粗糙度仪使用说明书

- 格式:pdf

- 大小:1.07 MB

- 文档页数:8

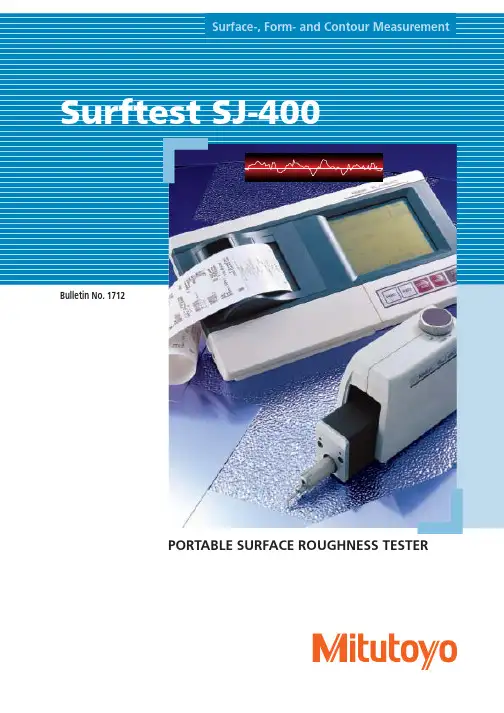

Requirement1Requirement2Requirement3Requirement4Revolutionary New Portable Surface Roughness Testers Make Their DebutLong-awaited performance and functionality are here: compact design, skidless and high-accuracy roughness measurements, multi-functionality and ease of operation.SJ-401SJ-402SJ-401Measurement/evaluationof stepped features and straightnessUltra-fine steps, straightness and waviness are easily measured by switching to skidless measurement mode. The ruler function enables simpler surface feature evaluation on the LCD monitor.Roughness parameters that conform to international standardsThe SJ-400 Series can evaluate 36 kinds of roughness parameters conforming to the latest ISO, DIN, and ANSI standards, as well as to JIS standards (1994/1982).Cylinder surface roughness measurements with a hand-held testerThe skidless measurement and R-surface compensation functions make it possible to evaluate cylinder surface roughness.Surftest SJ-400 SeriesHigh-accuracy measurements with a hand-held testerA wide range, high-resolution detector and an ultra-straight drive unit provide class-leading accuracy. DetectorMeasuring range: 800µmResolution: 0.000125µm (on 8µm range) Drive unitStraightness/traverse length SJ-401: 0.3µm/.98"(25mm) SJ-402: 0.5µm/1.96"(50mm)Requirement6Requirement5Advanced data processing with extended analysisThe SJ-400 Series allows data processing identical to that in the high-end class. These data analysis and report creation capabilities are achieved using the surface roughness analysis program FORMTRACEPAK V5 or SJ-Tools.Calculation Result ScreenMeasured Profile ScreenFine contourmeasurement with an auto-leveling tableDeep groove measurementUpside down measurementCylinder measurement with a support footMeasurement ApplicationsR-surface measurementConfirmation of measurement results and assessed profiles without a printoutThe large, integrated, touch-panel LCD monitor clearly displays evaluation results and measured profiles.SkidTraverse directionTraverse directionTraverse directionTraverse directionRuler Analysis ScreenTilt compensation function• The Tilt Compensation Datum Points are selectable from all of the profile (choose P1 and P2) or any arbitrary two sections on the profile (choose P1, P2, P3 and P4), as required. If you choose adjacent sections for tilt compensation then the characteristics of features of interest between these sections, such as scratch depth, etc, can be measured directly.Simplified surface feature evaluationwith the ruler function• This function determines the coordinate difference between two arbitrary points so feature characteristics, such as step height and width, etc, can be measured.Ruler function keyRuler keyCoordinate differenceRulerSkidless measurementSkidded measurementHeight adjustmentDAT screen guides the user when levelingAdjust the micrometer head by -0.928mm to levelTurn tilt adjustment knob by 1.37 turns counter-clockwise to levelWith the SJ-400 mounted on a stand, the DAT function also works with the optional leveling table.Powerful Support for LevelingThe height/tilt adjustment unit comes as standard for leveling the drive unit prior to making skidless measurements and, supported by guidance from the unique DAT function, makes it easy to achieve highly accurate alignment.(skidless measurement)Usually, a spherical or cylindrical surface (R-surface) cannot beevaluated, but, by removing the radius with a filter, R-surface data is processed as if taken from a flat surface.Built-in thermal printerA high quality, high-speed thermal printer prints out measured results. It can also print a BAC curve or an ADC curve as well as calculated results and assessed profiles. These results and profiles are printed out in landscape format, just as they appear on the LCD, in easy-to-understand form.Measurement of a cylindrical surfaceStatistical processing can be performed on multiple measurements for one roughness parameter. Histograms can be displayed and printed in addition to statistical results (mean, standard deviation, maximum/minimum value and acceptance ratio).More Measuring FunctionsThan Expected From a Compact TesterCalculation Result Screen with GO / NG judgment resultUpper and lower tolerance limits can be set for up to 3 roughness parameters. A GO/NG indication is displayed after a measurement. The calculation result is highlighted if NG.Calibration ScreenThe SJ-400 Series is equipped with Ra calibration and stepcalibration methods for detector calibration (gain adjustment). In both calibration methods only the calibrated value of the precision specimen needs to be entered. No other operations are required to calibrate the tester.The measurement conditions and data can be stored in the control unit or memory card (optional) and recalled as required. Batch printout of data after on-site measurement improves measuring efficiency.Key maskingLocks out input from the touch panel keys. This eliminates the possibility of the operator accidentally changing the calibration or measurement conditions.Real samplingThis function samples stylus displacement for a specified timewithout engaging detector traverse. This function has a wide range of uses, such as a simplified vibration meter or a displacement gage incorporated in another system.RecalculatingPreviously measured data can be recalculated for use in other evaluations by changing the current standard, assessed profile and roughness parameters.CustomizingThe SJ-400 Series can be set up to calculate and display only a subset of the roughness parameters available. Parameters can be added later for recalculation, if required.Customized ScreenGO signNG signInvalidatedStorage capacityMeasurement conditionsControl unit: 5 conditions Memory card: 20 conditionsMeasurement dataMemory card: 50 or more pieces of dataArbitrary length measurementThis function allows a sampling length to be arbitrarily set in .004" (0.1mm) increments SJ-401: .004" to .98" (0.1mm to 25mm), SJ-402: .004" to 1.96" (0.1mm to 50mm). It also allows the SJ-400 Series to make both narrow and wide range measurements.Simplified Communication Program (SJ Tools)One of the various functions of the Surftest SJ-400 Series is the ability to use RS-232 with a simplified communication program that allows the transfer of measurement data into a calculation software. The program must be used with Microsoft Excel to generate the inspection report and/or certificate.Required environment:* OS:* Spreadsheet software:Windows 2000-SP4 Microsoft Excel 2000Windows XP Microsoft Excel 2002 Windows Vista Microsoft Excel 2003Windows 7Microsoft Excel 2007Requires RS-232C cable (Optional)SJ-400 Series RS-232C cable Order No. 12AAA882*RS-232C cable D-sub9pin x 2 (store purchase) is a straight cable.*RS-232C a cannot be used in a USB connector.This program can be downloaded for free from the Mitutoyo website.http://www.mitutoyo.co.jpSee the FORMTRACEPAK brochure (Bulletin No. 2010) for more details.*Windows OS & Microsoft Excel are products of Microsoft Corporation.Carrying caseis a standard accessoryFor ultra small holeFor small slotted holeDetail-ABall ø0.5.02”(0.6)ø2.4ø0.3A737.743.87 1.72"(43.8)1.48"(37.7).33"(8.5)ø.02"(ø0.5).17"(4.3)ø.01"(ø0.3)ø.13"(ø3.2)ø.09"(ø2.4).12"(3.1).01(0.06"(1.6)ø.02"(ø0.6)90 (S=5/1)Detail - A .13"(3.4).06"(1.6).02"(0.6)A 12AAC732 [.08"(2m)]*112AAB404 [.18"(5m)]12AAB416 [.39"(10m)][ ]: Tip radius 12AAC733 [.08"(2m)]*1ø.55"(ø14).28"(ø7.2).14"(3.6).2(6.22"(5.6).11"(2.8)ø.12"(ø3)"(1.6).61"(15.6)ø7.2) R .22"(5.6).85"(21.5).14"(3.6).92"(23.5).14"(3.5).27"(6.8).29(7.5Stylus tip position 15012AAB344 12AAB345178-043-1 (mm)178-053-1 (inch/mm)Leveling table (for D.A.T. function)• Can be used with the XY leveling tables.Table swivels: ±1.5° Table size:5.12"x3.94" (130x100mm)Max. Loading: 15kgfMemory cardStores/recalls the measuring conditions (up to 20), measured data, and statistical data.Memory: 8MBMeasuring data output Others Manual column standColumn travel: 7.87"(200mm)Dimensions: 14.57"x7.87"x29.13"(370x200x740mm)Mass: 28.66 lbs. (13kg)264-005DP-1VRPerforms various statistical processingCylinder attachmentUsed to attach on a cylinderDiameter: ø.59" up to 2.36" (ø15mm up to 60mm)SPC connecting cablesConnects a control unit with DP-1VR.3'(1m): 9369376'(2m): 965014Reference step specimenUsed to calibrate detector sensitivity.Step nominal value: 2µm/10µmLCD protective sheetFor touch panel protection (10 sheet set)Five rolls 984'(25m)Standard paper: 270732178-009178-048 (mm)178-058 (inch/mm)178-611 (mm)178-612 (inch/mm)178-019Precision vise• Can be used with the XY leveling table.Input toolData input device for spreadsheet software.264-503A (120V)12AAB358Note: All information regarding our products, and in particular the illustrations, drawings, dimensional and performance data contained in this printed matter as well as other technical data are to be regarded as approximate average values. We therefore reserve the right to make changes to the corresponding designs. The stated standards, similar technical regulations, descriptions and illustrations of the products were valid at the time of printing. In addition, the latest applicable version of our General Trading Conditions will apply. Only quotations submitted by ourselves may be regarded as definitive.Mitutoyo products are subject to US Export Administration Regulations (EAR). Re-export or relocation of our products may require prior approval by an appropriate governing authority.Trademarks and RegistrationsDesignations used by companies to distinguish their products are often claimed as trademarks. In all instances where Mitutoyo America Corporation is aware of a claim, the product names appear in initial capital or all capital letters. The appropriate companies should be contacted for more complete trademark and registration information.© 2011 Mitutoyo America Corporation, Aurora IL 1110-04 Printed in USA, January 2011Specifications are subject to change without notice.。

