海尔(百德龙)XQB45-149洗衣机中文维修手册

- 格式:doc

- 大小:11.28 MB

- 文档页数:19

海尔家电无忧恢复系统用户手册名目软件使用许可协议 (3)1海尔无忧复原系统简介 (5)1.1 产品介绍 (5)1.2 运行环境 (5)1.3 安装和卸载 (5)1.3.1 软件安装 (5)1.3.2 程序卸载 (6)2使用入门 (7)2.1 软件激活 (7)2.2 系统启动 (8)2.3 功能介绍 (11)3Windows操纵台功能使用说明 (12)3.1 系统备份/复原 (12)3.1.1 系统备份 (12)3.1.2 系统复原 (14)3.2 驱动备份/复原 (17)3.2.1 驱动备份 (17)3.2.2 驱动复原 (19)3.5 系统杀毒 (21)4Linux操纵台 (22)4.1 系统复原 (22)4.2 数据挽救 (24)4.3 硬件信息 (26)4.4 系统杀毒 (26)5附录 (28)5.1 常见问题解答 (28)5.2 关心主题 (28)5.3 技术支持信息 (28)软件使用许可协议重要内容:感谢您购买海成信息技术的软件产品〔以下间称〝本软件〞或〝软件〞〕,请务必认真阅读和明白得〝本软件〞«协议»中规定的所有权益和限制。

本«协议»是您与海成信息技术之间有关附随〝软件〞的法律协议。

〝本软件〞包括附随的运算机软件,并可能包括印刷或其他形式的相关文档资料、材料。

您一旦单击〝我同意〞按钮,即表示您同意同意本«协议»各项条款的约束。

如您不同意本«协议»中的条款,您那么不要单击〝我同意〞按钮、安装或使用〝本软件〞。

假如没有专门声明,〝本软件〞或〝软件〞应包括运算机软件,并包括〔假如有的话〕相关媒体、印刷资料、电子文档,还包括提供给您的与本软件相关的任何更新或补充资料。

〝本软件〞版权〔包括但不限于:〝本软件〞所含或可能包含的任何程序、图象、照片、录音、录像、文字和其它内容〕归海尔或它的合法所有人享有,受著作权法及国际著作权条约和其它知识产权法、条约的爱护。

