自动化系毕业设计外文翻译(中英文对照)

- 格式:doc

- 大小:102.00 KB

- 文档页数:10

中英文资料外文翻译文献外文原文Automating Manufacturing Systems with PLCs2.1 INTRODUCTIONControl engineering has evolved over time. In the past humans were the main method for controlling a system. More recently electricity has been used for control and early electrical control was based on relays. These relays allow power to be switched on and off without a mechanical switch. It is common to use relays to make simple logical control decisions. The development of low cost computer has brought the most recent revolution,the Programmable Logic Controller (PLC). The advent of the PLC began in the1970s, and has become the most common choice for manufacturing controls.PLCs have been gaining popularity on the factory floor and will probably remain predominant for some time to come. Most of this is because of the advantages they offer. • Cost effective for controlling complex systems.• Flexible and can be reapplied to control other systems quickly and easily.• Computational abilities allow more sophisticated control.• Tr ouble shooting aids make programming easier and reduce downtime.• Reliable components make these likely to operate for years before failure.2.1.1 Ladder logicLadder logic is the main programming method used for PLCs. As mentioned before, ladder logic has been developed to mimic relay logic. logic diagrams was a strategic one. By selecting ladder logic as the main programming method, the amount of retraining needed forengineers and trades people was greatly reduced.Modern control systems still include relays, but these are rarely used for logic. A relay is a simple device that uses a magnetic field to control a switch, as pictured in Figure 2.1. When a voltage is applied to the input coil, the resulting current creates a magnetic field. The magnetic field pulls a metal switch (or reed) towards it and the contacts touch, closing the switch. The contact that closes when the coil is energized is called normally open. The normally closed contacts touch when the input coil is not energized. Relays are normally drawn in schematic form using a circle to represent the input coil. The output contacts are shown with two parallel lines. Normally open contacts are shown as two lines, and will be open (non-conducting) when the input is not energized. Normally closed contacts are shown with two lines with a diagonal line through them. When the input coil is not energized the normally closed contacts will be closed (conducting).Figure 2.1 Simple Relay Layouts and SchematicsRelays are used to let one power source close a switch for another (often high current) power source, while keeping them isolated. An example of a relay in a simple control application is shown in Figure 2.2. In this system the first relay on the left is used as normally closed, and will allow current to flow until a voltage is applied to the input A. The second relay is normally open and will not allow current to flow until a voltage is applied to the input B. If current is flowing through the first two relays then current will flow through the coil in the third relay, and close the switch for output C. This circuit would normally be drawn in the ladder logic form. This can be read logically as C will be on if A is off and B is on.Figure 2.2 A Simple Relay ControllerThe example in Figure 2.2 does not show the entire control system, but only the logic. When we consider a PLC there are inputs, outputs, and the logic. Figure 2.3 shows a more complete representation of the PLC. Here there are two inputs from push buttons.We can imagine the inputs as activating 24V DC relay coils in the PLC. This in turn drives an output relay that switches 115V AC, that will turn on a light. Note, in actual PLCs inputs are never relays, but outputs are often relays. The ladder logic in the PLC is actually a computer program that the user can enter and change. Notice that both of the input push buttons are normally open, but the ladder logic inside the PLC has one normally open contact, and one normally closed contact. Do not think that the ladder logic in the PLC need so match the inputs or outputs. Many beginners will get caught trying to make the ladder logic match the input types.Figure 2.3 A PLC Illustrated With RelaysMany relays also have multiple outputs (throws) and this allows an output relay to also be an input simultaneously. The circuit shown in Figure 1.4 is an example of this, it is called a seal in circuit. In this circuit the current can flow through either branch of the circuit, through the contacts labelled A or B. The input B will only be on when the output B is on. If B is off, and A is energized, then B will turn on. If B turns on then the input B will turn on, and keep output B on even if input A goes off. After B is turned on the output B will not turn off.Figure 2.4 A Seal-in Circuit2.1.2 ProgrammingThe first PLCs were programmed with a technique that was based on relay logic wiring schematics. This eliminated the need to teach the electricians, technicians and engineers how to program a computer - but, this method has stuck and it is the most common technique for programming PLCs today. An example of ladder logic can be seen in Figure 2.5. To interpret this diagram imagine that the power is on the vertical line on the left hand side, we call this the hot rail. On the right hand side is the neutral rail. In the figure there are two rungs, and on each rung there are combinations of inputs (two vertical lines) and outputs (circles). If the inputs are opened or closed in the right combination the power can flow from the hot rail, through the inputs, to power the outputs, and finally to the neutral rail. An input can come from a sensor, switch, or any other type of sensor. An output will be some device outside the PLC that is switched on or off, such as lights or motors. In the top rung the contacts are normally open and normally closed. Which means if input A is on and input B is off, then power will flow through the output and activate it. Any other combination of input values will result in the output X being off.Figure 2.5 A Simple Ladder Logic DiagramThe second rung of Figure 2.5 is more complex, there are actually multiple combinations of inputs that will result in the output Y turning on. On the left most part of the rung, power could flow through the top if C is off and D is on. Power could also (and simultaneously) flow through the bottom if both E and F are true. This would get power half way across the rung, and then if G or H is true the power will be delivered to output Y. In later chapters we will examine how to interpret and construct these diagrams.There are other methods for programming PLCs. One of the earliest techniques involved mnemonic instructions. These instructions can be derived directly from the ladderlogic diagrams and entered into the PLC through a simple programming terminal. An example of mnemonics is shown in Figure 2.6. In this example the instructions are read one line at a time from top to bottom. The first line 00000 has the instruction LDN (input load and not) for input A. . This will examine the input to the PLC and if it is off it will remember a 1 (or true), if it is on it will remember a 0 (or false). The next line uses an LD (input load) statement to look at the input. If the input is off it remembers a 0, if the input is on it remembers a 1 (note: this is the reverse of the LD). The AND statement recalls the last two numbers remembered and if the are both true the result is a 1, otherwise the result is a 0. This result now replaces the two numbers that were recalled, and there is only one number remembered. The process is repeated for lines 00003 and 00004, but when these are done there are now three numbers remembered. The oldest number is from the AND, the newer numbers are from the two LD instructions. The AND in line 00005 combines the results from the last LD instructions and now there are two numbers remembered. The OR instruction takes the two numbers now remaining and if either one is a 1 the result is a 1, otherwise the result is a 0. This result replaces the two numbers, and there is now a single number there. The last instruction is the ST (store output) that will look at the last value stored and if it is 1, the output will be turned on, if it is 0 the output will be turned off.Figure 2.6 An Example of a Mnemonic Program and Equivalent Ladder LogicThe ladder logic program in Figure 2.6, is equivalent to the mnemonic program. Even ifyou have programmed a PLC with ladder logic, it will be converted to mnemonic form before being used by the PLC. In the past mnemonic programming was the most common, but now it is uncommon for users to even see mnemonic programs.Sequential Function Charts (SFCs) have been developed to accommodate the programming of more advanced systems. These are similar to flowcharts, but much more powerful. The example seen in Figure 2.7 is doing two different things. To read the chart, start at the top where is says start. Below this there is the double horizontal line that says follow both paths. As a result the PLC will start to follow the branch on the left and right hand sides separately and simultaneously. On the left there are two functions the first one is the power up function. This function will run until it decides it is done, and the power down function will come after. On the right hand side is the flash function, this will run until it is done. These functions look unexplained, but each function, such as power up will be a small ladder logic program. This method is much different from flowcharts because it does not have to follow a single path through the flowchart..Figure 2.7 An Example of a Sequential Function CharStructured Text programming has been developed as a more modern programming language. It is quite similar to languages such as BASIC. A simple example is shown in Figure 2.8. This example uses a PLC memory location i. This memory location is for an integer, as will be explained later in the book. The first line of the program sets the value to 0. The next line begins a loop, and will be where the loop returns to. The next line recalls thevalue in location i, adds 1 to it and returns it to the same location. The next line checks to see if the loop should quit. If i is greater than or equal to 10, then the loop will quit, otherwise the computer will go back up to the REPEAT statement continue from there. Each time the program goes through this loop i will increase by 1 until the value reaches 10.Figure 2.8 An Example of a Structured Text Program2.1.3 PLC ConnectionsWhen a process is controlled by a PLC it uses inputs from sensors to make decisions and update outputs to drive actuators, as shown in Figure 2.9. The process is a real process that will change over