工业锅炉使用说明书中英文

- 格式:doc

- 大小:67.00 KB

- 文档页数:19

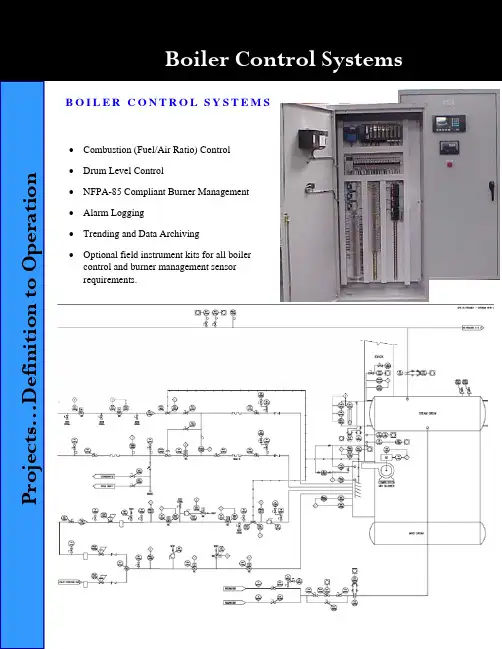

BOILER CONTROL SYSTEMSB U R N E R M A N A G E M E N TBasic Boiler Sequencing and Safety System•Provides safe start check, supervised start-up sequence, continuous interlock monitoring, flame detection andsafety shut-down functions. Maintains compliance with allapplicable codes and laws.D R U M LE V E L C O N T R O LSingle Element System•Simplest Approach•Measures drum level and regulates feedwater flow tomaintain that level. Adequate for single boiler utility plantswith relatively static loads.Two Element System•Measures drum level and steam flow and regulatesfeedwater flow to maintain drum level. Recommended forutility plants with multiple boilers and relatively staticloads.Three Element System•Measures drum level, steam flow and feedwater flow, and regulates feedwater flow to maintain drum level. Stronglyrecommended for utility plants with dynamic loads.C o m b u s t i o n C o n t r olSeries Metered System•Both fuel and air are metered. The boiler master sets the air flow setpoint. The air flow controller sets the fuel flow setpoint. Thisscheme is common where boiler loads are relatively static, with small,infrequent changes.Parallel Metered System•Both fuel and air are metered. The boiler master sets the fuel flow setpoint. The fuel flow and air flow control loops operate in parallel,with the air flow setpoint ratioed from the fuel flow. This approachprovides improved efficiency over series metered systems but is stilllimited to boilers with relatively slow load changes.Cross Limited SystemOxygen Trim System•The addition of oxygen trim to the combustion control systemallows the greatest efficiency possible. By measuring flue gas O2content, the combustion air flow can be “trimmed” to reduceexcess air flow to an absolute minimum, especially when usedwith a cross-limited system. Oxygen trim reduces the effects ofchanging air densities due to temperature and relative humidity.•This “lead-lag” method is similar to the parallel metered system but adds fuel and air flow interlocking (fuel flow follows air flow onload increases / air flow follows fuel flow on load decreases). Thisfeature prevents a hazardous “fuel rich” condition. Cross limitedsystems are strongly recommended where boiler load swings aredynamic and also alllows for precise fuel / air ratio control.Boiler Control System Selection MatrixItem Description Select1 Boiler control and burner management system for a single burner boiler including:-Boiler controller with boiler master controller and fuel/air ratio control & drum level controlbased on selected options below-Self-checking UV flame detector-Standard 559 Operator interface panelBoiler control / burner management cabinet options:2 1042 Operator interface terminal w/ floppy drive (replaces standard 559 operator interface)3 1042 Operator interface terminal w/ ZIP drive (replaces standard 559 operator interface)4 TrendManager analysis software5 Ethernet switch (for peer-peer communication)6 Spare analog input configuration per point (7 spares available)7 Spare discrete input configuration per point (11 spares available)8 Spare discrete output configuration per point (2 spares available)Fuel/air ratio control system configuration and field instrument options:9 Series metered fuel/air ratio control10 Parallel metered fuel/air ratio control11 Cross limited fuel/air ratio control12 Combustion air flow transmitter kit13 Fuel gas firing14 Fuel gas flow transmitter kit15 Fuel oil firing16 Fuel oil flow transmitter kit17 Oxygen trim control18 O2 Analyzer kitDrum level control configuration and field instrument options:19 Single element drum level control (drum level only measured)20 Drum level transmitter kit21 Two element drum level control (drum level and steam flow measured)22 Steam flow transmitter kit23 Three element drum level control (drum level, steam flow and feedwater flow measured)24 Feedwater flow transmitter kit25 Steam header pressure transmitter kit26 Drum pressure transmitter kit27 Steam condensing potBurner management field instrument options:28 Fuel gas high pressure switch kit29 Fuel gas low pressure switch kit30 Fuel oil high pressure switch kit31 Fuel oil low pressure switch kit32 Combustion air low pressure switch kit33 Combustion air flow @ purge switch kit34 Fuel oil / atomizing medium low differential pressure switch kit35 Atomizing steam low pressure switch kit36 Steam drum high pressure switch kitField Instrument configuration options:37 Transmitter configuration (per unit)38 Transmitter / Switch calibration (per unit)。

