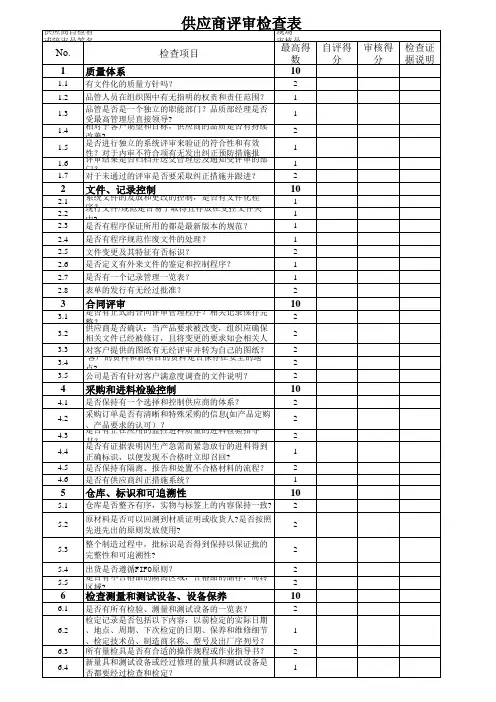

供应商评审检查表QSA(V4.0 20081216)

- 格式:xls

- 大小:432.50 KB

- 文档页数:2

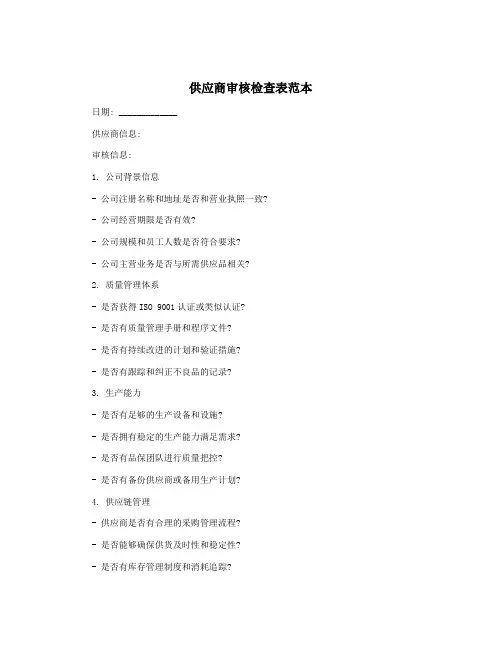

供应商审核检查表范本日期: _____________

供应商信息:

审核信息:

1. 公司背景信息

- 公司注册名称和地址是否和营业执照一致?

- 公司经营期限是否有效?

- 公司规模和员工人数是否符合要求?

- 公司主营业务是否与所需供应品相关?

2. 质量管理体系

- 是否获得ISO 9001认证或类似认证?

- 是否有质量管理手册和程序文件?

- 是否有持续改进的计划和验证措施?

- 是否有跟踪和纠正不良品的记录?

3. 生产能力

- 是否有足够的生产设备和设施?

- 是否拥有稳定的生产能力满足需求?

- 是否有品保团队进行质量把控?

- 是否有备份供应商或备用生产计划?

4. 供应链管理

- 供应商是否有合理的采购管理流程?

- 是否能够确保供货及时性和稳定性?

- 是否有库存管理制度和消耗追踪?

5. 财务状况

- 公司是否具有健全的财务管理系统?

- 是否能够提供财务报表和审计结果?

6. 法律合规性

- 公司是否遵守相关法律法规?

- 是否具有必要的许可证和证书?

- 是否存在过重大法律纠纷或违规记录?

备注:

______________________________________________________________________________ ___________

审核结论:

