专业英语(机械制造及其自动化)

- 格式:pptx

- 大小:381.68 KB

- 文档页数:40

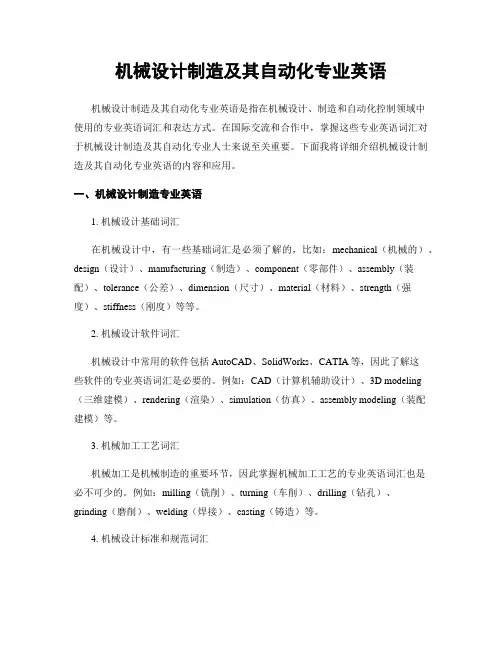

机械设计制造及其自动化专业英语机械设计制造及其自动化专业英语是指在机械设计、制造和自动化控制领域中使用的专业英语词汇和表达方式。

在国际交流和合作中,掌握这些专业英语词汇对于机械设计制造及其自动化专业人士来说至关重要。

下面我将详细介绍机械设计制造及其自动化专业英语的内容和应用。

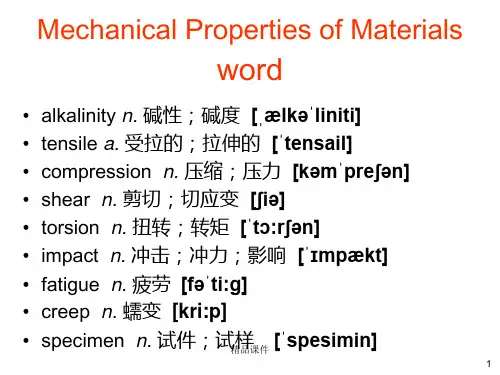

一、机械设计制造专业英语1. 机械设计基础词汇在机械设计中,有一些基础词汇是必须了解的,比如:mechanical(机械的)、design(设计)、manufacturing(制造)、component(零部件)、assembly(装配)、tolerance(公差)、dimension(尺寸)、material(材料)、strength(强度)、stiffness(刚度)等等。

2. 机械设计软件词汇机械设计中常用的软件包括AutoCAD、SolidWorks、CATIA等,因此了解这些软件的专业英语词汇是必要的。

例如:CAD(计算机辅助设计)、3D modeling (三维建模)、rendering(渲染)、simulation(仿真)、assembly modeling(装配建模)等。

