《压力开关说明书》(参考Word)

- 格式:docx

- 大小:1.37 MB

- 文档页数:21

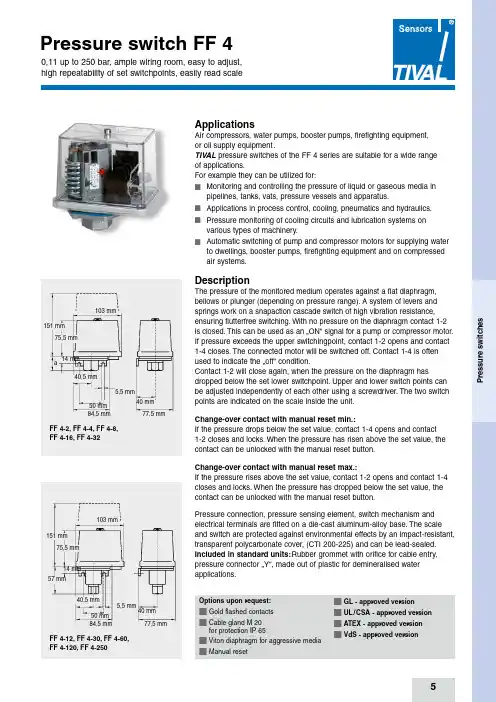

P r e s s u r e s w i t c h e s5ApplicationsAir compressors, water pumps, booster pumps, firefighting equipment, or oil supply equipment .TIVAL pressure switches of the FF 4 series are suitable for a wide range of applications.For example they can be utilized for:n Monitoring and controlling the pressure of liquid or gaseous media in pipelines, tanks, vats, pressure vessels and apparatus.n Applications in process control, cooling, pneumatics and hydraulics.n Pressure monitoring of cooling circuits and lubrication systems on various types of machinery.nAutomatic switching of pump and compressor motors for supplying water to dwellings, booster pumps, firefighting equipment and on compressed air systems.DescriptionThe pressure of the monitored medium operates against a flat diaphragm,b ellows or plunger (depending on pressure range). A system of levers and springs work on a snapaction cascade switch of high vibration resistance, ensuring flutterfree switching. With no pressure on the diaphragm contact 1-2 is closed. This can be used as an …ON“ signal for a pump or compressor motor.If pressure exceeds the upper switchingpoint, contact 1-2 opens and contact 1-4 closes. The connected motor will be switched off. Contact 1-4 is often used to indicate the …off“ condition.Contact 1-2 will close again, when the pressure on the diaphragm hasd ropped below the set lower switchpoint. Upper and lower switch points can be adjusted independently of each other using a screwdriver. The two switch points are indicated on the scale inside the unit.Change-over contact with manual reset min.:If the pressure drops below the set value, contact 1-4 opens and contact 1-2 closes and locks. When the pressure has risen above the set value, thec ontact can be unlocked with the manual reset button.Change-over contact with manual reset max.:If the pressure rises above the set value, contact 1-2 opens and contact 1-4 closes and locks. When the pressure has dropped below the set value, the contact can be unlocked with the manual reset button.Pressure connection, pressure sensing element, switch mechanism ande lectrical terminals are fitted on a die-cast aluminum-alloy base. The scale and switch are protected against environmental effects by an impact-resistant, transparent polycarbonate cover, (CTI 200-225) and can be lead-sealed.Included in standard units: Rubber grommet with orifice for cable e ntry, pressure connector …Y“, made out of plastic for demineralised watera pplications.Options upon request:n G old flashed contacts n C able gland M 20for protection IP 65n V iton diaphragm for aggressive media n M anual resetn G L - approved versionn U L / CSA - approved version n A TEX - approved version n V dS - approved versionFF 4-2, FF 4-4, FF 4-8, FF 4-16, FF 4-32103 mm5,5 mm40 mm 14 mm50 mm 84,5 mm77,5 mm151 mm75,5 mm 40,5 mmaFF 4-12, FF 4-30, FF 4-60,FF 4-120, FF 4-250103 mm5,5 mm40 mm 14 mm 50 mm 84,5 mm77,5 mm151 mm75,5 mm 40,5 mm57 mmControl pressure switch FF 4-... DAY Upper Lower Smallestswitch pt. switch pt. diff.*adjustable (bar) adjustable (bar) (bar) pressure (bar)0,11 ... 2 0,04 ... 1,89 0,07 0,110,22 ... 4 0,07 ... 3,75 0,15 0,250,5 ... 8 0,2 ... 7,5 0,3 0,5FF 4-10 DAY0,7 ... 10 0,3 ... 9,2 0,4 0,8FF 4-16 DAY 1 ... 16 0,4 ... 15 0,6 1Control pressure switch FF 4-... AAG / PAHUpper Lower Smallestswitch pt.switch pt.diff.*adjustable (bar)adjustable (bar)(bar)1 ... 120,5 ... 11,20,50,84 ... 30 1 ... 26,41,83,6High pressure switch with plastic plunger.Throttle is fitted as standard on these units. This must be removed for use with viscous media.Pressure connector: H (G 3/8“ Female thread, DIN 1725/2), stainless steel. VDE 0660, IEC 337-1, IEC 553-1Control pressure switch FF 4-... with manual reset Upper Lower Smallestswitch pt. switch pt. diff.adjustable (bar) adjustable (bar) (bar)0,11 ... 2 0,20,04 ... 1,89 0,10,22 ... 4 0,50,07 ... 3,75 0,20,5 ... 8 1,00,2 ... 7,5 0,41 ... 16 2,0Control pressure switch FF 444-... with UL / CSA-approval Upper Lower Smallestswitch pt. switch pt. diff.*adjustable (psi) adjustable (psi) (psi)3 ... 58 1 ... 54 2 415 ... 232 6 ... 217 9 14116 ... 870 58 ... 754 58 116P r e s s u r e s w i t c h e s10Media compatibility guideAccessoriesP r e s s u r e s w i t c h e s11Circuit diagramsChange-over contactwith manual reset min.Change-over contactwith manual reset max.Change-over contact DimensionsThrottle for FF 4-2 up to 32weight : ~ 3 g Order No.: 1011002Throttle screw for FF 4-12/30/60/120/250weight: ~ 3 g (stainless steel)Order No.: 10110035,5 mm6 mm4 mm G 3/8”G 1/2”Gauge fittingSteel, G 3/8” - G 1/2”, Type: H 124-114weight: ~ 18 g Order No.: 1071004P r e s s u r e s w i t c h e s12Pressure diagramsCharts show the smallest adjustable differential.Example per figure FF 4-4: If upper setting is at 3.25 bar, lower setting can be adjusted between 0.07and 3.0 bar (see arrows in the drawing).P r e s s u r e s w i t c h e s13Pressure diagrams。

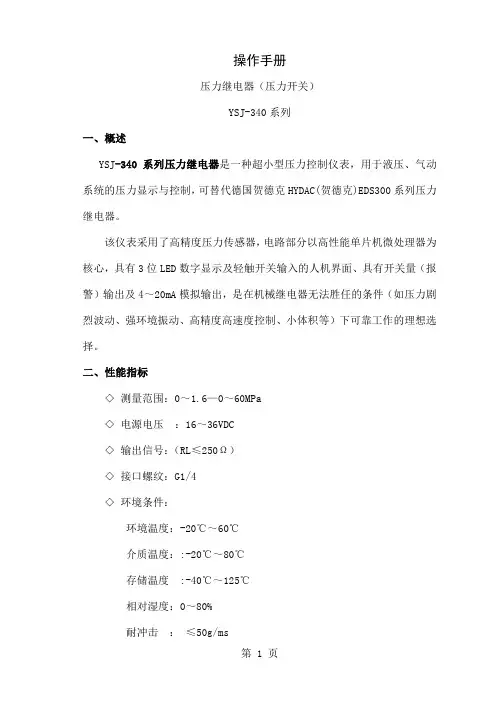

操作手册压力继电器(压力开关)YSJ-340系列一、概述YSJ-340系列压力继电器是一种超小型压力控制仪表,用于液压、气动系统的压力显示与控制,可替代德国贺德克HYDAC(贺德克)EDS300系列压力继电器。