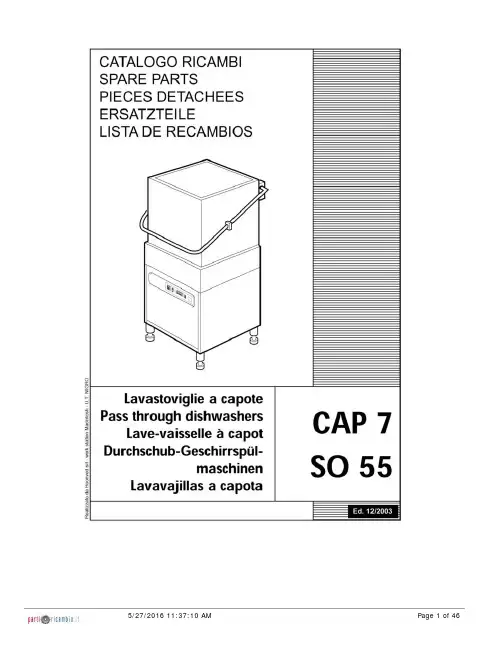

CAP 7 02/2004 ->>1Hood2Tank3Tank 03/06 >>4Rinse Assembly5Rinse Assembly 06/2007->>5Wash Arm6Control Box >> 06/057Control Box 07/05 ->>8Thermostats - Rack Support Guide -tank Filter >>06/059Thermostats - Rack Support Guide -tank Filter 07/05 >>10Rinse Aid Injector11Drain PumpCode Description190149BLOCCHETTO PERNO MANIGL.C25717SCREW PARTIAL FIL. 6X45 SS25730SCREW HEX.HD M 8 X 2525746SPACER, FLAT, DIAM.6/1825747SPACER, FLAT, DIAM. 825792SELF-LOCKING NUT 6 MA LOWER SIDE 25793SELF-LOCKING NUT 8 MA LOWER SIDE 26730SCREW TE M 8 X 20330239TIRANTE x MOLLE M8 L=285 mm. 331037MANIGLIONE CAP-C/LC ANNO 2001 33344CABLE CLIP 5030 STEAB33364STIFFENING PLATE FOR PLASTIC FOOT 33405REAR GUARD, C85-C155-7533406HOOD GUIDE "C95/C155/165"33408NEOPREN ADHESIVE GASKET 8 X 4 33409GASKET GUIDE "C"33410CHEESE-HD SCREW 6X35 SSA2 UNI 6107 33414REAR FRAME C95-C15533415HOUSING "C95/C155"33416HOUSING BODY ASSY, LC 380 NEW 33417REAR EXT. PANEL LC 38033435MICROSW.WITH LEVER FD503 LONG C75 33436SPACER WASHER ALGOFLON 18X8,5X1 33437BUSHING "NYLINER"33438BUSHING HANDLE C75-C140-C15533439FLANGE X BUSHING HANDLE C70-C155 33440SOCKET HD.DOWELS A2 6x8 UNI 5929 33443HANDLE C95-C155 ED65033444PIN FOR HANDLE"C85/C165"33446WIRE ROLLING HANDLE33448ROLLER ROLLING HANDLE 22X31,5 33519BUSH, SPRING HOLDER "C"-"G"33521THREADED SS BAR M8 L=200 mm. 33522SPRING FOR HANDLE "C"-"G"33532PLASTIC FOOT HOLDER33534FOOT, COMENDA, 30 MM34046NYLON ROIPE, DRAWER LIMIT STOP 341527CAPOT DOPPIA PARETE36421FRONT CONTROL PANEL CAP 7390164PANNELLO POSTER.ED 650/LC380/1160121TUBO GOMMA NERA 5X9 PRESSOST. 160301PILETTA SCARICO 1 1/2"161303TRAPPOLA ARIA LAVABICC.180109CONTRODADO DA 1 1/2" PLAST.200410GUAR.NEOP.11/2"D.65X47X325266FLAT GASKET 18 X 10 X 225746SPACER, FLAT, DIAM.6/1825747SPACER, FLAT, DIAM. 825751SPACER. SPLITTED, DIAM. 825776NUTS 8 MA SS 18/825783NUT 10 MA25792SELF-LOCKING NUT 6 MA LOWER SIDE 25808HOSE CLIP 27-51CLAM25810HOSE CLIP 55-7026966HOLE CLOSING PLUG27110DRAIN HOSE DIAM.33X150027155PLASTIC NUT10 M28218ISOLATOR 2 PINS 6 MA29562CENTRIF.WASH P. HP 1,2 400V32130HOSE CLIP 60-8033339HEAT.ELEM.3000W 230/400V(110227) 33358LOCK NUT 1/2" ES.30 SP.7"SS"33450THREADED NUT 65,4 C140 C85-C155 33451SUCTION ELBOW C85-14033452PROTECT.DISC PUMP SUCT. C85-C155 33454SUCTION HOSE C140/C11033455SLEEVE PRESSURE SIDE33456GASKET D.92X66X233459FILTER D.185 SNL C14033524ELBOW 1"1/2, DRAIN N-S-F-C33526NUT 1"1/2, ELBOW F45-C7533528OVERFLOW TUBE H189 C85-14033530DRAIN GASKET 1"1/2 45X33X333839MECH. SEAL PR/AR 13 BEFF33840S MECH. SEAL PR/AR 12 BPFF33845NUT M8, RIGHT H=5 MM33848PUMP HOUS.ZF650 RIGHT A60/M50 HOSE 33855GASKET OR. 158.34*3.5333856IMPELLER DIAM.105 6 ARMS M8 RIGHT 34057UPPER PLATE, PUMP ED 650 E34173CAPACITOR UF 1634363ELECT.WASH PUMP 1,2HP 440V3 60HZ 34484IMPELLER 120 6-BLADE, RIGHT ZF 800 34800WASH PUMP LGB HP1 230V1/55035324ELECTR.PUMP LGB HP1 230V1 60HZ35416TURNED IMPELLER 90mm/0120 LGB 35837 B.THERMOSTAT WITH MAN. RESET 68? 35913THERM. SUPP. PLATE- MANUAL RESET 37159CAVAL.FIS.RES.V.C81/90/98/CAP7 450134FASCETTA A FILO X TUB. 9,3-8,8 450516GUAINA TERM. 2 TUBI INOX H=109 460502GUARNIZ. 30X21X2 KLINGER 1/2"160121TUBO GOMMA NERA 5X9 PRESSOST. 160301PILETTA SCARICO 1 1/2"161303TRAPPOLA ARIA LAVABICC.180109CONTRODADO DA 1 1/2" PLAST.200410GUAR.NEOP.11/2"D.65X47X325266FLAT GASKET 18 X 10 X 225746SPACER, FLAT, DIAM.6/1825747SPACER, FLAT, DIAM. 825751SPACER. SPLITTED, DIAM. 825776NUTS 8 MA SS 18/825783NUT 10 MA25792SELF-LOCKING NUT 6 MA LOWER SIDE 25808HOSE CLIP 27-51CLAM25810HOSE CLIP 55-7026966HOLE CLOSING PLUG27110DRAIN HOSE DIAM.33X150027155PLASTIC NUT10 M28218ISOLATOR 2 PINS 6 MA29562CENTRIF.WASH P. HP 1,2 400V32130HOSE CLIP 60-8033339HEAT.ELEM.3000W 230/400V(110227) 33358LOCK NUT 1/2" ES.30 SP.7"SS"33450THREADED NUT 65,4 C140 C85-C155 33451SUCTION ELBOW C85-14033452PROTECT.DISC PUMP SUCT. C85-C155 33454SUCTION HOSE C140/C11033455SLEEVE PRESSURE SIDE33456GASKET D.92X66X233459FILTER D.185 SNL C14033524ELBOW 1"1/2, DRAIN N-S-F-C33526NUT 1"1/2, ELBOW F45-C7533528OVERFLOW TUBE H189 C85-14033530DRAIN GASKET 1"1/2 45X33X333839MECH. SEAL PR/AR 13 BEFF33840S MECH. SEAL PR/AR 12 BPFF33845NUT M8, RIGHT H=5 MM33848PUMP HOUS.ZF650 RIGHT A60/M50 HOSE 33855GASKET OR. 158.34*3.5333856IMPELLER DIAM.105 6 ARMS M8 RIGHT 34057UPPER PLATE, PUMP ED 650 E34173CAPACITOR UF 1634363ELECT.WASH PUMP 1,2HP 440V3 60HZ 34484IMPELLER 120 6-BLADE, RIGHT ZF 800 34800WASH PUMP LGB HP1 230V1/55035324ELECTR.PUMP LGB HP1 230V1 60HZ35416TURNED IMPELLER 90mm/0120 LGB 36348TERMOST.B.RIARMO MAN99?C-210?F 36351PIASTRA SUPP.TERM.RIAR.MAN.301 37159CAVAL.FIS.RES.V.C81/90/98/CAP7 450134FASCETTA A FILO X TUB. 9,3-8,8 450516GUAINA TERM. 2 TUBI INOX H=109 460502GUARNIZ. 30X21X2 KLINGER 1/2"Code Description00182HOSE 11X19 CASER/15"BLUE"180408PORTAG.T DOSAT.ATT.CENTR.RID.200117TUBO GOMMA 8x15 CALORFORM/1025700SCREW CHEESE-H. 4 X 8 KNURLED25745SPACER, FLAT, DIAM.625750SPACER, SPLITTED, DIAM. 625773NUTS 4 MA SS 18/825775NUT 6 MA25803HOSE CLIP 13-20 ABA26981FILTER X SOLENOID V.T/N28699CHEESE-HD SCREW TC 4 X 1030473GASKET, OR 11430933SOLENOID VALVE SING. 3/4"33276T-SHAPED CONNECTOR ?11,5-PART180413 33372GASKET 24X17X2 FASIT OMNIA33400HEAT.EL.FL.6000W 220/380V (110349) 33401COVER, HEATING ELEMENT H 50 (HIGH) 33402GASKET OR 6X56X6833403BOILER"F45/F80/C85/140"33424FE-ZN CLAMP 11-17 H=933430STANDARD SQ.BRACKET33453GASKET 60X54 REAR C14033460SHAFT ARM C95-155-16533461JUMPER, WASH RAMP ARMC140-C8533462REARWASH SUPPLY TUBE C14033470SUPP. LOWER W.ARM."C"WASH-L C110-14 33471SUPP.UPPER W.ARM."C"WASH-L.C110 NIC 33473FEEDING HOSE RINSE UPPER33474ELBOW RINSE33476FITTING FOR RINSE DELIV.M33477ELBOW FEM/FEM. 3/8 1/4 C140-15533502T SPLASHPROOF FOR ANTIVAC.VLV33505GASKET 30X21X2 KLINGER SIL33506ANTI-VACUUM VALVE "B-F-C"33540FITTING, RINSE DELIV. F33729HOSE, LOWER RINSE DELIVERY33803SPACE WASHER, GROWER DIAM.434133CONTROL QTY 14 LT.35388RINSE AID DISP."YELLOW" C/STS37330TUBO CARICO 10bar-90?-3/4"GCode Description00182HOSE 11X19 CASER/15"BLUE" 180408PORTAG.T DOSAT.ATT.CENTR.RID.Code Description190641BUSSOLA MULIN.RISC."C" V.S.Code Description200117TUBO GOMMA 8x15 CALORFORM/10 25700SCREW CHEESE-H. 4 X 8 KNURLED 25745SPACER, FLAT, DIAM.625750SPACER, SPLITTED, DIAM. 625773NUTS 4 MA SS 18/825775NUT 6 MA25803HOSE CLIP 13-20 ABACode Description261009VITE FISS. MULINELLO TUB.ACC.Code Description26981FILTER X SOLENOID V.T/N28699CHEESE-HD SCREW TC 4 X 1030473GASKET, OR 11430933SOLENOID VALVE SING. 3/4"33276T-SHAPED CONNECTOR ?11,5-PART180413 33372GASKET 24X17X2 FASIT OMNIA33400HEAT.EL.FL.6000W 220/380V (110349) 33401COVER, HEATING ELEMENT H 50 (HIGH) 33402GASKET OR 6X56X6833403BOILER"F45/F80/C85/140"33424FE-ZN CLAMP 11-17 H=933430STANDARD SQ.BRACKET33453GASKET 60X54 REAR C14033460SHAFT ARM C95-155-16533461JUMPER, WASH RAMP ARMC140-C8533462REARWASH SUPPLY TUBE C14033470SUPP. LOWER W.ARM."C"WASH-L C110-14 33471SUPP.UPPER W.ARM."C"WASH-L.C110 NIC 33473FEEDING HOSE RINSE UPPER33474ELBOW RINSE33476FITTING FOR RINSE DELIV.M33477ELBOW FEM/FEM. 3/8 1/4 C140-15533540FITTING, RINSE DELIV. F33729HOSE, LOWER RINSE DELIVERY33803SPACE WASHER, GROWER DIAM.434133CONTROL QTY 14 LT.Code Description34264RINSE JET WITH SPRING 34293JET LOCK SPRING34360GASKET OR 7 X 1 NBR 70Code Description35388RINSE AID DISP."YELLOW" C/STSCode Description35640SPACER WASHER, RINSE ARM, APS 60 35968BUSHING, TYPE H370 2023-2136006S.S.304 BUSHING, REVOLV.WASHARM 36011THRDD.BUSH FOR REV.WASHARM BUSH 36187BUSH TYPE H370 SM 2023-2036188STAIN.STEEL BUSH F. HOOD WASHARMCode Description37330TUBO CARICO 10bar-90?-3/4"GCode DescriptionVAG.INOX"Piatto"LC-CAP" 430344MULIN.RIS.INOX UGEL.PLAS.CAP10 450218MOLLA FISS.VITE MULIN.C95-155Code Description620535VALVOLA ANTIVUOTO "B-F-C"Code Description25432PRESSURE SWITCH RATED 60-4025697SELF-TAPPING SCREW CHEESE D747H.ROS 25752TOOTHED SPACER DIAM.4 D.E.25753TOOTHED SPACER.DIAM.5 D.E.25773NUTS 4 MA SS 18/825774NUTS 5 MA25776NUTS 8 MA SS 18/826236THERMOMETRE MT 228870PILOT LIGHT BULB -LUX FM6,3 230V. 28880NUT SCREW31324NOISE FILTER, TYPE 500131873REMOTE SWITCH 220-240V- B6-30-10 31982CONTACTOR CN9 - 220V 50 HZ32892NEON LIGHT BULB "GREEN" FL-T FM6,3 33344CABLE CLIP 5030 STEAB33348SUPPORT, ELECTR.PLANT33354ELECTRIC PLANT PROTECT.C140-7033357ADHESIVE GASKET 25X2,533745LIMITER 110? MANUAL RESET34265TANK PRESS.SWITCH BRACKET34312T.RELAY A2S FA 16A 230V34604COVER "ORANGE" PILOT LIGHT S.57.3 34605COVER "GREEN" PILOT LIGHT S.57.3 34622SWITCH ROLD CM 2-POLE. LINE34627PILOT LIGHT COVER "GREEN" TANK TEMP 34822TIMER CDC 4804 F1 120" 230V 4C36419KEYBOARD PROTECTION36421FRONT CONTROL PANEL CAP 736422CONTROL BOARD CAP 736439CONTROL BOARD SO 5536570STARTER FOR TIMER,M48 RAT-S230V x 3 450137ATTACCO A COLLARE C/BASE 31900Code Description121287TIMER ELT.UNI.SW UNITIMER 1.07150233MORS.TRIP.16MMQ 8WA1304150234MORS.UNIP.16MMQ 8WA120425432PRESSURE SWITCH RATED 60-4025697SELF-TAPPING SCREW CHEESE D747H.ROS 25715SCREW HEX.HD M 6 X 16 SS25746SPACER, FLAT, DIAM.6/1825752TOOTHED SPACER DIAM.4 D.E.25753TOOTHED SPACER.DIAM.5 D.E.25774NUTS 5 MA25775NUT 6 MA25776NUTS 8 MA SS 18/826236THERMOMETRE MT 228880NUT SCREW30006SPACER FOR PRINTED CIRC. HOLDER 31324NOISE FILTER, TYPE 500131873REMOTE SWITCH 220-240V- B6-30-10 31982CONTACTOR CN9 - 220V 50 HZ32892NEON LIGHT BULB "GREEN" FL-T FM6,3 33185LED BULB "GREEN"33187LED BULB "ORANGE"33344CABLE CLIP 5030 STEAB33348SUPPORT, ELECTR.PLANT33349INDICAT.PLATE, EARTHING33354ELECTRIC PLANT PROTECT.C140-7033357ADHESIVE GASKET 25X2,533745LIMITER 110? MANUAL RESET33891ROPE, ELECTR.PLANT LIMIT STOP34265TANK PRESS.SWITCH BRACKET34604COVER "ORANGE" PILOT LIGHT S.57.3 34605COVER "GREEN" PILOT LIGHT S.57.3 34622SWITCH ROLD CM 2-POLE. LINE34627PILOT LIGHT COVER "GREEN" TANK TEMP 36419KEYBOARD PROTECTION36421FRONT CONTROL PANEL CAP 736422CONTROL BOARD CAP 736439CONTROL BOARD SO 55450137ATTACCO A COLLARE C/BASE 31900 460287TARGHETTA X MORSETT.MONOFASECode Description191040MASCHERINA MANOPOLA TERMOSTATI 25417THERMOSTAT 30-90? MT. 225705SCREW HEX.HD M 5 X 16 SS 18/8 25746SPACER, FLAT, DIAM.6/1825753TOOTHED SPACER.DIAM.5 D.E.25774NUTS 5 MA331726SQUADRETTA 3 TERMOSTATI33365RIGHT SIDE CROSSBAR C140 COLB 33366LEFT SIDE CROSSBAR C140 COLB 33367FILTER SUPPORT CROSSBAR LC 380 33895PLAST. FILTER, TANK LEVEL, 650 E 36441RACK GUIDE IN ROUND BAR CAP 7 36465RACK GUIDE SPACER CAP7450315MANOPOLA TERMOSTATICode Description120525TERMOSTATO 2 TEMPER. IMIT TRZ 191040MASCHERINA MANOPOLA TERMOSTATI 25417THERMOSTAT 30-90? MT. 225705SCREW HEX.HD M 5 X 16 SS 18/8 25746SPACER, FLAT, DIAM.6/1825753TOOTHED SPACER.DIAM.5 D.E.25774NUTS 5 MA331726SQUADRETTA 3 TERMOSTATI33365RIGHT SIDE CROSSBAR C140 COLB 33366LEFT SIDE CROSSBAR C140 COLB 33367FILTER SUPPORT CROSSBAR LC 380 33895PLAST. FILTER, TANK LEVEL, 650 E 36441RACK GUIDE IN ROUND BAR CAP 7 36465RACK GUIDE SPACER CAP7450315MANOPOLA TERMOSTATICode Description00166ROLL TUBE TRANSP. 4X700182HOSE 11X19 CASER/15"BLUE"15229LOCK NUT AID DISPENSER18394SCREW CONTROL DISPENSER200117TUBO GOMMA 8x15 CALORFORM/1021679FILTER DET.-RINSE AID PREASS.25046UPPER DISPENSER ASSEMBLY25047LOWER DISPENSER ASSEMBLY25211NON RETURN VALVE RINSE AID DISP. 25251GASKET OR 201225757TOOTHED SPACER DIAM. 12 D.E.D787 25803HOSE CLIP 13-20 ABA25818CYLINDER SPRING (WIRE)28252FITTING SUCTION DISPENSER31596DIAPHRAGM, DISPENSER31643HOSE CLIP 7,3-7,831991SPRING GUIDE FOR DISPENSER32243GASKET OR 315632280OVAL HD. CROSS-SL. SCREW 4 X 1332831GASKET OR 206233424FE-ZN CLAMP 11-17 H=934124BRACKET, HOONVED DISPENSER35388RINSE AID DISP."YELLOW" C/STS 3539290? VALVE FITTING, RINSE AID H/C36204SINGLE COUNTERWEIGHT, DETERGENT HOSCode Description100342ELETTROP.SCAR.100W 220V 50Hz 25216DRAIN SLEEVE 50-52-T4(T5)25715SCREW HEX.HD M 6 X 16 SS25746SPACER, FLAT, DIAM.6/1825750SPACER, SPLITTED, DIAM. 625775NUT 6 MA25807HOSE CLIP 26-38 ABA33526NUT 1"1/2, ELBOW F45-C7533530DRAIN GASKET 1"1/2 45X33X3 34464SUPP.PLATE, DRAIN PUMP ED650 34465PIPE CONNECT. DRAIN PUMP ED650 36032DRAIN PIPE, DIA. 18,5X2500。

