富士康必备英语

- 格式:doc

- 大小:92.00 KB

- 文档页数:12

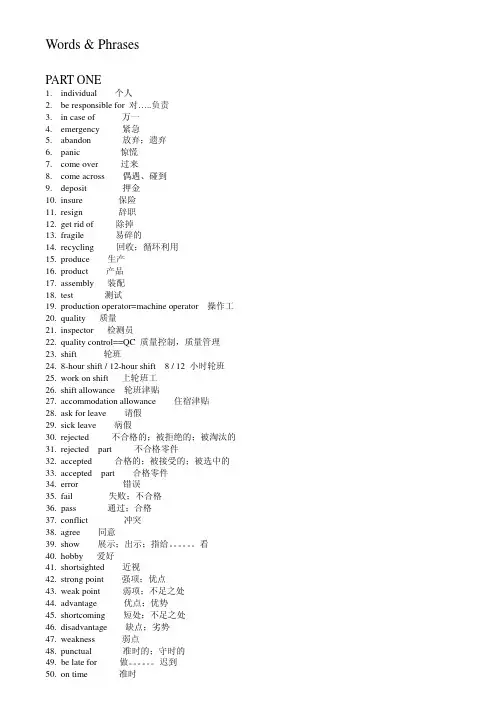

Words & PhrasesPART ONE1.individual 个人2.be responsible for 对…..负责3.in case of 万一4.emergency 紧急5.abandon 放弃;遗弃6.panic 惊慌e over 过来e across 偶遇、碰到9.deposit 押金10.insure 保险11.resign 辞职12.get rid of 除掉13.fragile 易碎的14.recycling 回收;循环利用15.produce 生产16.product 产品17.assembly 装配18.test 测试19.production operator=machine operator 操作工20.quality 质量21.inspector 检测员22.quality control==QC 质量控制,质量管理23.shift 轮班24.8-hour shift / 12-hour shift 8 / 12 小时轮班25.work on shift 上轮班工26.shift allowance 轮班津贴27.accommodation allowance 住宿津贴28.ask for leave 请假29.sick leave 病假30.rejected 不合格的;被拒绝的;被淘汰的31.rejected part 不合格零件32.accepted 合格的;被接受的;被选中的33.accepted part 合格零件34.error 错误35.fail 失败;不合格36.pass 通过;合格37.conflict 冲突38.agree 同意39.show 展示;出示;指给。

看40.hobby 爱好41.shortsighted 近视42.strong point 强项;优点43.weak point 弱项;不足之处44.advantage 优点;优势45.shortcoming 短处;不足之处46.disadvantage 缺点;劣势47.weakness 弱点48.punctual 准时的;守时的49.be late for 做。