该仪表采用了高精度压力传感器,电路部分以高性能单片机微处理器为核心,具有3位LED数字显示及轻触开关输入的人机界面、具有开关量(报警)输出及4~20mA模拟输出,是在机械继电器无法胜任的条件(如压力剧烈波动、强环境振动、高精度高速度控制、小体积等)下可靠工作的理想选择。

二、性能指标◇测量范围:0~1.6—0~60MPa◇电源电压:16~36VDC◇输出信号:(RL≤250Ω)◇接口螺纹:G1/4◇环境条件:环境温度:-20℃~60℃介质温度::-20℃~80℃存储温度:-40℃~125℃相对湿度:0~80%耐冲击:≤50g/ms耐振动:≤10g/(0~500HZ)◇输出信号精度:1.0◇过载压力:1.5%倍满量程压力◇最大功耗:≤3W触点容量:24VDC/1.2A(MAX)三、功能根据不同型号,装置可提供下列功能◇三位显示当前压力(正常工作)◇按压力、预设开关点输出开关量◇输出模拟量◇基本设定菜单◇提供四种不同输出模式:◇YSJ341带1路开关量输出(负载最大电流1.2A,无模拟量输出)◇YSJ342带2路开关量输出(负载最大电流1.2A,无模拟量输出)◇YSJ343带1路开关量输出(负载最大电流1.2A)和1路模拟量输出(4~20mA)◇YSJ344带2路开关量输出(负载最大电流1.2A)和1路模拟量输出(4~20mA)四、安装YSJ340可以通过压力管接头(DIN3852内螺纹G1/4),直接装在液压集成快上。

电气连接必须由国家认定合格的电工操作(参考中国电工国家标准规范)。

压力继电器的外壳必须同时良好的接地。

如安装在液压块里,块体通过液压系统接地时有保证的。

若用微型软管安装,客体必须单独接地。

技术参数测量元件:压阻硅测量元件材料:湿润部件:电子装置外壳:密封:不锈钢,材料号1.4301铝压铸件FKM操作元件:3个易响应按钮保护等级:IP65 保护类别:III工艺连接:G1/4 M尺寸:36×130 mm(不含连接插头)重量:约200 g量程[bar]:耐压压力[bar]:1050100200400600 1575150300600800线性误差:在+25℃下<±0.5%满量程A/D转换器:分辨率:扫描速率:10位(每个量程1024级)200/s电气连接:插头M12×1,4针温度影响:<±0.2%满量程/10K 补偿范围:-10℃ (70)可重复性:±0.1%满量程温度范围:介质:电子装置:贮藏:-25℃ (100)-10℃ (70)-30℃ (80)电源:15...32 V DC,反极性保护(SELV,PELV)数字显示:显示范围:显示速率:3位7段LED显示,红色,数字高度10 mm-1 (999)20/s错误显示:黄色LED和字母数字显示电力消耗:大约50 mA(不含负载)模拟输出:电流输出:负载:负载影响:扫描速率:电压输出:额定值:调节范围:4...20 mA最大RI=(Ub-12 V)/20 mA在Ub=24 V DC下RI=600Ω0.3%/100 Ω5 ms0...10 V DC最大10 mA25%...100%满量程PNP晶体管开关输出:开关功能:开关点和滞后的调节范围:开关频率:延迟:状态显示:常开/常闭、标准/窗口方式和诊断功能可调节0%...125%满量程最大100 Hz最大500 mA,防短路0.0 s...9.9 s可调节LED绿色附件:用于压力开关调节的接头体、阻尼螺钉、连接插头认证:cULus:文件号E42816用于压力控制的电子式压力开关,带有内置不锈钢隔膜、数字显示、2个开关输出或1个开关输出加1路模拟输出,线性误差0.5%满量程特点7段LED显示器,微处理器控制,带错误显示的自监视所有参数用键盘配置,可调节的键盘锁,结实耐用的结构,防震动和冲击,长期稳定性量程0...1 bar至0...600 bar表压力应用液压及气动系统、压机结构、润滑监视、仪表工程、机器/机床工业、汽车工业、注模机中的OEM应用4• •• •3124针插头4...20 mAM12 x 112/ 0.47118/4.6412/ 0.47"A"六角螺母36ø 30/1.18工艺连接(螺纹“A ”,不带接头体):G1/4尺寸(mm /英寸)连接图订购代码描述0499-016用于压力开关最佳方位调整的接头体G1/4 IG-G1/4外螺纹901-0677带0.2 mm 节流孔限制快速压力变化和高脉动率的阻尼螺钉907-0357连接插头M12×1,4针,带螺钉端子,直角型907-0344连接插头M12×1,4针,带螺钉端子,直通型压力范围0...10 bar 0...50 bar 0...100 bar 0...200 bar 0...400 bar 0...600 bar 2路开关输出0428-0170428-0180428-0190428-0200428-0210428-0221路开关输出1路模拟输出4...20 mA0428-1270428-1280428-1290428-1300428-1310428-132插头订购代码附件按需提供更多的量程。

