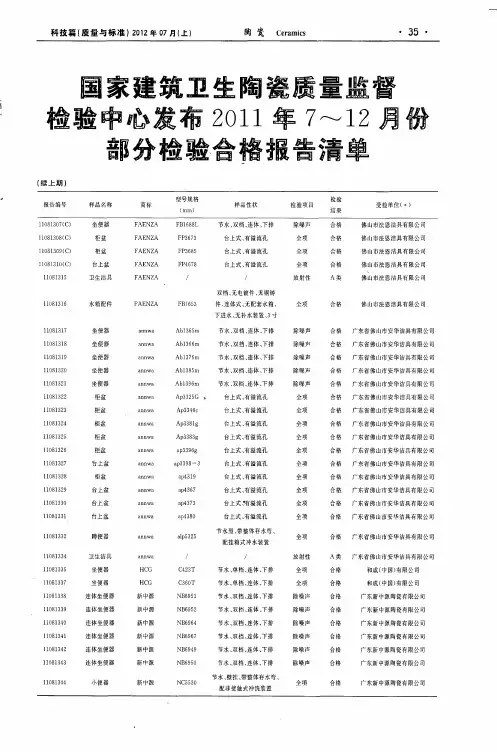

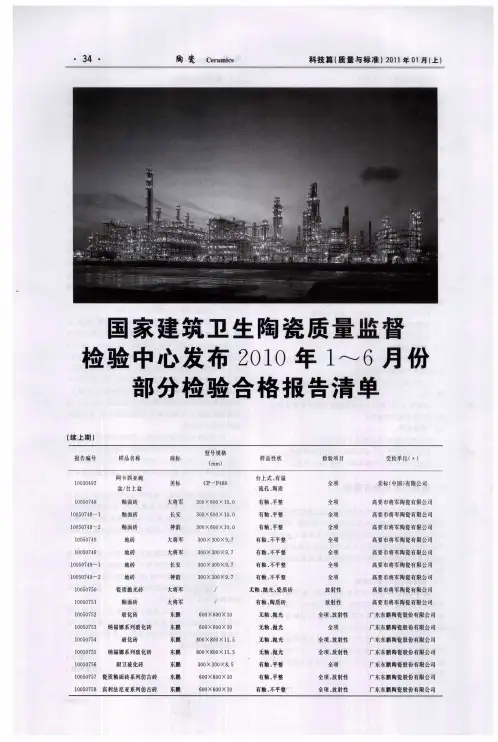

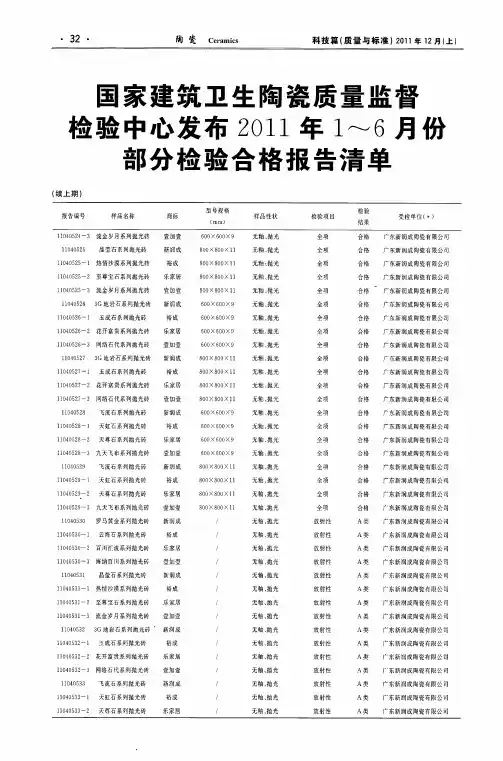

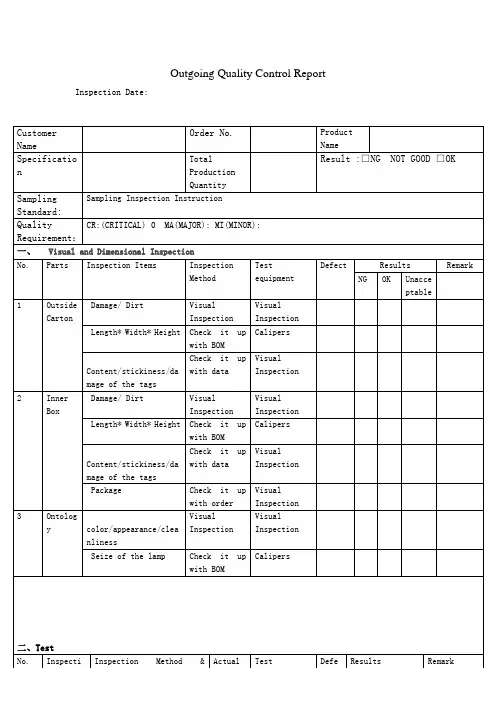

陶瓷检验报告英文版

- 格式:doc

- 大小:60.00 KB

- 文档页数:2

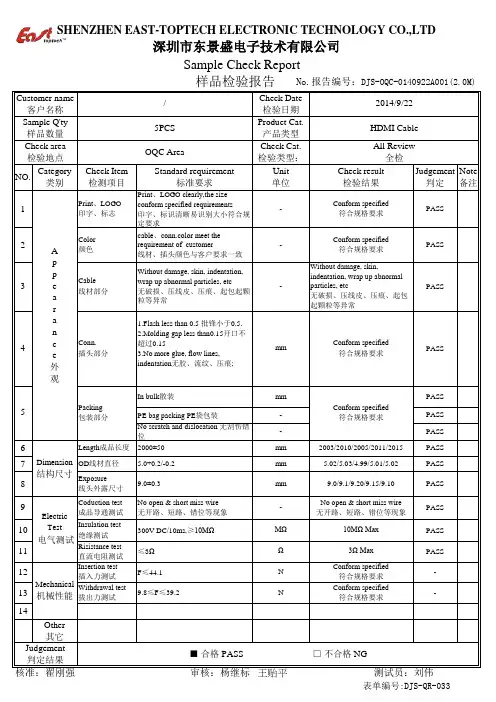

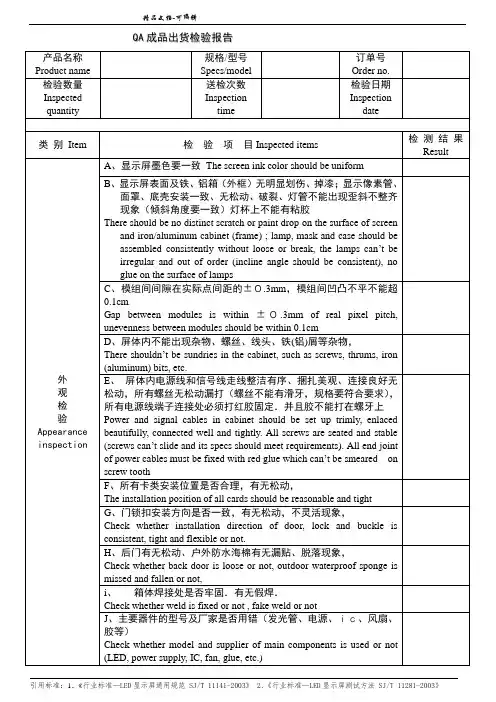

NO.Category 类别Standard requirement标准要求Judgement 判定Note 备注1Print 、LOGO clearly,the size conform specified requirements 印字、标识清晰易识别大小符合规定要求PASS2cable 、conn.color meet the requirement of customer线材、插头颜色与客户要求一致PASS3Without damage, skin, indentation,wrap up abnormal particles, etc 无破损、压线皮、压痕、起包起颗粒等异常PASS41.Flash less than 0.5 批锋小于0.5.2.Molding gap less than0.15开口不超过0.153.No more glue, flow lines,indentation 无胶、流纹、压痕;PASSIn bulk 散装PASS PE bag packing PE 袋包装PASS No scratch and dislocation 无刮伤错位PASS 62000±50PASS 7 5.0+0.2/-0.2PASS 89.0±0.3PASS 9No open & short miss wire无开路、短路、错位等现象PASS 10300V DC/10ms,≥10MΩPASS 11≤3ΩPASS 12F ≤44.1-139.8≤F ≤39.2-14Other 其它 Sample Check