集成电路引线框架冲压生产技术

- 格式:ppt

- 大小:9.65 MB

- 文档页数:53

一种高端制造业用引线框架铜带生产工艺

高端制造业用引线框架铜带生产工艺可以采用以下步骤:

1. 材料准备:选择高纯度的铜板作为原材料,并进行深度清洁处理,以确保材料表面无杂质。

2. 切割:将铜板按照设计要求切割成适当大小的方形或长方形铜片。

3. 冲压:使用冲压设备将铜片冲压成带有引线形状的构件。

冲压过程需要根据引线的设计要求来进行,确保构件的精度和质量。

4. 成型和折弯:利用成型和折弯设备对冲压成的铜片进行进一步成型和折弯,以形成引线框架的形状。

5. 清洁和抛光:对成型的引线框架进行清洁和抛光处理,以去除表面的氧化物和杂质,并使其表面光滑。

6. 检测和质量控制:对成品引线框架进行检测,包括外观检查、尺寸检测、引线间隙检测等,确保其质量符合设计要求。

7. 表面处理:根据实际需要,可以对引线框架进行表面处理,如镀金、镀锡等,提高其导电性和耐腐蚀性能。

8. 包装和出厂:将成品引线框架进行包装,并做好标识,以便于运输和销售。

以上是一种常见的高端制造业用引线框架铜带生产工艺,每个具体企业可以根据自身的要求和设备情况进行适当调整和优化。

冲压引线框架的制造工艺流程英文回答:The manufacturing process of stamping lead frames involves several steps to ensure the production of high-quality frames. Let me walk you through the process.1. Design and Engineering: The first step is to design the lead frame according to the specific requirements of the product. This involves creating a 2D or 3D model of the frame and determining the dimensions, material, and layout. Engineers use computer-aided design (CAD) software to create the design.2. Material Selection: Once the design is finalized, the next step is to select the appropriate material for the lead frame. Common materials used in lead frame manufacturing include copper alloys, such as phosphor bronze or brass. The material should have good electrical conductivity, thermal conductivity, and corrosionresistance.3. Material Preparation: The selected material is then prepared for the stamping process. This involves cutting the material into the desired size and shape, typically in the form of a strip or sheet. The material may undergo surface treatment, such as cleaning or coating, to improve its properties.4. Stamping: The prepared material is fed into a stamping press, where a die and a punch are used to shape the lead frame. The stamping process involves applying high pressure to the material, causing it to deform and take the shape of the die. The stamping press can be either mechanical or hydraulic, depending on the requirements of the project.5. Trimming and Forming: After the stamping process, the excess material is trimmed off, and the lead frame is formed into its final shape. Trimming is done using a cutting tool or a die, while forming may involve bending, folding, or curling the frame. These steps ensure that thelead frame has the desired dimensions and shape.6. Cleaning and Inspection: The stamped lead frames are then cleaned to remove any debris or contaminants. This is important to ensure the frames are free from defects and ready for further processing. After cleaning, the frames undergo a thorough inspection to check for any dimensional or visual defects. Automated inspection systems or manual inspection techniques may be used for this purpose.7. Surface Treatment: Depending on the application, the lead frames may undergo additional surface treatment processes, such as plating or coating. Plating can enhance the electrical conductivity and corrosion resistance of the frames, while coating can provide insulation or improve solderability.8. Packaging and Delivery: Once the lead frames pass the inspection and surface treatment, they are packaged and prepared for delivery to the customer. The packaging may vary depending on the size and quantity of the frames. Common packaging methods include trays, reels, or tubes.中文回答:冲压引线框架的制造工艺流程包括以下几个步骤,以确保生产出高质量的框架。