- 合格: □。

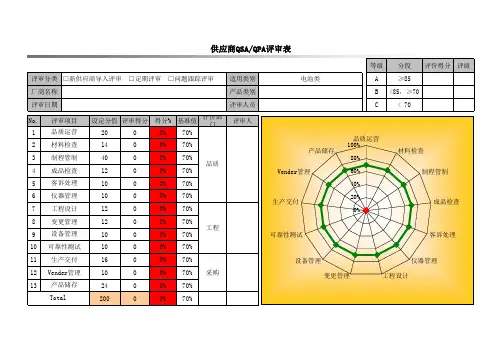

供应商审核检查表(总12页)--本页仅作为文档封面,使用时请直接删除即可----内页可以根据需求调整合适字体及大小--供应商审核检查表ADVANCED MICRO DEVICES SUPPLIER AUDIT CHECKLIST供应商(SUPPLIER):___________________________________________地址(LOCATION):_____________________________________________AMD审核成员(AMD AUDITORS):__________________________________________________________________日期(DATE):________________现场审核(ON-SITE AUDIT)_____ 书面审核(MAIL AUDIT)______注意:审核员在每个空格将输入一些关键数字,应答者应回答YES或NO,如果不适用回答N/ANOTE:On-site auditors will enter the key number rating in each space. For mail auditsurveys, respondents will answer yes or no, or use the key number rating system ineach space. If aquestion does not apply, answer N/A.质量承诺(QUALITY COMMITMENT)1.1是否有质量方针、目标或质量手册?Is there a quality policy, statement, or manual?_____是否定期评审、更新质量方针及手册?Is the quality policy or manual updated regularly?_____质量方针或手册是否包括本检查单提及的基本系统?Does the policy or manual include basic systems as identified in this checklist? _____对质量有影响的人员的职责与权限有无明文规定?Is the Quality function's authority and responsibilities clearly defined in writing? _____有无组织结构图?Is there an organization chart which identifies quality function elements?_____是否负责质量的人员有权拒绝不符合规定要求的物品?Does the Quality function clearly have the authority to withhold items that have not met an acceptable quality standard?_____有无书面的持续改进计划?Is there a documented quality improvement plan?_____意见(COMMENTS):____________________________________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________ __________________________________________________________________________________________总计(POINT TOTAL):________总体质量体系的要求(GENERAL QUALITY SYSTEM REQUIREMENTS)有无定义了过程质量控制点的过程流程图?Is there a current process flow chart with process or quality inspection pointsdefined?_____有无追溯交付到原材料的系统并能贯穿在进出货检验、过程检验之中?Is there a system for lot traceability of materials that will trace materials from raw supplies to shipped product, which contains, quantity in/out, inspectionperformed?_____有无进料检验的管理程序?Is there a system which indicates the acceptance of material throughout the process? _____有无描述过程检验,使产品达到规定要求的整个生产过程的验收?Does the Quality function maintain a system for the use and control of inspectionstamps or an alternate method of indicating acceptance and identification of theperson making the decision?_____意见(COMMENTS):____________________________________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________ __________________________________________________________________________________________总计(POINT TOTAL):________统计程序及质量控制(STATISTICAL PROCESS AND QUALITY CONTROL)有无书面的SPC系统文件?Is a SPC system defined and documented?_____是否有最高管理层参与评审SPC控制系统?Is there evidence of top management involvement?_____是否用统计的方法进行持续改进,以证明公司的质量方针、目标,是否达到?Do company policies/objectives reflect management's commitment to continuousimprovement through the use of statistical methods?_____是否建立了通过适当的特性来监控每个关键过程的程序,并且指明用何种统计技术?Have procedures and techniques been established to determine the appropriatecharacteristics to be monitored for each critical operation?_____是否有书面的文件规定当超出控制线时应提供适当的书面反应,并给予必要的行动?Is there a documented procedure defining out of control limits and significantpatterns within control limits which provides appropriate written responses foractions taken?_____有否使用控制图?Are control charts in use?_____控制图是否简明、扼要、清晰?Are the charts clear and concise?_____统计的控制线是否用于管制图中?Are statistical control limits used on the control charts? _____由谁发现失控情况?Who detects out of control condition(s)操作工operators_____ 主管supervisors_____ 维护人员maintenance_____工程师engineers_____ 经理managers__________谁对失控现象作出反应?Who responds to out of control condition(s)操作工operators_____ 主管supervisors_____ 维护人员maintenance_____工程师engineers_____ 经理managers__________当发生时有无及时的解决方案Is there prompt resolution of out of control conditions? _____有无制定记录控制图上的相关信息的程序,且被执行?Has a procedure been implemented for recording pertinent information on controlcharts?_____有无调整控制线的控制程序并执行?Has a procedure been implemented for establishing and adjusting control limits?_____有无建立减小过程变差的目标?Have goals been established to reduce variation in the process?_____意见(COMMENTS):____________________________________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________ __________________________________________________________________________________________总计(POINT TOTAL):________人员培训及证明(PERSONNEL TRAINING AND CERTIFICATION)有无建立关键过程、操作、检验员工的培训程序?Are there training procedures for personnel assigned to work on critical processes, operations, and inspections?_____培训计划是否包括下列几个方面?Does the training procedure include the following?操作姿势指导及测试?Hands-on instruction and testing._____在特定的时期结束时或效果不好的特定时期,再测试和再培训?Retesting or retraining of personnel at the end of a specific time period or when performance indicates poor performance for a specified time period._____有无取消颁发能力资格证的标准规定?The criteria for decertifying and recertifying personnel._____培训记录及培训人员名单是可利用的、可保留的?Are training records and a list of trained personnel available and maintained?_____人员是否被培训在工作中用到的统计方法,Are personnel trained to use statistics within the job,especially SPC/SQC methods?_____人员达到了何种水平?What level of personnel?_____意见(COMMENTS):____________________________________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________ __________________________________________________________________________________________总计(POINT TOTAL):________测量设备的控制(TEST AND MEASUREMENT EQUIPMENT CONTROL)有无程序规定测量设备的周期性校验?Is there a documented system for the automatic recall and periodic calibration of test and measuring equipment and measurement standards?_____若员工被允许使用自已的量测设备、那么此设备是否在公司规定的控制之中?If employees are permitted to use their own test and measuring equipment, is such equipment incorporated in the system?_____测试及测量设备的标准的校对是否基于制造商的定期(时间间隔)统计数据的基础上?Are test and measuring equipment and standards calibrated based on an establishedmanufacturer's interval or upon current statistical data?_____关于测量设备及测量标准的校对是否有文件化规定?Are procedures documented for the calibration of test and measuring equipment andMeasurement standards?_____公差的定义是否已被文件化?Are tolerances defined and documented?_____这份文件是否定义了对于超出公差的纠正措施?Do the procedures specify corrective action for an out of tolerance condition?