Research on the microstructural refinement of sulfur in medium carbon microalloyed steel

- 格式:pdf

- 大小:415.67 KB

- 文档页数:6

doi:10.3969/j.issn.l000484X.2020.24.021微小RNA对肿瘤微环境T细胞免疫调节作用研究的新进展杨秋玲刘朝奇①汪玉玲张丽轩李志英(三峡大学附属仁和医院妇产科,宜昌443000)中图分类号R730.3文献标志码A文章编号1000-484X(2020)24-3055-05[摘要]微小RNA(miRNA)是一类新近发现的小的、内源性的、进化上高度保守的单链非编码RNA,主要在基因表达的转录后水平起作用。

自第1个miRNA被发现以来,至今已发现并通过实验验证的与人类遗传信息相关的miRNAs超过500个,这些miRNAs涉及多种细胞的生理病理过程。

尤其是miRNAs对肿瘤微环境中T细胞介导的抗肿瘤免疫应答的调控作用,已成为近年来研究者们关注的焦点。

miRNAs的靶网络是庞大且复杂的,涉及多种信号分子和信号通路。

本文分别从调节/抑制T细胞、辅助T细胞及细胞毒性T细胞3个T细胞亚群综述了miRNAs对肿瘤微环境中T细胞的免疫调节作用。

[关键词]微小RNA;肿瘤;调节/抑制T细胞;辅助T细胞;细胞毒性T细胞New advances in study of immunomodulatory effects of microRNA on T cells in tumor microenvironmentYANG Qiu-Ling,LIU Zhao-Qi,WANG Yu-Ling,ZHANG Li-Xuan,LI Zhi-Ying.Department of Gynaecology and Obstetrics, Ren-he Hospital,Affiliated of China Three Gorges University,Yichang443000,China[Abstract]MicroRNA(miRNA)is a newly discovered small,endogenous,evolutionarily highly conserved single-strand noncoding RNA,which plays a key regulatory role at post-transcriptional level of gene expression.Since the first miRNA was discovered, more than500miRNAs related to human genetic information have been discovered and verified by experiments,and these miRNAs are involved in a variety of cellular physiological and pathological processes.In particular,regulatory effect of miRNAs on T cell mediated anti-tumor immune response in tumor microenvironment has become the focus of researchers in recent years.The target network of miRNAs is large and complex,involving a variety of signal molecules and signaling pathways.In this paper,the immunomodulatory effects of miRNAs on T cell in tumor microenvironment were reviewed from3T cell subsets including regulatory/suppressor T cell, helper T cell and cytotoxic T cell.[Key words]miRNA;Tumor;Regulatory/suppressor T cell;Helper T cell;Cytotoxic T cell根据GLOBOCAN数据库估计,2018年全球新增癌症病例约为1810万例,因癌症死亡人数约为960万[l]o众所周知,现今社会的医疗水平并不能对中晚期癌症患者有很好的治疗效果,并可能令癌细胞对放化疗药物产生耐药性。

114Univ. Chem. 2023, 38 (12), 114–119收稿:2023-06-27;录用:2023-08-01;网络发表:2023-08-11*通讯作者,Email:*****************.cn基金资助:2021年基础学科拔尖学生培养计划2.0研究课题(20211014);天津市首批虚拟教研室试点建设项目(化学类交叉人才培养课程建设虚拟教研室)•专题• doi: 10.3866/PKU.DXHX202306051 当表面活性剂遇到大环分子阮文娟,李悦,耿文超,郭东升*南开大学化学学院,天津 300071摘要:近年来,表面和胶体化学与大环化学的结合引起了科学家的普遍关注。

将多样的大环结构引入表面活性剂分子,不仅极大地丰富了表面活性剂分子的种类,还可以赋予其大环的主客体识别功能。

由此所开发出的大环两亲和超两亲分子已在生物成像和药物递送中表现出很高的应用潜力。

从传统表面活性剂到大环两亲和超两亲分子的发展、应用表明,不同领域的交叉融合对科学研究的发展是非常重要的。

关键词:表面活性剂;胶束;大环结构;大环两亲分子;超两亲分子中图分类号:G64;O6Encountering of Surfactants with Macrocyclic MoleculesWen-Juan Ruan, Yue Li, Wen-Chao Geng, Dong-Sheng Guo *College of Chemistry, Nankai University, Tianjin 300071, China.Abstract: In recent years, the combination of surface and colloid chemistry with macrocyclic chemistry has garnered widespread attention among scientists. The integration of diverse macrocyclic structures into surfactant molecules not only greatly enriches the diversity of surfactants, but also imparts them with the host-guest recognition functionality of macrocycles. Macrocyclic amphiphiles and supra-amphiphiles, developed from this approach, have demonstrated high potential in applications such as bioimaging and drug delivery. The evolution from traditional surfactants to macrocyclic amphiphiles and supra-amphiphiles underscores the importance of interdisciplinary integration in advancing scientific research.Key Words: Surfactants; Micelles; Macrocycles; Macrocyclic amphiphiles; Supra-amphiphiles表面活性剂及其所构筑的胶束是表面和胶体化学中所涉及的一类非常重要的体系。

