德菲尔曼操作手册

- 格式:doc

- 大小:6.42 MB

- 文档页数:22

OPERATOR'S MANUALINTERFACE UNITIF-NMEASC MODELwww.furuno.co.jpIMPORTANT NOTICES• This manual is intended for use by readers with a solid knowledge of English.• No part of this manual may be copied or reproduced without written permission.• If this manual is lost or worn, contact your dealer about replacement.• The contents of this manual and equipment specifications are subject to change without notice.• Store this manual in a convenient place for future reference.• FURUNO will assume no responsibility for the damage caused by improper use or modification of the equipment (including software) by an unauthorized agent or a third party.• When it is time to discard this product it must be done according to local regulations for disposal of industrial waste. For disposal in the USA, refer to the Electronics Industries Alliance (http:// /).SAFETY INSTRUCTIONSSAFETY INSTRUCTIONSTABLE OF CONTENTS FOREWORD (v)SYSTEM CONFIGURATION (vi)1.MOUNTING (1)1.1Equipment List (1)1.2Mounting Procedure (1)2.WIRING (2)3.ADJUSTMENTS (4)3.1LEDs and Equipment Status (4)3.2Setting Up NMEA Ports (5)3.3Heading, Pitch and Roll Offsets (8)4.OPERATION (9)5.MAINTENANCE, TROUBLESHOOTING (10)5.1Preventive Maintenance (10)5.2Replacing the Fuse (11)5.3Troubleshooting (11)5.4Self Test (12)5.5Memory Clear (13)SPECIFICATIONS.....................................................................................................SP-1 OUTLINE DRAWING...................................................................................................D-1 INTERCONNECTION DIAGRAM................................................................................S-1FOREWORDA Word to the Owner of the IF-NMEASCCongratulations on your choice of the FURUNO IF-NMEASC Interface Unit. We are confident you will see why the FURUNO name has become synonymous with quality and reliability.For 60 years FURUNO Electric Company has enjoyed an enviable reputation for quality marine electronics equipment. This dedication to excellence is furthered by our extensive global network of agents and dealers.This equipment is designed and constructed to meet the rigorous demands of the marine environ-ment. However, no machine can perform its intended function unless installed, operated and maintained properly. Please carefully read and follow the recommended procedures for installa-tion, operation and maintenance.Thank you for considering and purchasing FURUNO equipment.FeaturesThe IF-NMEASC is a dedicated interface unit for the SC-30 Satellite Compass. It receives NMEA 2000®* format heading, pitch, roll and GPS position data from the SC-30, converts them to NMEA 0183 format data and outputs the converted data to external equipment.• Input port: One NMEA 2000 format port• Four output ports: NMEA 0183x2, AD-10x1, Analog (pitch and roll)x1• Offsets for heading, pitch and roll*: NMEA 2000 is a registered trademark of the National Marine Electronics Association USA.SYSTEM CONFIGURATION1.MOUNTING1.1Equipment List1.2Mounting ProcedureWhen choosing a mounting location for the unit, keep the following points in mind:• Select a location where shock and vibration are minimal.• Locate the unit away from places subject to rain or water splash.• Keep the unit away from exhaust pipes and vents.• Locate the unit out of direct sunlight because of heat that can build up inside its cabinet.• The location should be well ventilated.• Observe the maintenance space mentioned in the outline drawing at the back of this manual and the compass safe distances in the safety instructions.• Fix the unit with four φ3x10 self-tapping screws (supplied).NameType Code No.Qty RemarksInterface Unit IF-NMEASC -1InstallationMaterials CP20-03001001-023-400 1 set • Cable ties (CN-150N, 12 pcs.)• Self-tapping screws (φ3x10, 4 pcs.)Spare PartsSP20-01301001-019-8001 setFuse FGMB 125V 2A (3 pcs.)2.WIRINGOpen the IF unit with your hands, detach the shield cover and connect external equipment, refer-ring to the illustration below and the interconnection diagram. Cables are mainly connected to the unit with WAGO connectors. See the instructions below for how to attach wiring to the connectors. The opener for the WAGO connectors is attached to the inside of the inner cover. Fix cables to their respective cable posts with cable ties (supplied). Run a ground wire (IV-2.0sq., local supply) between the ground terminal and ship's grounding bus. Supply power from breaker on mains switchboard.P o w e r c a b l eJ 8 (A n a l o g )J 7 (S C -30 S e n s o r )J 5 (N M E A 0183)J 4 (N M E A 0183)J 3 (A D -10)G r o u n d t e r m i n a lPower cable: AWG 16-20, and diameter less than 10 mm (JIS* cable DPYC-1.5 or equivalent)Cable postRecommended Cables2. WIRING Cable construction3.ADJUSTMENTS3.1LEDs and Equipment StatusThe six LEDs above the heading indication light, flash or go off according to equipment status.LED state and equipment statusLED LED state and equipment statusGPS ON: Both GPS antennas in the SC-30 are receiving from five or more satel-lites.OFF: One of the GPS antennas is receiving from 3 or fewer satellites. OUTPUT ON: All data is output from the SC-30 normally.Flashing: Motion (heading, roll, pitch) is output (heave is fixed at 0, positionand speed are normal) by dead reckoning.OFF: Heading output is stopped.PROCESSING ON: GPS processor is functioning properly.Flashing: Initializing for GPS.OFF: Not enough satellites received.SENSOR1ON: Rate gyro normal on all three axes.OFF: Rate gyro error.SENSOR2ON: Acceleration sensor normal on all three axes.OFF: Acceleration sensor error.CR33Flashing: Valid NMEA 2000 data is input.ON: No valid NMEA 2000 data is input.OFF: CPU error, or no power.3. ADJUSTMENTS3.2Setting Up NMEA PortsPorts J4 and J5 output data in NMEA 0183 format. Select the data to output from those ports, along with baud rate and output interval. The default settings are as shown in the table below.Default settings for ports 2 and 31.Grasp the cover at its right and left sides, pull the cover outward slightly and then lift the coverto remove it.2.Open the inner cover and turn on the power.On the circuit board, find the heading indication, several LEDs, and four operating buttons. The Heading LED is lit.3.Push the [Menu/Cancel] button several times to light the Sentence LED on the Port 2 line.4.Push the [Enter] button. The Sentence LED starts flashing and the sentence currently select-ed to output from port 2 is shown with a numeric. See the illustration below for numeric and data sentence.5.Push the [+] or [-] button to display the numeric corresponding to the data sentence you wishto output.6.Push the [Enter] button. The sentence LED stops flashing.Port no.SentenceBaud rate (bps)Tx interval (ms)J4 (Port 2)HDT (Heading)4800100J5 (Port 3)ATT (Heading, pitch, roll)HVE (Heave)3840025OUTPUT PROCESSING03OUTPUT PROCESSING0033. ADJUSTMENTS7.Push the [Menu/Cancel] button to light the Bps LED on the Port 2 line.8.Push the [Enter] button. The Bps LED starts flashing and the current bps setting appears.9.Push the [+] or [-] button to select desired baud rate. The choices are 4800, 9600, 19200 and38400 (bps).10.Push the [Enter] button. The bps LED stops flashing.11.Push the [Menu/Cancel] button to light the Output interval LED on the Port 2 line.12.Push the [Enter] button. The Output Interval LED starts flashing and the current output intervalsetting appears.OUTPUT