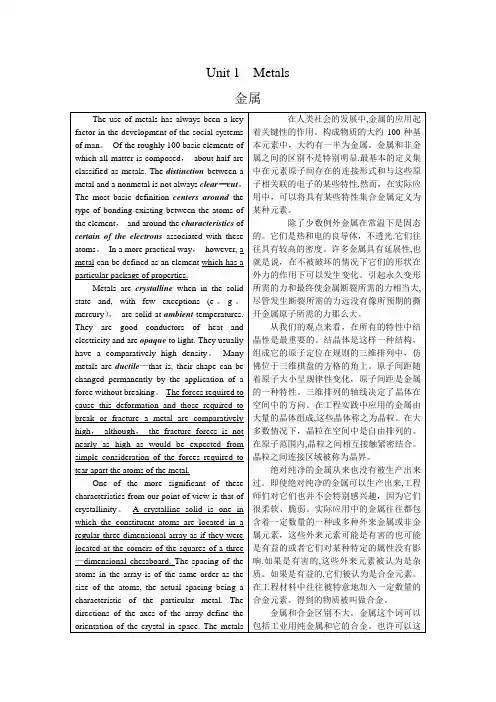

3. 机械加工工艺词汇机械加工是机械制造的重要环节,因此掌握机械加工工艺的专业英语词汇也是必不可少的。

例如:milling(铣削)、turning(车削)、drilling(钻孔)、grinding(磨削)、welding(焊接)、casting(铸造)等。

4. 机械设计标准和规范词汇在机械设计制造过程中,需要遵守一系列的标准和规范。

了解这些标准和规范的专业英语词汇是非常重要的。

例如:ISO(国际标准化组织)、ASME(美国机械工程师协会)、ASTM(美国材料与试验协会)、GD&T(几何公差与尺寸标注)等。

二、自动化专业英语1. 自动控制系统词汇自动化领域中,掌握自动控制系统的专业英语词汇是必要的。

例如:control system(控制系统)、feedback(反馈)、sensor(传感器)、actuator(执行器)、PID controller(比例积分微分控制器)、PLC(可编程逻辑控制器)等。

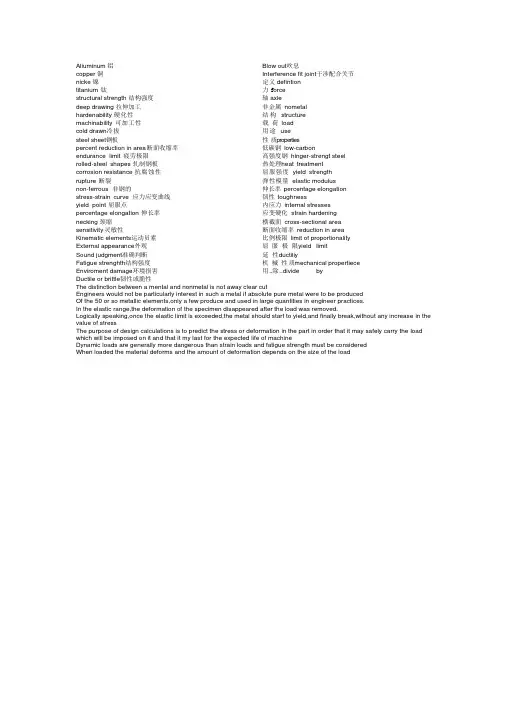

Aliuminum 铝copper 铜nicke 镍titanium 钛structural strength 结构强度deep drawing 拉伸加工hardenability 硬化性machinability 可加工性cold drawn冷拔steel sheet钢板percent reduction in area 断面收缩率endurance limit 疲劳极限rolled-steel shapes 轧制钢板corrosion resistance 抗腐蚀性rupture 断裂non-ferrous 非钢的stress-strain curve 应力应变曲线yield point 屈服点percentage elongation 伸长率necking 颈缩sensitivity 灵敏性Kinematic elements运动员素External appearance外观Sound judgment准确判断Fatigue strenghth结构强度Enviroment damage环境损害Ductile or brittle韧性或脆性Blow out吹息Interference fit joint干涉配合关节定义 defintion力 f orce轴axle非金属nometal结构structure载荷load用途use性质properties低碳钢low-carbon高强度钢hinger-strengt steel热处理heat treatment屈服强度yield strength弹性模量elastic modulus伸长率percentage elongation韧性toughness内应力internal stresses应变硬化strain hardening横截面cross-sectional area断面收缩率reduction in area比例极限limit of proportionality屈服极限yield limit延性ductiliy机械性质mechanical propertiece 用..除..divide byT he distinction between a mental and nonmetal is not away clear cutEngineers would not be particularly interest in such a metal if absolute pure metal were to be producedOf the 50 or so metallic elements,only a few produce and used in large quantities in engineer practices.In the elastic range,the deformation of the specimen disappeared after the load was removed.Logically speaking,once the elastic limit is exceeded,the metal should start to yield,and finally break,without any increase in the value of stressThe purpose of design calculations is to predict the stress or deformation in the part in order that it may safely carry the load which will be imposed on it and that it my last for the expected life of machineDynamic loads are generally more dangerous than strain loads and fatigue strength must be consideredWhen loaded the material deforms and the amount of deformation depends on the size of the load。

