Air Traffic Services Brief Flight Service Station (FSS) Modernization

- 格式:doc

- 大小:58.50 KB

- 文档页数:10

对我国通用航空飞行服务站的探讨发表时间:2016-06-21T15:24:00.223Z 来源:《科技中国》2016年4期作者:付麟淋[导读] 目前的通用航空飞行要么只能在指定的空域内长期飞行,要么必须每次向空管部门申请,导致飞行效率较低。

民航西南空管局四川成都 610202一通用航空发展的必要性在空域方面,我国的低空空域分为管制、监视、报告三类空域。

但目前大部分空域都处于管制状态,尚未完全开放给通用航空飞行。

因此目前的通用航空飞行要么只能在指定的空域内长期飞行,要么必须每次向空管部门申请,导致飞行效率较低。

在服务方面,实现为通用航空提供高效的服务,必须考虑通用航空飞行服务站的建立和运营。

与专门的军民航空管部门不同,通用航空飞行服务站是专门为通用航空提供服务的机构和设施,目前我国尚未建立。

我国目前还没有一个专门为通用航空飞机提供航行保障的FSS,仍采用运输航空的航行服务保障模式。

美国FSS的经验值得我国借鉴,民航局“十二五”期间已经启动了飞行服务站项目,随着低空空域改革的实施逐步建立试点并向全国推广。

开展通用航空飞行服务站技术及运营模式研究有利于我国的通用航空安全、有效飞行,提高我国低空空域的利用效率,解决阻碍,对我国通用航空飞行发展的计划申报、通航监视、气象情报咨询等技术难点,具有重要意义。

首先,我国现阶段通用航空空域使用和飞行计划的报批过程一般较长,由通用航空公司分别向军民航相关单位进行申请,各单位之间存在着繁杂的协调关系和环节。

设立飞行情报服务系统,空域使用和飞行计划都将由通用航空公司向任务所在地的飞行情报服务系统统一申报,再由飞行情报服务系统分别向当地空军和民航行业主管部门报备。

这将简化申报程序,减少审批环节,缩短任务准备时间,大大提高通用航空的工作效率。

第二,通用航空公司需要分别到民航气象部门和航行情报部门进行飞行前准备,对于作业地区的低空气象信息,民航气象部门通常不能提供详细资料,通用航空公司还需到地方气象部门去收集气象信息。

航空情报执照考试题库5.2航行通告第四节航行通告汉译英44001 :1998年7月19日12时30分,广州中南空管局航行通告室向民航总局国际航行通告室发布航行通告,说明如下内容:自98年7月27日l时51分至永久,深圳机场强制报告点“N2247.7E11327.4”代号为“APUKI”,请发布一个系列号为C0719/98的航行通告说明情况。

GG ZBBBYNYX191230 ZGGOOFXX(C0719/98 NOTAMNQ)ZGZU/QAPCH/IV/BO/E/000/999/2248N11327E025A)ZGSZ B)9807270151 C)PERMB)COMPULSORY REPORTING POINT N2247.7E11327.4 DESIGNATED ASAPUKI.)44002 :上海虹桥机场18号跑道Ⅰ类ILS自98年10月26日22时起升级为Ⅱ类ILS,请发布一个系列号为C1011/98的航行通告说明情况。

(C1011/98 NOTAMNQ)ZSHA/QISAW/I/NBO/A/000/999/3112N12120E025A)ZSSS B)9810262200 C)PERME)ILS CATⅠ FOR RWYl8 UPGRADE TO CAT Ⅱ.)44003 :1998年3月8日1200时,广州机场的Y号滑行道中线灯不工作,预计要两天时间才能修好。

请发布一个系列号为C0093/98的航行通告说明情况。

(C0093/98 NOTAMNQ)ZGZU/QLXAS//M/A/000/999/2311N11316E005A)ZGGG B)9803081200 C)9803101200ESTE)CENTRE LINE LIGHTS OF TWY Y UNSERVICEABLE.)44004 :1998年3月9日09时25分,接维修科通知,预计广州机场滑行道中线灯的维修要延迟,预计在3月11日15时能修好,3月8日曾发布过一个航行通告系列号为“C0093/98”的相关航行通告,请发布一个系列号为COl03/98的航行通告以继续说明情况。

面向低空飞行器的空中交通管理系统研究随着无人机的快速发展和普及,低空飞行器(Low-Altitude Aircraft)的数量迅速增加,给现有的空中交通管理系统带来了新的挑战。

为了确保低空飞行器的安全、高效、有序地运行,研究和开发面向低空飞行器的空中交通管理系统(Low-Altitude Air Traffic Management System,以下简称LAATMS)势在必行。

