peng et al.1997),on bubble persistence and bead in sparkling wines(Girbau-Sola et al.2002;Liger-Belair2005;Senee et al.1999), on lacquer-like bottle deposit in red wines(Peng et al.1996a,b;Waters et al.1994) and as allergens in rare cases of grape and wine allergy(Pastorello et al.2003; Sbornik et al.2007;Schad et al.2005;Vassilopoulou et al.2007).This chapter will focus on the role of endogenous wine proteins in white wine haze formation.It will not cover the other roles of protein listed above nor will it describe the roles and consequences of food proteins such as casein,egg white and isinglass,used in wine processing.Published scientific studies of these proteins and of protein haze in wine began in earnest in the late1950s and early1960s with work by J.Koch in Geisenheim (Koch and Sajak1959),H.W Berg,at the University of California,Davis(Bayly and Berg1967;Berg and Akiyoshi1961;Moretti and Berg1965)and B.Rankine at the Australian Wine Research Institute in Adelaide(Rankine1962).6C.2The Origin of Wine ProteinsWhere do the proteins come from that subsequently form hazes and deposits in wine?Are they grape derived or do they come from the yeast?This is question that has occupied researchers since the1950s.Bayly and Berg(1967)fermented a model juice solution and noted that protein levels contributed by the yeast were very low and probably negligible in most cases.Twenty years later,Hsu and Heather-bell(1987a)concluded the same using polyacrylamide gel electrophoresis.More recently,Ferreira et al.(2000)and Dambrouck et al.(2003)used modern immuno-logical techniques to confirm that wine proteins originate predominantly from the grape.A contrasting possibility was raised by Yokotsuka et al.(1991),who anal-ysed the protein profile of Vitis vinifera cv.Koshu grapes as well as the resulting wine made from the same grapes.In conflict with other authors,they found eight wine protein fractions not present in the juice and suggested they had come from yeast.Kwon(2004)demonstrated that there are multiple biological sources of wine proteins using nano-high-performance liquid chromatography/tandem mass spec-trometry,although the relative levels of proteins from microbiological sources was not established by this methodology.Waters et al.(1991,1992)described two major wine protein fractions in V. vinifera cv.Muscat Gordo Blanc wine.By SDS PAGE,these proteins had molec-ular masses of24and32kDa.By analysing the amino acid sequence of the pro-teins,Waters et al.(1996)showed that these24-kDa and32-kDa proteins shared homology with thaumatin and chitinases respectively and were highly similar to other plant pathogenesis-related(PR)proteins.Tattersall et al.(1997)further char-acterised the24-kDa protein,Vitis vinifera thaumatin-like protein1(VvTL1).This protein is highly expressed in conjunction with the onset of sugar accumulation and softening in the grape berry.It has also been observed that there is relatively high expression after v´e raison of chitinase encoding genes in V.vinifera cv.Shiraz grape berries(Robinson et al.1997).6C Proteins215 6C.3Characterization of Wine Proteins6C.3.1SizeIn the1960s,electrophoresis enabled separation of different sized wine proteins, with researchers at UC Davis(Bayly and Berg1967;Moretti and Berg1965),finding four different protein bands,varying in concentration within and among wines from different cultivars of V.vinifera.These researchers were thefirst to raise the possibility that certain protein fractions,rather than total protein,might be responsible for protein instability.Somers and Ziemelis(1973)used gelfiltration chromatography to separate wine proteins from other constituents and,by using the exclusion limit of their gel,concluded that the wine protein size was between10and 50kDa.Hsu and Heatherbell(1987a)discovered many different protein fractions with a range of11.2–65kDa.In a subsequent study(Hsu and Heatherbell1987b), it was suggested that low molecular weight proteins(20–30kDa)were important to heat instability of wines,rather than those with high molecular weights.This was later confirmed(Waters et al.1992).In an electrospray mass spectrometry study of the proteins in the juice of19cultivars of Vitis vinifera(Hayasaka et al.2001), a range of masses(13–33kDa)was observed.The proteins were identified as mainly thaumatin-like proteins(range of21,239–21,272Da)and chitinases(range of25,330–25,631Da).Small variations in the masses of these protein due to small variation in their polypeptide sequence form the basis of a robust method of varietal identification based on mass spectrometry(Hayasaka et al.2001).6C.3.2Isoelectric PointResearch into the isoelectric point of wine proteins has often been concurrent with studies of wine protein size.Proteins with low isoelectric points(pI)were found to be significant contributors to total wine protein(Moretti and Berg1965)and to wine haze(Bayly and Berg1967).Hsu and Heatherbell(1987a)confirmed this observation and suggested that the majority of wine proteins had a pI of4.1–5.8, whilst Lee(1986)suggested the major protein fractions of wine had a pI of4.8–5.7. Dawes et al.