Reportmm Coduction test 成品导通测试A p p e a r a n c e 外观Dimension 结构尺寸Judgement 判定结果■ 合格 PASS □ 不合格 NGSHENZHEN EAST-TOPTECH ELECTRONIC TECHNOLOGY CO.,LTD深圳市东景盛电子技术有限公司Conform specified 符合规格要求Mechanical 机械性能-3Ω Max 5.02/5.03/4.99/5.01/5.02Conform specified 符合规格要求9.0/9.1/9.20/9.15/9.10No open & short miss wire 无开路、短路、错位等现象2003/2010/2005/2011/2015-Electric Tes t电气测试-Insulation test 绝缘测试MΩOD 线材直径Conform specified 符合规格要求Color 颜色Cable 线材部分-10MΩ Max Conform specified 符合规格要求Conform specified 符合规格要求Without damage, skin,indentation, wrap up abnormal particles, etc无破损、压线皮、压痕、起包起颗粒等异常mm Check result 检验结果Check Date 检验日期2014-9-22Check Cat.检验类型:All Review 全检-Product Cat.产品类型HDMI CableCheck area 检验地点Unit 单位-Length 成品长度mm mmExposure线头外露尺寸mm OQC AreaCustomer name 客户名称Check Item 检测项目5Conn.插头部分Print 、LOGO 印字、标志Sample Q'ty 样品数量/5PCS Packing 包装部分Conform specified 符合规格要求Risistance test 直流电阻测试Withdrawal test 拔出力测试ΩInsertion test 插入力测试N NNo.报告编号:DJS-OQC-0140922A001(2.0M)表单编号:DJS-QR-033。