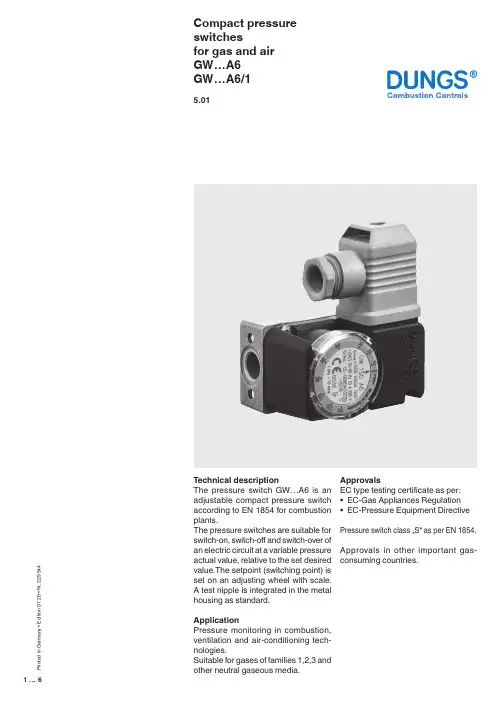

1 (6)Compact pressure switchesfor gas and air GW…A6GW…A6/15.01T echnical descriptionThe pressure switch GW…A6 is an adjustable compact pressure switch according to EN 1854 for combustion plants.The pressure switches are suitable for switch-on, switch-off and switch-over of an electric circuit at a variable pressure actual value, relative to the set desired value.The setpoint (switching point) is set on an adjusting wheel with scale. A test nipple is integrated in the metal housing as standard.ApplicationPressure monitoring in combustion, ventilation and air-conditioning tech -nologies.Suitable for gases of families 1,2,3 and other neutral gaseous media.ApprovalsEC type testing certificate as per: • EC-Gas Appliances Regulation • EC-Pressure Equipment Directive Pressure switch class …S“ as per EN 1854.Approvals in other important gas-consuming countries.P r i n t e d i n G e r m a n y • E d i t i o n 07.20 • N r . 229 544Functional descriptionSingle-acting pressure switch in over-pressure range.The pressure switches operate without any power supply.Switching responseGW…A6Short response time during pressure fluctuations.GW…A6/1Slow response time during short-term pressure fluctuations by additional damping nozzle.GW…A6 pressure switchThe control unit responds to pressure. If the setpoint is exceeded or undershot, the circuit is switched on, off or over.GW… / …A6 double pressure switchCombination of two flanged GW... A6 single pressure switches. The two setpoints are set separately and inde-pendently. A combination of different setpoint ranges is therefore possible. The two control units are fed from the same medium at the medium’s pres-sure.p↓ [mbar]p ↓ [mbar]2 (6)SpecificationsMax. operating pressure Pressure connectionMeasuring connection T emperature rangeMaterialsSwitching voltage Nominal current Switching currentElectrical connectionDegree of protection Setting toleranceDeviation GW 3 A6 - GW 150 A6 500 mbar (50 kPa)GW 500 A6 600 mbar (60 kPa)Standard (V0): centrally on housing bottom, G 1/4 inner threadas per ISO 228Special design (V3): additionally G 1/4 inner thread (side right)T est nipple integrated in metal housing ø9Ambient temperature -15 °C to +70 °CMedium temperatue -15 °C to +70 °CStorage temperature -30 °C to +80 °CHousing: Aluminium die castSwitch part: PolyamideDiaphragms: NBRSwitching contact: AgAC eff. min. 24 V max. 250 VDC min. 24 V max. 48 VGW 10…500 A6 GW 3 A6AC eff. max.10 A AC eff. max. 6 AAC eff. max.6 A at cos ϕ 1 AC eff. max. 4 A at cos ϕ 1AC eff. max.3 A at cos ϕ 0,6 AC eff. max. 2 A at cos ϕ 0,6 AC eff. min. 20 mA AC eff. min. 20 mA DC min. 20 mA DC min. 20 mA DC max. 1 A DC max. 1 AT erminal connection for line sockets as per DIN EN 175 301-803, 3-pin, protection-insulated without ground connectionIP 54 as per IEC 529 (EN 60529)± 15% switch point deviation referred to setpoint, adjusted for dropping pres-sure, vertical diaphragm positionPermissible deviation of the set value ≤ ± 15 % in the service life test according to EN 18543 (6)4 (6)Electrical connectionPressure connection5 (6)Compact pressure switchesfor gas and airGW…A6GW…A6/1Double pressure switchGW… / …A6We reserve the right to make any changes in the interest of technical progress.Head Offices and Factory Karl Dungs GmbH & Co. KG Karl-Dungs-Platz 1D-73660 Urbach, Germany T elefon +49 7181-804-0T elefax +49 7181-804-16Postal addressKarl Dungs GmbH & Co. KG Postfach 12 29D-73602 Schorndorf, Germany ******************** Internet 6 (6)。

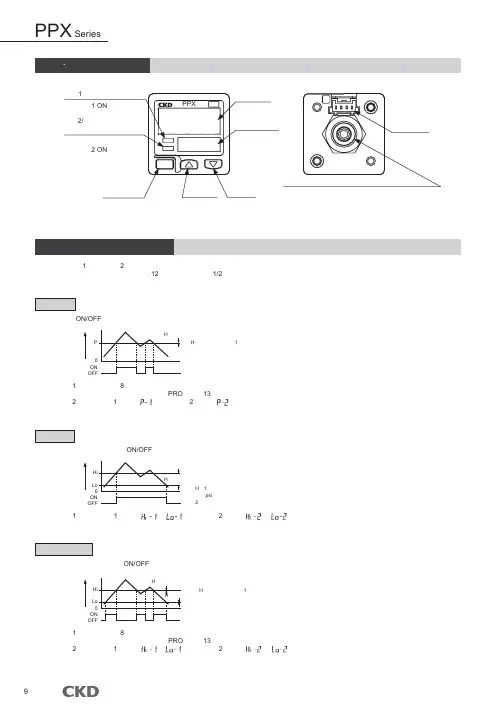

P2系列双显数字压力开关使用说明书一、主要特点:1、开放式仪表参数设定2、采用防水结构,外形美观、安装方便;3、设定参数密码锁定,断电后永久保存。

4、同时显示动作点压力值(SV)与当前压力值(PV)二、技术参数·压力范围:0~0.5Kpa…50Mpa·控制精度:±1字·过载能力:1.5倍·动作时间:不超过1ms·使用环境:环境温度 0~50℃相对湿度≤85%RH避免强腐蚀气体·测量精度:0.5%FS ±1字·分 辨 率:1、0.1、0.01字·工作电压:DC24V·功 耗:≤5W·显示方式:-199~999测量值显示-199~999设定值显示·结 构:铝盒密封安装,防水·螺纹接口:M20 x 1.5·控制方式:两路开关量输出,可设置动作点、上/下限动作、回差/带差继电器控制模块(用户可选):0.3A at 220VAC;2A at 30VDC 三极管控制模块(用户可选):1.5A at 30VDC双向可控硅制模块(用户可选):5A at 250VAC·参数设定:面板轻触式按键数字设定,参数设定后永久保存。

参数设定值密码锁定 ·保护方式:继电器输出状态LED指示电源欠压自动复位工作异常自动复位(Watch Dog)三、操作方式1、正确的接线请参照仪表随机接线图(见附录)接妥输入、输出信号线及电源线,并请确认无误。

2、仪表的上电本仪表无电源开关,接入电源即进入工作状态。

四、控制参数设定 (一)、仪表面板项 目 功 能PV 显示测量值 显示实时测量值 显示AL1动作值与AL2动作值显 示 器 SV 显示动作点在参数设定状态下,显示参数符号或设定值按压然后抬起按下不放保持5秒 SET 参数设定键1) 在显示模拟量输出值时则进入一级参数设定,显示参数CLK 符号。