三丰公司秉承持续创新向客户提供最新技术体验的理念。

因此保留对产品的技术规格进行变更的权利。

规格如有变更,恕不另行通知。

便携式表面粗糙度测量仪

Surftest SJ-210 系列(C15017测量开始/停止 粗糙度参数选择

开关 ON/OFF/外部输出

罩打开和关闭

支持多种粗糙度标准。

拥有多种参数和功能,如任意长度测量。

使用主件上面和其可开启盖里面的按钮可便于操作和设置。

按下测量开始按钮时,测量完成后显示测量结果。

置可充电电池可支持测量的进行,无需外的可选打印机可打印计算结果和实测累计测量距离超过所设定的门限水平时,输出报警显示。

(有助于维护针头更换策种类型的驱动装置可用:标准型、横向驱动型和退避型。

是否可选,视工件情况而定。

产品详细介绍:http://www.jd-17.com/jd-17_ChiClass_21234_1.html。

SRM-1(A)型表面粗糙度测量仪使用说明书宁波市科技园区联晟电子科技有限公司目录一.主要用途、使用范围——————————— 1二、 主要技术参数——————————————— 1三、产品主要结构概述————————————————— 3 1.测量仪总体结构————————————————— 3 2.主要部件概述—————————————————— 4 3.测量仪工作原理—————————————————7 四、安装与使用———————————————————— 8 1.使用前的准备与检查———————————————8 2.使用方法————————————————————9 3.注意事项———————————————————— 13 五.运输与贮存——————————————————— 14 附录一:表面粗糙度参数值与截止波长选取对照表附录二:新旧国标Ra参数值转化表附录三:简单故障自排表一、 主要用途、适用范围SRM-1(A)型表面粗糙度测量仪(以下简称“测量仪”)具备测量国标GB1031-83《表面粗糙度参数及其数值》规定的表面粗糙度评定参数之功能(Ra、Rz、Ry等参数的运算显示及打印),可配备标准、小孔、曲面等多种传感器,在测量附件支持下,可以测量平面、外圆、内孔、曲面、深孔、凹槽等形体制件的表面粗糙度;本测量仪产品测量范围宽,精度高,因此十分适合于生产现场计量(检验)站、企事业单位计量(实验)室,大中专学生实验室等对制件表面作较为精密的粗糙度测量之用。

测量仪可以在20±10℃温度范围和相对湿度不大于85%的条件下使用;测量仪工作时,在其附近不应有影响测量的强振动源和强电磁干扰源,不应有腐蚀性气体和较多尘埃存在。

二、 主要技术参数1. 测量参数:Ra、Rz、Ry2. 测量范围:Ra:0.025μm -6.30μm (曲面: Ra:0.025μm -1.0μm)Rz、Ry:0.100μm -25.00μm (曲面: Ra:0.100μm -6.3μm)3. 截止波长λc:0.25 mm、0.8 mm、2.5mm 可选4.显示器最小分辨数:0.001μm5. 量程设置:0.01μm 0-0.100μm(Ra)0.10μm -1.0μm(Ra)1.0μm -10.0μm(Ra)6. 测量行程:0.5 mm~13.5 mm7.评定长度:1倍,3倍,5倍取样长度8. 传感器测量速度:1.5mm/s(λc=0.25、0.8mm时)3.0mm/s(λc=2.5mm时)9. 传感器触针针尖半径:10μm±2.5μm ,5μm±1.0μm 可选10. 触针静测力及其变化率:静测力:≤0.016N测力变化率:≤800N/m 11. 传感器导头半径:标准、小孔传感器:≥40mm凹槽传感器≥20mm曲面传感器:≥0.25mm12. 系统误差:±10%(曲面:±15%)13. 示值变动性:≤6%(曲面:≤12%)14. 电源:AC 220V±22V,50Hz,0.5A15. 打印机:TPUP-A微型打印机(撞击式点阵打印)16. 测量仪基本配置尺寸:驱动器:130mm×80mm×68mm传感器:Φ6mm×55mm运算显示器:230mm*240mm*80mm注:SRM-1(A)型基本配置主要包括:标准传感器一支电机驱动器一台运算显示器(含打印机)一台V形工作块一块多刻线粗糙度校准样板一块信号线及信号控制线选件包括:立柱工作台、倾斜工作台、十字工作台、各种传感器、深孔测量附件、多刻线校准样板等三、产品主要结构概述1.测量仪总体结构测量仪主要由传感器、直线驱动器、运算显示器、测量工作台(立柱工作台、十字工作台、倾斜工作台 )等组成,其测量时的外形组合见图1和图2(配工作台)。

TR110袖珍式表面粗糙度仪使用说明书目录1.概述 (2)2.工作原理 (2)3.基本配置 (2)4.主机各部分名称详图 (3)5.测量操作 (4)5.1测量前的准备 (4)5.2开机、关机和背光 (4)5.3选择参数 (5)5.4测量 (6)5.5示值校准 (7)5.6米制/英制转换 (8)5.7自动关机 (9)5.8低电压报警 (9)5.9充电 (9)5.10复位 (9)6.日常维护与保养 (9)6.1保养 (9)6.2维修 (10)7.技术参数及功能特点 (10)7.1主要技术参数 (10)7.2主要功能 (11)7.3使用环境 (11)8.参数定义 (12)9.取样长度选择推荐表 (13)1.概述时代TR110袖珍式表面粗糙度仪是我公司2003年推出的新一代袖珍式表面粗糙度仪。

它具有测量精度高、测量范围宽、操作简便、便于携带、工作稳定等特点,可以广泛应用于各种金属与非金属加工表面的检测,该仪器是传感器主机一体化的袖珍式仪器,具有手持式特点,更适宜在生产现场使用。

TR110主要在以下几方面进行了改进:w TR110的外形符合当今设计新趋势,较上一代产品更具亲和力,操作更合理,具有舒适感。

w采用锂离子充电电池,可长时间工作,无记忆效应,可边充电边工作,充电时间短,电池寿命长。

w改进了电路的工作性能,降低了工作电压,功耗和电路噪声相应降低。

w改进了传感器的驱动机构、材料及加工工艺,装配更精确,测量更稳定。

w新设计的液晶显示界面增加了一些必要的提示信息,如:测量提示、低电压提示、等。

w增加了传感器测头保护门,有效的保护了传感器测头,保证了测量的精度。

w增加了背光,方便用户在光线较暗处使用。

w体积更小,重量更轻。

2 工作原理当传感器在驱动机构的驱动下沿被测表面作匀速直线运动时,其内部垂直于工作表面的触针随工作表面的微观不平轮廓产生垂直方向的位移,再通过传感器将位移变化量转换成电量的变化,将该电信号进行放大、滤波,送A/D转换为数字信号,经CPU处理,计算出Ra、Rz值并显示。