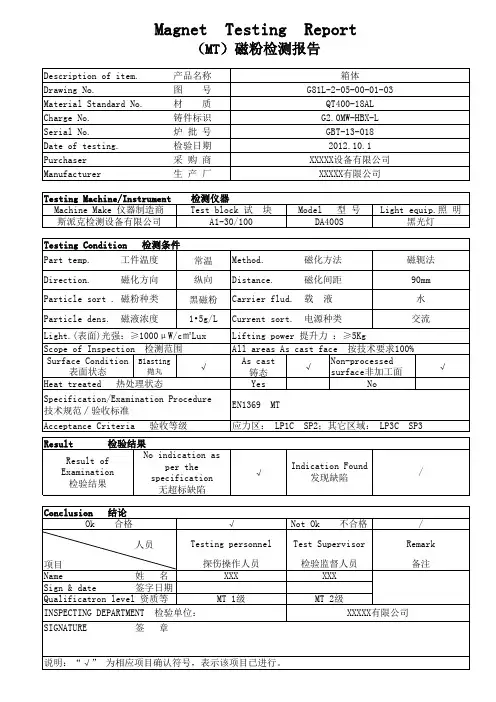

Tested by (name+signature) ............ : ...................................................... Witnessed by (name+signature) ...... : ...................................................... Supervised by (name+signature)...... : ...................................................... Approved by (name+signature) ........: ...................................................... Date of issue..................................... :.......... :Address ............................................ :Testing location/ procedure ..............: CBTL RMT SMT WMT TMPTesting location/ address.................. :............................ :Address ............................................ :Standard ........................................... : IEC 60598-2-1:1979+A1:1987 used in conjunction withIEC 60598-1:2003EN 60598-2-1:1979+A1:1987 used in conjunction withEN 60598-1:2004Test procedure ................................. : CB / CCANon-standard test method………….. :N/ATRF Originator .................................. : Intertek Semko ABMaster TRF....................................... : Dated 2004-09This publication may be reproduced in whole or in part for non-commercial purposes as long as the IECEE is acknowledged as copyright owner and source of the material. IECEE takes no responsibility for and will not assume liability for damages resulting from the reader's interpretation of the reproduced material due to its placement and context.Trade Mark ....................................... :Manufacturer .................................... :Model/Type reference....................... :Address ........................................... :Ratings ............................................. :................................................ .- test case does not apply to the test objec.t.................: N/A- test object does meet the requirement .....................:.. P(Pass)- test object does not meet the requiremen ................: F(Fail)....................................................................... ..Date of receipt of test item ......................................... ..Date (s) of performance of tests .................................:..The test results presented in this report relate only to the object tested.This report shall not be reproduced, except in full, without the written approval of the Issuing testing laboratory. "(see Enclosure #)" refers to additional information appended to the report."(see appended table)" refers to a table appended to the report.List of test equipment must be kept on file and available for review.Throughout this report a comma (point) is used as the decimal separator.In this report requirements valid for EN only are marked with (EN).1.2 (0.1)1.2 (0.3)1.4 (2.2) 1.4 (2.3) 1.4 (2.4)Yes / No Yes / No Luminaire for rough service .......................:1.5 (3.2) Mandatory markingsPosition of the marking Format of symbols/text1.5 (3.3) Additional informationLanguage of instructions 1.5 (3.3.1) Combination luminaires 1.5 (3.3.2) Nominal frequency in Hz 1.5 (3.3.3) Operating temperature 1.5 (3.3.4) Symbol or warning notice 1.5 (3.3.5) Wiring diagram 1.5 (3.3.6) Special conditions1.5 (3.3.7) Metal halide lamp luminaire – warning 1.5 (3.3.8) Limitation for semi-luminaires 1.5 (3.3.9) Power factor and supply current 1.5 Suitability for use indoors (3.3.10)1.5 Luminaires with remote control (3.3.11)1.5 Clip-mounted luminaire – warning (3.3.12)1.5 Specifications of protective shields (3.3.13)1.5 Symbol for nature of supply (3.3.14)1.5 Rated current of socket outlet (3.3.15)1.5 Rough service luminaire (3.3.16)Type of protection .......................................: Degree of protection ...................................: Luminaire only suitable for non-combustible surfaces .....................................................:Luminaire suitable for normally flammable surfaces ....................................................................: Luminaire suitable to be covered by insulating material .......................................................:Luminaire for normal use ........................... : More sections applicable .................................... :Information for luminaire design considered Standard Yes / No Yes / NoClass IP Yes / NoYes / No Yes / No1.4 (2.5)—————————最新精品文档,知识共享!1.5 Mounting instruction for type Y, type Z and some (3.3.17) type X attachments1.5 Non-ordinary luminaires with PVC cable(3.3.18)1.5 Adequate warning on the package (EN)(3.3.101)1.5 (3.4) Test with waterTest with hexaneLegible after testLabel attached1.6 (4.2) Components replaceable without difficulty1.6 (4.3) Wire ways smooth and free from sharp edges 1.6 (4.4) Lampholders1.6 (4.4.1) Integral lampholder1.6 (4.4.2) Wiring connection1.6 (4.4.3) Lampholder for end-to-end mounting1.6 (4.4.4) Positioning- pressure test (N) .................................. :- bending test (Nm) ................................. :1.6 (4.4.5) Peak pulse voltage1.6 (4.4.6) Centre contact1.6 (4.4.7) Parts in rough service luminaires resistance totracking1.6 (4.4.8) Lamp connectors1.6 (4.4.9) Caps and bases correctly used1.6 (4.5) Starter holdersStarter holder in luminaires other than class IIStarter holder class II construction1.6 (4.6) Terminal blocksTailsUnsecured blocks1.6 (4.7) Terminals and supply connections1.6 (4.7.1) Contact to metal parts1.6 (4.7.2) Test 8 mm live conductorTest 8 mm earth conductor1.6 (4.7.3) Terminals for supply conductors1.6 Welded connections:(4.7.3.1)- stranded or solid conductor- spot welding- welding between wires- Type Z attachment- mechanical test according to 15.8.2- electrical test according to 15.9- ageing test according to 15.9.2.3 and 15.9.2.4 1.6 (4.7.4) Terminals