_____这些校验是否遵循NISN、ASTM等标准?Is calibration traceable to nationally acceptable standards such as NIST, ASTM, etc._____校验记录是否包含以下信息?Does the calibration record include the following information?校验日期Calibration date._____校验人Person who calibrated the equipment._____下次校验的时间Next calibration due date._____适用的条件Applicable environmental conditions._____超出公差的设备在校验前有无保存记录?For out of tolerance equipment,initial reading before and final readingafter calibration._____5.3.4.6超差的情况是否有相应的纠正措施?Corrective actions taken for out of tolerance conditions._____5.3.4.7校验使用的基准物质有否进行校验?Unique identifier of the equipment being calibrated._____5.3.4.8有无使用的校验程序?Reference to the calibration procedure used._____5.3.5在使用前是否重新做测试及验证?Are acquired or reworked test and measuring equipment inspected and calibratedprior to use?_____有无预防性维护程序与日程安排?Are there preventive maintenance procedures and schedules maintained in each area? _____对于测量设备是否经常做相关的措施?Are regular correlation tests for measurement equipment conducted?_____测量设备是否有标识注明:校验日期、校验人、下次校验时间?Are labels utilized on test and measuring equipment and measurement standards to show the current calibration date, next calibration due date, and the person whoperformed the last calibration?_____是否有标识或其它方法表明测量设备或测试标准是过期的或超出公差范围的?Is there a system which uses tags or another method to identify past due or out oftolerance test and measuring equipment and measurement standards?_____对超出公差的测量设备是否会缩短其校验周期?Is the calibration interval for test and measuring equipment subject to decreasewhen identified as out of tolerance?_____意见(COMMENTS):____________________________________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________ __________________________________________________________________________________________总计(POINT TOTAL):________文件与资料变更的控制(DOCUMENTATION AND CHANGE CONTROL)书面化的资料是否包含以下各项?Are the following documented?主要的设计特性(适用时)Major design characteristics (if applicable)_____使用的材料Materials used._____过程控制程序Process procedures._____检验程序Inspection procedures._____有关成品的制造及测试所必须的程序和记录是否被控制?All other necessary procedures needed for manufacturing and testing of finished products._____有否建立文件变更的管理系统?Has a system been established to make changes in controlled documentation?_____有否建立文件变更的审批准则?Is there an established level of approval needed for documentation changes?_____更改内容、生效日期是否在图纸、程序等文件上标明或证实?Are change levels and effectivity dates indicated and verifiable on drawings,procedures, etc._____若允许,手工的改动是否有受控文件的控制?If permitted, are handwritten changes to controlled documentation limited?_____依靠什么手段?By what means_____________________________6.5.2在规定的期限内,文件总清单上是否被更新以反映经认可的手写变动?Are specification masters upgraded to reflectauthorized handwritten changeswithi n a specific time period?_____如何控制?How is this controlled________________________________________6.6现行的文件是否有有效文件总清单?Are there master document files for active specifications?_____6.7是否保留文件变更的记录?Is the revision history for specifications retained?_____有无一既定的方法用来清除所有生产、检验现场内作废的图纸的程序及说明?Is there a method for removing obsolete drawings, procedures, and specificationsfrom all production and inspection areas?_____对于受控文件及其它公司的记录是否建立或已有一个纠正措施程序?Have error correction procedures for controlled documentation and other companyrecords been establishedand implemented?_____程序是否包含以下各项?Does the procedure include the following:不允许使用修正液No use of correction fluid allowed._____不允许使用铅笔No use of pencil allowed._____不允许使用钢笔No use of felt-tip pens allowed._____不允许涂改错误No obliteration of errors allowed._____纠正人能识别Identification of person making the correction._____修正的日期(年、月、日)Date (month, day, year) of the correction?_____是否注明修正的原因Reason for correction if not obvious._____在自动分发系统中对可能会没有被接收的是否每年定期审阅?For specifications not received by automatic distribution, is there an annualreview of specifications that assures that only the latest specifications are in use? _____必要的标准、图纸是否在现场易于得到并被理解?Are necessary specifications, required drawings, and other drawings accessible toin-process personnel?_____意见(COMMENTS):____________________________________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________ __________________________________________________________________________________________总计(POINT TOTAL):________记录保存(RECORD RETENTION)以下记录是否被保存至所列出的期限内?Are the following records retained for the minimum time periods listed?人员的培训及测试(一年内的有效保存在整个雇用期间的记录)Personnel training and testing (one year active file retention, then archived for entire period of employment)._____检验操作记录、生产过程记录、进料和过程记录(一年)Inspection operations: production processes, incoming, and in-process (oneyear)._____有关图片、认证、质量一致性的检验(五年)Screening, qualification, and quality conformance inspection (five years)._____不良记录及分析(五年)Failure reports and analysis (five years)._____有关设计、材料、过程变更的书面记录(五年)Initial documentation and subsequent changes in design, materials, andprocessing (five years)._____设备的校验记录(五年)Equipment calibration (five years)._____预防性维护记录(五年)Preventive maintenance (one year)._____有关过程、利用率及材料控制的记录(一年)Process, utility, and material control (one year)._____证明产品的记录(5年)Product lot identification (five years)._____追溯产品的记录(5年)Product traceability (five years)._____意见(COMMENTS):________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________总计(POINT TOTAL):________异常时的纠正措施(NON-CONFORMANCE TO SPECIFICATION AND CORRECTIVE ACTION)不良材料是否被标识并隔离?Is non-conforming material identified and segregated from conforming material?_____不良材料是否定期做报告并提交管理层批阅?Are reports for non-conforming material regularly prepared and reviewed bymanagement for action?_____有无文件化的纠正措施系统?Is there a documented corrective action system?_____是否能提供预防同一问题再度发生的纠正措施?Does the system provide prompt, remedial action to prevent recurrence?_____对重大或重复发生的问题能否提供永久性的解决方案?Does the system provide permanent resolution to major or recurring problems?_____是否制定了所有纠正措施及措施被实施的跟进文件?Does the system provide documentation of and follow up on all corrective actions? _____有无MRB体统处理不良材料?Is there a Material Review Board (MRB) system to disposition non-conforming material?. SCAR,NCMR, etc.)_____所采取的纠正措施是否以内部检验结果及过程分析、自我审核、客户输入为基础?Are corrective actions and dispositions taken based upon internal material review,process analysis, self-audit results, and/or customer input?_____当不良品已被运往AMD时,供应商是否通知适当的AMD质量或采购人员?Does the supplier notify appropriate AMD Quality/Purchasing personnel when non-conforming material may have been shipped to AMD?