首先,LAATMS需要具备以下几方面的技术和功能。

首先是飞行器自主避障技术,能够实现避开障碍物、避免与其他飞行器碰撞的能力。

其次是精准的位置定位和导航技术,确保飞行器能够准确、稳定地飞行。

第三是实时数据传输和处理技术,能够及时获取和处理飞行器的航行信息,实现对其的监控和控制。

此外,为了加强空中交通的协调管理,还需要实现交通管制中心和飞行器之间的实时通信,以便进行航线规划、飞行许可和交通管制等工作。

在LAATMS的研究中,人工智能技术将起到重要的作用。

通过机器学习和深度学习等技术,可以对飞行器进行自主决策和智能调度,提高其飞行的安全性和效率。

例如,可以利用机器学习算法对飞行器的行为模式进行学习和预测,从而及时发现异常行为并采取相应措施。

此外,还可以利用深度学习技术对飞行器的感知能力进行增强,使其能够更好地感知周围环境,提高避障和导航的效果。

此外,为了保证LAATMS的可靠性和稳定性,还需要研究可靠的通信网络和数据安全技术。

由于低空飞行器数量庞大,传统的通信网络很难满足其大规模通信需求。

因此,研究如何建立可靠的低空通信网络,以满足飞行器之间、飞行器与地面之间的通信需求,是一个重要的课题。

同时,为了保证飞行器的数据安全,需要研究和开发数据加密和认证技术,以防止数据泄露和非法使用。

另外,LAATMS还需要考虑环境保护和航行规则的问题。

低空飞行器的增加可能对环境造成潜在的影响,例如噪音污染和空气污染等。

因此,LAATMS应该考虑如何最小化飞行器对环境的影响,制定相应的环境保护措施。

CNS/ATM:国际民航组织的通信、导航、监视和空中交通管理系统,或简称为新航行系统。

ACARS:(飞机通信寻址与报告系统)是一种在航空器和地面站之间通过无线电或卫星传输短消息(报文)的数字数据链系统。

RNA V/RNP:区域导航,允许航空器在路基导航信号覆盖范围内,或在航空器自备式导航系统能力范围内,在任意一条预订航线上飞行的一种导航方法。

所需导航性能,飞机在一个确定的航路、空域或区域内运行时,所需的导航性能精度。

ATN:航空电信网,是全球范围内,用于航空的数字通信网路和协议。

ADS/ADS-B:自动相关监视,作为一项监视技术,由飞机将机上导航和定位导航导出的数据通过数据链自动传送。

这些数据至少包括飞机识别、四维定位和所需附加数据。

广播式自动相关监视,是指在一系统中所有的飞机或车辆周期性的广播自己的四维信息、运动方向和速度等数据,该数据可以精确的表示飞机的位置、航向等信息。

TCASII:二类交通告警和防撞系统,可以提供本机临近空域中的交通状况显示,发出交通咨询TA并能再确实存在潜在的危险接近时提前向机组发出决断咨询RA。

SESAR:单一的欧洲天空ATM研究,是一项协同项目,旨在彻底改变欧盟领空和其空中交通管理。

PBN:基于性能的导航,是指在相应的导航基础设施条件下,航空器在指定的空域内或者沿航路、仪表飞行程序飞行时对系统精确性、完好性、可用性、连续性以及功能等方面的性能要求。

简述地空通信的组成:卫星通信、VHF通信、HF通信和SSR Mode S数据链,并在此基础上,逐步建设全球范围的航空电信网ATN。

简述地空数据链在空中交通服务中的应用:CPDLC(管制员与飞行员直接链路通信),提供ATC服务的地空数据通信。

D-FIS(数字化飞行信息服务),是一种地空间的数字化广播应用,支持ATIS、机场气象报告服务、终端气象服务、航行通告服务、机场预报服务等。

简述卫星导航的增强技术:广域增强系统(W AAS):是一个路基基准系统网络,利用差分解算技术改善基本GPS信号的精度、完好性和可用性。

航空情报服务(AIS)是在划定空域内负责提供航行安全、正常和效率所必需的7*24h的航空数据和航空情报的服务,其目的是要确保空中交通管理(ATM)系统安全、正常、经济和效率所必需的航空数据和航空情报以可持续的方式交换。

航空情报数据是民航安全运行和发展的根基。

根据民航组织对航空情报业务的发展要求,未来几年,中国航空情报业务将逐步从航空情报服务(AIS)向航空情报管理(AIM)发展,并建立中国民航的航空情报数据库及全球航空情报数据库,为中国民航现代空中交通管理系统(CAAMS)提供核心数据支持,为建设中国民航全系统信息管理(SWIM)助力。

1国际民航组织和中国民航对航空情报业务的发展要求1.1国际民航组织对航空情报业务的发展要求为确保航空界实现当前全球各地区现代化空中交通增长所需的全球化协调,平衡和改善容量增加和环境效率之间的关系,加快实施CNS/ATM系统,国际民航组织在《全球ATM运行概念》(Doc.9854)中提出未来ATM系统由空域组织和管理(AOM)、需求和容量平衡(DCB)、空域用户运行(AUO)、交通同步(TS)、冲突管理(CM)、机场运行(AO)以及信息管理(IM)七个部分组成,其中信息管理(IM)占核心地位,在ATM系统中发挥中枢作用(见图1)。

作为《全球ATM运行概念》(Doc.9854)的实施指导文件,《全球空中航行计划》(Doc.9750)提出航空系统组块升级(ASBU)的概念,将航空系统绩效改善领域分为4个组块(组块0、1、2、3),其中组块2研究中国民航航空情报服务(AIS)如何向航空张天(民航局空管局情报中心)中的全系统信息管理(SWIM),是信息管理(IM)的核心方案。

而SWIM第一阶段工作内容主要是通过数字化航空情报管理(AIM)提高运行效率和质量。

由国际民航组织对数字化航空情报管理(AIM)、全系统信息管理(SWIM)、信息管理(IM)的关系定义(见图2)可知,AIM是SWIM的重要组成部分,SWIM是IM的必经阶段。

ISSN 100020054CN 1122223 N 清华大学学报(自然科学版)J T singhua U niv (Sci &Tech ),2003年第43卷第7期2003,V o l .43,N o .711 379032907空中交通战略和战术级流量管理模型马正平, 崔德光(清华大学自动化系,北京100084)收稿日期:2003202225基金项目:国家自然科学基金资助项目(69784004)作者简介:马正平(19732),男(汉),四川,博士研究生。

通讯联系人:崔德光,副教授,E 2m ail :cui @ci m s .tsinghua .edu .cn摘 要:针对日益增长的空中交通流量,提出了适合中国空中交通的战略、战术级流量管理模型。

按照功能,分别提出了航路流量管理模型和机场流量管理模型以及终端区的流量管理模型。

根据空中交通中信息的实时性和多样性,分析了其中的信息流动,并在此基础上提出了新一代信息共享网络。

这些模型都应用于清华大学国家C I M S 工程研究中心与华北空管局合作开发的空中交通管制指挥检测系统(A TC 2C M S )中,并取得了很好的效果,同时也为上层管理者提供了战略性决策支持。