2Requirement1High-accuracy measurements with a hand-held testerA wide-range, high-resolution detector and an straight drive unit provide superior high-accuracy measurement in its class.<Detector>Measuring range: 800µmResolution: 0.000125µm (at 8µm range)<Drive unit>Straightness/traverse lengthSJ-401: 0.3µm/25mm SJ-402: 0.5µm/50mmRequirement5Advanced data processing with an extended analyzing programThe SJ-400 series allows data processing that is identical to that in the high-end class. These data analysis and report creation capabilities can be achieved with this system using the surface roughness analyzing program SURFPAK-SJ.Requirement3Measurement of cylinder surfaceroughness even with a compact typeThe skidless measurement and R-surface compensation functions make it possible to evaluate cylinder surface roughness.Requirement2Roughness parameters that conform tointernational standardsThe SJ-400 series performs 36 kinds of roughness measurements that conform to the latest ISO, DIN, and ANSI standards as well as to JIS standards (1994/1982).Now, long-awaited specifications and functions are at hand: compactness,skidless measurement, high-accuracy roughness detection, multi-function, and ease of operation.Revolutionary New Portable Surface Roughness Testers Make Their Debut!SJ-401SJ-402SJ-401Requirement4Measurement/evaluation of stepped features and straightnessUltra-fine steps, straightness and waviness can be measured by switching to the skidless measurement function. The ruler functionenables simpler surface feature evaluation on the LCD monitor.3Surftest SJ-400Calculation Result screen Measured Profile screenRequirement6Confirmation of a measurement results and an assessed profile without printoutUsing the integrated large touch-panel LCD monitor,measurement results and an assessed profile can be clearly displayed.Measurement ApplicationsRuler Analysis screenA variety of accessories•A stylus and a nosepiece can be selected according to the measurement condition. (See page 9 – 11.)Simplified surface feature evaluation with the ruler function•This function determines the coordinate difference between two arbitrary points, such as a step height and a pitch interval.The SJ-400 series employs a detector with exchangeable nosepiece that is interchangeable between skidless measurement and skid measurement. It allows optional evaluation according to measurement conditions.NosepieceRuler function keyRuler keyCoordinate differenceRulerStylusDetectorSurftest SJ-400DAT screen showing the amount to be adjustedThe D.A.T. FunctionThe height-tilt adjustment unit comes as standard for powerful support of the leveling operation at skidless measurement. This unique and convenient function has achieved high-accuracy measurement with ease of operation.Move the micrometer head by this amount.Digimaticmicrometer headLeveling table (for D.A.T.)When using with the stand,the D.A.T. function can work with the optional leveling table.Support for R-surface roughness measurement (skidless measurement)Usually a workpiece with a spherical or cylindrical surfacecannot be evaluated. By eliminating the round surface element with a filter, this function processes this R-surface data as if it was taken from a flat surface.Built-in thermal printerA high-quality, high-speed thermal printer prints out measured results. It can also print a BAC curve or an ADC curve as well as calculated result and assessed profile. These results and profiles can be printed out in landscape format, just as they appear on the LCD. They are presented in an easy-to-understand form.Measurement of a cylindricalsurfaceStatistical processing functionThis function performs statistical processing of multiplemeasurements for one roughness parameter. It is possible to display and print histograms in addition to statistical results (mean, standard deviation, maximum value/minimum value,and acceptance ratio).StatisticalHistogramsSwitchableSurftest SJ-400Calculation Result screen with GO / NG judgment resultAccording to the upper/lower tolerance limits set the GO/NG judgment sign is displayed and the calculation result is highlighted (max. for 3 roughness parameters).Calibration screenThe SJ-400 series is equipped with the Ra calibration and step calibration methods for detector calibration (gain adjustment).In both calibration methods only the reference value described in the precision specimen needs to be entered. No other operation such as volume control is required.and conditionsIt is possible to save the measurement conditions and measured data in the control unit or memory card (optional) and to recall the data from both.Batch printout of the measured data after performing on-site measurement and saving the data will raise measurement efficiency.This function invalidates the key operation on the touch panel.Since only the sheet key operation is valid, there is no chance for error in data, including calibration conditions and measurement conditions.This function samples a displacement of the stylus for the specified time without traversing the detector.It has a wide range of uses such as a simplified vibration meter or a displacement gage incorporated in another system.It is possible to recalculate already measured data for other evaluation by changing the current standard, assessed profile and roughness parameters.This function allows a sampling length to be arbitrarily set in 0.1mm increments (SJ-401: 0.1mm to 25mm, SJ-402: 0.1mm to 50mm). It also allows the SJ-400 series to make both narrow and wide range measurements.Customize functionThis function selects only the necessary parameters forcalculation/display from a variety of roughness parameters. It is also possible to add parameters later for recalculation.Customized screenGO signNG signInvalidatedSURFPAK-SJ SpecificationsEvaluation Curve displayAnalysis graph displayEvaluation condition displayMeasurement condition displayCalculation result display Analysis screenSurftest SJ-400Carrying case is a standard accessory10Detector178-396-2: 0.75mN measuring force, with 12AAC731 standard type stylus (2µm tip radius)178-397: 4mN measuring force, with 12AAB403 standard type stylus (5µm tip radius)Set configuration/Dimensionsø146.83.6146027.2ø8ø142410.42.8DetectorSkid nosepiece (12AAB344)Stylus ø14ø7103.13.61.3Skidless nosepiece (12AAB355)90°0.937.77.644.7ø2.4ø1.25.2A Distinguish colorDetail - A0.60.41.6ø0.690°(S=5/1)Detail - A ø2.415ø1.23.42.41.60.637.744.4ADistinguish color0.41.2ø0.390°(S=5/1)Detail - A ø2.48.9ø0.62.537.71.244.2ADistinguish colorø0.390°Distinguish color0.80.4Detail - A (S=5/1)ø2.437.72.5ø0.68.944.20.8Aø2.487.70.9Ø1.290°94.77.65.2A distinguish color Detail - Aø2.4137.70.97.6144.7ø1.290°5.2ADistinguish colorDetail - Aø14Ø7.2R 403.623.53.56.73.65.621.5 2.8Stylus tip positionø14ø3R 400.61.63.621.5 5.63.623.51.43.515.6ø7.23.8R2Stylus tip positionø14R 403.61.222.321.5ø1.926.73.53.8ø7.2Stylus tip positionø7ø141.33.6421.5103.5Stylus tip positionø14R 405.621.5 3.623.53.53.6ø7.26.87.5Stylus tip position150°Standard type12AAC731 (2µm)*112AAB403 (5µm)12AAB415 (10µm)( ): Tip radiusSmall hole type12AAC732 (2µm)*112AAB404 (5µm)12AAB416 (10µm)( ): Tip radiusExtra small hole type12AAC733 (2µm)*112AAB405 (5µm)12AAB417 (10µm)( ): Tip radiusExtra small hole typeDeep hole type12AAC734 (2µm)*112AAB406 (5µm)12AAB418 (10µm)( ): Tip radius2 x stylus12AAC740 (2µm)12AAB413 (5µm)12AAB425 (10µm)( ): Tip radius3 x stylus12AAC741 (2µm)*112AAB414 (5µm)12AAB426 (10µm)( ): Tip radius12AAB35512AAB34412AAB34512AAB34612AAB347Skidless nosepieceUnit: mmStylusApplicable skid nosepiece*1 Tip angle is 60°11Surftest SJ-400Deep groove type*212AAC735 (2µm)*112AAB409 (5µm)12AAB421 (10µm)( ): Tip radiusExtra deep groove type*212AAC736 (2µm)*112AAB408 (5µm)12AAB420 (10µm)( ): Tip radiusExtra deep groove type*212AAC737 (2µm)*112AAB407 (5µm)12AAB419 (10µm)( ): Tip radiusGear face typeEccentric type*2*1 Tip angle is 60° *2 At using this stylus, measuring force of the detector does not guarantee.12AAB339 (2µm)*112AAB410 (5µm)12AAB422 (10µm)( ): Tip radius12AAC739 (2µm)*112AAB412 (5µm)12AAB424 (10µm)( ): Tip radiusKnife edge type12AAC738 (2µm)*112AAB411 (5µm)12AAB423 (10µm)( ): Tip radiusWE-curve type12AAB33812AAB349StylusApplicable skid nosepiece12AAB35012AAB35112AAB35212AAB34812AAB35312AAB35413ø2.40.9ø1.290°14.237.744.7ADistinguish ColorDetail - A230.9ø2.424.2ø1.290°37.744.7A Detail - ADistinguish color3533.85.2ø1.2A Distinguish colorø2.4Ø2.490°37.745.2Detail - A60°60°7.66.437.743.8ø1.2ø2.4ADistinguish colorDetail - A7.6ø2.4ø1.20.937.744.7Ball ø1.5885.27.6ø2.4ø1.290°37.70.944.7ADistinguish colorDetail - AADetail - A37.70.990°ø0.6Distinguish color457.610ø2.4ø2.4ø14R 4012.80.61.41.43.53.819.5 1.821.54.53.6109ø7.2Stylus tip positionR24.4ø14ø7.2R 403.623.51.413.421.5 5.63.6 2.8103.5Stylus tip positionR2ø14ø7.2(8.4)3.63.819.51.821.53.513.4 2.55910Stylus tip positionø1.5ø14R 4017.9Ø7.23.521.553313.64.513.49 1.4511.610R210Stylus tip positionø14R 403.53.819.5 1.821.522.80.61.42720Ø7.29Stylus tip positionR21.44.4ø14R 401.43.50.521.5ø7.219.72.36.14.50.61.43.62.3R2Stylus tip position4.4ø14R 4021.56.7ø7.25.63.63.63.523.52.8Stylus tip positionFlat Unit: mm12Order No.178-019Mounting method Two-sliding- jaw Clamp opening 36mm/1.42”Clamp width 44mm/1.73”Clamp depth 16mm/.63”Height38mm/1.50”Stand, TablesManual column standColumn travel: 200mmDimensions: 370x200x740mm Mass: 13kg178-009178-042-1 (mm)178-052-1 (inch/mm)178-049 (mm)178-059 (inch/mm)XY leveling tables178-019Precision vise•Can be used with the XY leveling table.74313178-043-1 (mm)178-053-1 (inch/mm)Order No.178-042-1,178-052-1178-043-1,178-053-1178-049,178-059Table size130 x 100mm/5.12” x 3.94”Maximum loading weight 15KgInclination angle±1.5˚—Horizontal rotating angle ±3˚—X, Y axis displacement ±12.5mm/.49”±12.5mm/.49”±12.5mm/.49”Min. reading0.001mm/.00005”*0.001mm/.001”*0.001mm/.00005”*of the micrometer head Dimension 262 x 233 x 83mm220 x 189 x 83mm262 x 233 x 55mmMass6.3kg6kg5kg* Digital display13Surftest SJ-400Leveling table•Can be used with the XY leveling table.Table swivels: ±1.5°Table size: 130x100mm Max. Loading weight: 15kgMemory cardSaves/Retrieves the measuring conditions (up to 20), measured data, and statistical data.Memory: 8MBOthers 264-005DP-1VRPerforms various statistical processingCylinder attachmentUsed to attach on a cylinderDiameter: ø15mm up to 60mmSPC connecting cablesConnects a control unit with DP-1VR.1m: 9369372m: 965014Reference step specimenUsed to calibrate detector sensitivity.Step nominal value: 2µm/10µmLCD protective sheetFor touch panel protection (10 sheets set)Printer paperFive rolls (25m)Standard paper:270732Durable paper:12AAA879178-048 (mm)178-058 (inch/mm)178-611 (mm)178-612 (inch/mm)2 (.08")99 (3.90")79 (3.11")57.5(2.26")Ø50 (1.97")Input toolData input device for spread sheet software.264-503 (100V)264-503A (120V)264-503D (220V)264-503E (240/220V)12AAA84112AAA89612AAB358MichiganPhone: (734) 459-2810IllinoisPhone: (630) 978-5385CaliforniaPhone: (626) 961-9661MassachusettsPhone: (978) 692-8765IndianaPhone: (317) 577-6070North CarolinaPhone: (704) 875-8332Coordinate Measuring Machines Small Tool Instruments and Data ManagementHardness Measuring Sensor Systems Optical Measuring Digital Scale and DRO Systems Surface-, Form- and Contour MeasurementVision Measuring Systems Note: All information regarding our products, and in particular the illustrations, drawings, dimensional and performance data contained in this pamphlet, as well as other technical data are to be regarded as approximate average values. We therefore reserve the right to make changes to the corresponding designs, dimensions and weights. The stated standards, similar technical regulations, descriptions and illustrations of the products were valid at the time of printing. In addition, the latest applicable version of our General Trading Conditionswill apply. Only quotations submitted by ourselves may be regarded as definitive.Job No.11B-826.800308 (1) C N E , P r i n t e d i n J a p a n。