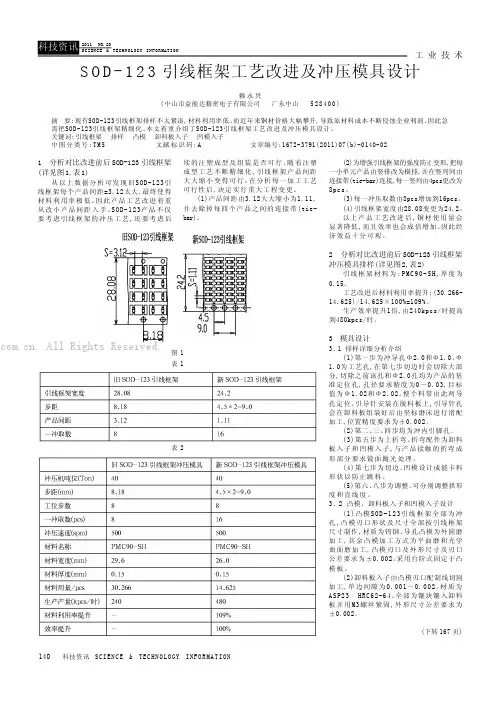

140科技资讯 SC I EN C E & TE C HN O LO G Y I NF O R MA T IO N工 业 技 术1 分析对比改进前后SOD-123引线框架(详见图1,表1)从以上数据分析可发现旧SOD-123引线框架每个产品间距=3.12太大,最终使得材料利用率极低。

因此产品工艺改进着重从改小产品间距入手。

SOD-123产品不仅要考虑引线框架的冲压工艺,还要考虑后续的注塑成型及组装是否可行。

随着注塑成型工艺不断精细化,引线框架产品间距大大缩小变得可行。

在分析每一加工工艺可行性后,决定实行重大工程变更。

(1)产品间距由3.12大大缩小为1.11,并去除掉每四个产品之间的连接带(tie-bar)。

S O D -123引线框架工艺改进及冲压模具设计赖永兴(中山市益能达精密电子有限公司 广东中山 528400)摘 要:现有SOD-123引线框架排样不太紧凑,材料利用率低。

而近年来铜材价格大幅攀升,导致原材料成本不断侵蚀企业利润。

因此急需把SOD-123引线框架精细化。

本文着重介绍了SOD-123引线框架工艺改进及冲压模具设计。

关键词:引线框架 排样 凸模 卸料板入子 凹模入子中图分类号:T M 5文献标识码:A 文章编号:1672-3791(2011)07(b)-0140-02(2)为增强引线框架的强度防止变形,把每一小单元产品由竖排改为横排,并在竖列间由连接带(tie-bar)连接,每一竖列由4pcs更改为8pcs。