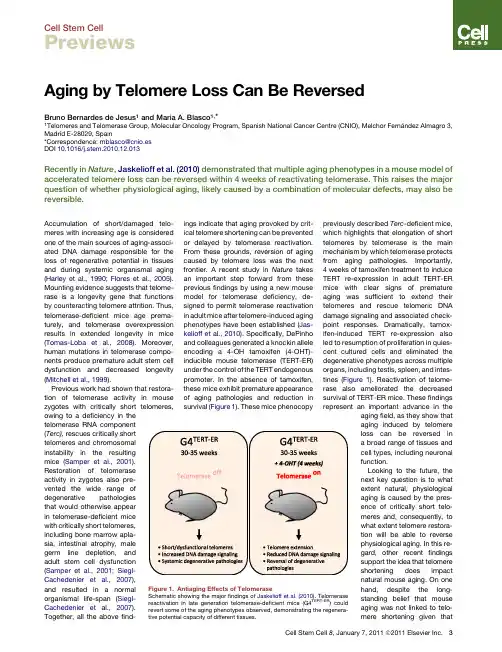

Aging by Telomere Loss Can Be ReversedBruno Bernardes de Jesus 1and Maria A.Blasco 1,*1Telomeresand Telomerase Group,Molecular Oncology Program,Spanish National Cancer Centre (CNIO),Melchor Ferna´ndez Almagro 3,Madrid E-28029,Spain*Correspondence:mblasco@cnio.es DOI 10.1016/j.stem.2010.12.013Recently in Nature ,Jaskelioff et al.(2010)demonstrated that multiple aging phenotypes in a mouse model of accelerated telomere loss can be reversed within 4weeks of reactivating telomerase.This raises the major question of whether physiological aging,likely caused by a combination of molecular defects,may also be reversible.Accumulation of short/damaged telo-meres with increasing age is considered one of the main sources of aging-associ-ated DNA damage responsible for the loss of regenerative potential in tissues and during systemic organismal aging (Harley et al.,1990;Flores et al.,2005).Mounting evidence suggests that telome-rase is a longevity gene that functions by counteracting telomere attrition.Thus,telomerase-deficient mice age prema-turely,and telomerase overexpression results in extended longevity in mice (Tomas-Loba et al.,2008).Moreover,human mutations in telomerase compo-nents produce premature adult stem cell dysfunction and decreased longevity (Mitchell et al.,1999).Previous work had shown that restora-tion of telomerase activity in mouse zygotes with critically short telomeres,owing to a deficiency in the telomerase RNA component (Terc),rescues critically short telomeres and chromosomal instability in the resulting mice (Samper et al.,2001).Restoration of telomerase activity in zygotes also pre-vented the wide range of degenerative pathologies that would otherwise appear in telomerase-deficient mice with critically short telomeres,including bone marrow apla-sia,intestinal atrophy,male germ line depletion,and adult stem cell dysfunction (Samper et al.,2001;Siegl-Cachedenier et al.,2007),and resulted in a normal organismal life-span (Siegl-Cachedenier et al.,2007).Together,all the above find-ings indicate that aging provoked by crit-ical telomere shortening can be prevented or delayed by telomerase reactivation.From these grounds,reversion of aging caused by telomere loss was the next frontier.A recent study in Nature takes an important step forward from these previous findings by using a new mouse model for telomerase deficiency,de-signed to permit telomerase reactivation in adult mice after telomere-induced aging phenotypes have been established (Jas-kelioff et al.,2010).Specifically,DePinho and colleagues generated a knockin allele encoding a 4-OH tamoxifen (4-OHT)-inducible mouse telomerase (TERT-ER)under the control of the TERT endogenous promoter.In the absence of tamoxifen,these mice exhibit premature appearance of aging pathologies and reduction in survival (Figure 1).These mice phenocopy previously described Terc -deficient mice,which highlights that elongation of short telomeres by telomerase is the main mechanism by which telomerase protects from aging pathologies.Importantly,4weeks of tamoxifen treatment to induce TERT re-expression in adult TERT-ER mice with clear signs of premature aging was sufficient to extend their telomeres and rescue telomeric DNA damage signaling and associated check-point responses.Dramatically,tamox-ifen-induced TERT re-expression also led to resumption of proliferation in quies-cent cultured cells and eliminated the degenerative phenotypes across multiple organs,including testis,spleen,and intes-tines (Figure 1).Reactivation of telome-rase also ameliorated the decreased survival of TERT-ER mice.These findings represent an important advance in the aging field,as they show that aging induced by telomere loss can be reversed in a broad range of tissues and cell types,including neuronal function.Looking to the future,the next key question is to whatextent natural,physiological aging is caused by the pres-ence of critically short telo-meres and,consequently,to what extent telomere restora-tion will be able to reverse physiological aging.In this re-gard,other recent findings support the idea that telomere shortening does impactnatural mouse aging.On onehand,despite the long-standing belief that mouseaging was not linked to telo-mere shortening giventhat Figure 1.Antiaging Effects of Telomerase Schematic showing the major findings of Jaskelioff et al.(2010).Telomerasereactivation in late generation telomerase-deficient mice (G4TERT-ER )couldrevert some of the aging phenotypes observed,demonstrating the regenera-tive potential capacity of different tissues.Cell Stem Cell 8,January 7,2011ª2011Elsevier Inc.3Cell Stem CellPreviewsmice are born with very long telomeres—much longer than human telomeres—mouse telomeres do suffer extensive shortening associated with aging(Flores et al.,2008).In particular,while mouse cells maintain relatively long telomeres during theirfirst year of life,there is a dramatic loss of telomeric sequences at2years of age,even in various stem cell populations, and this change is concomitant with the loss of regenerative capacity associated with mouse aging.In addition,telome-rase-deficient mice from thefirst genera-tion(G1TercÀ/À)exhibit a significant decrease in median and maximum longevity and a higher incidence of age-related pathologies and stem cell dysfunc-tion compared with wild-type mice(Flores et al.,2005;Garcia-Cao et al.,2006),indi-cating that,as in humans,telomerase activity is rate limiting for natural mouse longevity and aging.These results suggest that strategies aimed to increase telome-rase activity may delay natural mouse aging.Further supporting this notion,it was recently shown that overexpression of TERT in the context of mice engineered to be cancer resistant owe to increase expression of tumor suppressor genes(Sp53/Sp16/SARF/TgTERT mice)wassufficient to decrease telomere damagewith age,delay aging,and increase medianlongevity by40%(Tomas-Loba et al.,2008).However,it remains to be seenwhether telomerase reactivation late in lifewould be sufficient to delay natural mouseaging and extend mouse longevity withoutincreasing cancer incidence.In summary,these proof-of-principlestudies using genetically modified miceare likely to encourage the developmentof targeted therapeutic strategies basedon reactivation of telomerase function.Indeed,small molecule telomerase acti-vators have been reported recently andhave demonstrated some preliminaryhealth-span beneficial effects in humans(Harley et al.,2010).Identifying drugabletargets and candidate activators clearlyopens a new window for the treatment ofage-associated degenerative diseases.REFERENCESFlores,I.,Cayuela,M.L.,and Blasco,M.A.(2005).Science309,1253–1256.Flores,I.,Canela,A.,Vera,E.,Tejera,A.,Cotsare-lis,G.,and Blasco,M.A.(2008).Genes Dev.22,654–667.Garcia-Cao,I.,Garcia-Cao,M.,Tomas-Loba,A.,Martin-Caballero,J.,Flores,J.M.,Klatt,P.,Blasco,M.A.,and Serrano,M.(2006).EMBO Rep.7,546–552.Harley, C.B.,Futcher, A.B.,and Greider, C.W.(1990).Nature345,458–460.Harley, C.B.,Liu,W.,Blasco,M.,Vera, E.,Andrews,W.H.,Briggs,L.A.,and Raffaele,J.M.(2010).Rejuvenation Res.14,in press.Publishedonline September7,2010.10.1089/rej.2010.1085.Jaskelioff,M.,Muller,F.L.,Paik,J.H.,Thomas,E.,Jiang,S.,Adams,A.C.,Sahin,E.,Kost-Alimova,M.,Protopopov,A.,Cadinanos,J.,et al.(2010).Nature.10.1038/nature09603.Mitchell,J.R.,Wood,E.,and Collins,K.(1999).Nature402,551–555.Samper,E.,Flores,J.M.,and Blasco,M.A.(2001).EMBO Rep.2,800–807.Siegl-Cachedenier,I.,Flores,I.,Klatt,P.,andBlasco,M.A.(2007).J.Cell Biol.179,277–290.Tomas-Loba, A.,Flores,I.,Fernandez-Marcos,P.J.,Cayuela,M.L.,Maraver,A.,Tejera,A.,Borras,C.,Matheu,A.,Klatt,P.,Flores,J.M.,et al.(2008).Cell135,609–622.HGPS-Derived iPSCs For The AgesTom Misteli1,*1National Cancer Institute,NIH,Bethesda,MD20892,USA*Correspondence:mistelit@DOI10.1016/j.stem.2010.12.014In this issue of Cell Stem Cell,Zhang et al.(2011)generate patient-derived iPSCs for one of the major prema-ture aging diseases,Hutchinson-Gilford Progeria Syndrome(HGPS).These cells are a much-needed new tool to study HGPS,and their use may lead to novel insights into mechanisms of aging.Some problems in biology are more difficult to study than others.Human aging is certainly one of them.Most conclusions regarding molecular mecha-nism of human aging rely on mere correla-tion,and direct experimental testing is generally not feasible.One approach to dissect the molecular basis of human aging is to study naturally occurring premature aging disorders.One of the most dramatic and prominent of such diseases is Hutchinson-Gilford ProgeriaSyndrome(HGPS).Zhang et al.(2011)now report the generation of inducedpluripotent stem cells(iPSCs)fromHGPS cells,providing a powerful newtool to unravel the molecular and physio-logical mechanisms of premature andnormal aging.HGPS is a truly remarkable disease inmany ways.To start with,it affects anunusually wide spectrum of tissues andleads to the development of highly diversesymptoms ranging from depletion ofsubcutaneous fat to loss of hair andtendon contractures.The diversity ofaffected tissues pointed early on to stemcell defects as a likely disease mecha-nism.Most relevant in patients arevascular defects and recurring strokes,which invariably are fatal in patients intheir mid-to late teens(Hennekam,2006).The disease is exceedingly rare4Cell Stem Cell8,January7,2011ª2011Elsevier Inc.Cell Stem Cell Previews。