_____若允许返工,是否有限制返工的不良材料的程序?If rework is permitted, are there documented procedures and limits for reworkingnon-conforming material?_____是否有返工、拒收材料的检验的书面程序?Are there documented procedures requiring the re-inspection of rejected or reworkedm aterial?_____是否对不良材料的最终处理权限做了书面规定?Is documentation available to provide authority for the final disposition of non-conforming material?_____内审是否以确保程序被完全执行为基础?Are internal audits conducted on a regular basis to assure continued compliance to procedures?_____内审的结果及反应是否报告并被维持?Are results and responses to internal auditsreported and maintained?_____意见(COMMENTS):______________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________总计(POINT TOTAL):________客户联络(CUSTOMER INTERFACE)是否将AMD采购要求转化为制造命令并被适当的控制?Is the system for converting AMD purchase order requirements into manufacturingorders properly controlled?_____有无合同规定评审以确保制造命令与AMD当前最新的要求相一致?Is there a customer purchase order and specificatio review system which assures thatmanufacturing orders are updated to AMD's current requirements?_____当重要材料、过程发生变化或制造厂址发生变化时是否具有预先通知AMD的系统?Is there a system for advanced notification to AMD of major material or processchanges or change in the manufacturing plant location?_____是否具有让步系统使不良材料在运往AMD之前通知并获得AMD质量部、必要的制造、工程代表的批准?Is there a waiver system which notifies and obtains prior approval from AMD Qualityand the appropriate manufacturing engineering representatives before making shipment of non-conforming material to AMD?_____意见(COMMENTS):____________________________________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________ __________________________________________________________________________________________总计(POINT TOTAL):________采购控制、评定(CONTROL OF PURCHASED MATERIALS, CHEMICALS, AND SERVICES)是否定义了原料挑选、认证和供应商检讨的方法?Is the method of selection, qualification, and review of suppliers defined?_____质量功能是否进行资源检验、来料检验及供应商审核?Does the Quality function operate a source inspection,incoming inspection, or asupplier audit program?_____是否一批准的供应商名录?Is there an approved suppliers list?_____是否具有一能确保采购材料系统,包括物理、化学、视觉功能尺寸要求?Is there a system that provides assurance that purchased material meets physical, chemical,visual, functional, and dimensional requirements?_____对于易老化的、寿命、环境敏感的材料是否根据需要加以识别和维护?Are limited life, age controlled, or environmentally sensitive materials identified and maintained according to requirements?_____包装材料是否满足AMD的需求?Is packaging material controlled to AMD requirements?_____分包方处加工的材料是否满足AMD的要求?Are subcontractors used to process material to AMD requirements?_____有无确保每个分包商有能力加工、处理、满足AMD要求的材料系统在生意之间?Is there a system to assure that each subcontractor has the capability toprocess material to AMD requirements prior to placing business?_____有无一系统确保每个分包商有最新的标准及设备以满足所需的检验和实验?Is there a system to assure that each subcontractor has the latest applicablespecifications and the equipment available to perform required inspections and tests?_____每个分包商是否具有文件化的质量控制程序?Does each subcontractor have a documented quality control program?_____有无一系统能保证所有分包商的材料符合最新的标准?Is there a system to assure that all subcontracted material consistentlyconforms to the latest applicable specification?_____有无批准的分包商名单?Is there an approved subcontractors list?_____有无AMD已经批准的分包商加工AMD的材料?Has AMD approved subcontractors that handle processing of AMD materials?_____每个分包商未经AMD的允许不得泄露?Does each subcontractor have a non-disclosure agreement with AMD?_____意见(COMMENTS):____________________________________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________ __________________________________________________________________________________________总计(POINT TOTAL):________过程控制、检验方法及产品保证(PROCESS CONTROL, INSPECTION METHODS, AND PRODUCT ASSURANCE)过程检验是否被有效执行?Are in-process inspection activities performed?_____所必须的图纸、工程命令、标准及其它材料易于检验员得到?Do in-process inspectors have access to all required drawings, engineering orders, specifications, and other materials?_____成品的检验是否符合合同及图纸的要求?Is the finished product inspected to ensure that all contract requirements andcustomer drawings have been met?_____有无书面的检验指导书给QC?Are written instructions and procedures available to inspection personnel?_____有无书面的抽样方案?Is the sampling inspection plan defined and documented?_____检验程序中是否定义了检验、测量的设备?Is the test and measuring equipment required for inspections defined and documented in inspection procedures?_____是否具有检验及测试后的状态标识,以避免不良材料被投入使用?Is there a system for proper identification of the inspection status of in-processmaterials to prevent unauthorized use of non-conforming materials prior to approval for the move?_____过程是否被监控与要求一致?Are processes monitored to assure compliance with defined requirements?_____关键的工作区域中环境的要求是否被书面化并执行?Is environmental control and cleanliness documented and maintained in the critical work areas?_____意见(COMMENTS):________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________总计(POINT TOTAL):________包装、鉴定及海运(PACKING, IDENTIFICATION, AND SHIPPING)运输动作与书面规定是否一致?Are shipping operations performed in accordance with written instructions?_____材料上有无适当标签以提供追溯、鉴别用?Are packages labeled for proper traceability and identification of materials?_____包装及运输是否与AMD的要求相一致?Are industry and/or AMD packaging and shipping requirements available and being met? _____有无AMD所要求的如检验证明、检验数据等包含在运输中?Are all required documentation (inspection data,C of C, C of A, etc.) as specifiedby AMD's purchase orders or material specifications included with the shipment?_____意见(COMMENTS):________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________总计(POINT TOTAL):________审核评分AUDIT SUMMARY SHEET质量承诺Quality Commitment_____ out of _____总体质量体系的要求General Quality System Requirements_____ out of _____统计程序及质量控制SPC/SQC_____ out of _____人员培训及证明Training and Certification_____ out of _____测量设备的控制Test/Measurement Equipment Control_____ out of _____文件与资料变更的控制Documentation and Change Control_____ out of _____记录保存Record Retention_____ out of _____异常时的纠正措施Corrective Action_____ out of _____客户联络Customer Interface_____ out of _____采购控制、评定Material Control_____ out of _____过程控制、检验方法及产品保证Process Control/Inspection_____ out of _____包装、鉴定及海运Shipping/Packaging_____ out of _____TOTAL SCORE: _____ out of _____OVERALL PERCENTAGE RATING: ____________________________Note: Use of this summary is at the discretion of the AMD auditor(s).。