(1994)fractionated wine proteins on the basis of their pI and found that thefive different fractions all produced haze after heat treatment.Haze particle formation was found to differ between the fractions however,leading to a statement that other wine components,such as phenolic compounds,need to be considered to understand fully protein haze.6C.3.3StabilityThe unusual aspect of wine protein instability is that the proteins responsible for protein haze in the long term are,paradoxically,very stable themselves in the216 E.J.Waters and C.B.Colby short term and survive the vinification process.It is,therefore,not surprising that wine proteins are resistant to low pH and enzymatic or non-enzymatic proteoly-sis(Waters et al.1992).The mechanism for the resistance has not yet been fully elucidated,but resistance to low pH and proteolysis are characteristic of plant pathogenesis-related proteins in general.Experimental evidence suggests that it is also characteristic of the grape pathogenesis-related proteins involved,rather than phenolic association or glycosylation(Waters et al.1995b).Limited prote-olytic processing of the wine proteins can,however,occur during white table wine vinification(Waters et al.1998)and during the Champagne winemaking process (Manteau et al.2003).These data indicate that there could be scope to exploit this susceptibility to proteolysis under certain conditions and thus prevent wine protein haze.6C.3.4Levels in White WinesProtein levels in white wine have been reported by several authors and have been shown to differ by variety.Lee(1986)reported a range of protein concentration from18to81mg/L in14wines from different Australian regions and made from different varieties.Some of these wines appeared to have beenfined with bentonite prior to analysis.Pocock et al.(1998)reported concentrations in unfined Australian wines up to several hundred mg/L.Hsu and Heatherbell(1987b)found a range of 19–44mg/L in four different unfined white wines from Oregon,while a very large variation(20—260mg/L)was noted by Bayly and Berg(1967).6C.4Effect of Growing and Harvesting Conditionson Subsequent Wine Protein LevelsIn grapevines,the synthesis of the PR proteins is regulated in a developmental and tissue specific manner.In Vitis vinifera cv.Muscat Gordo Blanco berries,both the expression of the VvTL1gene,and the levels of the corresponding major thaumatin-like protein increased dramatically after the onset of berry softening(v´e raison) and continued throughout berry ripening(Tattersall et al.1997).Similar develop-mental patterns were also found in the expression of genes encoding chitinases, some identical to those involved in wine protein haze(Derckel et al.1996,1998; Robinson et al.1997).An immunological study of bruscana cv.Concord also showed that thaumatin-like proteins and chitinases accumulate during berry ripening (Salzman et al.1998).In all cultivars of V.vinifera studied so far,thaumatin-like proteins and chiti-nases are the major soluble components of grapes(Peng et al.1997;Pocock et al. 1998,2000;Tattersall et al.1997).The predominance of these PR proteins was clear at all stages of berry development following v´e raison(Pocock et al.2000).Impor-tantly,as the concentration of these proteins in the berries continually increases6C Proteins217 during ripening,it can be presumed that the haze forming potential increases as ripening proceeds(Murphey et al.1989;Pocock et al.2000;Tattersall et al.1997).6C.4.1Fungal InfectionWhile PR protein synthesis in healthy grapes appears to be triggered by v´e raison, this does not mean that the classical PR protein inducers–stress,wounding and pathogenic attack–cannot further modulate the levels of PR proteins in grapes. Grape PR proteins exhibit antifungal activity in vitro against common fungal pathogens of grapevines,including Uncinula necator,Botrytis cinerea,Phomopsis viticola,Elsinoe ampelina and Trichoderma harzianum(Giannakis et al.1998; Jayasankar