海尔洗衣机维修手册海尔洗衣机维修手册_图文导读:就爱阅读网友为您分享以下“海尔洗衣机维修手册_图文”的资讯,希望对您有所帮助,感谢您对的支持!7八、故障显示及自检8.1 维修注意事项故障诊断前,小心触电。

维修前应将电源插头拔掉;用手接触电脑板前,先接触接地,避免身体静电击穿电脑板原件。

变频型号要在8.2 自检程序进入方式:1同时按住“预约”按键和“强力洗”按键同时插电源插座上电进入自检模式,显示屏将会显示“tESt”与机器型号XXX交替显示,此时按下“启动”按钮,电脑板将执行检测台检测程序: 电机和噪音检测在显示“tESt”的情况下,按下速度键,显示区显示实时速度 a、顺时针10秒,50转 b、停10秒c、逆时针10秒,50转d、逆时针10秒,93转e、逆时针10秒,200转f、逆时针60秒,最高转g、显示End在测试完成之后显示End,按速度键将在电机停转之后重新开始测试程序;在自检运行过程中,将不接受任何按键8.3 型号选择进入方式:按额外漂洗键同时上电4秒之后,进入型号选择模式 A变频型号:1.默认显示区显示146b,按速度键在146b/126b/106b/96b/86b/145b/125b/105b/95b/85b之间循环2可调。

按温度按键存储设定值,之后断电即可。

2.电脑板未经修改之前默认为146b3.第一次型号按照从大到小选择146b/126b/106b/96b/86b/145b/125b/105b/95b/85b选择。

存储一次之后不可以再次更改 B非变频型号:1.默认显示区显示146,按速度键在 146/126/106/96/86/145/125/105/95/85之间可调。

按温度按键存储设定值,之后断电即可。

2.电脑板未经修改之前默认为1463.第一次型号按照从大到小选择146/126/106/96/86/145/125/105/95/85选择。

存储一次之后不可以再次更改8.4 故障显示及含义Err1:门锁异常Err2:排水异常Err3:温度传感器异常UNB:不平衡报警3九、故障诊断及处理89.1 非正常操作及其注意事项现象需确定的项电源插头是否脱落地区线路是否停电洗衣机不启动机门是否没关好(即显示Err1)是否按下电源按键,设定程序后是否按下启动/暂停键是否打开水龙头水压是否小于0.03MPa进水管是否弯折是否停水洗衣机不进水4机门是否关好洗衣机进水口过滤网是否堵塞是否已启动程序排水管的管口的高度是否在规定的80cm-100cm之间,低于80cm会出现此类现象洗衣机不排水洗衣机边进水边排水排水管是否弯曲、折叠、堵塞排水管管口高度是否高于地面100cm过滤器是否堵塞包装用固定螺栓是否已全部卸下脱水剧烈震动工作平面是否平整或底脚是否调平洗涤负载是否超出额定值是否突然停电或停水程序没结束就停止运是否处于暂停状态5行是否处于故障报警状态在洗涤过程中处于停是否停电或停水顿状态筒内有很多泡沫,分是否使用的是高泡洗衣机粉或手洗洗衣粉配器盒处有泡沫溢出是否洗涤剂过量甩干转速低后甩干时衣物分布不均匀增加了重新分布的次数(最多6次),间延长并根据最终不平衡状况自动调整转速,属正常现象是否洗涤的衣物太少,造成洗衣机偏心过大洗衣机不脱水是否洗涤的衣物打结、缠绕,分布不均匀6是否洗涤的是毛衣或吸水较多的衣物高转速机型串激电机,工作时转子与碳刷摩擦发出的声洗衣机脱水声音大音,这是正常现象注:在维修前请确认以上事项99.2 故障诊断及维修Err1检修方法:故障报警信息:门锁连续通电4次,每次间隔1秒,不能正常上锁;门锁连续通电4次,每次间隔1秒,不能正常解锁;门没有关闭到位,就启动程序。

洗衣机维修技术大全洗衣机工作原理洗衣机的洗涤过程主要是在机械产生的排渗、冲刷等机械作用和洗涤剂的润湿、分散作用下,将污垢拉入水中来实现洗净的目的。

首先充满于波轮叶片间的洗涤液,在离心力的作用下被高速甩向桶壁,并沿桶壁上升。

在波轮中心处,因甩出液体而形成低压区,又使得洗涤液流回波轮附近。

这样,在波轮附近形成了以波轮轴线为中心的涡流。

衣物在涡流的作用下,作螺旋式回转,吸入中心后又被甩向桶壁,与桶壁发生摩擦。

又由于波轮中心是低压区,衣物易被吸在波轮附近,不断地与波轮发生摩擦,如同人工揉搓衣物,污垢被迫脱离衣物。

其次,当衣物被放进洗涤液之后,由于惯性作用运动缓慢,在水流与衣物之间存在着速度差,使得两者发生相对运动,水流与衣物便发生相对摩擦,这种水流冲刷力同样有助于污垢离开衣物。

再次由于洗衣涌形状的不规则,当旋转着的水流碰到桶壁后,其速度和方向都发生了改变,形成湍流。

在湍流的作用下,衣物做无规则地运动并翻滚,其纤维不断被弯曲、绞纽扣拉长,衣物相互相摩擦,增大了洗涤的有效面积,提高衣物的洗净的均匀性。

全自动洗衣机是通过水位开关与电磁进水阀配合来控制进水、排水以及电机的通断:从而实现自动控制的。

电磁进水阀起着通、断水源的作用。

当电磁线圈断电时,移动铁芯在重力和弹簧力的作用下,紧紧顶在橡胶膜片上,并将膜片的中心小孔堵塞,这样阀门关闭,水流不通。

当电磁线圈通电后,移动铁芯在磁力作用下上移,离开膜片,并使膜片的中心小孔打开,于是膜片上方的水通过中心小孔流入洗衣桶内。

由于中心小孔的流通能力大于膜片两侧小孔的流通能力,膜片上方压强迅速减小,膜片将在压力差的作用下上移,闭门开启,水流导通。

水位开关实际上是一个压力开关。

气室的入口与洗衣桶中的贮气室相联接。

当水注入洗衣桶后,贮气室口很快被封闭,随水位上升,贮气室的水位也上升,被封闭的空气压强亦增大,水位开关中的波纹膜片2受压而胀起,推动顶杆3运动而使触点4改变,从而实现自动通断。

合肥荣事达三洋电器股份有限公司洗衣机维修手册2003年11月17日洗衣机的故障诊断异常情况发生时,修理之前需要了解以下日常检查注意事项情况:全自动洗衣机症状日常检查注意事项不运转●保险丝是否损坏、保险丝盒是否接触不良?●电源线插头是否插好?●水龙头是否打开?不排水●排水软管是否放下?●排水软管是否堵塞?(如插到地漏底部堵塞?)●排水软管是否接好?不进水● 水龙头是否打开?● 水管是否冻结?● 进水管口/进水阀过滤网是否堵塞?不脱水● 洗涤衣物是否偏置?● 排水软管是否放下?● 洗涤上盖是否没有合上?维修更换部件原则:更换部件必须先从价值低的部件更换,以免进一步扩大维修损失。