第15卷第7期孟宝,等:镁锂合金微型热管电场辅助超塑挤压成形19and Superplastic Forming of Negative Angle Box-ShapedParts[D]. Harbin: Harbin Institute of Technology, 2017:3-14.[5] 李淼泉, 吴诗. LY12CZ铝合金在强电场中的超塑性变形[J]. 塑性工程学报, 1996, 3(3): 41-46.LI Miao-quan, WU Shi. Superlastic Deformation of LY12CZ Aluminum Alloy under an Electric Field[J].Journal of Plasticity Engineering, 1996, 3(3): 41-46. [6] 蔡春波, 高少伟, 高桂丽, 等. 脉冲电流对Al-Cu-Mn-Zr合金时效处理组织及性能的影响[J]. 金属热处理,2023, 48(4): 104-110.CAI Chun-bo, GAO Shao-wei, GAO Gui-li, et al. Effectof Pulse Current on Microstructure and Properties of Al-Cu-Mn-Zr Alloy after Aging Treatment[J]. Heat Treatment of Metals, 2023, 48(4): 104-110.[7] WANG Yao-li, WANG Guang-xin, ZHANG Ke-ke. Elec-tro-Superplastic Solid State Welding of 40Cr/QCr0.5[J].Materials, 2018, 11(7): 1153.[8] WANG Guo-feng, LI Xiao, LIU Si-yu, et al. ImprovedSuperplasticity and Microstructural Evolution of Ti2AlNbAlloy Sheet during Electrically Assisted Superplastic GasBulging[J]. The International Journal of Advanced Manufacturing Technology, 2018, 99(1): 773-787.[9] YOSHIDA H, SASAKI Y. Low Temperature and HighStrain Rate Superplastic Flow in Structural Ceramics In-duced by Strong Electric-Field[J]. Scripta Materialia, 2018, 146: 173-177.[10] 林赟, 唐国翌, 孙强, 等. Inconel690合金的电致塑性拉拔研究[J]. 热加工工艺, 2010, 39(24): 80-82.LIN Yun, TANG Guo-yi, SUN Qiang, et al. Investigationof Electro-Plastic Drawing on Inconel690 Alloy[J]. HotWorking Technology, 2010, 39(24): 80-82.[11] 刘建龙, 王效岗, 王皓悦. 微挤压模具设计[J]. 模具技术, 2016(5): 26-29.LIU Jian-long, WANG Xiao-gang, WANG Hao-yue. TheDesign of Micro Extrusion Die[J]. Die and Mould Tech-nology, 2016(5): 26-29.[12] 李细锋, 曹旭东, 王斌, 等. 钛合金电辅助塑性成形技术研究进展[J]. 航空制造技术, 2021, 64(17): 22-30.LI Xi-feng, CAO Xu-dong, WANG Bin, et al. ResearchProgress on Electrically-Assisted Plastic Forming Techn-ology of Titanium Alloy[J]. Aeronautical ManufacturingTechnology, 2021, 64(17): 22-30.[13] 蔡贇, 孙朝阳, 万李, 等. AZ80镁合金动态再结晶软化行为研究[J]. 金属学报, 2016, 52(9): 1123-1132.CAI Yun, SUN Zhao-yang, WAN Li, et al. Study on Dy-namic Recrystallization Softening Behavior of AZ80 Magnesium Alloy[J]. Acta Metallurgica Sinica, 2016, 52(9): 1123-1132.[14] ZHANG Cun-sheng, WANG Cui-xue, ZHANG Qing-you,et al. Influence of Extrusion Parameters on Microstruc-ture, Texture, and Second-Phase Particles in an Al-Mg-SiAlloy[J]. Journal of Materials Processing Technology, 2019, 270: 323-334. [15] XU Jie, ZHU Xiao-cheng, SHAN De-bin, et al. Effect ofGrain Size and Specimen Dimensions on Micro-Formingof High Purity Aluminum[J]. Materials Science and En-gineering: A, 2015, 646: 207-217.[16] CHEN Liang, ZHAO Guo-qun, YU Jun-quan, et al.Analysis and Porthole Die Design for a Multi-Hole Ex-trusion Process of a Hollow, Thin-Walled Aluminum Pro-file[J]. The International Journal of Advanced Manufac-turing Technology, 2014, 74(1): 383-392.[17] DEMIRCI H İ, EVLEN H. Effect of Extrusion Ratio onthe Wear Behaviour of Al-Si and Al-Mg Alloys[J]. Jour-nal of Alloys and Compounds, 2012, 510(1): 26-32. [18] GUAN Yan-jin, ZHANG Cun-sheng, ZHAO Guo-qun, etal. Design of a Multihole Porthole Die for AluminumTube Extrusion[J]. Materials and Manufacturing Proc-esses, 2012, 27(2): 147-153.[19] YU Zi-jian, XU Chao, MENG Jian, et al. Effects of Ex-trusion Ratio and Temperature on the Mechanical Proper-ties and Microstructure of As-Extruded Mg-Gd- Y-(Nd/Zn)-Zr Alloys[J]. Materials Science and Engineer-ing: A, 2019, 762: 138080.[20] 尹传龙, 齐凯华, 翟军, 等. 难以挤压成型的铝型材断面形状的局部优化[J]. 铝加工, 2022(5): 25-28.YIN Chuan-long, QI Kai-hua, ZHAI Jun, et al. AluminumProfile does not Apply to Local Optimization of Extru-sion[J]. Aluminium Fabrication, 2022(5): 25-28.[21] 王少华, 刘惠, 陈宗强, 等. 大型带筋薄壁圆管铝型材挤压成形数值模拟[J]. 锻压技术, 2022, 47(4): 181-189.WANG Shao-hua, LIU Hui, CHEN Zong-qiang, et al.Numerical Simulation on Extrusion Forming for LargeRibbed Thin-Walled Circular Tube Aluminum Profile[J].Forging & Stamping Technology, 2022, 47(4): 181-189. [22] PARK S Y, KIM W J. Difference in the Hot CompressiveBehavior and Processing Maps between the As-Cast andHomogenized Al-Zn-Mg-Cu (7075) Alloys[J]. Journal ofMaterials Science & Technology, 2016, 32(7): 660-670. [23] LIN Y C, XIA Yu-chi, CHEN Xiao-min, et al. Constitu-tive Descriptions for Hot Compressed 2124-T851 Aluminum Alloy over a Wide Range of Temperature andStrain Rate[J]. Computational Materials Science, 2010,50(1): 227-233.[24] LIU Yong-da, XU Jie, ZHANG Zheng-wu, et al. Mi-cro-Extrusion Process and Microstructure Evolution ofMiniature Heat Pipe in 6063 Aluminum Alloy[J]. The In-ternational Journal of Advanced Manufacturing Technol-ogy, 2022, 120(9/10): 6463-6480.[25] SELLARS C M, MCTEGART W J. On the Mechanism ofHot Deformation[J]. Acta Metallurgica, 1966, 14(9): 1136-1138.[26] DONATI L, TOMESANI L. The Effect of Die Design onthe Production and Seam Weld Quality of Extruded Alu-minum Profiles[J]. Journal of Materials Processing Technology, 2005, 164/165: 1025-1031.责任编辑:蒋红晨精 密 成 形 工 程第15卷 第7期20 JOURNAL OF NETSHAPE FORMING ENGINEERING2023年7月收稿日期:2023–05–29 Received :2023-05-29基金项目:山东省重点研发项目(2021CXGC010206)Fund :Key R&D Project of Shandong Province(2021CXGC010206) 作者简介:王硕(1997—),男,硕士生,主要研究方向为超声微锻造辅助增材制造。

唐智鑫,钱怡霖,王荣荣,等. 随机质心映射优化法提升生防乳酸菌Lac9-3的粘附性及其对冷藏凡纳滨对虾(Litopenaeus vannamei )菌群结构的影响[J]. 食品工业科技,2023,44(12):130−137. doi: 10.13386/j.issn1002-0306.2022080170TANG Zhixin, QIAN Yilin, WANG Rongrong, et al. Random-Centroid Optimization (RCO) Method to Improve the Adhesion of Biocontrol Lactic Acid Bacteria (LAB) Lac 9-3 and Its Effect on the Microflora Structure of Refrigerated Litopenaeus vannamei [J].Science and Technology of Food Industry, 2023, 44(12): 130−137. (in Chinese with English abstract). doi: 10.13386/j.issn1002-0306.2022080170· 生物工程 ·随机质心映射优化法提升生防乳酸菌Lac 9-3的粘附性及其对冷藏凡纳滨对虾(Litopenaeus vannamei )菌群结构的影响唐智鑫,钱怡霖,王荣荣,李 苑,刘尊英*(中国海洋大学食品科学与工程学院,山东青岛 266003)摘 要:生防乳酸菌粘附是其在食品表面定植并发挥作用的第一步。

为进一步提升乳酸菌Lac 9-3在凡纳滨对虾表面的粘附性,探究其对冷藏凡纳滨对虾腐败菌生长的影响,本研究采用随机质心映射优化法(Random-Centroid Optimization ,RCO )优化了乳酸菌Lac 9-3的接种条件(包括接种液浓度、接种菌株生长阶段、浸泡时间与接种液pH )。

第44卷 第9期 包 装 工 程2023年5月PACKAGING ENGINEERING ·81·收稿日期:2023−03−15基金项目:国家自然科学基金(52071239) 作者简介:汪君(1997—)女,硕士生。

耐热线型小分子对有机硅耐温吸波涂层的增韧改性研究汪君a ,江源源a ,熊逾玲a ,王峰a ,马会茹b ,李维a ,雷丽文a ,陈志宏c(武汉理工大学 a.材料复合新技术国家重点实验室 b.化学化工与生命学院 c.理学院,武汉 430070) 摘要:目的 采用能与有机硅单体反应的耐热小分子对苯基硅树脂基吸波涂层进行增韧改性,调控有机硅树脂的交联网络结构,并将改性树脂与耐温吸波剂复合,制备具有高柔韧、高附着力和耐温的吸波涂层。

方法 将不同端基或链长的耐热增韧剂通过硅氢加成接枝到有机硅树脂基体,改变基体的交联网络结构,通过红外、扫描电镜、万能电子试验机、动态热机械分析仪和矢量网络分析仪测试其性能。

结果 随着乙烯基封端聚二甲基硅氧烷含量的增加,涂层的柔韧性提高,但耐温性能和附着力降低;当乙烯基封端聚二甲基硅氧烷质量分数为45%时,1 mm 涂层的柔韧性达20 mm ,附着力达7.73 MPa ,抗冲击性大于50 kg·cm 。

在300 ℃热处理15 h 后,改性涂层挠度从未改性时的1.08 mm 提升至1.35 mm ,涂层在高温工作后仍保持较好的柔韧性。

结论 采用耐热线型小分子对有机硅树脂交联网络结构进行改性,可有效地调控耐温吸波涂层的力学性能,为耐高温吸波涂层增韧及其工程应用提供参考。

关键词:吸波涂层;有机硅树脂;柔韧性;附着力;耐温中图分类号:TB484.2 文献标识码:A 文章编号:1001-3563(2023)09-0081-10 DOI :10.19554/ki.1001-3563.2023.09.010Toughening and Modification of Organic Silicone Heat-resistant Microwave AbsorbingCoatings with Heat-resistant Linear MoleculesWANG Jun a , JIANG Yuan-yuan a , XIONG Yu-ling a , WANG Feng a , MA Hui-ru b , LI Wei a ,LEI Li-wen a , CHEN Zhi-hong c(a. State Key Laboratory of Advanced Technology for Materials Synthesis and Processing b. School of Chemistry, Chemical Engineering and Life Sciences c. School of Science, Wuhan University of Technology, Wuhan 430070, China) ABSTRACT: The work aims to control the cross-linking network structure of silicone resin by toughening and modifying the phenyl silicone resin-based microwave absorbing coating with heat-resistant small molecules that can react with or-ganic silicone monomer, and compound the modified silicone resin with heat-resistant absorbent to develop heat-resistant microwave absorbing coatings with high flexibility, high adhesion and thermal stability. Toughening modifiers with dif-ferent end groups or chain length were grafted to silicone resin by hydrosilylation addition reaction to change the cros-slinking networks of the matrix. The properties of the coatings were tested by infrared spectrum, SEM, mechanical properties and dynamic mechanical thermal analyzer. With the increase in content of vinyl-terminated poly (dimethyl siloxanes), the flex-ibility of the coating was improved, whereas the heat-resistant and adhesion were reduced. When the content of vinyl-terminated poly (dimethyl siloxanes) increased to 45 wt. %, the flexibility of the 1 mm coating reached 20 mm, with adhesion as high as 7.73 MPa and impact resistance of higher than 50 kg∙cm. After working at 300 °C for 15 h, the flexibility of the coatingincreased from 1.08 mm for unmodified coating to 1.35 mm. Moreover, the modified coatings maintained good flexibility·82·包装工程2023年5月after heat treatment. Modifying the crosslinking networks of silicone resin with heat-resistant small molecules can effec-tively control the mechanical properties of heat-resistant microwave absorbing coatings and provide references for toughening and engineering applications of heat-resistant microwave absorbing coatings.KEY WORDS: microwave absorbing coatings; silicone resin; flexibility; adhesion; heat-resistant随着电子技术的扩展[1],微波探测技术在20世纪后期得到了快速发展[2]。