other than supply connection1.6 (4.7.5) Heat-resistant wiring/sleeves1.6 (4.7.6) Multi-pole plug- test at 30 N1.6 (4.8) Switches:- adequate rating- adequate fixing- polarized supply- compliance with 61058-1 for electronic switches 1.6 (4.9) Insulating lining and sleeves1.6 (4.9.1) RetainmentMethod of fixing........................................... :1.6 (4.9.2) Insulated linings and sleevesa) & c) Insulation resistance and electric strengthb) Ageing test. Temperature (°C) ............... :1.6 (4.10) Insulation of Class II luminaires1.6 No contact, mounting surface - accessible metal (4.10.1) parts - wiring of basic insulationSafe installation fixed luminairesCapacitors and switchesInterference suppression capacitors according toIEC 60384-141.6 Assembly gaps:(4.10.2)- not coincidental- no straight access with test probe1.6 Retainment of insulation:(4.10.3)- fixed- unable to be replaced; luminaire inoperative- sleeves retained in position- lining in lampholder1.6 (4.11) Electrical connections1.6 Contact pressure(4.11.1)1.6 Screws:(4.11.2)- self-tapping screws- thread-cutting screws- at least two self-tapping screws1.6 Screw locking:(4.11.3)- spring washer- rivets1.6 Material of current-carrying parts(4.11.4)1.6 No contact to wood(4.11.5)1.6 Electro-mechanical contact systems(4.11.6)1.6 (4.12) Mechanical connections and glands1.6 Screws not made of soft metal(4.12.1)Screws of insulating materialTorque test: torque (Nm); part ....................:Torque test: torque (Nm); part ....................:Torque test: torque (Nm); part ....................:1.6 Screws with diameter < 3 mm screwed into metal (4.12.2)1.6 Locked connections:(4.12.4)- fixed arms; torque (Nm) ............................ :- lampholder; torque (Nm) ........................... :- push-button switches; torque 0,8 Nm ....... :1.6 Screwed glands; force (N) ..........................:(4.12.5)1.6 (4.13) Mechanical strength1.6 Impact tests:(4.13.1)- fragile parts; energy (Nm) ......................... :- other parts; energy (Nm)........................... :1) live parts2) linings3) protection4) covers1.6 Straight test finger(4.13.3)1.6 Rough service luminaires(4.13.4)- IP54 or highera) fixedb) hand-heldc) delivered with a standd) for temporary installations and suitable formounting on a stand1.6 Tumbling barrel(4.13.6)1.6 (4.14) Suspensions and adjusting devices1.6 Mechanical load:(4.14.1)A) four times the weightB) torque 2,5 NmC) bracket arm; bending moment (Nm) ...... :D) load track-mounted luminairesE) clip-mounted luminaires, glass-shelve.Thickness (mm) ......................................... :metal rod. Diameter (mm) .......................... :Fixed luminaire or independent control gear withoutfixing devices1.6(4.14.2)1.6(4.14.3)1.6(4.14.4) 1.6(4.14.5) 1.6(4.14.6) 1.6 (4.15)1.6(4.15.2) 1.6 (4.16)1.6(4.16.1)1.6(4.16.2)1.6(4.16.3) 1.6 (4.17) Load to flexible cablesMass (kg) ....................................................:Stress in conductors (N/mm²) ..................... :Semi-luminaires – mass (kg) ..................... :Semi-luminaires – bending moment (Nm) .. :Adjusting devices:- flexing test; number of cycles ...................:- strands broken- electric strength test afterwardsTelescopic tubes: cords not fixed to tube; no strainon conductorsGuide pulleysStrain on socket-outletsFlammable materials:- glow-wire test 650 o C- spacing > 30 mm- screen withstanding test of 13.3.1- screen dimensions- no fiercely burning material- thermal protection- electronic circuits exemptedLuminaires made of thermoplastic material with lamp control geara) constructionb) temperature sensing controlc) surface temperatureLuminaires marked with F-symbolNo lamp control gearLamp control gear spacing:- spacing 35 mm- spacing 10 mmThermal protection:- in lamp control gear- external- fixed position- temperature marked lamp control gear"F" curve measuredDrain holesClearance at least 5 mm(compliance with Section 12)(see 12.6)最新精品文档,知识共享!1.6 (4.18) Resistance to corrosion:1.6 - rust-resistance(4.18.1)1.6 - season cracking in copper(4.18.2)1.6 - corrosion of aluminium(4.18.3)1.6 (4.19) Ignitors compatible with ballast1.6 (4.20) Rough service vibration1.6 (4.21) Protective shield:1.6 Shield fitted(4.21.1)1.6 Particles from a shattering lamp not impair safety (4.21.2)1.6 No direct path(4.21.3)1.6 Impact test on shield(4.21.4)Glow-wire test on lamp compartment1.6 (4.22) Attachments to lamps1.6 (4.23) Semi-luminaires comply class II1.6 (4.24) UV radiation, metal halide lamps1.6 (4.25) No sharp point or edges1.6 (4.26) Short-circuit protection:1.6 Uninsulated accessible SELV parts(4.26.1)1.6 Short-circuit test(4.26.2)1.6 Test chain according to Figure 29(4.26.3)最新精品文档,知识共享!Working voltage (V) ....................................:Voltage formPTIRated pulse voltage (kV) ............................ :1) Current-carrying parts of different polarity: cr (mm); cl (mm) ............................................. :2) Current-carrying parts and accessible parts: cr (mm); cl (mm) ............................................. :3) Parts becoming live due to breakdown ofbasic insulation and metal parts:cr (mm); cl (mm) ......................................... :4) Outer surface of cable where it is clamped and metal parts: cr (mm); cl (mm) ..................... :5) Not used6) Current-carrying parts and supporting surface: cr (mm); cl (mm) ............................................. :Sinusoidal [ ]Non-sinusoidal [ ]< 600 [ ] > 600 [ ]—————(see Annex 1) (see Annex 3)(see Annex 1) (see Annex 4)最新精品文档,知识共享!1.8 (7.2.1 + 7.2.3)Accessible metal partsMetal parts in contact with supporting surfaceResistance < 0,5Two self-tapping screws used Thread-forming screwsThread-forming screw used in a groove Connector