关键词:系统决策;空中交通;流量管理;实时系统;复杂系统控制中图分类号:N 945.25文献标识码:A文章编号:100020054(2003)0720903205M odels of stra teg ic and tactica l a spectsof a ir traff ic f low managem en tMA Zhe ngp ing ,CU ID e gua ng(D epart men t of Auto mation ,Tsi nghua Un iversity ,Be ij i ng 100084,Chi na )Abstract :A ir traffic flow vo lum es in China can be increased by strategic p lanning of air traffic flow m anagem ent .M odels w ere developed fo r en 2route flow m anagem ent,airpo rt flow m anagem ent and term inal area flow m anagem ent .T he real 2ti m e variati on of air traffic info r m ati on w as considered in the developm ent of a real 2ti m e info r m ati on sharing netwo rk.T he models wo rked very w ell in an A ir T raffic Contro l and Comm and M onito ring System ,developed by the N ati onal C I M S Engineering L abo rato ry and the N o rth China R egi onal Bureau of Ch ina A ir .T he system p rovides seni o r m anagers w ith real 2ti m e info r m ati on fo r strategic decisi on suppo rt .Key words :systemdecisi on;airtraffic;flowm anagem ent;real 2ti m e system s;comp lex system contro l 随着空中交通流量的不断增长,机场和空中交通阻塞的现象越来越严重,从而造成大量的航班延误。

◎航空航天中国科技信息 2021 年第 6 期・ CHINA SCIENCE AND TECHNOLOGY INFORMATION Mar.2021link appraisement industry南京莱斯信息技术股份有限公司邹国政(1985 -)男,汉族,江苏扬州人,本科,工程师,研究方向:民航空管、 信息自动化系统。

丿DOI :10.3969/j.issn.1001- 8972.2021.06.003可实现度可替代影响力行业关联度1刍0国政空管自动化系统采用C 类报文的飞行数据移交设计C 类数据移交指的是采用MH/4029.3规范中所定义的C 类数据来实现不同管制单位间的快速管制权限的移交,旨在解决如何让航班在飞行过程中更快速高效的管制电子移交,特别是解决高低空管制区 之间的垂直移交。

该技术应用在空管自动化系统中后极大地减轻了管制员工作负荷,保障了空管安全运行。

空管自动化系统是民航空管单位对空指挥的核心系统之 一,为空管对航空器的指挥工作提供空中飞行态势显示和各种飞行冲突的告警,提供飞机起飞、巡航及落地阶段的指挥 服务,保障飞行秩序及安全。

传统空管自动化系统工作模式中,航空器在相邻管制单 位之间的移交通常采用话音移交或AIDC 移交,特别对于在 高低空管制区间的移交只能采取话音移交,随着国内航班量的快速增长,空中交通流量也快速加大,在这种情况下,继续采用传统的话音移交,会占用管制员较多的精力,对空中 交通安全造成潜在的安全隐患。

因此需要更合适的技术手段来满足实际管制工作需要。

不同空管自动化系统互联现状分析在目前的民航规范中,相邻管制区之间对航空器权限的 移交主要有两种方式:第一种是电话移交,当飞机即将下一管制单位管制范围时,当前管制单位通过电话方式告知下一管制单位某航班即将进入,同时告知该航班的相关飞行信息。

电话移交在沟通交流中不可避免的会出现口误等情况,同时过多的语音通话 会分散管制员注意力,使管制员不能更好的集中精力去关注航空器的安全飞行。

英德拉AIRCON2100型空中交通管制自动化系统软件运行故障统计分析发布时间:2021-10-26T01:12:01.545Z 来源:《现代电信科技》2021年第11期作者:赵文文[导读] 民航空管自动化系统承担着全国大部分飞行流量的运行管理,是保障空管安全运行的最核心设备之一,其软件运行状况直接影响航空运输网络的平稳、高效、安全运行。

(空管局技术中心北京市 100015)摘要:本文以成都区域管制中心和西安区域管制中心AIRCON2100空管自动化系统为研究对象,通过对其2014年至2020年的软件故障发生和调查的结果为统计样本,分析系统运行的典型故障模块及变化趋势,采用风险矩阵法建立风险评估模型,对自动化系统软件运行风险进行评估,并提出具体控制措施,实现系统运行风险的有效防控。

关键词:空管自动化系统;风险矩阵;故障管理前言民航空管自动化系统承担着全国大部分飞行流量的运行管理,是保障空管安全运行的最核心设备之一,其软件运行状况直接影响航空运输网络的平稳、高效、安全运行。

AIRCON2100型空管自动化系统(以下简称“AIRCON2100”)由西班牙英德拉公司设计和制造,为区域、进近和塔台管制提供服务,主要软件模块包括监视数据处理、飞行数据处理,安全网、情景界面显示等。

本文以成都区域管制中心和西安区域管制中心AIRCON2100自2013年8月以来发生的软件故障为研究对象,通过建立风险评估模型,分析了影响系统稳定运行的重要故障,提出了针对性的改进和风险管控建议,为系统日后的运行维护提供参考,以期提高系用运行可靠性,延长系统生命周期。

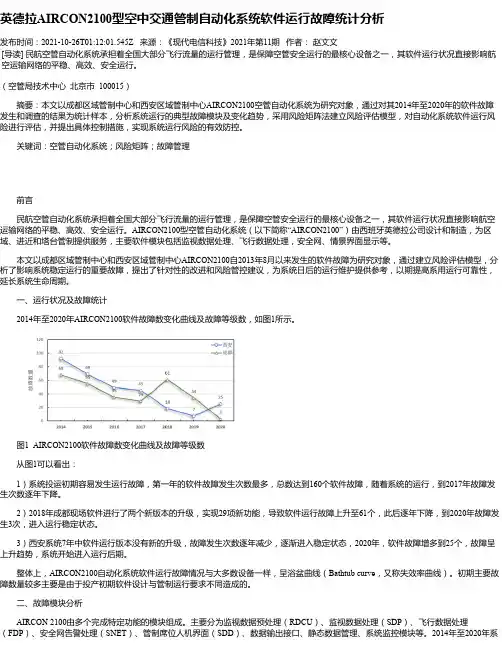

一、运行状况及故障统计2014年至2020年AIRCON2100软件故障数变化曲线及故障等级数,如图1所示。

图1 AIRCON2100软件故障数变化曲线及故障等级数从图1可以看出:1)系统投运初期容易发生运行故障,第一年的软件故障发生次数最多,总数达到160个软件故障,随着系统的运行,到2017年故障发生次数逐年下降。