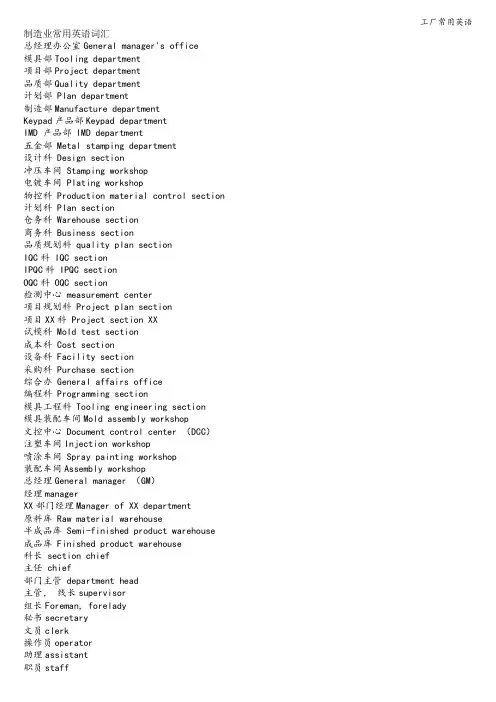

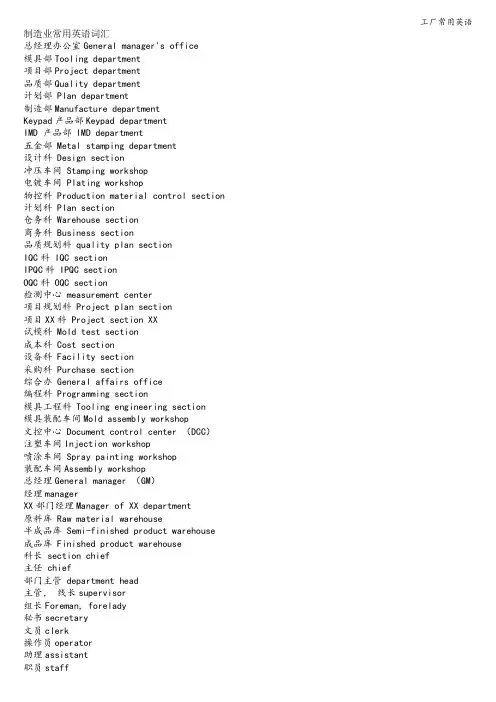

制造业常用英语词汇总经理办公室General manager's office模具部Tooling department项目部Project department品质部Quality department计划部 Plan department制造部Manufacture departmentKeypad产品部Keypad departmentIMD 产品部 IMD department五金部 Metal stamping department设计科 Design section冲压车间 Stamping workshop电镀车间 Plating workshop物控科 Production material control section 计划科 Plan section仓务科 Warehouse section商务科 Business section品质规划科 quality plan sectionIQC科 IQC sectionIPQC科 IPQC sectionOQC科 OQC section检测中心 measurement center项目规划科 Project plan section项目XX科 Project section XX试模科 Mold test section成本科 Cost section设备科 Facility section采购科 Purchase section综合办 General affairs office编程科 Programming section模具工程科 Tooling engineering section模具装配车间Mold assembly workshop文控中心 Document control center (DCC)注塑车间Injection workshop喷涂车间 Spray painting workshop装配车间Assembly workshop总经理General manager (GM)经理managerXX部门经理Manager of XX department原料库 Raw material warehouse半成品库 Semi-finished product warehouse 成品库 Finished product warehouse科长 section chief主任 chief部门主管 department head主管,线长supervisor组长Foreman, forelady秘书secretary文员clerk操作员operator助理assistant职员staff二、产品超声波焊接ultrasonic welding 塑胶件 Plastic parts塑材 Raw parts喷涂件 Painted parts装配件 Assembly parts零件 Component原料 Raw material油漆 Paint稀释剂 Thinner油墨 Ink物料编号part number三、模具注塑模具injection mold冲压模具Stamping tool模架mold base定模座板Fixed clamp plateA板A plateB板B plate支承板 support plate方铁 spacer plate回位销 Return pin导柱 Guide pin动模座板Moving clamp plate 顶针ejector pin单腔模具single cavity mold 多腔模具multi-cavity mold浇口gate合模力clamping force锁模力locking force开裂crack循环时间cycle time老化aging螺杆screw镶件 Insert主流道 sprue分流道runner浇口gate直浇口 direct gate点浇口pin—point gate测浇口edge gate潜伏浇口submarine gate浇口套sprue bush流道板runner plate排气槽vent分型线(面)parting line定模Fixed mold动模movable mold型腔cavity凹模cavity plate,凸模core plate斜销angle pin滑块slide拉料杆sprue puller定位环locating ring脱模斜度draft滑动型芯slide core螺纹型芯threaded core热流道模具hot—runner mold熔合纹weld line三板式模具three plate mold脱模ejection脱模剂release agent注射能力shot capacity注射速率injection rate注射压力injection pressure保压时间holding time闭模时间closing time电加工设备Electron Discharge Machining数控加工中心CNC machine center万能铁床Universal milling machine平面磨床Surface grinding machine万能摇臂钻床Universal radial movable driller 立式钻床Vertical driller倒角chamfer键Key键槽keyway间距pitch快速成型模Rapid prototype tool (RPT)四、品管SPC statistic process control品质保证Quality Assurance(QA)品质控制Quality control(QC)来料检验IQC Incoming quality control巡检IPQC In-process quality control校对calibration环境试验Environmental test光泽gloss拉伸强度tensile strength盐雾实验salt spray test翘曲warp比重specific gravity疲劳fatigue撕裂强度tear strength缩痕sink mark耐久性durability抽样sampling样品数量sample sizeAQL Acceptable Quality level批量lot size抽样计划sampling plan抗张强度 Tensile Strength抗折强度 Flexural Strength硬度 Rigidity色差 Color Difference涂镀层厚度 Coating Thickness导电性能 Electric Conductivity粘度 viscosity附着力 adhesion耐磨 Abrasion resistance尺寸 Dimension(喷涂)外观问题 Cosmetic issue不合格品 Non—conforming product限度样板 Limit sample五、生产注塑机injection machine冲床Punch machine嵌件注塑 Insert molding双色注塑 Double injection molding薄壁注塑 Thin wall