PROCESSING003OUTPUT PROCESSING003OUTPUT PROCESSING003. ADJUSTMENTS13.Push the [+] or [-] button to select desired output interval, referring to the table below.14.Push the [Enter] button. The output interval LED stops flashing.15.Set up Port 3 similar to how you did Port 2.16.Close the inner and outer covers.Sentence numberSentenceOutput interval (ms)4800 bps9600 bps19200 bps38400 bps1HDT 100, 200, 1000, 200025, 100, 200, 1000, 20002HDG 100, 200, 1000, 200025, 100, 200, 1000, 20003HDM 100, 200, 1000, 200025, 100, 200, 1000, 20004ATT, HVE 200, 1000, 2000100, 200, 1000, 200025, 100, 200, 1000, 20005VTG, GGA, ZDA 1000, 20006RMC, ZDA 1000, 20007ATT, HVE 200, 1000, 2000100, 200, 1000, 200025, 100, 200, 1000, 2000GGA, VTG, ZDA1000(<1000), 20001000(<1000), 20008HDT 100, 200, 1000, 200025, 100, 200, 1000, 2000RMC, ZDA1000(<1000), 20003. ADJUSTMENTS3.3Heading, Pitch and Roll OffsetsTurn on the IF unit and wait approx. three minutes for the satellite compass to settle. Then, check that heading, pitch and roll data are reasonable. If not, open the unit and enter appropriate off-set(s).1.Open the cover, referring to step 1 in the previous section for the procedure.2.Open the inner cover.On the circuit board, find the heading display, LED set, and operating buttons. The Heading LED is lit3.Push the [Menu/Cancel] button to light the applicable Offset LED (Heading, Pitch, or Roll) andpush the [Enter] button. The selected LED starts flashing and the display shows current offset for item e the [+] or [-] button to set offset. (You can push and hold down those buttons to speed upthe rate of incrementation.)Range of offsetHeading: ±6°Pitch, Roll: ±10°5.Push the [Enter] button to finish. The display shows current heading, pitch or roll indicationwith offset applied. The selected Offset LED stops flashing.6.Close the inner and outer covers.OUTPUT PROCESSING034.OPERATIONNormally, no operation is required except to power the unit (from the switchboard). The ST-BY LED on the cover is ON, OFF or flashing according to equipment state.Flashing: NMEA 2000 data is inputON: NMEA 2000 data is not inputOFF: Power loss, blown fuse, operation error5.MAINTENANCE, TROUBLE-SHOOTINGThis chapter provides the information for keeping your unit in good working order.5.1Preventive MaintenanceRegular maintenance is important for good performance. Following the procedures in the table be-low will help maintain performancePreventive maintenanceItem Check point RemedyReplace damaged cables.Cabling Visually check cabling forsigns of wear and damage.Ground Check ground wire.Check that ground wire is tightly fastened.Check ground point for corrosion.Cover Cleanliness of cover.Dust can be removed with a soft cloth. Do not usechemical based cleaners to clean the cover, as theycan remove paint and markings and deform the cov-er.5. MAINTENANCE, TROUBLESHOOTING5.2Replacing the FuseThe 2A fuse inside the unit protects it from overcurrent and equipment fault. If the power cannot be turned on, have a qualified technician check the fuse. If the fuse has blown, find out the cause before replacing it. If it blows again, contact your dealer for advice.5.3TroubleshootingThis section provides simple troubleshooting procedures which the user can follow to restore nor-mal operation. If normal operation cannot be restored, do not attempt to check inside the equip-ment. There are no user-serviceable parts inside.Simple troubleshooting proceduresItem TypeCode No,FuseFGMB 125V 2A PBF000-157-479-10Symptom Possible troubleRemedyPower cannot be turned on• Power at switchboard is turned off.• Disconnected or damaged power cable.• Blown fuse.• Check if power is on at switchboard.• Check if power cable is disconnected or damaged.• Have a qualified technician check thefuse.Data is not received from SC-30• Signal cable between the SC-30 and this equipment is dam-aged or disconnected.• SC-30 is no received satellite signal.• Check if sensor cable is disconnect-ed or damaged.• See the SC-30's operator's manual. Data is not received at external equip-ment• Disconnected or damaged in-terconnection cable.• Output settings may be incor-rect.• Check if cable is disconnected or damaged.• Have a qualified technician check the settings.Heading, pitch or roll data is not correct • Offsets entered in this equip-ment may be incorrect.• Have a qualified technician check the settings.5. MAINTENANCE, TROUBLESHOOTING5.4Self TestThe self tests check the equipment for proper operation.Self test 1This test checks the two GPS receivers, output circuit, processor and two sensors for proper op-eration.1.Remove the cover and shield cover from the equipment.2.Press the [Menu/Cancel] button several times to show "- - -.1" on the display. The LED lampsone by one in order, the Output Interval LED in the Port 3 line, and then the equipment goes into the test mode.3.Press the [Enter] button, and the test proceeds as below.• GPS receivers are checked. The GPS lamp lights if the receivers are normal.• Communication between this equipment and the SC-30 is checked. The OUTPUT LED lights if normal.• The CPU memory access is checked. THe PROCESSING LED lights if normal.• The rate gyro is checked. The SENSOR1 LED lights if normal.• The acceleration sensor is checked. The SENSOR2 LED lights if normal.When the test is finished, the nine LEDs below the display flash, and then the display shows "End.1".4.Press the [Enter] button to return to self test 1.5. MAINTENANCE, TROUBLESHOOTING Self test 2This test checks this unit's processor and output for proper operation.1.With the display showing " - - - .1", push the [Menu/Cancel] button. The display shows "- - - 2".2.Press the [Enter] button to start the test.If the results are normal all LEDs light. Then, the nine LEDs below the display flash and the display shows "End.2".3.Press the [Enter] button to return to the self test 2 display.5.5Memory ClearThe memory can be cleared to restore the default settings for the NMEA ports. Note that offsets are not cleared.1.Hold down the [Menu/Cancel] button together with the [+] button until the display shows "-CLR". At this time all Status and Settings LEDs are on.2.Press the [Enter] button to clear the memory and restore all default settings. "END C" appearsupon completion.3.After the memory is cleared, press the [Menu/Cancel] button to show the heading.5. MAINTENANCE, TROUBLESHOOTING This page is intentionally left blank.FURUNO IF-NMEASC SPECIFICATIONS OF INTERFACE UNITIF-NMEASCPORT1 INPUTNMEA 2000*, for data I/O between FURUNO satellite compass SC-30* NMEA 2000 is a registered trademark of the Nationa l MarineElectronics Association.2 OUTPUTPORTNMEA 0183: Two ports (HDT, HDG, HMD, ATT*, HVE*, VTG, GGA,RMC, ZDA)* ATT (heading, pitch, roll) and HVE (heave) are FURUNOproprietary sentences.AD-10: One portAnalog: One port (pitch, roll)3 NMEA 0183 OUTPUT INTERVALHDT, HDG, HDM, ATT, HVE: 25ms, 100 ms, 200 ms, 1 s, 2 sVTG, GGA, RMC, ZDA: 1 s, 2 s4 POWERSUPPLY12-24 VDC: 1.0-0.6 ACONDITIONS5 ENVIRONMENTAL5.1 Ambient Temperature -15°C to +55°C5.2 Humidity Less than 95% at 40°C5.3 Waterproofing IP205.4 Vibration - From 2 Hz to 5 Hz to up to 13.2 Hz with an excursion of ±1 mm ±10%-13.2 Hz to 100 Hz with a constant maximum acceleration of 7 m/s2 COLOR6 COATINGN2.51This page is intentionally left blank.The paper used in this manualis elemental chlorine free.9-52 Ashihara-cho,Nishinomiya, 662-8580, JAPAN。

