余热锅炉查值焓值表

- 格式:xlsx

- 大小:29.75 KB

- 文档页数:28

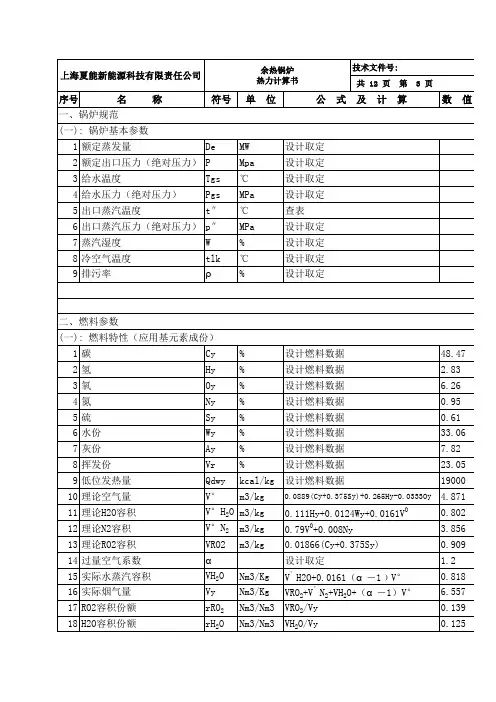

余热锅炉热力计算烟气特性及温焓计算结果汇总正文目录封皮计算批准热力计算书目录序号名称符号单位公式及计算数值(一):锅炉基本参数MW设计取定给水温度Tgs℃给水压力(绝对压力)Pgst″查表p″冷空气温度排污率%(一):燃料特性(应用基元素成份)碳Cy设计燃料数据氢Hy氧Oy氮Ny硫Sy水份Wy灰份Ay挥发份Vr低位发热量Qdwykcal/kg理论空气量V°m3/kg理论H2O容积理论N2容积理论RO2容积VRO2三、热平衡参数及计算(一):热平衡计算冷空气理论热焓Ilk排烟温度Tpy先假定,后校核排烟热焓Ipy查焓温表排烟热损失q2气体不完全燃烧热损失q3固体不完全燃烧热损失q4散热损失《标准》表4-1 锅炉总热损失∑q保热系数ψigs《标准》附表14 锅炉有效利用热QglBm2Hf《标准》附表4 先假定,后校核。