molding膜内注塑 IMD molding ( In—mold decoration)移印 Tampo printing丝印 Silk screen printing热熔 Heat staking超声熔接 Ultrasonic welding (USW)尼龙nylon黄铜 brass青铜 bronze紫(纯)铜 copper料斗hopper麻点pit配料compounding涂层coating飞边flash缺料 Short mold烧焦 Burn mark缩水 Sink mark气泡 Bubbles破裂 Crack熔合线 Welding line流痕 Flow mark银条 Silver streak黑条 Black streak表面光泽不良Lusterless表面剥离Pelling翘曲变形Deformation脏圬 Stain mark油污 Oil mark蓝黑点 Blue-black mark顶白 Pin mark拉伤 Scratch限度样品 Limit sample最佳样品 Golden sample预热preheating再生料recycle material机械手 Robot机器人 Servo robot试生产 Trial run; Pilot run (PR)量产 mass production切料头 Degate产能 Capacity能力 Capability参数 Parameter二次加工 Secondary process六.物控保质期shelf lifeABC分类法ABC Classification装配Assembly平均库存Average Inventory批号Batch Number批量生产Mass Production提货单Bill of Lading物料清单Bill of Material采购员Buyer检查点Check Point有效日期Date Available修改日期Date Changed结束日期Date Closed截止日期Date Due生产日期Date in Produced库存调整日期Date Inventory Adjust作废日期D ate Obsolete收到日期Date Received交付日期Date Released需求日期Date Required需求管理Demand Management需求Demand工程变更生效日期Engineering Change Effect Date 呆滞材料分析Excess Material Analysis完全跟踪Full Pegging在制品库存In Process Inventory投入/产出控制Input/ Output Control检验标识Inspection ID库存周转率Inventory Carry Rate准时制生产Just-in—time (JIT)看板Kanban人工工时Labor Hour最后运输日期Last Shipment Date提前期Lead Time负荷Loading仓位代码Location Code仓位状况Location Status批量标识Lot ID批量编号Lot Number批量Lot Size机器能力Machine Capacity机器加载Machine Loading制造周期时间Manufacturing Cycle Time制造资源计划Manufacturing Resource Planning (MRP II)物料成本Material Cost物料发送和接收Material Issues and Receipts物料需求计划Material Requirements Planning现有库存量On—hand Balance订单输入Order Entry零件批次Part Lot零件编号Part Number (P/N)零件Part领料单Picking List领料/提货Picking产品控制Product Control产品线Production Line采购订单跟踪Purchase Order Tracking需求量Quantity Demand毛需求量Quantity Gross安全库存量Safety Stock在制品Work in Process零库存Zero Inventories七.QS—9000中的术语APQP Advanced Product Quality Planning and Control Plan,产品质量先期策划和控制计划PPAP Production Part Approval Process,生产件批准程序FMEA Potential Failure Mode and Effects Analysis,潜在失效模式及后果分析MSA Measure System Analysis,测量系统分析SPC Statistical Process Control,统计过程控制审核 Audit能力 Capability能力指数 Capability Indices控制计划 Control Plans纠正措施 Corrective Action文件 Documentation作业指导书 Standard operation procedure (SOP); Work instruction不合格品 Nonconformance不合格 Nonconformity每百万零件不合格数 Defective Parts Per Million, DPPM预防措施 Preventive Action程序Procedures过程流程图 Process Flow Diagram, Process Flow Chart质量手册Quality Manual质量计划 Quality Plan质量策划 Quality Planning质量记录Quality Records原始数据Raw Data反应计划Reaction Plan返修Repair返工Rework现场Site分承包方Subcontractors产品product质量quality质量要求quality requirement顾客满意customer satisfaction质量管理体系quality management system质量方针quality policy质量目标quality objective质量管理quality management质量控制quality control质量保证quality assurance组织organization顾客customer供方supplier过程process服务service设计与开发design and development:特性characteristic可追溯性trace ability合格conformity缺陷defect纠正correction让步concession放行release报废scrap规范specification检验inspection试验test验证verification评审review测量measurement普通原因Common Cause均值Mean极差Range稳定性Stability计量型数据Variables Data变差Variation重复性Repeatability再现性Reproducibility稳定性Stability分辨率Resolution过程更改Process change质量功能展开QFD外观项目Appearance Item初始过程能力Preliminary Process Capability材料清单Bill of Material设计确认Design Validation设计验证Design Verification八.