Gas hob[en]Instruction manual22 Control knobs3 Auxiliary burner (up to 1kW)5 Rapid burner (up to 3kW)6Triple-flame wok burner (up to 4 kW)Safety precautions (2)Your new appliance...................................................................4Accessories .........................................................................................4Gas burners................................................................................4Switching on manually.......................................................................4Switching on automatically................................................................4Safety system......................................................................................4Switching off a burner........................................................................5Power levels.........................................................................................5Warnings...............................................................................................5Cooking guidelines.............................................................................5Cooking pans.............................................................................5Suitable pans.......................................................................................5Precautions for use. (5)Cleaning and maintenance........................................................6Cleaning...............................................................................................6Maintenance........................................................................................6Trouble shooting.........................................................................6Technical Assistance Service ...................................................7Warranty conditions............................................................................7Used appliances and packaging...............................................7Environmentally-friendly disposal.....................................................7Additional information on products, accessories, replacement parts and services can be found at and in the online shopRead these instructions carefully. You will only be able to use your appliance safely and effectively when you have read them. These operating and installation instructions should be retained, and passed onto the buyer if the appliance is sold.The manufacturer is exempt from all responsibility if the requirements of this manual are not complied with.The images shown in these instructions are for guidance only.Do not remove the appliance from its protective packaging until it is installed in the unit. Do not switch on the appliance if it is damaged in any way. Contact our Technical Assistance Service.This appliance is class 3 type, according to the EN 30-1-1 regulation for gas appliances: built-in appliance.Before installing your new hob, ensure that it is being installed according to the assembly instructions.This appliance cannot be installed on yachts or in caravans.This appliance must only be used in well ventilated places.This appliance is not intended for operation with an external clock timer or a remote control.All operations relating to installation, connection, regulation and conversion to other gas types must be performed by an authorised technician, respecting allapplicable regulations, standards and the specifications of the local gas and electricity suppliers. Special attention shall be paid to ventilation regulations.This appliance leaves the factory set to the gas type that is indicated on the specifications plate. If this needs to be changed, please consult the assembly instructions. It is recommended you contact the Technical Assistance Service to change to another gas type.This appliance has been designed for home use only, not for commercial or professional use. This appliance is only intended for cooking purposes, not as a heating system. The warranty will only be valid if the appliance is used for the purpose for which it was designed.Never leave the appliance unattended during operation.Do not use lids or protective barriers for children which are not recommended by the hob manufacturer. They may cause accidents such as those due to the overheating, ignition or detachment of fragments of materials.This appliance may be used by children8years old and older and by persons with reduced physical, sensory or mental capacity or a lack of experience or knowledge if they are supervised or they have been instructed about the safe use of the appliance and have understood the associated dangers.Never let children play with the appliance. Cleaning and user maintenance must not be carried out by unsupervised children. Risk of deflagration!Accumulation of unburned gas in an enclosed area carries a risk of deflagration. Do not subject the appliance to draughts. These might blow out the burners. Carefully read the instructions and warnings on the operation of gas burners.Risk of poisoning!The kitchen will become hot and humid and combustion products produced when this gas appliance is used. Make sure the kitchen is well ventilated, particularly when the hob is in operation: either keep the natural ventilation apertures open, or install a ventilation system (extractor hood). Intense prolonged use of the appliance may require additional or more effective ventilation: open a window or increase the power of the ventilation system.Risk of burns!The hotplates and their immediate vicinity get very hot. Never touch the hot surfaces. Keep children under 8 years old well away from this appliance.Risk of fire!■The hotplates get very hot. Do not rest inflammable objects on the hob. Do not store objects on the hob.■Do not store or use corrosive chemicals, products which produce fumes, inflammable materials or non-food products below or near this domestic appliance.■Fat or oil which is overheated can catch fire easily. Never leave fat or oil to heat up unattended. If oil or fats do catch fire, never use water to put the fire out. Put the fire out by covering the pan with a lid and switch off the hotplate.Risk of injuries!■Sudden changes in temperature may cause breakage of the glass. While using your hob, prevent any draughts and do not spill any cold liquids on it.■Pans which are damaged, are not the right size, hang over the edge of the hob or are not positioned correctly can cause serious injuries. Follow the advice and warnings provided relating to the cooking pans.■In the event of a malfunction, turn off the appliance’s gas and electricity supply. For repairs, call our Technical Assistance Service.■Do not tamper with the appliance's interior. If necessary, call our Technical Assistance Service.■If one of the control knobs will not turn, do not force it. Call the Technical Assistance Service immediately so that they can repair or replace them.Risk of electric shock!■Do not clean the appliance using steam cleaners.■Cracks or breaks in the glass may carry an electrocution risk. Disconnect the fuse from the fuse box. Notify the Technical Assistance Service.34Page 2 shows an overall view of your new appliance as well as the burner power.AccessoriesDepending on the model, the hob may include the following accessories. These can also be acquired from the Technical Assistance Service.The manufacturer accepts no liability if these accessories arenot used or are used incorrectly.There are indications to show which burner each control knob operates.It is essential to ensure that all the burner parts and pan supports are correctly installed for the appliance to work correctly. Do not swap the burner caps around.Switching on manually1.Press the chosen burner control knob and turn itanticlockwise to the required setting.e any type of lighter or flame (cigarette lighter, matches,etc.) and bring it close to the burner.Switching on automaticallyIf your hob can be switched on automatically (ignition sparkers):1.Press the chosen burner control knob and turn itanticlockwise to the maximum power setting.While the control knob is still pressed down, sparks are produced on all burners. The flame ignites.2.Release the control knob.3.Turn the control knob to the required setting.If it does not come on, turn the control knob to the off setting and repeat the steps above. This time, press and hold the control knob for longer (up to 10 seconds).: Risk of deflagration!If after 15 seconds the flame does not ignite, switch off the burner and open a nearby window or door. Wait at least one minute before trying to switch the burner back on.Safety systemDepending on the model, your hob may have a safety system (thermocouple) that prevents the flow of gas if the burners accidentally switch off.To ensure that this device is active:1.Switch on the burner as usual.2.Without releasing the control knob, press and hold it downfirmly for 4 seconds after lighting the flame.Additional wok pan support Only for use on wok burners with pans with a round base.The additional wok pan sup-port should be used to pro-long the appliance's usefullife.5Switching off a burnerTurn the corresponding control knob clockwise to the 0 setting.Power levelsThe progressive control knobs can be used to control the power needed, from minimum to maximum power.WarningsIt is normal to hear a soft whistling noise while the burner is operating.When first used, it is normal for the burner to give off odours. This does not pose any risk and does not indicate a malfunction. They will disappear in time.An orange-coloured flame is normal. This is caused by the presence of dust in the atmosphere, spilt liquids, etc.If the burner flames are accidentally blown out, switch off the burner operating control knob and do not try to relight it for at least 1 minute.A few seconds after the burner is switched off, a sound (thud) will be produced. This is not a fault - this means that the safety device is no longer operating.Keep the burner as clean as possible. If the ignition sparkers are dirty they will not light properly. Clean them periodically using a small non-wire brush. Bear in mind that the ignition sparkers must not suffer any serious impacts.Cooking guidelinesSuitable pansPrecautions for useThe following advice is intended to help you save energy and prevent pan damage:Setting ÛControl knob offHigh flame —Maximum capacity or aperture and elec-tricity onLow flame˜Minimum capacity or apertureBurner Very high - HighMediumLowWok burnerBoiling, steam-ing, griddling,toasting, paellas, Asian food (wok).Reheating and keeping things hot: cooked and pre-cooked dishes Rapid burner Escalopes,steaks, ome-lettes, frying Rice, white sauce, ragout Steaming: fish, vegeta-blesSemi-rapid burnerSteamed pota-toes, fresh vege-tables, vegetable stews, pasta Reheating, keeping things hot and making tasty casse-rolesAuxiliary burnerCooking: casse-roles, rice pud-ding, caramelDefrostingand slowcooking: veg-etables, fruit and frozen productsMelting: but-ter, choco-late, jelly Burner Minimum pan diameter Maximum pan diameter Wok burner 22cm 30cm Rapid burner 22cm 26cm Semi-rapid burner 14cm 20cm Auxiliary burner12cm16cmUse pans which are the right size for each burner.Do not use small pans on large burners. The flame must not touch the sides of the pan.Do not use damaged pans, which do not sit evenly on the hob. Pans may tip over.Only use pans with a thick, flat base.Do not cook without using a lid and make sure the lid is properly fitted. This wastesenergy.Always centre the pan over the burner, not to one side. Otherwise it could tip over.Do not place large pans on the burners near the control knobs. These may bedamaged by the very high temperatures.Place the pans on the pan supports, never directly on the burner.Make sure that the pansupports and burner caps are correctly positioned before using the appliance.Pans should be placed on the hob carefully.Do not strike the hob and do not place excessive weight on it.Never use two burners or heat sources to heat one single pan.Do not use grill pans,earthenware casserole dishes, etc. for a long period of timeon maximum power.6CleaningOnce the appliance is cool, use a sponge to clean it with soap and water.After each use, clean the surface of the respective burner parts once they have cooled down. If any residue is left (baked-on food, drops of grease etc.), however little, it will become stuck to the surface and more difficult to remove later. The holes and grooves must be clean for the flame to ignite properly. The movement of some pans may leave metal residue on the pan supports.Clean the burners and pan supports using soapy water and scrub with a non-wire brush.If the pan supports are fitted with rubber rests, ensure thatthese are also cleaned. The rests may come loose and the pan support may scratch the hob.Always dry the burners and pan supports completely. Water droplets or damp patches on the hob at the start of cooking may damage the enamel.After cleaning and drying the burners, make sure the burner caps are correctly positioned on the diffuser.Caution!■Do not use steam cleaners. This could damage the hob.■Never use abrasive products, steel scourers, sharpimplements, knives, etc. to remove bits of hardened food from the hob.■Do not use knives, scrapers or similar implements to clean the point where the glass meets the burner trims, the metal frames or the glass/aluminium panels, if fitted.MaintenanceAlways clean off any liquid as soon as it is spilt. This willprevent food remains from sticking to the hob surface and you will save yourself any unnecessary effort.Never slide pans across the glass surface, as you may scratch it. In addition, try not to drop heavy or sharp objects on the glass. Never strike any part of the hob.Grains of sand that may come from cleaning fruits and vegetables will scratch the glass surface.Melted sugar, or foods which contain a lot of sugar which may have spilt, should be cleaned off the hotplate immediately,using the glass scraper.Sometimes certain faults detected can be easily resolved. Before calling the Technical Assistance Service, bear in mind the following advice:FaultPossible causeSolutionThe general electrical sys-tem is malfunctioning.Defective fuse.Check the fuse in the main fuse box and change it if it is damaged.The automatic safety switch or circuit breaker has tripped.Check the main control panel to see if the auto-matic safety switch or circuit breaker has tripped.The automatic switching on function does not work.There may be food or cleaning products stuckbetween the ignition sparkers and the burners.The space between the ignition sparker and the burner must be clean.The burners are wet.Dry the burner caps carefully.The burner caps are not correctly positioned.Check that the burner caps are correctly posi-tioned.The appliance is not earthed, is poorly connected or the earthing is faulty.Contact the installation technician.The burner flame is not uni-form.The burner components are not correctly posi-tioned.Correctly place the parts on the appropriateburner.The grooves on the burner are dirty.Clean the grooves on the burner.The gas flow is not normal or there is no gas.The gas supply is blocked by gas taps.Open all gas taps.If the gas is supplied from a gas cylinder, check that it is not empty.Change the gas cylinder.The kitchen smells of gas. A gas tap has been left on.Turn off the taps.Incorrect coupling of gas cylinder.Check that the coupling is sound.Possible gas leak.Shut off the gas supply, ventilate the premises and immediately notify an authorised installation techni-cian to check and certify the installation. Do not use the appliance until ensuring that there is no gas leak in the installation or appliance itself.The burner immediatelyswitches off after releasing the control knob.The control knob was not held down for long enough.Once the burner is on, hold the control knob down a few seconds longer.The grooves on the burner are dirty.Clean the grooves on the burner.7When contacting our Technical Assistance Service, please provide the product number (E-Nr.) and production number (FD) of the appliance. This information is given on thespecifications plate located on the lower section of the hob and on the label in the user manual.Warranty conditionsIn the unlikely event that the appliance is damaged or does not meet your expectations in terms of quality, please inform us assoon as possible. For the warranty to be valid, the appliance must not have been tampered with, or used inappropriately.The applicable warranty conditions are those set out by the company's representative office in the country of purchase. Detailed information is available from retail outlets. Proof of purchase must be presented to obtain the benefits of the warranty.We reserve the right to introduce changes.If the ) symbol is shown on the specifications plate, bear in mind the following instructions:Environmentally-friendly disposalDispose of packaging in an environmentally-friendly manner.The packaging of your appliance has been manufactured using only the materials which are strictly necessary to guarantee efficient protection during transport. These materials are 100% recyclable, thus reducing the environmental impact. You can also contribute to caring for the environment by following the advice below:■Dispose of the packaging in the appropriate recycling bin.■Before you get rid of an old appliance, make sure you disable it. Contact your local authority to find out the address of your nearest recycling centre to dispose of your appliance.■Do not pour used oil down the sink. Collect it in a sealed container and take it to an appropriate collection point or, failing that, place it in the rubbish bin (it will end up in a controlled dump; this is probably not the best option, but it will avoid contaminating ground water)This appliance is labelled in accordance with European Directive 2012/19/EU concerning used electrical and electronic appliances (waste electrical and electronic equipment - WEEE). The guideline determines the framework for the return and recycling of used appliances as applicable throughout the EU.A*9000904470*9000904470Robert Bosch Hausgeräte GmbH Carl-Wery-Straße 3481739 München Germany。

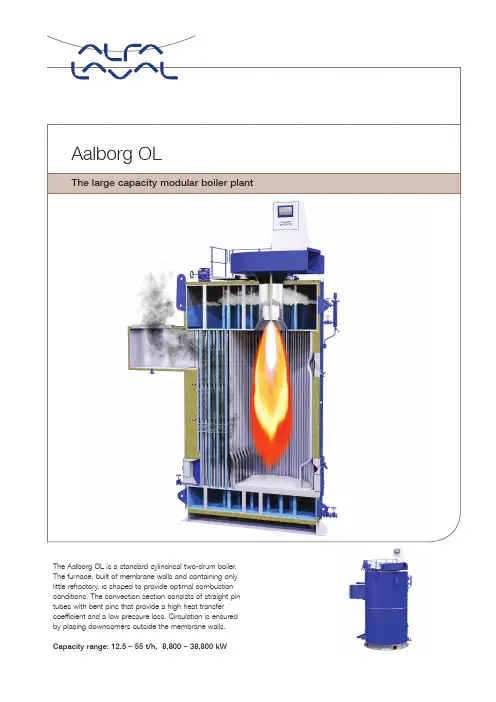

The Aalborg OL is a standard cylindrical two-drum boiler. The furnace, built of membrane walls and containing only little refractory, is shaped to provide optimal combustion conditions. The convection section consists of straight pin tubes with bent pins that provide a high heat transfer coefficient and a low pressure loss. Circulation is ensured by placing downcomers outside the membrane walls.

Capacity range: 12.5 – 55 t/h, 8,800 – 38,800 kW

Aalborg OLThe large capacity modular boiler plantMDD00231EN 1507Standard product range Capacity & dimensionsStandard scope of supply has the boiler mounted on a skirt. Design with feet is optional.*) boiler dry weight incl. burner, insulation, valves, and refractory.