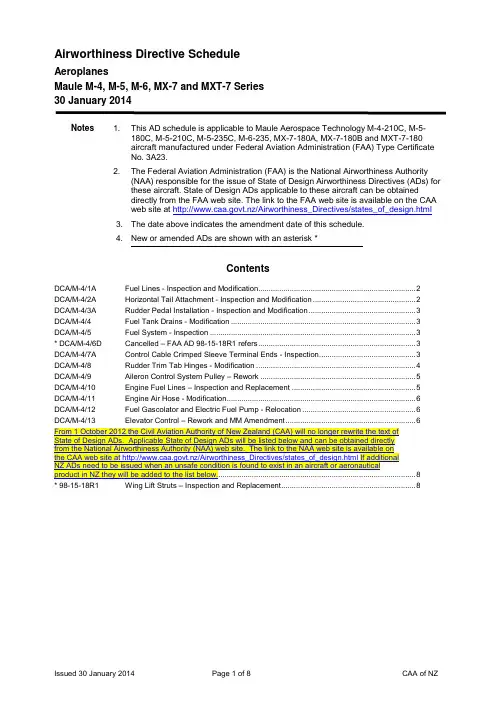

Airworthiness Directive ScheduleAeroplanesMaule M-4, M-5, M-6, MX-7 and MXT-7 Series30 January 2014Notes 1.This AD schedule is applicable to Maule Aerospace Technology M-4-210C, M-5-180C, M-5-210C, M-5-235C, M-6-235, MX-7-180A, MX-7-180B and MXT-7-180aircraft manufactured under Federal Aviation Administration (FAA) Type CertificateNo. 3A23.2. The Federal Aviation Administration (FAA) is the National Airworthiness Authority(NAA) responsible for the issue of State of Design Airworthiness Directives (ADs) forthese aircraft. State of Design ADs applicable to these aircraft can be obtaineddirectly from the FAA web site. The link to the FAA web site is available on the CAAweb site at /Airworthiness_Directives/states_of_design.html3. The date above indicates the amendment date of this schedule.4. New or amended ADs are shown with an asterisk *ContentsDCA/M-4/1A Fuel Lines - Inspection and Modification (2)DCA/M-4/2A Horizontal Tail Attachment - Inspection and Modification (2)DCA/M-4/3A Rudder Pedal Installation - Inspection and Modification (3)DCA/M-4/4Fuel Tank Drains - Modification (3)DCA/M-4/5Fuel System - Inspection (3)* DCA/M-4/6D Cancelled – FAA AD 98-15-18R1 refers (3)DCA/M-4/7A Control Cable Crimped Sleeve Terminal Ends - Inspection (3)DCA/M-4/8Rudder Trim Tab Hinges - Modification (4)DCA/M-4/9Aileron Control System Pulley – Rework (5)DCA/M-4/10Engine Fuel Lines – Inspection and Replacement (5)DCA/M-4/11Engine Air Hose - Modification (6)DCA/M-4/12Fuel Gascolator and Electric Fuel Pump - Relocation (6)DCA/M-4/13Elevator Control – Rework and MM Amendment (6)From 1 October 2012 the Civil Aviation Authority of New Zealand (CAA) will no longer rewrite the text ofState of Design ADs. Applicable State of Design ADs will be listed below and can be obtained directlyfrom the National Airworthiness Authority (NAA) web site. The link to the NAA web site is available onthe CAA web site at /Airworthiness_Directives/states_of_design.html If additionalNZ ADs need to be issued when an unsafe condition is found to exist in an aircraft or aeronauticalproduct in NZ they will be added to the list below (8)* 98-15-18R1Wing Lift Struts – Inspection and Replacement (8)DCA/M-4/1A Fuel Lines - Inspection and ModificationApplicability:Models M-4-210C, S/Ns 1001C through 1117CModels M-5-210C, S/Ns 6001C through 6069C, 6072C, 6076C, 6077C, 6079C,6080C, 6084C and 6087CRequirement:To prevent fuel leakage in the cabin area and allow fuel line flexibility, accomplish the following instructions per Maule Aircraft Corporation Service Letter 31:1. Turn the fuel tank selector valve to off position.2. Remove the engine fuel injector return line from the firewall to the fuel header tank.(The fuel line is located in cabin wall to left of pilot’s feet.)3. Short line inspection - Inspect the short line connected at the firewall to the checkvalve for cracking around the flares. If cracks are found, replace line with aserviceable line.4. Long line replacement - Remove existing long line and install an 8 - inch long, ¼inch diameter aluminium tube between the return check valve and the header tank,using appropriate tube and fittings. This line is to incorporate a 1.5 to 2.0 inchdiameter loop in the middle. Use caution when bending the tubing to prevent kinking.This looped tubing must be installed with the plane of the loop horizontal so that nolow undrainable spots exist.5. The check valve must be reinstalled with the arrow pointing aft.6. Functional check the return line for leaks and repair as necessary.(FAA AD 75-11-02 refers)Compliance:Within the next 50 hours TIS, unless already accomplished.Effective Date:DCA/M-4/1 - 21 May 1975DCA/M-4/1A - 22 February 2007DCA/M-4/2A Horizontal Tail Attachment - Inspection and ModificationApplicability:Model M-4-210C aircraft, S/Ns 1001C to 1117CModel M-5-180C aircraft, S/Ns 8001C to 8004CModel M-5-210C aircraft, S/Ns 6001C to 6206CModel M-5-235C aircraft, S/Ns 7001C to 7283CRequirement:Inspect per Parts (1) and (5) of Maule Aircraft Corporation Service Bulletin No 1.Defective parts are to be repaired or renewed, before further flight.Modify per Parts (3) and (4) of Maule SB No 1.(FAA AD 79-12-01 refers)Compliance:Within the next 50 hours TIS or by 22 March 2007 whichever is the sooner, unless already accomplished.Effective Date:DCA/M-4/2 - 20 December 1979DCA/M-4/2A - 22 February 2007DCA/M-4/3A Rudder Pedal Installation - Inspection and ModificationApplicability:Model M-4-210C aircraft, S/N 1001C through 1117CModel M-5-180C aircraft, S/N 8001CModel M-5-210C aircraft, S/N 6001C through 6204CModel M-5-235C aircraft, S/N 7001C through 7254CRequirement:Inspect and modify rudder pedal installation per FAA AD 81-14-02. Repair or renew cracked components before further flight. Maule SB 2 refers.(FAA AD 81-14-02 refers)Compliance:Within the next 50 hours TIS, unless already accomplished.Effective Date:DCA/M-4/3 - 7 August 1981DCA/M-4/3A - 22 February 2007DCA/M-4/4 Fuel Tank Drains - ModificationApplicability:All model M-4 and M-5 seriesRequirement:Modify main and auxiliary fuel tank drain valve installations per Maule SB 5 and SL 32 respectively.(FAA AD 84-09-07 refers)Compliance:Within the next 50 hours TISEffective Date:29 June 1984DCA/M-4/5 Fuel System - InspectionApplicability:Model M-5-180C aircraft, S/N 8001C through 8014C, 8016C through 8019C and 8021CModel M-5-210C aircraft, S/N 6001C through 6206CModel M-5-220C aircraft, S/N 5001C through 5057CModel M-5-235C aircraft, S/N 7001C through 7045C and 7047C through 7052C Requirement:To preclude possible fuel flow restriction in crossover supply line, inspect and rectify as necessary, per Maule SB 7.(FAA AD 86-17-11 refers)Compliance:Within the next 50 hours TISEffective Date:14 November 1986* DCA/M-4/6D Cancelled – FAA AD 98-15-18R1 refersEffective Date:21 January 2014DCA/M-4/7A Control Cable Crimped Sleeve Terminal Ends - InspectionApplicability:Model M-4-210C aircraft, S/N 1001C through 1117CModel M-5-210C aircraft, S/N 6001C through 6206CModel M-5-235C aircraft, S/N 7001C through 7248C, 7250C through 7353C, A7354C,A7355C, 7356C, 7357C, A7358C, 7359C, A7360C, A7361C, 7362C through 7365C,A7366C, A7367C, 7368C through 7376C, 7445C, 7451C, 7460C, 7467C, 7470C,7478C through 7480C, 7484C through 7487C, and 7515CModel M-5-180C aircraft, S/N 8001C through 8014C, 8016C through 8019C, 8021C,8023C through 8042C, 8044C through 8064C, and 8068C through 8094C.Model M-6-235 aircraft, S/N 7249C, 7356C, 7379C through 7444C, 7446C through7450C, 7452C through 7459C, 7461C through 7466C, 7468C, 7469C, 7471C through7475C, 7488C through 7507C, 7509C, 7511C through 7514C, and 7517CModel MX-7-180A aircraft, S/N 20001C through 20063CModel MX-7-180B aircraft, S/N 22001C through 22016CModel MXT-7-180 aircraft, S/N 14000C through 14095CRequirement:To detect and correct improper crimping of the Nicopress sleeve, which could cause a control cable to slip from the sleeve and result in loss of rudder, elevator, aileron, orflap control, accomplish the following:-1. Inspect all Nicopress sleeve terminal ends for correct size compression per MauleMSB 20. Adjust or replace any terminal compressions that are outside of the limitsspecified in the MSB prior to further flight.2. Do not install a Nicopress sleeve without assuring that the terminal compressionsare within the limits specified in MSB 20.