time. Actuators will drive the system to new states (or modes of operation). This means that the controller is limited by the sensors available, if an input is not available, the controller will have no way to detect a condition.Figure 2.9 The Separation of Controller and ProcessThe control loop is a continuous cycle of the PLC reading inputs, solving the ladder logic, and then changing the outputs. Like any computer this does not happen instantly. Figure 2.10 shows the basic operation cycle of a PLC. When power is turned on initially the PLC does a quick sanity check to ensure that the hardware is working properly.If there is a problem the PLC will halt and indicate there is an error. For example, if the PLC power is dropping andabout to go off this will result in one type of fault. If the PLC passes the sanity check it will then scan (read) all the inputs. After the inputs values are stored in memory the ladder logic will be scanned (solved) using the stored values not the current values. This is done to prevent logic problems when inputs change during the ladder logic scan. When the ladder logic scan is complete the outputs will be scanned (the output values will be changed). After this the system goes back to do a sanity check, and the loop continues indefinitely. Unlike normal computers, the entire program will be run every scan. Typical times for each of the stages is in the order of milliseconds.Figure 2.10 The Scan Cycle of a PLC2.1.4 Ladder Logic InputsPLC inputs are easily represented in ladder logic. In Figure 2.11 there are three types of inputs shown. The first two are normally open and normally closed inputs, discussed previously. The IIT (Immediate InpuT) function allows inputs to be read after the input scan, while the ladder logic is being scanned. This allows ladder logic to examine input values more often than once every cycle.Figure 2.11 Ladder Logic Inputs2.1.5 Ladder Logic OutputsIn ladder logic there are multiple types of outputs, but these are not consistently available on all PLCs. Some of the outputs will be externally connected to devices outside the PLC, but it is also possible to use internal memory locations in the PLC. Six types of outputs are shown in Figure 2.12. The first is a normal output, when energized the output will turn on, and energize an output. The circle with a diagonal line through is a normally on output. When energized the output will turn off. This type of output is not available on all PLC types. When initially energized the OSR (One Shot Relay) instruction will turn on for one scan, but then be off for all scans after, until it is turned off. The L (latch) and U (unlatch) instructions can be used to lock outputs on. When an L output is energized the output will turn on indefinitely, even when the output coil is deenergized. The output can only be turned off using a U output. The last instruction is the IOT (Immediate OutpuT) The last instruction is the IOT (Immediate OutpuT)that will allow outputs to be updated without having to wait for the ladder logic scan to be completed.3.1 INPUTS AND OUTPUTSInputs to, and outputs from, a PLC are necessary to monitor and control a process. Both inputs and outputs can be categorized into two basic types: logical or continuous. Considerthe example of a light bulb. If it can only be turned on or off, it is logical control. If the light can be dimmed to different levels, it is continuous. Continuous values seem more intuitive, but logical values are preferred because they allow more certainty, and simplify control. As a result most controls applications (and PLCs) use logical inputs and outputs for most applications. Hence, we will discuss logical I/O and leave continuous I/O for later.Outputs to actuators allow a PLC to cause something to happen in a process. A short list of popular actuators is given below in order of relative popularity.Solenoid Valves - logical outputs that can switch a hydraulic or pneumatic flow. Lights - logical outputs that can often be powered directly from PLC output boards.Motor Starters - motors often draw a large amount of current when started, so they require motor starters, which are basically large relays.Servo Motors - a continuous output from the PLC can command a variable speed or position.Outputs from PLCs are often relays, but they can also be solid state electronics such as transistors for DC outputs or Triacs for AC outputs. Continuous outputs require special output cards with digital to analog converters.Inputs come from sensors that translate physical phenomena into electrical signals. Typical examples of sensors are listed below in relative order of popularity.Proximity Switches - use inductance, capacitance or light to detect an object logically. Switches - mechanical mechanisms will open or close electrical contacts for a logical signal. Potentiometer - measures angular positions continuously, using resistance.LVDT (linear variable differential transformer) - measures linear displacement continuously using magnetic coupling.Inputs for a PLC come in a few basic varieties, the simplest are AC and DC inputs. Sourcing and sinking inputs are also popular. This output method dictates that a device does not supply any power. Instead, the device only switches current on or off, like a simple switch. Sinking - When active the output allows current to flow to a common ground. This is best selected when different voltages are supplied. Sourcing - When active, current flows from asupply, through the output device and to ground. This method is best used when all devices use a single supply voltage. This is also referred to as NPN (sinking) and PNP (sourcing). PNP is more popular. This will be covered in detail in the chapter on sensors.3.1.1 InputsIn smaller PLCs the inputs are normally built in and are specified when purchasing the PLC. For larger PLCs the inputs are purchased as modules, or cards, with 8 or 16 inputs of the same type on each card. For discussion purposes we will discuss all inputs as if they have been purchased as cards. The list below shows typical ranges for input voltages, and is roughly in order of popularity. PLC input cards rarely supply power, this means that an external power supply is needed to supply power for the inputs and sensors. The example in Figure 3.1 shows how to connect an AC input card.Figure 3.1 An AC Input Card and Ladder LogicIn the example there are two inputs, one is a normally open push button, and the second is a temperature switch, or thermal relay. (NOTE: These symbols are standard and will be discussed later in this chapter.) Both of the switches are powered by the positive/ hot output ofthe 24Vac power supply - this is like the positive terminal on a DC supply. Power is supplied to the left side of both of the switches. When the switches are open there is no voltage passed to the input card. If either of the switches are closed power will be supplied to the input card. In this case inputs 1 and 3 are used - notice that the inputs start at 0. The input card compares these voltages to the common. If the input voltage is within a given tolerance range the inputs will switch on. Ladder logic is shown in the figure for the inputs. Here it uses Allen Bradley notation for PLC-5 racks. At the top is the location of the input card I:013 which indicates that the card is an Input card in rack 01 in slot 3. The input number on the card is shown below the contact as 01 and 03.Many beginners become confused about where connections are needed in the circuit above. The key word to remember is circuit, which means that there is a full loop that the voltage must be able to follow. In Figure 3.1 we can start following the circuit (loop) at the power supply. The path goes through the switches, through the input card, and back to the power supply where it flows back through to the start. In a full PLC implementation there will be many circuits that must each be complete. A second important concept is the common. Here the neutral on the power supply is the common, or reference voltage. In effect we have chosen this to be our 0V reference, and all other voltages are measured relative to it. If we had a second power supply, we would also need to connect the neutral so that both neutrals would be connected to the same common. Often common and ground will be confused. The common is a reference, or datum voltage that is used for 0V, but the ground is used to prevent shocks and damage to equipment. The ground is connected under a building to a metal pipe or grid in the ground. This is connected to the electrical system of a building, to the power outlets, where the metal cases of electrical equipment are connected. When power flows through the ground it is bad. Unfortunately many engineers, and manufacturers mix up ground and common. It is very common to find a power supply with the ground and common mislabeled.One final concept that tends to trap beginners is that each input card is isolated. This means that if you have connected a common to only one card, then the other cards are not connected. When this happens the other cards will not work properly. You must connect acommon for each of the output cards.3.1.2.Output ModulesAs with input modules, output modules rarely supply any power, but instead act as switches. External power supplies are connected to the output card and the card will switch the power on or off for each output. Typical output voltages are listed below, and roughly ordered by popularity.120 Vac24 Vdc12-48 Vac12-48 Vdc5Vdc (TTL)230 VacThese cards typically have 8 to 16 outputs of the same type and can be purchased with different current ratings. A common choice when purchasing output cards is relays, transistors or triacs. Relays are the most flexible output devices. They are capable of switching both AC and DC outputs. But, they are slower (about 10ms switching is typical), they are bulkier, they cost more, and they will wear out after millions of cycles. Relay outputs are often called dry contacts. Transistors are limited to DC outputs, and Triacs are limited to AC outputs. Transistor and triac outputs are called switched outputs. Dry contacts - a separate relay is dedicated to each output.This allows mixed voltages (AC or DC and voltage levels up to the maximum), as well as isolated outputs to protect other outputs and the PLC. Response times are often greater than 10ms. This method is the least sensitive to voltage variations and spikes. Switched outputs - a voltage is supplied to the PLC card, and the card switches it to different outputs using solid state circuitry (transistors, triacs, etc.) Triacs are well suited to AC devices requiring less than 1A. Transistor outputs use NPN or PNP transistors up to 1A typically. Their response time is well under 1ms.中文翻译自动化制造系统与PLC2.1介绍控制工程随着时间的推移在不断发展。