(3)每一冲压取数由8pcs增加到16pcs。

(4)引线框架宽度由28.08变更为24.2。

以上产品工艺改进后,铜材使用量会显著降低,而且效率也会成倍增加。

因此经济效益十分可观。

2 分析对比改进前后SOD-123引线框架冲压模具排样(详见图2,表2)引线框架材料为:PM C 90-S H,厚度为0.15。

工艺改进后材料利用率提升:(30.266-14.625)/14.625×100%=109%。

引线框架及其生产工艺引线框架是电子元器件中重要的一部分,它主要的作用是将芯片与外部电路进行连接。

下面是关于引线框架及其生产工艺的详细介绍。

一、引线框架概述引线框架是电子元器件中的一种重要组件,主要用于将芯片与外部电路进行连接。

它通常由金属材料制成,具有精细的几何形状和尺寸,以确保其与芯片和外部电路的正确连接。

引线框架的设计和制造对于确保电子设备的性能和质量至关重要。

二、引线框架的生产工艺引线框架的生产工艺主要包括以下步骤:设计、材料选择、冲压成型、电镀、检测等。

1. 设计引线框架的设计是生产工艺的第一步。

设计师会根据客户的需求和要求,利用专业设计软件进行设计。

设计过程中需要考虑框架的几何形状、尺寸、材料、电镀层等因素,以确保其能够满足客户的需求。

2. 材料选择引线框架的材料选择是生产工艺中的重要环节。

常用的材料包括铜、铁、镍等金属材料,以及相应的合金材料。

选择材料时需要考虑其物理、化学和机械性能,以及成本等因素。

3. 冲压成型冲压成型是引线框架生产工艺中的重要环节。

通过冲压成型设备,将金属材料加工成所需的几何形状和尺寸。

冲压成型过程中需要注意模具的设计和加工精度,以及冲压参数的选择,以确保成品的精度和质量。

4. 电镀电镀是引线框架生产工艺中的另一个重要环节。

电镀的目的是在引线框架表面形成一层金属薄膜,以提高其导电性能和耐腐蚀性。

电镀过程中需要注意控制电镀液的成分和浓度,以及电镀时间和电流强度等因素,以确保成品的表面质量和性能。

5. 检测检测是引线框架生产工艺中的最后环节。

通过检测设备和方法,对引线框架的尺寸、表面质量、导电性能等进行检测,以确保其符合客户的要求和质量标准。

常见的检测方法包括外观检测、尺寸检测、性能测试等。

三、引线框架的应用和发展趋势引线框架作为电子元器件中的重要组件,被广泛应用于各类电子产品中,如集成电路、半导体芯片、传感器等。

随着科技的不断发展,引线框架的应用领域也在不断扩展,同时其生产工艺也在不断改进和完善。

冲压引线框架的制造工艺流程英文回答:The manufacturing process of stamping lead frame involves several steps to ensure the final product meets the required specifications.Firstly, the lead frame design is created using computer-aided design (CAD) software. This design includes the dimensions, shape, and layout of the lead frame. Once the design is finalized, a tool and die maker creates the necessary tools for the stamping process.Next, the lead frame material, usually a thin sheet of metal such as copper or alloy, is loaded into the stamping machine. The machine uses a die to cut and shape the material according to the design. This process is repeated multiple times to create multiple lead frames from a single sheet of material.After the stamping process is complete, the lead frames are inspected for any defects or imperfections. Any faulty lead frames are discarded, while the rest move on to the next step in the manufacturing process.The lead frames then undergo a cleaning process to remove any debris or residue from the stamping process. This ensures that the lead frames are free from contaminants that could affect their performance in the final product.Once cleaned, the lead frames may undergo additional processes such as plating or coating to improve their conductivity or resistance to corrosion. These processes help enhance the overall quality and durability of the lead frames.Finally, the lead frames are packaged and shipped to the customer for use in various electronic devices such as integrated circuits or semiconductor packages.Overall, the manufacturing process of stamping leadframe requires precision, attention to detail, and quality control to produce high-quality components for electronic devices.中文回答:冲压引线框架的制造工艺流程涉及几个步骤,以确保最终产品符合所需规格。

专利名称:一种SMA-400引线框架的冲压制作工艺专利类型:发明专利

发明人:戴永波

申请号:CN202111232922.1

申请日:20211022

公开号:CN113967692A

公开日:

20220125

专利内容由知识产权出版社提供

摘要:本发明属于冲压加工技术领域,尤其是一种SMA‑400引线框架的冲压制作工艺,包括引线框架上冲压麻点;引线框架上冲压V沟槽;切边、冲孔;产品上小圆孔;产品上方孔下料;产品外形下料;产品上方孔冲压;基岛折弯;基岛对面小边折弯;气缸定长下料;步距校正,保证能和塑封模具匹配;框架横弯调整,保证产品平整;定长切断产品。

本发明通过设置有冲压麻点、V勾槽和切边冲孔,冲压麻点的作用是消除引线框架材料的内应力,可以使产品平整,V沟槽的作用是防止镀锡流到引线上,可以起到阻断的作用,在每一道工序进级时,靠孔进行定位,切边用来起到粗定位的作用,切边消除引线框架的毛边可以使框架的宽度尺寸更加的精确,可以有效提高冲压精度。

申请人:吴江翔实模具有限公司

地址:215000 江苏省苏州市吴江区松陵镇八坼社区八坼金和路188号

国籍:CN

代理机构:苏州谨和知识产权代理事务所(特殊普通合伙)

代理人:唐静芳

更多信息请下载全文后查看。

冲压引线框架的制造工艺流程英文回答:The manufacturing process of stamping lead frames involves several steps. First, a design for the lead frame is created using computer-aided design (CAD) software. This design includes the dimensions, shape, and layout of the lead frame.Once the design is completed, the next step is to select the appropriate material for the lead frame. Common materials used for stamping lead frames include copper alloys, such as phosphor bronze or brass. The chosen material should have good electrical conductivity and mechanical properties.After selecting the material, the lead frame is manufactured through a series of processes. These processes typically include blanking, forming, and plating.In the blanking process, a sheet of the chosen material is cut into individual lead frame blanks. This is usually done using a stamping press, which applies a high force to the sheet to create the desired shape. The blanks are then separated from the surrounding material.Next, the formed blanks are shaped into the final lead frame design. This is achieved through a process called forming, which involves bending, folding, and/or stretching the metal. Forming can be done using various methods, such as progressive or transfer stamping.Once the lead frame is formed, it undergoes plating to enhance its performance and protect it from corrosion. Plating involves depositing a thin layer of metal, such as tin or gold, onto the surface of the lead frame. This layer improves the lead frame's conductivity and solderability.After plating, the lead frame may undergo additional processes, such as trimming and inspection. Trimming involves removing any excess material from the lead frame, while inspection ensures that the lead frame meets therequired specifications.Finally, the finished lead frames are packaged and prepared for shipment to customers. They can then be used in various electronic devices, such as integrated circuits or semiconductor packages.中文回答:冲压引线框架的制造工艺流程包括几个步骤。