(FAA AD 2000-09-06 refers)Compliance: 1. Within the next 100 hours TIS unless already accomplished.2. From 22 February 2007.Effective Date:DCA/M-4/7 - 25 May 2000DCA/M-4/7A - 22 February 2007DCA/M-4/8 Rudder Trim Tab Hinges - ModificationApplicability Model M-4 aircraft, S/Ns 3 thru 94Model M- 4C aircraft, S/Ns 1C thru 10CModel M-4S aircraft, S/Ns 1S thru 3SModels M-4T aircraft, S/Ns 1T thru 3TModel M-4-210 aircraft, S/Ns 1001 thru 1045Model M-4-210C aircraft, S/Ns 1001C thru 1064CModel M-4-220S aircraft, S/Ns 2001S thru 2003SModel M-4-220C aircraft, S/Ns 2001C thru 2006C.Requirement:To prevent loss of rudder trim tab control due to the possibility of the hinges corroding and seizing, modify the rudder trim tab hinges per the instructions in Maule AircraftCorporation Service Letter Number 14, dated February 19, 1968, or per anmanufacturer approved modification.(FAA AD 68-07-08 refers)Compliance:Within the next 50 hours TIS, unless already accomplished.Effective Date:22 February 2007DCA/M-4/9 Aileron Control System Pulley – ReworkApplicability Model M-4 aircraft, S/Ns 3 through 94Model M-4T aircraft S/Ns 1T through 3TModel M-4C aircraft S/Ns 1C through 11CModel M-4S aircraft S/Ns 1S through 3SModel M-4-210 aircraft S/Ns 1001 through 1045Model M-4-210C aircraft, S/Ns 1001C through 1075C, 1079C and 1080CModel M-4-220C aircraft, S/Ns 2001C through 2029C and 2032C.Requirement:To prevent the aileron pulley assembly fitted at the bottom of the control column separating from its bearing, accomplish the following instructions per Maule ServiceLetter No. 19, dated September 4, 1969.Remove the aileron control pulley to control column attachment bolt. Re-assemble theaileron control pulley assembly with the addition of washers P/Ns AN 970-5 and AN960-516, and bolt P/N AN 5-27 instead of the original bolt in the following order fromfront to rear:i. AN 5-27 bolt, head forward.ii. AN 970-5 washer.iii. AN 960-516 washer.iv. Original pulley.v. Control column.vi. AN 960-516 washer.vii. AN 365-524 nut(FAA AD 69-20-02 refers)Compliance:Within the next 50 hours TIS, unless already accomplished.Effective Date:22 February 2007DCA/M-4/10 Engine Fuel Lines – Inspection and ReplacementApplicability:Model M-5- 210C aircraft, S/N 6190C through 6204CModel M-5-235C aircraft, S/N 7061C through 7160C, 7163C through 7167C, 7169Cthrough 7192C, 7194C and 7197C.Requirement:To prevent restriction of fuel flow to the engine, due to the possibility of the ends of the fuel lines being crushed by the hose attachment clamps, accomplish the followinginstructions per Maule Service Letter 39:Remove the wing root fairings on both sides to gain access to both main tank outlets(two outlets per tank).If the fuel line tube clamps do not have hexagonal heads, no further action is required.If the fuel line tube clamps have hexagonal heads, drain the fuel tanks and loosen theclamp(s). Pull the fuel hoses off the fuel lines and the tank outlets and inspect thelines for deformation.If any fuel lines are deformed, replace as required per the instructions in SL 39, beforefurther flight.(FAA AD 78-13-08 refers)Compliance:Within the next 50 hours TIS, unless already accomplished.Effective Date:22 February 2007DCA/M-4/11 Engine Air Hose - ModificationApplicability:Model M-5-235C aircraft, S/Ns 7322C, 7350C, A7354C, A7355C, A7358C, A7360C, A7361C, 7364C, 7365C, A7366C and A7367CModel M-6-235 aircraft, S/Ns 7356C, 7379C, 7380C, 7382C through 7388C and7390C.Requirement:To prevent engine failure, install a drain tube P/N 5393A and two hose clamps P/N 10047A-32 to the engine air hose, per the instructions in Maule Service Bulletin No. 3,dated November 6, 1981.(FAA AD 82-03-05 refers)Compliance:Within the next 50 hours TIS, unless already accomplished.Effective Date:22 February 2007DCA/M-4/12 Fuel Gascolator and Electric Fuel Pump - RelocationApplicability:Model M-4-210 aircraft, S/N 1001 through 1045Model M-4-210C aircraft, S/N 1001C through 1080CRequirement:To prevent an engine fire due the fuel gascolator and electric fuel pump being located too close to the dual exhaust system, relocate the gascolator and fuel pump to theleft-side of the aircraft, per the instructions in Maule Service Bulletin No. 10, datedSeptember 16, 1994.(FAA AD 96-10-05 refers)Compliance:Within the next 50 hours TIS, unless already accomplished.Effective Date:22 February 2007DCA/M-4/13 Elevator Control – Rework and MM AmendmentApplicability:Model M-4-210C aircraft, all S/NModel M-5-180C aircraft, all S/NModel M-5-210C aircraft, all S/NModel M-5-235C aircraft, all S/NModel M-6-235 aircraft, S/N 7249C, 7356C, 7379C through 7444C, 7446C through7450C, 7452C through 7459C, 7461C through 7466C, 7468C, 7469C, 7471C through7475C, 7488C through 7514C, 7516C through 7522CModel MX-7-180A aircraft, S/N 20001C through 20064CModel MX-7-180B aircraft, S/N 22001C through 22025C, 22027CModel MXT-7-180 aircraft, S/N 14000C through 14125CRequirement:To prevent opposite elevator movement due to possible reversed elevator control rigging which could result in loss of aircraft control, accomplish the following:1. With yellow enamel paint colour code the top of the rear elevator control horn,the elevator control cable end (which is attached to the top of the rear control horn),the bottom of the forward elevator control horn and the elevator control cable end(which is attached to the bottom of the forward control horn), per Maule AerospaceTechnology, Inc. MSB No. 30, dated 4 March 2008.2. Insert the following text into the rigging procedure section of the aircraftmaintenance manual:“CAUTION – BEFORE FURTHER FLIGHT WHENEVER ELEVATOR CABLES ARERECONNECTED OR NEW CABLES FITTED: Always inspect elevator operation bymoving the control backwards and confirming that the elevator is in the UP position.” Note: Requirement 2 of this AD may be accomplished by inserting a copy of this AD or the text on the bottom of page 3 of MSB No. 30 into the rigging procedure section ofaircraft maintenance manual.(FAA AD 2008-24-02 refers)Compliance: 1. By 30 December 2009 or the next time the elevator control cable is disconnected for any reason, whichever occurs sooner.2. By 30 December 2009 or the next time the elevator control cable is disconnectedfor any reason, whichever occurs sooner.Effective Date:30 December 2008From 1 October 2012 the Civil Aviation Authority of New Zealand (CAA) will no longer rewrite the text of State of Design ADs. Applicable State of Design ADs will be listed below and can be obtained directly from the National Airworthiness Authority (NAA) web site. The link to the NAA web site is available on the CAA web site at/Airworthiness_Directives/states_of_design.htmlIf additional NZ ADs need to be issued when an unsafe condition is found to exist in an aircraft or aeronautical product in NZ they will be added to the list below.* 98-15-18R1Wing Lift Struts – Inspection and ReplacementNote: FAA AD 98-15-18R1 supersedes DCA/M-4/6D. For aircraft already in compliance with cancelled AD DCA/M-4/6D, compliance with FAA AD 98-15-18R1 is required at thenext inspection required by the cancelled AD.An inspection method accomplished in accordance with RadiographicTechnique 57-20-01 Rev 1may be used as an alternate to the two inspectionmethods defined in paragraph (i)(1) and (i)(2) of FAA AD 98-15-18R1. If theradiographic technique is used, inspect at intervals not to exceed 4 years.Effective Date:21 January 2014。