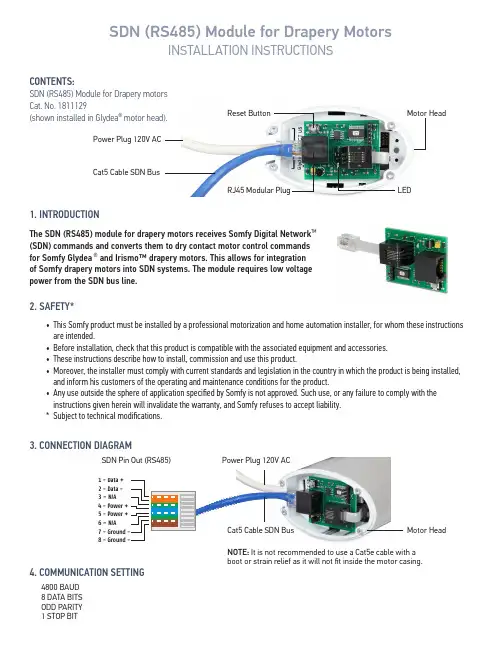

This Somfy product must be installed by a professional motorization and home automation installer, for whom these instructions are intended.Before installation, check that this product is compatible with the associated equipment and accessories.These instructions describe how to install, commission and use this product.Moreover, the installer must comply with current standards and legislation in the country in which the product is being installed, and inform his customers of the operating and maintenance conditions for the product.Any use outside the sphere of application specified by Somfy is not approved. Such use, or any failure to comply with the instructions given herein will invalidate the warranty, and Somfy refuses to accept liability.Subject to technical modifications.• • • • • * 1. INTRODUCTIONCONTENTS:SDN (RS485) Module for Drapery motors Cat. No. 1811129(shown installed in Glydea ® motor head).3. CONNECTION DIAGRAM4. COMMUNICATION SETTING4800 BAUD 8 DATA BITS ODD PARITY 1 STOP BIT2. SAFETY*Power Plug 120V ACPower Plug 120V ACMotor HeadSDN Pin Out (RS485)Cat5 Cable SDN BusCat5 Cable SDN Bus Motor HeadRJ45 Modular PlugLEDReset Button 1 - Data +2 - Data -3–N/A 4 - Power +5 - Power +6–N/ASDN (RS485) Module for Drapery MotorsINSTALLATION INSTRUCTIONSThe SDN (RS485) module for drapery motors receives Somfy Digital Network TM (SDN) commands and converts them to dry contact motor control commands for Somfy Glydea ® and Irismo™ drapery motors. This allows for integration of Somfy drapery motors into SDN systems. The module requires low voltage power from the SDN bus line.NOTE: It is not recommended to use a Cat5e cable with a boot or strain relief as it will not fit inside the motor casing.Open Somfy Digital Newtork Motor Configuration software.Select the correct COM port.Then click on CONNECT.Click on “Get MTR Addr”. The default address, 103254, will appear if not programmed. When using theLegacy Motor Configuration Software, the default address, ABCDEF, will appear if not programmed.Assign a unique 6 bit hex address to Group 1 consisting of 6 characters using A-F and 0-9. This willthen be used to generate the motor address for the module.NOTE: *Group locations 2 through 6 must be programmed with any Hex address except for FFFFFF or000000. The default group address in these locations is FFFFFF.Up to 5 Group Addresses can also be assigned at this time in locations 2 through 6. These addresseswill be used to receive commands (see fig. 1. at right).Click on “Set”. Allow 10 seconds for data transfer between PC and Control.Click on “Get MTR Addr”. Note this converted address as it will be used to communicate with themodule once installed in a system.Click on “Get” under GROUP ADDRESSES and verify the group addresses are set correctly.Programming is complete. The module can now be installed in a system.1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 6. ASSIGN ADDRESS5. INITIAL SETUPTo generate command strings, download the latest SDN String Calculator software from https:///support/tools/configuration-tools-software . A USB to RS485 converter (#9015260) is required.1. Click on “Group Motor Address”.2. Enter the Motor Address just assigned. Click on “All Commands”.3. Click on “Calculate”. All the command strings will be filled in automatically.4. Only the following commands can be used with the Glydea Motor: UP, STOP and DOWNTo change the Motor Address back to the default (103254), legacy (ABCDEF), press and hold the reset button until the LED turns on.8. RESET TO DEFAULT9. OPERATING PROCEDURE7. GET COMMANDS1. Program control with desired group addresses.2. Connect the SDN to DCT control to the SDN via Cat-5 cable and to the Glydea or Irismo motor via 6 conductor modular cable.3. Send the group command over the SDN (using the motor address programmed in the steps above) to move the motor.To assign motor addresses, download the latest Somfy Digital Network Motor Configuration software from https:///support/tools/configuration-tools-software .If using with legacy ILT systems, download the Legacy Motor Configuration Software version 3.5.6.Initial programming of the module must be completed before installing into an existing SDN or ILT system using the steps below:* Fig. 1Connect the SDN module directly to a Somfy Bus and Sensor Station Power Supply (#1822440).Ensure the appropriate Somfy Digital Network Motor Configuration Software was downloaded and installed on your computer for either LegacyILT systems or SDN systems.Connect the computer running the configuration software to the Power Supply using a USB to a RS485 converter (#9015260).1. 2. 3. A USB to RS485 converter (#9015260) is required© C o p y r i g h t S o m f y S y s t e m s , I n c . 2/2017。

REFLEXW软件使用指南一说明本手册主要用来指导用户如何使用REFLEXW软件,它并不包括所有的细节。

如果需要了解全部细节,请参阅英文版手册。

二安装及打开软件安装软件时,只需点击setup即可。

另外,必须安装软件狗的驱动程序CbnSetup.exe,安装时也是点击即可。

打开软件时,必须将软件狗插到并口上,然后从“开始”→“程序”→“REFLEX”→ “REFLEXW”进入。

当显示出“Projectdirectory”菜单时,即可使用该软件。

(最好在桌面上建立快捷键)。

进入菜单后,建议选择菜单中的“new project”, 出现“enter name of the new project”。

输入任务名(如a1等),点击OK, 进入“Reflex_win”主菜单。

点击“Modules”, 选择各相关模块。

三输入和第一次显示GPR数据下面介绍如何输入和显示GPR数据,我们用MALA公司的RAMAC/GPR数据做例子,用其它数据时仅需改变一些选项即可。

一、输入GPR数据1.进入2D数据分析(2D-dataanalysis)2.用选项File/Open/import(文件/打开/输入)进入import(输入)菜单,此时出现REFLEXWData Import(数据输入)菜单(见右图)3.输入下列参数:input format(输入格式):RAMACoutput format(输出格式):16 bit integer(16 位整数)filename specification(指定文件名):original name(原始名,举例)选择X或Y作为剖面方向(ProfileDirection)及Y或X作为剖面常数(ProfileConstant)选择道增量(traceincrement)和/或坐标(coordinates)是否从原始数据读出(从ControlOption)4.点击选项Convert to Reflex,出现一个文件打开菜单,并在任务目录下出现子目录ASCII。

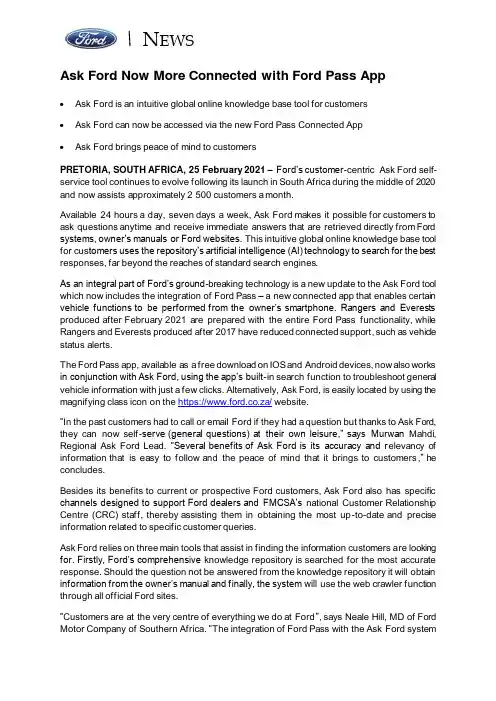

N EWSAsk Ford Now More Connected with Ford Pass App•Ask Ford is an intuitive global online knowledge base tool for customers•Ask Ford can now be accessed via the new Ford Pass Connected App•Ask Ford brings peace of mind to customersPRETORIA, SOUTH AFRICA, 25 February 2021–Ford’s customer-centric Ask Ford self-service tool continues to evolve following its launch in South Africa during the middle of 2020 and now assists approximately 2 500 customers a month.Available 24 hours a day, seven days a week, Ask Ford makes it possible for customers to ask questions anytime and receive immediate answers that are retrieved directly from Ford systems, owner’s manuals or Ford websites. This intuitive global online knowledge base tool for cus tomers uses the repository’s artificial intelligence (AI) technology to search for the best responses, far beyond the reaches of standard search engines.As an integral part of Ford’s ground-breaking technology is a new update to the Ask Ford tool which now includes the integration of Ford Pass – a new connected app that enables certain vehicle functions to be performed from the owner’s smartphone. Rangers and Everests produced after February 2021 are prepared with the entire Ford Pass functionality, while Rangers and Everests produced after 2017 have reduced connected support, such as vehicle status alerts.The Ford Pass app, available as a free download on IOS and Android devices, now also works in conjunction with Ask Ford, using the app’s built-in search function to troubleshoot genera l vehicle information with just a few clicks. Alternatively, Ask Ford, is easily located by using the magnifying class icon on the https://www.ford.co.za/ website.“In the past customers had to call or email Ford if they had a question but thanks to Ask Ford, they can now self-serve (general questions) at their own leisure,” says Murwan Mahdi, Regional Ask Ford Lead. “Several benefits of Ask Ford is its accuracy and r elevancy of information that is easy to follow and the peace of mind that it brings to customers,” he concludes.Besides its benefits to current or prospective Ford customers, Ask Ford also has specific channels designed to support Ford dealers and FMCSA’s national Customer Relationship Centre (CRC) staff, thereby assisting them in obtaining the most up-to-date and precise information related to specific customer queries.Ask Ford relies on three main tools that assist in finding the information customers are looking for. Firstly, Ford’s comprehensive knowledge repository is searched for the most accurate response. Should the question not be answered from the knowledge repository it will obtain information from the owner’s manual and finally, the system will use the web crawler function through all official Ford sites.“Customers are at the very centre of everything we do at Ford”, says Neale Hill, MD of Ford Motor Company of Southern Africa. “The integration of Ford Pass with the Ask Ford systemclearly demonstrates how we’re constantly able to find new ways to meet these evolving needs more accurately and in a shorter timeframe. We continue to build on these platforms to deliver a complete, easy-to use and intuitive end-to-end interface for our customers.”# # #Read the latest news from Ford South Africa by visiting the Newsroom:https://www.ford.co.za/about-ford/newsroom/# # #About Ford Motor CompanyFord Motor Company (NYSE: F) is a global company based in Dearborn, Michigan. The company designs, manufactures, markets and services a full line of Ford trucks, utility vehicles, and cars –increasingly including electrified versions – and Lincoln luxury vehicles; provides financial services through Ford Motor Credit Company; and is pursuing leadership positions in electrification; mobility solutions, including self-driving services; and connected vehicle services. Ford employs approximately 186,000 people worldwide. For more information regarding Ford, its products and Ford Motor Credit Company, please visit or www.quickpic.co.za - follow us at /FordSouthAfrica , /FordSouthAfrica ,/FordSouthAfrica or /FordSouthAfricaContact(s): Duduzile Nxele FeFord Motor Company of Southern Africa Fo+27 12 842 2337 +2***************fseAndrew LeopoldMeropa Communications+27 11 506 7234*****************.za。