全自动洗衣机故障诊断XQB45-428,XQB46-366,XQB45-438,XQB46-376,XQB45-448,XQB46-128,XQB48-628,XQB46-148,XQB48-648,XQB50-149,XQB50-356,XQB46-138,XQB48-668,XQB46-328,XQB50-68,XQB50-98,XQB50-218,XQB50-78,XQB50-168,XQB50-158,XQB50-238,XQB50-258,XQB52-338,XQB52-348,XQB55-118,XQB55-118A,XQB55-268S,XQB60-228S,XQB60-88,XQB60-88A,XQB65-888,XQB70-388,XQB80-8S,XQB80-8SA一、 故障现象:全部动作失灵※1、XQB45-448,46-138,48-668XQB52-338,52-348,55-118XQB80-8S,80-8SA2、XQB50-78、XQB50-168、XQB60-88 3、XQB45-428,46-366,45-438XQB80-8S,XQB80-8SA二、 故障现象:中途异常停机三、故障现象:异常噪音、振动大※1、XQB45-448,46-138,48-668XQB52-338,52-348,55-118XQB80-8S,80-8SA2、XQB45-428,46-366,45-438XQB80-8S,XQB80-8SA※1、XQB45-448,46-138,48-668XQB52-338,52-348,55-118XQB80-8S,80-8SA2、XQB45-428,46-366,45-438XQB80-8S,XQB80-8SA八、故障现象:油状污垢附着九、故障现象:异常报警1、进水异常:水位指示发光管表示:⑴XQB60-88、XQB60-88A、XQB65-888、XQB80-8S(全自动侧):高、低、极少点亮⑵XQB45-448、XQB46-138、XQB48-668、XQB50-68、XQB50-78、XQB50-98、XQB50-218 、XQB50-158、XQB50-168、XQB50-238、XQB50-258、XQB55-118、XQB55-118A:高、低、少量点亮程序指示发光管表示:⑴XQB46-148、XQB48-648、XQB50-149、XQB50-356:快洗、浸泡、轻洗、毛毯点亮⑵XQB46-128、XQB48-628:快洗、轻洗、毛毯点亮⑶XQB45-428、XQB46-366、XQB45-438、XQB46-376:浸泡、轻洗、毛毯、快洗点亮分洗侧发光管表示:⑴XQB80-8S(分洗侧):12、6、3+补给水或精漂、标准、节约+补给水点亮⑵XQB80-8SA(分洗侧):12、6、3点亮数码管表示:⑴XQB46-328、XQB52-338、XQB52-348、XQB55-268S、XQB60-228S、XQB70-388、XQB80-8SA(全自动侧):E1显示2、排水异常:水位指示发光管表示:⑴XQB60-88、XQB60-88A、XQB65-888、XQB80-8S(全自动侧):高、中、极少点亮⑵XQB45-448、XQB46-138、XQB48-668、XQB50-68、XQB50-78、XQB50-98、XQB50-218 、XQB50-158、XQB50-168、XQB50-238、XQB50-258、XQB55-118、XQB55-118A:高、中、少量点亮⑶XQB45-428、XQB46-366、XQB45-438、XQB46-376:标准、轻洗、毛毯、快洗点亮程序指示发光管表示:⑴XQB46-148、XQB48-648、XQB50-149、XQB50-356:快洗、标准、轻洗、毛毯点亮⑵XQB46-128、XQB48-628:标准、轻洗、毛毯点亮分洗侧发光管表示:⑴XQB80-8S(分洗侧):12、6、3+排水或精漂、标准、节约+排水点亮⑵XQB80-8SA(分洗侧):精漂、标准、节约点亮数码管表示:⑴XQB46-328、XQB52-338、XQB52-348、XQB55-268S、XQB60-228S、XQB70-388、XQB80-8SA(全自动侧):E2显示3、脱水异常:水位指示发光管表示:⑴XQB60-88、XQB60-88A、XQB65-888、XQB80-8S(全自动侧):高、中、低点亮⑵XQB45-448、XQB46-138、XQB48-668、XQB50-68、XQB50-78、XQB50-98、XQB50-218 、XQB50-158、XQB50-168、XQB50-238、XQB50-258、XQB55-118、XQB55-118A:高、中、低点亮⑶XQB45-428、XQB46-366、XQB45-438、XQB46-376:标准、浸泡、毛毯、快洗点亮程序指示发光管表示:⑴XQB46-148、XQB48-648、XQB50-149、XQB50-356:快洗、标准、浸泡、毛毯点亮⑵XQB46-128、XQB48-628:标准、快洗、毛毯点亮数码管表示:⑴XQB46-328、XQB52-338、XQB52-348、XQB55-268S、XQB60-228S:U3显示——衣物偏置、机器不平?⑵XQB46-328、XQB52-338、XQB52-348、XQB55-268S、XQB60-228S、XQB70-388:U4显示——洗涤上盖打开?⑶XQB80-8SA(全自动侧):E3显示——衣物偏置、机器不平?⑷XQB80-8SA(全自动侧):E4显示——洗涤上盖打开?4、水位传感器异常:水位指示发光管表示:⑴XQB60-88、XQB60-88A、XQB65-888:中、低、极少点亮⑵XQB45-448、XQB46-138、XQB48-668、XQB50-68、XQB50-78、XQB50-98、XQB50-218 、XQB50-158、XQB50-168、XQB50-168、XQB50-238、XQB50-258、XQB55-118、XQB55-118A、XQB80-8S(全自动侧):中、低、少量点亮数码管表示:⑴XQB46-328、XQB52-338、XQB52-348、XQB55-268S、XQB60-228S、XQB70-388、XQB80-8SA(全自动侧):EA显示5、其它异常:程序指示发光管表示:⑴XQB46-148、XQB48-648、XQB50-149、XQB50-356:快洗、标准、浸泡、轻洗点亮——电脑板电源损坏?⑵XQB45-428、XQB46-366、XQB45-438、XQB46-376:标准、浸泡、轻洗、快洗点亮——洗涤中断?⑶XQB46-128、XQB48-628:标准、快洗、轻洗点亮——洗涤上盖打开?数码管表示:⑴XQB46-328、XQB52-338、XQB52-348、XQB55-268S、XQB60-228S、XQB70-388:EC显示——负载检测异常?数码管表示:⑴XQB46-328、XQB52-338、XQB52-348、XQB55-268S、XQB60-228S、XQB70-388:U5显示——儿童锁设置?十、全自动洗衣机的分解步骤:1、后板的拆装方法:a.取下进水阀盖/烘干口塑贴/烘干口盖b.松开后板紧固螺钉,拆下后板。