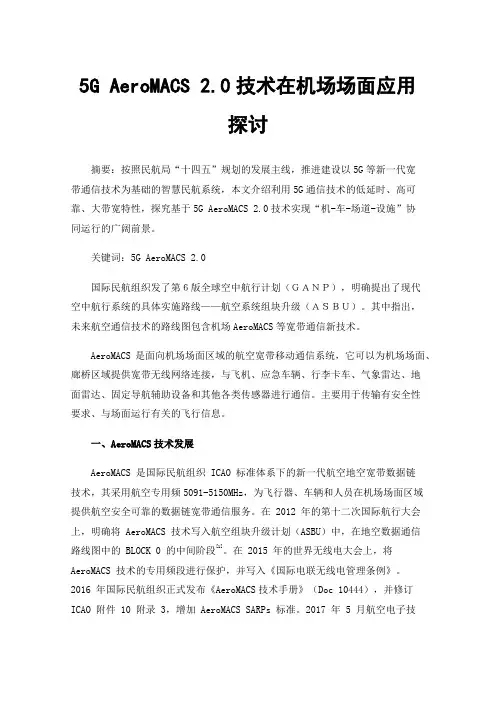

5G AeroMACS 2.0技术在机场场面应用探讨摘要:按照民航局“十四五”规划的发展主线,推进建设以5G等新一代宽带通信技术为基础的智慧民航系统,本文介绍利用5G通信技术的低延时、高可靠、大带宽特性,探究基于5G AeroMACS 2.0技术实现“机-车-场道-设施”协同运行的广阔前景。