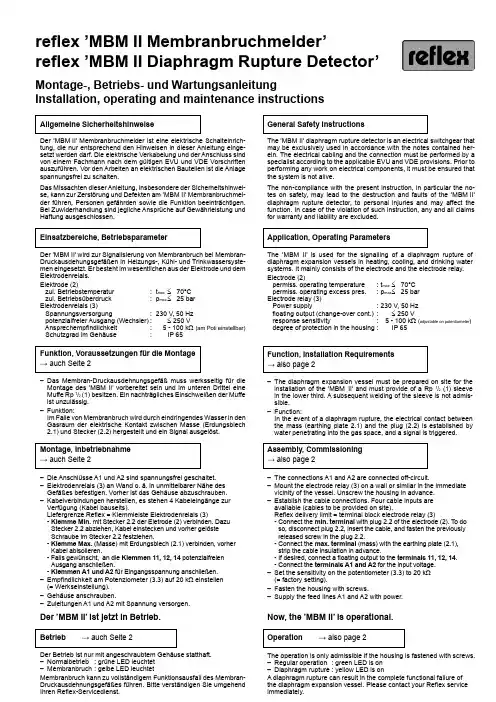

reflex ’MBM II Membranbruchmelder’reflex ’MBM II Diaphragm Rupture Detector’Montage-, Betriebs- und WartungsanleitungInstallation, operating and maintenance instructionsAllgemeine SicherheitshinweiseDer ’MBM II’ Membranbruchmelder ist eine elektrische Schalteinrich-tung, die nur entsprechend den Hinweisen in dieser Anleitung einge-setzt werden darf. Die elektrische Verkabelung und der Anschluss sind von einem Fachmann nach dem gültigen EVU und VDE Vorschriften auszuführen. Vor den Arbeiten an elektrischen Bauteilen ist die Anlage spannungsfrei zu schalten.Das Missachten dieser Anleitung, insbesondere der Sicherheitshinwei-se, kann zur Zerstörung und Defekten am ’MBM II’ Membranbruchmel-der führen, Personen gefährden sowie die Funktion beeinträchtigen. Bei Zuwiderhandlung sind jegliche Ansprüche auf Gewährleistung und Haftung ausgeschlossen.Montage, Inbetriebnahme → auch Seite 2– Die Anschlüsse A1 und A2 sind spannungsfrei geschaltet.– Elektrodenrelais (3) an Wand o. ä. in unmittelbarer Nähe des Gefäßes befestigen. Vorher ist das Gehäuse abzuschrauben.– Kabelverbindungen herstellen, es stehen 4 Kabeleingänge zur Verfügung (Kabel bauseits).Liefergrenze Reflex = Klemmleiste Elektrodenrelais (3)- Klemme Min. mit Stecker 2.2 der Eletrode (2) verbinden. Dazu Stecker 2.2 abziehen, Kabel einstecken und vorher gelöste Schraube im Stecker 2.2 festziehen.- Klemme Max. (Masse) mit Erdungsblech (2.1) verbinden, vorher Kabel abisolieren.- Falls gewünscht, an die Klemmen 11, 12, 14 potenzialfreien Ausgang anschließen.- Klemmen A1 und A2 für Eingangsspannung anschließen.– Empfindlichkeit am Potenziometer (3.3) auf 20 k Ω einstellen (= Werkseinstellung).– Gehäuse anschrauben.– Zuleitungen A1 und A2 mit Spannung versorgen.Der ’MBM II’ ist jetzt in Betrieb.Betrieb → auch Seite 2Der Betrieb ist nur mit angeschraubtem Gehäuse statthaft.– Normalbetrieb : grüne LED leuchtet – Membranbruch : gelbe LED leuchtetMembranbruch kann zu vollständigem Funktionsausfall des Membran-Druckausdehnungsgefäßes führen. Bitte verständigen Sie umgehend Ihren Reflex-Servicedienst.Funktion, Voraussetzungen für die Montage → auch Seite 2– Das Membran-Druckausdehnungsgefäß muss werksseitig für die Montage des ’MBM II’ vorbereitet sein und im unteren Drittel eine Muffe Rp 1/2 (1) besitzen. Ein nachträgliches Einschweißen der Muffe ist unzulässig.– Funktion:Im Falle von Membranbruch wird durch eindringendes Wasser in den Gasraum der elektrische Kontakt zwischen Masse (Erdungsblech 2.1) und Stecker (2.2) hergestellt und ein Signal ausgelöst.Einsatzbereiche, BetriebsparameterDer ’MBM II’ wird zur Signalisierung von Membranbruch bei Membran-Druckausdehungsgefäßen in Heizungs-, Kühl- und Trinkwassersyste-men eingesetzt. Er besteht im wesentlichen aus der Elektrode und dem Elektrodenrelais.Elektrode (2)zul. Betriebstemperatur : t max ≤ 70°C zul. Betriebsüberdruck : p max ≤ 25 bar Elektrodenrelais (3)Spannungsversorgung : 230 V, 50 Hz potenzialfreier Ausgang (Wechsler) : ≤ 250 V Ansprechempfindlichkeit : 5 - 100 k Ω (am Poti einstellbar) Schutzgrad im Gehäuse : IP 65General Safety InstructionsThe ’MBM II’ diaphragm rupture detector is an electrical switchgear that may be exclusively used in accordance with the notes contained her-ein. The electrical cabling and the connection must be performed by a specialist according to the applicable EVU and VDE provisions. Prior to performing any work on electrical components, it must be ensured that the system is not alive.The non-compliance with the present instruction, in particular the no-tes on safety, may lead to the destruction and faults of the ’MBM II’ diaphragm rupture detector, to personal injuries and may affect the function. In case of the violation of such instruction, any and all claims for warranty and liability are excluded.Assembly, Commissioning → also page 2– The connections A1 and A2 are connected off-circuit.– Mount the electrode relay (3) on a wall or similar in the immediate vicinity of the vessel. Unscrew the housing in advance.– Establish the cable connections. Four cable inputs are available (cables to be provided on site).Reflex delivery limit = terminal block electrode relay (3)- Connect the min. terminal with plug 2.2 of the electrode (2). T o do so, disconnect plug 2.2, insert the cable, and fasten the previously released screw in the plug 2.2.- Connect the max. terminal (mass) with the earthing plate (2.1), strip the cable insulation in advance.- If desired, connect a floating output to the terminals 11, 12, 14. - Connect the terminals A1 and A2 for the input voltage.– Set the sensitivity on the potentiometer (3.3) to 20 k Ω (= factory setting).– Fasten the housing with screws.– Supply the feed lines A1 and A2 with power.Now, the ’MBM II’ is operational.Operation → also page 2The operation is only admissible if the housing is fastened with screws.– Regular operation : green LED is on – Diaphragm rupture : yellow LED is onA diaphragm rupture can result in the complete functional failure of the diaphragm expansion vessel. Please contact your Reflex service immediately.Function, Installation Requirements → also page 2– The diaphragm expansion vessel must be prepared on site for the installation of the ’MBM II’ and must provide of a Rp 1/2 (1) sleeve in the lower third. A subsequent welding of the sleeve is not admis-sible.– Function:In the event of a diaphragm rupture, the electrical contact between the mass (earthing plate 2.1) and the plug (2.2) is established by water penetrating into the gas space, and a signal is triggered.Application, Operating ParametersThe ’MBM II’ is used for the signalling of a diaphragm rupture ofdiaphragm expansion vessels in heating, cooling, and drinking water systems. It mainly consists of the electrode and the electrode relay.Electrode (2)permiss. operating temperature : t max ≤ 70°C permiss. operating excess pres. : p max ≤ 25 bar Electrode relay (3) Power supply : 230 V, 50 Hz floating output (change-over cont.) : ≤ 250 V response sensitivity : 5 - 100 k Ω (adjustable on potentiometer ) degree of protection in the housing : IP 65reflex ’MBM II Membranbruchmelder’reflex ’MBM II Diaphragm Rupture Detector’S I 0216A / 03 - 06 T e c h n i s c h e Än d e r u n g e n v o r b e h a l t e n T e c h n i c a l d e t a i l s s u b j e c t t o m o d i f i c a t i o nMontage- und LieferübersichtOverview of the Installation and Delivery1 Rp 1/2 sleeve on the vessel2 Electrode , with vessels which have a constant pre-set pressure sealed into the vessel sleeve (1) in the factory, otherwise enclosed for on-site installation. 2.1 Earthing plate 2.2 detachable plug2.3 Angle3 Electrode relay in the housing3.1 green LED, is on during the regular operation 3.2 yellow LED, is on during in case of a diaphragm rupture3.3 Potentiometer to adjust the response sensitivity 4 Transport protection for the electrode (2), channel section made of foamed material,remove prior to the installationKonformitätserklärungDas Elektrodenrelais ist für den Einsatz im ’MBM II’ geeignet und wird folgenden Normen gerecht:VDE 0435, VDE 0609, VDE 0110, VBG 4, IEC 158-1,IEC 255-0-20, IEC 255-3 & 6, IEC 255-8 & 17, IEC 255-22-1, IEC 255-22-2, IEC 255-5, IEC 801-4, IEC 67.1.5 1 & 18, DIN 46277, IEC 529, DIN 40050, NFC 20010 Zulassungen: UL, CSA Declaration of ConformityThe electrode relay is suited for the deployment in the ’MBM II’ and complies with the following standards:VDE 0435, VDE 0609, VDE 0110, VBG 4, IEC 158-1,IEC 255-0-20, IEC 255-3 & 6, IEC 255-8 & 17, IEC 255-22-1, IEC 255-22-2, IEC 255-5, IEC 801-4, IEC 67.1.5 1 & 18, DIN 46277, IEC 529, DIN 40050, NFC 20010 Approvals:UL, CSANetwork 230 V, 50 Hz6,4 mm x 2,5 mm, NSGAFÖU (bauseits) 6.4 mm x 2.5 mm, NSGAFÖU (on site)2.22.32.141 Muffe Rp 1/2 am Gefäß2 Elektrode , bei Gefäßen mit konstantem Vordruck werksseitig in Behältermuffe (1) eingedichtet, ansonsten beigelegt zur bauseitigen Montage. 2.1 Erdungsblech2.2 abziehbarer Stecker 2.3 Winkel3 Elektrodenrelais im Gehäuse3.1 grüne LED, leuchtet bei Normalbetrieb 3.2 gelbe LED, leuchtet bei Membranbruch 3.3 Potenziometer zur Einstellung der Ansprechempfindlichkeit4 Transportschutz für Elektrode (2), U-Profil aus Schaumstoff, vor derMontage abnehmen33.33.23.1Reflex Winkelmann GmbH + Co. KG Gersteinstraße 1959227 AhlenTelefon: +49 23 82 / 70 69-0Telefax: +49 23 82 / 70 69-588www.reflex.de。