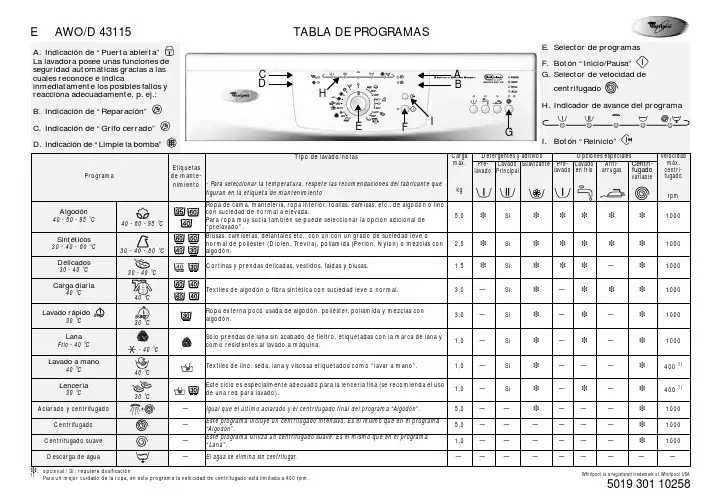

E AWO/D 43115TABLA DE PROGRAMAS❉:opcional / Sí : requiere dosificación1)Para un mejor cuidado de la ropa, en este programa la velocidad de centrifugado está limitada a 400 rpm.5019 301 10258Whirlpool is a registered trademark of Whirlpool USAProgramaEtiquetas de mante-nimiento Tipo de lavado/notas- Para seleccionar la temperatura, respete las recomendaciones del fabricante quefiguran en la etiqueta de mantenimientoCarga máx.kgDetergentes y aditivos Opciones especialesVelocidad máx.centri-fugado rpmPre-lavado Lavado PrincipalSuavizante Pre-lavado Lavado en frío Anti-arrugas Centri-fugado variableAlgodón40 - 60 - 95 °C40 - 60 - 95 °CRopa de cama, mantelería, ropa interior, toallas, camisas, etc., de algodón o lino con suciedad de normal a elevada.Para ropa muy sucia también se puede seleccionar la opción adicional de “prelavado”.5,0❉Sí❉❉❉❉❉1000Sintéticos 30 - 40 - 60 °C 30 - 40 - 60 °CBlusas, camisetas, delantales etc., con un con un grado de suciedad leve o normal de poliéster (Diolen, T revira), poliamida (Perlon, Nylon) o mezclas con algodón.2,5❉Sí❉❉❉❉❉1000Delicados30 - 40 °C 30 - 40 °CCortinas y prendas delicadas, vestidos, faldas y blusas.1,5❉Sí❉❉❉—❉1000Carga diaria40 °C40 °CT extiles de algodón o fibra sintética con suciedad leve o normal.3,0—Sí❉—❉❉❉1000Lavado rápido30 °C30 °CRopa externa poco usada de algodón, poliéster, poliamida y mezclas con algodón.3,0—Sí❉—❉—❉1000LanaFrío - 40 °C- 40 °C Sólo prendas de lana sin acabado de fieltro, etiquetadas con la marca de lana y como resistentes al lavado a máquina.1,0—Sí❉—❉—❉1000Lavado a mano40 °C 40 °C T extiles de lino, seda, lana y viscosa etiquetados como “lavar a mano”.1,0—Sí❉———❉4001)Lencería 30 °C30 °CEste ciclo es especialmente adecuado para la lencería fina (se recomienda el uso de una red para lavado).1,0—Sí❉—❉—❉4001)Aclarado y centrifugado—Igual que el último aclarado y el centrifugado final del programa “Algodón”.5,0——❉———❉1000Centrifugado —Este programa incluye un centrifugado intensivo. Es el mismo que en el programa “Algodón”.5,0——————❉1000Centrifugado suave —Este programa utiliza un centrifugado suave. Es el mismo que en el programa “Lana”.1,0——————❉1000Descarga de agua—El agua se elimina sin centrifugar.—————————A.Indicación de “Puerta abierta”La lavadora posee unas funciones de seguridad automáticas gracias a las cuales reconoce e indicainmediatamente los posibles fallos y reacciona adecuadamente, p. ej.:B.Indicación de “Reparación”C.Indicación de “Grifo cerrado”D.Indicación de “Limpie la bomba”E.Selector de programasF.Botón “Inicio/Pausa”G.Selector de velocidad de centrifugadoH.Indicador de avance del programaI.Botón “Reinicio”DHC FIGEB A5019 301 10258Whirlpool is a registered trademark of Whirlpool USAAñada detergente según lo indicado en la primera página y en las instrucciones de uso. Cierre la puerta y gire el selector de programas al programa y la temperatura que desee. Destella el indicador luminoso situado junto al botón “Inicio/Pausa”.Pulse los botones de las opciones que desee. Seencienden los indicadores luminosos correspondientes.Si no es posible una combinación de programa y opciones adicionales, los indicadores luminosos se apagan automáticamente. Las combinaciones de opciones que no son posibles quedan automáticamente desactivadas.Botón “Prelavado”•Sólo para cargas de ropa muy sucia (por ejemplo con arena, suciedad gruesa). El tiempo del ciclo aumenta aproximadamente 15 minutos.Botón “Lavado en frío”•El agua sólo se calienta hasta 20 °C•Opción adecuada para ropa delicada con una temperatura máxima recomendada en la etiqueta de 30 °C.•Sólo se puede seleccionar en el paso de temperatura mínima de cada programa.Botón “Antiarrugas”•Puede utilizarse junto con los programas “Algodón”, “T ejidos sintéticos” y “Carga diaria” para facilitar el planchado.•Mejora la calidad del agua y realiza un centrifugado suave.Botón “Centrifugado variable”•Cada programa posee una velocidad máxima de centrifugado predefinida.•Pulse el botón para ajustar otra velocidad de centrifugado.•Si selecciona la velocidad de centrifugado “0” el centrifugado final se cancela pero los niveles intermedios del centrifugado continúan durante el aclarado. El agua se elimina sin centrifugar.DATOS DE CONSUMOPrograma T emperatura (°C)Carga(kg)Agua(l)Energía(kWh)Duración aprox. delprograma (horas :minutos)*Algodón 955,049**1,902:00Algodón ***605,0440,852:20Algodón 405,0440,602:00T ejidos sintéticos 602,550**0,70 1.30T ejidos sintéticos 402,5450,551:15T ejidos delicados 301,5500,500:45Prendas mixtas 403,0450,451:00Lavado rápido303,0400,400:30Lana401,0550,600:45Lavado a mano 401,0450,600:40Lencería301,0450,500:40Los datos de consumo se midieron en condiciones normalizadas de acuerdo con la norma CEI/EN 60456. Los valores de consumo en el hogar pueden variar respecto a los valores de la tabla según la presión y temperatura del agua, la carga y el tipo de lavado.*El indicador de tiempo restante puede desviarse de los valores de la tabla, porque considera las condiciones de la vivienda que corresponden en ese momento.**Para reducir la temperatura del agua, se agrega agua fría al final del ciclo principal de lavado, antes de que la bombavacíe el agua.***Programa de referencia para la etiqueta de energía.AÑADA DETERGENTE, CIERRE LA PUERTA Y SELECCIONE EL PROGRAMASELECCIONE CUALQUIER OPCIÓN Abra el grifo y pulse el botón “Inicio/Pausa”. Destella el indicador luminoso situado junto al botón“Inicio/Pausa”. El indicador de secuencia del programa muestra la fase actual del programa, de izquierda a derecha a través de Lavado, Aclarado y Centrifugado/Descarga.•Cuando termina la fase del programa, se apaga el indicador luminoso correspondiente.Antes del inicio y de la finalización de un programa, los indicadores luminosos se encienden para señalar que se puede abrir la puerta. Mientras el programa de lavado esté en marcha, la puerta permanece cerrada y por ninguna razón se debe intentar forzar su apertura. En caso de una necesidad urgente de abrirla durante un programa en marcha, consulte “Cancelación (Reinicio) de un programa antes de que termine”.“Reparación”El indicador de “Reparación” se puede encender por el fallo de un componente eléctrico. Consulte la “Guía para la solución de problemas” incluida con lasinstrucciones de uso; si el fallo continúa, póngase en contacto con el Servicio posventa.“Grifo cerrado”La lavadora no recibe alimentación de agua o es insuficiente. Abra el grifo; si la indicación sigue encendida, consulte la “Guía para la solución de problemas” incluida con las instrucciones de uso.“Limpie la bomba”La lavadora no descarga el agua. Compruebe si el tubo de descarga está doblado o si hay que limpiar el filtro; en este último caso, consulte en las instrucciones de uso (“Extracción del filtro”).•T odos los indicadores de secuencia delprograma están apagados y se enciende el indicador de “Puerta abierta”.1.Gire el selector de programas a la posición de “Apagado/O”.2.Cierre el grifo.3.Abra la puerta y retire la ropa.4.Deje la puerta entreabierta para facilitar el secadodel tambor.1.Pulse el botón “Inicio/Pausa” para detenertemporalmente el programa. El indicador destella.2.Seleccione el nuevo programa (con latemperatura), las opciones suplementarias y (si lo desea) otra velocidad de centrifugado.3.Pulse nuevamente el botón “Inicio/Pausa”. Elnuevo programa continúa el programa de lavado en la fase en que se interrumpió el anterior. En este programa no es necesario añadir más detergente.El botón “Reinicio” permite cancelar un programa antes del final.•Pulse el botón “Reinicio” durante, almenos, 3 segundos. El agua se descarga antes de poder abrir la puerta.INICIO DEL PROGRAMAINDICACIÓN DE “PUERTA ABIERTA”INDICACIONES ROJAS FIN DEL PROGRAMACAMBIO DE PROGRAMA O DE OPCIONES DESPUÉS DEL INICIO DEL PROGRAMA CANCELACIÓN (REINICIO) DE UN PROGRAMA ANTES DE QUE TERMINE。