关键词:5G AeroMACS 2.0国际民航组织发了第6版全球空中航行计划(GANP),明确提出了现代空中航行系统的具体实施路线——航空系统组块升级(ASBU)。

其中指出,未来航空通信技术的路线图包含机场AeroMACS等宽带通信新技术。

AeroMACS是面向机场场面区域的航空宽带移动通信系统,它可以为机场场面、廊桥区域提供宽带无线网络连接,与飞机、应急车辆、行李卡车、气象雷达、地面雷达、固定导航辅助设备和其他各类传感器进行通信。

主要用于传输有安全性要求、与场面运行有关的飞行信息。

一、AeroMACS技术发展AeroMACS 是国际民航组织 ICAO 标准体系下的新一代航空地空宽带数据链技术,其采用航空专用频5091-5150MHz,为飞行器、车辆和人员在机场场面区域提供航空安全可靠的数据链宽带通信服务。

在 2012 年的第十二次国际航行大会上,明确将 AeroMACS 技术写入航空组块升级计划(ASBU)中,在地空数据通信路线图中的 BLOCK 0 的中间阶段[1]。

在 2015 年的世界无线电大会上,将AeroMACS 技术的专用频段进行保护,并写入《国际电联无线电管理条例》。

2016 年国际民航组织正式发布《AeroMACS技术手册》(Doc 10444),并修订ICAO 附件 10 附录 3,增加 AeroMACS SARPs 标准。

2017 年 5 月航空电子技术委员会颁布《AeroMACS 发射机与航空器安装标准》ARINC DOC 766,即AeroMACS 航电设备安装及通信标准。

二、AeroMACS网络组成AeroMACS 采用基于由WiMAX论坛定义的IEEE802.16 -2009架构,同时AeroMACS 也是一种支持模块化和灵活部署的全IP网络。

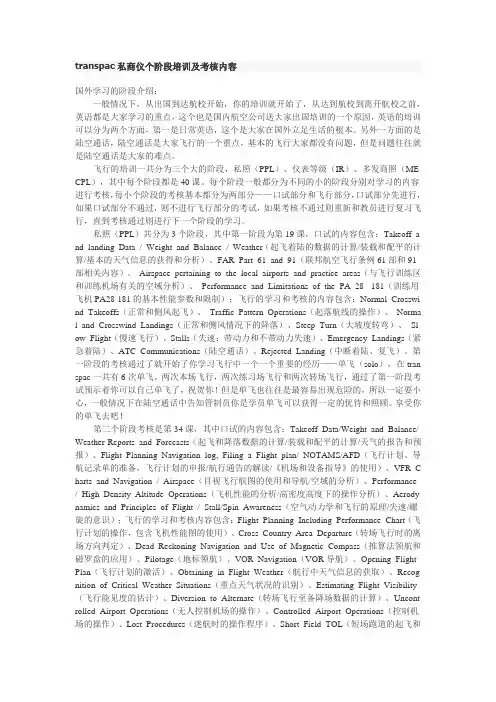

transpac私商仪个阶段培训及考核内容国外学习的阶段介绍:一般情况下,从出国到达航校开始,你的培训就开始了,从达到航校到离开航校之前,英语都是大家学习的重点,这个也是国内航空公司送大家出国培训的一个原因,英语的培训可以分为两个方面,第一是日常英语,这个是大家在国外立足生活的根本。

另外一方面的是陆空通话,陆空通话是大家飞行的一个重点,基本的飞行大家都没有问题,但是问题往往就是陆空通话是大家的难点。

飞行的培训一共分为三个大的阶段,私照(PPL)、仪表等级(IR)、多发商照(ME CPL),其中每个阶段都是40课。

每个阶段一般都分为不同的小的阶段分别对学习的内容进行考核,每小个阶段的考核基本都分为两部分——口试部分和飞行部分,口试部分先进行,如果口试部分不通过,则不进行飞行部分的考试,如果考核不通过则重新和教员进行复习飞行,直到考核通过则进行下一个阶段的学习。

私照(PPL)共分为3个阶段,其中第一阶段为第19课,口试的内容包含:Takeoff a nd landing Data / Weight and Balance / Weather(起飞着陆的数据的计算/装载和配平的计算/基本的天气信息的获得和分析)、FAR Part 61 and 91(联邦航空飞行条例61部和91部相关内容)、Airspace pertaining to the local airports and practice areas(与飞行训练区和训练机场有关的空域分析)、Performance and Limitations of the PA 28- 181(训练用飞机PA28-181的基本性能参数和限制);飞行的学习和考核的内容包含:Normal Crosswi nd Takeoffs(正常和侧风起飞)、Traffic Pattern Operations(起落航线的操作)、Norma l and Crosswind Landings(正常和侧风情况下的降落)、Steep Turn(大坡度转弯)、Sl ow Flight(慢速飞行)、Stalls(失速:带动力和不带动力失速)、Emergency Landings(紧急着陆)、ATC Communications(陆空通话)、Rejected Landing(中断着陆、复飞)。