Products Solutions ServicesBrief Operating Instructions Proline Prosonic Flow EUltrasonic time-of-flight sensorThese instructions are Brief Operating Instructions; they are not a substitute for the Operating Instructions pertaining to the device.Sensor Brief Operating Instructions Contain information about the sensor.Transmitter Brief Operating Instructions → 3.KA01329D/06/EN/01.1771382750Proline Prosonic Flow E2Endress+HauserProline Prosonic Flow E Brief Operating Instructions for the deviceEndress+Hauser 3Brief Operating Instructions for the deviceThe device consists of a transmitter and a sensor.The process of commissioning these two components is described in two separate manuals:•Sensor Brief Operating Instructions•Transmitter Brief Operating InstructionsPlease refer to both Brief Operating Instructions when commissioning the device as the contents of the manuals complement one another:Sensor Brief Operating InstructionsThe Sensor Brief Operating Instructions are aimed at specialists with responsibility for installing the measuring device.•Incoming acceptance and product identification •Storage and transport •InstallationTransmitter Brief Operating InstructionsThe Transmitter Brief Operating Instructions are aimed at specialists with responsibility for commissioning, configuring and parameterizing the measuring device (until the first measured value).•Product description •Installation•Electrical connection •Operation options •System integration •Commissioning•Diagnostic informationAdditional device documentationThese Brief Operating Instructions are the Sensor Brief Operating Instructions .The "Transmitter Brief Operating Instructions" are available via:•Internet: /deviceviewer•Smart phone/tablet: Endress+Hauser Operations AppDetailed information about the device can be found in the Operating Instructions and the other documentation:•Internet: /deviceviewer•Smart phone/tablet: Endress+Hauser Operations AppTable of contents Proline Prosonic Flow E4Endress+HauserTable of contents1Document information (5)1.1Symbols used (5)2Basic safety instructions (6)2.1Requirements for the personnel ............................................................62.2Designated use ........................................................................72.3Workplace safety ......................................................................82.4Operational safety ......................................................................82.5Product safety .........................................................................82.6IT security ............................................................................83Incoming acceptance and product identification (9)3.1Incoming acceptance ....................................................................93.2Product identification (10)4Storage and transport (10)4.1Storage conditions ....................................................................104.2Transporting the product (10)5Installation (12)5.1Installation conditions ..................................................................125.2Mounting the measuring device ...........................................................165.3Post-mounting check (17)6Disposal (17)6.1Removing the measuring device ..........................................................176.2Disposing of the measuring device (17)Proline Prosonic Flow E Document information 1 Document information1.1 Symbols used1.1.1 Safety symbols1.1.2 Symbols for certain types of information1.1.3 Electrical symbolsEndress+Hauser5Basic safety instructions Proline Prosonic Flow E6Endress+Hauser1.1.4 Tool symbols1.1.5 Symbols in graphics2Basic safety instructions2.1Requirements for the personnelThe personnel must fulfill the following requirements for its tasks:‣Trained, qualified specialists must have a relevant qualification for this specific function and task.‣Are authorized by the plant owner/operator.‣Are familiar with federal/national regulations.‣Before starting work, read and understand the instructions in the manual andsupplementary documentation as well as the certificates (depending on the application).‣Follow instructions and comply with basic conditions.Proline Prosonic Flow E Basic safety instructionsEndress+Hauser72.2 Designated useApplication and mediaThe measuring device described in these Brief Operating Instructions is intended only for flow measurement of gases.Depending on the version ordered, the measuring device can also measure potentially explosive, flammable, poisonous and oxidizing media.Measuring devices for use in hazardous areas, in hygienic applications or where there is an increased risk due to process pressure, are labeled accordingly on the nameplate.To ensure that the measuring device remains in proper condition for the operation time:‣Keep within the specified pressure and temperature range.‣Only use the measuring device in full compliance with the data on the nameplate and the general conditions listed in the Operating Instructions and supplementary documentation.‣Based on the nameplate, check whether the ordered device is permitted for the intended use in the hazardous area (e.g. explosion protection, pressure vessel safety).‣Use the measuring device only for media to which the process-wetted materials are sufficiently resistant.‣If the measuring device is not operated at atmospheric temperature, compliance with the relevant basic conditions specified in the associated device documentation is absolutely essential: "Documentation" section.‣Protect the measuring device permanently against corrosion from environmental influences.Incorrect useNon-designated use can compromise safety. The manufacturer is not liable for damage caused by improper or non-designated use.L WARNINGDanger of breakage due to corrosive or abrasive fluids!‣Verify the compatibility of the process fluid with the sensor material.‣Ensure the resistance of all fluid-wetted materials in the process.‣Keep within the specified pressure and temperature range.Verification for borderline cases:‣For special fluids and fluids for cleaning, Endress+Hauser is glad to provide assistance in verifying the corrosion resistance of fluid-wetted materials, but does not accept any warranty or liability as minute changes in the temperature, concentration or level of contamination in the process can alter the corrosion resistance properties.Residual risksL WARNINGThe electronics and the medium may cause the surfaces to heat up. This presents a burn hazard!‣For elevated fluid temperatures, ensure protection against contact to prevent burns.Basic safety instructions Proline Prosonic Flow E8Endress+Hauser2.3 Workplace safetyFor work on and with the device:‣Wear the required personal protective equipment according to federal/national regulations.For welding work on the piping:‣Do not ground the welding unit via the measuring device.If working on and with the device with wet hands:‣Due to the increased risk of electric shock, gloves must be worn.2.4 Operational safetyRisk of injury!‣Operate the device in proper technical condition and fail-safe condition only.‣The operator is responsible for interference-free operation of the device.2.5 Product safetyThis measuring device is designed in accordance with good engineering practice to meet state-of-the-art safety requirements, has been tested, and left the factory in a condition in which it is safe to operate.It meets general safety standards and legal requirements. It also complies with the EUdirectives listed in the device-specific EU Declaration of Conformity. Endress+Hauser confirms this by affixing the CE mark to the device.2.6 IT securityWe only provide a warranty if the device is installed and used as described in the Operating Instructions. The device is equipped with security mechanisms to protect it against any inadvertent changes to the device settings.IT security measures in line with operators' security standards and designed to provide additional protection for the device and device data transfer must be implemented by the operators themselves.Proline Prosonic Flow E Incoming acceptance and product identificationEndress+Hauser93Incoming acceptance and product identification3.1Incoming acceptanceA0028673Are the order codes on the delivery note (1)and the product sticker(2) identical?A0028673Are the goods undamaged?A0028673Do the nameplate data match the ordering information on the delivery note?A0028673Is the CD-ROM with the TechnicalDocumentation (depends on deviceversion) and documents present?