2013 届本科毕业设计(论文)外文文献翻译学院:电气与自动化工程学院专业:自动化姓名:学号:外文出处: Springer-Verlag London Limited 2012(用外文写)附件: 1.外文资料翻译译文;2.外文原文。

附件1:外文资料翻译译文基于PLC的自动化系统的远程诊断的设计:远程诊断性能评价的影响因素Ramnath Sekar & Sheng-Jen Hsieh & Zhenhua Wu收稿日期:2010年6月16号接受日期:2012年5月17号施普林格出版社伦敦有限公司2012摘要在故障诊断中的性能故障排除任务通常是在不同工业领域的应用研究。

在以前进行了几个实验的研究中了解过程接口的能力,以协助当地的故障诊断和疑难排解,同时考虑到接口影响,故障性质和专业知识的疑难解答。

虽然有几个远程诊断架构已经提出和已经制定标准远程诊断的水平,在何种程度上的远程诊断体系结构的设计,可以帮助在诊断和远程故障诊断的影响因素性能没有被频繁的问题的疑难解答。

“本文的目的是了解影响远程故障诊断的性能的因素,包括远程诊断架构,故障类型,层次的专业知识,远程疑难解答,当地运营商和技术水平。

实验是在其中进行故障排除,使用三个层次的远程诊断体系结构诊断不同类型的故障,在可编程逻辑控制器根据离散自动化装配系统,同时加入当地工程师和新手驾驶员。

结果表明,故障是因为测量或监测相关的诊断远程专家故障排除工具的问题,远程系统变量故障排除性能的提升能增加远程诊断体系结构的水平。

与此相反,新手疑难排解,与这些故障的诊断有显著差异,在远程故障诊断性能方面观察三者之间的架构,对新手疑难排解遇到的一些问题与管理提供更多的信息。

专家们展现出更好的信息收集能力,他们花了更多的时间在每个信息源,完成来自较少的转换之间的信息故障诊断。

监控系统参数无关故障导致显著减少了远程故障诊断性能,与所有三个架构比较,相关的监控系统参数故障为专家和新手排解疑难问题。

外文出处:Farhadi, A. (2008). Modeling, simulation, and reduction of conducted electromagnetic interference due to a pwm buck type switching power supply. Harmonics and Quality of Power, 2008. ICHQP 2008. 13th International Conference on, 1 - 6.Modeling, Simulation, and Reduction of Conducted Electromagnetic Interference Due to a PWM Buck Type Switching Power Supply IA. FarhadiAbstract:Undesired generation of radiated or conducted energy in electrical systems is called Electromagnetic Interference (EMI). High speed switching frequency in power electronics converters especially in switching power supplies improves efficiency but leads to EMI. Different kind of conducted interference, EMI regulations and conducted EMI measurement are introduced in this paper. Compliancy with national or international regulation is called Electromagnetic Compatibility (EMC). Power electronic systems producers must regard EMC. Modeling and simulation is the first step of EMC evaluation. EMI simulation results due to a PWM Buck type switching power supply are presented in this paper. To improve EMC, some techniques are introduced and their effectiveness proved by simulation.Index Terms:Conducted, EMC, EMI, LISN, Switching SupplyI. INTRODUCTIONFAST semiconductors make it possible to have high speed and high frequency switching in power electronics []1. High speed switching causes weight and volume reduction of equipment, but some unwanted effects such as radio frequency interference appeared []2. Compliance with electromagnetic compatibility (EMC) regulations is necessary for producers to present their products to the markets. It is important to take EMC aspects already in design phase []3. Modeling and simulation is the most effective tool to analyze EMC consideration before developing the products. A lot of the previous studies concerned the low frequency analysis of power electronics components []4[]5. Different types of power electronics converters are capable to be considered as source of EMI. They could propagate the EMI in both radiated and conducted forms. Line Impedance Stabilization Network (LISN) is required for measurement and calculation of conducted interference level []6. Interference spectrum at the output of LISN is introduced as the EMC evaluation criterion []7[]8. National or international regulations are the references forthe evaluation of equipment in point of view of EMC []7[]8.II. SOURCE, PATH AND VICTIM OF EMIUndesired voltage or current is called interference and their cause is called interference source. In this paper a high-speed switching power supply is the source of interference.Interference propagated by radiation in area around of an interference source or by conduction through common cabling or wiring connections. In this study conducted emission is considered only. Equipment such as computers, receivers, amplifiers, industrial controllers, etc that are exposed to interference corruption are called victims. The common connections of elements, source lines and cabling provide paths for conducted noise or interference. Electromagnetic conducted interference has two components as differential mode and common mode []9.A. Differential mode conducted interferenceThis mode is related to the noise that is imposed between different lines of a test circuit by a noise source. Related current path is shown in Fig. 1 []9. The interference source, path impedances, differential mode current and load impedance are also shown in Fig. 1.B. Common mode conducted interferenceCommon mode noise or interference could appear and impose between the lines, cables or connections and common ground. Any leakage current between load and common ground couldbe modeled by interference voltage source.Fig. 2 demonstrates the common mode interference source, common mode currents Iandcm1 and the related current paths[]9.The power electronics converters perform as noise source Icm2between lines of the supply network. In this study differential mode of conducted interference is particularly important and discussion will be continued considering this mode only.III. ELECTROMAGNETIC COMPATIBILITY REGULATIONS Application of electrical equipment especially static power electronic converters in different equipment is increasing more and more. As mentioned before, power electronics converters are considered as an important source of electromagnetic interference and have corrupting effects on the electric networks []2. High level of pollution resulting from various disturbances reduces the quality of power in electric networks. On the other side some residential, commercial and especially medical consumers are so sensitive to power system disturbances including voltage and frequency variations. The best solution to reduce corruption and improve power quality is complying national or international EMC regulations. CISPR, IEC, FCC and VDE are among the most famous organizations from Europe, USA and Germany who are responsible for determining and publishing the most important EMC regulations. IEC and VDE requirement and limitations on conducted emission are shown in Fig. 3 and Fig. 4 []7[]9.For different groups of consumers different classes of regulations could be complied. Class Afor common consumers and class B with more hard limitations for special consumers are separated in Fig. 3 and Fig. 4. Frequency range of limitation is different for IEC and VDE that are 150 kHz up to 30 MHz and 10 kHz up to 30 MHz respectively. Compliance of regulations is evaluated by comparison of measured or calculated conducted interference level in the mentioned frequency range with the stated requirements in regulations. In united European community compliance of regulation is mandatory and products must have certified label to show covering of requirements []8.IV. ELECTROMAGNETIC CONDUCTED INTERFERENCE MEASUREMENTA. Line Impedance Stabilization Network (LISN)1-Providing a low impedance path to transfer power from source to power electronics converter and load.2-Providing a low impedance path from interference source, here power electronics converter, to measurement port.Variation of LISN impedance versus frequency with the mentioned topology is presented inFig. 7. LISN has stabilized impedance in the range of conducted EMI measurement []7.Variation of level of signal at the output of LISN versus frequency is the spectrum of interference. The electromagnetic compatibility of a system can be evaluated by comparison of its interference spectrum with the standard limitations. The level of signal at the output of LISN in frequency range 10 kHz up to 30 MHz or 150 kHz up to 30 MHz is criterion of compatibility and should be under the standard limitations. In practical situations, the LISN output is connected to a spectrum analyzer and interference measurement is carried out. But for modeling and simulation purposes, the LISN output spectrum is calculated using appropriate software.基于压降型PWM开关电源的建模、仿真和减少传导性电磁干扰摘要:电子设备之中杂乱的辐射或者能量叫做电磁干扰(EMI)。

生产自动化毕业论文中英文资料外文翻译文献随着科技的不断进步和人们对效率的追求,生产自动化已经成为现代工业的重要组成部份。

生产自动化通过引入先进的机械和电子设备,以及自动化控制系统,实现了生产过程的自动化和智能化。

本文将介绍一些关于生产自动化的研究和应用的外文翻译文献。

1. 文献一:《生产自动化的发展与趋势》这篇文献介绍了生产自动化的发展历程和未来的趋势。

文章指出,生产自动化的发展可以追溯到20世纪初,随着电子技术和计算机技术的不断进步,生产自动化得到了快速发展。

未来,生产自动化将更加注重智能化和柔性化,以适应不断变化的市场需求。

2. 文献二:《生产自动化在汽车创造业中的应用》这篇文献探讨了生产自动化在汽车创造业中的应用。

文章指出,汽车创造业是生产自动化的典型应用领域之一。

通过引入机器人和自动化生产线,汽车创造商可以大大提高生产效率和产品质量。

此外,生产自动化还可以减少人力成本和人为错误。

3. 文献三:《生产自动化对工作环境和员工的影响》这篇文献研究了生产自动化对工作环境和员工的影响。

文章指出,尽管生产自动化可以提高生产效率,但它也带来了一些负面影响。

例如,自动化设备的噪音和振动可能对员工的健康造成影响。

此外,自动化还可能导致一些工人失去工作机会。

因此,为了最大限度地发挥生产自动化的优势,必须采取适当的安全措施和培训计划。

4. 文献四:《生产自动化在食品加工行业中的应用》这篇文献讨论了生产自动化在食品加工行业中的应用。

文章指出,食品加工是一个复杂而繁琐的过程,生产自动化可以大大提高生产效率和产品质量。

通过引入自动化设备和控制系统,食品加工商可以减少人为错误和污染风险。

此外,生产自动化还可以实现对食品生产过程的精确控制和监测。

5. 文献五:《生产自动化在医药创造业中的应用》这篇文献探讨了生产自动化在医药创造业中的应用。

文章指出,医药创造是一个高度精细和复杂的过程,生产自动化可以提高生产效率和产品质量的同时,确保药品的安全和一致性。

景德镇陶瓷学院毕业设计(论文)有关外文翻译院系:机械电子工程学院专业:自动化姓名:肖骞学号: 201010320116指导教师:万军完成时间: 2014.5.8说明1、将与课题有关的专业外文翻译成中文是毕业设计(论文)中的一个不可缺少的环节。