et al.2003;Monteiro et al.2003a;Salzman et al.1998;Tattersall et al. 2001).It would be tempting to speculate that the antifungal activity observed in vitro reflects the main function of the PR proteins in vivo,and that their expression in fruit after v´e raison represents a preemptive defense mechanism for fruit.Jayasankar et al. (2003)added further credence to this hypothesis by demonstrating that grapevines regenerated after in vitro selection with E.ampelina culturefiltrates had greater dis-ease resistance and high constitutive expression of PR proteins,including VvTL1. Studies in which the synthesis of PR proteins is modified by gene technology would allow us to investigate this hypothesis further.Increased expression of some PR genes and enhanced concentrations of some PR proteins have been observed in leaves and berries from grapevines infected with pathogens(B´e zier et al.2002;Derckel et al.1998;Jacobs et al.1999;Renault et al. 1996;Robert et al.2002).In glasshouse experiments,Monteiro et al.(2003b) observed increased levels of thaumatin-like proteins in berries infected with U. necator compared to uninfected berries.Jacobs et al.(1999)demonstrated that chitinase and beta-1,3-glucanase activity increased in grape berries and leaves in response to powdery mildew infection,and that expression of genes,VvChi3, VvGlub,and VvTL2,coding for PR proteins,was also strongly induced.Of these three putative gene products,only VvTL2has been detected as a soluble protein in grape juices and wines(Waters et al.1996).Girbau et al.(2004)demonstrated that powdery mildew infection of V.vinifera cv.Chardonnay grape bunches resulted in increased levels of a grape minor thaumatin like protein,VvTL2,in wine.At high levels of infection(>30%of berries in a bunch infected),this had a significant impact on the level of haziness in the wine following a heat test.Contrary to expectations that fungal diseases would lead to elevated levels of PR proteins in berries,Marchal et al.(1998)observed that juice from berries infected by B.cinerea showed reduced protein levels,and suggested that proteolytic enzymes from B.cinerea were responsible for this.Secretion of proteases by B. cinerea has been observed in culture media and on fruits such as apple(Zalewska-Sobczak et al.1981)and tomato(Brown and Adikaram1983).Girbau et al.(2004) also examined the impact of infection of grapes with B.cinerea in the vineyard and showed that infection resulted in marked decreases in the levels of PR proteins in218 E.J.Waters and C.B.Colby the berries.Similar although less dramatic trends of reductions in protein levels were seen in laboratory experiments in which otherwise healthy berries were inoculated with B.cinerea(Girbau et al.2004).Protein levels were also reduced in juice when B.cinerea was grown in this medium(Girbau et al.2004).The reduction in protein levels in the juice from Botrytis-infected grapes could, as suggested by Marchal et al.(1998),be due to proteolytic degradation of grape PR proteins by enzymes of B.cinerea,although there are other plausible explanations for these observations.If these effects are due to the activity of proteolytic enzymes from B.cinerea,these enzymes have the potential to replace bentonitefining for protein stabilization in oenology,a goal of many research efforts worldwide.6C.4.2Water StressThe effect of water stress on the expression of PR proteins in grapes has been exam-ined by analysing the PR protein content of V.vinifera cv.Shiraz berries from a replicated irrigation trial(Pocock et al.2000).The lack of irrigation gave clear physiological signs of vine water stress but did not lead to elevated levels of PR proteins in the berries.At afixed amount of protein per berry,however,the protein concentration in the juice from water stressed berries was higher than that from irrigated berries because berries from irrigated vines were larger and thus berry solutes were less concentrated.This effect of water stress on berry size is a general phenomenon(Smart and Coombe1983)and it is likely that anecdotal reports that haze problems are greater in drought years are due to changes in berry sizes in these years rather than a direct physiological response of the berries to water stress in the form of enhanced PR protein production.Studies of gene expression under carefully controlled experimental conditions involving water stress would add further support to this hypothesis.6C.4.3Mechanical HarvestingPaetzold et al.