肿瘤坏死因子受体超级家族(tumor necrosis fac⁃tor receptor superfamily,TNFRSF)的死亡受体(death receptor)以及它们的配体在胚胎正常发育及机体免疫和炎症反应过程中扮演了重要角色。

外胚层发育不良受体(ectodysplasin A2receptor,EDA2R)是一个在20年前被鉴定出来的TNFRSF成员(TNFRSF27)[1],在肿瘤发生、雄激素性脱发等过程中起到重要的作用,但对于该受体作系统性介绍的综述文章尚未见报道。

本文就该受体的研究进展作一系统性的综述,旨在为相关研究提供新的思路。

1EDA2R的蛋白结构和配体1.1EDA2R的蛋白结构EDA2R基因位于人类染色体Xq12,全长约43kb,有6个外显子(GenBank登录号:NG_013271),外胚层发育不良受体EDA2R的研究进展蓝希钳1,2,肖海婷1,2,罗怀容1,2,陈建宁1,2(西南医科大学药学院:1衰老与再生医学实验室,2药理学教研室,四川泸州646000)【摘要】外胚层发育不良受体EDA2R(ectodysplasin A2receptor)是肿瘤坏死因子受体超级家族(tumor necrosis factor recep⁃tor superfamily,TNFRSF)中的一个较新的成员,在发育中的胚胎里有很高的表达,在成年人和动物的多个器官组织中也有表达。

与其它TNFRSF成员不同,尽管EDA2R蛋白在胞内没有死亡结构域(death domain,DD),但它仍可激活NF-κB和JNK通路,并介导细胞的凋亡。

本文广泛回顾了近年来与EDA2R有关的文献,就该蛋白分子的相关研究进展进行综述,以期为与该蛋白相关的分子功能或其介导的相关疾病的研究提供新的思路。

【关键词】EDA2R受体肿瘤坏死因子受体超级家族死亡结构域凋亡【中图分类号】R34文献标志码A doi:10.3969/j.issn.2096-3351.2021.03.018Research progress of ectodysplasin A2receptorLAN Xi-qian1,2,XIAO Hai-ting1,2,LUO Huai-rong1,2,CHEN Jian-ning1,2 1Key Laboratory for Aging and Regenerative Medicine;2Department of Pharmacology,School of Pharmac,South⁃west Medical University,Luzhou646000,Sichuan,China【Abstract】Ectodysplasin A2receptor(EDA2R)is a relatively new member of the tumor necrosis factor re⁃ceptor superfamily(TNFRSF),and it is highly expressed in developing embryos and is also expressed in multiple organs and tissues of adult human and animals.Different from other TNFRSF members,EDA2R protein does not contain the death domain in the intracellular region,but it can still activate the NF-κB and JNK pathways and medi⁃ate cell apoptosis.This article reviews related articles on EDA2R in recent years and related research advances in this protein,in order to provide new ideas for research on molecular functions associated with EDA2R or related dis⁃eases mediated by EDA2R.【Key words】Ectodysplasin A2receptor Tumor necrosis factor receptor superfamily Death domain Apoptosis基金项目:泸州市科技局-西南医科大学联合项目(2018LZXNYD-ZK12);西南医科大学-泸州市中医医院基地项目(2019-LH005)第一作者简介:蓝希钳,博士。

CHEMICAL INDUSTRY AND ENGINEERING PROGRESS 2017年第36卷第5期·1658·化 工 进展乙酸蒸汽催化重整制氢的研究进展王东旭1,肖显斌2,李文艳1(1华北电力大学能源动力与机械工程学院,北京 102206;2华北电力大学生物质发电成套设备国家工程实验室,北京 102206)摘要:通过生物油蒸汽重整制备氢气可以减少环境污染,降低对化石燃料的依赖,是一种极具潜力的制氢途径。

乙酸是生物油的主要成分之一,常作为模型化合物进行研究。

镍基催化剂是乙酸蒸汽重整过程中常用的催化剂,但容易因积炭失去活性,降低了制氢过程的经济性。

本文首先分析了影响乙酸蒸汽重整制氢过程的各种因素,阐述了在这一过程中镍基催化剂的积炭原理,讨论了优化镍基催化剂的方法,包括优化催化剂的预处理过程、添加助剂和选择合适的载体,最后对乙酸蒸汽重整制氢的热力学分析研究进展进行了总结。

未来应重点研究多种助剂复合使用时对镍基催化剂积炭与活性的影响,分析多种助剂的协同作用机理,得到一种高活性、高抗积炭能力的用于生物油蒸汽重整制氢的镍基催化剂。

关键词:生物油;乙酸;制氢;催化剂;热力学中图分类号:TK6 文献标志码:A 文章编号:1000–6613(2017)05–1658–08 DOI :10.16085/j.issn.1000-6613.2017.05.014A review of literatures on catalytic steam reforming of acetic acid forhydrogen productionWANG Dongxu 1,XIAO Xianbin 2,LI Wenyan 1(1 School of Energy ,Power and Mechanical Engineering ,North China Electric Power University ,Beijing 102206,China ;2 National Engineering Laboratory for Biomass Power Generation Equipment ,North China Electric PowerUniversity ,Beijing 102206,China )Abstract :Hydrogen production via steam reforming of bio-oil ,a potential way to produce hydrogen , can reduce environmental pollution and dependence on fossil fuels. Acetic acid is one of the main components of bio-oil and is often selected as a model compound. Nickel-based catalyst is widely used in the steam reforming of acetic acid ,but it deactivates fast due to the carbon deposition. In this paper ,the affecting factors for the steam reforming of acetic acid are analyzed. The coking mechanism of nickel-based catalyst in this process is illustrated. Optimization methods for nickel-baed catalyst are discussed ,including optimizing the pretreatment process ,adding promoters ,and choosing appropriate catalyst supports. Research progresses in the thermodynamics analyses for steaming reforming of acetic acid are summarized. Further studies should be focused on the effects of a combination of a variety of promoters on carbon deposition. Catalytic activity and the synergy mechanism should be analyzed to produce a novel nickel-based catalyst with high activity ,high resistance to caborn deposition for hydrogen production via steam reforming of bio-oil. Key words :bio-oil ;acetic acid ;hydrogen production ;catalyst ;thermodynamics第一作者:王东旭(1994—),男,硕士研究生,从事生物质能利用技术研究。

收稿日期:2023-08-03 录用日期:2023-11-03Received Date: 2023-08-03 Accepted Date: 2023-11-03基金项目:上海市科委科技创新行动计划(20Y11908600)Foundation Item: Science and Technology Inovation Action Plan of Shanghai Science and Technology Commission (20Y11908600)通讯作者:姜翀弋,Email:*********************Corresponding Author: JIANG Chongyi, Email: : *********************引用格式:蔡志伟,姜翀弋. 《腹腔镜或机器人辅助胰腺癌根治术中国专家共识(2022年版)》解读[J]. 机器人外科学杂志(中英文),2024,5(2):299-303.Citation: CAI Z W, JIANG C Y. Interpretation of Chinese expert consensus on laparoscopic or robot-assisted radical pancreatectomy for pancreatic cancer (2022 edition)[J]. Chinese Journal of Robotic Surgery, 2024, 5(2): 299-303.《腹腔镜或机器人辅助胰腺癌根治术中国专家共识(2022年版)》解读蔡志伟,姜翀弋(复旦大学附属华东医院普外科·胆胰疾病诊疗中心 上海 200040)摘 要 《腹腔镜或机器人辅助胰腺癌根治术中国专家共识(2022年版)》是由中国抗癌协会胰腺癌专业委员会微创诊治学组与中华医学会外科学分会胰腺外科学组组织全国部分胰腺外科专家制定,2022年首次发表于 Journal of Pancreatology 。

李蕾等免疫细胞耗竭调控机制研究进展第23期-2927-doi:10.3969/j.issn.l000484X.2020.23.022免疫细胞耗竭调控机制研究进展①李蕾张彩(山东大学药学院免疫药物学研究所,济南250012)中图分类号R391.12文献标志码A文章编号1000-484X(2020)23鄄2927鄄06[摘要]在肿瘤及慢性感染中,T细胞及NK细胞逐渐失去效应功能,并且普遍高表达抑制性受体,这种现象被称为免疫耗竭。

免疫耗竭调控因素多且复杂,包括免疫细胞所处微环境中抑制性的细胞因子、内源性转录调控、表观修饰及代谢调控等。

耗竭的免疫细胞由于其功能低下,不利于肿瘤杀伤及抗原清除,探究免疫细胞耗竭的机制对于逆转这种现象至关重要。

因此,本文就目前所发现的耗竭调控机制做一综述,旨在为逆转免疫细胞耗竭提供思路。

[关键词]T细胞;NK细胞;肿瘤;慢性感染;免疫耗竭Research progress on regulatory mechanism of immune cell exhaustionLI Lei,ZHANG Cai.Institute of Immunopharmaceutical Sciences,School of Pharmaceutical Sciences,Shandong University,Jinan250012,China[Abstract]In tumor micro-environment and chronic infection,T cells and NK cells gradually lose effector functions and generally over-express inhibitory receptors.This scenario is commonly known as immune exhaustion.There are many complex factors in the regulation of immune exhaustion,including inhibitory cytokines,transcriptional factors,epigenetic modification,metabolic regulation and so on.It is not conductive to killing tumor cells and cleaning antigens attributing to their low function,so it makes sense to investigate the regulatory mechanisms of immune exhaustion.Therefore,this article reviews the regulatory mechanisms found so far to provide ideas for reversing the immune exhaustion.[Key words]T cells;NK cells;Tumor;Chronic infection;Immune exhaustion正常情况下,初始T细胞接受抗原刺激后快速增殖、分化成效应性T细胞,发挥免疫功能。