MCDU/FMGC简介大多数飞机的设置和飞行计划将在MCDU的帮助下完成,MCDU包括各种系统,如FMGC系统。

MCDU:多功能控制显示单元•FMGC->飞行管理和制导计算机•现代客机航空电子设备的基本组成部分。

FMGC是FMGS(飞行管理和制导系统)的一个组成部分,FMGS是一个专门的计算机系统,可以自动执行各种各样的飞行任务,减少机组人员的工作量,使现代民用飞机不再搭载飞行工程师或导航员。

主要功能是飞行计划的飞行管理。

所有的FMS都包含一个导航数据库。

导航数据库包含构建飞行计划的元素。

FMGS将飞行计划发送给电子飞行仪表系统(EFIS)、导航显示器(ND)或多功能显示器(MFD)。

•ATSU->空中交通服务单元,未完全模拟•通过空中无线电或卫星在飞机和地面站之间传输短信息的数字数据链路系统。

•OPTIONS->设置各种飞机选项•允许您更改燃油负载、有效负载、动力和空气地面车、车门控制、车厢灯或推出控制。

这是一个虚构的自定义接口,由FS Labs实验室构建,作为一个工具供您使用。

•允许您配置安装在当前机身上的飞机设备,自定义各种参数,如显示参数、机组系统、ADIRUS校准时间、设置冷暗和其他面板状态,以及飞机故障/故障的配置。

•FAILURES->飞行模拟故障•允许您为训练目的配置各种飞机故障和故障(例如发动机熄火)。

MCDU主菜单页58注:FMGC和ATSU菜单仅在飞机通电时出现。

MCDU/FMGC简介•F GC->飞行管理和制导计算机LSK:行选择键•I:“i ect to直飞”页面通过创建从飞机当前位置到任何选定航路点的直飞航段来修改飞行计划•P OG:“P og ess ”进程页面显示与主飞行计划相关的动态飞行信息和数据•PE F : “Pe fo mance ”性能页面提供与每个飞行阶段相关的性能数据、速度和各种垂直预测•INIT : INIT A初始化页面(飞行计划初始化、出发点等)和INIT B(零燃料重心、零燃料重量、航程油量)•ATA :导航数据索引页•F-PLN :显示飞行计划数据•A NAV : “”F GS无线电导航页面显示由调谐或飞行员选择的导航设备(如VO NBs信标、等导航设备)•FUEL P E:燃料和时间预测信息和燃料管理数据•SEC F-PLN :显示备用飞行计划数据•ATC CO: ATSU显示(空中交通服务单元)菜单•AI PO T :显示飞行计划页面,包括当前飞行计划的下一个机场•C U ENU:查看主菜单页(见上一页)•A OWS (SLEW KEYS) : F GC循环浏览选定页面的上一页和下一页。

Air Traffic Services Brief: Flight Service Station (FSS) Modernization: Lockheed Martin to Provide Flight Services for the 21st Century

Updates and Actions In late April, the FSS system, referred to as Flight Service for the Twenty-first Century (FS21) being run by Lockheed Martin under contract with the FAA, began experiencing serious problems. An aggressive consolidation schedule, combined with computer glitches and a busy flying season overwhelmed the new system. As the watchdog for the pilot community, AOPA's staff reacted quickly, working directly with the FAA and Lockheed Martin to resolve safety of flight and service issues.

AOPA continues to remain in very close contact with the FAA and Lockheed Martin officials to make sure they understand the severity of the flight service station problems and quickly resolve them.

Aided by this new technology, Lockheed Martin will manage to consolidate the 58 existing flight service stations to 16 stations along with three new hub sites located in Prescott, Ariz., Fort Worth, Tex., and Leesburg, Va. (Washington Hub).

The issue On February 1, 2005, the Federal Aviation Administration (FAA) announced that Lockheed Martin has been awarded its contract to run the flight service system. The announcement was the culmination of a 14-month study to compare the costs of providing flight services by the FAA versus the costs of contracting services to commercial companies. The FAA studied operations at 58 of the agency's 61 automated flight service stations (FSSs) throughout the United States. The FSS functions in Alaska were excluded from the study and will continue to be operated by the FAA. The study was conducted under the guidelines of the Office of Management and Budget (OMB) Circular A-76, which direct government agencies to examine functions that might be performed by commercial sources.

The driving factors of the FSS A-76 study were the General Accounting Office (GAO) and Inspector General (IG) reports, published in 2001, which were critical of the current FSS program. These reports outline the escalating cost to maintain the current FSS program, the FAA's inability to effectively modernize the current FSS computer system, and widespread inefficiencies in the current FSS program. The current FSS system costs more than $550 million annually, which breaks down to an approximate cost of $15 per pilot contact. The reports recommend consolidation of FSSs, citing significant cost savings.

Lockheed Martin has been awarded a $1.9 billion; 10-year contract that is estimated will save the government $2.2 billion. This figure is based on the FAA's cost accounting analysis of the current AFSS program for the 58 locations, which cost $435 million a year to operate. Over 10 years, this would cost the government $4.3 billion. Not included in this figure are approximately $2 million in personnel and equipment costs that the government will continue to incur, even after Lockheed takes over provision of the services.

In the case of the FSS A-76 study, four commercial companies (called service providers) and the FAA itself, in partnership with Harris Corporation, an FSS equipment manufacturer, have submitted proposals for a new FSS system. The FAA makes its own business case that it is the most efficient organization (MEO) to run flight services. The other bidders include aerospace companies Lockheed Martin, Northrop Grumman, Raytheon, and Computer Sciences Corporation.

The contract went into effect on October 1, 2005, with no impact on continuity of service, a "seamless" change for pilots, in that Lockheed Martin took over FSS as a "turnkey" operation. Implementation of a modernized FSS system began in January 2007 and will be completed by July 2007.

Lockheed Martin's flight services system is called "Flight Services 21" (FS21) and, when complete, will provide a fully integrated nationwide network that gives all flight service specialists and pilots access to flight plan information from a single, common database.

The importance to our members The FSS system is the only official source for aviation weather and is, therefore, an essential general aviation service. Unfortunately, the current FSS system is in a state of decline and disrepair. It relies on obsolete 1970s computer technology that no longer meets today's operational requirements.

AOPA has been part of the A-76 process from the beginning and was successful in ensuring that the study had a customer service focus and