进口工质温度t'工质流量占总流量百分比进口水焓i'出口水焓i″《标准》公式7-62出口工质温度烟气中水蒸汽容积份额rH2O查烟气特性表三原子气体容积份额rq有效辐射层厚度smkq1/(m.kgf/cm2) 《标准》公式5-19 Gykg/kg烟气中飞灰浓度μfh烟气减弱系数k烟气黑度αy《标准》公式5-17x《标准》公式5-33 Qf(二):凝渣管管子直径dmm管子壁厚δ横向排数Z1纵向排数Z2横向节距S1纵向节距S2受热面面积H烟气流通面积F受炉膛辐射受热面积有效角系数有效辐射受热面积Hfs《标准》公式5-4《标准》公式7-46烟气入口温度ひ'由前一部件出口烟气温度获得烟气入口温焓I'烟气出口温度ひ″烟气出口温焓I″烟气侧放热量Qrp《标准》公式7-2 平均烟气温度ひpj(ひ'+ひ″)/2取炉膛工质出口温度《标准》公式7-62 温压Δt《标准》公式7-50烟气流速m/s《标准》公式7-14节距修正系数Cs《标准》公式7-28,29,30 管排修正系数Cz《标准》公式7-32,33 对流放热系数αdkcal/(m2.h.℃)《标准》公式7-27管壁积灰层表面温度tb《标准》公式7-48 α《标准》公式7-42 辐射放热系数αf《标准》公式7-41 吸收炉膛辐射热量《标准》公式7-7 烟气对管壁放热系数α1αd+αf热有效系数传热系数k《标准》公式7-13 传热量Qcr《标准》公式7-1 凝渣管总吸热量QQf+Qcr误差ΔQ允许误差Δ《标准》7.6.2条(三):锅炉管束管子类型光管烟气冲刷方式混合冲刷管子排列方式顺排管子厚度纵向冲刷长度L当量直径ddl横冲对流受热面积Hd《标准》7.1.1条纵冲对流受热面积Hdz横冲烟气流通截面面积《标准》7.3.12条纵冲烟气流通截面面积进口烟温ひ′进口烟焓I′出口烟温出口烟焓管内工质平均温度t《标准》附表13平均温压《标准》公式7-49 烟气计算温度t+Δt横冲烟气平均流速w纵冲烟气平均流速气体减弱系数《标准》公式3-28 飞灰减弱系数kfh《标准》公式5-22 《标准》公式6-42 横冲对流放热系数αdhx《标准》公式7-24 纵冲对流放热系数αdzx《标准》公式7-36 《标准》7.2.1条横冲传热系数Khx《标准》公式7-10 纵冲传热系数Kzx《标准》公式7-40 ΔQ<Δ计算有效(四):省煤器烟气与工质流向管径对流受热面面积烟气流通截面面积漏风系数由前一部件出口水温获得工质流速wgz《标准》公式7-17烟气平均温度(ひ'+ひ″)/2烟气平均流速(五):空气预热器管子长度受热面积几何结构计算空气流通面积f空预器平均空气量与理论空气量之比《标准》公式3-15 热空气出口焓Ick《标准》公式7-6 热空气出口温度tck平均烟温(ひ′+ひ″)/2烟气侧对流放热系数平均空气温度tpj(trk+tlk)/2空气流速wk《标准》公式7-15 空气横冲放热系数α2Ψ《标准》7.2.5条《标准》公式7-11 逆流温压△tnl大温差τd《标准》7.5.7条小温差τx参数PR温压修正系数《标准》线算图22 △t《标准》公式7-53 △Q传热部件计算结果汇总名称及符号单位入口烟气温度出口烟气温度吸热量烟速工质入口温度工质出口温度介质流速炉膛/凝渣管锅炉管束省煤器烟气特性及温焓表αpjVH2ONm3/kgVyγRO2γH2OγqαfhCfh 100℃200℃300℃400℃500℃600℃700℃800℃900℃1000℃1100℃1200℃1300℃1400℃1500℃1600℃1700℃1800℃1900℃2000℃共13页第11页SHL29-1.6/150/90-AII锅炉热力计算书SHL29-1.6/150/90-AII锅炉热力计算书审核技术文件号:RS37-RL技术文件号:RS37-RL共12页第1页共12页第2页共12页第3页共12页第4页共12页第5页共12页第6页共12页第7页共12页第8页共12页第9页共12页第10页共12页第11页共12页第12页技术文件代号:锅炉型号上海夏能新能源科技有限责任公司上海夏能新能源科技有限责任公司余热锅炉热力计算书技术文件号:上海夏能新能源科技有限责任公司余热锅炉热力计算书本计算依据1JB/T7603-1994烟道式余热锅炉设计导则2《工业锅炉设计++标准方法》简称《标准方法》注:计算公式中凡是注明《标准方法》,即依据《工业锅炉设计计算标准方法》计算,公式中未注明出处者即依据《烟道式余热锅炉设计导则》。