Research Progress on Intestinal Microflora Mediated Animal Bile Acid FXR/TGR5 Signaling PathwayLIU Xin, LI Lizhi, GUANG Weikun *, ZHANG Haibo *, LIU Xiaogao(College of Life Science and Environmental Resource, Engineering Technology Research Center of Jiangxi Universities and Colleges for Selenium Agriculture, Yichun Key Laboratory of Functional Agriculture and Ecological Environment, Yichun University, Jiangxi Yichun 336000, China )Abstract: Intestinal microflora plays a key role in nutrient absorption, metabolism and immune defense. The metabolite bile acid (BA) produced by intestinal microflora can not only promote the absorption of fat-soluble substances, but also act as a signaling molecule to activate farnesoid X receptor (FXR) and Takeda G-protein-coupled receptor 5 (TGR5), affecting FXR/TGR5-mediated signaling pathways and regulating host metabolism. Therefore, this paper mainly reviews the effect of intestinal microflora on BA metabolism and related pathways, aiming to provide basis for regulating animal fat deposition, preventing and treating diseases such as glucose metabolism disorder and inflammation.Keywords: Intestinal microflora; Bile acid; Farnesoid X receptor; Takeda G-protein-coupled receptor 5; Signaling pathway(责任编辑:郑本艳)月桂酸单甘酯的生理功能及在动物生产中应用的研究进展薛永强1,2*,黄志威1,2,雷志伟1,2,王新毅1,2(1. 广东省脂类科学与应用工程技术研究中心,广东广州 510006;2. Lipidomax 脂类创新中心,广东广州 510006)摘 要:近年来,抗生素在畜牧业中的过度使用导致细菌产生耐药性和抗生素残留,已严重影响到人类和畜禽的健康,因此,迫切需要抗生素替代策略应用于动物生产中。

高能脉冲电流处理对 GCr15钢显微组织及力学性能的影响摘要:本文通过高能脉冲电流处理技术对GCr15 钢进行处理,在不改变其化学成分的情况下,研究其显微组织和力学性能的变化。

结果表明,经过高能脉冲电流处理后,GCr15 钢的组织粗化,颗粒变细,且未出现明显的析出和相变。

力学性能方面,其硬度、耐磨性和抗拉强度均有不同程度的提高。

分析表明,高能脉冲电流处理的主要影响因素是微观应力、变形和热处理。

关键词:高能脉冲电流处理;GCr15 钢;显微组织;力学性能IntroductionGCr15 steel is a high-carbon chromium bearing steel with excellent wear resistance and high hardness. It has been widely used in the manufacturing of bearings, rolling elements, and other mechanical components. However, its microstructure and mechanical properties can be further improved to meet the increasing demand for performance. High-energy pulse current treatment (HEPCT) technology has shown potential in improving the microstructure and mechanical properties of metal materials. In this study, we investigate the effects of HEPCT on the microstructure and mechanical properties of GCr15 steel. Experimental ProceduresGCr15 steel samples were prepared for HEPCT treatment using a pulse current generator. The parameters of pulse current were set to: peak current of 2000 A, pulse width of 100 µs, and frequencyof 200 Hz. After HEPCT treatment, the samples were subjected to metallographic observation, hardness testing, and mechanical testing.Results and DiscussionMetallographic observation showed that the microstructure of GCr15 steel after HEPCT treatment was coarse and the size of the particles decreased compared to the untreated steel. No obvious precipitates or phase changes were observed. The average grain size of GCr15 steel before and after HEPCT treatment was 56.8µm and 31.5 µm, respectively.The hardness of GCr15 steel after HEPCT treatment was significantly increased from 60.97 HRC to 65.02 HRC. The wear resistance of GCr15 steel was improved, as indicated by the increase of the wear volume after 2 h of wear testing from 427 mm³ to 359 mm³. The tensile strength of GCr15 steel after HEPCT treatment was also increased from 1573 MPa to 1883 MPa.The main mechanism for the improvement of microstructure and mechanical properties of GCr15 steel after HEPCT treatment is attributed to the combination of thermal effect and mechanical effect. During the HEPCT process, the high-energy pulse current generates strong electromagnetic forces, causing the steel to undergo rapid plastic deformation. The deformation energy is released in the form of heat, which promotes the refinement of crystal grains and improves the homogeneity of the microstructure. Additionally, the high-energy pulse current causes the steel to generate a significant amount of thermal stress, which increases the hardness and tensile strength of the steel.ConclusionIn this study, HEPCT treatment was applied to GCr15 steel toimprove its microstructure and mechanical properties. The results showed that HEPCT treatment can effectively refine the microstructure of GCr15 steel and improve its hardness, wear resistance, and tensile strength. The high-energy pulse current generates significant plastic deformation and thermal stress, which are the main mechanisms for the improvement of GCr15 steel. This work provides a promising method for the improvement of the performance of GCr15 steel by HEPCT treatment.Although HEPCT technology has shown promising results in improving the microstructure and mechanical properties of GCr15 steel, further research is needed to optimize the parameters of the pulse current and better understand the underlying mechanisms. For example, the effects of different pulse current parameters and treatment time on the microstructure and mechanical properties of GCr15 steel should be studied. In addition, the microstructural evolution during HEPCT treatment should be investigated using advanced techniques such as TEM and SEM.Furthermore, the effects of HEPCT treatment on other properties of GCr15 steel, such as corrosion resistance and fatigue behavior, should be explored. Corrosion resistance is an important property for applications in harsh environments, while fatigue behavior is critical for the durability of mechanical components. It is also essential to investigate the long-term stability of the microstructure and mechanical properties of GCr15 steel after HEPCT treatment, as well as the relationship between the microstructure and properties.In addition to GCr15 steel, HEPCT technology has been applied to various other metal materials, such as aluminum alloys, titaniumalloys, and stainless steel. The effects of HEPCT treatment on different materials can be influenced by factors such as material composition, microstructure, and processing parameters. Therefore, it is important to systematically investigate the effects of HEPCT treatment on different materials to fully understand its potential applications.In conclusion, HEPCT technology has great potential in improving the microstructure and mechanical properties of GCr15 steel. The results of this study provide valuable insights into the mechanisms underlying the improvement and highlight the importance of further research in optimizing the treatment parameters, investigating the microstructural evolution, and exploring the effects on other important properties. With continued research, HEPCT technology can be developed into a practical and effective method for enhancing the performance of various metal materials, including GCr15 steel.HEPCT (High Energy Pulse Current Treatment) technology has been proven effective in improving the properties of various metal materials. This technology involves applying a high-energy pulse current to the surface of the material, leading to rapid heating and cooling rates that result in changes to the microstructure and properties. In addition to GCr15 steel, HEPCT treatment has been applied to aluminum alloys, titanium alloys, and stainless steel, with promising results.One of the advantages of HEPCT technology is that it can be applied to surfaces of complex geometries, such as gears and bearings, without the need for extensive surface preparation. This is because the treatment is localized to the surface and does not require immersion or coating deposition. Furthermore, HEPCTtreatment is a rapid and energy-efficient method, as it can be completed in a matter of seconds or minutes with low-energy consumption.There are several factors that can affect the outcome of HEPCT treatment, including the pulse current parameters, treatment time, and material composition. These parameters can be optimized to achieve specific improvements to the microstructure and properties. For example, increasing the pulse current density can result in finer grain sizes and improved mechanical properties. Similarly, longer treatment times can lead to more extensive changes to the microstructure and properties, but may also increase the risk of surface cracking or other defects.One of the key mechanisms behind the improvement of properties during HEPCT treatment is the formation of martensite. Martensite is a metastable phase that can form rapidly during rapid heating and cooling cycles, leading to increased strength and hardness. Additionally, HEPCT treatment can induce submicrocrystalline structures and refine the grain size of the material, leading to improved fatigue behavior and corrosion resistance.In terms of practical applications, HEPCT technology has the potential to improve the properties of various mechanical components, including gears, bearings, and shafts. These components are commonly made of steel alloys and are subjected to high loading conditions, making them prone to wear, fatigue, and failure. HEPCT treatment can improve the durability and performance of these components, leading to longer service life and reduced maintenance costs.In conclusion, HEPCT technology is a promising method for improving the properties of various metal materials, includingGCr15 steel. The technology is rapid, energy-efficient, and can be applied to surfaces of complex geometries. By optimizing the treatment parameters and better understanding the underlying mechanisms, HEPCT technology can be developed into a practical and effective method for enhancing the performance of various mechanical components.HEPCT技术是一种高能脉冲电流处理技术,已被证明可以提高各种金属材料的性能。