常用缩略词语OEM Original Equipment ManufacturerANOVA 方差分析法 Analysis of VarianceDFMEA 设计失效模式及后果分析 Design Failure Mode and Effects Analysis DOE 试验设计 Design of ExperimentGR&R 量具的重复性和再现性Gage Repeatability and Reproducibility PFMEA 过程失效模式及后果分析Process Failure Mode and Effect Analysis QSR 质量体系要求Quality System RequirementQFD 质量功能展开 Quality Function DeploymentBOM 物料清单 Bill of MaterialCpk 稳定过程的能力指数 Capability for stable processLCL 下控制限 Lower Control LimitUCL 上控制限 Upper Control LimitLSL 工程规范下限 Lower Specification LimitX(—)--R图均值一极差图 Average-Range Chart防错(POKA—YOKE)Mistake ProofingETA 预计到达 Estimate to be arrivePO 定单 Purchase orderM/C 机器 machineRFQ 报价需求 Request for quotationMFI 熔融流动指数 Melt flow indexFAI 全尺寸检测报告 First article inspectionCOC 材质证明 Certificate of complianceALT 加速老化试验 Accelerated life testCRR 承认书 Component review reportOT 加班 Over timeCAP 矫正计划 Corrective action planR&D 研发 Research and DevelopmentASAP 尽快 As soon as possibleECN工程更改通知Engineering change noticeDCN 设计更改通知 Design change noticeOTD 准时交货 On time delivery九.通用词语确保 ensure构想 construct会签 con-sign功能 Function机构 organization外观 appearance适用 apply to作业流程 Operation flow附件 attachment商务人员 business personnel汇总 summarize指定相关人员 designated personnel新产品开发说明会 new product development explanation meeting拟定 Prepare委托 entrust认证 qualify电子档 Soft copy3D文件 3D database移转 Transfer执行 ConductXXX申请单 XXX Application form客户要求 Customer requirement启动 Kick off评估 Evaluation作业员 Operator批准,承认 Approval合同评审 Contract review可靠性 Reliability相关的 Relevant程序 Procedure制程 Process流程图 Flow chart产品 Product生产 Production资材 Logistics责任 Responsibility跟进 Follow-up交付 Delivery汇总 Summarize外协加工 subcontract指定相关人员 designated personnel 编号 number附件 attachment产品名称 Description周期循环时间 Cycle time模具号 Mold No,数量 quantity ( Qt’y )备注 remarkSAP号 SAP No.客户 Customer表单 Form初步的 Preliminary版本 Version根本原因 Root cause(喷漆)夹具 Fixture(设备)小夹具 Jig设备 Equipment设施 Facility送,提交(样品)Submit责任部门,责任人 Responsible by (大的)目标 Objective(小的,具体的)目标 Target格式 Format上岗证 Qualification card需求 Requirement现场 On site查检表 Checklist试产 pilot增值税 VAT—--value-added tax品质专业英语大全零件材料类的专有名词CPU: central processing unit(中央处理器)IC: Integrated circuit(集成电路)Memory IC: Memory Integrated circuit(记忆集成电路)RAM: Random Access Memory(随机存取存储器)DRAM: Dynamic Random Access Memory(动态随机存取存储器)SRAM: Staic Random Access Memory(静态随机存储器)ROM: Read-only Memory(只读存储器)EPROM:Electrical Programmable Read—only Memory(电可抹只读存诸器)EEPROM: Electrical Erasbale Programmable Read-only Memory(电可抹可编程只读存储器)CMOS: Complementary Metal-Oxide—Semiconductor(互补金属氧化物半导体)BIOS: Basic Input Output System(基本输入输出系统)Transistor:电晶体LED:发光二极体Resistor:电阻Variator:可变电阻Capacitor:电容Capacitor array:排容Diode:二极体Transistor:三极体Transformer:变压器(ADP)Oscillator:频率振荡器(0sc)Crystal:石英振荡器XTAL/OSC:振荡产生器(X)Relay:延时器Sensor:感应器Bead core:磁珠Filter:滤波器Flat Cable:排线Inductor:电感Buzzer:蜂鸣器Socket:插座Slot:插槽Fuse:熔断器Current:电流表Solder iron:电烙铁Magnifying glass:放大镜Caliper:游标卡尺Driver:螺丝起子Oven:烤箱TFT:液晶显示器Oscilloscope:示波器Connector:连接器PCB:printed