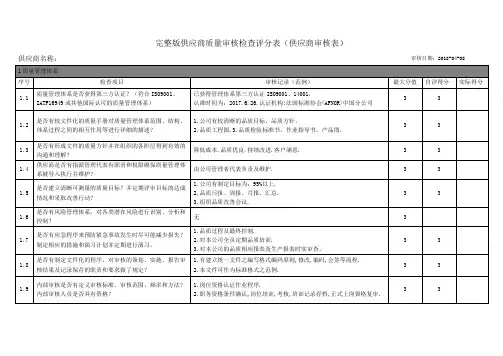

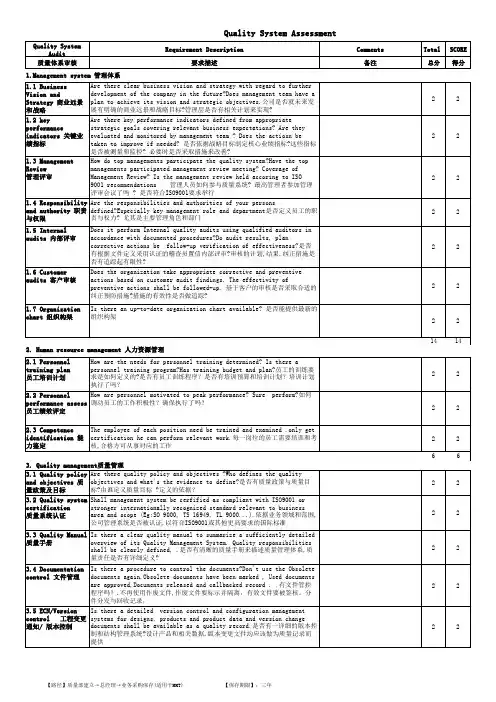

1.Management system 管理体系861212 9.Outing and service 出货与服务9.4 Contract Review System 合同评审系统Does the organization have a formal contract review system in place to convert customer’s requirements into organization internal requirements with respect to requests for quotation, purchaseagreements, purchase orders, internal plans and specifications etc.The organization shall be able to provide evidence of the use of the contract review system. 是否有正式合同评估系统将客户的要求转换组织内部的要求,如报价,采购协议,定单,内部计划和规格等,是否能提供执行的证据229.5 Customer satisfaction program客户满意度调查Are there an active customer satisfaction program based on delivery performance, customer feedback, customer surveys and interviews,etc. Management shall take actions based on the results of theprogram.是否有基于交货业绩,客户反馈,评审,面谈等对客户满意度调查?基于调查的结果是否采取对策?2210.1Product qualification 样品认证Whether does have a function team participate sample approve in the phase of prototype and pre-production.? Does quality engineer attend this team or not ?.是否有专门的样品小组参与样品承认和试产,预生产? 质量部门是否参与?2210.3New Product Introduction 新产品导入Does the supplier shall have a clear process for product transfer from sample phase to volume production. The organization shall review the volume production readiness of the product in final design review or another relevant review. The organization shall organize New Product Introduction and training to productionpersonnel. These actions shall be completed prior to first volume production.供应商是否有详细流程来规范产品从样品到量产的移转流程? 是否有审核其资料已经准备就绪?量产前完成相关人员的培训2210.2 Qualificationmanagement 认证管理record ? Do the supplier submit sample qualification template before mass production 承认的结果数据是否保存?是否能在量产之前提交迈凯实样品承认表?2211.1 Environment Management System 环境体系认证Does the factory fulfill valid environmental standards?是否通过了环境审核?Is the audit enterprise regular?审核公司正规吗?2211.2 MDF submissionIs the supplier capable of declaring the raw material content according to Efore requirements221009610.Product Verification, Qualification and Validation 产品验证,确认与验证11. Environment issues 环境管理。