earthing first1.8 (7.2.2 + 7.2.3)Earth continuity in joints etc.1.8 (7.2.4) Locking of clamping meansCompliance with 4.7.31.8 (7.2.5) Earth terminal integral part of connector socket 1.8 (7.2.6) Earth terminal adjacent to mains terminals 1.8 (7.2.7) Electrolytic corrosion of the earth terminal 1.8 (7.2.8) Material of earth terminalContact surface bare metal 1.8Class II luminaire for looping-in(7.2.10)Double or reinforced insulation to functional earth 1.8Earthing core coloured green-yellow(7.2.11)Length of earth conductorSeparately approved; component listPart of the luminaireSeparately approved; component listPart of the luminaire1.10 (5.2) Supply connection and external wiring1.10 Means of connection ................................... :(5.2.1)Connecting leads (EN)- without a means for connection to the supply- terminal block specified- relevant information provided- compliance with 4.6, 4.7.1, 4.7.2, 4.10.1, 11.2, 12and 13.2 of Part 11.10 Type of cable ..............................................:(5.2.2)Nominal cross-sectional area (mm²) ........... :1.10 Type of attachment, X, Y or Z(5.2.3)1.10 Type Z not connected to screws(5.2.5)1.10 Cable entries:(5.2.6)- suitable for introduction- adequate degree of protection1.10 Cable entries through rigid material have rounded (5.2.7) edges1.10 Insulating bushings:(5.2.8)- suitably fixed- material in bushings- material likely to deteriorate- tubes or guards made of insulating material1.10 Locking of screwed bushings(5.2.9)1.10 Cord anchorage:(5.2.10)- covering protected from abrasion- clear how to be effective- no mechanical or thermal stress- no tying of cables into knots etc.- insulating material or lining1.10 Cord anchorage for type X attachment:(5.2.10.1)a) at least one part fixedb) types of cablec) no damaging of the cabled) whole cable can be mountede) no touching of clamping screwsf) metal screw not directly on cableg) replacement without special toolGlands not used as anchorageLabyrinth type anchorages1.10 Adequate cord anchorage for type Y and type Z(5.2.10.2)attachment1.10 Tests:(5.2.10.3)- impossible to push cable; unsafe- pull test: 25 times; pull (N) ........................:- torque test: torque (Nm) ........................... :- displacement 2 mm- no movement of conductors- no damage of cable or cord1.10 External wiring passing into luminaire(5.2.11)1.10 Looping-in terminals(5.2.12)1.10 Wire ends not tinned(5.2.13)Wire ends tinned: no cold flow1.10 Mains plug same protection(5.2.14)Class III luminaire plug1.10 Appliance inlets (IEC 60320)(5.2.16)Appliance couplers of class II type1.10 No standardized interconnecting cables properly(5.2.17) assembled1.10 Used plug in accordance with(5.2.18) - IEC 60083- other standard1.10 (5.3) Internal wiring1.10 Internal wiring of suitable size and type(5.3.1)Through wiring- not delivered/ mounting instruction- factory assembled- socket outlet loaded (A) ............................ :(see Annex 2) - temperatures ............................................ :Green-yellow for earth only1.10 Internal wiring connected directly to fixed wiring(5.3.1.1)Cross-sectional area (mm²) ........................ :Insulation thicknessExtra insulation added where necessary1.10 Internal wiring connected to fixed wiring via internal current-limiting device (5.3.1.2)Adequate cross-sectional area and insulationthickness1.10 Double or reinforced insulation for class II(5.3.1.3)1.10 Conductors without insulation(5.3.1.4)1.10 SELV current-carrying parts(5.3.1.5)1.10 Insulation thickness other than PVC or rubber(5.3.1.6)1.10 Sharp edges etc.(5.3.2)No moving parts of switches etc.Joints, raising/lowering devicesTelescopic tubes etc.No twisting over 3601.10 Insulating bushings:(5.3.3)- suitable fixed- material in bushings- material likely to deteriorate- cables with protective sheath1.10 Joints and junctions effectively insulated(5.3.4)1.10 Strain on internal wiring(5.3.5)1.10 Wire carriers(5.3.6)1.10 Wire ends not tinned(5.3.7)Wire ends tinned: no cold flow最新精品文档,知识共享!1.11 Live parts not accessible(8.2.1)Basic insulated parts not used on the outer surfacewithout appropriate protectionProtection in any positionDouble-ended tungsten filament lampInsulation lacquer not reliableDouble-ended high pressure discharge lampRelevant warning according to 3.2.18 fitted to theluminaire1.11 Portable luminaire adjusted in most unfavourable (8.2.2) position1.11 Class II luminaire:(8.2.3)- basic insulated metal parts not accessible duringstarter or lamp replacement- basic insulation not accessible other than duringstarter or lamp replacement- glass protective shields not used assupplementary insulationClass I luminaire with BC lampholder1.11 Portable luminaire:(8.2.4)- protection independent of supporting surface- terminal block completely covered1.11 Compliance with the standard test finger or relevant (8.2.5) probe1.11 Covers reliably secured(8.2.6)1.11 Discharging of capacitors 0,5 F(8.2.7)Portable plug connected luminaire with capacitorOther plug connected luminaire with capacitorDischarge device on or within capacitorDischarge device mounted separately最新精品文档,知识共享!1.12 (12.3) Endurance test:- mounting-position .....................................:- test temperature (o C) ................................ :- total duration (h)........................................ :- supply voltage: Un factor; calculated voltage (V)....................................................................:- lamp used .................................................:1.12 After endurance test:(12.3.2)- no part unserviceable- luminaire not unsafe- no damage to track system- marking legible- no cracks, deformation etc.1.12 (12.4) Thermal test (normal operation) (see Annex 2) 1.12 (12.5) Thermal test (abnormal operation) (see Annex 2) 1.12 (12.6) Thermal test (failed lamp control gear condition):1.12 Through wiring or looping-in wiring loaded by a(12.6.1) current of (A) ................................ :- case of abnormal conditions ..................... :- electronic lamp control gear- measured winding temperature (o C) at 1,1 Un :- measured mounting surface temperature ( o C) at1,1 Un .........................................................:- calculated mounting surface temperature (o C) :- track-mounted luminaires1.12 Temperature sensing control(12.6.2)- case of abnormal conditions ..................... :- thermal link- manual reset cut-out- auto reset cut-out- measured mounting surface temperature ( o C)....................................................................:- track-mounted luminaires1.12 (12.7) Thermal test (failed lamp control gear in plastic luminaires):1.12 Through wiring or lopping-in wiring loaded by a(12.7.1) current of (A) .................................. :- case of abnormal conditions ..................... :- measured winding temperature (o C) at 1,1 Un :- measured temperature of fixing point/ exposedpart (o C) at 1,1 Un ....................................... :- calculated temperature of fixing point/ exposedpart (o C) ......................................................: ————————————最新精品文档,知识共享!Temperature sensing control1.12(12.7.2)- thermal link- manual reset cut-out- auto reset cut-out- measured temperature of fixing point/ exposedpart ( C) .....................................................:最新精品文档,知识共享!1.13 (9.2) Tests for ingress of dust, solid objects and moisture:- classification according to IP ....................: IP- mounting position during test .................... :- fixing screws tightened; torque (Nm) ........ :- tests according to clauses ........................:- electric strength test afterwardsa) no deposit in dust-proof luminaireb) no talcum in dust-tight luminairec) no trace of water on current-carrying parts orwhere it could become a hazardd) i) For luminaires without drain holes – no waterentryd) ii) For luminaires with drain holes – nohazardous water entrye) no water in watertight luminairef) no contact with live parts (IP 2X)f) no entry into enclosure (IP 3X and IP 4X)f) no contact with live parts (IP3X and IP4X)1.13 (9.3) Humidity test 48 h ————最新精品文档,知识共享!1.14 Insulation resistance test(10.2.1)Cable or cord covered by metal foil or replaced by ametal rodInsulation resistance (M ):SELV:- between current-carrying parts of different polarity....................................................................:- between current-carrying parts and mountingsurface ........................................................:- between current-carrying parts and metal parts ofthe luminaire ...............................................:Other than SELV:- between live parts of different polarity ......:- between live parts and mounting surface . :- between live parts and metal parts ........... :- between live parts of different polarity throughaction of a switch ........................................:1.14 Electric strength test(10.2.2)Dummy lampLuminaires with ignitors after 24 h testLuminaires with manual ignitorsTest voltage (V):SELV:- between current-carrying parts of different polarity....................................................................:- between current-carrying parts and mountingsurface ........................................................:- between current-carrying parts and metal parts ofthe luminaire ...............................................:Other than SELV:- between live parts of different polarity ......:- between live parts and mounting surface . :- between live parts and metal parts ........... :- between live parts of different polarity throughaction of a switch ........................................:1.14 Leakage current (mA) ................................. :(10.3.1)最新精品文档,知识共享!1.15 Ball-pressure test:(13.2.1)- part tested; temperature (o C) .................... :- part tested; temperature (o C) .................... : 1.15 Needle flame test (10 s):(13.3.1)- part tested ................................................. :- part tested ................................................. : 1.15 Glow wire test (650 o C):(13.3.2)- part tested ................................................. :- part tested ................................................. : 1.15 Tracking test: part tested ............................: (13.4.1)(2.2)(3.3)(4.5.1)(4.5.1)(5.2.1)(13.3) (13.3) (13.3.2) Class 0 not acceptedDK: power supply cord with labelIT: warning label on Class 0 luminaireDK: socket-outletsFR: socket-outletsDK, FI, SE, GB: type of plugDK: Needle flame test during 30 s for luminaires in access routesGB: Requirements according to United Kingdom Building RegulationFR: Glow-wire test 850o C alt. 750o C for luminaires in premises open to publictype/model technical data standardThe codes above have the following meaning:A - The component is replaceable with another one, also certified, with equivalent characteristicsB - The component is replaceable if authorised by the test houseC - Integrated component tested together with the applianceD - Alternative componentcode manufacturer/trademarkmark(s) ofconformityobject/part No.Type reference ............................................ :Lamp used ..................................................:Lamp control gear used .............................. :Mounting position of luminaire ....................:Supply wattage (W)..................................... :Supply current (A) ....................................... :Calculated power factor ..............................:Table: measured temperatures corrected for ta = 25 。