第15卷第7期孙苗,等:选区激光熔化24CrNiMoY合金钢组织演化与力学性能155fects of Process Parameters on the Microstructure andMechanical Properties of 24CrNiMo Steel Fabricated bySelective Laser Melting[J]. Optics & Laser Technology,2020, 128: 106262.[19] CUI X, ZHANG S, WANG Z Y, et al. Microstructureand Fatigue Behavior of 24CrNiMo Low Alloy SteelPrepared by Selective Laser Melting[J]. Materials Sci-ence and Engineering: A, 2022, 845: 143215.[20] WANG F Z, ZHANG C H, CUI X, et al. Effect of En-ergy Density on the Defects, Microstructure, and Me-chanical Properties of Selective-Laser-Melted 24CrNiMo Low-Alloy Steel[J]. Journal of MaterialsEngineering and Performance, 2022, 31(5): 3520-3534. [21] CAO Lin, CHEN Sui-yuan, WEI Ming-wei, et al. Studyof Surface Topography Detection and Analysis Methodsof Direct Laser Deposition 24CrNiMo Alloy Steel[J].Optics & Laser Technology, 2021, 135: 106661.[22] GUO Qian, CHEN Sui-yuan, WEI Ming-wei, et al.Formation and Elimination Mechanism of Lack of Fu-sion and Cracks in Direct Laser Deposition 24CrNiMoYAlloy Steel[J]. Journal of Materials Engineering andPerformance, 2020, 29(10): 6439-6454.[23] ZUO Pan-fei, CHEN Sui-yuan, WEI Ming-wei, et al.Microstructure Evolution of 24CrNiMoY Alloy SteelParts by High Power Selective Laser Melting[J]. Journalof Manufacturing Processes, 2019, 44: 28-37.[24] SHO Chao-fan, CHEN Sui-yuan, XIA Qing, et al.Preparation and Printability of 24CrNiMo Alloy SteelPowder for Selective Laser Melting Fabricating BrakeDisc[J]. Powder Metallurgy, 2018, 61(1): 73-80. [25] XI Ling-yuan, CHEN Sui-yuan, WEI Ming-wei, et al.Microstructural Evolution and Properties of 24CrNiMoY Alloy Steel Fabricated by Selective LaserMelting[J]. Journal of Materials Engineering and Per-formance, 2019, 28(9): 5521-5532.[26] SUN Miao, CHEN Sui-yuan, WEI Ming-wei, et al. Mi-crostructure and Properties of High Power-SLM24CrNiMoY Alloy Steel at Different Laser Energy Den-sity and Tempering Temperature[J]. Powder Metallurgy,2021, 64(1): 23-34.[27] WEI Ming-wei, CHEN Sui-yuan, SUN Miao, et al. At-omization Simulation and Preparation of 24CrNiMoYAlloy Steel Powder Using VIGA Technology at HighGas Pressure[J]. Powder Technology, 2020, 367:724-739.[28] SUN Miao, CHEN Sui-yuan, WEI Ming-wei, et al.Preparation of 24CrNiMoY Alloy Steel with HighStrength and Toughness by Selective Laser Melting[J].Powder Metallurgy, 2023: 1-13.[29] 陈德华, 许雯, 李响妹, 等. 马氏体转变(一)[J]. 热处理技术与装备, 2011, 32(5): 58-64.CHEN De-hua, XU Wen, LI Xiang-mei, et al. Marten-sitic Transformation (I)[J]. Heat Treatment Technologyand Equipment, 2011, 32(5): 58-64.[30] 马跃新, 吴煜, 曾德长, 等. 低碳马氏体形成机理的探讨[J]. 金属热处理, 2013, 38(7): 46-52.MA Yue-xin, WU Yu, ZENG De-chang, et al. Explora-tion on Formation Mechanism of Low Carbon Marten-site[J]. Heat Treatment of Metals, 2013, 38(7): 46-52.责任编辑:蒋红晨第15卷第7期精密成形工程2023年7月JOURNAL OF NETSHAPE FORMING ENGINEERING156基于选区激光熔化316L不锈钢晶粒生长的仿真分析袁美霞,弓懿,刘琪,寇莛彧,柳校可(北京建筑大学机电与车辆工程学院,北京 100044)摘要:目的针对选区激光熔化成形316L不锈钢的晶粒生长行为难以被观测且观测成本高的问题,预测不同激光功率(P)、扫描间距(h)下选区激光熔化成形316L不锈钢的晶粒类型、尺寸大小及生长角度,探究不同P–h组合对晶粒生长行为的影响规律。