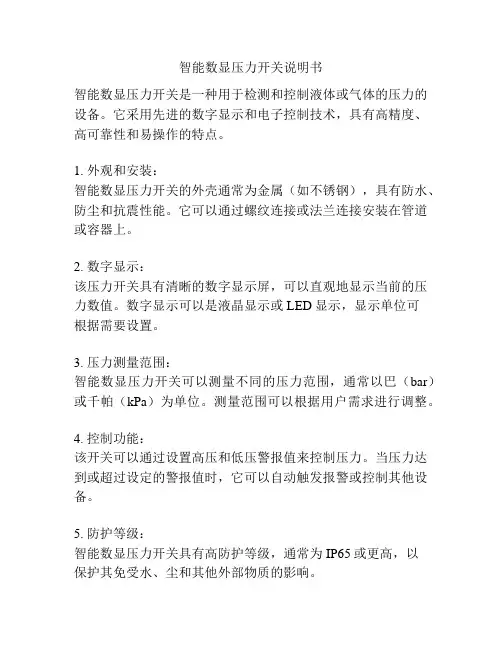

智能数显压力开关说明书智能数显压力开关是一种用于检测和控制液体或气体的压力的设备。

它采用先进的数字显示和电子控制技术,具有高精度、高可靠性和易操作的特点。

1. 外观和安装:智能数显压力开关的外壳通常为金属(如不锈钢),具有防水、防尘和抗震性能。

它可以通过螺纹连接或法兰连接安装在管道或容器上。

2. 数字显示:该压力开关具有清晰的数字显示屏,可以直观地显示当前的压力数值。

数字显示可以是液晶显示或LED显示,显示单位可根据需要设置。

3. 压力测量范围:智能数显压力开关可以测量不同的压力范围,通常以巴(bar)或千帕(kPa)为单位。

测量范围可以根据用户需求进行调整。

4. 控制功能:该开关可以通过设置高压和低压警报值来控制压力。

当压力达到或超过设定的警报值时,它可以自动触发报警或控制其他设备。

5. 防护等级:智能数显压力开关具有高防护等级,通常为IP65或更高,以保护其免受水、尘和其他外部物质的影响。

6. 输出信号:该开关可以提供模拟信号输出,如4-20mA或0-10V,以及继电器输出。

这些输出可以与其他设备(如数据记录器或PLC)连接,实现数据采集和远程控制。

7. 设定和调整:智能数显压力开关通常具有用户友好的菜单,可以通过按钮或旋钮进行设定和调整。

操作简单,无需额外的外部设备。

8. 适用领域:智能数显压力开关广泛应用于工业自动化、液压系统、空气压缩机、水处理等领域,以监测和控制压力的变化。

请注意,以上仅为智能数显压力开关的一般说明,具体产品的功能和操作方式可能会有所不同。

购买和使用前,请仔细阅读产品说明书和操作指南。

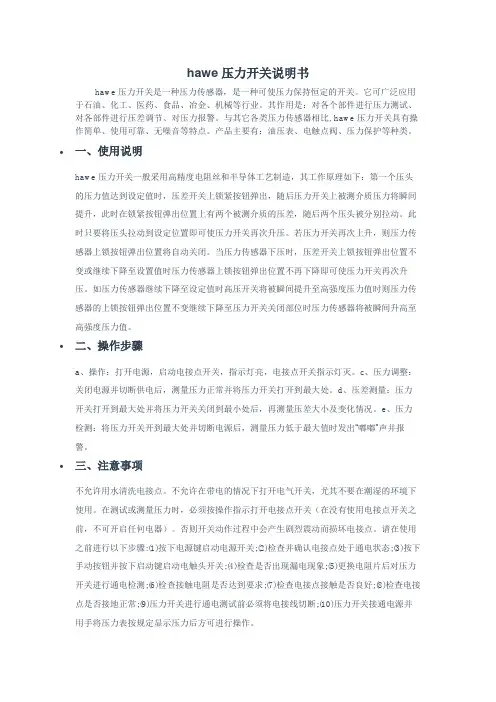

hawe压力开关说明书hawe压力开关是一种压力传感器,是一种可使压力保持恒定的开关。

它可广泛应用于石油、化工、医药、食品、冶金、机械等行业。

其作用是:对各个部件进行压力测试、对各部件进行压差调节、对压力报警。

与其它各类压力传感器相比, hawe压力开关具有操作简单、使用可靠、无噪音等特点。

产品主要有:油压表、电触点阀、压力保护等种类。

•一、使用说明hawe压力开关一般采用高精度电阻丝和半导体工艺制造,其工作原理如下:第一个压头的压力值达到设定值时,压差开关上锁紧按钮弹出,随后压力开关上被测介质压力将瞬间提升,此时在锁紧按钮弹出位置上有两个被测介质的压差,随后两个压头被分别拉动。

此时只要将压头拉动到设定位置即可使压力开关再次升压。

若压力开关再次上升,则压力传感器上锁按钮弹出位置将自动关闭。

当压力传感器下压时,压差开关上锁按钮弹出位置不变或继续下降至设置值时压力传感器上锁按钮弹出位置不再下降即可使压力开关再次升压。

如压力传感器继续下降至设定值时高压开关将被瞬间提升至高强度压力值时则压力传感器的上锁按钮弹出位置不变继续下降至压力开关关闭部位时压力传感器将被瞬间升高至高强度压力值。

•二、操作步骤a、操作:打开电源,启动电接点开关,指示灯亮,电接点开关指示灯灭。

c、压力调整:关闭电源并切断供电后,测量压力正常并将压力开关打开到最大处。

d、压差测量:压力开关打开到最大处并将压力开关关闭到最小处后,再测量压差大小及变化情况。

e、压力检测:将压力开关开到最大处并切断电源后,测量压力低于最大值时发出“嘟嘟”声并报警。

•三、注意事项不允许用水清洗电接点。

不允许在带电的情况下打开电气开关,尤其不要在潮湿的环境下使用。

在测试或测量压力时,必须按操作指示打开电接点开关(在没有使用电接点开关之前,不可开启任何电器)。

否则开关动作过程中会产生剧烈震动而损坏电接点。

请在使用之前进行以下步骤:(1)按下电源键启动电源开关;(2)检查并确认电接点处于通电状态;(3)按下手动按钮并按下启动键启动电触头开关;(4)检查是否出现漏电现象;(5)更换电阻片后对压力开关进行通电检测;(6)检查接触电阻是否达到要求;(7)检查电接点接触是否良好;(8)检查电接点是否接地正常;(9)压力开关进行通电测试前必须将电接线切断;(10)压力开关接通电源并用手将压力表按规定显示压力后方可进行操作。

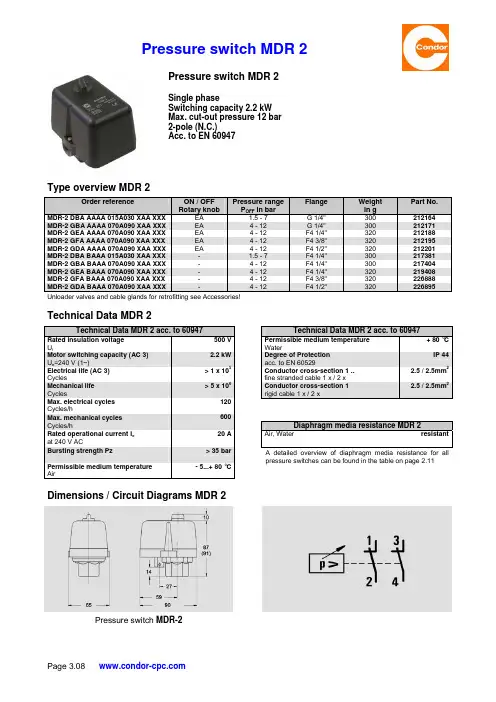

Page 3.08 Pressure switch MDR 2Single phaseSwitching capacity 2.2 kW Max. cut-out pressure 12 bar 2-pole (N.C.) Acc. to EN 60947Type overview MDR 2Order referenceON / OFF Rotary knobPressure range P OFF in barFlangeWeight in gPart No.MDR-2 DBA AAAA 015A030 XAA XXX EA 1.5 - 7 G 1/4" 300 212164 MDR-2 GBA AAAA 070A090 XAA XXX EA 4 - 12 G 1/4" 300 212171 MDR-2 GEA AAAA 070A090 XAA XXX EA 4 - 12 F4 1/4" 320 212188 MDR-2 GFA AAAA 070A090 XAA XXX EA 4 - 12 F4 3/8" 320 212195 MDR-2 GDA AAAA 070A090 XAA XXX EA 4 - 12 F4 1/2" 320 212201 MDR-2 DBA BAAA 015A030 XAA XXX - 1.5 - 7 F4 1/4" 300 217381 MDR-2 GBA BAAA 070A090 XAA XXX - 4 - 12 F4 1/4" 300 217404 MDR-2 GEA BAAA 070A090 XAA XXX - 4 - 12 F4 1/4" 320 219408 MDR-2 GFA BAAA 070A090 XAA XXX - 4 - 12 F4 3/8" 320 226888 MDR-2 GDA BAAA 070A090 XAA XXX-4 - 12F4 1/2"320226895Unloader valves and cable glands for retrofitting see Accessories!Technical Data MDR 2Technical Data MDR 2 acc. to 60947Technical Data MDR 2 acc. to 60947Rated insulation voltage U i500 V Permissible medium temperature Water+ 80 °C Motor switching capacity (AC 3) U e =240 V (1~)2.2 kW Degree of Protection acc. to EN 60529IP 44Electrical life (AC 3) Cycles> 1 x 105Conductor cross-section 1 .. fine stranded cable 1 x / 2 x 2.5 / 2.5mm2Mechanical life Cycles> 5 x 106Conductor cross-section 1 rigid cable 1 x / 2 x 2.5 / 2.5mm2Max. electrical cycles Cycles/h120Max. mechanical cycles Cycles/h600 Diaphragm media resistance MDR 2Rated operational current I e at 240 V AC20 A Air, WaterresistantBursting strength Pz> 35 bar Permissible medium temperature Air- 5...+ 80 °CA detailed overview of diaphragm media resistance for all pressure switches can be found in the table on page 2.11Dimensions / Circuit Diagrams MDR 2Pressure switch MDR-2Pressure switch MDR 2 Page 3.09Accessories MDR 2OrderreferenceDescriptionWeight in gPart No.Unloader valvesEV 2 With screw connection for 6 mm plastic or copper discharge tubes 25 200666 EV 2S With quick-connect for 6 mm plastic discharge tubes25 200680 EV 2W90° with screw connection for 6 mm plastic or discharge copper tubes 25 200697 EV 2Wi90° with screw connection for 1/4" mm plastic or discharge copper tubes 15 200703 EV 2WS 90° with quick-connect for 6 mm plastic discharge tubes 15 200710Delayed unloader valves AEV 2S With quick-connect for 6 mm plastic discharge tubes 25 200741 AEV 2W 90° with screw connection for 6 mm plastic or copper discharge tubes 15 200758 AEV 2Wi 90° with screw connection for 1/4" mm plastic or copper discharge tubes 15 200765 AEV 2WS 90° with quick-connect for 6 mm plastic discharge tubes 15 200772Cable glands WN Grommet 6 200888 PG 11 G Conduits for mounting of cable glands (Inner thread) 6 200895 PG 11 V Cable gland complete 12 200901 PG 11 Z With strain relief 12 200925 PG 11 ZK With strain relief and cable support 12 200918 PG 13.5 G Conduits for mounting of cable glands (Inner thread) 6 200963 PG 13.5 V Cable gland complete 12 200932 PG 13.5 Z With strain relief 12 200956 PG 13.5 ZK With strain relief and cable support 12 200949Cover H2 (Haube MDR 2)Cover without On/Off lever (Neutral version without marking) 40 217510 H2-EA (HaubeMDR 2+EA)Cover with On/Off lever for manual On/Off (neutral version, without marking) 40229445Unloader valves / Delayed unloader valvesEV 2EV 2SAEV 2SEV 2W / EV 2WiAEV 2W / AEV 2WiEV 2WSAEV 2WSPressure switch MDR 2Page 3.10 Cable glands MDR 2WNPG .. GPG .. VPG .. ZPG .. ZKDimensions, Accessories MDR 2EV 2EV 2SAEV 2SEV 2W / EV 2Wi AEV 2W / AEV 2WiEV 2WS AEV 2WSPressure DiagramsPressure switch MDR 2。