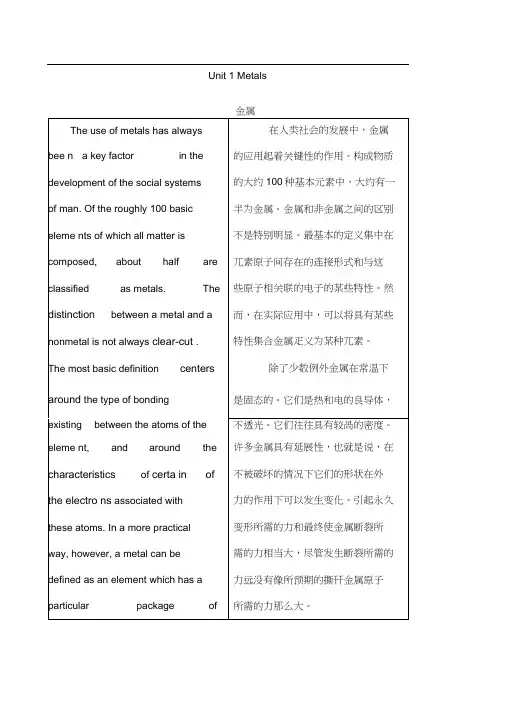

Unit 1 Metals金属绝对纯净的金属从来也没有被生产出来过。

即使绝对纯净的金属可以生产出来,工程师们对它们也并不会特别感兴趣,因为它们很柔软、脆弱。

实际应用中的金属往往都包含着一定数量的一种或多种外来金属或非金属元素,这些外来元素可能是有害的也可能是有益的或者它们对某种特定的属性没有影响。

如果是有害the crystals of the various grains are ran domly orie nted in space. The gra ins are everywhere in in timate con tact with oneanother and joined together on an atomic scale. The region at which they join is known as a grain boun dary.An absolutely pure metal (i.e. one composed of only one type of atom) has never been produced. Engin eers would not be particularly in terested in such a metal even if it were to be produced, because it would be soft and weak. The metals used commercially in evitably con ta in small amounts of one or more foreig neleme nts, either metallic or nonmetallic. These foreig neleme nts may be detrimental , they may be 它们的重量占所有生产出来的金属重量的98%在结构应用(也就是说,可以承受载荷的结构)中居于其次位置的是铝、铜、镍和钛。

U 1The use of metals has always a key factor in the development of the social systems of man. Of the roughly ['rʌfl ɪ] 100 basic elements of which all matter is composed, about half are classified as metals.金属的开发利用在人类社会系统的发展中扮演了了重要的角色,世界的物质大概由100种基本元素构成,其中一半是金属元素。

The distinction[dɪ'stɪŋkʃən] between a metal and a nonmetal is not always clear cut. The most basic definition centers around the type of bonding existing between the atoms of the element, and around the characteristics [,kærəkt ə'ristiks] of certain of the electrons[ɪ'lɛk,trɑn] associated with these atoms.金属与非金属的区分不是十分的清晰,最重要(基本)的在于元素原子之间的连接形式以及和原子相关联的电子的确定特性。

in a more practical['præktikəl] way, however, a metal can be defined as an element which has a particular package of properties.然而,在更多的实践当中,金属定义为具有一种整体特性的元素。

Unit 1 Metals金属Unit 2 Selection of Construction Materials工程材料的选择淬透性:指在规定条件下,决定钢材淬硬深度和硬度分布的特性。

即钢淬火时得到淬硬层深度大小的能力,它表示钢接受淬火的能力。

钢材淬透性好与差,常用淬硬层深度来表示。

淬硬层深度越大,则钢的淬透性越好。

钢的淬透性是钢材本身所固有的属性,它只取决于其本身的内部因素,而与外部因素无关。

钢的淬透性主要取决于它的化学成分,特别是含增大淬透性的合金元素及晶粒度,加热温度和保温时间等因素有关。

淬透性好的钢材,可使钢件整个截面获得均匀一致的力学性能以及可选用钢件淬火应力小的淬火剂,以减少变形和开裂。

淬透性主要取决于其临界冷却速度的大小,而临界冷却速度则主要取决于过冷奥氏体的稳定性,影响奥氏体的稳定性主要是:1.化学成分的影响碳的影响是主要的,当C%小于1.2%时,随着奥氏体中碳浓度的提高,显著降低临界冷却速度,C曲线右移,钢的淬透性增大;当C%大于时,钢的冷却速度反而升高,C曲线左移,淬透性下降。