进口瓷砖验收报告范文大全英文回答:Imported Ceramic Tile Acceptance Report.Introduction:This report aims to provide a comprehensive evaluation of the imported ceramic tiles. The acceptance process includes visual inspection, measurement, and performance testing. Both English and Chinese languages will be used to address the findings.Visual Inspection:During the visual inspection, we carefully examined the appearance of the ceramic tiles. We checked for any cracks, chips, or other visible defects. We also assessed the overall color and pattern consistency. The visual inspection revealed that the imported ceramic tiles have ahigh level of craftsmanship and excellent visual appeal.视觉检查:在视觉检查过程中,我们仔细检查了进口瓷砖的外观。

我们检查了是否有任何裂纹、缺口或其他可见缺陷。

我们还评估了整体颜色和图案的一致性。

视觉检查显示,进口瓷砖具有高水平的工艺和出色的视觉效果。

Measurement:Accurate measurements are crucial to ensure the tiles fit properly during installation. We measured the dimensions of the tiles, including length, width, and thickness. The measurements were consistent and within the specified tolerances. This indicates that the imported ceramic tiles meet the dimensional requirements.尺寸测量:准确的尺寸测量对确保瓷砖在安装过程中适合非常重要。

瓷器花纹研究报告作文英语Title: Research Report on Porcelain PatternsIntroduction:Porcelain, with its delicate craftsmanship and intricate patterns, has been highly cherished and valued as an art form for centuries. This research report aims to explore the history and significance of porcelain patterns, highlighting their importance in Chinese culture and their impact on global artistic trends.Historical Development:The production of porcelain dates back to the Eastern Han Dynasty (25-220 BC) in China. Initially, porcelain makers focused on creating functional pieces with simple designs. However, during the Tang Dynasty (618-907 AD), more attention was given to the aesthetic aspects of porcelain, leading to the development of various patterns, including floral, geometric, and landscape designs. Significance in Chinese Culture:Porcelain patterns hold great cultural significance in Chinese society. They often symbolize good fortune, wealth, and luck. For instance, the peony pattern represents prosperity, while the lotus symbolizes purity. These patterns are commonly used in traditional Chinese wedding ceremonies and festivals, adding an auspicious element to the occasion.Global Influence:Over time, Chinese porcelain patterns began to captivate artists and collectors from around the world. During the Ming Dynasty (1368-1644 AD), porcelain production reached its pinnacle, andEuropean traders eagerly imported these exquisite pieces. The blue and white porcelain patterns, featuring motifs such as dragons and phoenixes, became particularly popular in Europe, inspiring artists such as Vincent van Gogh and Pablo Picasso.Evolution of Techniques:The techniques used to create porcelain patterns have greatly evolved over time. During the Yuan Dynasty (1279-1368 AD), the underglaze copper-red technique was developed. This technique involves painting motifs onto the porcelain before applying a transparent glaze, and then firing it at high temperatures. This technique was later replaced by the blue and white porcelain using cobalt-blue pigments during the Ming Dynasty.Revitalization of Traditional Patterns:In recent years, there has been a renewed interest in traditional porcelain patterns in China. Craftsmen and artists are working diligently to preserve and revitalize these patterns through modern interpretations. By combining traditional designs with contemporary elements, they aim to appeal to younger generations and rejuvenate the art form.Conclusion:Throughout history, porcelain patterns have played a vital role in Chinese culture and have left a lasting impact on the global artistic scene. Appreciating the intricate beauty of these patterns allows us to better understand the rich heritage and creativity of Chinese craftsmanship. As we continue to cherish and study porcelain patterns, we ensure the preservation and development of this valuable art form for generations to come.。

