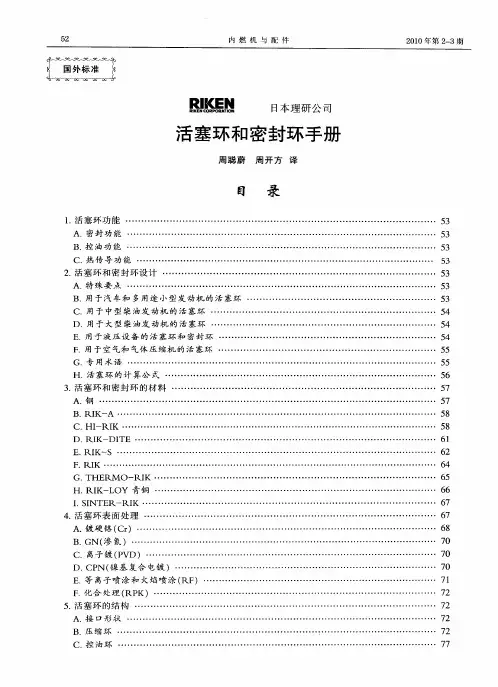

活塞环手册

- 格式:pdf

- 大小:3.05 MB

- 文档页数:61

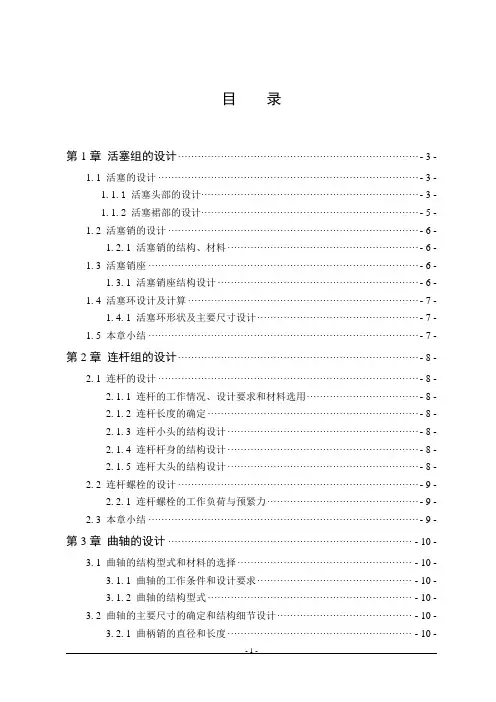

目录第1章活塞组的设计·········································································- 3 -1.1 活塞的设计 ···············································································- 3 -1.1.1活塞头部的设计··································································- 3 -1.1.2活塞裙部的设计··································································- 5 -1.2 活塞销的设计 ············································································- 6 -1.2.1 活塞销的结构、材料 ··························································- 6 -1.3 活塞销座 ··················································································- 6 -1.3.1 活塞销座结构设计 ·····························································- 6 -1.4 活塞环设计及计算 ······································································- 7 -1.4.1 活塞环形状及主要尺寸设计·················································- 7 -1.5 本章小结 ··················································································- 7 -第2章连杆组的设计·········································································- 8 -2.1 连杆的设计 ···············································································- 8 -2.1.1 连杆的工作情况、设计要求和材料选用··································- 8 -2.1.2 连杆长度的确定 ································································- 8 -2.1.3 连杆小头的结构设计 ··························································- 8 -2.1.4 连杆杆身的结构设计 ··························································- 8 -2.1.5 连杆大头的结构设计 ··························································- 8 -2.2 连杆螺栓的设计 ·········································································- 9 -2.2.1 连杆螺栓的工作负荷与预紧力··············································- 9 -2.3 本章小结 ··················································································- 9 -第3章曲轴的设计 ·········································································· - 10 -3.1 曲轴的结构型式和材料的选择 ····················································· - 10 -3.1.1 曲轴的工作条件和设计要求··············································· - 10 -3.1.2 曲轴的结构型式 ······························································ - 10 -3.2 曲轴的主要尺寸的确定和结构细节设计········································· - 10 -3.2.1 曲柄销的直径和长度 ························································ - 10 -- 1 -3.2.2 主轴颈的直径和长度 ························································ - 10 -3.2.3 曲柄 ············································································· - 11 -3.3本章小结 ················································································ - 11 -第4章曲柄连杆机构的创建 ···························································· - 12 -4.1活塞的创建 ············································································· - 12 -4.2连杆的创建 ············································································· - 12 -4.3曲轴的创建 ...........................................................错误!未定义书签。