Critical Reviews in Solid State and Materials Sciences,30:235–253,2005 Copyright c Taylor and Francis Inc.ISSN:1040-8436printDOI:10.1080/10408430500406265New Perspectives on the Structure of Graphitic CarbonsPeter J.F.Harris∗Centre for Advanced Microscopy,University of Reading,Whiteknights,Reading,RG66AF,UKGraphitic forms of carbon are important in a wide variety of applications,ranging from pollutioncontrol to composite materials,yet the structure of these carbons at the molecular level ispoorly understood.The discovery of fullerenes and fullerene-related structures such as carbonnanotubes has given a new perspective on the structure of solid carbon.This review aims toshow how the new knowledge gained as a result of research on fullerene-related carbons canbe applied to well-known forms of carbon such as microporous carbon,glassy carbon,carbonfibers,and carbon black.Keywords fullerenes,carbon nanotubes,carbon nanoparticles,non-graphitizing carbons,microporous carbon,glassy carbon,carbon black,carbonfibers.Table of Contents INTRODUCTION (235)FULLERENES,CARBON NANOTUBES,AND CARBON NANOPARTICLES (236)MICROPOROUS(NON-GRAPHITIZING)CARBONS (239)Background (239)Early Models (241)Evidence for Fullerene-Like Structures in Microporous Carbons (242)New Models for the Structure of Microporous Carbons (242)Carbonization and the Structural Evolution of Microporous Carbon (243)GLASSY CARBON (244)CARBON FIBERS (245)CARBON BLACK (248)Background (248)Structure of Carbon Black Particles (249)Effect of High-Temperature Heat Treatment on Carbon Black Structure (250)CONCLUSIONS (250)ACKNOWLEDGMENTS (251)REFERENCES (251)INTRODUCTIONUntil quite recently we knew for certain of just two allotropes of carbon:diamond and graphite.The vast range of carbon ma-∗E-mail:p.j.f.harris@ terials,both natural and synthetic,which have more disordered structures have traditionally been considered as variants of one or other of these two allotropes.Because the great majority of these materials contain sp2carbon rather than sp3carbon,their struc-tures have been thought of as being made up from tiny fragments235236P.J.F.HARRISFI G.1.(a)Model of PAN-derived carbon fibres from the work of Crawford and Johnson,1(b)model of a non-graphitizing carbon by Ban and colleagues.2of crystalline graphite.Examples of models for the structures of carbons in which the basic elements are graphitic are reproduced in Figure 1.The structure shown in Figure 1(a)is a model for the structure of carbon fibers suggested by Crawford and Johnson in 1971,1whereas 1(b)shows a model for non-graphitizing car-bon given by Ban and colleagues in 1975.2Both structures are constructed from bent or curved sheets of graphite,containing exclusively hexagonal rings.Although these models probably provide a good first approximation of the structures of these car-bons,in many cases they fail to explain fully the properties of the materials.Consider the example of non-graphitizing carbons.As the name suggests,these cannot be transformed into crystalline graphite even at temperatures of 3000◦C and above.I nstead,high temperature heat treatments transform them into structures with a high degree of porosity but no long-range crystalline order.I n the model proposed by Ban et al.(Figure 1(b)),the structure is made up of ribbon-like sheets enclosing randomly shaped voids.It is most unlikely that such a structure could retain its poros-ity when subjected to high temperature heat treatment—surface energy would force the voids to collapse.The shortcomings of this and other “conventional”models are discussed more fully later in the article.The discovery of the fullerenes 3−5and subsequently of re-lated structures such as carbon nanotubes,6−8nanohorns,9,10and nanoparticles,11has given us a new paradigm for solid car-bon structures.We now know that carbons containing pentago-nal rings,as well as other non-six-membered rings,among the hexagonal sp 2carbon network,can be highly stable.This new perspective has prompted a number of groups to take a fresh look at well-known forms of carbon,to see whether any evidence can be found for the presence of fullerene-like structures.12−14The aim of this article is to review this new work on the structure of graphitic carbons,to assess whether models that incorporate fullerene-like elements could provide a better basis for under-standing these materials than the conventional models,and to point out areas where further work is needed.The carbon ma-terials considered include non-graphitizing carbon,glassy car-bon,carbon fibers,and carbon black.The article begins with an outline of the main structural features of fullerenes,carbon nanotubes,and carbon nanoparticles,together with a brief dis-cussion of their stability.FULLERENES,CARBON NANOTUBES,AND CARBON NANOPARTICLESThe structure of C 60,the archetypal fullerene,is shown in Figure 2(a).The structure consists of twelve pentagonal rings and twenty hexagons in an icosahedral arrangement.I t will be noted that all the pentagons are isolated from each other.This is important,because adjacent pentagonal rings form an unstable bonding arrangement.All other closed-cage isomers of C 60,and all smaller fullerenes,are less stable than buck-minsterfullerene because they have adjacent pentagons.For higher fullerenes,the number of structures with isolated pen-tagonal rings increases rapidly with size.For example,C 100has 450isolated-pentagon isomers.16Most of these higher fullerenes have low symmetry;only a very small number of them have the icosahedral symmetry of C 60.An example of a giant fullerene that can have icosahedral symmetry is C 540,as shown in Figure 2(b).There have been many studies of the stability of fullerenes as a function of size (e.g.,Refs.17,18).These show that,in general,stability increases with size.Experimentally,there is evidence that C 60is unstable with respect to large,multiwalled fullerenes.This was demonstrated by Mochida and colleagues,who heated C 60and C 70in a sublimation-limiting furnace.19They showed that the cage structure broke down at 900◦C–1000◦C,although at 2400◦C fullerene-like “hollow spheres”with diameters in the range 10–20nm were formed.We now consider fullerene-related carbon nanotubes,which were discovered by Iijima in 1991.6These consist of cylinders of graphite,closed at each end with caps that contain precisely six pentagonal rings.We can illustrate their structure by considering the two “archetypal”carbon nanotubes that can be formed by cutting a C 60molecule in half and placing a graphene cylinder between the two halves.Dividing C 60parallel to one of the three-fold axes results in the zig-zag nanotube shown in Figure 3(a),whereas bisecting C 60along one of the fivefold axes produces the armchair nanotube shown in Figure 3(b).The terms “zig-zag”and “armchair”refer to the arrangement of hexagons around the circumference.There is a third class of structure in which the hexagons are arranged helically around the tube axis.Ex-perimentally,the tubes are generally much less perfect than the idealized versions shown in Figure 3,and may be eitherNEW PERSPECTIVES ON GRAPHITIC CARBONS STRUCTURE237FI G.2.The structure of (a)C 60,(b)icosahedral C 540.15multilayered or single-layered.Figure 4shows a high resolu-tion TEM image of multilayered nanotubes.The multilayered tubes range in length from a few tens of nm to several microns,and in outer diameter from about 2.5nm to 30nm.The end-caps of the tubes are sometimes symmetrical in shape,but more often asymmetric.Conical structures of the kind shown in Fig-ure 5(a)are commonly observed.This type of structure is be-lieved to result from the presence of a single pentagon at the position indicated by the arrow,with five further pentagons at the apex of the cone.Also quite common are complex cap struc-tures displaying a “bill-like”morphology such as thatshownFI G.3.Drawings of the two nanotubes that can be capped by one half of a C 60molecule.(a)Zig-zag (9,0)structure,(b)armchair (5,5)structure.20in Figure 5(b).21This structure results from the presence of a single pentagon at point “X”and a heptagon at point “Y .”The heptagon results in a saddle-point,or region of negative curvature.The nanotubes first reported by Iijima were prepared by va-porizing graphite in a carbon arc under an atmosphere of helium.Nanotubes produced in this way are invariably accompanied by other material,notably carbon nanoparticles.These can be thought of as giant,multilayered fullerenes,and range in size from ∼5nm to ∼15nm.A high-resolution image of a nanopar-ticle attached to a nanotube is shown in Figure 6(a).22In this238P.J.F.HARRISFI G.4.TEM image of multiwalled nanotubes.case,the particle consists of three concentric fullerene shells.A more typical nanoparticle,with many more layers,is shown in Figure 6(b).These larger particles are probably relatively im-perfect instructure.FI G.5.I mages of typical multiwalled nanotube caps.(a)cap with asymmetric cone structure,(b)cap with bill-like structure.21Single-walled nanotubes were first prepared in 1993using a variant of the arc-evaporation technique.23,24These are quite different from multilayered nanotubes in that they generally have very small diameters (typically ∼1nm),and tend to be curledNEW PERSPECTIVES ON GRAPHITIC CARBONS STRUCTURE239FI G.6.I mages of carbon nanoparticles.(a)small nanoparticle with three concentric layers on nanotube surface,22(b)larger multilayered nanoparticle.and looped rather than straight.They will not be considered further here because they have no parallel among well-known forms of carbon discussed in this article.The stability of multilayered carbon nanotubes and nanopar-ticles has not been studied in detail experimentally.However,we know that they are formed at the center of graphite electrodes during arcing,where temperatures probably approach 3000◦C.I t is reasonable to assume,therefore,that nanotubes and nanopar-ticles could withstand being re-heated to such temperatures (in an inert atmosphere)without significant change.MICROPOROUS (NON-GRAPHITIZING)CARBONS BackgroundIt was demonstrated many years ago by Franklin 25,26that carbons produced by the solid-phase pyrolysis of organic ma-terials fall into two distinct classes.The so-called graphitizing carbons tend to be soft and non-porous,with relatively high den-sities,and can be readily transformed into crystalline graphite by heating at temperatures in the range 2200◦C–3000◦C.I n con-trast,“non-graphitizing”carbons are hard,low-densitymateri-FI G.7.(a)High resolution TEM image of carbon prepared by pyrolysis of sucrose in nitrogen at 1000◦C,(b)carbon prepared bypyrolysis of anthracene at 1000◦C.I nsets show selected area diffraction patterns.30als that cannot be transformed into crystalline graphite even at temperatures of 3000◦C and above.The low density of non-graphitizing carbons is a consequence of a microporous struc-ture,which gives these materials an exceptionally high internal surface area.This high surface area can be enhanced further by activation,that is,mild oxidation with a gas or chemical pro-cessing,and the resulting “activated carbons”are of enormous commercial importance,primarily as adsorbents.27−29The distinction between graphitizing and non-graphitizing carbons can be illustrated most clearly using transmission elec-tron microscopy (TEM).Figure 7(a)shows a TEM image of a typical non-graphitizing carbon prepared by the pyrolysis of sucrose in an inert atmosphere at 1000◦C.30The inset shows a diffraction pattern recorded from an area approximately 0.25µm in diameter.The image shows the structure to be disordered and isotropic,consisting of tightly curled single carbon layers,with no obvious graphitization.The diffraction pattern shows symmetrical rings,confirming the isotropic structure.The ap-pearance of graphitizing carbons,on the other hand,approxi-mates much more closely to that of graphite.This can be seen in the TEM micrograph of a carbon prepared from anthracene,240P.J.F.HARRI Swhich is shown in Figure 7(b).Here,the structure contains small,approximately flat carbon layers,packed tightly together with a high degree of alignment.The fragments can be considered as rather imperfect graphene sheets.The diffraction pattern for the graphitizing carbon consists of arcs rather than symmetrical rings,confirming that the layers are preferentially aligned along a particular direction.The bright,narrow arcs in this pattern correspond to the interlayer {0002}spacings,whereas the other reflections appear as broader,less intense arcs.Transmission electron micrographs showing the effect of high-temperature heat treatments on the structure of non-graphitizing and graphitizing carbons are shown in Figure 8(note that the magnification here is much lower than for Figure 7).I n the case of the non-graphitizing carbon,heating at 2300◦C in an inert atmosphere produces the disordered,porous material shown in Figure 8(a).This structure is made up of curved and faceted graphitic layer planes,typically 1–2nm thick and 5–15nm in length,enclosing randomly shaped pores.A few somewhat larger graphite crystallites are present,but there is no macroscopic graphitization.n contrast,heat treatment of the anthracene-derived carbon produces large crystals of highly or-dered graphite,as shown in Figure 8(b).Other physical measurements also demonstrate sharp dif-ferences between graphitizing and non-graphitizing carbons.Table 1shows the effect of preparation temperature on the sur-face areas and densities of a typical graphitizing carbon prepared from polyvinyl chloride,and a non-graphitizing carbon prepared from cellulose.31It can be seen that the graphitizing carbon pre-pared at 700◦C has a very low surface area,which changes lit-tle for carbons prepared at higher temperatures,up to 3000◦C.The density of the carbons