(1990)observed that mechanically harvested grapes produced must with increased protein content compared to that of hand harvested fruit pressed as whole bunches.They suggested that the lack of stems during crushing led to lower polyphenolic content in the must from mechanically harvested fruit com-pared to that from hand harvested fruit and therefore more protein was lost in complexes with phenolics from must from hand harvested fruit.Dubourdieu and Canal-Llaub`e res(1989)showed that wine made after maceration of destalked grapes for18h contained more protein than wine made after immediate pressing of whole bunches.Pocock and colleagues(Pocock and Waters1998;Pocock et al.1998) examined the impact of mechanical harvesting alone,not destemming,on the PR proteins in grapes and wine.Mechanical harvesting,with its associated prolonged transport of the fruit,resulted in higher PR protein levels in the juice and wine. Indeed mechanical harvesting of white grapes and subsequent transport was found6C Proteins219 to double the amount of bentonite required for prevention of protein haze when compared to fruit harvested by hand and transported from the same vineyard before destemming and crushing(Pocock and Waters1998).This does not appear to be a result of increased protein synthesis in response to wounding as comparisons among hand harvested berries,mechanically harvested intact berries and the predominant form of mechanically harvested fruit:a mixture of broken fruit and juice,indicated little if any protein was produced as a result of stress caused by mechanical har-vesting.Increases in protein content of juice from mechanically harvested fruit thus appear to be due to extraction or release of protein from or associated with pulp and skins rather than a physiological wounding response by the berry.6C.5Haze Formation in WineThe mechanism of protein haze formation in wines is not fully understood.Slow denaturation of wine proteins is thought to lead to protein aggregation,flocculation into a hazy suspension and,finally,formation of visual precipitates.The importance of non-proteinaceous factors in white wine protein haze formation such as proan-thocyanidins(Koch and Sajak1959;Waters et al.1995a;Yokotsuka et al.1991) have been suspected for some time.Other factors such as polysaccharides,alcohol levels and pH have also been implicated(Mesquita et al.2001;Siebert et al.1996a). It has been observed that grape protein added to model wine does not precipitate or produce haze when heated,whereas visually obvious hazes occur when the same protein is added to a commercial wine(Pocock2006).The current theory of the mechanism of haze formation formulated by Pocock (2006)is as follows.Individual grape PR proteins probably exist as separate glob-ular entities freely soluble in wine,tightly coiled and containing between six and eight disulfide bridges.Thefirst step in the process of haze formation is to uncoil these proteins,or to denature them.This is accelerated by heating.The second step involves aggregation of the denatured proteins as haze particles.The size and amount of protein haze formed in a wine is strongly influenced by other wine components.Pocock(2006)has demonstrated that one wine component, the sulfate anion,previously referred to as factor X,is essential for haze formation. If the sulfate anion is not present,heating does not result in sufficient denaturation of the proteins to lead to their aggregation,thus a haze will not form.Sulfate is one of the Hofmeister series of anions,a ranking of the ability of vari-ous ions to precipitate proteins(Kunz et al.2004).In simple terms,precipitation of proteins by kosmotropic anions occurs due to‘salting out’–a competition between the anion and the protein for water of solvation resulting in a loss of water from the protein surface.This process is classically applied in ammonium sulfate pre-cipitation as thefirst step in many protein purification schemes,although the levels employed are several fold higher than those in wine.In the particular case of white wine,this loss of water of solvation,even by a relatively low amount of sulfate anion,by a protein in a solution containing a variety of cations and other anions and220 E.J.Waters and C.B.Colby between9vol.%and13vol.