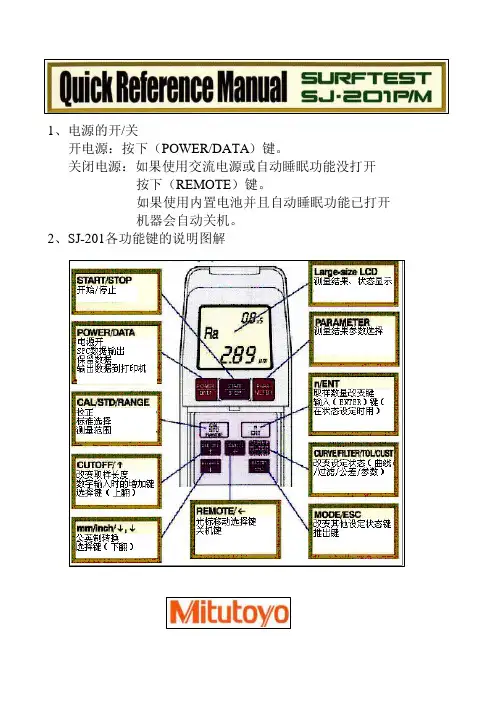

1、电源的开/关开电源:按下(POWER/DATA)键。

关闭电源:如果使用交流电源或自动睡眠功能没打开按下(REMOTE)键。

如果使用内置电池并且自动睡眠功能已打开机器会自动关机。

2、SJ-201各功能键的说明图解仪器校正说明:1、按下(CAL/STD/RANG)键,屏幕出现CAL字和闪动的参考数值,与所用的标准块上的值对照,如不一样,请使用(REMOTE)键移动光标,使用(CUTOFF)和(mm/inch键改变数值,使他和标准样板上的数值一样。

2、按下(N/ENT)键3、按图所示放置好粗糙度仪和标准样板。

4、按下(START/STOP)键进行测量。

5、测量完成后按下(N/ENT)键,完成整个校正过程。

测量放好工件和仪器,按下(START/STOP)键,就开始测量,并自动获得结果。

转换测量结果显示参数按下(PARAMETER)键就可实现参数转换。

改变测量状态1、在测量状态下按下(CUTOFF)键,截取长度可在0.25---0.85---2.5mm之间变换。

2、改变取样长度在测量状态下按下(N/ENT)取样长度在X1--X3--X5--L之间转换(如:0.8 X 1、0.8 X 3、0.8 X 5,L是直接输入取样长度。

)3、改变测量轮廓1/在测量状态下按下(CURVE/FILTER/TOL/CUST)键,进入轮廓设定状态。

(显示CRV 和闪动的轮廓代号)2/按(CUTOFF)或(mm/inch)键改变轮廓代号。

每次按动轮廓代号会按照一定顺序改变:SJ-201P:P--r--d--PSJ-201M:P--r--CnO--P3/按下(N/ENT)键输入新设定。

粗糙度测量方法1、仪器的正确摆放如图:驱动器应该与工件垂直,并紧贴工件表面。

2、传感器测头需水平于被测表面。

驱动器与高度规的连接通过使用12AAA222连接附件,可以很轻松的实现各种方向的测量,适应各种不同表面的零件。

错误判断和解决错误现象可能的原因:驱动器和显示器没有连接好解决办法:检查连接。

MAHR粗糙度仪使用和设置MAHR粗糙度仪在现场常用的有两种:M1和M2。

区别在于M2有上下左右4个按键,而且可测量参数比M1多,其使用和设置方法大致相同,现以M1为例说明粗糙度仪的使用和设置。

一.使用连接驱动单元和仪器。

按START键,仪器开始工作。

最后一次使用的仪器设置仍有效。

探头定位在被测件上。

按START键,启动测量;此时如再按START键,仪器中断工作。

测量结束后,自动打印测试报告(在“自动打印”设置为1的情况下)。

按Ra、Rz、Rmax、Pc键屏幕显示参数。

按测量报告键打印测量报告。

按着走纸键打印纸自动走出。

二.设置在设置没有屏蔽时,可以改变设置状态(在“屏蔽设置”设置为0的情况下)。

1)探头扫描长度设置:按Lt/Lc键可以改变探头扫描长度,可以选择1.750mm(0.250*5),5.600mm(0.8*5),17.50mm(2.500*5)。

2)其它设置:按着START键,再按走纸键,可打开设置的目录。

按参数键可翻看目录,其对应关系为:),按▼键或▲键可改变所选的修改区的值。

注意:为了使测量仪在关机后仍保存着已改变的仪器设置,必须用该设置进行一次无错的测量。

Perthometer M1 的设置目录:语言中文选择操作提示所用的语言单位mm 选择输出结果和设置的单位标准ISO 选标准自动关机0 开或关仪器的自动关机屏蔽设置0 开或关仪器的屏蔽设置V.24 9600 N81 20 选择接口V.24的波特率及工作方式探头型号100 选择探头型号Batt >> 33.2 % 充电电池的电容量(和充电形式)的显示标定启动探头的评定修正值0 % 设置探头的修正值n 5 选采样区数n短截止波长0 选标准的或短的截止波长的Lc自动打印 1 开或关测量报告的自动打印轮廓 1 开或关测量报告中的轮廓图3)标定和探头的修正值的设置标定:a)定位驱动单元,使探头准确地定位在粗糙度样块上,即探头针尖处于垂直位置,并且整个扫描长度在这个已定义的粗糙度区域内。