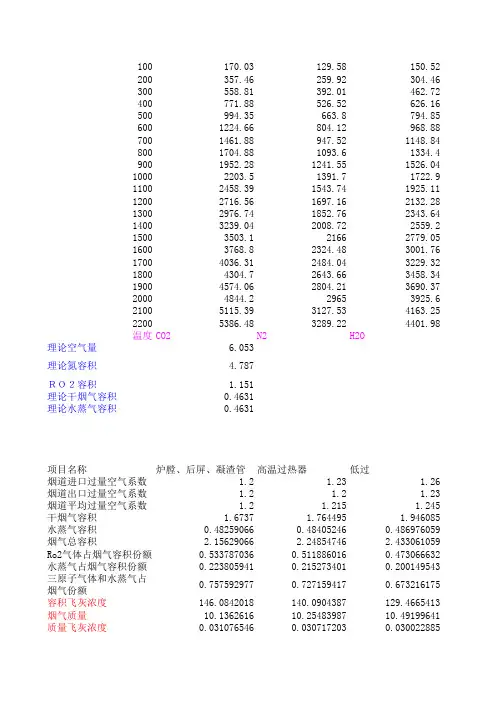

100170.03129.58150.52200357.46259.92304.46300558.81392.01462.72400771.88526.52626.16500994.35663.8794.856001224.66804.12968.887001461.88947.521148.848001704.881093.61334.49001952.281241.551526.0410002203.51391.71722.911002458.391543.741925.1112002716.561697.162132.2813002976.741852.762343.6414003239.042008.722559.215003503.121662779.0516003768.82324.483001.7617004036.312484.043229.3218004304.72643.663458.3419004574.062804.213690.3720004844.229653925.621005115.393127.534163.2522005386.483289.224401.98温度CO2N2H2O理论空气量 6.053理论氮容积 4.787RO2容积 1.151理论干烟气容积0.4631理论水蒸气容积0.4631项目名称炉膛、后屏、凝渣管高温过热器低过烟道进口过量空气系数 1.2 1.23 1.26烟道出口过量空气系数 1.2 1.2 1.23烟道平均过量空气系数 1.2 1.215 1.245干烟气容积 1.6737 1.764495 1.946085水蒸气容积0.482590660.484052460.486976059烟气总容积 2.15629066 2.24854746 2.433061059 Ro2气体占烟气容积份额0.5337870360.5118860160.473066632水蒸气占烟气容积份额0.2238059410.2152734010.200149543三原子气体和水蒸气占烟气0.7575929770.7271594170.673216175容积飞灰浓度146.0842018140.0904387129.4665413烟气质量10.136261610.2548398710.49199641质量飞灰浓度0.0310765460.0307172030.030022885885.709802132.43801.5987925.452130.04 1796.668926266.361612.2770853.2665261.42 2734.027812402.692437.4825783.0655395.16 3698.859816541.763279.27328113.4531.56 4690.202485684.154141.15995144.4275671.35 5707.594428829.745022.41622176.337813.9 6750.429924978.325921.77096208.908959.56 7815.340721129.126834.56336241.6681107.36 8897.0832541282.327761.88296275.27851257.84 9996.171391437.38699.9769309.961409.7 11111.008711594.899653.86917345.241563.54 12238.524351753.4410613.57232379.891719.24 13380.729541914.2511586.95525428.41876.16 14529.04322076.212567.2386494.8652033.92 15687.688162238.913552.0617553.772193 16855.289622402.8814544.63264576.452353.28 18032.390382567.3415540.10902650.792513.96 19211.467372731.8616535.94858687.962676.06 20397.506682898.8317546.61799742.772838.41 21587.074563065.618556.0768791.283002 22787.301083233.7919574.13087831.63165.33 23983.891563401.6420590.12692869.43329.7理论烟气焓湿空气理论空气焓飞灰的焓干空气高温省煤器高温空气预热器低温省煤器低温空气预热器1.28 1.31 1.31 1.331.26 1.28 1.33 1.361.27 1.295 1.32 1.3452.09741 2.248735 2.40006 2.5513850.4894123910.4918487240.4942850560.4967213892.586822391 2.7405837242.8943450563.0481063890.444947440.419983520.3976720040.3776114920.1891944310.17946860.1707761330.1629606470.6341418710.599452120.5684481370.540572138121.7710196114.9390173108.8329117103.342849610.6896268610.8872573111.0848877611.282518210.029467820.028*******.028*******.027919299130.1780.81071.481561100.909282910.959124 261.42169.12172.3908421132.198984937.358886 395.01263.73304.5898261163.524646964.832004 531.563604468.1144721194.747503991.342669 671.35458.55662.8619751225.5526971017.391943 814.44559.86888.4146721255.2774441042.835496 960.4663.28143.6921161280.2292761064.910796 1108.96767.29423.9213921300.8169541081.742534 1259.64873.910724.738351321.3884241099.088136 1412.698412046.126771340.8957751114.837321 1567.28109613387.022551354.1062671127.515637 1723.32120614741.128811385.3917821142.205196 1880.45136016126.520591410.8353261148.313656 2038.4157117537.355921414.5145751158.644955 2198.7175818951.87051388.7956491167.601461 2359.36183020340.666141450.5360421177.100766 2520.25206621791.202191415.4149041179.076992 2682.182********.617091442.9831851186.039303 2844.68235824649.600281439.9696451189.567883 3007.8251226089.569921444.1573291200.226515 3171.42264027533.727251437.5896931196.590483 3335.2276028971.31694#VALUE!#VALUE!CO飞灰、炉渣Hy焓增理论烟气焓增a”= 1.2炉膛、屏、凝渣管1095.5295241125.2296311119.5774871149.551135.6094631165.76355 2220.7591541156.9551492269.1274671181.7112301.3730081198.21542 3377.7143031188.7783673450.838781214.0323499.5884321230.8679 4566.492671220.6041034664.8708691246.4614730.4563341263.69844 5787.0967741251.9903855911.3315721278.4285994.1547711296.0532 7039.0871591282.2580867189.7596451309.2397290.207971327.22582 8321.3452451307.6130488498.9983741334.9978617.4337931353.25267 9628.9582931328.6365429833.9951941356.4569970.6864611375.00252 10957.594831349.53124211190.451321377.67411345.688981396.43594 12307.126081369.51254312568.125381398.12912742.124921417.20716 13676.638621382.89736213966.25471411.68814159.332081430.88252 15059.535981414.5932715377.943151443.79515590.21461463.26242 16474.129251440.24382716821.737911469.65217053.477011489.25799 17914.373081444.0592*******.390241473.60418542.735011493.30042 19358.432351418.57277719764.99421448.3520036.035431468.20132 20777.005121480.40033321213.34411510.26521504.236761530.17415 22257.405461445.29009122723.608731475.16523034.410911495.08207 23702.695551473.30326724198.7741503.62324529.492981523.83674 25175.998811470.25340925702.397351500.53726053.329711520.72635 26646.252221474.69895127202.934531505.24127574.056061525.60165 28120.951181468.06957528708.17511498.54929099.657721518.86938 29589.02075#VALUE!30206.72456#VALUE!30618.5271#VALUE! Hy焓增Hy焓增Hy焓增a”= 1.23a”= 1.26a”= 1.28高温过热器低温过热器高温省煤器1159.6574271190.0842349.7413211222.9723572.7129091256.1224828.8345331289.5556118.389571322.4917440.8804561354.2068795.0869221380.63610175.723361402.82211578.545471424.57913003.124231445.82414448.948151459.67415908.621771492.46417401.085671518.66618919.752171522.84520442.597281497.97821940.575731560.03823500.614181524.95725025.571431554.15726579.728251551.0128130.738371556.14329686.881641549.34931236.2309#VALUE! Hy焓增a” 1.31高温空气预热器。