circuit board(印刷电路板)PCBA: printed circuit board assembly(电路板成品)PP:并行接口HDD:硬盘FDD:软盘PSU:power supply unit(电源供应器)SPEC:规格Attach:附件Case: 机箱,盖子Cover:上盖Base:下盖Bazel:面板(panel)Bracket:支架,铁片Lable:贴纸Guide:手册Manual:手册,指南Card:网卡Switch:交换机Hub:集线器Router:路由器Sample:样品Gap:间隙Sponge:海绵Pallet:栈板Foam:保利龙Fiber:光纤Disk:磁盘片PROG:程序Barcode:条码System:系统System Barcode:系统条码M/B:mother board:主板CD—ROM:光驱FAN:风扇Cable:线材Audio:音效K/B:Keyboard(键盘)Mouse:鼠标Riser card:转接卡Card reader:读卡器Screw:螺丝Thermal pad:散热垫Heat sink:散热片Rubber:橡胶垫Rubber foot:脚垫Bag:袋子Washer:垫圈Sleeve:袖套Config:机构Label hi-pot:高压标签Firmware label:烧录标签Metal cover:金属盖子Plastic cover:塑胶盖子Tape for packing:包装带Bar code:条码Tray:托盘Collecto:集线夹Holder:固定器,L铁Connecter:连接器IDE:集成电路设备,智能磁盘设备SCSI:小型计算机系统接口Gasket:导电泡棉AGP:加速图形接口PCI:周边组件扩展接口LAN:局域网USB:通用串形总线架构Slim:小型化COM:串型通讯端口LPT:打印口,并行口Power cord:电源线I/O:输入,输出Speaker:扬声器EPE:泡棉Carton:纸箱Button:按键,按钮Foot stand:脚架部门名称的专有名词QS:Quality system品质系统CS:Coutomer Sevice 客户服务QC:Quality control品质管理IQC:Incoming quality control 进料检验LQC:Line Quality Control 生产线品质控制IPQC:In process quality control 制程检验FQC:Final quality control 最终检验OQC:Outgoing quality control 出货检验QA:Quality assurance 品质保证SQA:Source(supplier) Quality Assurance 供应商品质保证(VQA)CQA:Customer Quality Assurance客户质量保证PQA rocess Quality Assurance 制程品质保证QE:Quality engineer 品质工程CE:component engineering零件工程EE:equipment engineering设备工程ME:manufacturing engineering制造工程TE:testing engineering测试工程PPE roduct Engineer 产品工程IE:Industrial engineer 工业工程ADM: Administration Department行政部RMA:客户退回维修CSDI:检修PC:producing control生管MC:mater control物管GAD: General Affairs Dept总务部A/D: Accountant /Finance Dept会计LAB: Laboratory实验室DOE:实验设计HR:人资PMC:企划RD:研发W/H:仓库SI:客验PD: Product Department生产部PA:采购(PUR: Purchaing Dept)SMT:Surface mount technology 表面粘着技术MFG:Manufacturing 制造MIS:Management information system 资迅管理系统DCC:document control center 文件管制中心厂内作业中的专有名词QT:Quality target品质目标QP:Quality policy目标方针QI:Quality improvement品质改善CRITICAL DEFECT:严重缺点(CR)MAJOR DEFECT:主要缺点(MA)MINOR DEFECT:次要缺点(MI)MAX:Maximum最大值MIN:Minimum最小值DIA iameter直径DIM imension尺寸LCL:Lower control limit管制下限UCL:Upper control limit管制上限EMI:电磁干扰ESD:静电防护EPA:静电保护区域ECN:工程变更ECO:Engineering change order工程改动要求(客户)ECR:工程变更需求单CPI:Continuous Process Improvement 连续工序改善Compatibility:兼容性Marking:标记DWG rawing图面Standardization:标准化Consensus:一致Code:代码ZD:Zero defect零缺点Tolerance:公差Subject matter:主要事项Auditor:审核员BOM:Bill of material物料清单Rework:重工ID:identification识别,鉴别,证明PILOT RUN: (试投产)FAI:首件检查FPIR:First Piece Inspection Report首件检查报告FAA:首件确认SPC:统计制程管制CP: capability index(准确度)CPK: capability index of process(制程能力) PMP:制程管理计划(生产管制计划)MPI:制程分析DAS efects Analysis System 缺陷分析系统PPB:十亿分之一Flux:助焊剂P/N:料号L/N:Lot Number批号Version:版本Quantity:数量Valid date:有效日期MIL—STD:Military-Standard军用标准ICT: In Circuit Test (线路测试)ATE:Automatic Test Equipment自动测试设备MO: Manafacture Order生产单T/U: Touch Up (锡面修补)I/N:手插件P/T:初测F/T: Function Test (功能测试—终测)AS 组立P/K:包装TQM:Total quality control全面品质管理MDA:manufacturing defect analysis制程不良分析(ICT) RUN—IN:老化实验HI-pot:高压测试FMI:Frequency Modulation Inspect高频测试DPPM: Defect Part Per Million(不良率的一种表达方式:百万分之一) 1000PPM即为0。