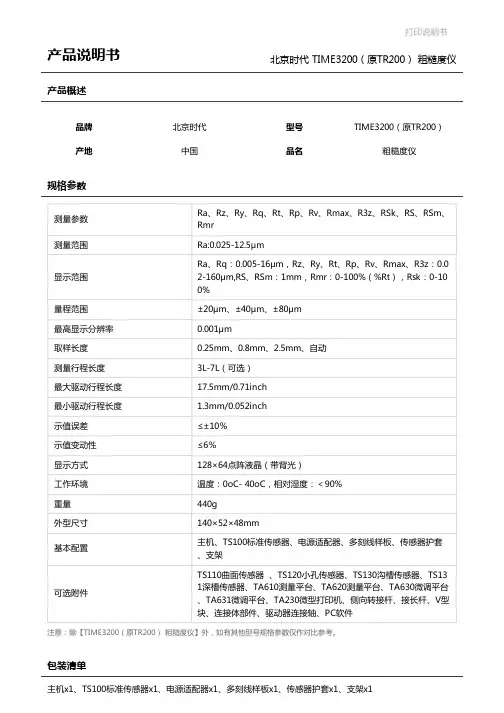

北京时代 TIME3200(原TR200) 粗糙度仪产品说明书产品概述品牌北京时代型号TIME3200(原TR200)产地中国品名粗糙度仪规格参数测量参数Ra、Rz、Ry、Rq、Rt、Rp、Rv、Rmax、R3z、RSk、RS、RSm、Rmr测量范围Ra:0.025-12.5μm显示范围Ra、Rq:0.005-16μm,Rz、Ry、Rt、Rp、Rv、Rmax、R3z:0.0 2-160μm,RS、RSm:1mm,Rmr:0-100%(%Rt),Rsk:0-10 0%量程范围±20μm、±40μm、±80μm最高显示分辨率0.001μm取样长度0.25mm、0.8mm、2.5mm、自动测量行程长度3L-7L(可选)最大驱动行程长度17.5mm/0.71inch最小驱动行程长度 1.3mm/0.052inch示值误差≤±10%示值变动性≤6%显示方式128×64点阵液晶(带背光)工作环境温度:0oC- 40oC,相对湿度:<90%重量440g外型尺寸140×52×48mm基本配置主机、TS100标准传感器、电源适配器、多刻线样板、传感器护套、支架可选附件TS110曲面传感器 、TS120小孔传感器、TS130沟槽传感器、TS13 1深槽传感器、TA610测量平台、TA620测量平台、TA630微调平台、TA631微调平台、TA230微型打印机、侧向转接杆、接长杆、V型块、连接体部件、驱动器连接轴、PC软件注意:除【TIME3200(原TR200) 粗糙度仪】外,如有其他型号规格参数仅作对比参考。

包装清单主机x1、TS100标准传感器x1、电源适配器x1、多刻线样板x1、传感器护套x1、支架x1打印说明书售后保障保修天数:365天【注意】选购该产品自客户签收日期起计算,保修期1年。

保修期内运费分担界限:寄出者支付。

使用不当造成损坏不在保修范围内。

HOMMELWERKEHOMMEL 粗糙度轮廓仪 T1000操作指南版本:T1C.02/2n标准:16.03.00编号:526152目录页码1 介绍/安全指南1-11.1 总体概述1-11.2 安全指南1-21.2.1 操作条件1-21.2.2 电源1-31.2.3 正确使用1-31.3 解体和处理1-32 首次操作2-12.1 产品包2-12.2 安装2-12.3 使用性, 进给器装置2-22.3.1 连接2-2插入探头2-22.4 电源2-32.4.1 主操作2-32.4.2 电池操作2-32.5 上纸2-42.6 开机2-42.6.1 总述2-42.6.2 波形版本2-42.6.3 测量2-42.7 关机2-52.7.1 自动2-52.7.2 手动2-52.8 重新设置/初始化2-63 设备说明3-13.1 操作元件和指示器3-13.1.1 HOMMEL粗糙度仪T1000的正面3-13.1.2 HOMMEL粗糙度仪T1000的背面3-33.1.3 HOMMEL粗糙度仪T1000的键盘功能3-43.1.4 打印机3-64 程序说明4-14.1 操作模式4-14.2 菜单等级4-34.3 操作指南4-44.3.1 菜单规定范围内的运动4-44.3.2 数值输入4-54.3.3 文本输入4-64.4 安全4-64.4.1 激活口令包括4-74.4.2 改变口令4-74.5 系统设置4-85 粗糙度测量技术5-15.1 表面粗糙度5-15.2 粗糙度测量-探测原则5-15.2.1 探测目标源5-22.2.2 扫描系统—概述5-3I5.3 表面图形元素5-35.4 取样长度/切割粗糙度图形5-45.4.1 过滤器选择λc(切割)5-45.4.2 噪音过滤器选择λc/λs 5-55.5 表面参数5-65.5.1 图形总高度 Pt, Wt, Rt 5-65.5.2 最大粗糙度图形高度Rz 5-75.5.3 算数平均粗糙度值Ra 5-85.5.4 峰值计数PRc 5-85.5.5 均方根粗糙度值 Rq 5-95.5.6 倾斜度Rsk 5-95.5.7 深度/曲度Rku 5-105.5.8 RSm, PSm, WSm图形不规则值的平局间距5-105.5.9 平均的中间峰-谷高度R3z 5-115.5.10 粗糙度图形材料比Rmr(c) 5-115.5.11 材料比曲线参数Rk, Rpk, Rvk, Mr1, Mr2 5-126 创建测量程序6-16.1 菜单总述6-16.2 打开6-66.3 基础菜单6-66.3.1 程序输入菜单6-106.3.2 系统配置6-256.3.3 通道配置6-257 系统设置/服务7-17.1 系统设置7-17.1.1 总体介绍7-17.1.2 设置日期/时间7-17.1.3 系统配置7-27.2 服务功能7-48 调整/测量8-18.1 调整, 总述8-18.2 调整菜单8-18.3 调整程序8-28.3.1 手动校直8-28.3.2 自动校直8-38.3.3 参考运行波线20 8-48.4 调整程序8-48.5 出具测量报告8-59 选项顶部/波形9-110.2 初始化/重新设置10-210.3 服务和维护10-210.3.1 总述10-210.3.2 常规间隔下的工作10-210.3.3 使用清洁剂10-2用丙酮或乙醇来溶解漆或标签! 10-210.4 技术规格10-310.4.1 HOMMEL粗糙度仪T1000 10-310.4.2 一体的打印机10-410.4.3 线性进给器10-510.4.4 表面探测10-5II缩略语/词汇/符号IIIIV1 介绍/安全指南 HOMMELWERKE 1.介绍/安全指南1.1 总述便携式的HOMMEL 粗糙度仪T1000与LV16扫描驱动器一起可以进行表面粗糙度的测量。

粗糙度测试仪操作说明

粗糙度测试仪使⽤说明

⼀、操作步骤:

1.打开仪器电源适配器开关,按下仪器启动按钮和计算机主机电源按钮;

2.等待计算机启动好后,打开Vision64软件,此时出现初始化界⾯,同时能听到仪器内部初始化运转声⾳。

待初始化完成后,软件进⼊操作界⾯;

3.在样品托盘上放置样品;

4.点击Open打开相应的测试模块Recipe;

5.在软件界⾯Z轴控制⾯板中进⾏对焦,直到视野中出现⼲涉条纹;

6.根据样品情况选择恰当的放⼤倍率,之后使⽤仪器左侧与前部的样品台倾斜调节旋钮调节视野中条纹数⽬,最终通过Z轴控制⾯板调节保持0级条纹(最亮条纹)处于视野中央;

7.调节光强Intensity,光强应尽可能⼤,但必须保证不使图像最亮区域发红即可,⼀般此处选⽤⾃动光强Auto;

8.根据所测量样品的粗糙程度(纵深)设置适当的扫描速度、回溯扫描⾼度(Backscan)、扫描深度(Length);

9.点击界⾯左上⾓Measurement按钮开始测试;

10.待测试完成后保存原始数据(Save > Save DataSet)或进⾏截图保存;

⼆、注意事项:

1.对焦时应遵循由下⾄上的对焦原则,即事先将镜头置于离样品较近的⾼度,然后向上移动镜头调焦,防⽌物镜在调焦过程中撞击样品⽽损坏;