陶瓷验货不良缺陷中英文对照黑点:black spot裂缝(碰破,碰裂,碰伤):flaw, cracking漏白:vacant spot漏银粉(杯口):leskage of silver line at the cup edge针孔:pinhole落渣:impurity色差:different colors刮破,划伤:scratch色脏:stain on surface打磨陋底:rough bottom釉泡:tiny air bubble in glaze, glaze bubble爆花(断花):decal broken缺釉:vacant spot in glaze破碎:broken釉面不平:rough glaze杯口不平:rough in cup mouth,not smooth in cup mouth裂釉:glaze cracking挂釉:superfluous glaze, excess glaze黑底:black in bottom rim底印歪斜:deformitied backstamp底印断开:backstamp broken花纸歪斜:decal is not upright盖子不严:lids not matching well歪把:handle is not upright毛刺:rough surface模线明显:mould line on xxx is too obvious粘接不良:sticking not good enough胶水印:trails of gluewater变形:distortion污渍:besmirched缩釉:crawling粘釉:glaze sticking托底:center curvature薄釉:thin glaze裂把:handle cracking磕碰:chip, knocking窑灰:kiln dust无(漏)填色: no color in画功马虎: hand paint not good花纸氧化: decal oxidation底印烤焦:backstamp overburned断线(手绘不完全): hand paint incomplete 上色不均: color uneven制品缺陷名词术语2。

陶瓷生产流程英文版外贸陶瓷必看!!以下以贴花和手绘,分别介绍釉上彩和釉下彩的工艺流程:第一种;Decaled Dinnerwareling 练泥Various raw materials including feldspar, silica, clay and pottery stone are mixed and fine-milled in the ball mill.2.Filter press & Vacuum extrusion 摞泥The clay body is made by filter-pressing the slip. The pressed body de-aired and extruded to the required size through the pug mill.3.Green Making 制坯Using appropriated roller head and plaster mould, green body is formed. For the irregular shapes such as teapots and figurines, slip casting is used. In casting, liquid clay (slip) is poured into plaster moulds and the green shape forms on the mould as the water is absorbed through the plaster mould.4.Finishing 修坯The rough edges and foot of the green ware are cleaned with wet sponge by automatic edge-cleaning machine or by skilled hand5.Glazing 上釉To seal the surface of the biscuit body and to give the product its glossy finish, glaze is applied using automatic glaze spraying line.6.Glost firing 烧釉Carefully loading the glazed ware onto a kiln car, the glazed ware is fired at 1280∑C. At the temperature, the glaze powder melts and turns into a transparent glass layer covering the biscuit body. The glost-fired ware is inspected and ready for the decoration.7.Lithography 贴花The printed decal is transferred onto the glost ware and dried.8.Decoration firing 二次烧结The decal and the ware are fired at appropriated temperatures and the printed patterns permanently fuse onto the glaze layer to give permanent durable decoration.9.Inspeciton & Packaging 修整成箱Experienced eyes in the inspection area checks for possible faults in the ware and the finished ware is packaged as necessary。

[Your Position][Your Company][Company Address][City, State, Zip Code][Email Address][Phone Number][Date][Recipient's Name][Recipient's Position][Recipient's Company][Company Address][City, State, Zip Code]Dear [Recipient's Name],I am writing to you today with the utmost enthusiasm to recommend [Person's Name], a talented ceramic artist, for any opportunity that may arise in your esteemed organization. Having known [Person's Name] for the past [Number] years, both professionally and personally, I can confidently attest to their exceptional skills, unwavering dedication, and artistic vision in the field of ceramics.[Person's Name] has been a student of mine at [Your Institution] since [Year], where they have consistently demonstrated a passion for ceramics and a remarkable ability to grasp complex artistic concepts. Under my guidance, [Person's Name] has honed their skills in various ceramic techniques, including hand-building, wheel-throwing, glazing, and kiln-firing. Their dedication to perfecting their craft is evident in the meticulous attention to detail and the originality of their designs.One of the qualities that set [Person's Name] apart from their peers is their innate creativity. They have a unique talent for combining traditional ceramic methods with contemporary influences, resulting in artwork that is both visually stunning and thought-provoking. Their portfolio is a testament to their ability to produce high-quality, innovative pieces that captivate audiences.In addition to their technical proficiency and creative flair, [Person's Name] possesses excellent interpersonal and communication skills. They are a team player who collaborates effectively with others, and they have a natural ability to inspire and motivate those around them. This was particularly evident during our time together at [Your Institution], where [Person's Name] often took the initiative to mentor younger students and share their knowledge and experience.[Person's Name] has also been an active participant in the ceramic community, often volunteering their time to participate in exhibitions, workshops, and community events. Their dedication to promoting the art of ceramics is truly commendable, and it reflects their commitment to the broader artistic community.During [Person's Name]'s tenure at [Their Last Company/Institution], they have been recognized for their exceptional contributions to the ceramic program. They received numerous accolades, including [Specific Awards or Recognitions], which are a testament to their talent and hard work.I am confident that [Person's Name] will bring the same level of commitment and passion to your organization. Their artistic abilities, coupled with their strong work ethic and collaborative spirit, make them an ideal candidate for any position related to ceramics or the visual arts.Should you require any further information or wish to discuss [Person's Name]'s qualifications in more detail, please do not hesitate to contact me at [Your Phone Number] or via email at [Your Email Address]. I am more than willing to provide a reference or answer any questions you may have.Thank you for considering this recommendation. I am certain that [Person's Name] will be a valuable asset to your team and contribute significantly to your organization's success.Sincerely,[Your Name][Your Position][Your Company][City, State, Zip Code][Email Address][Phone Number]。