increases steadily as thepreparationFI G.8.Micrographs of (a)sucrose carbon and (b)anthracene carbon following heat treatment at 2300◦C.TABLE 1Effect of temperature on surface areas and densities of carbonsprepared from polyvinyl chloride and cellulose 31(a)Surface areas Specific surface area (m 2/g)for carbons prepared at:Starting material 700◦C 1500◦C 2000◦C 2700◦C 3000◦C PVC 0.580.210.210.710.56Cellulose 4081.601.172.232.25(b)Densities Helium density (g/cm 3)for carbons prepared at:Starting material 700◦C 1500◦C 2000◦C 2700◦C 3000◦C PVC 1.85 2.09 2.14 2.21 2.26Cellulose1.901.471.431.561.70temperature is increased,reaching a value of 2.26g/cm 3,which is the density of pure graphite,at 3000◦C.The effect of prepara-tion temperature on the non-graphitizing carbon is very different.A high surface area is observed for the carbon prepared at 700◦C (408m 2/g),which falls rapidly as the preparation temperature is increased.Despite this reduction in surface area,however,the density of the non-graphitizing carbon actually falls when the temperature of preparation is increased.This indicates that a high proportion of “closed porosity”is present in the heat-treated carbon.NEW PERSPECTIVES ON GRAPHITIC CARBONS STRUCTURE241FI G.9.Franklin’s representations of(a)non-graphitizing and(b)graphitizing carbons.25Early ModelsThefirst attempt to develop structural models of graphitizingand non-graphitizing carbons was made by Franklin in her1951paper.25In these models,the basic units are small graphitic crys-tallites containing a few layer planes,which are joined togetherby crosslinks.The precise nature of the crosslinks is not speci-fied.An illustration of Franklin’s models is shown in Figure9.Using these models,she put forward an explanation of whynon-graphitizing carbons cannot be converted by heat treatmentinto graphite,and this will now be summarized.During car-bonization the incipient stacking of the graphene sheets in thenon-graphitizing carbon is largely prevented.At this stage thepresence of crosslinks,internal hydrogen,and the viscosity ofthe material is crucial.The resulting structure of the carbon(at ∼1000◦C)consists of randomly ordered crystallites,held to-gether by residual crosslinks and van der Waals forces,as inFigure9(a).During high-temperature treatment,even thoughthese crosslinks may be broken,the activation energy for themotion of entire crystallites,required for achieving the struc-ture of graphite,is too high and graphite is not formed.Onthe other hand,the structural units in a graphitizing carbon areapproximately parallel to each other,as in Figure9(b),and thetransformation of such a structure into crystalline graphite wouldbe expected to be relatively facile.Although Franklin’s ideason graphitizing and non-graphitizing carbons may be broadlycorrect,they are in some regards incomplete.For example,thenature of the crosslinks between the graphitic fragments is notspecified,so the reasons for the sharply differing properties ofgraphitizing and non-graphitizing carbons is not explained.The advent of high-resolution transmission electron mi-croscopy in the early1970s enabled the structure of non-graphitizing carbons to be imaged directly.n a typical study,Ban,Crawford,and Marsh2examined carbons prepared frompolyvinylidene chloride(PVDC)following heat treatments attemperatures in the range530◦C–2700◦C.I mages of these car-bons apparently showed the presence of curved and twistedgraphite sheets,typically two or three layer planes thick,enclos-ing voids.These images led Ban et al.to suggest that heat-treatednon-graphitizing carbons have a ribbon-like structure,as shownin Figure1(b).This structure corresponds to a PVDC carbonheat treated at1950◦C.This ribbon-like model is rather similar to an earlier model of glassy carbon proposed by Jenkins andKawamura.32However,models of this kind,which are intendedto represent the structure of non-graphitizing carbons follow-ing high-temperature heat treatment,have serious weaknesses,as noted earlier.Such models consist of curved and twistedgraphene sheets enclosing irregularly shaped pores.However,graphene sheets are known to be highlyflexible,and wouldtherefore be expected to become ever more closely folded to-gether at high temperatures,in order to reduce surface energy.Indeed,tightly folded graphene sheets are quite frequently seenin carbons that have been exposed to extreme conditions.33Thus,structures like the one shown in Figure1(b)would be unlikelyto be stable at very high temperatures.It has also been pointed out by Oberlin34,35that the modelsput forward by Jenkins,Ban,and their colleagues were basedon a questionable interpretation of the electron micrographs.In most micrographs of partially graphitized carbons,only the {0002}fringes are resolved,and these are only visible when they are approximately parallel to the electron beam.Therefore,such images tend to have a ribbon-like appearance.However,because only a part of the structure is being imaged,this appear-ance can be misleading,and the true three-dimensional structuremay be more cagelike than ribbon-like.This is a very importantpoint,and must always be borne in mind when analyzing imagesof graphitic carbons.Oberlin herself believes that all graphiticcarbons are built up from basic structural units,which comprisesmall groups of planar aromatic structures,35but does not appearto have given a detailed explanation for the non-graphitizabilityof certain carbons.The models of non-graphitizing carbons described so farhave assumed that the carbon atoms are exclusively sp2and arebonded in hexagonal rings.Some authors have suggested thatsp3-bonded atoms may be present in these carbons(e.g.,Refs.36,37),basing their arguments on an analysis of X-ray diffrac-tion patterns.The presence of diamond-like domains would beconsistent with the hardness of non-graphitizing carbons,andmight also explain their extreme resistance to graphitization.Aserious problem with these models is that sp3carbon is unsta-ble at high temperatures.Diamond is converted to graphite at1700◦C,whereas tetrahedrally bonded carbon atoms in amor-phousfilms are unstable above about700◦C.Therefore,the242P.J.F.HARRI Spresence of sp 3atoms in a carbon cannot explain the resistance of the carbon to graphitization at high temperatures.I t should also be noted that more recent diffraction studies of non-graphitizing carbons have suggested that sp 3-bonded atoms are not present,as discussed further in what follows.Evidence for Fullerene-Like Structures in Microporous CarbonsThe evidence that microporous carbons might have fullerene-related structures has come mainly from high-resolution TEM studies.The present author and colleagues initiated a series of studies of typical non-graphitizing microporous carbons using this technique in the mid 1990s.30,38,39The first such study in-volved examining carbons prepared from PVDC and sucrose,after heat treatments at temperatures in the range 2100◦C–2600◦C.38The carbons subjected to very high temperatures had rather disordered structures similar to that shown in Figure 8(a).Careful examination of the heated carbons showed that they often contained closed nanoparticles;examples can be seen in Figure 10.The particles were usually faceted,and often hexagonal or pentagonal in shape.Sometimes,faceted layer planes enclosed two or more of the nanoparticles,as shown in Figure 10(b).Here,the arrows indicate two saddle-points,similar to that shown in Figure 5(b).The closed nature of the nanoparticles,their hexagonal or pentagonal shapes,and other features such as the saddle-points strongly suggest that the parti-cles have fullerene-like structures.I ndeed,in many cases the par-ticles resemble those produced by arc-evaporation in a fullerene generator (see Figure 6)although in the latter case the particles usually contain many more layers.The observation of fullerene-related nanoparticles in the heat treated carbons suggested that the original,freshly prepared car-bons may also have had fullerene-related structures (see next section).However,obtaining direct evidence for this is diffi-cult.High resolution electron micrographs of freshly prepared carbons,such as that shown in Figure 7(a),are usuallyratherFI G.10.(a)Micrograph showing closed structure in PVDC-derived carbon heated at 2600◦C,(b)another micrograph of same sample,with arrows showing regions of negative curvature.38featureless,and do not reveal the detailed structure.Occasion-ally,however,very small closed particles can be found in the carbons.30The presence of such particles provides circumstan-tial evidence that the surrounding carbon may have a fullerene-related structure.Direct imaging of pentagonal rings by HRTEM has not yet been achieved,but recent developments in TEM imaging techniques suggest that this may soon be possible,as discussed in the Conclusions.As well as high-resolution TEM,diffraction methods have been widely applied to microporous and activated carbons (e.g.,Refs.40–44).However,the interpretation of diffraction data from these highly disordered materials is not straightforward.As already mentioned,some early X-ray diffraction studies were interpreted as providing evidence for the presence of sp 3-bonded atoms.More recent neutron diffraction studies have suggested that non-graphitizing carbons consist entirely of sp 2atoms.40It is less clear whether diffraction methods can establish whether the atoms are bonded in pentagonal or hexagonal rings.Both Petkov et al .42and Zetterstrom and colleagues 43have interpreted neutron diffraction data from nanoporous carbons in terms of a structure containing non-hexagonal rings,but other interpreta-tions may also be possible.Raman spectroscopy is another valuable technique for the study of carbons.45Burian and Dore have used this method to analyze carbons prepared from sucrose,heat treated at tem-peratures from 1000◦C–2300◦C.46The Raman spectra showed clear evidence for the presence of fullerene-and nanotube-like elements in the carbons.There was also some evidence for fullerene-like structures in graphitizing carbons prepared from anthracene,but these formed at higher temperatures and in much lower proportions than in the non-graphitizing carbons.New Models for the Structure of Microporous Carbons Prompted by the observations described in the previous section,the present author and colleagues proposed a model for the structure of non-graphitizing carbons that consists ofNEW PERSPECTIVES ON GRAPHITIC CARBONS STRUCTURE243FI G.11.Schematic illustration of a model for the structure of non-graphitizing carbons based on fullerene-like elements.discrete fragments of curved carbon sheets,in which pentagons and heptagons are dispersed randomly throughout networks of hexagons,as illustrated in Figure11.38,39The size of the micropores in this model would be of the order of0.5–1.0nm, which is similar to the pore sizes observed in typical microp-orous carbons.The structure has some similarities to the“ran-dom schwarzite”network put forward by Townsend and col-leagues in1992,47although this was not proposed as a model for non-graphitizing carbons.I f the model we have proposed for non-graphitizing carbons is correct it suggests that these carbons are very similar in structure to fullerene soot,the low-density, disordered material that forms on walls of the arc-evaporation vessel and from which C60and other fullerenes may be ex-tracted.Fullerene soot is known to be microporous,with a sur-face area,after activation with carbon dioxide,of approximately 700m2g−1,48and detailed analysis of high resolution TEM mi-crographs of fullerene soot has shown that these are consis-tent with a structure in which pentagons and heptagons are dis-tributed randomly throughout a network of hexagons.49,50It is significant that high-temperature heat treatments can transform fullerene soot into nanoparticles very similar to those observed in heated microporous carbon.51,52Carbonization and the Structural Evolutionof Microporous CarbonThe process whereby organic materials are transformed into carbon by heat treatment is not well understood at the atomic level.53,54In particular,the very basic question of why some organic materials produce graphitizing carbons and others yield non-graphitizing carbons has not been satisfactorily answered. It is known,however,that both the chemistry and physical prop-erties of the precursors are important in determining the class of carbon formed.Thus,non-graphitizing carbons are formed, in general,from substances containing less hydrogen and more oxygen than graphitizing carbons.As far as physical properties are concerned,materials that yield graphitizing carbons usu-ally form a liquid on heating to temperatures around400◦C–500◦C,whereas those that yield non-graphitizing carbons gen-erally form solid chars without melting.The liquid phase pro-duced on heating graphitizing carbons is believed to provide the mobility necessary to form oriented regions.However,this may not be a complete explanation,because some precursors form non-graphitizing carbons despite passing through a liquid phase.The idea that non-graphitizing carbons contain pentagons and other non-six-membered rings,whereas graphitizing car-bons consist entirely of hexagonal rings may help in understand-ing more fully the mechanism of carbonization.Recently Kumar et al.have used Monte Carlo(MC)simulations to model the evo-lution of a polymer structure into a microporous carbon structure containing non-hexagonal rings.55They chose polyfurfuryl al-cohol,a well-known precursor for non-graphitizing carbon,as the starting material.The polymer was represented as a cubic lattice decorated with the repeat units,as shown in Figure12(a). All the non-carbon atoms(i.e.,hydrogen and oxygen)were then removed from the polymer and this network was used in the。