Steam Design Thermal output Height K Height K Diameter D Height H Height H Width B Boiler dry Boiler Boiler dry Boiler ope- capacity pressure at 100% MCR (incl. retraction (incl. retraction (incl. (boiler weight*) operation weight*) ration weight of burner lance) of burner lance - insulation) increased weight (boiler (boiler boiler increased 200 mm) increased increased 200 mm 200 mm) 200 mm)

生物颗粒燃料熔炼炉使用维护、保养说明书Operation and Maintenance Instruction of Bio-mass Pellet FuelSmelting Furnace泰州杰利瑞节能科技发展有限公司Taizhou Jie Lirui Energy Technology Development Co., Ltd敬告!Attention!请用户使用前详细阅读产品使用维护、保养说明书,并请在使用过程中严格遵循产品使用维护、保养说明书,若由用户使用不当引起的损坏制造商将不承担责任,碳化硅石墨坩埚属易耗件,不在质保范围。

Please read the product operation and maintenance instruction carefully before use, and strictly follow the product operation and maintenance instruction during the operation. In case of any damage caused by improper use, the manufacturer will not be liable; the silicon carbide graphite crucible is subject to vulnerable part and excluded in the warranty scope.目录Catalog1 概述Introduction2 组成Components3 主要技术参数Main technical parameters4 主要用途及适用范围Main applications and applicable scopes5 配电要求Power distribution requirements6 安装Installation7 启动前检查Check before start-up8 烘炉Dry-off operation for furnace9 使用与维护Operation and maintenance10 碳化硅石墨坩埚使用注意事项Precautions for using silicon carbide graphite crucible11 常见故障与排除Common faults and troubleshooting12 运输及开箱检查Transportation and out-of-box inspection13 技术支持Technical support 1 概述Introduction生物颗粒燃料熔炼炉(以下简称“熔炼炉”)采用半气化复合燃烧技术,具有低碳环保、高效节能、操作维护简单的特点,是替代燃油炉、燃气炉、焦碳炉、电炉的最佳产品,可以降低30%~60%的能耗成本。

8U .52.40.03 / 01.13 C h a n g e s r e s e r v e dUser information manualPictured: Q85SN, Q130SN Q85SP , Q130SPNotice! This manual must be retained for future reference.- Do not store or use gasoline or other flammablevapors and liquids in the vicinity of this or any other appliance.- WHAT TO DO IF YOU SMELL GAS - Do NOT try to light any appliance.- Do NOT touch any electrical switch. - Do NOT use any phone in your building.- Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’sinstructions.- If you cannot reach your gas supplier, call the firedepartment.WARNING!If you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life.High efficiency condensing gas boilerQ85SN/Q130SN/Q175SN/Q205SN/Q175CN Q85SP/Q130SP/Q175SP/Q205SP/Q175CPAddress: 103 International Drive, Peachtree City, GA, 30269Toll-free: 1-800-621-9419 • Fax: 678-829-1666 • WARNING!Installation and service must be performed by a licensed professional, service agency or the gas supplier.O p e r a t i n g i n s t r u c t i o n s R i n n a i Q -S e r i e s2Contents of instructionsThese instructions contain important information for the safe use of Rinnai Q-Series gas boilers.These user instructions are intended for the owner or responsible tenant of the premises where the boiler is installed.Subject to technical changesChanges may be made to the illustrations, process steps and technical data as a result of our policy of continuous improvement without prior notice.Updating of documentationPlease contact us if you have any suggestions for improvements or corrections.Find our contact details on the back of this manual.O p e r a t i n g i n s t r u c t i o n s R i n n a i Q -S e r i e s3Please observe these instructions in the interest of your own safety.The boiler is designed to heat water for a central heating system and, if applicable, generating domestic hot water. The boiler is delivered with a burner controller pre-installed.The boiler can be fitted with a modulating outdoor reset control ARV12 (included), a room controller RS100 (optional), a zone controller (optional) or an On/Off thermostat or relay panel end switch(accessories).The following defined terms are used throughout the documentation to bring attention to the presence of hazards of various risk levels. Notices give important information concerning the operation of the product.DANGER:Indicates the presence of hazards that will cause severe personal injury, death or substantial property damage.WARNING:Indicates the presence of hazards that can cause severe personal injury, death or substantial property damage .CAUTION:Indicates presence of hazards that will or can cause minor personal injury or property damage.NOTICE:Indicates special instructions on installation, operation or maintenance that are important but not related to personal injury or propertydamage.CAUTIONWARNINGNOTICEiDANGERO p e r a t i n g i n s t r u c t i o n s R i n n a i Q -S e r i e s4These operating instructions describe the operation of the Rinnai Q-Series condensing gas boilers. This manual is for the end user. For installation and servicing there is a installation & servicing instructions manual for the installer.Read this manual fully before operating the boiler. In case of doubt or errors contact your installer. The manufacturer reserves the right to change the specifications and dimensions without prior notice.Work on the boiler must be carried out by a State licenced contractor, (Ref: Gas Safety Installation and Use) using correctly calibrated instruments with current test certification.O p e r a t i n g i n s t r u c t i o n s R i n n a i Q -S e r i e sO p e r a t i n g i n s t r u c t i o n s R i n n a i Q -S e r i e s6Should overheating occur or the gas supply fail to shut off, do not turn off or disconnect the electrical supply to the pump. Instead, shut off the gas supply at a location external to the appliance.Protection for corrosionDo not use any sprays, chlorine containing agents, solvents, paint etc. around the boiler or around the air intake supply entrance of the boiler. These substances have negative influences on the boiler and can lead to corrosion resulting in failure ofthe boiler.DANGERNOTICEiChecking the water pressureCheck the water pressure in the central heating installation regularly.Use only potable water for filling.Additives only after clearance by Rinnai.Contact your installer in case of doubt.Spray cans containing chloro-/fluorcarbons Ammonium and/or ammonium solutions Permanent wave solutions (hair product)Chlorinated waxes and/or cleanersSwimming pool chemicals based on chlorine Calcium chloride used for thawingSodium chloride used for water softening Refrigerant leaksPaint or varnish removersHydrochloric acid/muriatic acid Cements and gluesAntistatic fabric softeners used in clothes dryersChlorine-type bleaches, detergents, and cleaning solvents found in household laundry roomsAdhesives used to fasten building products and other similar productsDry cleaning/laundry areas and establishments Swimming poolsMetal fabrication plants Beauty shopsRefrigeration repair shops Photo processing plants Auto body shopsPlastic manufacturing plantsFurniture refinishing areas and establishments New building construction Remodeling areasGarages with workshopsWARNINGO p e r a t i n g i n s t r u c t i o n s R i n n a i Q -S e r i e s7has an integrated domestic hot water feature.The boiler is provided with a integrated control system. Because an outdoor sensor is connected to the boiler, the boiler works weather dependantly. This means that the boiler control measures the outside temperature and flow temperature. With this data the boiler calculates the optimal flow temperature for the installation.When the boiler is connected to an RS100 room thermostat information can be retrieved from the boiler. For more information about the Rinnai thermostats. Please refer to the user manuals.On the bottom left side of the front panel there is a small door. Through the transparent panel you can see the boiler status on the display. After opening this door you will find the function buttons. On the following pages you will find the explanation of the function buttons and display messages.O p e r a t i n g i n s t r u c t i o n s R i n n a i Q -S e r i e s8Only licensed professionals who are trained for these boilers are permitted to make alterations in the controller to program the boiler to the installation.1. Display .See following pages for further information.2. ON-OFF SwitchThis switch turns the power supply to the boiler on or off.3. Central Heating program button.Switching the Central Heating on or off (Led on/off);4. Hot Water program button.Switching the Domestic Hot Water (DHW) facility on or off (Led on/off);5. Pump program button.When the pump program LED is ON, the pumpis switched into a continuous circulation mode. When the pump mode is switched OFF, LED is off the pump is control by the boiler processor. In most situations it is best to leave the pump mode OFF and let the boiler control cycle the pump as needed.During freezing temperatures it is possible (when there is no outside sensor connected), to manually place the circulation pump in constant circulation mode, thus reducing the chance of freezing pipes (garage, attic or other cold spaces / rooms) which are sensitive to frost.NOTICEiNOTICEiO p e r a t i n g i n s t r u c t i o n s R i n n a i Q -S e r i e s96 Mode-button.Only for Service personel 7 Step-button.After briefly pressing, the water pressure can be retrieved.After pressing for 5 seconds it switches from the Good-state to technical read out and vice versa (see following pages);8 Reset-button.When a fault occurs it will be shown by the flashing E (Error) with a number code after which the boiler is shut down. After pressing the reset key you can try to start the boiler again. If the error message keeps occurring contact your installer.DO NOT attempt to make repairs or remove any of the boiler panels. Contact a licensed professional to make necessary repairs oradjustments.WARNINGO p e r a t i n g i n s t r u c t i o n s R i n n a i Q -S e r i e s10Two boiler displays, “Good or Technical” see below.Goodor standard read out.During this reading the display will only show what is necessary. Under normal circumstances the display will give a Good reading. In case of a fault this will be shown with, alternate display of Good, with an E or BL code. See further "Errors, maintenance and warranty" .TechnicalThe second way is a technical read out. In normal situations the following will be shown:• on the left the status in which the boiler is active (see bottom of this page);• on the right the supply temperature in °F; • the water pressure in the installation in PSI. When a message (E or BL code) is necessary this will be shown instead of the technical read out.Operation indication(in the first display position by technical read out)No heat demand Fan pre/post purge Ignition phaseBurner active on central heating Burner active on DHW Fan checkBurner off when room thermostat is demanding Pump overrun phase for central heating Pump overrun phase for hot waterBurner off because of to high flow temperatureAutomatic de-aeration program (Press no button for 17 min.)O p e r a t i n g i n s t r u c t i o n s R i n n a i Q -S e r i e s11The installation will function optimally with a water pressure of between 16 and 18 PSI.If the water pressure drops below 12 PSI, the display will show FILL . During this message the boiler will remain functioning at a reduced level. After replenishing the system (see following chapter) just above 22 PSI the message FILL will disappear and the boiler will function normally again.When the water pressure drops below 10 PSI, the display will show a flashing FILL text.The boiler will shut down and will function normally again after replenishing the system to just above 22 PSI.To retreive the water pressure on the display from the Good reading:- Press the Step key once briefly. The water pressure will be shown.Press the Step key briefly to return to the Good reading .Water pressure is too high (>42 PSI), if HIGH indication remains continuously visible, the boiler is taken out of operation. The installation pressure needs to be decreased by draining water until thepressure is between 16 and 18 PSI.Message ' Water pressure too low' on your RS100 thermostat.On the display of the RS100 a low water pressure can be indicated. For further information see the relevantuser manual.O p e r a t i n g i n s t r u c t i o n s R i n n a i Q -S e r i e s12The central heating installation needs to be filled with potable (drinking) water. For topping up the installation you use the filling loop according to the following procedure:Contact your licensed professional installer if your installation is not provided with a filling loop.1 Switch all functions off (heating, DHW and pump);2 Briefly push the 'STEP'-button: P x.x = water pressure in PSI;3 Slowly open the filling loop (Indication on display increases);4 Fill up slowly to between 16 and 18 PSI;5 STOP appears on the display;6 Close the filling loop;7 De-aerate the complete installation , start at the lowest point;8 Check the water pressure and if necessary top it up; 9 Close the filling loop;10 Activate functions required (heating, DHWand/or pump );11 If A xx appears on the display, wait for 17 minutes;12 Check the waterpressure and if necessary top it up to 16 to 18 PSI13 Close the filling loop;14 Press the ‘STEP’-button;15 Be sure that the filling loop is closed.After the automatic de-aeration programm (A xx) is finished the boiler will return to the Good reading or Technical reading.NOTICEiO p e r a t i n g i n s t r u c t i o n s R i n n a i Q -S e r i e s13Holiday period:Adjust the thermostat* to the holiday period. See the user thermostat manual. The hot water facility can be switched off by means of the program button on the control panel.Re-setting the central heating system: , , when these are activated. Switch off the power supply. When the boiler is being drained one should take into account that a part of the heating water will remain in the boiler. When risk of freezing arises one should take care that the remaining central heating water in the boiler does not freeze.Holiday* If you have a RS100 thermostat it is provided with a holiday program. The holiday period can be adjusted on the thermostat itself. The central heating and DHW supply are switched off during that period. There is also the option that only the central heating is switched off. With all of these possibilities the freeze protection system is active.Check the water pressure regularly and top up the installation when necessary.The working pressure of the installation should be between 16 and 18 PSIO p e r a t i n g i n s t r u c t i o n s R i n n a i Q -S e r i e s14If a fault is detected the boiler will be blocked. This will be reflected, by an alternate display of Good, with an E of Error or a BL of Blocking and a number code.You can try to reset the boiler by pressing the Reset key once. If the problem remains please contact your installer and inform them about the fault and give them the number code.If you discover any leaks from the boiler contact your installer.We advise you to obtain a service contract with your installer for regular maintance and adjustment to keep your boiler safe and in good condition.The casing of the boiler consists of metal and plastic parts which can be cleaned with a normal non abrasive cleaning agent.Periodic cleaning of the condensate collection and disposal system must be carried out.Before putting the boiler into operation after periodic cleaning fill the condensate trap with 1.27 cups / 300 ml of water.Step 1: Condensate trap- First remove the condensation cup (7); Check this for impurities. If there are no impurities it is not necessary to clean the condensate cup - Grease the O-rings again with acid free O-ring grease to make fitting easier;- If there is a leak at the condensation cup (7) or tray (9) the complete condensate trap unit (10) has to be replaced by # 809000054;Step 2: Refitting is done in reverse order.Note that all gaskets seal completely.NOTICEi NOTICEi NOTICEi NOTICEiO p e r a t i n g i n s t r u c t i o n s R i n n a i Q -S e r i e s15Maintenance or changes to the appliance may only be carried out by a licensed professional.You can find the warranty conditions in the warranty card which is supplied with the boiler.NOTICEiE. & O. E.T h i s r e n e w e d p u b l i c a t i o n c a n c e l s a l l p r e v i o u s i n s t a l l a t i o n i n s t r u c t i o n s . T h e c o m p a n y r e s e r v e s t h e r i g h t t o c h a n g e t h e s p e c i fi c a t i o n s a n d d i m e n s i o n s w i t h o u t p r i o r n o t i c e .Distributor for the USARinnai America Corporate • 103 International Drive • Peachtree City, GA 30269To l l F r e e : (800) 621-9419 • Te l : (678) 829-1700 • F a x : (678) 829-1666 • E -m a i l : i n f o @r i n n a i.u s • I n t e r n e t : w w w.r i n n a i.u s800000010 01/2013。