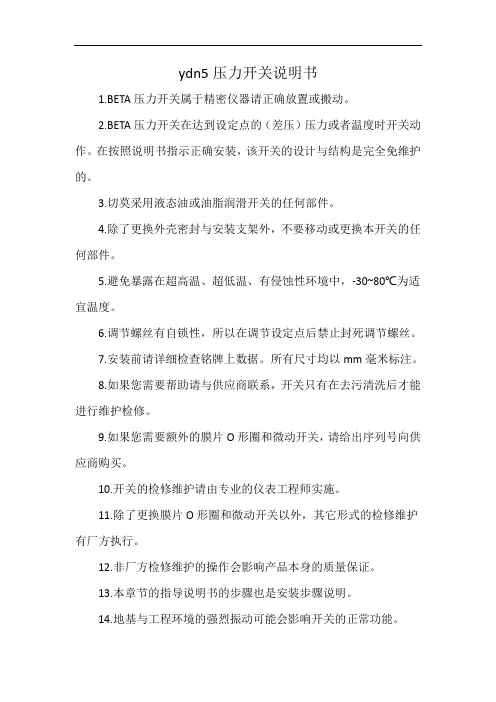

ydn5压力开关说明书

1.BETA压力开关属于精密仪器请正确放置或搬动。

2.BETA压力开关在达到设定点的(差压)压力或者温度时开关动作。

在按照说明书指示正确安装,该开关的设计与结构是完全免维护的。

3.切莫采用液态油或油脂润滑开关的任何部件。

4.除了更换外壳密封与安装支架外,不要移动或更换本开关的任何部件。

5.避免暴露在超高温、超低温、有侵蚀性环境中,-30~80℃为适宜温度。

6.调节螺丝有自锁性,所以在调节设定点后禁止封死调节螺丝。

7.安装前请详细检查铭牌上数据。

所有尺寸均以mm毫米标注。

8.如果您需要帮助请与供应商联系,开关只有在去污清洗后才能进行维护检修。

9.如果您需要额外的膜片O形圈和微动开关,请给出序列号向供应商购买。

10.开关的检修维护请由专业的仪表工程师实施。

11.除了更换膜片O形圈和微动开关以外,其它形式的检修维护有厂方执行。

12.非厂方检修维护的操作会影响产品本身的质量保证。

13.本章节的指导说明书的步骤也是安装步骤说明。

14.地基与工程环境的强烈振动可能会影响开关的正常功能。

221 Code Process R ange & Temp.(6) Vac 0-600 1000 2000- Material Limits in.H 2O psi psi 3000 °F psi B-Buna N 0 to 150 ● ● ● ● V-Viton 20 to 300 ● ● ● T-Teflon 0 to 150 ● ● ● ● S-SS (5)(10) 0 to 300 ● ● P -Monel (5)(10) 0 to 300 ● ● NOTES: 1. Standard switch. 2. D ual switches are 2 SPDT snap-action switches not independently adjustable. 3. Estimated dc rating, 2.5A, 28 Vdc (not UL listed). 4. Estimated dc rating, .4A, 120 Vdc (not UL listed). 5. Available on pressure only. 6. A mbient operating temperature limits –20 to 150°F , all styles. Setpoint shift of ±1% of range per 50°F is normal. Switch calibrated at 70°F reference. 7. Items are wetted by process fluid. 8. Refer to Option Table. 9. O rder Option XUD, stainless steel process connection.10. On differential switches, stainless steel is available in 15, 30, 60 and 90 psid ranges only. Includes Teflon O-ring and 316 SS connection. TO ORDER THIS B-SERIES PRESSURE SWITCH:Pressure and Differential Pressure Switches, Watertight Enclosure, Type 400, B-Series • C hoice of actuators, including designs for fire-safe and NACE applications (8)• Readily available • Standard pressure connection materials: Pressure psi ranges - 316L stainless steel Differential psid ranges- Nickel-plated brass (9) of water ranges - Epoxy coated carbon steel B4 - P ressure switch, type 400, watertightenclosure meets NEMA 3, 4, 4X and 13, IP66 requirementsD4 - D ifferential pressure switch, type 400,watertight enclosure meets NEMA 3, 4, 4X and 13, IP66 requirementsThis general purpose Ashcroft ® switch series is ideal for use in virtually all Industrial and OEM applications.• Watertight NEMA 4X enclosure, IP66• Choice of switch elements for all applications, including hermeti-cally sealed• Wide choice of wetted materials, including all-welded Monel or stainless steel• Fixed or limited adjustable deadband• Approved for UL, CSA and FM (8) ratings • Setpoints adjustable from 15-100% of range4 - OPTIONS (See pages 238-239)5 - STANDARD PRESSURE RANGES (See page 235) 3 - ACTUATOR SEAL (7) Order D escription/Maximum Electrical Ratings Code UL/CSA Listed SPDT 20(4) Narrow deadband 15A, 125/250 Vac 21(9) Ammonia service 5A, 125/250 VacHermetically sealed22(3) switch, narrow 5A, 125/250 Vac deadband 23 Heavy duty ac 20A,125/250 Vac15A,125/250/480 Vac 24(1)General purpose 1/2A, 125 Vdc 1/4A, 250 Vdc 25 Heavy duty dc 10A,125/ Vac or dc 1/8HP 125/ Vac or dc 26(4)Sealed environment 15A, 125/250 Vac proof 27 High temp. 300°F 15A, 125/250 Vac 28Manual reset trip 15A, 125/250 Vac on increasing 29 Manual reset trip 15A, 125/250 Vac on decreasing 31 Low level (gold) 1A,125/250 Vac contactsHermetically sealed32 switch, general 11A, 125/250 Vac purpose 5A, 30 Vdc50 Variable deadband 15A,125/250 Vac UL/CSA Listed Dual SPDT (2)We recommend hermetically sealed switch elements for improved reliability. The hermetically sealed switch provides uncompromising contact protection in harsh or corrosive environments. The Ashcroft 400 Series is also approved for installation in Division II hazardous areas when supplied with hermetically sealed contacts.L-recognized component, LOOK FOR THIS AGENCY MARK ON OUR PRODUCTS。