其次是合金元素的影响,除钴外,绝大多数合金元素溶入奥氏体后,均使C曲线右移,降低临界冷却速度,从而提高钢的淬透性。

2.奥氏体晶粒大小的影响奥氏体的实际晶粒度对钢的淬透性有较大的影响,粗大的奥氏体晶粒能使C曲线右移,降低了钢的临界冷却速度。

但晶粒粗大将增大钢的变形、开裂倾向和降低韧性。

3.奥氏体均匀程度的影响在相同冷度条件下,奥氏体成分越均匀,珠光体的形核率就越低,转变的孕育期增长,C曲线右移,临界冷却速度减慢,钢的淬透性越高.4.钢的原始组织的影响钢的原始组织的粗细和分布对奥氏体的成分将有重大影响。

5。

部分元素,例如Mn,Si等元素对提高淬透性能起到一定作用,但同时也会对钢材带来其他不利的影响。

可锻性(forgeability)金属具有热塑性,在加热状态(各种金属要求温度不同),可以进行压力加工,称为具有可锻性。

机械设计制造及其自动化专业的英语Mechanical Design and Manufacturing AutomationMechanical Design and Manufacturing Automation is a specialized field that combines principles of mechanical engineering, manufacturing, and automation to design and develop complex manufacturing systems and processes. Graduates of this program are equipped with the knowledge and skills to create innovative solutions for industries such as aerospace, automotive, biomedical, and consumer goods.Curriculum for this program typically covers topics such as computer-aided design (CAD), computer-aided manufacturing (CAM), robotics, materials science, and control systems. Students also learn about project management, quality control, and compliance with industry standards and regulations.Career opportunities for graduates of Mechanical Design and Manufacturing Automation include positions in design engineering, manufacturing engineering, process engineering, and automation engineering. Graduates may also pursue careers in research and development, technical sales, or pursue advanced degrees in related fields.This field is constantly evolving, with new technologies and innovations shaping the future of manufacturing. Graduates who stay current with industry trends and advancements will be well-positioned to succeed and contribute to the growth of this exciting field.The Mechanical Design and Manufacturing Automation program focuses on training students on the design and development ofmechanical systems and their associated manufacturing processes. The curriculum includes courses in engineering mechanics, materials science, thermodynamics, fluid mechanics, computer-aided design and manufacturing, and automation and control systems.Students in this program also learn about modern manufacturing technologies such as CNC machining, rapid prototyping, and robotics. They are trained to use industry-standard software such as SolidWorks, AutoCAD, and CAMWorks to design, simulate, and manufacture mechanical components and systems.Graduates from the Mechanical Design and Manufacturing Automation program are equipped with the skills needed to work as mechanical designers and engineers in a variety of industries such as automotive, aerospace, and industrial manufacturing. They may also pursue careers in research and development, product design, or project management.。

Unit 1 Metals金属Unit 2 Selection of Construction Materials工程材料的选择淬透性:指在规定条件下,决定钢材淬硬深度和硬度分布的特性。

即钢淬火时得到淬硬层深度大小的能力,它表示钢接受淬火的能力.钢材淬透性好与差,常用淬硬层深度来表示。

淬硬层深度越大,则钢的淬透性越好。

钢的淬透性是钢材本身所固有的属性,它只取决于其本身的内部因素,而与外部因素无关。

钢的淬透性主要取决于它的化学成分,特别是含增大淬透性的合金元素及晶粒度,加热温度和保温时间等因素有关。

淬透性好的钢材,可使钢件整个截面获得均匀一致的力学性能以及可选用钢件淬火应力小的淬火剂,以减少变形和开裂。

淬透性主要取决于其临界冷却速度的大小,而临界冷却速度则主要取决于过冷奥氏体的稳定性,影响奥氏体的稳定性主要是:1。

化学成分的影响碳的影响是主要的,当C%小于1.2%时,随着奥氏体中碳浓度的提高,显著降低临界冷却速度,C曲线右移,钢的淬透性增大;当C%大于时,钢的冷却速度反而升高,C曲线左移,淬透性下降.其次是合金元素的影响,除钴外,绝大多数合金元素溶入奥氏体后,均使C曲线右移,降低临界冷却速度,从而提高钢的淬透性.2。