DG型工业锅炉给水泵Type DG Industrial Boiler Feed Pump安装使用说明书Instruction On Installation And Operation湖南湘电长泵(长沙水泵厂)长一制泵有限公司ChangYi Pump Manufacturing Co.,Ltd. Of XiangDian ChangSha Pump Works一、概述DG型泵系单吸、多级、节段式离心清水泵,适用于中、低压及次高压锅炉给水、工厂、城市高扬程输水。

供输送清水或物理化学性质似于清水的液体,输送介质温度:-20℃~150℃(DG85-80、200DG43除外、此两种泵输送介质温度为-20℃~150℃)。

泵进口压力不得超过0.59MPa(6kgf/cm2)。

参数范围:流量Q 6~346m3/h扬程H 102~1056m型号说明本型泵的型号有三种表示方法,举例分述如下:1)例40DG140×6型号中:40----泵吸入口直径为40毫米DG1---多级,节段式锅炉给水泵40----单级扬程为40米6----级数为6级此种型号表示的泵有:40DG1402)例DG25─50×5型号中:DG---多级,节段式锅炉给水泵25---流量为25米3/时50---单级扬程为50米5---级数为5级此种型号表示的泵有:DG25-50 DG46-50 DG85-67 DG155-673)例DG80─30×4型号中:DG---多级,节段式锅炉给水泵80---吸入口直径为80米30---单级扬程为30米4---级数为4级此种型号表示的泵有:DG80-30Ⅰ.GeneralType DG pump is single-suction, multi-stage, segmental centrifugal pump. It is used for feeding water of low-middle pressure boiler as well as pumping high lift water of factory and city. It is provided for delivering clear water or other liquid which is physically similar to clear water. The temperature of the liquid for type DG85-80 and 200DG43 pump is -20℃~150℃,the temperature of liquid for the others usually is -20℃~105℃. The maximum inlet pressure is not allowed more than 0.59MPa(6kgf/cm2).Performance rangeCapacity Q:6~346m3/hHead H:102~1056mDescription of pump typeExample 1 40DG140×640------------Inlet diameter of pump(mm).DG1---------Single-suction, multi-stage, boiler feed water pump.40-----------Single-stage head of pump(m).6-------------Pump stage numberSuch as type 40DG140.Example 2 DG25-50×5DG----------Single-suction, multi-stage, boiler feed water pump.25-----------Pump capacity(m3/h).50-----------Single-stage head of pump(m).5-------------Pump stage number.Such as type DG25-50 、DG46-50、DG85-67、DG155-67.Example 3 DG80-30×4DG----------Single-suction, multi-stage, boiler feed water pump.80-----------Inlet diameter of pump(mm).30-----------Single-stage head of pump(m).4-------------Pump stage number.Such as type DG80-30.二、结构说明本型泵主要由壳体部分,转子部分,平衡机构,轴承部分及密封部件组成。

运行培训主要从以下方面考虑一. 锅炉结构二. 锅炉燃烧特点三. 锅炉运行操作程序四. 事故处理SZL20-1.25-AⅡ锅炉安装使用说明书目录第一部分设计说明 (3)一、锅炉概述 (3)二、锅炉结构简介 (5)三、锅炉性能特点 (7)第二部分安装说明 (8)一、前言 (8)二、安装前的准备 (8)三、锅炉大件的安装 (10)四、筑炉 (10)五、煤闸门的调整 (12)六、调速箱的安装 (12)七、出渣机的安装 (12)八、烟风道装置及省煤器的安装 (12)九、风机(鼓、引风机)的安装 (12)十、管道、仪表、阀门的安装 (13)十一、平台扶梯的安装 (13)十二、电控箱的安装 (13)十三、水压试验 (14)十四、烘炉 (14)十五、煮炉 (15)第三部分使用说明 (17)一、调整安全阀 (17)二、升火 (17)三、运行 (19)四、排污及放水 (23)五、停炉 (24)六、维护保养 (27)七、受压元件的检验和水压试验 (29)第一部分设计说明一锅炉概述SZL20-1.25-AⅡ型锅炉为我厂在借鉴了国内外成功运行的各种类型锅炉有益的经验、技术的基础上,优化设计的双锅筒、纵置式自然循环水管锅炉。

本锅炉在设计中,充分考虑了用户的煤质和水质要求,适合机组在满负荷状态下的稳定运行。

1、锅炉规范额定蒸发量 20t/h饱和蒸汽温度 193.3℃额定蒸汽压力(表压) 1.25MPa给水温度 60℃预热器入口风温 30℃2、燃料本锅炉适用于燃用低位发热值16500~21700KJ/kg范围内,挥发份≮25%、灰分≤35%的Ⅱ类烟煤。

颗粒度:0~3mm<30%,最大颗粒度≯30mm设计煤种的收到基成分:序号名称符号单位数值1 碳Car % 46.552 氢Har % 3.063 氧Oar % 6.114 氮Nar % 0.865 硫Sar % 1.946 灰分Aar % 32.487 水分War % 98 挥发分Var % 38.59 低发热值Qnet.ar KJ/kg 176943、锅炉给水及锅水品质指标锅炉给水及锅水应符合GB1576中华人民共和国《工业锅炉水质》标准表1规定。

目录一、概述 (2)二、燃油(气)蒸气、承压热水锅炉技术规范 (3)三、锅炉使用前注意事项 (4)四、燃油(气)蒸气、承压热水锅炉本体结构概述 (5)五、安装要求 (7)六、蒸气、承压热水锅炉运行调试 (8)七、蒸气、承压热水锅炉的操作说明 (9)八、蒸气、承压热水锅炉的保养与维修 (10)九、蒸气、承压热水锅炉安装示意图 (11)一、概述为了确保锅炉的安全运行和劳动人民生命财产安全,本系列锅炉的设计、制造、安装、使用、维修都必须严格执行《蒸气锅炉安全技术监察规程》、《热水锅炉安全技术监察规程》、JB/T1619-2002《锅壳锅炉本体制造技术条件》、GB1576-2001《工业锅炉水质》、GB13271-2001《锅炉大气污染物排放标准》、JB/1615-93《锅炉油漆和包装技术条件》。