OildynePressure SwitchesFor AC Power3.4-345 bar (50-5000 psi) Range43Typical ApplicationsPressure switches sense when a pre-selected fluid pressure is reached or lost and make or break an electrical circuit. Their operation can stop or start a machine’s cycle, actuate indicator lights or sequential operations. Properly installed, their operation is auto-matic and limited by your imagination and need.• Spring rangeDuplex models contain two separate switches which can be activated by one or two sensing ports depend-ing on the subplate configuration. See dimensional data for options.• environmentally resistantEnvironmentally resistant models are available on spe-cial order for certain hazardous location service.SubplatesSubplates are available for in-line mounting of Oildyne pressure switches. This allows further flexibility in mounting to existing equipment. Ports in 1/8 NPT or 7/16-20 (SAE-4) straight thread are standard. The duplex switch has two types of subplates, one with a port for each side of the switch, the other with one port only, for both sides of the switch.Pressure Switch Features• VersatileOur designs allow the switches to be used in any mounting orientation. They can sense hydraulic fluid pressure or air/gas pressure. A simple spring change allows the same basic switch to be used through a wide range of pressure settings.• durableHeavy-duty electrical contacts are rated for 15 amps at 125, 250 or 460 VAC. Normally open and normally closed contacts are provided.• reliableRepeatability is accomplished through a combination of a PTFE seal and a hardened, nickel-plated steel piston. This use of low-friction materials and the de-sign of the unique PTFE seal (or diaphragm*) prevents the piston from sticking. Repeatability, sensitivity and reliability are excellent. Limited piston movement pre-vents inertial forces from damaging the piston stop.*Used for lower pressure differential applications.Single Switchduplex Switchtriplex SwitchPRESSURE SETTING EASYMAKES CHANGINGADJUSTING SCREW LEAK PROOF OPERATION O-RING SEAL FOR1/2" PIPE CONDUIT CONNECTIONALL ALUMINUM CONSTRUCTIONELECTRICAL CONNECTIONSFOR ACCESS TOEASILY REMOVED COVER AND NORMALLY CLOSED CONTACTSSWITCH WITH NORMALLY OPEN HEAVY DUTY ELECTRICALAND ZERO LEAKAGE MINIMUM FRICTION PTFE SEALS FOR SPRINGDRAIN LINES NEEDEDSEALED PISTON, NO DISC OR DIAPHRAGMSINTERED METAL STAINLESS STEEL construction44Catalog HY22-1121/USfeatures and applications Pressure SwitchesParker Hannifin Corporation Oildyne DivisionMinneapolis, MN 55428 USA45DimensionsSingle Pressure SwitchSubplates (Single & duplex)Catalog HY22-1121/USdimensions Pressure SwitchesParker Hannifin Corporation Oildyne DivisionMinneapolis, MN 55428 USA46DifferentialThis is the pressure required to open and close theswitch contacts. It is a constant value dependent on the characteristics of the switch. The differential will be in the range as shown on the above table. For minimum differential, select the lightest spring including the maxi-mum setting desired.Spring Selection GuideSingle SwitchPK-01B Subplate (1/8” Pipe)PK-50B Subplate (SAE-4 Str. Thd.)duplex SwitchPK-01C Subplate (1/8” Pipe) Two PortsPK-50C Subplate (SAE-4 Str. Thd.)Two Ports PK-01D Subplate (1/8” Pipe) One Port PK-50D Subplate (SAE-4 Str. Thd.)One Porttriplex Specify Subplate PK-50H (SAE-4Str. Thd.) and Three Single SwitchSpecifications from Chart at Left.Standard Product Ordering CodeCatalog HY22-1121/UStechnical Information Pressure Switchesnote: 100 psi = 6.9 bar.Parker Hannifin Corporation Oildyne DivisionMinneapolis, MN 55428 USASpring numberSpring range adjustment range repeatability Plus or Minusdifferential range Spring color 150 - 100 psi 50 to 100 psi 2 psi 50 to 90 psi Green 2100 - 300 psi 75 to 300 psi 4 psi 50 to 100 psi Black 3300 - 500 psi 150 to 500 psi 5 psi 50 to 125 psi Red 4500 - 1000 psi 200 to 1000 psi 8 psi 50 to 150 psi Blue 51000 - 2000 psi 300 to 2000 psi 15 psi 75 to 250 psi White 62000 - 3000 psi 400 to 3000 psi 20 psi 75 to 250 psi Yellow 73000 - 4000 psi 500 to 4000 psi 25 psi 125 to 350 psi Orange 84000 - 5000 psi500 to 5000 psi50 psi150 to 450 psiPink。