2.为保证测量的准确性,对焦以及调节倾斜前请确认⽬前测量模块所采⽤的测量模式(VSI或PSI),可辨识条件下Tilt后应保证对应模式视野中条纹的数⽬:VSI模式0-15条,PSI模式<5条。

制订:张智畅 2013.03.02 审核:。

TR220手持式粗糙度仪 使用说明书北京时代山峰科技有限公司TEL:010-******** 010-********FAX:010-******** 010-********1概述 (3)1.1测量原理 (3)1.2标准配置 (3)1.3仪器各部分名称 (3)1.4基本连接方法 (3)1.4.1传感器装卸 (3)1.4.2电源适配器及电池充电 (3)2测量操作 (3)2.1测量前的准备 (3)2.1.1开机 (3)2.1.2测量必备条件检测 (3)2.1.3零位调整 (3)2.1.4测量条件的选择 (3)2.2测量 (3)2.3测量条件设置 (3)2.3.1取样长度的设置 (3)2.3.2评定长度的设置 (3)2.3.3量程的设置 (3)2.3.4滤波器的设置 (3)2.3.5参数的设置 (3)2.3.6 C(RPc µm)设置 (3)2.3.7 C(RPc %)设置 (3)2.4功能选择 (3)2.4.1打印 (3)2.4.1.1打印选择参数 (3)2.4.1.2打印轮廓图形 (3)2.4.1.3打印支承率曲线 (3)2.4.1.4打印Rk参数图形 (3)2.4.1.5打印参数和图形 (3)2.4.2图形 (3)2.4.2.1滤波轮廓 (3)2.4.2.2不滤波轮廓 (3)2.4.2.3支承率曲线 (3)2.4.2.3 Rk参数图形 (3)2.4.2.4直接轮廓 (3)2.4.3触针位置 (3)2.4.4示值校准 (3)2.5系统设置 (3)2.5.1语言 (3)2.5.2单位 (3)2.5.3液晶背光 (3)2.5.4液晶亮度 (3)2.5.5时间校准 (3)2.6与PC机通讯 (3)3关机 (3)4快捷键的使用 (3)4.1按键: (3)4.1.1参数设置为除Rk以外的其他参数 (3)4.1.2参数设置为Rk参数 (3)4.2按键: (3)4.3按键 (3)4.4按键: (3)4.4.1测值存储 (3)4.4.2读取存储值 (3)5可选附件及其使用 (3)5.1可调支架及传感器护套 (3)5.2测量平台 (3)5.3接长杆 (3)5.4磁性表座连接杆 (3)5.5传感器 (3)5.5.1 TS100标准传感器 (3)5.5.2 TS110曲面传感器 (3)5.5.3 TS120小孔传感器 (3)5.5.4 TS130深槽传感器 (3)5.5.5 TS131深槽传感器 (3)6技术参数 (3)6.1传感器 (3)6.2驱动参数 (3)6.3示值误差 (3)6.4示值变动性 (3)6.5显示内容 (3)6.5.1菜单 (3)6.5.1图形 (3)6.5.2参数 (3)6.5.3提示信息 (3)6.6轮廓和滤波器 (3)6.7取样长度 (3)6.9粗糙度参数和显示范围 (3)6.10测量范围和分辨力 (3)6.11电源 (3)6.12温度/湿度范围 (3)6.13外形尺寸和重量 (3)6.14连接打印机 (3)6.15连接PC机 (3)7日常维护与保养 (3)7.1故障处理 (3)7.2故障信息 (3)8参考资料 (3)8.1轮廓和滤波 (3)8.1.1轮廓 (3)8.1.2滤波器 (3)8.2驱动行程长度 (3)8.2.1 RC滤波器 (3)8.2.2 PC-RC滤波器 (3)8.2.3 Gauss滤波器 (3)8.2.4 D-P直接轮廓 (3)8.3TR220粗糙度参数定义 (3)8.3.1轮廓算术平均偏差Ra (3)8.3.2轮廓均方根偏差Rq (3)8.3.3轮廓的最大高度Rz (3)8.3.4轮廓最大高度Ry (3)8.3.6轮廓最大峰高Rp (3)8.3.7轮廓最大谷深Rv (3)8.3.8轮廓微观不平度的平均间距RSm (3)8.3.9轮廓的单峰平均间距RS (3)8.3.10轮廓支承长度率Rmr (3)8.3.11轮廓的偏斜度RSk (3)8.3.12第三峰谷高度平均值R3z (3)8.3.13粗糙度峰计数RPc (3)8.3.14核心粗糙度深度Rk (3)8.3.15支承率Mr1、Mr2 (3)8.3.16去除的峰值高度Rpk (3)8.3.17去除的谷值深度Rvk (3)9附表 (3)9.1屏幕显示放大倍数 (3)9.2取样长度选择推荐表 (3)1概述TR220手持式粗糙度仪是北京时代之峰科技有限公司开发的一个新产品,该仪器适用于生产现场,科研实验室和工厂计量室。

•The large LCD window makes it easy to readmeasurement resultand analysis graph at a glance. The profile-speed thermal printer prints out clear and fast.•Designed to increaseoperability – the large keypads are used for measuringoperations, while the touch panelLCD is used for setting various measurement conditions.•Measured data can be downloaded to a PC. Various analyses can be made by using Surfpak-SJ, dedicated software for surface texture analysis.A portable surface roughness testerwith a touch-panel LCD and a built-in printer.Surftest SJ-301Conforming to various standards•Conforming to the JIS (1994/1982),ISO, DIN, and ANSI standards.•Additionally, the horizontal roughness parameters S, Sm, tp (mr) can be reported. The SJ-301 also performs such special parameters as plateau rate and RK-related parameters.Storing measurement conditions and data•The SJ-301 main unit can store a maximum of 5 sets of measuring conditions. Individual measuring conditions can be selected for each workpiece.•The measuring conditions stored in the SJ-301 can be recalled and switched by direct key operations.•Measured data can be saved at the measurement site and be printed out or recalculated later.•By using an optional memory card, a maximum of 20 sets of measuring conditions, measured data, and statistical results can be stored.High-speed thermal printer•Equipped with a highly sophisticated,high-speed thermal printer.•Selectable orientation for printout –Choose the portrait for conventional printout or the landscape for printing out the image as it is displayed.•BAC (Bearing Area Curve) and ADC (Amplitude Distribution Curve) can be printed out.Key-masking function•This function limits touch panel operation to prevent the detector calibration data and measuring conditions from being altered or deleted.•Measuring conditions can be easily controlled among multiple users.Landscape printoutPortrait printoutResistance to environment•The SJ-301 keypads have excellentdurability -- No need to worry about oil stains from the user's hand.Reading profiles in the LCD window•Measurement results and analysis profiles can be read in the LCD window.•Signal waves can be scrolled smaller or larger, enabling the operator to read fine details.Customization function•The user can select only theparameters needed from a variety of surface roughness parameters provided.Mobility•A built-in buttery in the SJ-301 makes it possible to inspect surface roughness even at a site where there is no electrical outlet available.•Portable and convenient – the drive unit and the detector can be stored in the display unit. (Carrying case is a standard accessory.)•Measurement can be performed while the display unit is in the carrying case.The carrying case can be used to protect the display unit.Auto calibration•Calibration can be easily performed by simply inputting and measuring the Ra value inscribed on the roughness reference specimen.•No adjustment with a tool, such as a volume adjustment, etc. is required.Statistical analysis functions•Statistical analysis of one parameter is possible.•Displays and prints frequency histograms as well as statisticalcalculation results (average, standard deviation, maximum value, minimum value, pass ratio).GO/NG judgement function•Tolerance values in three-steps can be set for the surface roughness parameters.•Judgment symbol is displayed in the result display for a quick judgment of GO/NG.Selectable language for display/printoutDisplay/printout language is selectable from among English, German, French,Italy, Spanish and Japanese.Surftest SJ-301 Arbitrary evaluationlength•An arbitrary evaluation length withinthe range of 0.3 mm - 12.5 mm (Unit:0.1 mm) can be set.•Measurement in a limited space, wheremeasurement is difficult under themeasuring conditions in accordancewith JIS standards, is made possible byusing the start-up OFF function.One-step detectorreplacement•Special detectors are available formeasurements that cannot beperformed with a standard detector -such as measurement of small-diameters and deep-grooves.•No tool is required for replacing thedetector. Simply pull out and insert adetector.•Just one SJ-301 can performmeasurement on a variety ofworkpieces, since various types ofdetectors, depending on theworkpiece, can be used.25.2mm (.99")Approx. 21mm (.83")horizontallyApprox. 2mm (.08")verticallyHigh-accuracy detector•SJ-301 employs a differentialinductance method, which is used inhigh-end models.•Measurement with a high-accuracyand a wide measuring range of350µm.•Parameters that require high-accuracyfeed such as Sm and S can bemeasured with the SJ-301.•The detector can be retracted into thedrive unit when the SJ-301 is notperforming a measurement.room to build a highly expandable desktop evaluation system.Surftest SJ-301Specifications**Evaluation length can be specified arbitrary in the range from 0.3mm (.01”) to 12.5mm (.49”).Roughness specimenSurftest SJ-301MichiganPhone: (734) 459-2810IllinoisPhone: (630) 978-5385CaliforniaPhone: (626) 961-9661MassachusettsPhone: (978) 692-8765IndianaPhone: (317) 577-6070North CarolinaPhone: (704) 875-8332Coordinate Measuring Machines Small Tool Instruments and Data ManagementHardness Measuring Sensor Systems Optical Measuring Digital Scale and DRO Systems Surface-, Form- and Contour MeasurementVision Measuring Systems Note: All information regarding our products, and in particular the illustrations, drawings, dimensional and performance data contained in this pamphlet, as well as other technical data are to be regarded as approximate average values. We therefore reserve the right to make changes to the corresponding designs, dimensions and weights. The stated standards, similar technical regulations, descriptions and illustrations of the products were valid at the time of printing. In addition, the latest applicable version of our General Trading Conditions will apply. Only quotations submitted by ourselves may be regarded as definitive.Job No.11B-7。