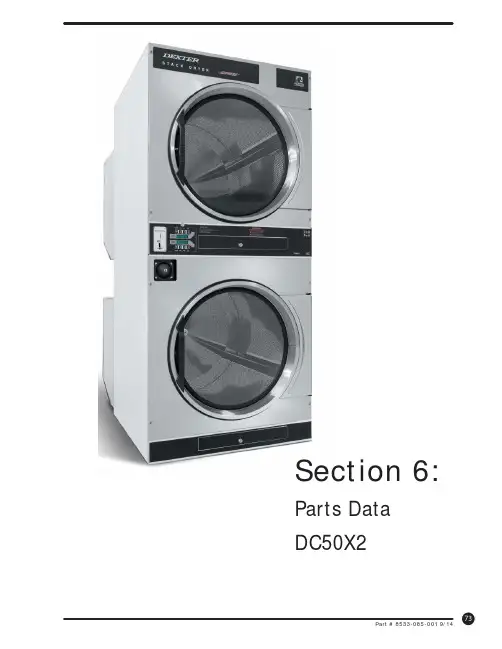

Section 6: Parts DataDC50X264310131211216547Cabinet GroupKey Part Number Description Quantity * 9960-285-008Door Assy., Loading Complete-Wht (2)* 9960-285-011Door Assy., Loading Complete-SS (2)* 9960-285-007Door Assy., Loading Complete-Chrome/BLK/SS (2)1 9960-284-002Door Assy., Loading-SS(ring only) (2)1 9960-284-004Door Assy., Loading-Chrome(ring only) (2)2 9982-353-002Plate Assy., Hinge (Wht) No Pin (2)2 9982-353-001Plate Assy., Hinge (SS) No Pin (2)* 9545-012-015Screw, Hinge to Door (8)* 8640-413-002Nut, Hinge to Door (8)3 9212-002-004Glass, Door (2)4 9206-413-002Gasket, Glass Black (2)* 9548-117-000Support, Door Glass (2)5 9206-420-005Gasket, Outer Rim Black (2)6 9244-082-001Handle, Loading Door (2)* 9545-018-017Screw, Handle 1/4-20 x 3/8 (4)* 9531-033-003Stud, Door Catch (2)* 8640-413-001Nut, Hex (2)* 8640-413-003Nut, Acorn (2)* 9086-015-002Catch, Loading Door (2)* 8638-190-009Pop Rivet for mtg. catch (4)* 8641-582-006Lockwasher (4)* 8640-399-001Spring Nut (6)7 9989-521-003Panel Assy., Front- Lower (Wht) (1)7 9989-521-001Panel Assy., Front- Lower (SS) (1)8 9989-517-003Panel Assy., Front- Upper (Wht) (1)8 9989-517-001Panel Assy., Front- Upper (SS) (1)* 9277-054-001Insulation Front Panel, half moon (top) (2)* 9277-054-002Insulation Front Panel, half moon (bottom) (2)9 9545-008-014Screw, FLHDCR, 10B x 1 (14) (6)* 8641-585-001 Lockwasher* 8640-399-001Nut, Spring (12)10 9544-069-002Strap, Hinge (Wht) (2)10 9544-069-005Strap, Hinge (SS/Black) (2)* 9545-012-028Screw, Hinge to Panel (8)11 9545-052-001Screw, Door to Hinge Strap (Special Black Type) (2)12 8641-436-003Washer, Fiber (2)13 9021-041-001Acceptor, Coin (1)* 9486-149-001Retainer, Coin Acceptor (2)14 9545-053-002Screw (4)* 9801-099-001Switch, Optical (1)Cabinet Group ContinuedKey Part Number Description Quantity15 9994-032-001Escutcheon, Upper (1)16 9435-039-002Trim, Overlay-Upper Blue (1)16 9435-039-001 Trim, Overlay-Upper Black (1)17 9994-033-001Escutcheon, Lower (1)18 9435-023-001Trim, Overlay-Lower Blue (1)18 9435-031-001Trim, Overlay-Lower Black (1)* 9545-020-009Screw (20)19 9412-167-002Nameplate Stack Dryer Express Blue (1)19 9412-167-001Nameplate Stack Dryer Express Black (1)20 9866-005-001Lint Drawer Assembly Blue (2)20 9866-005-004Lint Drawer Assembly Black (2)21 9435-024-001Overlay Trim, Lint Drwr-Blue (1)21 9435-032-001Overlay Trim, Lint Drwr-Black (1)* 9532-074-003Felt Seal ( back of lint screen assembly ) (2)* 9805-033-002Lint Screen Assembly ONLY (no front) (2)* 9555-057-008Replaceable Lint Screen Only (2)22 8650-012-004Lock and Key, Lint Drawer (2)* 6292-006-010Key 6101 only (2)* 9095-043-001Cam, Lock (2)* 9545-008-001Lint Screen Strap Hold Down Screws 10Bx 1/4 (32)23 9857-198-001Controls Assy, Blue (1)23 9857-198-003Controls Assy, Black (1)* 9627-869-001Harness, Electronic Control (1)24 8650-012-003Lock and Key, Control (1)* 9095-041-001Cam, Lock (1)* 6292-006-007Key only 6324 (1)* 9627-855-003Harness, Heat Sensor (1)* 8640-276-002Wire Nut Connector Grey (4)25 9501-004-003Sensor Temp Control (2)26 9501-008-001Bracket for Heat Sensor Mounting (Under Basket) w/ sensor..2* 9545-045-005Screw, Round Head (Mounts sensor; phillips head) (2)* 9209-037-002Gromm.et, 3/16 ID (2)* 8544-006-001Leg, Leveling 1/2” (4)* 9074-320-001 Cover, Cabinet (Top) (1)* 9277-041-017 Insulation Cabinet Cover (1)* 9732-276-001Kit for Dryers without Neutral and using 208-240 volt (1)* 9732-102-013LP Kit for 50Lb Stk Dryers (1)* 9732-243-001Stack Dryer Trunion Puller (1)* 9544-041-002 Strap - Bead Tie (1)27 9942-038-005 Vault, Coin Box (1)* 9545-008-024 Screws, Mounting-Coin Vault (2)28 9897-099-002 Coin Box Assy, Large Blue (1)28 9807-099-004 Coin Box Assy, Large Black (1)191526252792531089Control Parts GroupKey Part Number Description Quantity * 9857-198-001Controls Assy, Electronic Mounted With Membrane Switch, BLU (1)* 9857-198-003Controls Assy, Electronic Mounted With Membrane Switch, BLK (1)1 9826-008-001 Trough Assembly (1)2 9032-062-002 Button-Push, Control, Blue (2)2 9032-062-001 Button-Push, Control, Black (2)3 9538-166-011Spacer-Metal, 4mm (4)4 9486-158-001 Retainer-Push Button (2)5 8640-424-002Nut-Hex, Elastic stop, #4-40 (4)6 8652-130-038Terminal-Grounding clip (1)7 9534-365-001Spring-Flat, Control (1)8 9545-008-001Screw-Hex, #10B x 1/4 (2)9 9545-044-010 Screw-Hex, #10B x 1/4 (10)9 8641-582-005Washer-External tooth, #6 (10)10 9435-038-001Overlay-Control, Coin, Black (1)10 9435-038-002Overlay-Control, Coin, Blue (1)11 9021-041-001Acceptor-Coin, Optical (1)* 9486-149-001Retainer, Coin Acceptor (1)12 9545-053-002Screw (4)* 9801-099-001 Optical Sensor, Replacement (1)Note: Jumpers required if using 1.5 Control on Older Machines (P9 Connection)* 8220-155-001 Wire Assy, Jumper, 30Lb Stack Coin (1)* 8220-155-002 Wire Assy, Jumper, 50Lb Stack Coin (1)Door Switch GroupPart NumberDescription Quantity9539-487-001Door Switches (2)Hinge Plate Cover1 9074-340-002 Cover-Hinge, Black .....................................................................22 8636-008-010 Screw-TRHDCR, 10B x 3/8, Black.. (4)12Bearing Housing GroupKey Part Number Description Quantity J1 9241-189-002 Housing, Bearing (2)J2 9036-159-003Bearing, Ball Rear..................................................................... .2 * 9538-183-001 Spacer, Bearing (2)* 9036-159-001Bearing, Ball Front .................................................................... .2 J5 9545-017-017Bolt, 1/2 x 3/4 . (8)J7 8640-417-002Nut, 1/2 (8)* 9803-201-001Bearing Housing Complete Ass’y (includes bearings,spacer) (2)J4 9545-017-018Screw 1/2 x 1 1/2 (4)Burner Housing GroupKey Part Number Description Quantity * 9803-207-001 Housing Assembly, Burner (2)1a 9452-730-001Service Burner Plate Front... (2)1 9452-729-001 Service Plate baffl e Recirculation Chamber Clean Out (2)* 9545-008-006Screws (8)2 9545-008-001Screw (16)18 9003-220-001Angle, Burner Support (2)* 9545-008-006Screw (4)17 9048-020-002Burner, Main (4)* 9545-008-006Screw 10AB x 3/8” (4)* 9454-824-001 Panel, Back Burner Housing (2)4 9545-008-001Screw 10B x1/4” (8)5 9875-002-003Electrode Assy, Ignition (2)19 9545-045-001Screw, Electrode Mtg 8B x 1/4” (4)7 9379-186-001Valve, Gas Shut Off (1)8 9857-134-001Control Assy, Gas (2)9 9381-012-001Manifold, Assy (2)* 9425-069-021Orifi ce, Burner-Natural #27 (4)* 9425-069-022Orifi ce, Burner-LP #44 (4)10 9029-175-001Bracket, Manifold (2)22 8615-104-038Pipe Plug in end of Burner Manifold (2)* 9545-008-006Screw (4)12 9576-203-002Thermostat, Hi-Limit (2)* 9538-142-001Spacer, Hi-Limit (4)* 9545-045-007 Screw 8B x 3/4” (4)13 9074-329-001Cover, Hi-Limit Stat Ignitor (2)* 9545-008-006Screw (6)* 9576-207-008Thermostat, Safety Shutoff (2)* 9545-008-006Screw (4)15 9825-062-001Cover, Safety Stat (2)* 9545-008-024Screw (6)16 9857-116-003Control, Ignition Fenwall (3 trybox) (2)* 9732-102-013Kit, LP Conversion 50Lb Stack Kit (2)* 9838-018-003Welded One Piece Gas Pipe Assembly (1)Part # 8533-085-001 9/14Burner Housing Group Photos10221092221851A141594851613Rear ViewKey Part Number Description Quantity * 9627-861-001Wire Harness Overtemperature Switch/Air Switch (2)* 9801-098-001Switch Assy, Air Flow (2)1 9539-461-009Switch, Air Flow (2)2 9029-200-001 Bracket, Switch- Air Flow (2)3 9008-007-001Actuator, Switch (2)4 9451-169-002Pin, Cotter (2)5 9545-020-001Screw 4-40 x 5/8” (4)* 8640-401-001Nut, Special Twin .#4-40 (2)* 9550-169-003Shield, Switch (2)6 9376-322-001Motor, Drive (2)7 9452-770-001Plate, Motor Mounting (1)* 9545-029-008Bolt 3/8” - 16 x 3/4” (8)* 8641-582-003Lockwash Spring 3/8 (8)8 9545-018-019Screw, Motor Plate to Back Assy. 1/4-20x 2 1/2 (8)* 8641-582-007Lockwasher 1/4 (8)9 9538-163-006Spacr (8)* 8641-581-017Flat Washer 1/4 x 7/8 (24)* 9209-086-002Rubber Grommet (8)* 9538-166-006Grommet Spacers (8)* 9545-028-013Screw, Set (4)10 9962-018-002Back Assy, Blower Hsg (2)11 9991-053-001Support Assy, Intermed. Pulley (2)12 9545-029-010Bolt, Rd Hd 3/8-16 x 1 1/4 (6)12 8640-415-004Nut Flange Wizlock 3/8” - 16 (6)12 8641-581-035Washer, Flat (6)13 9545-029-003Bolt, 3/8-16 x 1 1/2 (2)14 9861-022-001Arm Assy-Tension, Complete (2)* 9487-200-003Ring-Retaining (6)15 9908-048-003Pulley Assy, Intermediate with bronze fl ange bearing (2)* 9036-145-002Bronze Flange Bearing (4)16 9908-047-002Pulley Driven Tumbler (2)17 9040-076-009Belt, Drive Motor (2)18 9040-073-011Belt, Driven Intermediate to Tumbler (2)19 9534-151-000Spring, Tension (2)20 9099-012-005Chain, Tension (2)21 9248-022-002Hook, Tension (2)* 9451-146-001Pin, Damper Hinge (2)* 9074-334-001 Cover Duct Upper (1)22 9973-032-001 Heat Recirculation Assembly Duct (2)* 9453-169-013Motor Pulley - Driver (1)* 9545-028-013Set Screws (2) (2)* 9278-043-001Impeller23 8641-581-026Washer, Flat 1/2” for Tumbler Pulley (2)24 9545-017-009Bolt, 1/2”-13 x 1 1/4 (2)25 8641-582-016Washer, Star 1/2” for Tumbler Pulley (2)* 9545-008-001Screw 10 Bx 1/4” (6)* 9545-014-004Bolt, 5/16-18 x 5/8” (8) (8)5/16-18* 8640-400-003Nut,* 9538-184-001Spacer, Shaft (2)* 9487-234-005Ring Tolerance (2)* 9125-007-001Damper Inside Duct Exhaust (2)* 9125-007-002Damper Inside Duct Exhaust (1)* 8520-141-000Nut, Spring (4)* 9074-335-001Cover Duct Lower (1)* 9545-008-024Screw 10ABx 3/8” (72)* 9029-173-001Bracket for Wire Harness Under Burner Housing (2)Part # 8533-085-001 9/14Part # 8533-085-001 9/14Rear View Photos1264722Rear Panel & Cover GroupKey Part Number Description Quantity19208-090-001Rear Guard Side Panel 1 (2)4 9545-008-024Screws 10 AB x 3/8 (30)5 8502-649-001Label - Connection Electrical (1)8 9208-089-001Rear Guard Back Panel (2)10 8502-600-001Label Warning & Notice (1)11 8502-645-001Label - Instructions (1)12 9109-113-001Transition Assembly Outlet (1)13 9074-320-001 Top Cover Dryer Panel (1)14 9550-188-001 Top Burner Housing Heat Shield Inlet (1)15 9074-321-001 Top Panel Burner Housing Cover (1)Part # 8533-085-001 9/141851113121514Tumbler GroupKey Part Number Description Quantity 9848-131-001Tumbler Assembly Galvanized w/spider (2)G2 9568-013-001Spider Assembly (2)G3 9497-226-002Rod, Tumbler (6)G4 8640-417-005Nut, 1/2 - 13 (6)G6 8641-590-002Washer, Special (6).............................................................................AR G7 9552-013-000Shim* 9848-130-002Tumbler Assembly Stainless Steel (2)G1 9848-130-001Tumber Assembly Galvanized (2)Part # 8533-085-001 9/14Control Assembly GroupKey Part Number DescriptionQuantity* 9857-189-001 Control Assmbly Complete (all below included) .............................1* 9108-117-001 Control Box Cover ..................................................................... 1* 8220-001-478 Wire Assembly Green 7” ............................................................ 1* 8639-621-007 Screw #10-32 x 12 Green ............................................................1* 8641-582-006 Lockwasher Ext Tooth #10 ..........................................................13 9897-026-002 Terminal Block Main Power Middle ...............................................14 9897-026-001 Terminal Block ............................................................................2* 9545-045-012 Screw #8 ABx 1/2 for terminal block ............................................6 5 8711-011-001 Transformer Ignition ...................................................................2* 9545-008-024 Screws 10AB x 3/8” ...................................................................46 9982-348-001 Plate Assembly MTG Ignition Control............................................2* 9545-008-024 Screws 10B x 1/4” MTG Above Plate and Others ...........................47 9857-116-003 Ignition Control ..........................................................................2* 8640-411-003 #6-32 Nuts ................................................................................48 9631-403-009 Wire Assembly High Voltage Upper ..............................................19 9627-860-001 Wire Harness Ignition Control Upper ............................................110 9627-860-002 Wire Harness Ignition Control Lower ............................................1* 9053-067-002 Bushing Wire 7/8” .......................................................................413 9200-001-002 Fuseholder Assembly ..................................................................314 8636-018-001 Fuse 1.5 Amp .............................................................................315 5192-299-001 Relay Power ...............................................................................216 9897-035-001 Terminal Block Assembly Main Power Inlet ...................................1* 9545-008-024 Screw #8 AB x 1/2” ....................................................................2* 8220-062-036 Wire Assembly Red/Black 14” ......................................................1* 8220-062-037 Wire Assembly Red/White 14” .....................................................1* 8220-062-038 Wire Assembly White 14” ............................................................221 9627-864-004 Wire Harness Motor Extension .....................................................2* 9527-007-001 Stand Off - Wire Saddle / Arrowhead ..........................................13* 9545-031-005 Screw 6 B x 3/8” ........................................................................422 9558-029-003 Strip Terminal Marker (Behind Input Power) ..................................124 9627-863-001 Wire Harness Main Extension Access Under Burner Housing .........123 9631-403-008 Wire Ass’y - High Voltage Lower ..................................................125 9627-859-001 Wire Harness - Main Power (1)Part # 8533-085-001 9/14Control Assembly GroupPart # 8533-085-001 9/1416252223245Coin AccecptorKey Part Number Description Quantity1 9021-041-001Coin Accecptor, Optical (1)Replacement (1)2 9801-099-001Sensor-Optical,3 9545-039-002Screw, Heighth Bar, 3mm (2)* 9486-136-001 Retainer, Coin Acceptor (1)* 9545-053-002 Screw (4)Part # 8533-085-001 9/14NotesPart # 8533-085-001 9/14NotesPart # 8533-085-001 9/14Section 7: VoltageConversionPart # 8533-085-001 9/14Part # 8533-085-001 9/14Instructions - Convert a Dual Voltage Stack Dryer from 120V to 208-240V with Neutral Wire Only1. Remove incoming power from the dryer. Use a known working voltmeter to check power.2. Remove the cover of both the upper and lower control box assemblies from the dryer using a 5/16” wrench.3. Move the black/blue wire from the N position of the main power terminal block to the L2 position of the mainpower terminal block in the upper control box assembly. See Figure 6 below.4. Move the white wire of the upper motor harness to an upper inner left terminal in the middle terminal block in thelower control box assembly. See Figure 6 below.5. Move the orange wire of the upper motor harness to an upper inner left terminal in the middle terminal block inthe lower control box assembly. See Figure 6 below.6. Move the white wire of the lower motor harness to a lower inner left terminal in the middle terminal block in thelower control box assembly. See Figure 6 below.7. Move the orange wire of the lower motor harness to a lower inner left terminal in the middle terminal block in thelower control box assembly. See Figure 6 below.8. Reconnect power to the dryer and test to ensure proper operation; one line voltage to L1, one line voltage to L2,the neutral to N, and the earth ground to E.9. Reinstall the cover of both the upper and lower control box assemblies from the dryer using a 5/16” wrench.Part # 8533-085-001 9/14NotesPart # 8533-085-001 9/14Section 9: MaintenancePart # 8533-085-001 9/14MaintenanceDaily1. Clean lint screen by unlocking and sliding out in their tracks for access. Use soft brush ifnecessary. Failure to do so will slow drying and increase gas usage and temperatures through out the dryer.2. Check lint screen for tears. Replace if necessary.Monthly1. Remove lint accumulation from end bells of motor.2. Clean lint from lint screen compartment.3. Remove lint and dirt accumulation from top of the dryer and all areas above, and around theburners and burner housing. Failure to keep this portion of the dryer clean can lead to a buildup of lint creating a fi re hazard.4. Inspect Recirculation burner housing for excessive buildup.5. Place a few drops of light oil on top and bottom pivots of the clothes door hinge.6. Grease bearings and shaft of intermediate drive pulley.Quarterly1. Check belts for looseness, wear or fraying.2. Inspect gasket of door glass for excessive wear.3. Check tightness of all fasteners holding parts to support channel.4. Check tightness of tumbler shaft retaining nut. MUST MAINTAIN 150 FOOT LBS.5. Remove lint accumulation from primary air ports in burners.6. Grease pivot pins and tension arms where in contact with each other.Semiannually1. Remove and clean main burners.2. Remove all orifi ces and examine for dirt and hole obstruction.3. Remove all lint accumulation. Remove front panel, lint screen housing and remove lintaccumulation.Annually1. Check intermediate pulley bearings for wear.2. Check and remove any lint accumulation from exhaust system.NOTE: DRYER MUST NOT BE OPERATED WITHOUT LINT SCREEN IN PLACE。