此环节是培养学生阅读专业外文和检验学生专业外文阅读能力的一个重要环节。

通过此环节进一步提高学生阅读专业外文的能力以及使用外文资料为毕业设计服务,并为今后科研工作打下扎实的基础。

2、要求学生查阅与课题相关的外文文献3篇以上作为课题参考文献,并将其中1篇(不少于3000字)的外文翻译成中文。

中文的排版按后面格式进行填写。

外文内容是否与课题有关由指导教师把关,外文原文附在后面。

3、指导教师应将此外文翻译格式文件电子版拷给所指导的学生,统一按照此排版格式进行填写,完成后打印出来。

4、请将封面、译文与外文原文装订成册。

5、此环节在开题后毕业设计完成前完成。

6、指导教师应从查阅的外文文献与课题紧密相关性、翻译的准确性、是否通顺以及格式是否规范等方面去进行评价。

指导教师评语:签名:年月日TMS320LF2407, TMS320LF2406, TMS320LF2402TMS320LC2406, TMS320LC2404, MS320LC2402DSP CONTROLLERSThe TMS320LF240x and TMS320LC240x devices, new members of the ‘24x family of digital signal processor (DSP) controllers, are part of the C2000 platform of fixed-point DSPs. The ‘240x devices offer the enhanced TMS320 architectural design of the ‘C2xx core CPU for low-cost, low-power, high-performance processing capabilities. Several advanced peripherals, optimized for digital motor and motion control applications, have been integrated to provide a true single chip DSP controller. While code-compatible with the existing ‘24x DSP controller devices, the ‘240x offers increased processing performance (30 MIPS) and a higher level of peripheral integration. See the TMS320x240x device summary section for device-specific features.The ‘240x family offers an array of memory sizes and different peripherals tailored to meet the specific price/performance points required by various applications. Flash-based devices of up to 32K words offer a reprogrammable solution useful for:◆Applications requiring field programmability upgrades.◆Development and initial prototyping of applications that migrate toROM-based devices.Flash devices and corresponding ROM devices are fully pin-to-pin compatible. Note that flash-based devices contain a 256-word boot ROM to facilitate in-circuit programming.All ‘240x devices offer at least one event manager module which has been optimized for digital motor control and power conversion applications. Capabilities of this module include centered- and/or edge-aligned PWM generation, programmable deadband to prevent shoot-through faults, and synchronized analog-to-digital conversion. Devices with dual event managers enable multiple motor and/or convertercontrol with a single ‗240x DSP controller.The high performance, 10-bit analog-to-digital converter (ADC) has a minimum conversion time of 500 ns and offers up to 16 channels of analog input. The auto sequencing capability of the ADC allows a maximum of 16 conversions to take place in a single conversion session without any CPU overhead.A serial communications interface (SCI) is integrated on all devices to provide asynchronous communication to other devices in the system. For systems requiring additional communication interfaces; the ‘2407, ‘2406, and ‘2404 offer a 16-bit synchronous serial peripheral interface (SPI). The ‘2407 and ‘2406 offer a controller area network (CAN) communications module that meets 2.0B specifications. To maximize device flexibility, functional pins are also configurable as general purpose inputs/outputs (GPIO).To streamline development time, JTAG-compliant scan-based emulation has been integrated into all devices. This provides non-intrusive real-time capabilities required to debug digital control systems. A complete suite of code generation tools from C compilers to the industry-standard Code Composerdebugger supports this family. Numerous third party developers not only offer device-level development tools, but also system-level design and development support.PERIPHERALSThe integrated peripherals of the TMS320x240x are described in the following subsections:●Two event-manager modules (EV A, EVB)●Enhanced analog-to-digital converter (ADC) module●Controller area network (CAN) module●Serial communications interface (SCI) module●Serial peripheral interface (SPI) module●PLL-based clock module●Digital I/O and shared pin functions●External memory interfaces (‘LF2407 only)Watchdog (WD) timer moduleEvent manager modules (EV A, EVB)The event-manager modules include general-purpose (GP) timers, full-compare/PWM units, capture units, and quadrature-encoder pulse (QEP) circuits. EV A‘s and EVB‘s timers, compare units, and capture units function identically. However, timer/unit names differ for EV A and EVB. Table 1 shows the module and signal names used. Table 1 shows the features and functionality available for the event-manager modules and highlights EV A nomenclature.Event managers A and B have identical peripheral register sets with EV A starting at 7400h and EVB starting at 7500h. The paragraphs in this section describe the function of GP timers, compare units, capture units, and QEPs using EV A nomenclature. These paragraphs are applicable to EVB with regard to function—however, module/signal names would differ.Table 1. Module and Signal Names for EV A and EVBEVENT MANAGER MODULESEV AMODULESIGNALEVBMODULESIGNALGP Timers Timer 1Timer 2T1PWM/T1CMPT2PWM/T2CMPTimer 3Timer 4T3PWM/T3CMPT4PWM/T4CMPCompare Units Compare 1Compare 2Compare 3PWM1/2PWM3/4PWM5/6Compare 4Compare 5Compare 6PWM7/8PWM9/10PWM11/12Capture Units Capture 1Capture 2Capture 3CAP1CAP2CAP3Capture 4Capture 5Capture 6CAP4CAP5CAP6QEP QEP1QEP2QEP1QEP2QEP3QEP4QEP3QEP4External Inputs DirectionExternalClockTDIRATCLKINADirectionExternal ClockTDIRBTCLKINBGeneral-purpose (GP) timersThere are two GP timers: The GP timer x (x = 1 or 2 for EV A; x = 3 or 4 for EVB) includes:● A 16-bit timer, up-/down-counter, TxCNT, for reads or writes● A 16-bit timer-compare register, TxCMPR (double-buffered with shadowregister), for reads or writes● A 16-bit timer-period register, TxPR (double-buffered with shadowregister), for reads or writes● A 16-bit timer-control register,TxCON, for reads or writes●Selectable internal or external input clocks● A programmable prescaler for internal or external clock inputs●Control and interrupt logic, for four maskable interrupts: underflow,overflow, timer compare, and period interrupts● A selectable direction input pin (TDIR) (to count up or down whendirectional up-/down-count mode is selected)The GP timers can be operated independently or synchronized with each other. The compare register associated with each GP timer can be used for compare function and PWM-waveform generation. There are three continuous modes of operations for each GP timer in up- or up/down-counting operations. Internal or external input clocks with programmable prescaler are used for each GP timer. GP timers also provide the time base for the other event-manager submodules: GP timer 1 for all the compares and PWM circuits, GP timer 2/1 for the capture units and the quadrature-pulse counting operations. Double-buffering of the period and compare registers allows programmable change of the timer (PWM) period and the compare/PWM pulse width as needed.Full-compare unitsThere are three full-compare units on each event manager. These compare units use GP timer1 as the time base and generate six outputs for compare and PWM-waveform generation using programmable deadband circuit. The state of each of the six outputs is configured independently. The compare registers of the compare units are double-buffered, allowing programmable change of the compare/PWM pulse widths as needed.Programmable deadband generatorThe deadband generator circuit includes three 8-bit counters and an 8-bit compare register. Desired deadband values (from 0 to 24 µs) can be programmed into the compare register for the outputs of the three compare units. The deadband generation can be enabled/disabled for each compare unit output individually. The deadband-generator circuit produces two outputs (with or without deadband zone) for each compare unit output signal. The output states of the deadband generator are configurable and changeable as needed by way of the double-buffered ACTR register.PWM waveform generationUp to eight PWM waveforms (outputs) can be generated simultaneously by each event manager: three independent pairs (six outputs) by the three full-compare units with programmable deadbands, and two independent PWMs by the GP-timer compares.PWM characteristicsCharacteristics of the PWMs are as follows:●16-bit registers●Programmable deadband for the PWM output pairs, from 0 to 24 µs●Minimum deadband width of 50 ns●Change of the PWM carrier frequency for PWM frequency wobbling asneeded●Change of the PWM pulse widths within and after each PWM period asneeded●External-maskable power and drive-protection interrupts●Pulse-pattern-generator circuit, for programmable generation of asymmetric,symmetric, and four-space vector PWM waveforms●Minimized CPU overhead using auto-reload of the compare and periodregistersCapture unitThe capture unit provides a logging function for different events or transitions. The values of the GP timer 2 counter are captured and stored in the two-level-deep FIFO stacks when selected transitions are detected on capture input pins, CAPx (x = 1, 2, or 3 for EV A; and x = 4, 5, or 6 for EVB). The capture unit consists of three capture circuits.Capture units include the following features:●One 16-bit capture control register, CAPCON (R/W)●One 16-bit capture FIFO status register, CAPFIFO (eight MSBs areread-only, eight LSBs are write-only)●Selection of GP timer 2 as the time base●Three 16-bit 2-level-deep FIFO stacks, one for each capture unit●Three Schmitt-triggered capture input pins (CAP1, CAP2, and CAP3)—oneinput pin per capture unit. [All inputs are synchronized with the device (CPU)clock. In order for a transition to be captured, the input must hold at itscurrent level to meet two rising edges of the device clock. The input pinsCAP1 and CAP2 can also be used as QEP inputs to the QEP circuit.]●User-specified transition (rising edge, falling edge, or both edges) detection●Three maskable interrupt flags, one for each capture unitEnhanced analog-to-digital converter (ADC) moduleA simplified functional block diagram of the ADC module is shown in Figure 1. The ADC module consists of a 10-bit ADC with a built-in sample-and-hold (S/H) circuit. Functions of the ADC module include:●10-bit ADC core with built-in S/H●Fast conversion time (S/H + Conversion) of 500 ns●16-channel, muxed inputs●Autosequencing capability provides up to 16 ―autoconversions‖ in a singlesession. Each conversion can be programmed to select any 1 of 16 inputchannels●Sequencer can be operated as two independent 8-state sequencers or as onelarge 16-state sequencer (i.e., two cascaded 8-state sequencers)●Sixteen result registers (individually addressable) to store conversion values●Multiple triggers as sources for the start-of-conversion (SOC) sequence✧S/W – software immediate start✧EV A – Event manager A (multiple event sources within EV A)✧EVB – Event manager B (multiple event sources within EVB)✧Ext – External pin (ADCSOC)●Flexible interrupt control allows interrupt request on every end of sequence(EOS) or every other EOS●Sequencer can operate in ―start/stop‖ mode, allowing multiple―time-sequenced triggers‖ to synchronize conversions●EV A and EVB triggers can operate independently in dual-sequencer mode●Sample-and-hold (S/H) acquisition time window has separate prescalecontrol●Built-in calibration mode●Built-in self-test modeThe ADC module in the ‘240x has been enhanced to provide flexible interface to event managers A and B. The ADC interface is built around a fast, 10-bit ADC module with total conversion time of 500 ns (S/H + conversion). The ADC module has 16 channels, configurable as two independent 8-channel modules to service event managers A and B. The two independent 8-channel modules can be cascaded to form a 16-channel module. Figure 2 shows the block diagram of the ‘240x ADC module.The two 8-channel modules have the capability to autosequence a series of conversions, each module has the choice of selecting any one of the respective eight channels available through an analog mux. In the cascaded mode, the autosequencer functions as a single 16-channel sequencer. On each sequencer, once the conversion is complete, the selected channel value is stored in its respective RESULT register. Autosequencing allows the system to convert the same channel multiple times, allowing the user to perform oversampling algorithms. This gives increased resolution over traditional single-sampled conversion results.FromTMS320LF2407, TMS320LF2406, TMS320LF2402TMS320LC2406, TMS320LC2404, MS320LC2402数字信号处理控制器TMS320LF240x和TMS320LC240x系列芯片作为’24x系列DSP控制器的新成员,是C2000平台下的一种定点DSP芯片。