•If one of the conditions is not satisfied, contact your Endress+Hauser Sales Center.•Depending on the device version, the CD-ROM might not be part of the delivery! The Technical Documentation is available via the Internet or via the Endress+Hauser Operations App .Storage and transport Proline Prosonic Flow E10Endress+Hauser3.2 Product identificationThe following options are available for identification of the measuring device:•Nameplate specifications•Order code with breakdown of the device features on the delivery note •Enter serial numbers from nameplates in W@M Device Viewer(/deviceviewer ): All information about the measuring device is displayed.•Enter the serial number from the nameplates into the Endress+Hauser Operations App or scan the 2-D matrix code (QR code) on the nameplate with the Endress+Hauser Operations App : all the information for the measuring device is displayed.1Example of a nameplate 1Order code2Serial number (Ser. no.)3Extended order code (Ext. ord. cd.)42-D matrix code (QR code)For detailed information on the breakdown of the specifications on the nameplate, see the Operating Instructions for the device .4Storage and transport4.1Storage conditionsObserve the following notes for storage:‣Store in the original packaging to ensure protection from shock.‣Do not remove protective covers or protective caps installed on process connections. They prevent mechanical damage to the sealing surfaces and contamination in the measuring tube.‣Protect from direct sunlight to avoid unacceptably high surface temperatures.‣Store in a dry and dust-free place.‣Do not store outdoors.4.2 Transporting the productTransport the measuring device to the measuring point in the original packaging.Proline Prosonic Flow E Storage and transportEndress+Hauser11Do not remove protective covers or caps installed on process connections. They prevent mechanical damage to the sealing surfaces and contamination in the measuring tube.4.2.1 Measuring devices without lifting lugsL WARNINGCenter of gravity of the measuring device is higher than the suspension points of the webbing slings.Risk of injury if the measuring device slips.‣Secure the measuring device against slipping or turning.‣Observe the weight specified on the packaging (stick-on label).4.2.2 Measuring devices with lifting lugsL CAUTIONSpecial transportation instructions for devices with lifting lugs ‣Only use the lifting lugs fitted on the device or flanges to transport the device.‣The device must always be secured at two lifting lugs at least.4.2.3 Transporting with a fork liftIf transporting in wood crates, the floor structure enables the crates to be lifted lengthwise or at both sides using a forklift.Installation Proline Prosonic Flow E 12Endress+Hauser5Installation 5.1 Installation conditionsNo special measures such as supports are necessary. External forces are absorbed by the construction of the device.5.1.1 Mounting positionMounting locationOrientationThe direction of the arrow on the nameplate helps you to install the sensor according to theflow direction.Install the measuring device in a parallel plane free of external mechanical stress.Proline Prosonic Flow E InstallationEndress+Hauser 13Inlet and outlet runsIf possible, the sensor should be installed upstream from valves, T-pieces, elbows etc. To attain the specified level of accuracy of the measuring device, the below mentioned inlet and outlet runs must be maintained at minimum. If there are several flow disturbances present, the longest specified inlet run must be maintained.For the dimensions and installation lengths of the device, see the "Technical Information"document, "Mechanical construction" section.Installation Proline Prosonic Flow E2Minimum inlet and outlet runs with various flow obstructions190 ° elbow or T-section2Pump3 2 × 90 ° elbow, 3-dimensional4Control valveOutlet runs when installing external devicesIf installing an external device, observe the specified distance.PT Pressure5.1.2 Requirements from environment and processAmbient temperature rangeTransmitter•Prosonic Flow E 100: –25 to +60 °C (–13 to +140 °F)•Prosonic Flow E Heat: –25 to +55 °C (–13 to +131 °F) as per EN 1434environmental class BLocal display Prosonic Flow E 100: –20 to +60 °C (–4 to +140 °F), readability of the displaymay be impaired at temperatures outside the temperature range. Sensor•Prosonic Flow E 100: –25 to +60 °C (–13 to +140 °F)•Prosonic Flow E Heat: –25 to +55 °C (–13 to +131 °F) as per EN 1434environmental class B14Endress+HauserProline Prosonic Flow E Installation Endress+Hauser 15‣If operating outdoors:Avoid direct sunlight, particularly in warm climatic regions.System pressureIt is important that cavitation does not occur, or that gases entrained in the liquids do not outgas. This is prevented by means of a sufficiently high system pressure.For this reason, the following mounting locations are recommended:•At the lowest point in a vertical pipe •Downstream from pumps (no danger of vacuum)Thermal insulationIn the case of some fluids, it is important to keep the heat radiated from the sensor to the transmitter to a low level. A wide range of materials can be used for the required insulation.NOTICEElectronics overheating on account of thermal insulation!‣Observe maximum permitted insulation height of the transmitter neck so that the transmitter head is completely free.tMaximum insulation thickness 2 cm (0.79 in)a Minimum distance from transmitter to insulationInstallation Proline Prosonic Flow E16Endress+Hauser5.2Mounting the measuring device 5.2.1 Required toolsFor transmitter•For turning the transmitter housing: Open-ended wrench8 mm •For opening the securing clamps: Allen key3 mm •For turning the transmitter housing: Open-ended wrench8 mm •For opening the securing clamps: Allen key3 mmFor sensorFor flanges and other process connections: Corresponding mounting tools5.2.2 Preparing the measuring device 1.Remove all remaining transport packaging.2.Remove any protective covers or protective caps present from the sensor.3.Remove stick-on label on the electronics compartment cover.5.2.3 Mounting the measuring device L WARNINGDanger due to improper process sealing!‣Ensure that the inside diameters of the gaskets are greater than or equal to that of the process connections and piping.‣Ensure that the gaskets are clean and undamaged.‣Install the gaskets correctly.1.Ensure that the direction of the arrow on the sensor matches the flow direction of the medium.2.Install the measuring device or turn the transmitter housing so that the cable entries do not point upwards.Proline Prosonic Flow E DisposalEndress+Hauser 175.3 Post-mounting check Is the device undamaged (visual inspection)?Does the measuring device conform to the measuring point specifications?For example:•Process temperature•Process pressure (refer to the section on "Pressure-temperature ratings" in the "Technical Information"document on the CD-ROM provided)•Ambient temperature range•Measuring rangeHas the correct orientation for the sensor been selected → 12?•According to sensor type•According to medium temperature•According to medium properties (outgassing, with entrained solids)Does the arrow on the sensor match the direction of flow of the medium through the piping → 12?Are the measuring point identification and labeling correct (visual inspection)?Is the device adequately protected from precipitation and direct sunlight?Are the securing screw and securing clamp tightened securely? 6Disposal 6.1Removing the measuring device 1.Switch off the device.L WARNINGDanger to persons from process conditions.‣Beware of hazardous process conditions such as pressure in the measuring device, high temperatures or aggressive fluids.2.Carry out the mounting and connection steps from the "Mounting the measuring device"and "Connecting the measuring device" sections in reverse order. Observe the safety instructions.6.2 Disposing of the measuring deviceL WARNINGDanger to personnel and environment from fluids that are hazardous to health.‣Ensure that the measuring device and all cavities are free of fluid residues that are hazardous to health or the environment, e.g. substances that have permeated into crevices or diffused through plastic.Disposal Proline Prosonic Flow E 18Endress+HauserObserve the following notes during disposal:‣Observe valid federal/national regulations.‣Ensure proper separation and reuse of the device components.。