海尔洗衣机12个常见故障维修!附err1---err9故障代码解释一、洗衣机不启动原因分析:l、插座是否符合要求,是否接触良好。

2、机门是否关严,微延时开关接触是否良好。

3、电机插线接触不良或电机坏。

4、是否点按了开始键(启动/暂停按键启动后灯一直点亮),并有蜂鸣声提示。

5、水龙头是否打开。

检排方法:1、检查电源插头及插座,使其接触良好。

2、通电状态下检查微延时开关是否良好,若良好则属于接触问题,应夹紧插线。

3、夹紧电机插线或更换电机。

4、重新按开始/暂停键。

5、打开水龙头,重新选择程序开始。

二、洗衣机不进水原因分析:1、操作不当或水压太低(低于0.05Mpa)等。

2、机门是否关严,微延时开关接触是否良好。

3、进水电磁阀故障。

4、水位开关故障。

检排方法:1、重新检查:(l)水龙头是否打开(2)进水管是否弯折、堵塞(3)电磁阀是否堵塞(4)程序指示位置是否准确(5)水压力是否太低2、检查门钩与门锁接触是否良好,不良则调整;通电状态下检查微延时开关是否良好。

3、通电检查电磁阀是否良好,重新紧固。

4、嘴吹水位开关,应有“咔嗒”声,若无则更换三、洗衣机不排水原因分析:1、操作不当。

2、排水泵故障或堵。

3、洗衣机内水位过高,规定时间内未排尽。

检排方法:1、重新检查:①排水管是否弯折堵塞,清洗过滤器②排水管口高度是否在80-100cm之间③检查程序设置是否准确④重新设定排水程序2、将电源线 N.L两端接通排水泵,运转是否正常,不良则更换。