时代集团公司北京时代之峰科技有限公司TimeSurf For TR200使用手册目录1 系统的安装与卸载 (3)1.1 安装 (3)1.2 卸载 (5)1.3 注册 (6)2 与TR200通信的功能 (6)2.1 联机 (7)2.2 断开联机 (7)2.3 启动测量 (7)2.4 载入数据 (8)2.5 拾取针位 (9)2.6 配置 (9)3 数据管理功能 (10)3.1 打开文件 (10)3.2 保存文件 (11)3.3 保存数据 (11)3.4 打开数据库 (12)4 参数计算功能 (13)5 数据分析的功能 (13)5.1 未滤波曲线 (13)5.2 粗糙度曲线 (14)5.3 粗糙度和未滤波曲线 (15)5.4 支撑率曲线 (15)6 辅助功能 (16)6.1 显示辅助线 (16)6.2 隐藏辅助线 (17)6.3 缩放功能 (17)6.4 全屏显示 (18)6.5 默认视图 (18)6.6 坐标轴变化 (18)6.7 状态栏显示 (19)6.8 快捷菜单 (19)7 打印功能 (19)7.1 打印预览 (19)7.2 预览放大 (20)7.3 预览缩小 (20)7.4 关闭预览 (20)7.5 打印 (20)8 帮助功能 (21)9 登陆时代集团网站 (21)1 系统的安装与卸载1.1 安装当TimeSurf For TR200在安装时,会依次出现下面的画面:点击“next”进入系统的安装接受"许可协议",点击“next”选择程序的安装目录,点击“next”点击Install,开始安装安装成功!1.2 卸载当用户需要卸载程序,可以从windows的"控制面板"——"添加/卸载程序"中卸载程序。

如图所示:windows的控制面板卸载TimeSurf For TR200 V1.1当软件安装完毕后,运行软件会出现如下所示的窗口:点击确定按钮显示如下窗口:如果用户没有购买此软件,其可以点击“试用”按钮,这样用户可以得到免费使用5次,使用5次后此软件将不能再使用,如果用户想继续使用请与本公司联系购买此软件,已经购买此软件的用户安装好此软件后请把上面窗口中的序列号以邮件的形式发到本公司的邮箱TimeSurfpw@,我们会把注册码发回给用户,用户将注册码填入上面窗口中后点“注册”按钮后,程序将会执行,并且这个注册窗口以后将不会再出现。

Elcometer 224 表面粗糙度仪

操作说明书

1. 按键开机。

2. 语言选择

a) 关上仪器

b) 按住左边第一个件不放。

c) 开机

d) 放开左键

e) 按↑或者↓找到需要的语言,然后按选择键(最右边)确认。

此时显示屏上出现的语言就是所需的语言

3. 调零。

在使用仪器之前,一定要在坚硬的表面调零。

可以用随机配的零板也可以用类似材料如窗

户玻璃

a) 按“零”键

b) 当显示屏上出现提示语言时候,把探头放在零板上。

显示屏会出现“0”,这时候就可以使用仪

器了

4. 开机进行测量

a) 取下探头盖子,把探头紧紧刚在被测表面(如果接触不好会影响读数),以便探头尖部伸入波

谷的底部。

b) 从显示屏上读数。

TR200手持式粗糙度仪(光洁仪)(图示)TR200手持式粗糙度仪适用于生产现场,可测量多种机加工零件的表面粗糙度,根据选定的测量条件计算机相应的参数,在液晶显示器上清晰地显示全部测量结果及图形,并可在打印机上输出,亦可与PC机进行通讯。

TR200手持式粗糙度仪仪器特点:高精度电感传感器可测量显示13个粗糙度参数采用DSP(数字信号处理器)进行数据处理和控制,速度快,功耗低机电一体化设计,体积小,重量轻,使用方便高品质锂离子充电电池,容量高,无记忆效应,连续工作大于20小时连接时代TA系列打印机,可以打印测量参数及轮廓标准RS232接口,可与PC机通讯可选配曲面传感器测量凹凸面,小孔传感器测量内孔粗糙度流行的菜单操作方式具有图形显示功能传感器触针位置指示带存储功能的自动关机多语言工作方式选择TR200手持式粗糙度仪主要技术参数:测量参数:RA、RZ、RY、RQ、RP、RM、RT、R3Z、RMAX、SK、S、SM、TP;测量范围:RA:0.025Μ~12.5Μ;显示范围:RZ、R3Z、RY、RT、RP、RMAX、:0.02Μ~160Μ;SM、S:1MMTP:1~100%(%RY)取样长度L:0.25MM, 0.8MM, 2.5MM评定长度LN:1L~5L(可选)测量行程长度:3L~7L(可选)示值误差:≤±10%示值变动性:< 6%传感器类型:电感传感器针尖角度:90°针尖半径:5Μ针尖材料:金刚石最高分辨力:0.001ΜM可测量最小孔径:2MM可测量曲面最小曲率半径:3MM滤波器:RC、PC-RC、GAUSS、D-P标准:符合ISO/DIN/JIS/ANSI轮廓曲线:滤波轮廓、不滤波轮廓和TP曲线显示:128×64点阵液晶(带背光),可显示全部参数及图形数据输出:标准RS232接口,可连接PC机和打印机打印轮廓放大比:VV:200X~20000X VH:20X、50X、200X电池容量:10000MAH(大于3000次测量)充电电压:220V,50HZ工作温度:5~40℃主机外形尺寸:141MM×56MM×48MM主机重量:440克TR200手持式粗糙度仪标准配置:TR200主机TS100标准传感器多刻线标准样板电源适配(220V,50HZ)护套支架通讯电缆改锥使用说明书合格证书包装箱TR200手持式粗糙度仪可选附件YJQOZ:TS110曲面传感器TS120小孔传感器TA610测量平台TA620测量平台TA630微调平台TA631微调平台TA220S打印机TA210打印机磁性表座连接轴PC软件(DATA VIEW FOR TR200)延长杆侧向转接杆连接体部件以上PDF产品资料由维库仪器仪表网()整合提供。

HuamingTR210表面粗糙度测量仪使用说明书有限公司华鸣仪器设备有限公司华鸣仪器设备目录概述 (1)1.1.概述1.1测量原理 (2)1.2标准配置 (2)1.3仪器各部分名称 (4)1.4基本连接方法 (7)1.4.1传感器装卸 (7)1.4.2充电器及电池充电 (8)测量操作 (8)2.测量操作2.2.1测量前的准备 (8)2.2开机 (9)2.3修改测量条件 (10)2.4系统设置 (14)2.5功能选择 (15)3可选附件及其使用 (20)3.1高度支架及传感器护套 (20)3.2测量平台 (21)3.3加长杆 (22)3.5传感器 (23)4.1传感器 (25)4.2驱动参数 (25)4.3示值误差 (25)4.4示值变动性 (25)4.5显示内容 (26)4.6轮廓和滤波器 (26)4.7取样长度 (26)4.8评定长度 (27)4.9粗糙度参数和显示范围 (27)4.10测量范围和分辨力 (27)4.11电源 (27)4.12温度/湿度范围 (28)4.13外形尺寸和重量 (28)4.14连接打印机 (28)日常维护与保养 (28)5.5.日常维护与保养5.1故障处理 (28)5.2故障信息 (29)电池开关 (30)6.6.电池开关参考资料 (31)7.7.参考资料7.1轮廓和滤波 (31)7.2驱动行程长度 (32)7.3TR210粗糙度参数定义 (33)取样长度选择推荐表 (35)8.8.取样长度选择推荐表概述1.1.概述TR210表面粗糙度测量仪是适合于生产现场环境和快速测量需要的一种小型手持式仪器,它操作简便,功能全面,测量快捷,精度稳定,携带方便,根据选定的测量条件计算相应的参数,在液晶显示器上清晰地显示出来,也可在打印机上输出。