%ethanol may be enough to affect the tertiary structure and/or aggregation of proteins.Whilst sulfate appears to be fundamental to haze formation,other wine compo-nents such as phenolic compounds remain as candidate haze modulators.One pos-sibility is that white wine phenolic compounds affect the particle size of denatured aggregated proteins,possibly through crosslinking.Several researchers(Oh et al. 1980;Siebert et al.1996b)have suggested a hydrophobic mechanism for the inter-action between phenolic compounds and proteins,in which the protein has afixed number of phenolic binding sites.More of these sites are exposed when the protein is denatured.Protein haze in white wine thus differs in several aspects from protein haze in beer.It is well established that beer protein haze is due to interactions between proteins,derived from the barley storage protein hordein and rich in proline,and hop polyphenolic compounds(Bamforth1999;Miedl et al.2005;Siebert1999; Siebert and Lynn2003).White wine proteins are not derived from storage proteins of grape seed nor are they as rich in proline as hordein.In addition,wine protein haze formation cannot be eliminated by removing polyphenolic compounds by PVPP (Pocock et al.2006)while in beer this has been applied as a commercial strategy (Leiper et al.2005;Madigan et al.2000).6C.6Bentonite FiningThe major winemaking process to affect the levels of proteins in wine is bentonite fining.Bentonite,a montmorillonite clay,is used almost universally throughout the wine industry for the prevention of wine protein haze through removal of proteins before bottling(Blade and Boulton1988;Ferreira et al.2002;Høj et al.2000). The adsorption of wine proteins onto bentonite is principally attributed to cationic exchange with the bentonite clay.Wine proteins are positively charged at wine pH, and thus can be exchanged onto bentonite,which carries a net negative charge (Blade and Boulton1988;Ferreira et al.2002;Høj et al.2000).A number of studies have indicated that different protein fractions require dis-tinct bentonite concentrations for protein removal and consequent heat stabilisation (Duncan1992;Ferreira et al.2002).Bentonitefining has been shown to remove higher pI(5.8–8.0)and intermediate molecular weight(MW;32–45kDa)proteins first(Hsu and Heatherbell1987b).However,these represent only a small portion of the soluble proteins.Proteins with a MW of60–65kDa,and with wide pI range(4.1–8.0)were highly resistant to removal by bentonitefining(i.e.required significant bentonite addition)and typically remained in protein-stabilised wine (Hsu and Heatherbell1987b).Hsu and Heatherbell(1987b)concluded that it is nec-essary to remove lower pI(4.1–5.8),lower MW(12.6kDa and20–30kDa)proteins, which represent a major component of proteins present,to protein stabilise wines. Contrary to thesefindings,a study by Dawes et al.(1994)found that there was no bentonite selectivity based on isoelectric point,and that bentonitefining resulted in the removal of all the different protein fractions.Further,the amount of protein6C Proteins221 depletion(across all protein fractions)observed in this study corresponded linearly with the level of bentonite addition(percentage reduction in protein concentration per g/L of bentonite added ranged from70%to89%).These different conclusions in the published literature might be attributed in part to the different methods used to fractionate proteins and assess their levels.Several authors have investigated the extent of adsorption of standard and model proteins by bentonite.Gougeon et al.(2002,2003)studied the absorption of two homopolypeptide preparations with average MW around20kDa onto a synthetic bentonite.Their data suggested that these polypeptides tended to unfold and take on a more random coil structure upon ing a range of physical measures, Gougeon et al.(2002,2003)also hypothesized that the polypeptides were primarily absorbed near the edges of the bentonite sheets rather than within the interlayer spaces between the sheets.The adsorption of the standard protein,bovine serum albumin(BSA)by bentonite in model wine solutions was studied by Blade and Boulton(1988).Adsorption was shown to be independent of temperature,but varied slightly with protein content,pH and ethanol content.In another study(Achaeran-dio et al.2001),bentonite adsorption was evaluated with three proteins(BSA, ovalbumin,lysozyme)in a model wine solution.The effect of ethanol content and protein molecular weight on the adsorption capacity of bentonite was also studied. Adsorption capacity tended to increase with increasing ethanol concentrations with regard to adsorption of BSA and lysozyme,however,no change was observed for ovalbumin.Blade and Boulton(1988)showed that maximal absorption was reached rapidly,and complete within30s of the addition.This is consistent with an earlier