毕业设计/论文外文文献翻译系别自动化系专业班级机械电子工程0603班姓名评分指导教师2010 年4月29日毕业设计/论文外文文献翻译要求:1.外文文献翻译的内容应与毕业设计/论文课题相关。

2.外文文献翻译的字数:非英语专业学生应完成与毕业设计/论文课题内容相关的不少于2000汉字的外文文献翻译任务(其中,汉语言文学专业、艺术类专业不作要求),英语专业学生应完成不少于2000汉字的二外文献翻译任务。

格式按《华中科技大学武昌分校本科毕业设计/论文撰写规范》的要求撰写。

3.外文文献翻译附于开题报告之后:第一部分为译文,第二部分为外文文献原文,译文与原文均需单独编制页码(底端居中)并注明出处。

本附件为封面,封面上不得出现页码。

4.外文文献翻译原文由指导教师指定,同一指导教师指导的学生不得选用相同的外文原文。

驱动桥设计随着汽车对安全、节能、环保的不断重视,汽车后桥作为整车的一个关键部件,其产品的质量对整车的安全使用及整车性能的影响是非常大的,因而对汽车后桥进行有效的优化设计计算是非常必要的。

驱动桥处于动力传动系的末端,其基本功能是增大由传动轴或变速器传来的转矩,并将动力合理地分配给左、右驱动轮,另外还承受作用于路面和车架或车身之间的垂直力力和横向力。

驱动桥一般由主减速器、差速器、车轮传动装置和驱动桥壳等组成。

驱动桥作为汽车四大总成之一,它的性能的好坏直接影响整车性能,而对于载重汽车显得尤为重要。

驱动桥设计应当满足如下基本要求:1、符合现代汽车设计的一般理论。

2、外形尺寸要小,保证有必要的离地间隙。

3、合适的主减速比,以保证汽车的动力性和燃料经济性。

4、在各种转速和载荷下具有高的传动效率。

5、在保证足够的强度、刚度条件下,力求质量小,结构简单,加工工艺性好,制造容易,拆装,调整方便。

6、与悬架导向机构运动协调,对于转向驱动桥,还应与转向机构运动协调。

智能电子技术在汽车上得以推广使得汽车在安全行驶和其它功能更上一层楼。

编号:桂林电子科技大学信息科技学院毕业设计(论文)外文翻译(译文)系别:电子工程系专业:电子信息工程学生姓名:韦骏学号:0852100329指导教师单位:桂林电子科技大学信息科技学院姓名:梁勇职称:讲师2012 年6 月5 日设计与实现基于Modbus 协议的嵌入式Linux 系统摘要:随着嵌入式计算机技术的飞速发展,新一代工业自动化数据采集和监测系统,采用核心的高性能嵌入式微处理器的,该系统很好地适应应用程序。