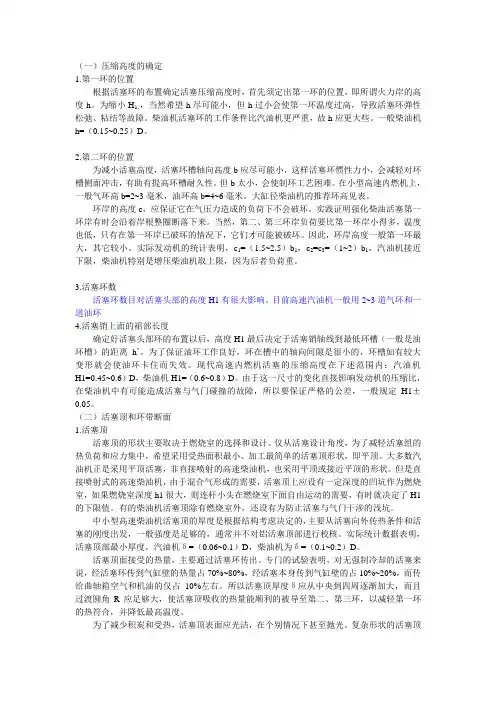

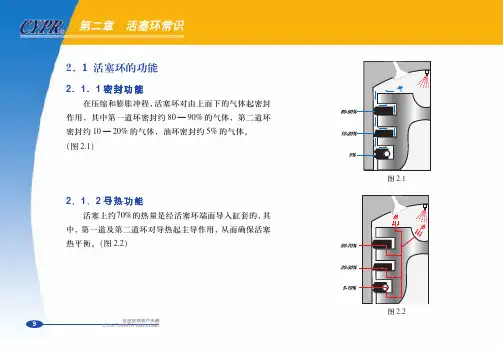

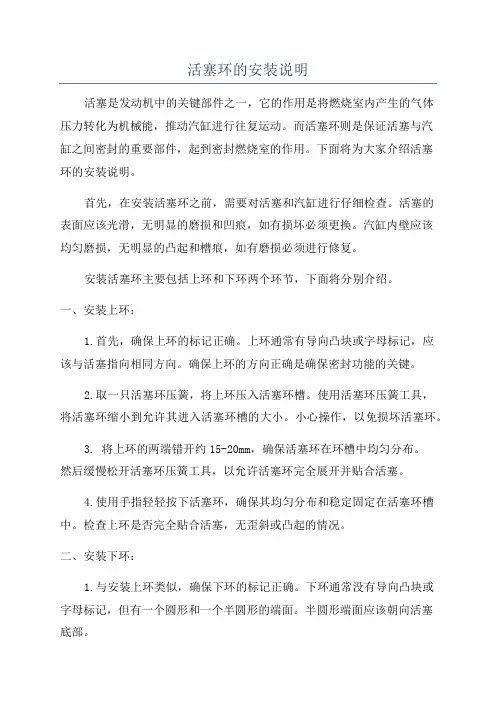

(一)压缩高度的确定1.第一环的位置根据活塞环的布置确定活塞压缩高度时,首先须定出第一环的位置,即所谓火力岸的高度h。

为缩小H1,,当然希望h尽可能小,但h过小会使第一环温度过高,导致活塞环弹性松弛、粘结等故障。

柴油机活塞环的工作条件比汽油机更严重,故h应更大些。

一般柴油机h=(0.15~0.25)D。

2.第二环的位置为减小活塞高度,活塞环槽轴向高度b应尽可能小,这样活塞环惯性力小,会减轻对环槽侧面冲击,有助有提高环槽耐久性。

但b太小,会使制环工艺困难。

在小型高速内燃机上,一般气环高b=2~3毫米,油环高b=4~6毫米。

大缸径柴油机的推荐环高见表。

环岸的高度c,应保证它在气压力造成的负荷下不会破坏。

实践证明强化柴油活塞第一环岸有时会沿着岸根整圈断落下来。

当然,第二、第三环岸负荷要比第一环岸小得多,温度也低,只有在第一环岸已破坏的情况下,它们才可能被破坏。

因此,环岸高度一般第一环最大,其它较小。

实际发动机的统计表明,c1=(1.5~2.5)b1,c2=c3=(1~2)b1,汽油机接近下限,柴油机特别是增压柴油机取上限,因为后者负荷重。

3.活塞环数活塞环数目对活塞头部的高度H1有很大影响。

目前高速汽油机一般用2~3道气环和一道油环4.活塞销上面的裙部长度确定好活塞头部环的布置以后,高度H1最后决定于活塞销轴线到最低环槽(一般是油环槽)的距离h’。

为了保证油环工作良好,环在槽中的轴向间隙是很小的,环槽如有较大变形就会使油环卡住而失效。

现代高速内燃机活塞的压缩高度在下述范围内:汽油机H1=0.45~0.6)D,柴油机H1=(0.6~0.8)D。

由于这一尺寸的变化直接影响发动机的压缩比,在柴油机中有可能造成活塞与气门碰撞的故障,所以要保证严格的公差,一般规定H1±0.05。

(二)活塞顶和环带断面1.活塞顶活塞顶的形状主要取决于燃烧室的选择和设计。

仅从活塞设计角度,为了减轻活塞组的热负荷和应力集中,希望采用受热面积最小、加工最简单的活塞顶形状,即平顶。

活塞环(Piston Ring)崁入活塞槽沟的环,分为两种:压缩环和机油环。

压缩环可用来密封燃烧室内的压缩空气;机油环则用来刮除汽缸上多余的机油。

活塞环是一种具有较大向外扩张变形的金属弹性环,它被装配到剖面与其相应的环形槽内。

往复和旋转运动的活塞环,依靠气体或液体的压力差,在环外圆面和气缸以及环和环槽的一个侧面之间形成密封。

[编辑本段]注意事项安装活塞环时应注意1)活塞环平装入气缸套内,接口处要有一定的开口间隙。

2)活塞环应装在活塞上,在环槽中,沿高度方向要有一定的边间隙。

3)镀铬环应装在第一道,开口不要对着活塞顶部的涡流凹坑方向。

4)各活塞环开口在互相错开120℃,均不准对着活塞销孔。

5)锥形断面活塞环,安装时锥面应向上。

6)扭转环安装时,倒角或切槽应向上。

7)安装组合环时,应先装轴向衬环,再装扁平环和波形环。

波形环上边装两片扁平环,下边装一片扁平环,开口应相互错开。