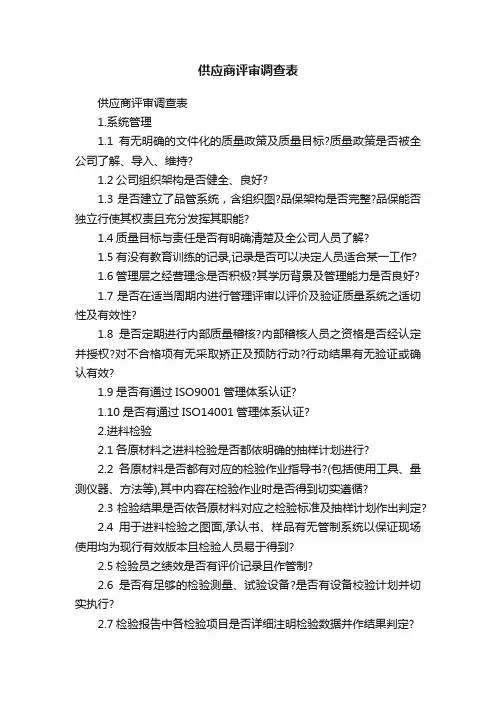

供应商评审调查表供应商评审调查表1.系统管理1.1有无明确的文件化的质量政策及质量目标?质量政策是否被全公司了解、导入、维持?1.2公司组织架构是否健全、良好?1.3是否建立了品管系统,含组织图?品保架构是否完整?品保能否独立行使其权责且充分发挥其职能?1.4质量目标与责任是否有明确清楚及全公司人员了解?1.5有没有教育训练的记录,记录是否可以决定人员适合某一工作?1.6管理层之经营理念是否积极?其学历背景及管理能力是否良好?1.7是否在适当周期内进行管理评审以评价及验证质量系统之适切性及有效性?1.8是否定期进行内部质量稽核?内部稽核人员之资格是否经认定并授权?对不合格项有无采取矫正及预防行动?行动结果有无验证或确认有效?1.9是否有通过ISO9001管理体系认证?1.10是否有通过ISO14001管理体系认证?2.进料检验2.1各原材料之进料检验是否都依明确的抽样计划进行?2.2各原材料是否都有对应的检验作业指导书?(包括使用工具、量测仪器、方法等),其中内容在检验作业时是否得到切实遵循?2.3检验结果是否依各原材料对应之检验标准及抽样计划作出判定?2.4用于进料检验之图面,承认书、样品有无管制系统以保证现场使用均为现行有效版本且检验人员易于得到?2.5检验员之绩效是否有评价记录且作管制?2.6是否有足够的检验测量、试验设备?是否有设备校验计划并切实执行?2.7检验报告中各检验项目是否详细注明检验数据并作结果判定?2.8检验区域有无之明确划分?检验后良品与不良品是否作正确存放?不良品有无标识并作记录?2.9有无MRB作业流程?所有被拒收原材料之结果是否都由MRB 作出判定?2.10原材料不良是否都向供货商提出CAR?有无对供货商改善行动进行检查并作效果确认?2.11有无对原材料特别是主要原材料供货商质量状况进行定期统计评估,以作与供货商提升质量之依据?3.制程管制3.1每一工作站别是否都有作业说明书明确规定该站别所用之机器、设备、治具、工具及作业流程?3.2作业说明书是否明确规定机器设置参数(如温度速度)、工作规格以及材料名称、料号等?3.3有无文件化的制程流程图(或QC工程图或制程管制计划)?3.4制程流程图、作业说明书在发布前是否经核准并作版本版序管制?3.5有无确定重要制程(及特殊制程)及重要制程参数?重要制程参数是否纳入SPC管制?3.6检验站之设置是否合理并配备适当检验人员?每一检验站有无规定检验项目记录?3.7有无明确的检验标准,样品及抽样方式?3.8有无将检验结果统计整理成质量数据并定期通报相关部门?3.9有无首件检查制度?首件检查之时机及项目内容是否合理?3.10良品、不良品、在制品有无作标识以清楚识别,并置于正确区域?3.11有无制程流程卡可清楚识别在制品流程卡上已完成之工序是否都有QAPASS章以保证只有良品才会流至下一工序?3.12不良品是否经授权人员审核并按规定处理?返工/返修后的产品是否经得检验合格后方可进入下一道工序?3.13有无文件化的设备维修保养制度并切实执行?3.14生产设备、工装、治具等是否有足够能力及精度满足稳定生产之需要?3.15有无标准工时之计算以控制产量?3.16整个生产线是否依生产流程之顺序及设备和空间状况作统筹规划?是否顺畅有效率?3.17生产现场是否实行5S制度?是否清洁整齐有序?3.19成品及重要制程之半成品有无良品率之统计?有无提升良品率之计划以降低质量成本并切实实施?4.最终检验出货检验及装运出货4.1有无文件化的最终检验及出货检验作业程序?4.2有无成品检验、出货检验作业指导书及合理的抽样计划?4.3有无缺陷等级划分及缺陷判断标准?4.4有无按规定做落地、振动、环境试验或其它可靠性试验并提供试验报告?4.5最终检验、试验所需之设备仪器是否是足够可用?4.6合格之成品是否清楚标识且经审核并及时处理?4.7对于成品不合格之信息是否及时采取纠正预措施且相关部门积极参与?4.8包装容器能是否有效保护产品以防损坏变质?4.9出货前有无使用检查表对产品包装数量、方式、货品识别标签进行准确复核以判断是否符合规定要求?4.10有无出货检验报告?内容是否具体详实,符合客户规范?4.11有无产品标识追溯的文件化程序以保证实现从客户处的产品追溯到各工序?4.12是否有定期交环保成品送第三方检测检验进行检验以确认其是否符合环境物质管理标准?5.客诉服务5.1有无处理客户投诉的文件化的作业程序?5.2有无明确部门或人员负责客户投诉处理?5.3有无明确客户投诉信息的传递途径?5.4客户投诉经负责部门或人员初步分析后是否迅速传递至责任部门采取改善措施?5.5有无客户特殊要求(特殊规格或特殊配合需要)转化系统以保证客户特殊要求被执行?5.6有无明确规定客户投诉回复时间?是否在规定时间内将详细书面改善措施回复给客户?5.7客户投诉处理是否有改善效果追踪(PDCA)?5.8是否定期对客户投诉进行统计以作改善之依据?6.仓储管理及物料管制6.1有无文件化的仓储管理作业程序以规范搬运、储存、包装、防护、交付作业?6.2仓库有无合理之区域划分(如原材料仓、成品仓、半成品仓、待验区、退货区等)及库位划分?运输通道是否畅通?6.3有无规范搬运工具、堆放高度(或层数)、包装方式等以防物品损坏或变质?6.4对环境有特殊要求之物品是否存放在温度、湿度符合要求之场所?6.5静电敏感材料是否采取静电防护措施?6.6存货记录是否准确显示货品数量,存放位置及进出状况?6.7仓库内物料摆放是否整齐有序?周围环境是否干净整洁?6.8有无物料存放周期之规定?过期物料是否重新验判?6.9所有物料都有相应标识显示其状态(良品、不良品、原材料、半成品、成品等)?6.10有无物料先进先出(FIFO)之管制?执行成效如何?6.11有无处理客户退回品之文件化程序?7.培训7.1公司人力资源政策是否有明确的书面规定:禁止招募、使用童工(16岁以下),该规定有无切实执行?7.2有无文件化的培训程序?7.3有无确认与质量有关所有人员培训需求之系统?有无按培训需求制定培训计划并依计划实施培训?7.4有无与不同工作性质不同工作层别相适应之培训教材体系?7.5培训讲师之资格有无清楚规定及授权?7.6所有与质量有关人员特别是检验人员及重要制程作业人员是否必须接受过相应培训且合格后方能上岗?7.7有无规定接受培训人员之考核方法(理论考试或实践考核)?考核结果是否作为相应人员合格上岗之依据?7.8是否对特殊工作岗位(如电工)作明确定义?其作业人员之资格是否经认定及授权?7.9培训纪录是否完整并保存?8.文件管制8.1有无文件化的文件管制程序明确定义管制文件范围(质量手册、程序文件、设计文件及技术图面、作业说明书、稽核文件等)并保证管制文件确实受控?8.2能否保证所有与质量有关人员易于得到恰当且现行有效管制文件?过时或作废文件是否及时从所有使用场所撤走? 8.3有无规定管制文件之审核权限?管制文件在发布前是否经授权人员审核通过?8.4有无工程变更管制系统、工程变更在实施前是否经授权人员审核通过并及时发布到使用场所?8.5质量记录有无保存时限规定?质量记录是否能充分证明质量系统运行之有效性并作改善之依据?9.产能、成本、交期、配合9.1客户订单是否有系统之检查工单之版本更新?9.2确认客户订单前是否确认客户产品规格与订单一致?9.3客户通知产品规格变更是否有图面及承认书或ECN做依据?9.4客户往来文件、要求、通知、合约等是否完善管理?9.5业务及工程部门是否有能力处理客户对产品生产制程之要求?9.6客户订单中如有特殊要求,公司内部文件是否也记录客户之特殊要求?9.7客户订单中提供之相关技术文件是否妥善保管不外流?9.8是否有建立客户服务响应时间即客户满意指针之一的管理系统?9.9是否有对客户制定定期的降价计划.目标,执行成效如何?9.10是否有定期的运输、材料、制程计划成本缩减?9.11现有成本/价格水平(参考我司相近材料或半成品成本/价格)9.12现有机器、设备、产能、交期可达到水平状况(参考我司现有状况9.13是否有相关产能的应急和备援以及扩充计划;10.模具工程能力10.1模具维修与保养是否确实执行、数据是否健全?10.2有无建立模具履历表管制模具状况、成品质量与产能?(进出记录)10.3设计人员的设计水平状况?10.4开模、修模或相关经验是否丰富?10.5作业流程与管控是否顺畅?10.6技術人員的水平及人員編制是否充足?10.7硬件设备状况(加工生产设备);10.8软件设备状况(指脑绘图软件重要加工设备编程软件);。