奥氏体晶粒大小的影响奥氏体的实际晶粒度对钢的淬透性有较大的影响,粗大的奥氏体晶粒能使C曲线右移,降低了钢的临界冷却速度.但晶粒粗大将增大钢的变形、开裂倾向和降低韧性。

3.奥氏体均匀程度的影响在相同冷度条件下,奥氏体成分越均匀,珠光体的形核率就越低,转变的孕育期增长,C曲线右移,临界冷却速度减慢,钢的淬透性越高.4。

钢的原始组织的影响钢的原始组织的粗细和分布对奥氏体的成分将有重大影响。

5。

部分元素,例如Mn,Si等元素对提高淬透性能起到一定作用,但同时也会对钢材带来其他不利的影响。

可锻性(forgeability)金属具有热塑性,在加热状态(各种金属要求温度不同),可以进行压力加工,称为具有可锻性。

2、应力和应变在任何工程结构中独立的部件或构件将承受来自于部件的使用状况或工作的外部环境的外力作用。

如果组件就处于平衡状态,由此而来的各种外力将会为零,但尽管如此,它们共同作用部件的载荷易于使部件变形同时在材料里面产生相应的内力。

有很多不同负载可以应用于构件的方式。

负荷根据相应时间的不同可分为:(a)静态负荷是一种在相对较短的时间内逐步达到平衡的应用载荷。

(b)持续负载是一种在很长一段时间为一个常数的载荷, 例如结构的重量。

这种类型的载荷以相同的方式作为一个静态负荷; 然而,对一些材料与温度和压力的条件下,短时间的载荷和长时间的载荷抵抗失效的能力可能是不同的。

(c)冲击载荷是一种快速载荷(一种能量载荷)。

振动通常导致一个冲击载荷, 一般平衡是不能建立的直到通过自然的阻尼力的作用使振动停止的时候。

(d)重复载荷是一种被应用和去除千万次的载荷。

(e)疲劳载荷或交变载荷是一种大小和设计随时间不断变化的载荷。

上面已经提到,作用于物体的外力与在材料里面产生的相应内力平衡。

因此,如果一个杆受到一个均匀的拉伸和压缩,也就是说, 一个力,均匀分布于一截面,那么产生的内力也均匀分布并且可以说杆是受到一个均匀的正常应力,应力被定义为应力==负载 P /压力 A,因此根据载荷的性质应力是可以压缩或拉伸的,并被度量为牛顿每平方米或它的倍数。

如果一个杆受到轴向载荷,即是应力,那么杆的长度会改变。

如果杆的初始长度L和改变量△L已知,产生的应力定义如下:应力==改变长△L /初始长 L因此应力是一个测量材料变形和无量纲的物理量 ,即它没有单位;它只是两个相同单位的物理量的比值。

一般来说,在实践中,在荷载作用下材料的延伸是非常小的, 测量的应力以*10-6的形式是方便的, 即微应变, 使用的符号也相应成为ue。

从某种意义上说,拉伸应力与应变被认为是正的。

压缩应力与应变被认为是负的。

因此负应力使长度减小。

当负载移除时,如果材料回复到初始的,无负载时的尺寸时,我们就说它是具有弹性的。

Unit 1 MetalsUnit 2 Selection of Construction Materials工程材料的选择淬透性:指在规定条件下,决定钢材淬硬深度和硬度分布的特性.即钢淬火时得到淬硬层深度大小的能力,它表示钢接受淬火的能力。