本仪器给出的参数符合GB/T3505-2000《产品几何技术规范表面结构轮廓法表面结构的述语、定义及参数》本仪器全面严格执行了国际标准。

粗糙度仪使用说明书

简 介

粗糙度仪又称为便携式粗糙度仪、粗糙度表面测量仪、粗糙度仪价格、粗糙度仪厂家、表面粗糙度测量仪、表面粗糙度测试仪、粗糙度检测仪、机加工粗糙度测试仪、粗糙度测试仪厂家、粗糙度测试仪价格、袖珍表面粗糙度仪,数字式粗糙度仪,便携式粗糙度检测仪,表面粗糙度测定仪,数显粗糙度仪,手持式粗糙度检测仪,金属表面粗糙度测量仪,粗糙度测试仪,便捷式粗糙度仪,数字式表面粗糙度仪,数显粗糙度测试仪,便携式粗糙度测试仪,袖珍式表面粗糙度仪价格,袖珍式表面粗糙度仪,便携式粗糙度测量仪,便携式表面粗糙度仪,表面粗糙度检查仪,手持式粗糙度测量仪、手持式粗糙度仪、便携式粗糙度仪、精密粗糙度测试仪、袖珍式粗糙度测量仪、袖珍式粗糙度检测仪、表面粗糙度检验仪、手持粗糙度测量仪、表面粗糙度检查仪、手持粗糙度仪、手持式粗糙度测量仪、高精度粗糙度仪是适合于生产现场环境和移动测量需要的一种手持式仪器,可测量多种机加工零件的表面粗糙度,可根据选定的测量条件计算相应的参数,并在显示器上显示出全部测量参数和轮廓图形。

该仪器它操作简便,功能全面,测量快捷,精度稳定,携带方便,能测量最新国际标准的主要参数,本仪器全面严格执行了国际标准。

测量参数符合国际标准并兼容美国、德国、日本、英国等国家的标准。

适用于车间检定站、实验室、计量室等环境的检测。

一、概述

OU1300型表面粗糙度测量仪是适合于生产现场环境和移动测量需要的一种手持式仪器,可测量多种机加工零件的表面粗糙度,可根据选定的测量条件计算相应的参数,并在显示器上显示出全部测量参数和轮廓图形。

该仪器它操作简便,功能全面,测量快捷,精度稳定,携带方便,能测量最新国际标准的主要参数,本仪器全面严格执行了国际标准。

测量参数符合国际标准并兼容美国、德国、日本、英国等国家的标准。

适用于车间检定站、实验室、计量室等环境的检测。

1.1 主要特点

●机电一体化设计,体积小,重量轻,使用方便;

●采用 DSP 芯片进行控制和数据处理,速度快,功耗低;

●大量程,多参数 Ra,Rz,Rq,Rt。

●高端机器增加 Rp,Rv,R3z,R3y,RzJIS,Rsk,Rku,Rsm,Rmr 等参数;

●128×64 OLED 点阵显示器,数字/图形显示;高亮无视角;

●显示信息丰富、直观、可显示全部参数及图形;

●兼容 ISO、DIN、ANSI、JIS 多个国家标准;

●内置锂离子充电电池及充电控制电路,容量高、无记忆效应;

●有剩余电量指示图标,提示用户及时充电;

●可显示充电过程指示,操作者可随时了解充电程度

●连续工作时间大于 20 小时

●超大容量数据存储,可存储 100 组原始数据及波形。

●实时时钟设置及显示,方便数据记录及存储。

●具有自动休眠、自动关机等节电功能

●可靠防电机走死电路及软件设计

- 1 -

●显示测量信息、菜单提示信息、错误信息及开关机等各种提示说明信息;

●全金属壳体设计,坚固、小巧、便携、可靠性高。

●中/英文语言选择;

●可连接电脑和打印机;

●可打印全部参数或打印用户设定的任意参数。

●可选配曲面传感器、小孔传感器、测量平台、传感器护套、

接长杆等附件。

1.2 测量原理

本仪器在测量工件表面粗糙度时,先将传感器搭放在工件被测表面上,然后启动仪器进行测量,由仪器内部的精密驱动机构带动传感器沿被测表面做等速直线滑行,传感器通过内置的锐利触针感受被测表面的粗糙度,此时工件被测表面的粗糙度会引起触针产生位移,该位移使传感器电感线圈的电感量发生变化,从而在相敏检波器的输出端产生与被测表面粗糙度成比例的模拟信号,该信号经过放大及电平转换之后进入数据采集系统,DSP 芯片对采集的数据进行数字滤波和参数计算,测量结果在显示器上给出,也可在打印机上输出,还可以与PC 机进行通讯。

1.3 仪器各部分名称

传感器

- 2 -

! !

- 3 -

- 4 -

电源开关键,长按 2 秒开关机。

触针位置键,用于切换触针位置显示和主参数显示

启动测量键,用于启动仪器进入测量状态

参数选择键,用于查看各种参数和图形结果

记录保存键/打印键,用于存储测量结果或打印数据

上箭头键,用于切换选择项目,调整设定数值

下箭头键,用于切换选择项目,调整设定数值

菜单/确认键,用于进入菜单设置和确认参数。

取消/退出键,用于退出菜单和取消设置。

1.4

按键定义

1.5 电池充电

当电池电压过低时,即显示屏上的电池提示符 显示电压过低时,应尽快给仪器充电。

本仪器使用仪器侧面的USB 口进行充电,可以使用自带的电源适配器进行充电,也可以用计算机的USB 口进行充电,如使用其他的电源适配器进行充电时,其输出电压应为5V 直流电源,电流应大于800mA 。

充电时,仪器有充电动画显示,充满后动画结束,显示充满符号。

本仪器采用是锂离子电池,无记忆效应。

可以随时充电,充电时仪器可照常工作

最长充时间约2 .5 小时。

注:充电时,先将保证仪器侧面的电源开关是置于下方ON 的位置

安装时,用手拿住探头主体部分,按图所示将探头插入仪器底部的传感器连接套中,然后轻推到底。

拆卸时,用手拿住传感器的探头主体部分或保护套管的根部,慢慢地向外拉出。

1、传感器的触针是本仪器的关键零件,应给予高度重视。

2、在进行传感器装卸的过程中,应特别注意不要碰及触针,以免造成损坏,影响测量。

- 5 -

感谢以下网站对本资料的大力支持:

测厚仪 超声波测厚仪

钢板测厚仪 金属测厚仪

管道测厚仪 钢管测厚仪

厚度测量仪 超声测厚仪

高温测厚仪 壁厚测量仪

覆层测厚仪 膜厚仪

涂层测厚仪 镀层测厚仪

油漆测厚仪 漆膜测厚仪

锌层测厚仪 防腐层测厚仪

麦考特测厚仪 尼克斯测厚仪

磁感应测厚仪 涡流测厚仪

膜厚测试仪 覆层测厚仪

电镀层测厚仪 涂镀层测厚仪

镀锌层测厚仪 电解测厚仪

氧化膜测厚仪 磁性测厚仪

干膜测厚仪 湿膜测厚仪

镀铬测厚仪 超声波探伤仪

超声波探伤仪 超声探伤仪

数字超声波探伤仪

焊缝探伤仪 超声波探伤仪

金属探伤仪 便携式探伤仪

钢结构探伤仪 磁粉探伤仪

邵氏硬度计 橡胶硬度计

便携式硬度计 便携式硬度计

尼克斯测厚仪 里氏硬度计

轧辊硬度计 巴氏硬度计

韦氏硬度计 w-20韦氏硬度计

模具硬度计 超声波硬度计

洛氏硬度计 金属硬度计

硬度测试仪 布氏硬度计

肖氏硬度计 铸件硬度计

轧辊硬度计 硬度仪

钢板硬度计 铝合金硬度计

电火花检测仪 电火花检漏仪

电火花检测仪 漆膜划格器

表面粗糙度仪 粗糙度测量仪

粗糙度测试仪 喷砂粗糙度仪

光洁度仪 便携式粗糙度仪

粗糙度仪 附着力测试仪

百格刀测试 百格刀

LED观片灯 黑白密度计

光泽度仪 特价机票

无损检测资源网 无损检测仪器

无损123 网站目录

标线测厚仪 硬度计

超声波测厚仪 涂层测厚仪

硬度计http://www.yingduji.top 无损检测http://www.wusunjiance.top

探伤仪http://www.tanshangyi.top 硬度计

测厚仪http://www.cehouyi.top 布氏硬度计

洛氏硬度计 便携硬度计

钢管硬度计 磷化膜测厚仪

934-1巴氏硬度计 钢轨探伤仪

lx-a邵氏硬度计 邵氏橡胶硬度计 涂层测厚仪 防腐层检测仪。