[编辑本段]应用范围活塞环广泛地用在各种动力机械上,如蒸汽机、柴油机、汽油机、压缩机、液压机等,广泛用于汽车,火车,轮船,游艇等。

一般活塞环安装在活塞的环槽里,它和活塞、缸套、缸盖等元件组成腔室做功。

[编辑本段]活塞环对燃油发动机的意义活塞环是燃油发动机内部的核心部件,它和汽缸,活塞,汽缸壁等一起完成燃油气体的密封常用汽车发动机有柴油和汽油发动机两种,由于其燃油性能不同,其使用的活塞环也不尽相同,早期的活塞环靠铸造形成,但随着技术的进步,钢制的高功率活塞环诞生,且随着对发动机功能,环境要求的不断提高,各种先进的表面处理应用其中,如溶射,电镀,镀铬,气体氮化,物理沉积,表面涂层,锌锰系磷化处理等,使活塞环的功能大大提高。

[编辑本段]功能活塞环作用包括密封、调节机油(控油)、导热(传热)、导向(支承)四个作用。

密封:指密封燃气,不让燃烧室的气体漏到曲轴箱,把气体的泄漏量控制在最低限度,提高热效率。

漏气不仅会使发动机的动力下降,而且会使机油变质,这是气环的主要任务;调节机油(控油):把气缸壁上多余的润滑油刮下,同时又使缸壁上布有薄薄的油膜,保证气缸和活塞及环的正常润滑。

活塞环的安装说明活塞是发动机中的关键部件之一,它的作用是将燃烧室内产生的气体压力转化为机械能,推动汽缸进行往复运动。

而活塞环则是保证活塞与汽缸之间密封的重要部件,起到密封燃烧室的作用。

下面将为大家介绍活塞环的安装说明。

首先,在安装活塞环之前,需要对活塞和汽缸进行仔细检查。

活塞的表面应该光滑,无明显的磨损和凹痕,如有损坏必须更换。

汽缸内壁应该均匀磨损,无明显的凸起和槽痕,如有磨损必须进行修复。

安装活塞环主要包括上环和下环两个环节,下面将分别介绍。

一、安装上环:1.首先,确保上环的标记正确。

上环通常有导向凸块或字母标记,应该与活塞指向相同方向。

确保上环的方向正确是确保密封功能的关键。

2.取一只活塞环压簧,将上环压入活塞环槽。

使用活塞环压簧工具,将活塞环缩小到允许其进入活塞环槽的大小。

小心操作,以免损坏活塞环。

3. 将上环的两端错开约15-20mm,确保活塞环在环槽中均匀分布。

然后缓慢松开活塞环压簧工具,以允许活塞环完全展开并贴合活塞。

4.使用手指轻轻按下活塞环,确保其均匀分布和稳定固定在活塞环槽中。

检查上环是否完全贴合活塞,无歪斜或凸起的情况。

二、安装下环:1.与安装上环类似,确保下环的标记正确。

下环通常没有导向凸块或字母标记,但有一个圆形和一个半圆形的端面。

半圆形端面应该朝向活塞底部。

2.取一只活塞环压簧,将下环压入活塞环槽。

使用活塞环压簧工具,将活塞环缩小到允许其进入活塞环槽的大小。

小心操作,以免损坏活塞环。

3. 将下环的两端错开约15-20mm,确保活塞环在环槽中均匀分布。

然后缓慢松开活塞环压簧工具,以允许活塞环完全展开并贴合活塞。

4.使用手指轻轻按下活塞环,确保其均匀分布和稳定固定在活塞环槽中。

检查下环是否完全贴合活塞,无歪斜或凸起的情况。

安装活塞环时需要注意以下几点:1.活塞环与活塞环槽的配合应该紧密但能够自如地活动。

活塞环太紧会导致卡滞和不良的密封,而活塞环太松会导致燃气泄漏。

2.确保上环和下环的标记正确,这对安装后的密封性至关重要。