它符合消费等的严格要求的功能,如可靠性,成本,尺寸和功耗等。

在工业自动化应用系统,Modbus 通信协议的工业标准,广泛应用于大规模的工业设备系统,包括DCS,可编程控制器,RTU 及智能仪表等。

为了达到嵌入式数据监测的工业自动化应用软件的需求,本文设计了嵌入式数据采集监测平台下基于Modbus 协议的Linux 环境采集系统。

串行端口的Modbus 协议是实现主/从式,其中包括两种通信模式:ASCII 和RTU。

因此,各种药膏协议的设备能够满足串行的Modbus通信。

在Modbus 协议的嵌入式平台实现稳定和可靠。

它在嵌入式数据监测自动化应用系统的新收购的前景良好。

关键词:嵌入式系统,嵌入式Linux,Modbus 协议,数据采集,监测和控制。

1、绪论Modbus 是一种通讯协议,是一种由莫迪康公司推广。

它广泛应用于工业自动化,已成为实际的工业标准。

该控制装置或不同厂家的测量仪器可以链接到一个行业监控网络使用Modbus 协议。

Modbus 通信协议可以作为大量的工业设备的通讯标准,包括PLC,DCS 系统,RTU 的,聪明的智能仪表。

随着嵌入式计算机技术的飞速发展,嵌入式数据采集监测系统,使用了高性能的嵌入式微处理器为核心,是一个重要的发展方向。

在环境鉴于嵌入式Linux 的嵌入式工业自动化应用的数据,一个Modbus 主协议下的采集监测系统的设计和实现了这个文件。

因此,通信设备,各种药膏协议能够满足串行的Modbus。

外文资料翻译Power System AutomationPower system integration is the act of communication data to, or among IED s in the I&C system and remote users. Substation integration refers to combining data from the IED′s local to a substation so that there is a single point of contact in the substation for all of the I&C data. Poletop devices often communicate to the substation via wireless or fiber connections. Remote and local substation and feeder control is passed through the substation controller acting as a single point of contact. Some systems bypass the substation controller by using direct connections to the poletop devices, such as RTU s, protective relays, and controllers.Power system automation is the act of automatically controlling the power system via I&C devices. Substation automation refers to using IED data, control and automation capabilities within the substation, and control commands from remote users to control power system devices. Since true substation automation relies on substation integration, the terms are often used interchangeably.Power system automation includes processes associated with generation and delivery of power. A subset of the process deal with delivery of power at transmission and distribution levels, which is power delivery automation. Together, monitoring and control of power delivery system in the substation and on the poletop reduce the occurrence of outages and shorten the duration of outages that do occur. The IED′s, communications protocols, and communications methods described in previous sections, work together as a system to perform power system automation.Though each utility is unique, most consider power delivery automation of transmission and distribution substation and feeders to include : Supervisory Control and Data Acquisition(SCADA)-operatorsupervision and control;Distribution Automation-fault location, auto-isolation, auto-sectionalizing, and auto-restoration;Substation Automation-breaker failure, reclosing, battery monitoring, dead substation transfer, and substation load transfer;Energy Management System (EMS)-load flow, VAR and voltage monitoring and control, generation control, transformer and feeder load balancing;Fault analysis and device maintenance.System without automated control still have the advantages of remote monitoring and operator control of power system devices, which includes: Remote monitoring and control of circuit breakers and automated switches;Remote monitoring of non-automated switches and fuses;Remote monitoring and control of capacitor banks;Remote monitoring and voltage control;Remote power quality monitoring and control.IED s described in the overview are used to perform power system integration and automation. Most designs require that the one IED act as the substation controller and perform data acquisition and control of the other IED s. The substation controllers is often called upon to support system automation tasks as well. The communications industry uses the term client/server for a device that acts as a master, or client, retrieving data from some devices and then acts as a slaver, a server, sending this data to other devices. The client/server collecting and concentrating dynamically. A data concentrator creates a substation databases by collecting and concentrating dynamic data from several devices. In this fashion, essential subsets of data from each IED are forwarded to a master through one data transfer. The concentrator databases is used to pass data between IED s that are not directly connected.A substation archive client/server collects and archives data from several devices. The archive data is retrieved when it is convenient for the userto do so.The age of the IED s now in substations varies widely. Many of these IED s are still useful but lack the most recent protocols. A communications processor that can communicate with each IED via a unique baud rate and protocol extends the time that each IED is useful. Using a communications processor for substation integration also easily accommodates future IED s. It is rare for all existing IED s to be discarded during a substation integration upgrade project.The benefits of monitoring, remote control, and automation of power delivery include improved employee and public safety, and deferment of the cost of purchasing new equipment. Also, reduced operation and maintenance costs are realized through improved use of existing facilities and optimized performance of the power system through reduced losses associated with outages and improved voltage profile. Collection of information can result in better planning and system design, and increased customer satisfaction will result from improved responsiveness, service reliability, and power quality.Power system automation includes a variety of equipment. The principal items are listed and briefly described below.Instrument transformers are used to sense power system current and voltage. They are physically connected to power system apparatus and convert the actual power system signals, which includes high voltage and current magnitudes, down to lower signal levels.Transducers convert the analog output of an instrument transformer from one magnitude to another or from one value type to another, such as from an ac current to dc voltage.As the name implies, a remote terminal device, RTU, is an IED that can be installed in a remote location, and acts as a termination point for filed contacts. A dedicated pair of copper conductors are used to sense every contract and transducer value. These conductors originated at the power system device, are installed in trenches or overhead cable trays, and are thenterminated on panels within the RTU. The RTU can transfer collected data to other devices and receive data and control commands from other device through a serial port. User programmable RTUs are referred to as “smart RTUs.”A communication switch is a device that switches between several serial ports when it is told to do so. The remote user initiates communications with the port switch via a connection to the substation , typically a leased line or dial-up telephone connection. Once connected, the user can route their communication through the port switch to one of the connected substation IEDs. The port switch merely “passes through” the IED communication.A meter is an IED that is used to create accurate measurement of power system current, voltage, and power values. Metering values such as demand and peak are saved within the meter to create historical information about the activity of the power system.A digital fault recorder ,is an IED that records information about power system disturbances. It is capable of storing data in digital format when triggered by conditions detected on the power system. Harmonics, frequency, and voltage are examples of data captured by DFRs.Load tap changer are devices used to change the tap position on transformers. These devices work automatically or can be controlled via another local IED or form a remote operator or process.Recloser controllers remotely control the operation of automated reclosers and switches. These devices monitor and store power system conditions and determine when to perform control actions. They also accept commands form a remote operator or process.电力系统自动化电力系统集成是在I&C系统中的IED和远程用户之间进行数据通信的操作。