锅炉采用氩弧焊和手工焊,水压试验按JB/T7985-95标准要求执行,锅炉安装应符合国家有关规定。

●承压热水锅炉型号:W N S ××-×× / ×× / ××-Q(Y)76543211、卧式2、内燃3、室燃4、额定热功率MW5、额定工作压力MPa6、××/××出、回水温度℃7、燃料的种类:轻油、天然气、城市煤气、石油液化气等●蒸气锅炉型号:W N S ××-××-Q(Y)6543211、卧式2、内燃3、室燃4、额定蒸发量Kg/h5、额定工作压力MPa6、燃料的种类:轻油、天然气、城市煤气、石油液化气等二、锅炉技术规范1、蒸气锅炉参数表WNS0.5- WNS1- WNS2- WNS3- WNS4- WNS6- WNS8- WNS10- WNS15 0.7 1.0 0.7 1.0 1.0 1.25 1.0 1.25 1.0 1.25 1.6 1.0 1.25 1.6 1.0 1.25 1.6 1.25 1.6 1.25 -Y(Q) -Y(Q) -Y(Q) -Y(Q) -Y(Q) -Y(Q) -Y(Q) -Y(Q) -Y(Q)2、承压热水锅炉参数表注:燃烧机使用的电源(AC)380V,50HZ三、锅炉使用前注意事项1、锅炉房布置应符合《蒸气锅炉安全技术监察规程》、《热水锅炉安全技术监察规程》和GB50041~91《锅炉房设计规范》。

boiler 锅炉(guōlú)boiler unit 锅炉(guōlú)机组stationary boiler 固定式锅炉(guōlú) steam boiler/generator 蒸汽锅炉utility boiler 电站(diàn zhàn)锅炉industrial boiler 工业锅炉hot water boiler 热水锅炉indoor boiler 室内锅炉ourdoor boiler 露天锅炉package boiler 快装锅炉shop-assembled boiler 组装锅炉field-assembled boiler 散装锅炉field-erected boilersupercritical pressure boiler 超临界压力锅炉subcritical pressure boiler 亚临界压力锅炉superhigh pressure boiler 超高压锅炉high pressure boiler 高压锅炉medium pressure boiler 中压锅炉low pressure boiler 低压锅炉natural circulation boiler 自然循环锅炉forced circulation boiler 强制循环锅炉assisted circulation boiler 辅助循环锅炉controlled circulation boiler 控制循环锅炉once-through boiler 直流锅炉combined circulation boiler 复合循环锅炉low circulation-ratio boiler 低循环倍率锅炉solid-fuel fired boiler 固体燃料锅炉liquid-fuel fired boiler 液体燃料锅炉coal fired boiler 燃煤锅炉oil fired boiler 燃油锅炉gas fired boiler 燃气锅炉multi-fuel fired boiler 混烧锅炉boiler with dry-ash furnace 固态排渣锅炉boiler with dry-bottom furnaceboiler with slag-tap furnace 液态排渣锅炉boiler with wet-bottom furnace supercharged boiler 增压锅炉water tube boiler 水管锅炉cross drum boiler 横锅筒(汽包)锅炉longitudinal drum boiler 纵锅筒(汽包)锅炉shell boiler 锅壳锅炉horizontal boiler 卧式锅壳锅炉vertical boiler 立式锅炉stationary boiler of locomotive type 固定式机车锅炉锅炉专业英语分类对照π-type boiler(two-pass boiler) π型锅炉box-type boiler 箱型锅炉tower boiler 塔型锅炉D-type boiler D型锅炉rated capacity 额定蒸发量nominal capacitymaximum continuous rating 最大连续蒸发量rated heating capacity 额定供热量nominal steam condition 额定蒸汽参数nominal steam parameternominal steam pressure 额定蒸汽压力nominal steam temperature 额定蒸汽温度(nominal) hot water temperature 热水温度feed water temperature 给水温度return water temperature 回水温度circulation circuit 循环回路steam generating circuitsteam purification 蒸汽净化steam temperature control 汽温调节feed water 给水condensate 凝结水make-up water 补给水boiler water 锅水;炉水boiling crisis 沸腾换热恶化as-fired fuel 炉前燃料fire bed 火床fuel bedfire line 最高火界additive 添加剂flue gas dew point 烟气露点boiler circulation 水循环mechanical carry-over 机械携带moisture carry-overvaporous carry-over 溶解携带water separation 汽水分离steam washing 蒸汽清洗stage evaporation 分段蒸发pressurized firing 压力燃烧negative-pressure firing 负压燃烧grate firing 火床燃烧suspension firing 火室燃烧;悬浮燃烧tangential firing 切向燃烧opposed firing 对冲燃烧cyclone-furnace firing 旋风燃烧fluidized-bed combustion 沸腾燃烧gas recirculation 烟气再循环natural draft 自然通风mechanical draft 机械(jīxiè)通风balanced draft 平衡(pínghéng)通风forced draft 正压通风(tōng fēng)induced draft 负压(fù yā)通风zone control 分段送风pressure atomization 压力雾化;机械雾化mechanical atomizationtwin-fluid atomization 双流体雾化rotary-cup atomization 旋杯雾化;转杯雾化direct leakage 直接泄漏infiltration leakagebypass leakage 间接泄漏entrained leakageboiler proper 锅炉本体heating surface 受热面radiant heating surface 辐射受热面convection heating surface 对流受热面pressure part 受压部件;受压元件cylindrical shell 筒体head 封头;端盖header 集箱;联箱tube panel 管屏up flow riser tube panel 垂直上升管屏ribbon panel 回带管屏spirally-wound tubes 水平围绕管圈tube bundle 管束gas pass 烟道gas ductconvection pass 对流烟道parallel gas passes 并联烟道air duct 风道arch 拱furnace arch 折焰角water-cooled hopper bottom 冷灰斗wall with refractory lining 卫燃带refractory beltsupporting tube 悬吊管design pressure 设计压力maximum allowable working pressure 最高允许工作压力maximum allowable metal temperature 最高许用壁温furnace enclosure design pressure 炉膛设计压力heat input 输入热量heat output 锅炉有效利用热量fuel consumption 燃料消耗量calculated fuel consumption 计算燃料消耗量ash-retention efficiency 排渣率load range at constant temperature (保持)额定汽温的负荷范围injection flow(rate) 喷水量blowdown flow(rate) 排污量theoretical air 理论空气量excess air ratio 过量空气系数hot air temperature 热风温度exhaust gas temperature 排烟温度theoretical combustion temperature 理论燃烧温度adiabatic temperaturefurnace outlet gas temperature 炉膛出口烟气温度furnace exit gas temperaturepressure drop 汽水阻力draft loss 通风阻力pressure dropstack draft 自生通风压头available static head 运动压头circulation ratio 循环倍率circulation velocity 循环水速steam quality by mass 质量含汽率;干度mass velocity 质量流速critical steam quality 临界含汽率steam quality at minimum heat transfer coefficient 最高壁温处含汽率furnace volume 炉膛容积furnace volume heat release rate 炉膛容积热负荷heat liberation rate in furnacefurnace cross-section heat release rate 炉膛截面积热负荷furnace plan heat release rateburner zone wall heat release rate 燃烧器区域炉壁热负荷furnace wall heat release rate 炉壁热负荷furnace wall heat flux density 炉壁热流密度critical heat flux density 临界热流密度grate heat release rate 炉排(面积)热负荷burner heat input 燃烧器热功率ignition energy 点火能量evaporation rate 受热面蒸发率percentage of economizer evaporation 省煤器沸腾率primary air 一次风secondary air 二次风tertiary air 三次(sān cì)风imaginary circle 假想(jiǎxiǎng)切圆percentage of air space 通风(tōng fēng)截面比fineness 煤粉细度explosion mixture limits 爆炸(bàozhà)界限furnace 炉膛;炉胆fire box 火箱smoke box 烟箱burner 燃烧器tilting burner 摆动式燃烧器igniter 点火器oil atomizer 油雾化器register 调风器stabilizer 稳燃器wind box 风箱burner port 燃烧器喷口burner quarlgrate 炉排hand-fired grate 手烧炉排stoker-fired grate 机械炉排mechanical stokertravelling grate stoker 链条炉排chain grate stoker 链带式炉排bar grate stoker 横梁式炉排louvre stoker 鳞片式炉排vibrating stoker 振动炉排inclined reciprocating grate 往复炉排spreader stoker 抛煤机air compartment 风室reinjection system 飞灰复燃装置drum 锅筒;汽包steam drum 上锅筒water drum 下锅筒shell 锅壳drum internals 锅筒内部装置;汽包内部装置steam washer 清洗装置cyclone separator 旋风分离器turbo separator 轴流式分离器baffle plate 缝隙挡板corrugated scrubber 百叶窗分离器screen separator 钢丝网分离器perforated distribution plate 多孔板dry pipe 集汽管evaporating heating surface 蒸发受热面water-cooled wall 水冷壁membrane wall 膜式水冷壁division wall 双面水冷壁anti-clinker box 防焦箱gererating tube bank 锅炉管束boiler convection tube bankboiler (slag) screen 防渣管fire tube;smoke tube 烟管;火管mixer 混合器superheater 过热器radiant superheater 辐射过热器wall superheater 墙式过热器platen superheater 屏式过热器convection surperheater 对流过热器steam-cooled wall 包墙过热器steam-cooled roof 顶棚管过热器reheater 再热器attemperator 减温器desuperheatersurface type attemperator 面式减温器surface type desuperheaterspray type attemperator 喷水减温器spray type desuperheaterbiflux 汽-汽热交换器reheater superheater attemperator bypass damper 旁路挡板economizer 省煤器steaming economizer 沸腾式省煤器steel tube economizer 钢管省煤器finned tube economizer 鳍片管省煤器cast-iron gilled tube economizer 铸铁省煤器air heater 空气预热器tubular air heater 管式空气预热器rotary air heater 回转式空气预热器regenerative air heaterrotating-plate type regenerative air heater 受热面回转式预热器Ljungstrom type air heaterstationary-plate type regenerative air heater 风罩回转式预热器rothemuhle type air heatersteam air heater 暖风器boiler structure 锅炉构架top-supported structure by beams 支承式锅炉构架top-supported structure by hangers 悬吊式锅炉构架buckstay 刚性梁inner casing 内护板outer casing 外护板boiler steam and water circuit 锅炉(guōlú)汽水系统boiler external piping 锅炉(guōlú)范围内管道start-up system 启动(qǐdòng)系统start-up flash tank 启动(qǐdòng)分离器safety valve 安全阀safety relief valve 安全泄放阀water level indicator 水位表injector 注水器boiler setting 炉墙soot blower 吹灰器slag removal equipment 除渣设备boiler efficiency 锅炉效率;锅炉热效率boiler operating availability 锅炉可用率boiler forced outage rate 锅炉事故率feed water condition 给水品质steam purity 蒸汽品质moisture in steam 蒸汽湿度boiler water concentration 锅水浓度;炉水浓度total dissolved salt 总含盐量total solid (matter) 全固形物dissolved solid (matter) 溶解固形物suspended solid (matter) 悬浮物total hardness (总)硬度alkalinity 碱度heat loss 热损失heat loss due to exhaust gas 排烟热损失heat loss due to unburned gases 气体(化学)未完全燃烧热损失heat loss due to unburned carbon inrefuse 固体(机械)未完全燃烧热损失heat loss due to radiation 散热损失heat loss due to sensible