钢材淬透性好与差,常用淬硬层深度来表示。

淬硬层深度越大,则钢的淬透性越好。

钢的淬透性是钢材本身所固有的属性,它只取决于其本身的内部因素,而与外部因素无关。

钢的淬透性主要取决于它的化学成分,特别是含增大淬透性的合金元素及晶粒度,加热温度和保温时间等因素有关。

淬透性好的钢材,可使钢件整个截面获得均匀一致的力学性能以及可选用钢件淬火应力小的淬火剂,以减少变形和开裂。

淬透性主要取决于其临界冷却速度的大小,而临界冷却速度则主要取决于过冷奥氏体的稳定性,影响奥氏体的稳定性主要是:1.化学成分的影响碳的影响是主要的,当C%小于1.2%时,随着奥氏体中碳浓度的提高,显著降低临界冷却速度,C曲线右移,钢的淬透性增大;当C%大于时,钢的冷却速度反而升高,C曲线左移,淬透性下降.其次是合金元素的影响,除钴外,绝大多数合金元素溶入奥氏体后,均使C曲线右移,降低临界冷却速度,从而提高钢的淬透性.2。

奥氏体晶粒大小的影响奥氏体的实际晶粒度对钢的淬透性有较大的影响,粗大的奥氏体晶粒能使C曲线右移,降低了钢的临界冷却速度。

但晶粒粗大将增大钢的变形、开裂倾向和降低韧性。

3。

奥氏体均匀程度的影响在相同冷度条件下,奥氏体成分越均匀,珠光体的形核率就越低,转变的孕育期增长,C曲线右移,临界冷却速度减慢,钢的淬透性越高。

4。

钢的原始组织的影响钢的原始组织的粗细和分布对奥氏体的成分将有重大影响。

5。

部分元素,例如Mn,Si等元素对提高淬透性能起到一定作用,但同时也会对钢材带来其他不利的影响.可锻性(forgeability)金属具有热塑性,在加热状态(各种金属要求温度不同),可以进行压力加工,称为具有可锻性。

Basic Concept in MechanicsThe branch of scientific analysis which deals with motions time and forces is called mechanics and is made up of two parts statics and dynamics.Statics deals with the analysis of Stationary ,i .e.,those in which time is not a factor,and dynamics deals with systems which change with time .对运动、时间和作用力进行科学分析的分支称为力学 它由静力学和动力学俩部分组成。

静力学对静止系统进行分析 即在其中不考虑时间这个因素 动力学对随时间而变化的系统进行分析。

Forces are transmitted into machine members through mating surfaces ,e.g.,form a gear to a shaft or form one gear through meshing teeth to another gear,from a V belt to a pulley,or from a cam to a follower. It is necessary to know the magnitudes of these forces for a variety of Reasons. The distribution of the forces at the boundaries or mating surfaces must be reasonable and their intensities must be within the working limits of the materials composing thesurfaces. For example if the force operating on a journal bearing becomes too high it will squeeze out the oil film and cause metal-to-metal contact overheating and rapid failure of the bearing. If the forces betweens gear teeth are too large the oil film may be squeezed out from between them. This could result in flaking and spalling of the metal noise rough motion and eventual failure. In the study of mechanics we are principally interested in determining the magnitude direction and location of the Forces.力通过接触表面传到机器中的各构件上。

机械设计制造及自动化专业英语翻译Translation of Mechanical Design, Manufacturing, and Automation MajorIntroductionKey Concepts2. Manufacturing: This refers to the transformation of raw materials into finished products through various production processes. It includes techniques such as casting, machining, welding, and assembly. The goal is to optimize efficiency, quality, and cost-effectiveness.Courses1. Engineering Mechanics: This course covers the fundamental principles of mechanics, including statics, dynamics, and strength of materials. Students learn how to analyze and predict the behavior of mechanical systems and structures underdifferent conditions.3. Manufacturing Processes: This course introduces students to various manufacturing techniques, such as machining, casting, and welding. They learn how to select the appropriate processfor different types of products and understand the factors that affect production efficiency and quality.4. Industrial Robotics: This course provides an in-depth understanding of robotic systems and their applications in industrial settings. Students learn about robot programming, control, and integration to automate manufacturing processes and improve productivity.5. Control Systems: This course covers the principles of control theory and their application in automation. Students learn about sensor technology, feedback control loops, and programming techniques to design and implement control systems for mechanical processes.Conclusion。