中文2570字外文文献翻译院、部:电气与信息工程学院学生姓名:指导教师:职称讲师专业:自动化班级: 09级01班完成时间: 2013.06.06出处:Computing, Communication, Control, and Management, 2008. CCCM'08. ISECS International Colloquium on. IEEE, 2008, 1: 538-541Component-based Safety Computer of Railway SignalInterlocking System1 IntroductionSignal Interlocking System is the critical equipment which can guarantee traffic safety and enhance operational efficiency in railway transportation. For a long time, the core control computer adopts in interlocking system is the special customized high-grade safety computer, for example, the SIMIS of Siemens, the EI32 of Nippon Signal, and so on. Along with the rapid development of electronic technology, the customized safety computer is facing severe challenges, for instance, the high development costs, poor usability, weak expansibility and slow technology update. To overcome the flaws of the high-grade special customized computer, the U.S. Department of Defense has put forward the concept:we should adopt commercial standards to replace military norms and standards for meeting consumers’demand [1]. In the meantime, there are several explorations and practices about adopting open system architecture in avionics. The United Stated and Europe have do much research about utilizing cost-effective fault-tolerant computer to replace the dedicated computer in aerospace and other safety-critical fields. In recent years, it is gradually becoming a new trend that the utilization of standardized components in aerospace, industry, transportation and other safety-critical fields.2 Railways signal interlocking system2.1 Functions of signal interlocking systemThe basic function of signal interlocking system is to protect train safety by controlling signal equipments, such as switch points, signals and track units in a station, and it handles routes via a certain interlocking regulation.Since the birth of the railway transportation, signal interlocking system has gone through manual signal, mechanical signal, relay-based interlocking, and the modern computer-based Interlocking System.2.2 Architecture of signal interlocking systemGenerally, the Interlocking System has a hierarchical structure. According to the function of equipments, the system can be divided to the function of equipments; the system can be divided into three layers as shown in figure1.Man-Machine Interface layerInterlocking safety layerImplementation layerOutdoorequiptmentsFigure 1 Architecture of Signal Interlocking System3 Component-based safety computer design3.1 Design strategyThe design concept of component-based safety critical computer is different from that of special customized computer. Our design strategy of SIC is on a base of fault-tolerance and system integration. We separate the SIC into three layers, the standardized component unit layer, safety software layer and the system layer. Different safety functions are allocated for each layer, and the final integration of the three layers ensures the predefined safety integrity level of the whole SIC. The three layers can be described as follows:(1) Component unit layer includes four independent standardized CPU modules. A hardware “SAFETY AND” logic is implemented in this year.(2) Safety software layer mainly utilizes fail-safe strategy and fault-tolerant management. The interlocking safety computing of the whole system adopts two outputs from different CPU, it can mostly ensure the diversity of software to hold with design errors of signal version and remove hidden risks.(3) System layer aims to improve reliability, availability and maintainability by means of redundancy.3.2 Design of hardware fault-tolerant structureAs shown in figure 2, the SIC of four independent component units (C11, C12, C21, C22). The fault-tolerant architecture adopts dual 2 vote 2 (2v2×2) structure, and a kind of high-performance standardized module has been selected as computing unit which adopts Intel X Scale kernel, 533 MHZ.The operation of SIC is based on a dual two-layer data buses. The high bus adopts thestandard Ethernet and TCP/IP communication protocol, and the low bus is Controller Area Network (CAN). C11、C12 and C21、C22 respectively make up of two safety computing components IC1 and IC2, which are of 2v2 structure. And each component has an external dynamic circuit watchdog that is set for computing supervision and switching.Diagnosis terminal C12C21C22&&Watchdog driverFail-safe switch Input modle Output Modle InterfaceConsole C11High bus(Ether NET)Low bus (CAN)Figure 2 Hardware structure of SIC3.3 Standardized component unitAfter component module is made certain, according to the safety-critical requirements of railway signal interlocking system, we have to do a secondary development on the module. The design includes power supply, interfaces and other embedded circuits.The fault-tolerant processing, synchronized computing, and fault diagnosis of SIC mostly depend on the safety software. Here the safety software design method is differing from that of the special computer too. For dedicated computer, the software is often specially designed based on the bare hardware. As restricted by computing ability and application object, a special scheduling program is commonly designed as safety software for the computer, and not a universal operating system. The fault-tolerant processing and fault diagnosis of the dedicated computer are tightly hardware-coupled. However, the safety software for SIC is exoteric and loosely hardware-coupled, and it is based on a standard Linux OS.The safety software is vital element of secondary development. It includes Linux OS adjustment, fail-safe process, fault-tolerance management, and safety interlocking logic. The hierarchy relations between them are shown in Figure 4.Safety Interlock LogicFail-safe processFault-tolerance managementLinux OS adjustmentFigure 4 Safety software hierarchy of SIC3.4 Fault-tolerant model and safety computation3.4.1 Fault-tolerant modelThe Fault-tolerant computation of SIC is of a multilevel model:SIC=F1002D(F2002(S c11,S c12),F2002(S c21,S c22))Firstly, basic computing unit Ci1 adopts one algorithm to complete the S Ci1, and Ci2 finishes the S Ci2via a different algorithm, secondly 2 out of 2 (2oo2) safety computing component of SIC executes 2oo2 calculation and gets F SICi from the calculation results of S Ci1 S Ci2, and thirdly, according the states of watchdog and switch unit block, the result of SIC is gotten via a 1 out of 2 with diagnostics (1oo2D) calculation, which is based on F SIC1 and F SIC2.The flow of calculations is as follows:(1) S ci1=F ci1 (D net1,D net2,D di,D fss)(2) S ci2=F ci2 (D net1,D net2,D di,D fss)(3) F SICi=F2oo2 (S ci1, S ci2 ),(i=1,2)(4) SIC_OutPut=F1oo2D (F SIC1, F SIC2)3.4.2 Safety computationAs interlocking system consists of a fixed set of task, the computational model of SIC is task-based. In general, applications may conform to a time-triggered, event-triggered or mixed computational model. Here the time-triggered mode is selected, tasks are executed cyclically. The consistency of computing states between the two units is the foundation of SIC for ensuring safety and credibility. As SIC works under a loosely coupled mode, it is different from that of dedicated hardware-coupled computer. So a specialized synchronization algorithm is necessary for SIC.SIC can be considered as a multiprocessor distributed system, and its computational model is essentially based on data comparing via high bus communication. First, an analytical approach is used to confirm the worst-case response time of each task. To guarantee the deadline of tasks that communicate across the network, the access time and delay of communication medium is set to a fixed possible value. Moreover, the computational model must meets the real time requirements of railway interlocking system, within the system computing cycle, we set many check points P i(i=1,2,... n) , which are small enough for synchronization, and computation result voting is executed at each point. The safetycomputation flow of SIC is shown in Figure 5.S t a r tS t a r t0τ1τ2τ1P2P0τ1τ2τ1P2P0T0TC1i Ci 21T2T1T2T…………………n+1τn+1τn Pn Pn τn τclockclockS a f e t y f u n c t i o n s T a s k s o f i n t e r l o c k i n g l o g i c i :p:c h e c k p o i n t I n i t i a l i z e S y n c h r o n i z a t i o n G u a r a n t e e S y n c h r o n o u s T i m e t r i g g e rFigure 5 Safety computational model of SIC4. Hardware safety integrity level evaluation4.1 Safety IntegrityAs an authoritative international standard for safety-related system, IEC 61508 presents a definition of safety integrity: probability of a safety-related system satisfactorily performing the required safety functions under all the stated conditions within a stated period of time. In IEC 61508, there are four levels of safety integrity are prescribe, SIL1~SIL4. The SIL1 is the lowest, and SIL4 highest.According to IEC 61508, the SIC belongs to safety-related systems in high demand or continuous mode of operation. The SIL of SIC can be evaluated via the probability of dangerous per hour. The provision of SIL about such system in IEC 61508, see table 1.Table 1-Safety Integrity levels: target failure measures for a safety function operating in high demand orcontinuous mode of operationSafety Integrity levelHigh demand or continuous mode of Operation (Probability of a dangerous Failure per hour)4 ≥10-9 to <10-83 ≥10-8 to <10-72 ≥10-7 to <10-61 ≥10-6 to <10-54.2 Reliability block diagram of SICAfter analyzing the structure and working principle of the SIC, we get the bock diagram of reliability, as figure 6.2002200220022002NET1NET2NET1NET2λ=1×10-7DC=99%Voting=1002D λ=1×10-7DC=99%Voting=1002D λ=1×10Β=2%βD =1%DC=99%Voting=1002D High busLogic subsystem Low busFigure 6 Block diagram of SIC reliability5. ConclusionsIn this paper, we proposed an available standardized component-based computer SIC. Railway signal interlocking is a fail-safe system with a required probability of less than 10-9 safety critical failures per hour. In order to meet the critical constraints, fault-tolerant architecture and safety tactics are used in SIC. Although the computational model and implementation techniques are rather complex, the philosophy of SIC provides a cheerful prospect to safety critical applications, it renders in a simpler style of hardware, furthermore, it can shorten development cycle and reduce cost. SIC has been put into practical application, and high performance of reliability and safety has been proven.模块化安全铁路信号计算机联锁系统1概述信号联锁系统是保证交通安全、提高铁路运输效率的关键设备。

南京理工大学紫金学院毕业设计(论文)外文资料翻译系:机械系专业:车辆工程专业姓名:宋磊春学号:070102234外文出处:EDU_E_CAT_VBA_FF_V5R9(用外文写)附件:1。

外文资料翻译译文;2.外文原文.附件1:外文资料翻译译文CATIA V5 的自动化CATIA V5的自动化和脚本:在NT 和Unix上:脚本允许你用宏指令以非常简单的方式计划CATIA。

CATIA 使用在MS –VBScript中(V5.x中在NT和UNIX3。

0 )的共用部分来使得在两个平台上运行相同的宏。

在NT 平台上:自动化允许CATIA像Word/Excel或者Visual Basic程序那样与其他外用分享目标。

ATIA 能使用Word/Excel对象就像Word/Excel能使用CATIA 对象。

在Unix 平台上:CATIA将来的版本将允许从Java分享它的对象。

这将提供在Unix 和NT 之间的一个完美兼容。

CATIA V5 自动化:介绍(仅限NT)自动化允许在几个进程之间的联系:CATIA V5 在NT 上:接口COM:Visual Basic 脚本(对宏来说),Visual Basic 为应用(适合前:Word/Excel ),Visual Basic。

COM(零部件目标模型)是“微软“标准于几个应用程序之间的共享对象。

Automation 是一种“微软“技术,它使用一种解释环境中的COM对象。

ActiveX 组成部分是“微软“标准于几个应用程序之间的共享对象,即使在解释环境里。

OLE(对象的链接与嵌入)意思是资料可以在一个其他应用OLE的资料里连结并且可以被编辑的方法(在适当的位置编辑).在VBScript,VBA和Visual Basic之间的差别:Visual Basic(VB)是全部的版本。