Instruction ManualHigh Precision Digital Pressure SwitchThe intended use of this digital pressure switch is to measure, monitorand display pressure and to provide an output signal.These safety instructions are intended to prevent hazardous situationsand/or equipment damage. These instructions indicate the level ofpotential hazard with the labels of “Caution,” “Warning” or “Danger.”They are all important notes for safety and must be followed in additionto International Standards (ISO/IEC) *1), and other safety regulations.*1) ISO 4414: Pneumatic fluid power - General rules relating to systems.ISO 4413: Hydraulic fluid power - General rules relating to systems.IEC 60204-1: Safety of machinery - Electrical equipment of machines.(Part 1: General requirements)ISO 10218-1: Robots and robotic devices - Safety requirements forindustrial robots - Part 1: Robots.•Refer to product catalogue, Operation Manual and HandlingPrecautions for SMC Products for additional information.• Keep this manual in a safe place for future reference.Caution Caution indicates a hazard with a low level of risk which, ifnot avoided, could result in minor or moderate injury.Warning Warning indicates a hazard with a medium level of riskwhich, if not avoided, could result in death or serious injury.Danger Danger indicates a hazard with a high level of risk which, ifnot avoided, will result in death or serious injury.Warning•Always ensure compliance with relevant safety laws andstandards.•All work must be carried out in a safe manner by a qualified person incompliance with applicable national regulations.•This product is class A equipment intended for use in an industrialenvironment. There may be potential difficulties in ensuringelectromagnetic compatibility in other environments due to conductedor radiated disturbances.Otherwise electric shock, malfunction or product damage can result.•Refer to the operation manual on the SMC website (URL:https://) for more safety instructions.2 Specifications2.1 General specifications∗1: Value without digital filter (at 0 ms).∗2: If the applied pressure fluctuates around the set value, the hysteresis must beset to a value more than the amount of fluctuation or chattering will occur.∗3: This setting is only available for models with the units selection function. OnlyMPa or kPa is available for models without this function.∗4: The response time indicates when the set value is 90% in relation to the stepinput.2.2 Piping / Weight specificationsProduct No. M5 01 N01 C4H C6H N7H C4L C6L N7LPort size M5 x0.8 R1/8NPT1/8φ4 mmφ5/32inchφ6mmφ1/4inchφ4 mmφ5/32inchφ6mmφ1/4inchMaterialsinfluidcontactPressure-sensing part SiliconPiping port(Common) PBT, CB156, heat resistant PPS, O-ring: HNBRPiping port -C3604(electrolessnickelplating),SUS304,NBRPOM, SUS304, NBR, C3604Weight Body [g] 22 32 34 25 26 27 28 28 34Lead wire +connector +35 g2.3 Cable specificationsConductor area 0.15 mm2 (AWG26)Insulator outside diameter 1.0 mmColour Brown, Blue, Black (3 core)Sheath outside diameter φ3.4WarningSpecial products (-X) might have specifications different from thoseshown in this section. Contact SMC for specific drawings.3 Name and function of product partsOperation light: Displays the switch operating condition.LCD display: Displays the current status of pressure, setting mode,selected display units and error code.4 types of display can be selected for the main display:Single colour of constant red or green; or switching fromred to green or green to red corresponding to the output.The indication for the sub display is orange.SET button: Press this button to change mode and to confirmsettings.Unit display: Indicates the units currently selected (only for kPa andMPa).4 Installation4.1 InstallationWarningDo not install the product unless the safety instructions have been readand understood.4.1.1 Mounting•Mount the optional bracket and panel mount adapter to the pressureswitch.4.1.2 Mounting with bracket•Mount the bracket to the body with mounting screws (Self tappingscrews: Nominal size 3 x 8L (2 pcs)), then set the body to thespecified position.∗: Tighten the bracket mounting screws to a torque of 0.5 ±0.05 N•m.Self-tapping screws are used and should not be re-used several times.•Bracket A (Part No.: ZS-46-A1)•Bracket B (Part No.: ZS-46-A2)4.1.3 Mounting with panel mount adapter•Mount part (a) to the front of the body and fix it. Then insert the bodywith (a) into the panel until (a) comes into contact with the panel frontsurface. Next, mount part (b) to the body from the rear and insert ituntil (b) comes into contact with the panel.•Panel mount adapter (Part No.: ZS-46-B)∗: The panel mount adapter can be rotated through 90 degrees for mounting.ORIGINAL INSTRUCTIONSProduct No.ZSE20(Vacuumpressure)ZSE20F(Compoundpressure)ISE20(Positivepressure)Applicable fluid Air, non-corrosive and non-flammable gasPressureRated pressure range 0.0 to-101.0 kPa-100.0 to100.0 kPa-0.100 to1.000 MPaDisplay / Set pressurerange10.0 to-105.0 kPa-105.0 to105.0 kPa-0.105 to1.050 MPaDisplay / Min. settingunit 0.1 kPa 0.001 MPaProof pressure 500 kPa 1.5 MPaPowersupply Power supply voltage 12 to 24 VDC (±10%), ripple max. 10% (p-p)Current consumption 25 mA or lessProtection Polarity protectionAccuracy Display accuracy±2% F.S. ±1 digit(at ambient temperature 25 ±3 o C)Repeatability ±0.2% F.S. ±1 digitTemperaturecharacteristics ±2% F.S. (25o C standard)SwitchoutputOutput type NPN or PNP open collector 1 outputOutput mode Hysteresis mode, window comparator mode, erroroutput, switch output offSwitch operation Normal output, reversed outputMaximum loadcurrent 80 mAMaximum appliedvoltage 28 V (NPN output)Internal voltage drop(Residual voltage) 1 V or less (Load current 80 mA)Delay time ∗11.5 ms or less (delay time for anti-chatter function:20,100,500,1000,2000, 5000 ms)Hysteresis Hysteresis modeVariable from 0 ∗2WindowcomparatormodeShort circuitprotection ProvidedDisplayUnit ∗3MPa, kPa, kgf/cm2, bar, psi,InHg, mmHgMPa, kPa,kgf/cm2, bar,psiDisplay type LCDNumber of displays 3-screen display (Main display, sub display x 2)Display colour Main display: Red/GreenSub display: OrangeNumber of displaydigitsMain display: 4 digits (7-segments)Sub display: 4 digits (Upper 1 digit 11-segments,7-segments for others)Operation light LED is ON when switch output is ON(OUT1: Orange)Digital filter ∗40, 10, 50, 100, 500, 1000, 5000 msEnvironmentEnclosure IP40Withstand voltage 1000 VAC for 1 minute between terminals andhousingInsulation resistance 50 MΩ or more between terminals and housing(with 50 VDC megger)Ambient temperaturerangeOperation: -5 to 50 o C, Storage: -10 to 60 o C(no condensation or freezing)Operating humidityrangeOperation, Storage: 35 to 85%RH(no condensation)Length of lead wire withconnector 2 m4.2 EnvironmentWarning•Do not use in an environment where corrosive gases, chemicals, salt water or steam are present.•Do not use in an explosive atmosphere.•Do not expose to direct sunlight. Use a suitable protective cover. •Do not install in a location subject to vibration or impact. Check the product specifications.•Do not mount in a location exposed to radiant heat.4.3 PipingCaution•Before piping make sure to clean up chips, cutting oil, dust etc. •When installing piping or fittings, ensure sealant material does not enter inside the port. When using seal tape, leave 1 thread exposed on the end of the pipe/fitting.•Tighten fittings to the specified tightening torque.4.3.1 Tightening the connection thread•For connecting to the body (piping specification: -M5)After hand tightening, apply a spanner of the correct size to the spanner flats of the piping body, and tighten with a 1/6 to 1/4 rotation. As a reference, the tightening torque is 1 to 1.5 N•m.(When replacing the piping adapter ZS-46-N#, tighten it using the same method).•Piping specification: -01, -N01After hand tightening, hold the hexagonal spanner flats of the pressure port with a spanner, and tighten with 2 to 3 rotations.As a reference, the tightening torque is 3 to 5 N•m.Piping specification: -C4H, -C6H, -N7H, -C4L, -C6L, -N7LFirst, tighten by hand, then use a wrench appropriate for the hexagonflats of the body to tighten an additional 1/6 to 1/4 turn.As a reference, the tightening torque is 1 to 1.5 N•m.When tightening, do not hold the pressure switch body with a spanner.4.3.2 Wiring connections•Connections should be made with the power supply turned off.•Use a separate route for the product wiring and any power or highvoltage wiring. Otherwise, malfunction may result due to noise.•If a commercially available switching power supply is used, be sure toground the frame ground (FG) terminal. If the switching power supply isconnected for use, switching noise will be superimposed and it will notbe able to meet the product specifications. In that case, insert a noisefilter such as a line noise filter/ferrite between the switching powersupplies or change the switching power supply to a series powersupply.4.3.3 How to use connectorConnector attachment / detachment•When connecting the connector, insert it straight onto the pins, holdingthe lever and connector body, and lock the connector by pushing thelever hook into the concave groove on the housing.•To detach the connector, remove the hook from the groove by pressingthe lever downward, and pull the connector straight out.Connector pin numbers4.4 LubricationCaution•SMC products have been lubricated for life at manufacture, and donot require lubrication in service.•If a lubricant is used in the system, use turbine oil Class 1 (noadditive), ISO VG32. Once lubricant is used in the system, lubricationmust be continued because the original lubricant applied duringmanufacturing will be washed away.Power is supplied.The product code is displayedfor approximately 3 sec. after supplying power.∗: Within approximately 0.2 second after power-on, the switch starts.5.1 Default Pressure settingWhen the pressure exceeds the set value, the switch will turn on. Whenthe pressure falls below the set value by the amount of hysteresis ormore, the switch will turn off. The default setting is to turn on thepressure switch when the pressure reaches the center of theatmospheric pressure and upper limit of the rated pressure range. If thiscondition, shown to the below, is acceptable, then keep these settings.[3 step setting mode (hysteresis mode)]In the 3 step setting mode, the set value (P_1 or n_1, P_2 or n_2) andhysteresis (H_1 or H_2) can bethe set value, follow the operation below. The hysteresis setting can beon the sub display.The set value on the sub display (right) will start flashing.simultaneously for 1 second or longer, the set value is displayed as [- - -],and the set value will be the same as the current pressure valueThe Pressure switch turns on within a set pressure range (from P1L toP1H) during window comparator mode.Set P1L, the lower limit of the switch operation, and P1H, the upper limitof the switch operation and WH1 (hysteresis) following the instructionsgiven above. (When reversed output is selected, the sub display (left)shows [n1L] and [n1H].)∗: Set OUT2 in the same way. (ex. P_2, H_2)Setting of the normal/reverse output switching and hysteresis/window comparatormode switching are performed with the function selection mode [F 1] Setting ofOUT1 or [F 2] Setting of OUT2.7 Simple Setting mode(1) button between 1 and 3 seconds inmeasurement mode. [SEt] is displayed on the main display. When thebutton is released while in the [SEt] display, the current pressure valueis displayed on the main display, [P_1] or [n_1] is displayed on the subdisplay (left), and the set value is displayed on the sub display (right)(Flashing).button to set the value. Then, the setting moves to hysteresis setting.(The snap shot function can be used).button to set the value. Then, the setting moves to the delay time of theswitch output. (The snap shot function can be used).Delay time setting can prevent the output from chattering.The delay time can be set in the range 0.00 to 60.00 sec. in 0.01 sec.increments.button for 2 seconds or longer to complete the setting.(If the button is pressed for less than 2 seconds, the setting will move tothe OUT2 setting).In the window comparator mode, set P1L, the lower limit of the switchoperation, and P1H, the upper limit of the switch operation, WH1(hysteresis) and dt1 (delay time) following the instructions above.(When reversed output is selected, the sub display (left) shows [n1L]and [n1H]). ∗: Set OUT2 in the same way.button between 3 and 5 seconds,display the function to be changed [F□□].button for 2 seconds or longer in functionselection mode to return to measurement mode.∗:Some products do not have all the functions. If no function is available orselected due to configuration of other functions, [- - -] is displayed on the subdisplay (right).8.1 Default Function settingsThe default setting is as follows.If no problem is caused by this setting, keep these settings.•[F 0] Display units, switch output specifications and diagnosticinformation selection function.Units specification Pressure range Default setting"Nil" or MISE20 MPaZSE20(F) kPaPISE20psiZSE20(F)•[F 1] Setting of OUT1Item Default settingOutput mode Hysteresis modeReversed output Normal outputPressure settingISE20 : 0.500 MPaZSE20 : -50.5 kPaZSE20F : 50.0 kPaHysteresisISE20 : 0.050 MPaZSE20 : 5.1 kPaZSE20F : 5.0 kPaDelay time 1.5 msecDisplay colour OUT1 ON: Green / OUT1 OFF: Red•[F 2] Setting of OUT2 is the same setting as [F 1] OUT1.•Other parameter settingsItem Default setting[F 3] Digital filter setting 0.00 s[F 4] Auto-preset function Not used[F 6] Fine adjustment of display value 0%[F10] Sub display setting std (Standard)[F11] Display resolution setting 1000-split[F80] Power saving mode OFF[F81] Security code OFF[F82] Input of line name AAAA[F90] Setting of all functions OFF[F98] Output check N/A (normal output)[F99] Reset to default settings OFF•Snap shot functionThe current pressure value can be stored to the switch output ON/OFFset point.•Peak/bottom value indicationThe maximum (minimum) pressure when the power is supplied isdetected and updated.•Zero clear functionThe displayed value can be adjusted to zero if the measured pressureis within ±7%F.S (±3.5%F.S. for compound pressure) of the zero point•Key-lock functionThe key-lock function is used to prevent errors occurring due tounintentional changes of the set values.For further details refer to the operation manual on the SMC website(URL: https://).10 How to OrderRefer to the operation manual on the SMC website (URL:https://) for How to order information.11 Outline DimensionsRefer to the operation manual or catalogue on the SMC website (URL:https://) for Outline Dimensions.12 Maintenance12.1 General MaintenanceCaution•Not following proper maintenance procedures could cause theproduct to malfunction and lead to equipment damage.•If handled improperly, compressed air can be dangerous.•Maintenance of pneumatic systems should be performed only byqualified personnel.•Before performing maintenance, turn off the power supply and besure to cut off the supply pressure. Confirm that the air is released toatmosphere.•After installation and maintenance, apply operating pressure andpower to the equipment and perform appropriate functional andleakage tests to make sure the equipment is installed correctly.•If any electrical connections are disturbed during maintenance,ensure they are reconnected correctly and safety checks are carriedout as required to ensure continued compliance with applicablenational regulations.•Do not make any modification to the product.•Do not disassemble the product, unless required by installation ormaintenance instructions.13 Limitations of Use13.1 Limited warranty and Disclaimer/Compliance RequirementsRefer to Handling Precautions for SMC Products.Caution•SMC products are not intended for use as instruments for legalmetrology.Measurement instruments that SMC manufactures or sells have notbeen qualified by type approval tests relevant to the metrology(measurement) laws of each country.Therefore, SMC products cannot be used for business or certificationordained by the metrology (measurement) laws of each country.This product shall not be disposed of as municipal waste. Check yourlocal regulations and guidelines to dispose of this product correctly, inorder to reduce the impact on human health and the environment.15 ContactsRefer to or www.smc.eu for your local distributor /importer.URL: https:// (Global) https://www.smc.eu (Europe)SMC Corporation, 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021, JapanSpecifications are subject to change without prior notice from the manufacturer.© 2021 SMC Corporation All Rights Reserved.Template DKP50047-F-085M。