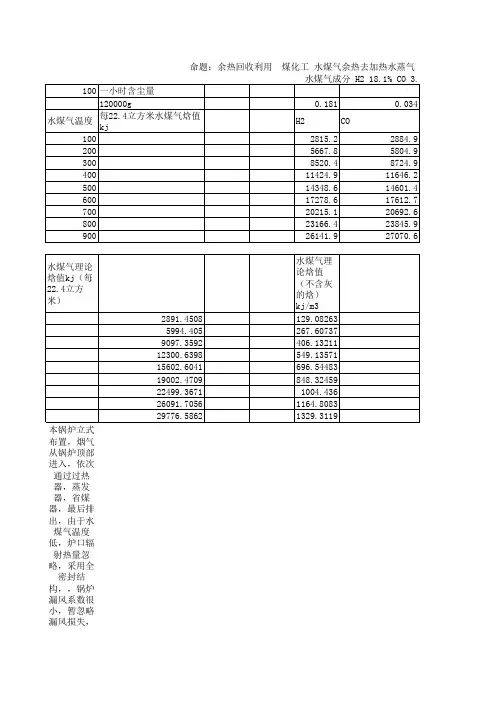

命题:余热回收利用 煤化工 水煤气余热去加热水蒸气 80热平衡1进炉烟气量2入炉烟温3入炉烟焓4出炉烟温5出炉烟焓6烟气带入热功率kj/h7烟尘带入的热功率8入炉总热功率9漏风系数10烟气带走的热功率kj/h11烟尘带走的热功率12散热损失kj/h 13汽化吸热功率kj/h 14给水温度15过热蒸汽焓kj/kg 16给水焓kj/kg 17排污率18饱和水焓kj/kg 19产汽量t/h 20给水压力Mpa 21锅筒压力MPa 22饱和温度23饱和蒸汽焓kj/kg 24饱和水焓kj/kg 25省煤器出口水温26省煤器出口焓kj/kg 27过热器吸热量kj/h 28省煤器吸热量kj/h 29蒸发受热面吸热量kj/h0.0040.1750.2260.38CH4CO2H2O N23293.52470.83287.52882.36691.75951.86626.85803.110089.99432.89966.18723.913888.913366.71335711640.418225.317668.916830.214580.223151.422271.320405.917564.228659.12712024096.220606.634704.632172.627907.223715.241232.637395.931842.526891.8灰的焓kj/kg每m3灰的焓kj 水煤气的理论焓值kj/m358.60.4688129.551425117.20.9376268.5449661175.81.4064407.5385071234.41.8752551.010*******2.344698.8888259351.62.8128851.1373938410.23.28161007.717631468.83.75041168.558686527.44.21921333.531084120008001168.559100129.551414022405.29298.938904814022704.231554617.1566400气 800℃ 12000Nm3/h 冷却到100℃ 另一工艺需水蒸气400℃ 1MPa 设计换热器 蒸汽流量? 常规水0500100015001234567814022.7042312454064.420.888135713203214.5852782.053.869570035无排污1.24481.18180.60722782.05794.8475170.60727181720965.0622519067.8328214031.531常规水20℃系列19。