heat in slag 灰渣物理热损失unburned combustible in flue dust 飞灰可燃物含量;飞灰含碳量unburned carbon in flue dustunburned combustible in slag 炉渣可燃物含量;炉渣含碳量unburned carbon in slagunburned combustible in sifting 漏煤可燃物含量dust loading 烟气含尘量dust densityload range of boiler 锅炉负荷调节范围turndown ratio 燃烧器调节比air leakage factor 漏风系数set pressure 整定压力start-to-discharge pressure 前泄压力popping pressure 起座压力reseating pressure 回座压力blowdown 回座压差discharge capacity 排放量;排汽能力boiler efficiency test 锅炉效率试验;锅炉热效率试验hydrostatic test 水压试验hydrostatic deformation test 验证性水压试验air leakage test 漏风试验pressure decay test 风压试验load test 负荷试验circulation test 水循环试验thermal chemical test 热化学试验sounding of tube by balls 通球试验safety valve operating test 安全阀校验flue gas analysis 烟气分析Orsat (gas analyser) 奥氏(烟气)分析器suction pyrometer 抽气式热电偶(高温计)venturi pneumatic pyrometer 气力式高温计heat flux meter 热流计start-up 启动filling 上水water level 水位initial water level 点火水位purge 吹扫blowoff 放水drain 疏水blowdown 排污raising pressure 升压bringing a boiler onto the line 并汽start-up pressure 启动压力start-up flow rate 启动流量shutdown 停炉outageout of service 停用banking fire 压火storage 停炉保护chemical cleaning 化学清洗boiling-out (碱)煮炉flushing 冲管steam-line blowing 吹管passivating 钝化drying-out 烘炉flow stagnation 停滞flow reversal 倒流separation of two-phase fluid 汽水分层steam binding 汽塞steam blanketingpriming 汽水(qìshuǐ)共腾foaming 泡沫(pàomò)共腾external deposit 烟气(yān qì)侧沉积物internal deposit 汽水(qìshuǐ)侧沉积物slagging 结渣fouling 积灰clogging 堵灰pitting attack 点状腐蚀ductile gouging 延性腐蚀hydrogen damage 氢脆caustic embrittlement 苛性脆化high temperature corrosion 高温腐蚀low temperature corrosion 低温腐蚀overheating 超温;过热flashback 回火blow off 脱火loss of ignition 熄火;灭火furnace explosion 炉膛爆炸furnace implosion 炉膛内爆furnace puff 炉膛爆燃blow hole 火口secondary combustion 二次燃烧1.parameter/参数rated capacity 额定蒸发量nominal capacitymaximum continuous rating 最大连续蒸发量rated heating capacity 额定供热量nominal steam condition 额定蒸汽参数nominal steam parameternominal steam pressure 额定蒸汽压力nominal steam temperature 额定蒸汽温度(nominal)hot water temperature 热水温度feed water temperature 给水温度return water temperature 回水温度circulation circuit 循环回路steam generating circuitsteam purification 蒸汽净化steam temperature control 汽温调节feed water 给水condensate 凝结水make-up water 补给水boiler water 锅水,炉水boiling crisis 沸腾换热恶化as-fired fuel 炉前燃料fire bed,fuel bed 火床fire line 最高火界additive 添加剂flue fas dew point 烟气露点Components for CFBC boiler (CFBC锅炉的主要部件)2.基本工作原理boiler circulation 水循环mechanical carry - over 机械携带moisture carry - overvaporous carry - over 溶解携带water separation 汽水分离steam washing 蒸汽清洗stage evaporation 分段蒸发pressurized firing 压力燃烧negative - pressure firing 负压燃烧grate firing 火床燃烧suspension firing 火室燃烧,悬浮燃烧tangential firing 切向燃烧opposed firing 对冲燃烧cyclone - furnace firing 旋风燃烧fluidized - bed combustion 沸腾燃烧gas recirculation 烟气再循环natural draft 自然通风mechanical draft 机械通风balanced draft 平衡通风forced draft 正压通风induced draft 负压通风zone control 分段送风pressure atomization 压力雾化,机械雾化mechanical atomizationtwin-fluid atomization 双流体雾化rotary-cup atomization 旋杯雾化,转杯雾化direct leakage 直接泄漏infiltration leakagebypass leakage 间接泄漏entrained leakage3.structure/结构boiler proper 锅炉本体heating surface 受热面radiant heating surface 辐射受热面convection heating surface 对流受热面pressure part 受压部件/元件cylidrical shell 筒体head(drum)封头head(heater)端盖header 集箱tube panel 管屏up flow riser tube panel 垂直上升管屏ribbon panel 回带管屏spirally - wound tubes 水平围绕管圈tube bundle 管束gas pass ,gas duct 烟道炉内/炉外convection pass 对流(duìliú)烟道parallel gas pass 并联(bìnglián)烟道air duct 风道(fēnɡ dào)arch 拱furnace arch 折焰角water - cooled hopper bottom 冷灰斗wall with refractory lining 卫燃带refractory beltsupporting tube 悬吊管4.设计参数(cānshù)和指标design pressure 设计压力maximum allowable working pressure 最高允许工作压力maximum allowable metal temperature 最高许用壁温furnace enclosure design pressure 炉膛设计压力heat input 输入热量heat output 锅炉有效利用热量fuel consumption 燃料消耗量calculated fuel consumption 计算燃料消耗量ash-retention efficiency 排渣率额定汽温的负荷范围injection flow(rate) 喷水量blowdown flow(rate) 排污量theoretical air 理论空气量excess air ratio 过量空气系数hot air tempereture 热风温度exhaust gas tempereture 排烟温度theoretical combustion tempereture 理论燃烧温度adiabatic tempereturefurnace outlet gas tempereture 炉膛出口烟气温度funace exit gas tempereturepressure drop 汽水阻力draft loss (用于负压燃烧)通风阻力pressure drop(压力燃烧)stack draft 自生通风压头available static head 运动压头circulation ratio 循环倍率circulation velocity 循环水速steam quality by mass 质量含汽率,干度mass velocity 质量流速critical steam quality 临界含汽率steam quality at minimum heat transfer coefficient 最高壁温处含汽率furnace volume 炉膛容积furnace volume heat release rate 炉膛容积热负荷heat liberation rate in furnacefurnace cross-section heat release 炉膛截面积热负荷furnace plan heat release rateburner zone wall heat release rate 燃烧器区域热负荷furnace wall heat release rate 炉壁热负荷fernace wall heat flux density 炉壁热流密度critical heat flux density 临界热流密度grate heat release rate 炉排(面积)热负荷burner heat input 燃烧器热功率ignition energy 点火能量evaporation rate 受热面蒸发率percentage of economizer evaporation 省煤器沸腾率Primary air 一次风Secondary air 二次风imaginary circle 假想切圆percentage of air space 通风截面积fineness 煤粉细度explosion mixture limits 爆炸界限5.主要零部件,元件和附件炉膛和燃烧设备furnace 炉膛fire box 火箱smoke box 烟箱burner 燃烧器tilting burner 摆动式燃烧器igniter 点火器oil atomizer 油雾化器register 调风器stabilizer 稳燃器Wind box 风箱burner port/burner fquarrel 燃烧器喷口grate 炉排inclined reciprocating grate 往复炉排pnleum 风室6.drum & drum internal 锅筒及其内部装置drum 锅筒steam drum 上锅筒/汽包water drum 下锅筒shell 锅壳drum linternals 锅筒/汽包内部装置steam washer 清洗装置cyclone scrubber 旋风分离器turbo separator 轴流式分离器baffle plate 波形板coffugated scrubbber 百叶窗分离器screen separator 钢丝(ɡānɡ sī)分离器perforated distribution plate 多孔板dry pipe 集汽管7.evaporating heating surface/蒸发(zhēngfā)受热面evaporating heating surface 蒸发(zhēngfā)受热面water-cooled wall 水冷壁membrane wall 膜式水冷壁division wall 双面水冷壁anti -clinker box 防焦箱generating tube bank 锅炉(guōlú)管束boiler convection tube bank 锅炉管束boiler (slag) screen 放渣管smoke tube 火管mixer 混合器8.superheater &reheater/ 过热器及再热器superheater 过热器radiant superheater 辐射过热器wall superheater 包墙过热器platen superheater 屏式过热器convection superheater 对流过热器steam-cooled wall 汽冷包墙steam -cooled roof 汽冷顶棚reheater 再热器attemperator 减温器surface type attemperator 面式减温器Spray type attemperator 喷水减温器bypass damper 旁路挡板biflux 汽-汽热交换器9.economizer 省煤器economizer 省煤器steam economizer 沸腾式省煤器steel tube economizer 钢管省煤器finned tube economizer 鳍片省煤器cast-lron economizer 铸铁省煤器10.air heater / 空气预热器air heater 空气预热器tubular air heater 管式空气预热器steam air heater 暖风管11.structure / 构架boiler structure 锅炉构架top-supported struture by beams 支撑式锅炉构架top -supported structure by hangers 悬吊式锅炉构架buckstay 刚性梁inner casing 内护板outer casing 外护板12.piping & accessory / 管道及附件boiler steam and water circuit 锅炉汽水系统boiler external piping 锅炉范围内管道start-up system 启动系统start-up flash tank 启动排污罐safety valve 安全阀safety relief valve 安全泄放阀water level indicator 水位表injector 注水器level switch 电接点水位计13.Others 其他boiler setting 炉墙soot blower 吹灰器slag removal equipment 除渣设备14.technic index/ 技术指标boiler efficiency 锅炉效率(热效率)boiler operating availability 锅炉可用率boiler forced outage rate 锅炉事故率feed water condition 给水品质steam purity 蒸汽品质moisture in steam 蒸汽湿度boiler water concentration 锅水浓度,炉水浓度total dissolved salt 总含盐量tatal solid(matter)全固形物dissolved solid(matter) 溶解固形物suspended solid(matter) 悬浮物tatal hardness (总)硬度alkalinity 碱度heat loss 热损失heat loss due to exhaust gas 排烟热损失heat loss due to unburned gases 气体(化学)未完全燃烧热损失heat loss due to unburned carbon in refuse 固体(机械)未完全燃烧热损失heat loss due to flue dust 散热损失heat loss due to sensible heat in slag 灰渣物理热损失undurned combustible in flue dust 飞灰可燃物含量undurned cabon in flue dust 飞灰含碳量undurned cabon in slag 炉渣含碳量undurned combustible in sifting 漏煤可燃物含量dust loading/dust density 烟气含尘量load range of bioler 锅炉负荷调节范围turndown ratio 燃烧器调节比air leakage factor 漏风(lòu fēng)系数set pressure 整定压力(yālì)start-to-discharge pressure 前泄压力(yālì) popping pressure 起座压力(yālì)reseating pressure 回座压力blowdown 回座压差discharge capacity 排放量。