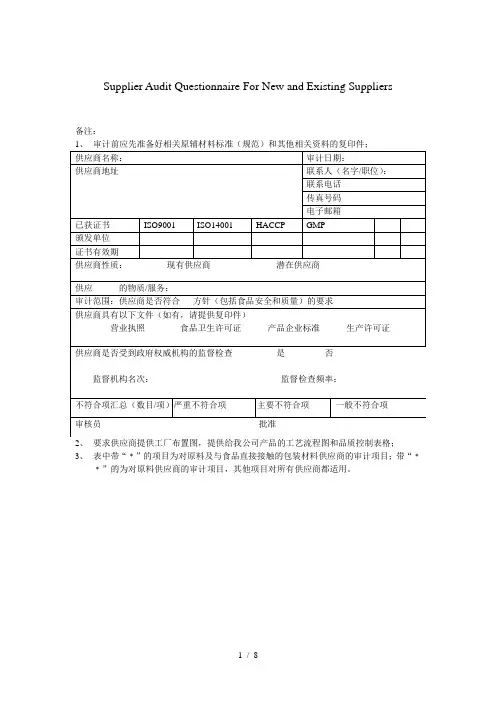

供应商现场评审检查表客户满意1、是否有文件化过程来测定客户满意度,包括:测定频率、交付产品的质量、客户中断应急管理、现场退货,交付业绩以及通知客户吗?2、量化监控于供应商制造的客户满意度,并被理解和跟踪。

3、有适当的计划和程序去提高客户满意,基于纠正措施处理,以及闭环评审制度的实施。

4、为大客户设立了多功能服务团队质量体系1、你们有质量体系标准认证,如IS09000 / TS16949吗?2、有季度管理评审来验证质量体系运行的有效性吗?3、每个部门都有明确定义和可测量的目标,着重关注质量方针,目标、审核结果、数据分析、纠正措施和预防措施。

4、管理人员定期按计划评审项目管理的完成情况。

管理人员应评审纠正措施计划以确保任何过期项目制定计划,并形成在目前的项目管理计划中。

5、内部审核频率应该基于不合格的趋势进行修正。

6、内部审核可以用来验证质量体系被跟踪。

7、正式的商务/业务/制造系统在应用(如:产能计划,工作场所控制,ERP,等等).8、主动告知可能影响交货或质量问题,记录在案,并执行。

9、供应商是否有一个最终产品的标识流程,包括条形码识别(如果需要)。

10、当产品/过程不同于已批准的加工工艺或工艺过程时,在进一步加工处理之前,供应商是否获得客户批准或让步接收?当这种情况发生的时候,是否在包装上适当地进行标识?商务系统1、是否有开发和开展以客户为中心(以顾客为关注焦点、顾客导向)的战略,以确保业务组合的多样性?2、是否有证据和使用工具,如电子数据接口(EDI),RFQ(询价单),先期策划与调度按排(APS)?3、是否为一旦发生紧急情况的时候准备了充分的应急反应计划以满足顾客的需求,如:公用事业设施中断,劳动力短缺的危机、关键设备的故障,以及现场退货?4、是否有制定明确的产品责任/召回问题处理程序流程?5、供应商是否有一个长期的持续改进计划,包括系统可持续发展地方识别关键的商业运作和产品的风险与机会吗?6、是否对采购订单进行评审,包括:对数量,价格,交货日期,交货方式,任何额外的特别的要求或指示的承诺?如果出现任何差异,在接受签署订单之前这些差异是否得到解决?7、执行特定任务或作业的人员应具备资格认定,是基于实适当的教育、培训、和/或经验。