XA00643F-A/00/B2/01.1171158144Safety InstructionsLevelflexFMP54/56/57PROFIBUS PAZone 20/21DIP A20/21 T A , T* IP66en -Document: XA00643F-ASafety instructions for electrical apparatus for explosion-hazardous areas Èä3zh -文档:XA00643F-A爆炸环境中电气仪表的安全指南Èä9Levelflex FMP54/56/57XA00643F-A 2Endress+HauserXA00643F-A Levelflex FMP54/56/57LevelflexFMP54/56/57PROFIBUS PATable of ContentsAssociated documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4Supplementary documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4Manufacturer's certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4Extended order code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4Safety instructions: General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6Safety instructions: Special conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6Safety instructions: Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6Temperature tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7Connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Endress+Hauser3Levelflex FMP54/56/57XA00643F-A4Endress+HauserAssociated documentation This document is an integral part of the following Operating Instructions:BA01006F/00 (FMP54), BA01009F/00 (FMP56/57)The Operating Instructions pertaining to the device apply.Supplementary documentation Explosion-protection brochure:CP021Z/00The Explosion-protection brochure is available:•In the download area of the Endress+Hauser website: → Download → Advanced → Documentation Code: CP021Z•On the CD for devices with CD-based documentationManufacturer's certificates NEPSI Declaration of Conformity Certificate number:GYJ11.1553XAffixing the certificate number certifies conformity with the standards:•GB3836.1-2010•GB12476.1-2000•GB12476.4-2010, with the following standard under :-IEC61241-0:2004Extended order codeThe extended order code is indicated on the nameplate, which is affixed to the device in such a way that it is clearly visible. Additional information about the nameplate is provided in the associated Operating Instructions.Structure of the extended order code •Basic specificationsThe features that are absolutely essential for the device (mandatory features) are specified in the basic specifications. The number of positions depends on the number of features available. The selected option of a feature can consist of several positions.•Optional specificationsThe optional specifications describe additional features for the device (optional features). The number of positions depends on the number of features available.The features have a 2-digit structure to aid identification (e.g. JA). The first digit (ID) stands for the feature group and consists of a number or a letter (e.g. J = test, certificate).The second digit constitutes the value that stands for the feature within the group (e.g. A = 3.1 material (wetted parts), inspection certificate).More detailed information about the device is provided in the following tables. These tables describe the individual positions and IDs in the extended order code which are relevant to hazardous locations.FMP5x-*************+A*B*C*D*E*F*G*..------------------------------------------------------------------------Device typeBasic specificationsOptional specifications* =PlaceholderAt this position, an option (number or letter) selected from the specification is displayed instead of the placeholders.XA00643F-A Levelflex FMP54/56/57Endress+Hauser 5Device type: FMP54, FMP56, FMP57Basic specificationsOptional specificationsPosition Selected option Description1, 2ApprovalNF Zone 20/21DIP A20/21 T A , T* IP663Power Supply; Output G 2-wire, PROFIBUS PA4Display; Operation A C Without LCD, via communicationLCD SD02, push button + data backup function 5HousingB CDual compartment, 316L (GT18)Dual compartment, Alu coated (GT20)9, 10SealAB (only FMP56)A4 (only FMP57)B3 (only FMP56/57)D1 (only FMP54)D2 (only FMP54)Viton,–30...120 °C Viton,–30...150 °C EPDM, –40...120 °CGraphite, –196...280 °C (XT)Graphite, –196...450 °C (HT)ID Selected option DescriptionMxProbe DesignMBME (only FMP54)Sensor remote, 3 m/9 ft cable, detachable + mounting bracketCoax ground tube multiple punchedLevelflex FMP54/56/57XA00643F-A6Endress+HauserSafety instructions:General•Staff must meet the following conditions for mounting, electrical installation, commissioning and maintenance of the device:-Be suitably qualified for their role and the tasks they perform -Be trained in explosion protection -Be familiar with national regulations•For installation, use and maintenance of the device, users must also observe the requirements stated in the Operating Instructions and the standards:-GB50257-1996: "Code for construction and acceptance of electric device for explosion atmospheres and fire hazard electrical equipment installation engineering".-GB15577-2007: "Safety regulations for dust explosive prevention and protection".-GB12476.2-2006: "Electrical apparatus for use in the presence of combustible dust,Part 1-2: Electrical apparatus protected by enclosures and surface temperature limitation - Selection, installation and maintenance".•Install the device according to the manufacturer's instructions and national regulations.•Do not operate the device outside the specified electrical, thermal and mechanical parameters.•Only use the device in media to which the wetted materials have sufficient durability.•Refer to the temperature tables for the relationship between the permitted ambient temperature for the sensor and/or transmitter, depending on the range of application, and the temperature class.•Modifications to the device can affect the explosion protection and must be carried out by staff authorized to perform such work by Endress+Hauser.•When replacing the probe electronics or opening the connection between the remote cable and the probe, a jumper plug must be used or a short-circuit must be established between the probe contact and the potential equalization conductor to avoid electrostatically charging the probe.•After mounting and connecting the probe, ingress protection of the housing must be at least IP66. Perform the following to achieve the degree of protection: - Screw the cover tight.-Mount the cable entry correctly.Safety instructions:Special conditions Permitted ambient temperature range at the electronics housing: –40 °C ≤ T a ≤ +80 °C.Observe the information in the temperature tables.Safety instructions:Installationå 1A Zone 211Tank; Zone 20, Zone 212Electronics compartment Ex iaD; Electronic insert 3Connection compartment DIP A214Power supply5Potential equalization line 6Potential equalizationXA00643F-A Levelflex FMP54/56/57Endress+Hauser 7•In the case of process connections made of polymeric material or with polymeric coatings, avoid electrostatic charging of the plastic surfaces.•After aligning (rotating) the housing, retighten the fixing screw (see Operating Instructions).•When mounting the device:-Exclude any mechanical damage or friction during the application. -Pay particular attention to flow conditions and tank fittings.•Continuous service temperature of the connecting cable: –40 to ≥ +85 °C; in accordance with the range of service temperature taking into account additional influences of the process conditions (T a,min and T a,max +20 K).•In the event of additional or alternative special varnishing on the housing or other metal parts: -Observe the danger of electrostatic charging and discharge. -Do not rub surfaces with a dry cloth.•Only use certified cable entries or sealing plugs.The metal sealing plugs supplied meet this requirement.•Before operation:-Screw in the cover all the way.-Tighten the securing clamp on the cover.Intrinsic safety•The device can be connected to the Endress+Hauser FXA291 service tool: refer to the Operating Instructions.Temperature tables Èä15Connection dataBasic specification, Position 1, 2 (Approval) = NF Connection compartment DIP A21Electronics compartment Ex i Service interface (CDI)Taking the following values into consideration, the device can be connected to the Endress+Hauser FXA291 service tool or a similar interface:Basic specification, Position 3 (Power Supply; Output) = G TRC [07]Terminal 1 (+), 2 (–)Terminal 3 (+), 4 (–)Power supply:Output PFS:U N = 32 V DC I max = 25 mA U m = 250 V ACU N = 35 V DC I n = 70 mA U m = 250 V ACService interface U i = 7.3 Veffective inner inductance L i = negligible effective inner capacitance C i = negligible U o = 7.3 V I o = 100 mA P o = 160 mWpermitted outer inductance L o = negligible permitted outer capacitance C o = negligibleLevelflex FMP54/56/57XA00643F-A 8Endress+HauserXA00643F-A Levelflex FMP54/56/57LevelflexFMP54/56/57PROFIBUS PA目录相关资料 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10辅助文档 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10制造商证书 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10扩展订货号 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10安全指南:概述 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12安全指南:特殊条件 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12安全指南:安装 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12温度表 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13连接数据 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Endress+Hauser9Levelflex FMP54/56/57XA00643F-A相关资料本文档是下列操作手册的组成部分:BA01006F/00 (FMP54), BA01009F/00 (FMP56/57)应遵守设备的操作手册。