DG型气体压力开关

使用说明书

●请阅读和保持一个安全的地方

解释符号

●, 1, 2, 3 ... = 功能

➔ = 用法说明

所有工作必须在阅读操作说明后才能进行!

警告!不正确的安装、调整、修改、操作或维护可能导致伤害或物质损失。

使用前先阅读说明书。

这个单位必须安装依照本条例的实施。

标准声明

We, the manufacturer, hereby declare that the products DG.., marked with product ID No. CE 0085AP0467, comply with the essential requirements of the following Directives:

– 90/396/EEC in conjunction with EN 1854,

– 73/23/EEC in conjunction with the relevant standards.

The relevant products correspond to the type tested by the notified body 0085. Comprehensive quality assurance is guaranteed by a certified Quality System pursuant to DIN EN ISO 9001 according to annex II, para-graph 3 of Directive 90/396/EEC.Elster Kromschröder GmbH, Osnabrück

测试

➔电源电压、环境温度和外壳——看类型的标签。

➔最大介质温度:-15 + 80°C。

在系统暴露于更高的热应力、热设备上时压力开关必须安装在上游。

DG..B型

➔正压时1号位置为进气

DG..U型, DG..H型, DG..N型

➔正压时1号或者2号位置为进气,气体为空气、天然气或者烟气(其他位置密封),通风时气体从3号或者4号位置离开。

➔负压时3号或者4号位置为进气,气体为空气、天然气或者烟气(其他位置密封),通风时气体从1号或者2号位置离开。

➔对于压差时,用1号或2号和3号或4号,气体为空气、天然气或者烟气,其他位置密封。

➔在连接3号和4号位置时使用过滤垫,防止气体中的杂质弄脏电触点。

➔ DG..B, DG..U switch with rising pressure.

➔ DG..H switches and locks off with rising pressure – with manual reset.

➔ DG..N switches and locks off with falling pressure – with manual reset.

➔ Fit an upstream restrictor if the system is subject to greatly fl uctuating pressures (see acces-

sories).

➔ The service life will be shorter if subject to ozone concentrations exceeding 200 µg/m3.

Installation

➔Fitting position as required, pref-erably with diaphragm vertical, with unobstructed view of the adjustment dial. Ensure that no dirt or moisture can penetrate open ventilation ports.

➔ The housing may not contact masonry. Minimum clearance 20 mm.

➔ Avoid subjecting the DG to strong or violent vibrations.

➔ Condensation must not be allowed to get into the housing. At subzero temperatures malfunctions/failures due to icing can occur.

➔ When using silicone tubes, only use silicone tubes which have been suffi ciently cured.

➔ Continuous operation at high temperatures accelerates the ageing of elastomer materials.

➔ Protect from direct sunlight (even with IP 65).

DG..B..S

➔ Do not connect gas but only O2 or NH3 to the positive pressure port 1.Ensure that no grease is used during installation.

DG

1 Flush the pipework.

2 Use suitable sealing material.

3 If dirt can accumulate at port

3 or 4, use the fi lter, Order No. 74916199.

4 Fit the DG.

Tightness test

Adjusting the switching pressure ps

1Disconnect the system from the electrical power supply.

Wiring

DG

➔ 24–250 V AC:

I = 0.05–5 A, cos ϕ = 1,

I = 0.05–1 A, cos ϕ = 0.6;

DG..G

➔ 12–250 V AC:

I = 0.01–5 A, cos ϕ = 1,

I = 0.01–1 A, cos ϕ = 0.6;

12–48 V DC:

I = 0.1–1 A.

➔ If the DG..G has switched a voltage > 24 V and a current > 0.1 A once, the gold plating on the contacts will have been burnt through. It can then only be operated at this power rating or higher power rating.

➔ Contacts 3 and 2 close when subject to increasing pressure. Contacts 1 and 3 close when subject to falling pressure.

1Disconnect the system from the electrical power supply.

2 3 4

5。