R.S N/A审核发现不符合内容OK NG1.4####√2.4####√3.4####现场询问带班人员,通过以过程为模式的管理,持续改进稳步提高产品质量,以诚信服务为导向,不断增强客户满意度√4.4####制定公司的KPI,并每月对不达标的KPI进行分析,并改善√5.4####通过系统抽查,抽查2021年绞线车间4月份培训,并对培训后的结果进行评价√R.S N/A审核发现不符合内容OKNG1.4####√2.4####√3.4####√R.S N/A审核发现不符合内容OKNG1.4####√2.4####√3.3####915机台 TX54/0.18,绞线员工米交接班记录本机速1000+/-100m/min,实际为1500√√4.3####车间看板职业卫生报告已经过期,未及时更新√R.S N/A审核发现不符合内容OK NG1.3####部分设备5S 部不到位√2.4####3.3####仓库不良品区未按照文件中的要求进行放置√R.S N/A审核发现不符合内容OKNG1.4####绞线机台工艺卡AX201903150017 19/9/0.32,要求记录13条的张力,实际只有12条√2.4####√3.4####√4.4####√5.4####√R.S N/A审核发现不符合内容OKNG1.4####√2.3####实验室镀层厚度记录表0120T有检验人员签字,无检测数据√3.4####√R.S N/A审核发现不符合内容OKNG1.4####√2.4####根据出货计划实施出货√3.4####WIPC001包装作业指导有规定√4.4####PD610-01风险和机遇应对控制程序,√5.4####每月5号进行统计汇总,并实施相应的改善措施√6.4####PFRE003工程变更管理程序,抽查Z1-03-02 按照要求进行工程变更√R.S N/A审核发现不符合内容OKNGH A B C D E F G 有无紧急对应体系和方法?对应能力如何?每月是否对各客户进行纳期达成率统计?如有纳期不理想时有无采取相应措施?有无变更部品管理规定?有无管理台帐及记录?供应商管理评分成品管理评分有无按客户的排期进行生产前能力评估?异常时有无书面联络给客户?是否按客户的排期进行出货?有无出货计划表?有无包装作业管理规定?包装要求是否明确?检查管理评分检查规格,判定基准是否明确?检查员是否理解检查规格?实施状况如何?检查结果有否记录(DATE)?是否按抽样标准进行抽样?依据检查结果对LOT的判定,处理及向相关部门的反馈是否适切?是否有QC工程表与作业标准书,内容是否适切?文件规定的内容是否得到了实施?工程能力能否达到客户的纳期、品质要求?工程内不良有无使用统计手法进行原因分析及对策?工程内不良有无使用统计手法进行原因分析及对策?有无按客户的排期制定月、日生产计划表?实施状况如何?整理、整顿、清扫(5S)是否充分实施?作业环境是否适当?材料、半成品、完成品的保管状态是适当?良品、不良品及半成品、成品的标识,区分是否明确?工程管理(制造的日常管理)评分是否采用品质统计手段进行质量管理?有无采取相应的措施?客户情报有否发行,配布及回览,是否进行配布以确得可见性?检查基准书、其他相关资料是否规定的管理方法?实施状况如何?对旧文件的管理(改版)是否确切地在执行?新旧版本有无明确标识?环境、现品管理评分品质保证体制的基本要点是否在组织上予以保证实态是否相仿?品质保证责任者是否对品质保证业务的正常运作实施监控,是否采取了适当的改善行动。

食品生产企业供应商审核检查表

审核条款

序列 审核要求 级别 满分 得分 审核描述

1、质量管理和保证

10

0.0

1.1 经营管理者对企业经营有诚信的理念与对食品安全的方针或承诺和目标,公司

要承担生产合法产品的义务和履行对顾客的责任,包括对评审和持续改进的承诺;公司的最高层管理者应确保方针和目标传达到所有与产品安全性,合法性

和质量所有相关的员工。

(没有方针或承诺的可直接定为D 级)

关键项

30

1.2 具有合法的营业执照和其他相关法规要求的证件,并是最新更新的(请审核员

对原件拍照入报告),且没有产品分包的行为。

(失效或没有合法的营业执照和其他相关法规要求的证件时,无论最终审核结果如何只评为E 级) 关键项

30

1.3 明确食品安全管理组织结构,设有质量管理(QC)或者质量保证(QA)部门,并

明确QA 、QC 工作职责与资质要求(证书)。

质量部门的所属合理(没有的视实际质量和安全管理程度评为C 级或D 级,不合理的直接定为D 级) 关键项

30

1.4

通过食品安全相关体系的认证(HACCP/ISO 22000/ IFS/ BRC/ SQF/ AIB/FSSC22000)或者食品质量管理体系ISO9000。

(如有请详细记录) 基础项

20

1.5 工厂制定书面的文件管理制度和记录管理制定并严格执行。

关键项 30。

文件編號(Document No.) : (C-0-6-2-QW1401-02)

邱靜怡item 缺失地點

(Place)

缺失項目(Defect description)矯正及預防措施(Corrective and preventive action)負責人(People in charge)完成日期(Due date)進度(Status Confirmation)備註(Remark)1)Systems

Management

沒有將MSI SQMS 文件納入外來文件管控2)Training &

Education 人員對GP 管控要求不熟悉(只有GP 負責人員了解管控要求)

倉庫人員未按流程作業(發料後未及時在

bill 卡上消帳)

倉庫尾數箱/打開箱未密封保存作好管控

供應商稽核未對制程CheckList作確認

(目前只有品質系統稽核)

供應商稽核时由品管部、生技部、釆购部各派出人员到供应商现场进行稽核郑万洪2009-1-5始供應商管理未按年初排定計劃執行(統一

安排在10月-12月進行)微星科技股份有限公司

Micro Star International Co., Ltd.

聯 絡 人(Contact person)

供應商稽核缺失表( Supplier Audit Finding List)

供 應 廠 商 名 稱(Supplier Name)

睿得科技股份有限公司供 應 廠 商 地 址(Supplier Add.)

台北市中山區復興北路150號9樓之一Department:(部門)MSI 稽 查 日 期(MSI Audit date)

2008-12-16業務部門連 絡 電 話(Contact phone)

886-2-2717-0303 EXT 555MSI 稽 查 人 員(MSI Auditor)

Charleyyuan/Doctorwu/Fountainhu Supplier Management

4)Warehouse Management 3)。