FU TillerOperation Manual ContentsPreface (3)Revision History (4)Glossary (5)Abbreviations (5)Definitions (5)Safety Information (6)Warranty (7)Introduction (8)Enabling FU control (9)Control allowed/not allowed (10)Control handover (11)Take control (11)Release/take control (11)Steering (11)Alarm handling (12)Dimming (12)Alarm speaker and lamp test (13)PrefaceThe Alphatron AlphaPilot MFM system is a type approved heading control system, designed to fit vessels of any size, including high speed crafts.The FU Tiller is part of the AlphaPilot MFM system and is used for steering in manual FU steering mode.•Thoroughly read this operation manual before operating the equipment.•We recommend keeping this manual nearby the equipment to ensure ready access to it.GlossaryThe glossary contains a list of abbreviations and a list of definitions.AbbreviationsAbbreviations as used in this manual are explained in the table below.DefinitionsThe meaning of standard definitions as used in this manual are explained in the table below.Safety InformationThe signal words DANGER, WARNING and CAUTION used in this manual indicate the degree of hazard that may be encountered by the user. These words are defined as follows:DANGER Indicates a hazardous situation which, if not avoided, will result in deathor serious injury. This signal word is limited to the most extremesituations.WARNING Indicates a hazardous situation which, if not avoided, could result in deathor serious injury.CAUTION Indicates a hazardous situation which, if not avoided, could result in minoror moderate injury.The signal word NOTICE used in this manual indicates information considered important but not related to injury. It is typically used to prevent damage to equipment or property.To safely operate this system, the following DANGERS, WARNINGS, and CAUTIONS must be adhered to. Failure to comply with the precautions or with specific dangers, warnings, and cautions elsewhere in this manual violates safety standards of design, manufacture, and intended use of the equipment. ALPHATRON MARINE assumes no liability for the customer's failure to comply with these requirements.WARNING Do not disassemble or modify the equipment. Otherwise, it may cause a fire, or you may suffer an electrical shock.WARNING Immediately turn off the power and disconnect the power supply cable if the equipment is generating any smoke or odour or is overheated. Immediately inform your local service agent of the symptom to have it repaired. Prolonged equipment operation under such a condition can cause a fire or electric shock.WARNING Do not place a container containing liquid on the equipment. Otherwise, it may cause a fire, or you may suffer an electrical shock if knocked over.WARNING When unplugging the instrument, be sure to remove the cord terminal correctly. If the cord is pulled, the cord may get damaged resulting in a fire or an electrical shock.WarrantyTo not to adversely affect the warranty, the following notices must be adhered to.NOTICE Operating personnel must not remove equipment covers. Only personnel trained and certified by ALPHATRON MARINE must make component replacement and internal adjustment.NOTICE Do not disassemble or modify the equipment. Failure to observe this instruction may cause equipment failure, and it will void the warranty.NOTICE Any modification to this equipment without prior written permission from ALPHATRON MARINE will void the warranty.NOTICE Installation of this product shall only be done by a certified installation company approved by either ALPHATRON MARINE or by an official ALPHATRON MARINE distributor. Acting otherwise will void the warranty.NOTICE This product contains no operator serviceable parts. Service and repair shall only be carried out by personnel trained and certified by ALPHATRON MARINE.NOTICE Do not place a container containing liquid on the equipment. The equipment can be damaged if knocked over.NOTICE When cleaning the surface, do not use any organic solvent such as thinner or benzine. Otherwise, the paint and markings on the surface may get damaged. For cleaning the surface, remove the dust and debris and wipe with a clean dry cloth.IntroductionThe FU Tiller is part of the AlphaPilot MFM system and is used for steering in manual FU steering mode. The FU Tiller is typically used in combination with an AlphaPilot MFM control unit.The FU Tiller has 1 handle and multiple buttons:-The alarm speaker button will illuminate when there is an alarm. The button is used to mute the speakers of the FU Tiller and interconnected modules.-Buttons DIM - and DIM + are used to control the brightness level of the FU Tiller and interconnected modules.-Button FU is used to release/take FU control.-The handle is used to steer (step less control).Figure 1: FU TillerEnabling FU controlPush the button FU to enable FU control*. The control mode indicator FU and handle indicator will illuminate, meaning that FU mode is enabled, and that the handle is enabled.*Note that control must be allowed, see subsection ‘Control allowed/not allowed’ on page 10. Note that another active controller may need to allow control handover first, see su bsection ‘Control handover‘ on page 11.Figure 3: FU mode enabledFigure 2: STBY mode enabledControl allowed/not allowedWhen not in control, the FU Tiller is in standby mode and handle is disabled (the control mode indicator STBY is illuminated and the handle indicator is not illuminated). Button FU is illuminated when allowed to take control (see Figure 4 and Figure 5).FU control is steering in manual FU steering mode; therefore, the Mode Switch must be in position MAN (Mode Switch 3 Pos) or AUTO|MAN (Mode Switch 2 Pos).FU control is not allowed when the Mode Switch is in position NFU (Mode Switch 2 Pos & Mode Switch 3 Pos) or AUTO (Mode Switch 3 Pos)).When a non-illuminated button is pushed, the speaker produces 4 short successive beeps to indicate that the operation is not valid.Figure 4: Enabling FU controlnot allowedFigure 5: Enabling FU controlallowedControl handoverIf applicable, handover of control must be allowed first by the active controller to allow the FU Tiller to take control (i.e. enable FU control).The method for control handover is pre-set during commissioning. Two system settings are possible, namely ‘Take control’ or ‘Release/take control’.Take controlAny controller can take control. Control handover allowance is not applicable.Procedure for FU Tiller:-Push the button FU to enable FU control. Control mode indicator FU and the handle indicator will illuminate, meaning that the FU mode and the handle is enabled.Release/take controlAny controller can take control, only when the active controller allows control handover. Procedure for FU Tiller:-Take controlAllow control handover from the active controller (refer to the respective operation manual for the procedure). Button FU will illuminate to indicate that FU control is allowed. Push the button FU to enable FU control. Control mode indicator FU and the handle indicator willilluminate, meaning that the FU mode and the handle is enabled.-Release controlTo allow control handover to another controller, push the button FU, until control modeindicator FU flashes (this indicates that control handover is allowed).NOTE: The FU Tiller stays in control until control is transferred to another controller.NOTE: Control mode indicator FU keeps flashing until control is transferred to anothercontroller. There is no timeout. The speaker produces 3 short successive beeps with 10seconds interval to indicate that the operation is not finished.NOTE: The FU Tiller goes into standby mode when control is transferred to anothercontroller.SteeringIn FU control, the steering gear will move the rudder as per FU value command (rudder angle). Moving the handle to the neutral position will cause the rudder to move to the centre position. Turning the handle farthest to the left will cause the rudder to move to a predefined maximum rudder angle, turning the handle farthest to the right will cause the rudder to move to the predefined maximum rudder angle in the opposite direction.11 | SteeringAlarm handlingThe alarm speaker button is only illuminated when there is an internal alarm. When an alarm occurs, the alarm speaker button will flash in an uninterrupted sequence, and the speaker will beep in an uninterrupted sequence.Figure 6: AlarmactiveThe alarm speaker can be muted via the alarm speaker button.When the alarm (is read and) acknowledged on the AlphaPilot MFM control unit, then the illumination will be constant, and the speaker will be muted (if not muted already via the FU Tiller). When the alarm is accepted (e.g. problem solved), then the illumination on the alarm speaker button will turn off.DimmingButtons DIM - and DIM + are always illuminated (dimmed to a pre-set brightness level) and control is always allowed.Push the button DIM - or DIM + to simultaneously adjust the brightness level of all indicators on the FU Tiller and interconnected modules.12 | Alarm handlingAlarm speaker and lamp testSimultaneously push and hold button DIM - and DIM + to test the alarm speaker and the indicators; The alarm speaker will beep continuously and all indicators (buttons, control mode indicators, and handle indicator) will illuminate continuously, until the buttons are released.13 | Alarm speaker and lamp test。