它能产生独立的计划,它也能建立ActiveX 和服务器。

它可以被编辑。

VB中提供了一个补充文件名为“在线丛书“(VB的5。

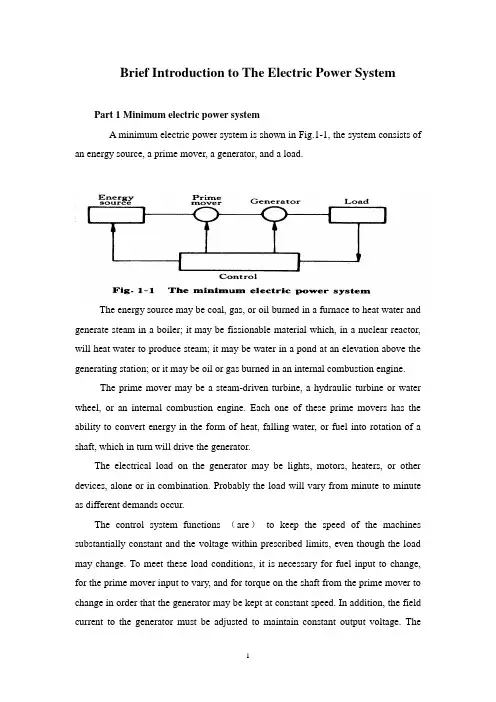

Brief Introduction to The Electric Power SystemPart 1 Minimum electric power systemA minimum electric power system is shown in Fig.1-1, the system consists of an energy source, a prime mover, a generator, and a load.The energy source may be coal, gas, or oil burned in a furnace to heat water and generate steam in a boiler; it may be fissionable material which, in a nuclear reactor, will heat water to produce steam; it may be water in a pond at an elevation above the generating station; or it may be oil or gas burned in an internal combustion engine.The prime mover may be a steam-driven turbine, a hydraulic turbine or water wheel, or an internal combustion engine. Each one of these prime movers has the ability to convert energy in the form of heat, falling water, or fuel into rotation of a shaft, which in turn will drive the generator.The electrical load on the generator may be lights, motors, heaters, or other devices, alone or in combination. Probably the load will vary from minute to minute as different demands occur.The control system functions (are)to keep the speed of the machines substantially constant and the voltage within prescribed limits, even though the load may change. To meet these load conditions, it is necessary for fuel input to change, for the prime mover input to vary, and for torque on the shaft from the prime mover to change in order that the generator may be kept at constant speed. In addition, the field current to the generator must be adjusted to maintain constant output voltage. Thecontrol system may include a man stationed in the power plant who watches a set of meters on the generator output terminals and makes the necessary adjustments manually. In a modern station, the control system is a servomechanism that senses generator-output conditions and automatically makes the necessary changes in energy input and field current to hold the electrical output within certain specifications..Part 2 More Complicated SystemsIn most situations the load is not directly connected to the generator terminals. More commonly the load is some distance from the generator, requiring a power line connecting them. It is desirable to keep the electric power supply at the load within specifications. However, the controls are near the generator, which may be in another building, perhaps several miles away.If the distance from the generator to the load is considerable, it may be desirable to install transformers at the generator and at the load end, and to transmit the power over a high-voltage line (Fig.1-2). For the same power, the higher-voltage line carries less current, has lower losses for the same wire size, and provides more stable voltage.In some cases an overhead line may be unacceptable. Instead it may be advantageous to use an underground cable. With the power systems talked above, the power supply to the load must be interrupted if, for any reason, any component of the system must be moved from service for maintenance or repair. Additional system load may require more power than the generator can supply. Another generator with its associated transformers and high-voltage line might be added.It can be shown that there are some advantages in making ties between the generators (1) and at the end of the high-voltage lines (2 and 3), as shown in Fig.1-3. This system will operate satisfactorily as long as no trouble develops or no equipmentneeds to be taken out of service.The above system may be vastly improved by the introduction of circuit breakers, which may be opened and closed as needed. Circuit breakers added to the system, Fig.1-4, permit selected piece of equipment to switch out of service without disturbing the remainder of system. With this arrangement any element of the system may be deenergized for maintenance or repair by operation of circuit breakers.Of course, if any piece of equipment is taken out of service, then the total load must be carried by the remaining equipment. Attention must be given to avoid overloads during such circumstances. If possible, outages of equipment are scheduled at times when load requirements are below normal.Fig.1-5 shows a system in which three generators and three loads are tied together by three transmission lines. No circuit breakers are shown in this diagram, although many would be required in such a system.Part 3 Typical System LayoutThe generators, lines, and other equipment which form an electric system are arranged depending on the manner in which load grows in the area and may be rearranged from time to time.However, there are certain plans into which a particular system design may be classified. Three types are illustrated: the radial system, the loop system, and the network system. All of these are shown without the necessary circuit breakers. In each of these systems, a single generator serves four loads.The radial system is shown in Fig.1-6. Here the lines form a “tree” spreading out from the generator. Opening any line results in interruption of power to one or more of the loads.The loop system is illustrated in Fig.1-7. With this arrangement all loads may be served even though one line section is removed from service. In some instances during normal operation, the loop may be open at some point, such as A. In case a line section is to be taken out, the loop is first closed at A and then the line section removed. In this manner no service interruptions occur.Fig.1-8 shows the same loads being served by a network. With this arrangement each load has two or more circuits over which it is fed.Distribution circuits are commonly designed so that they may be classified as radial or loop circuits. The high-voltage transmission lines of most power systems are arranged as network. The interconnection of major power system results in networks made up by many line sections.Part 4 Auxiliary EquipmentCircuit breakers are necessary to deenergize equipment either for normal operation or on the occurrence of short circuits. Circuit breakers must be designed to carry normal-load currents continuously, to withstand the extremely high currents that occur during faults, and to separate contacts and clear a circuit in the presence of fault. Circuit breakers are rated in terms of these duties.When a circuit breaker opens to deenergize a piece of equipment, one side of the circuit breaker usually remains energized, as it is connected to operating equipment. Since it is sometimes necessary to work on the circuit breaker itself, it is also necessary to have means by which the circuit breaker may be completely disconnected from other energized equipment. For this purpose disconnect switches are placed in series with the circuit breakers. By opening these disconnectors, thecircuit breaker may be completely deenergized, permitting work to be carried on in safety.Various instruments are necessary to monitor the operation of the electric power system. Usually each generator, each transformer bank, and each line has its own set of instruments, frequently consisting of voltmeters, ammeters, wattmeters, and varmeters.When a fault occurs on a system, conditions on the system undergo a sudden change. V oltages usually drop and currents increase. These changes are most noticeable in the immediate vicinity of fault. On-line analog computers, commonly called relays, monitor these changes of conditions, make a determination of which breaker should be opened to clear the fault, and energize the trip circuits of those appropriate breakers. With modern equipment, the relay action and breaker opening causes removal of fault within three or four cycles after its initiation.The instruments that show circuit conditions and the relays that protect the circuits are not mounted directly on the power lines but are placed on switchboards in a control house. Instrument transformers are installed on the high-voltage equipment, by means of which it is possible to pass on to the meters and relays representative samples of the conditions on the operating equipment. The primary of a potential transformer is connected directly to the high-voltage equipment. The secondary provides for the instruments and relays a voltage which is a constant fraction of voltage on the operating equipment and is in phase with it;similarly, a current transformer is connected with its primary in the high-current circuit. The secondary winding provides a current that is a known fraction of the power-equipment current and is in phase with it.Bushing potential devices and capacitor potential devices serve the same purpose as potential transformers but usually with less accuracy in regard to ratio and phase angle.中文翻译:电力系统的简介第一部分:最小电力系统一个最小电力系统如图1-1所示,系统包含动力源,原动机,发电机和负载。

自适应PID控制器基于Ziegler Nichols自整定方法的参数的PLC摘要本文介绍一种改进的PID控制器是作为一个动态的系统控制器和必要的步骤,是解释以表达对所提出的PID控制算法是更多的功能比传统的PID控制算法。

在这里齐格勒-尼科尔斯的过程中反应的方法是澄清,以候任自校正,及的优势,自我调整中有详细的解释。

之后,自适应丕三维控制器的算法,给出了使用自整定方法的初始参数。

在这丕三维,比例和积分参数是在控制的自适应算法和衍生产品的参数是一个不断发现,在齐格勒尼科尔斯基于自整定方法。

最后,完整的算法是测试在可编程逻辑控制器,和结果,这项测试是提供和解释。

PID控制器一比例积分微分控制器或PID控制器是一种常见的用于控制器在工业控制应用。

控制器的比较衡量的过程产值(元Y )与参考设定值()值。

差异或错误信号( e )是处理,然后计算控制信号为操纵的过程中的投入,使系统输出达到所期望的参考价值。

不同于简单的控制算法,PID控制器可以调整的过程中投入的基础上,历史和变化率的错误信号,这使更准确和更稳定的控制。

在这方面的文件,不同结构的PID控制器是使用。

图1结构的PID控制器图1结构的PID控制器众所周知,衍生金融工具可以计算或获得如果错误变缓慢。

由于反应衍生工具,以高频率的投入是远远高于其反应慢变信号[ 13 ] 。

因此,衍生金融工具的输出在图1是smoothened为高频率的噪音,用一阶过滤器,它使用的输出系统(y )的。

衍生工具使用错误的信号可以形成高,衍生金融工具的输出时,误差信号具有较高的高频成分。

因此,在本文件中衍生金融工具的投入使用过滤的输出系统。

在这里,过滤器smoothens信号和抑制高频率的噪音,由于过滤器的时间(TF )的常数(图2 )。

在应用,其TF应大于6月24日ts采样周期[ 6 ,16 ] 。

图2 ,稳定系统的输出响应(PLC模拟)在图1 ,积分信号是由错误乘以增益(k )和除以积分时间,和饱和度的差异除以积分时间。