study(Lee1986),in which Gew¨u rztraminer winefined with bentonite was rendered stable one minute after bentonite addition and with later studies of in-line dosing described below(Muhlack et al.2006;Nordestgaard et al.2006).In comparison, bentonitefining in a winery setting typically takes one to two weeks,depending on the tank size and rate of bentonite addition used.Bentonite regeneration refers to the desorption of adsorbed wine protein from the bentonite surface,and would permit bentonite to be reused.However,a commercial process for bentonite regeneration does not currently exist,and thus bentonite is only used once before being discarded.An early study(Armstrong and Chesters1964) investigated the effect of pH on the desorption of pepsin from bentonite.In this study,62.8%of the pepsin(pI2.8),which had been adsorbed onto the bentonite at pH3.0,was desorbed by raising the pH to5.2using sodium hydroxide.In a more recent study(Churchman1999),the batch treatment of bentonite-protein complexes with a range of bases at a variety of different concentrations,durations and agita-tion methods was examined.The greatest degree of desorption was achieved with sodium carbonate at a low solid:solution ratio and with agitation.Similar results were obtained with sodium hydroxide at pH12and13(protein released per gram of bentonite=52and65mg/g respectively).However,from the study it was concluded that the use of alkaline pH and salts was ineffective for substantial removal of pro-tein from bentonites.Instead,the study suggested protein degradation followed by a treatment to displace the products of protein breakdown from the bentonite was required.For example,a batchwise treatment that employed hydrogen peroxide,222 E.J.Waters and C.B.Colby sodium carbonate and photo-oxidation with UV radiation was found to be effective in removing residual protein from bentonite.As discussed by Waters et al.(2005),in both these studies,protein was desorbed from bentonite by increasing the pH,but only in a batch system.As adsorption and desorption are equilibrium processes,it is hardly surprising that residual pro-tein was retained on the bentonite surface.In contrast,in a continuousflow sys-tem,fresh reactant could be continually fed to the adsorption system,while ion exchange products could be continually transported away from the system,driving the exchange process to completion.Continuousflow contactors,such as continuous stirred tanks,packed bed columns andfluidised beds,are commonplace in many chemical industries,as is continuous catalyst regeneration(Fogler1992).There-fore,it was postulated that effective regeneration of bentonite might be achieved by treatment with a base such as sodium hydroxide in a simple continuousflow system (Waters et al.2005).However,the difficulty in regenerating bentonite by salts and alkalis could also suggest that protein adsorption on bentonite may involve other mechanisms than solely cation exchange;thus complete regeneration of bentonite by such a process may not be feasible.6C.6.1The Sensory Impact of Bentonite FiningOne of the perceived disadvantages of bentonitefining is that it is thought to reduce flavor and aroma of wines.This perception is not supported by strong evidence in the normal operational range of bentonite additions by winemakers.Sensory evalu-ation of wines treated with bentonite showed no significant differences between the control and thefined samples(Leske et al.1995).Similarly,using difference testing, Pocock et al.(2003)reported that bentonitefining of a Chardonnay and Semillon wine had no effect on wine aroma and palate.This contrasts with previousfindings (Miller et al.1985)that demonstrated reduced concentration of aroma compounds after bentonite addition to juice,must or wine.More recently Pollnitz et al.(2003) elegantly confirmed that aroma compounds can be absorbed by bentonite,as did Cabaroglu et al.2003,although the later study found no sensory effect of bentonite fining of V.vinifera cv.Muscat Ottonel or Gewurztraminer wine.Rankine(1989) stated that bentonitefining results in the loss of aroma andflavor and Mart´ınez-Rodriguez and Polo(2003)extended this conclusion to sparkling wines when ben-tonite is added to the tirage solution.This has led to the widespread conclusion, throughout both literature and industry,that bentonitefining at typical addition rates has a detrimental effect on wine aroma andflavor,despite the fact that the conclu-sions of Miller et al.(1985)were influenced by many factors and“should not be considered general”(Miller et al.1985).Similarly,Leske et al.(1995)concluded that“lack of significant differences observed in this trial suggests that the negative effect offining may not be evident to a consumer in a commercial situation”and “the magnitude of any such[negative sensory]effect will presumably depend on the individual wine,the bentonite chosen,and the rate of addition chosen”.。