四、洗衣机振动噪音大原因分析:1、包装螺丝未卸下。

2、洗衣机离墙太近3、洗衣机载荷超过标定值4、机内有异物。

5、洗衣机是否水平。

6、内部螺栓、螺丝松动。

7、皮带松动。

8、三角架总成不好。

9、加热管紧固螺栓是否松动10、电机固定螺栓是否松动检排方法:1、卸下包装螺丝。

2、调整洗衣机与墙距离。

3、减少洗衣载荷。

4、排除机内异物。

5、调整洗衣机至水平。

6,旋紧洗衣机内部螺栓螺丝,包括:(l)减震器固定螺栓(2)配重块固定螺栓(3)水加热管螺丝(4)电机固定螺栓7,增加皮带张力。

合肥荣事达三洋电器股份有限公司洗衣机维修手册2003年11月17日洗衣机的故障诊断异常情况发生时,修理之前需要了解以下日常检查注意事项情况:全自动洗衣机症状日常检查注意事项不运转●保险丝是否损坏、保险丝盒是否接触不良?●电源线插头是否插好?●水龙头是否打开?不排水●排水软管是否放下?●排水软管是否堵塞?(如插到地漏底部堵塞?)●排水软管是否接好?不进水● 水龙头是否打开?● 水管是否冻结?● 进水管口/进水阀过滤网是否堵塞?不脱水● 洗涤衣物是否偏置?● 排水软管是否放下?● 洗涤上盖是否没有合上?维修更换部件原则:更换部件必须先从价值低的部件更换,以免进一步扩大维修损失。

全自动洗衣机故障诊断XQB45-428,XQB46-366,XQB45-438,XQB46-376,XQB45-448,XQB46-128,XQB48-628,XQB46-148,XQB48-648,XQB50-149,XQB50-356,XQB46-138,XQB48-668,XQB46-328,XQB50-68,XQB50-98,XQB50-218,XQB50-78,XQB50-168,XQB50-158,XQB50-238,XQB50-258,XQB52-338,XQB52-348,XQB55-118,XQB55-118A,XQB55-268S,XQB60-228S,XQB60-88,XQB60-88A,XQB65-888,XQB70-388,XQB80-8S,XQB80-8SA一、 故障现象:全部动作失灵※1、XQB45-448,46-138,48-668XQB52-338,52-348,55-118XQB80-8S,80-8SA2、XQB50-78、XQB50-168、XQB60-88 3、XQB45-428,46-366,45-438XQB80-8S,XQB80-8SA二、 故障现象:中途异常停机三、故障现象:异常噪音、振动大※1、XQB45-448,46-138,48-668XQB52-338,52-348,55-118XQB80-8S,80-8SA2、XQB45-428,46-366,45-438XQB80-8S,XQB80-8SA※1、XQB45-448,46-138,48-668XQB52-338,52-348,55-118XQB80-8S,80-8SA2、XQB45-428,46-366,45-438XQB80-8S,XQB80-8SA八、故障现象:油状污垢附着九、故障现象:异常报警1、进水异常:水位指示发光管表示:⑴XQB60-88、XQB60-88A、XQB65-888、XQB80-8S(全自动侧):高、低、极少点亮⑵XQB45-448、XQB46-138、XQB48-668、XQB50-68、XQB50-78、XQB50-98、XQB50-218 、XQB50-158、XQB50-168、XQB50-238、XQB50-258、XQB55-118、XQB55-118A:高、低、少量点亮程序指示发光管表示:⑴XQB46-148、XQB48-648、XQB50-149、XQB50-356:快洗、浸泡、轻洗、毛毯点亮⑵XQB46-128、XQB48-628:快洗、轻洗、毛毯点亮⑶XQB45-428、XQB46-366、XQB45-438、XQB46-376:浸泡、轻洗、毛毯、快洗点亮分洗侧发光管表示:⑴XQB80-8S(分洗侧):12、6、3+补给水或精漂、标准、节约+补给水点亮⑵XQB80-8SA(分洗侧):12、6、3点亮数码管表示:⑴XQB46-328、XQB52-338、XQB52-348、XQB55-268S、XQB60-228S、XQB70-388、XQB80-8SA(全自动侧):E1显示2、排水异常:水位指示发光管表示:⑴XQB60-88、XQB60-88A、XQB65-888、XQB80-8S(全自动侧):高、中、极少点亮⑵XQB45-448、XQB46-138、XQB48-668、XQB50-68、XQB50-78、XQB50-98、XQB50-218 、XQB50-158、XQB50-168、XQB50-238、XQB50-258、XQB55-118、XQB55-118A:高、中、少量点亮⑶XQB45-428、XQB46-366、XQB45-438、XQB46-376:标准、轻洗、毛毯、快洗点亮程序指示发光管表示:⑴XQB46-148、XQB48-648、XQB50-149、XQB50-356:快洗、标准、轻洗、毛毯点亮⑵XQB46-128、XQB48-628:标准、轻洗、毛毯点亮分洗侧发光管表示:⑴XQB80-8S(分洗侧):12、6、3+排水或精漂、标准、节约+排水点亮⑵XQB80-8SA(分洗侧):精漂、标准、节约点亮数码管表示:⑴XQB46-328、XQB52-338、XQB52-348、XQB55-268S、XQB60-228S、XQB70-388、XQB80-8SA(全自动侧):E2显示3、脱水异常:水位指示发光管表示:⑴XQB60-88、XQB60-88A、XQB65-888、XQB80-8S(全自动侧):高、中、低点亮⑵XQB45-448、XQB46-138、XQB48-668、XQB50-68、XQB50-78、XQB50-98、XQB50-218 、XQB50-158、XQB50-168、XQB50-238、XQB50-258、XQB55-118、XQB55-118A:高、中、低点亮⑶XQB45-428、XQB46-366、XQB45-438、XQB46-376:标准、浸泡、毛毯、快洗点亮程序指示发光管表示:⑴XQB46-148、XQB48-648、XQB50-149、XQB50-356:快洗、标准、浸泡、毛毯点亮⑵XQB46-128、XQB48-628:标准、快洗、毛毯点亮数码管表示:⑴XQB46-328、XQB52-338、XQB52-348、XQB55-268S、XQB60-228S:U3显示——衣物偏置、机器不平?⑵XQB46-328、XQB52-338、XQB52-348、XQB55-268S、XQB60-228S、XQB70-388:U4显示——洗涤上盖打开?⑶XQB80-8SA(全自动侧):E3显示——衣物偏置、机器不平?⑷XQB80-8SA(全自动侧):E4显示——洗涤上盖打开?4、水位传感器异常:水位指示发光管表示:⑴XQB60-88、XQB60-88A、XQB65-888:中、低、极少点亮⑵XQB45-448、XQB46-138、XQB48-668、XQB50-68、XQB50-78、XQB50-98、XQB50-218 、XQB50-158、XQB50-168、XQB50-168、XQB50-238、XQB50-258、XQB55-118、XQB55-118A、XQB80-8S(全自动侧):中、低、少量点亮数码管表示:⑴XQB46-328、XQB52-338、XQB52-348、XQB55-268S、XQB60-228S、XQB70-388、XQB80-8SA(全自动侧):EA显示5、其它异常:程序指示发光管表示:⑴XQB46-148、XQB48-648、XQB50-149、XQB50-356:快洗、标准、浸泡、轻洗点亮——电脑板电源损坏?⑵XQB45-428、XQB46-366、XQB45-438、XQB46-376:标准、浸泡、轻洗、快洗点亮——洗涤中断?⑶XQB46-128、XQB48-628:标准、快洗、轻洗点亮——洗涤上盖打开?数码管表示:⑴XQB46-328、XQB52-338、XQB52-348、XQB55-268S、XQB60-228S、XQB70-388:EC显示——负载检测异常?数码管表示:⑴XQB46-328、XQB52-338、XQB52-348、XQB55-268S、XQB60-228S、XQB70-388:U5显示——儿童锁设置?十、全自动洗衣机的分解步骤:1、后板的拆装方法:a.取下进水阀盖/烘干口塑贴/烘干口盖b.松开后板紧固螺钉,拆下后板。

洗衣机技术手册分类(一)按洗涤方式/结构原理分1、波轮式(涡卷式)洗衣机:因是日本在引进英国喷流式洗衣机的基础上研制,也叫日本式洗衣机。

优点:结构简单,体积小,重量轻,操作方便,耗电量少,洗净率高。

缺点:漂洗衣物不均匀,损衣率高。

类型:(1)普通型波轮洗衣机(2)半自动双桶型:洗衣机+脱水机(3)全自动波轮洗衣机2、滚筒式洗衣机:被洗涤的衣物放在滚筒内,衣物半浸没于水中,滚筒作有规律的间歇的正反转动,靠滚筒内凸筋把衣物带至高处再跌下,起揉搓作用,从而完成洗涤过程。

类型:(1)前装式滚筒洗衣机(2)顶装式滚筒洗衣机3、搅拌式或摆动(叶)式洗衣机:洗衣机有一根主柱,由电动机带动摆动叶绕定轴作周期往复运动,每次转动角度小于360度,由此来洗涤衣物。

其它:喷流式、喷射式、振动式(二)按自动化程度分1、普通型洗衣机:搅拌动作为电动机带动正转、反转及停靠定时器控制,而进水、排水、脱水等则是手动。

特点:结构简单,价格低,体积小,安装易,使用方便。

2、半自动型洗衣机:(1)半自动单筒型:没有脱水机,洗涤、漂洗、进出水均自动按设定程序与时间进行,脱水则靠人工。

(2)半自动双筒型:由洗涤、脱水两部分组成,自动完成洗涤、漂洗,但不能自动脱水。

需脱水时,由人工把洗净的衣物放入甩干桶中脱水。

特点:体积较大3、全自动型洗衣机:衣物可按选定的工作程序自动完成洗涤、漂洗、脱水、甩干、进水、排水等功能动作,工作中无需人看管。

类型:(1)机械全自动型:由电动程控器控制。

(2)电脑全自动型:由电脑程控器控制。

特点:结构复杂,价格贵,维修、保养复杂。

(三)按结构形式:单桶、双桶、多桶型(四)按触电保护:分为三个等级,Ⅰ类,Ⅰ类,Ⅱ类洗衣机。

干衣机干衣机:是利用电加热来使洗好的衣物中的水分即时蒸发干燥的清洁类家用电器。

一、分类(一)按结构形式分1、柜式机:是将衣服用衣架挂在烘箱内进行干燥,容量较大;2、滚筒式机:是将衣服直接放进滚筒内,在体积上比柜式机要小,可用专用架子与洗衣机组合在一起使用。