boiler锅炉boiler unit锅炉机组stationary boiler固定式锅炉steam boiler/generator蒸汽锅炉utility boiler电站锅炉industrial boiler工业锅炉hot water boiler热水锅炉indoor boiler室内锅炉outdoor boiler露天锅炉package boiler快装锅炉shop-assembled boiler组装锅炉field-assembled boiler散装锅炉field-erected boiler 超临界压力锅炉supercritical pressure boilersubcritical pressure boiler亚临界压力锅炉superhigh pressure boiler超高压锅炉high pressure boiler高压锅炉medium pressure boiler中压锅炉low pressure boiler低压锅炉natural circulation boiler自然循环锅炉forced circulation boiler强制循环锅炉assisted circulation boiler辅助循环锅炉controlled circulation boiler控制循环锅炉once-through boiler直流锅炉combined circulation boiler复合循环锅炉low circulation-ratio boiler低循环倍率锅炉solid-fuel fired boiler固体燃料锅炉liquid-fuel fired boiler液体燃料锅炉coal fired boiler燃煤锅炉oil fired boiler燃油锅炉gas fired boiler燃气锅炉multi-fuel fired boiler混烧锅炉boiler with dry-ash furnace固态排渣锅炉boiler with dry-bottom furnaceboiler with slag-tap furnaceboiler with wet-bottom furnacesupercharged boiler增压锅炉water tube boiler水管锅炉cross drum boiler横锅筒(汽包)锅炉longitudinal drum boiler纵锅筒(汽包)锅炉shell boiler锅壳锅炉horizontal boiler卧式锅壳锅炉vertical boiler立式锅炉stationary boiler of locomotive type固定式机车锅炉π-type boiler(two-pass boiler)π型锅炉box-type boiler箱型锅炉tower boiler塔型锅炉D-type boilerD型锅炉rated capacity额定蒸发量nominal capacity最大连续蒸发量maximum continuous ratingrated heating capacity额定供热量nominal steam condition额定蒸汽参数nominal steam parameter额定蒸汽压力nominal steam pressurenominal steam temperature额定蒸汽温度(nominal) hot water temperature热水温度feed water temperature给水温度return water temperature回水温度circulation circuit循环回路steam generating circuit蒸汽净化steam purificationsteam temperature control汽温调节feed water给水condensate凝结水make-up water补给水boiler water锅水;炉水boiling crisis沸腾换热恶化as-fired fuel炉前燃料fire bed火床fuel bed最高火界fire lineadditive添加剂flue gas dew point烟气露点boiler circulation水循环mechanical carry-over机械携带moisture carry-over溶解携带vaporous carry-overwater separation汽水分离steam washing蒸汽清洗stage evaporation分段蒸发pressurized firing压力燃烧negative-pressure firing负压燃烧grate firing火床燃烧suspension firing火室燃烧;悬浮燃烧tangential firing切向燃烧opposed firing对冲燃烧cyclone-furnace firing旋风燃烧fluidized-bed combustion沸腾燃烧gas recirculation烟气再循环natural draft自然通风mechanical draft机械通风balanced draft平衡通风forced draft正压通风induced draft负压通风zone control分段送风pressure atomization压力雾化;机械雾化mechanical atomization双流体雾化twin-fluid atomizationrotary-cup atomization旋杯雾化;转杯雾化direct leakage直接泄漏infiltration leakage间接泄漏bypass leakageentrained leakage锅炉本体boiler properheating surface受热面radiant heating surface辐射受热面convection heating surface对流受热面pressure part受压部件;受压元件cylindrical shell筒体head封头;端盖header集箱;联箱tube panel管屏up flow riser tube panel垂直上升管屏ribbon panel回带管屏spirally-wound tubes水平围绕管圈tube bundle管束gas pass烟道gas duct对流烟道convection passparallel gas passes并联烟道air duct风道arch拱furnace arch折焰角water-cooled hopper bottom冷灰斗wall with refractory lining卫燃带refractory belt悬吊管supporting tubedesign pressure设计压力maximum allowable working pressure最高允许工作压力maximum allowable metal temperature最高许用壁温furnace enclosure design pressure炉膛设计压力heat input输入热量heat output锅炉有效利用热量fuel consumption燃料消耗量calculated fuel consumption计算燃料消耗量ash-retention efficiency排渣率load range at constant temperature(保持)额定汽温的负荷范围injection flow(rate)喷水量blowdown flow(rate)排污量theoretical air理论空气量excess air ratio过量空气系数hot air temperature热风温度exhaust gas temperature排烟温度theoretical combustion temperature理论燃烧温度adiabatic temperature炉膛出口烟气温度furnace outlet gas temperaturefurnace exit gas temperature汽水阻力pressure dropdraft loss通风阻力pressure drop自生通风压头stack draftavailable static head运动压头circulation ratio循环倍率circulation velocity循环水速steam quality by mass质量含汽率;干度mass velocity质量流速critical steam quality临界含汽率steam quality at minimum heat transfer coefficient 最高壁温处含汽率furnace volume炉膛容积furnace volume heat release rate炉膛容积热负荷heat liberation rate in furnace炉膛截面积热负荷furnace cross-section heat release ratefurnace plan heat release rate燃烧器区域炉壁热负荷burner zone wall heat release ratefurnace wall heat release rate炉壁热负荷furnace wall heat flux density炉壁热流密度critical heat flux density临界热流密度grate heat release rate炉排(面积)热负荷burner heat input燃烧器热功率ignition energy点火能量evaporation rate受热面蒸发率percentage of economizer evaporation省煤器沸腾率primary air一次风secondary air二次风tertiary air三次风imaginary circle假想切圆percentage of air space通风截面比fineness煤粉细度explosion mixture limits爆炸界限furnace炉膛;炉胆fire box火箱smoke box烟箱burner燃烧器tilting burner摆动式燃烧器igniter点火器oil atomizer油雾化器register调风器stabilizer稳燃器wind box风箱burner port燃烧器喷口burner quarl炉排gratehand-fired grate手烧炉排stoker-fired grate机械炉排mechanical stoker链条炉排travelling grate stokerchain grate stoker链带式炉排bar grate stoker横梁式炉排louvre stoker鳞片式炉排vibrating stoker振动炉排inclined reciprocating grate往复炉排spreader stoker抛煤机air compartment风室reinjection system飞灰复燃装置drum锅筒;汽包steam drum上锅筒water drum下锅筒shell锅壳drum internals锅筒内部装置;汽包内部装置steam washer清洗装置cyclone separator旋风分离器turbo separator轴流式分离器baffle plate缝隙挡板corrugated scrubber百叶窗分离器screen separator钢丝网分离器perforated distribution plate多孔板dry pipe集汽管evaporating heating surface蒸发受热面water-cooled wall水冷壁membrane wall膜式水冷壁division wall双面水冷壁anti-clinker box防焦箱gererating tube bank锅炉管束safety valve安全阀safety relief valve安全泄放阀water level indicator水位表injector注水器boiler setting炉墙soot blower吹灰器slag removal equipment除渣设备boiler efficiency锅炉效率;锅炉热效率boiler operating availability锅炉可用率boiler forced outage rate锅炉事故率feed water condition给水品质steam purity蒸汽品质moisture in steam蒸汽湿度boiler water concentration锅水浓度;炉水浓度total dissolved salt总含盐量total solid (matter)全固形物dissolved solid (matter)溶解固形物suspended solid (matter)悬浮物total hardness(总)硬度alkalinity碱度heat loss热损失heat loss due to exhaust gas排烟热损失heat loss due to unburned gases气体(化学)未完全燃烧热损失heat loss due to unburned carbon in refuse固体(机械)未完全燃烧热损失heat loss due to radiation散热损失heat loss due to sensible heat in slag灰渣物理热损失unburned combustible in flue dust飞灰可燃物含量;飞灰含碳量unburned carbon in flue dust炉渣可燃物含量;炉渣含碳量unburned combustible in slagunburned carbon in slag漏煤可燃物含量unburned combustible in siftingdust loading烟气含尘量dust density锅炉负荷调节范围load range of boilerturndown ratio燃烧器调节比air leakage factor漏风系数set pressure整定压力start-to-discharge pressure前泄压力popping pressure起座压力reseating pressure回座压力blowdown回座压差discharge capacity排放量;排汽能力boiler efficiency test锅炉效率试验;锅炉热效率试验hydrostatic test水压试验hydrostatic deformation test验证性水压试验air leakage test漏风试验pressure decay test风压试验load test负荷试验circulation test水循环试验thermal chemical test热化学试验sounding of tube by balls通球试验safety valve operating test安全阀校验flue gas analysis烟气分析Orsat (gas analyser)奥氏(烟气)分析器suction pyrometer抽气式热电偶(高温计)venturi pneumatic pyrometer气力式高温计heat flux meter热流计start-up启动filling上水water level水位initial water level点火水位purge吹扫blowoff放水drain疏水blowdown排污raising pressure升压bringing a boiler onto the line并汽start-up pressure启动压力start-up flow rate启动流量shutdown停炉outage停用out of servicebanking fire压火storage停炉保护chemical cleaning化学清洗boiling-out(碱)煮炉flushing冲管steam-line blowing吹管passivating钝化drying-out烘炉flow stagnation停滞flow reversal倒流separation of two-phase fluid汽水分层steam binding汽塞steam blanketing汽水共腾primingfoaming泡沫共腾external deposit烟气侧沉积物internal deposit汽水侧沉积物slagging结渣fouling积灰clogging堵灰pitting attack点状腐蚀ductile gouging延性腐蚀hydrogen damage氢脆caustic embrittlement苛性脆化high temperature corrosion高温腐蚀low temperature corrosion低温腐蚀overheating超温;过热flashback回火blow off脱火loss of ignition熄火;灭火furnace explosion炉膛爆炸furnace implosion炉膛内爆furnace puff炉膛爆燃blow hole火口secondary combustion二次燃烧Components for CFBC boiler (CFBC锅炉的主要部件)fouling积灰clogging堵灰pitting attack点状腐蚀ductile gouging延性腐蚀hydrogen damage氢脆caustic embrittlement苛性脆化high temperature corrosion高温腐蚀low temperature corrosion低温腐蚀overheating超温;过热flashback回火blow off脱火loss of ignition熄火;灭火furnace explosion炉膛爆炸furnace implosion炉膛内爆furnace puff炉膛爆燃blow hole火口secondary combustion二次燃烧1.parameter/参数rated capacity额定蒸发量nominal capacity最大连续蒸发量maximum continuous ratingrated heating capacity额定供热量nominal steam condition额定蒸汽参数nominal steam parameter额定蒸汽压力nominal steam pressurenominal steam temperature额定蒸汽温度(nominal)hot water temperature热水温度feed water temperature给水温度return water temperature回水温度circulation circuit循环回路steam generating circuit蒸汽净化steam purificationsteam temperature control汽温调节feed water给水condensate凝结水make-up water补给水boiler water锅水,炉水boiling crisis沸腾换热恶化as-fired fuel炉前燃料fire bed,fuel bed火床fire line最高火界additive添加剂flue fas dew point烟气露点Coupling耦合、联轴Couple联轴器CPLCrane起重机Critical临界的Critical speed临界速度Crusher碎渣机Current transformer CT电流互感器Cube立方(体)Cubicle illumination箱内照明Curdle凝固Current电流、当前Cursor光标Curve曲线Custom习惯、海关Custom keys用户键Cutter切削工具Cyanic青色、深蓝色Cycle循环、周期、周波Cymometer频率表Cyclome classifier旋风分离器Cylinder 汽缸CYLD日负荷曲线Daily load curveDaily load日负荷Damage损坏、破坏Damper阻尼器、挡板DMPRDanger危险、危险物Dank潮湿Danger zone危险区Data数据Data base数据库Data acquisition system数据采集系统DASData highway数据高速公路Date日期Data pool数据库Dc lub oil pump直流润滑油泵Dead band死区Deaerator除氧器DEA/DEAE/DEAERDecimeter分米Decrease减少DECDeep深度、深的、深Default默认、缺席Degree度、等级Demand要求、查问Delay延迟Delay time延时Delete删除Demineralized water除盐水Demineralizer除盐装置Deposit沉积结垢Desalt除盐设备Description说明、描述Destination目标、目的地Desuperheater减温器Desuperheater water减温水DSHWTEDetail细节Detect发现、检定Deviate偏离、偏差Device设备、仪器Diagnosis诊断Diagram图形、图表Diagram directory图目录Diagram number图形号Diameter直径Diaphragm膜片、隔板Dielectric介质、绝缘的Diesel generator柴油发电机Difference差异、差别、差额Differential protection差动保护Diff press差压Diff expansion胀差DIFFEXPDifferential pressure差压DP/DSPDigital数字的Digital electric hydraulic电调Digital input/output数字量输入/输出Digital-to-analog数/模转换D/ADioxde二氧化碳Direct current直流(电)DCDirect digital control直接数字控制DDCDisassembly拆卸Disaster事故、故障Disc叶轮Disaster shutdown事故停机Discharge排除、放电、卸载Discharge current放电电流、泄漏电流Disconnector隔离器、隔离开关Disconnect switch隔离开关Discrete input/output离散输入/输出Disk磁盘Disk manage commands磁盘管理命令Dispatch调度、发送派遣Dispatcher调度员Dispatching station调度站(局)Displacement位移Displacement pump活塞泵Display显示、列屏Distance距离Distilled water蒸馏水DISTLWTRDistributed分布\分配\配电(水、汽)Distributed control system集散控制系统DCSDistributed processing unit分布处理单元DPUDistributing board配电盘Distribution network配电网络Distribution substation二次变电站Disturbance扰动Diverter vlv切换线Divided by除以Design设计、发明Division分界、部门Division wall分割屏Documentation文件Door门Dosing pump加药泵Dowel pin定位销Down pipe下降管Download下载Downtime停机时间Dozer推土机Draft通风、草图Drain疏水、排放DRNDrain pump疏水泵Drain tank疏水箱Drawing图样、牵引Drill钻孔、钻头、钻床Drive驱动、强迫Drn collector疏水收集器Drop站Drowned pump潜水泵Drum汽包Drum-type boiled汽包式锅炉Dry干、干燥Dual双重的Duct风道、管道Dust灰尘Dust helmet防尘罩Dust catcher除尘器、吸尘器Duty责任Dynamic动态的Dynamometer功率表E/ Earth大地Earth fault接地故障Earth connector接地线、接地Earth lead接地线、接地Eccentricity偏心、扰度Econ recirc vlv省煤器再循环线Economizer省煤器ECONEdit编辑Efficiency效率Eject pump射水泵Ejection射出Ejector抽气器Electric电的Elbow弯管、弯头Electric-hydraulic control电/液控制Electrical电的、电气的Electrical lockout solenoid vlv电磁阀锁阀Electrical machine电机Electrical service供电Electric power industry电力工业Electrode电极Electric power company电力公司Electric power system电力系统Electronic电子的、电子学的Electrotechnics电工学、电工技术Electrostaic precipitator静电除尘器Electrostatic静电的Element元件、零件、单元Elevation标高ELEVElevator升降机Ellipse椭圆Emergency decree安规Emerg lub oil事故润滑油Emerg off事故停/关闭Emerg seal oil事故密封油Emergency紧急事故EMERGEmergency drain事故疏水Emergency governet/intercepter危急遮断器Employee雇员Empty排空Enclosure外壳、包围End末端、终结End cover端盖Energize激励、加电Energy能、能量Energy meter电度表Energy source能源Engineer keyboard工程师键盘Engineer station工程师站Engineer's console工程师操作站Engineering工程Enter开始、使进入Entry输入Equalizer valve平衡线Equipment设备Erase删除Error错误Escape valve安全线Evaporate蒸发、冷化Evaporating蒸发量Event事件Excess超过、过度Excess combustion air过剩燃烧空气Excitation励磁Exciter励磁机Exhaust排汽EXHExhaust portion排汽段Exit出口Expansion/ EXP膨胀Expansion tank扩容箱Expenditure费用Expert专家、能手Explosion爆炸Exponent指数幂External外部的、表面的。