冲压引线框架的制造工艺流程英文回答:The manufacturing process of a stamped lead frame involves several steps. First, the lead frame design is created, taking into consideration the specific requirements of the product it will be used for. This design includes the shape, size, and configuration of the lead frame.Next, a die is created based on the lead frame design. The die is a specialized tool that will be used to stamp the lead frame out of a metal sheet. The die contains the negative image of the lead frame design and is made from hardened steel.Once the die is ready, the metal sheet is fed into a stamping press. The stamping press applies pressure to the metal sheet, forcing it into the die and shaping it according to the lead frame design. The stamping process isrepeated multiple times to produce the desired quantity of lead frames.After stamping, the lead frames undergo a series of secondary operations. These operations may include trimming excess material, bending or forming the leads, and adding any necessary features or markings. These secondary operations are performed using various tools and equipment, depending on the specific requirements of the lead frame.Once the lead frames have been stamped and processed, they are inspected for quality and any defects are identified and corrected. This ensures that the lead frames meet the required specifications and will perform as intended.Finally, the finished lead frames are packaged and prepared for shipment to the customer. They may be packedin trays, reels, or other suitable containers, depending on the customer's requirements.Overall, the manufacturing process of a stamped leadframe involves designing, die creation, stamping, secondary operations, inspection, and packaging. Each step is crucial in ensuring the quality and functionality of the lead frames.中文回答:冲压引线框架的制造工艺流程包括多个步骤。

引线框架材料研发制造方案一、实施背景随着科技的迅速发展,电子产品日益普及,对高性能引线框架材料的需求持续增长。

传统引线框架材料在性能、成本和环保方面已无法满足现代电子产品的严苛要求。

因此,开展新型引线框架材料的研发和制造,对于满足市场和环境需求,推动电子产业升级具有重要意义。

二、工作原理引线框架材料是一种用于集成电路封装的关键基础材料,其作用是提供电信号传输路径,保护芯片免受外部机械和化学因素的影响。

新型引线框架材料的研发工作原理主要涉及以下几个方面:首先,通过成分设计,调整材料的化学组成;其次,利用先进的加工技术,如精密铸造、高精度冲压等,改变材料的微观结构;最后,通过热处理工艺,优化材料的性能。

三、实施计划步骤1.市场需求分析:对电子产品市场进行深入调研,了解用户需求和行业趋势。

2.材料选择与设计:根据市场需求,选择合适的材料成分,并进行微观结构设计。

3.加工工艺研究:研发先进的加工技术,确保材料制造的精确性和一致性。

4.性能测试与优化:通过实验测试,评估材料的各项性能指标,如导电率、耐腐蚀性、机械强度等,并进行持续优化。

5.中试生产:在确保工艺成熟和产品质量稳定后,进行中试生产,以验证大规模生产的可行性和经济效益。

6.市场推广与合作:与电子制造商合作,推广新型引线框架材料,并建立长期合作关系。

四、适用范围本方案适用于各类电子产品制造商,特别是需要高性能、低成本和环保型引线框架材料的电子产品制造商。

五、创新要点1.材料创新:通过成分设计和微观结构调整,提高材料的综合性能。

2.加工技术创新:研发新型加工技术,提高生产效率和质量。

3.环保设计:注重环保理念,采用绿色生产工艺和环保材料。

4.市场应用创新:根据市场需求,提供定制化产品和服务。

六、预期效果1.提高电子产品性能和可靠性。

2.降低生产成本和提高生产效率。

3.实现环保生产和可持续发展。

4.增强市场竞争力,拓展市场份额。

5.推动电子产业的技术创新和产业升级。