酿酒高中作文英语Brewing Wine。

Wine has a long history, and it has become an important part of people's lives. As a high school student, I am interested in the process of brewing wine. Wine brewing is a complex and fascinating process that involves a combination of art and science.The first step in brewing wine is selecting the right grapes. Grapes are the most important ingredient in wine, and the quality of the grapes will determine the quality of the wine. Different types of grapes will produce different types of wine, so winemakers must carefully consider which grapes to use for their wine.Once the grapes have been selected, they are crushed to release their juice. This juice is then fermented with the help of yeast, which converts the sugars in the grape juice into alcohol. The fermentation process can take anywherefrom a few days to a few weeks, depending on the type of wine being made.After the fermentation process is complete, the wine is aged in barrels or tanks. This aging process allows the flavors and aromas of the wine to develop and mature. Some wines are aged for just a few months, while others are aged for several years.Finally, the wine is bottled and labeled. The bottling process is a crucial step in wine brewing, as it determines the quality and presentation of the wine. The bottles are sealed with corks or screw caps, and then they are ready to be enjoyed.In addition to the basic steps of wine brewing, there are many other factors that can affect the quality of the wine. For example, the climate and soil in which the grapes are grown can have a significant impact on the flavor of the wine. The skill and expertise of the winemaker are also important, as they must carefully monitor and control the fermentation and aging processes to ensure that the wineturns out just right.As a high school student, I am fascinated by the art and science of wine brewing. I hope to learn more about this ancient craft and perhaps even try my hand at brewing my own wine someday. I believe that understanding the process of wine brewing will not only give me a greater appreciation for this timeless beverage, but also teach me valuable lessons about patience, perseverance, and the importance of attention to detail.。

葡萄酒的制作过程英文作文1. Crushing the grapes: The first step in making wineis crushing the grapes. This is usually done by either hand or by using a machine. The grapes are crushed to release their juices, which will eventually become the wine.2. Fermentation: After the grapes are crushed, thejuice is left to ferment. Fermentation is a natural process where yeast converts the sugars in the grape juice into alcohol. This process can take anywhere from a few days to several weeks, depending on the type of wine being made.3. Aging: Once fermentation is complete, the wine is aged in barrels or tanks. This allows the flavors and aromas to develop and mellow over time. Some wines are aged for just a few months, while others may be aged for several years.4. Clarification: After aging, the wine is clarified to remove any solids or impurities. This is done by eitherfiltering the wine or by allowing it to settle and then carefully siphoning off the clear liquid.5. Bottling: Once the wine has been clarified, it is ready to be bottled. The wine is carefully transferred from the aging barrels or tanks into individual bottles. The bottles are then sealed with a cork or screw cap to keep the wine fresh.6. Labeling: After the wine is bottled, it is labeled with information such as the type of wine, the vintage, and the producer. The labels are often designed to be visually appealing and informative, helping consumers make choices about which wines to purchase.7. Distribution: Once the wine is labeled, it is ready to be distributed and sold. This can be done through various channels, such as wine shops, restaurants, or online retailers. Wineries may also choose to export their wines to other countries, expanding their customer base.8. Enjoyment: Finally, the wine is ready to be enjoyed!Whether it's a glass with dinner, a celebration with friends, or a special occasion, wine is meant to be savored and appreciated. Cheers!。