MODEL PART NUMBER MTN GPL Mynute J 24 CSI 20017329 (F8F) 20017330 (F9F) Mynute J 24 RSI 20017331 (F1G) 20017332 (F2G)ExportCod.E448 Rev.2.0 (09/2010)Wall hung boilersMynute J CSI/RSIElectric/Case Components Drawing 12Electric/Case Components Drawing 1 POS. DESCRIPTION 24csi 24rsi2 Frame assembly 20011411 2001141112 Quick primer pressure gauge 20005580 2000558018 Cover 20005574 2000557420 Printed circuit board 20011424 2001142426 Instrumental panel 20011427 2001577927 Knob 20005579 2000557928 Knob 20005575 -31 Case Assembly 20017860 2001786034 Fixing flange 20014344 2001434475 Printed circuit board kit 20011443 20011443470 Ignition transformer TR6 R10026031 R10026031500 Power wiring harness 20005572 20005572501 Cable R1547 R1547502 Wiring harness 20011449 20011449503 Low tension cable 20013966 200125443Hydraulic Components 1 Drawing 24Hydraulic Components 1 Drawing 2 POS. DESCRIPTION 24csi 24rsi1 Exchanger R8037 -2 Fitting/union R10026151 -4 Non return valve R10025056 R100250566 By-pass casing R10024641 R100246417 By-pass valve R2047 R20479 3-way heating manifold and cartridge (first version) R10026508 R100273439 3-way heating manifold and cartridge 20021496 2002420410 3 way valve cartridge (first version) R10025305 R1002530510 3 way valve cartridge 20017597 2001759711 Actuator (first version) R10025304 R1002530411 Actuator 20017594 2001759412 Clip (first version) R10025450 R1002545012 Clip 20017598 2001759813 Clip R10025449 R1002544920 Filling cock R10025060 -22 Safety valve R10025055 R1002505524 Flow governor R10024987 -25 Pipe 20011423 2001254326 Dhw actuator 20013968 -27 Pipe 20012328 2001232828 Pipe 20012329 -29 Pipe 20012330 -30 Water supply stop cock R1888 -37 Pipe R10025840 2001254247 Cover for by-pass assembly R10024643 R1002464348 Cock R10024646 R1002464663 Pipe R10025058 R10025058200 Washer R5023 R5023201 Washer R5026 -279 Connection R10025089 -280 Connection R10025090 R10025090288 Ring R6898 R6898290 Clip R2165 R2165343 Pump plug R2216 R2216432 Clip R10024958 R10024958433 Clip R10024986 -434 Nipple R10024985 -435 Fitting/union R10025059 R10025059436 Clip R10025062 R10025062438 O ring R10024988 -439 Washer R10025067 -441 Clip R10025063 R10025063442 O ring R10025065 R10025065443 O ring R10025064 R10025064444 Washer R10025066 R10025066501 Nipple - R10026914502 Nipple - R10026915504 Fitting/union - R10026916521 NTC sensor R10027351 -619 Pressure 20003181 20003181621 Washer R5038 -700 Hydraulic control cable (first version) 20013587 20013587700 Hydraulic control cable 20017596 200175965Hydraulic Components 2 Drawing 36Hydraulic Components 2 Drawing 3 POS. DESCRIPTION 24csi 24rsi1 7 lt. expansion vessel 20029826 200298262 Pipe R10028603 R100286033 Pump R10027571 R100275717 Pipe 20011421 200114218 Heat exchanger 20011419 200114199 Pipe 20011420 20011420200 Washer R5023 R5023290 Clip R2165 R2165299 Washer R10022726 R10022726302 Washer R5025 R5025520 NTC-sensor 20004832 20004832594 O ring 20000131 20000131624 Clip R5472 R5472625 High limit thermostat 20005585 20005585627 Spring pipe 20005546 200055467Burner Components - Air Box Drawing 48Burner Components - Air Box Drawing 4 POS. DESCRIPTION 24csi 24rsi3 Collector 20005584 200055844 N.G. burner 20005551 200055515 Spark / ignition electrode R10025985 R1002598512 Pipe 20011422 2001142213 Gas valve 20007784 2000778414 Gas pipe 20005553 2000555315 3/4" gas cock R2266 R226616 Combustion chamber cover 20011414 2001141417 Gas valve solenoid R10020838 R1002083818 Plug 20005550 2000555027 Hole cover 20005586 20005586200 Washer R5023 R5023201 Washer R5026 R5026629 Kit cable grommet 20005595 20005595640 Clip 20011042 20011042700 G20 conversion kit 20019506 20019506701 Lpg conversion kit 20019507 20019507702 G25 conversion kit R01005508 R010055089Combustion Chamber Components - Flue Drain Drawing 510Combustion Chamber Components - Flue Drain Drawing 5 POS. DESCRIPTION 24csi 24rsi2 Back insulatin panel 20005561 200055613 Insulation panel 20005562 200055624 Front insulation panel 20005560 200055607 Flue draught diverter 20005596 2000559610 Fan 20026724 2002672411 Pressure connection 20021548 2002154812 Fumes connection 20011048 2001104813 Segnal amplifier 20025687 2002568717 Washer 20005552 2000555222 Flange Ø 44 R10021730 R1002173022 Flange Ø 42 R10027845 R1002784523 Cap smoke analysis 20005549 2000554925 Pressure switch R10023908 R1002390874 Fan support kit 20021597 20021597640 Clip 20011042 20011042700 Combustion cable 20021583 2002158311Rev. data Descrizione1.0 23/11/09 Aggiunte trasformazioni, aggiunte flange fumi2.0 28/09/2010 E00120090668 : cablaggio combustione – E00120090733 : circolatoreE00120090736: gruppo distributore zero brassE00120100139 : Vaso espansione - E00120090680 : staffa ventilatoreE00120100083 : Amplificatore di segnale - E00120100343: ventilatoreE00120100374: gruppo distributore zero brass solo riscaldamentoE00120100427: vaso espansione - Inserita presa pressione ventilatoreConsumers’ statutory rights are not affected.。