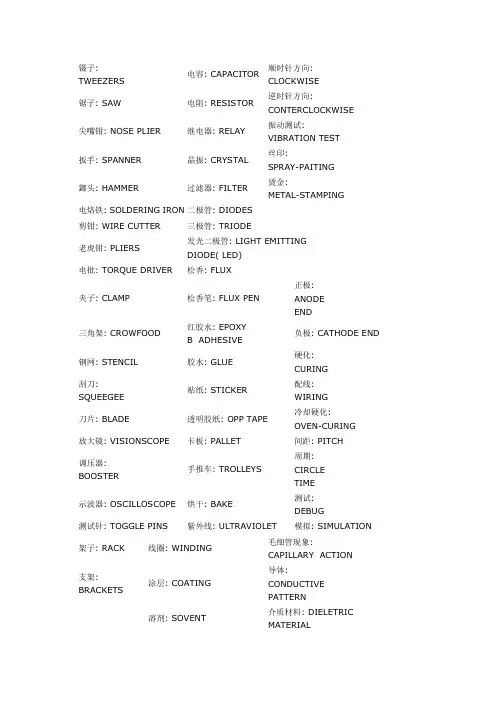

镊子: TWEEZERS 电容: CAPACITOR顺时针方向:CLOCKWISE锯子: SAW电阻: RESISTOR 逆时针方向: CONTERCLOCKWISE尖嘴钳: NOSE PLIER继电器: RELAY 振动测试: VIBRATION TEST扳手: SPANNER晶振: CRYSTAL 丝印:SPRAY-PAITING鎯头: HAMMER过滤器: FILTER 烫金:METAL-STAMPING电烙铁: SOLDERING IRON 二极管: DIODES 剪钳: WIRE CUTTER三极管: TRIODE老虎钳: PLIERS 发光二极管: LIGHT EMITTING DIODE( LED)电批: TORQUE DRIVER松香: FLUX夹子: CLAMP松香笔: FLUX PEN 正极: ANODE END三角架: CROWFOOD 红胶水: EPOXYB ADHESIVE负极: CATHODE END钢网: STENCIL胶水: GLUE 硬化: CURING刮刀: SQUEEGEE 贴纸: STICKER配线:WIRING刀片: BLADE透明胶纸: OPP TAPE 冷却硬化: OVEN-CURING放大镜: VISIONSCOPE卡板: PALLET间距: PITCH调压器: BOOSTER 手推车: TROLLEYS周期:CIRCLETIME示波器: OSCILLOSCOPE烘干: BAKE 测试: DEBUG测试针: TOGGLE PINS紫外线: ULTRAVIOLET模拟: SIMULATION架子: RACK线圈: WINDING 毛细管现象: CAPILLARY ACTION支架: BRACKETS 涂层: COATING导体:CONDUCTIVEPATTERN溶剂: SOVENT介质材料: DIELETRICMATERIAL隔热板: FELT 镀通孔: PTH( PLATED THROUGH HOLE)锡条: SOLDE BAR 不合格品: NONCONFIRMING UNITS锡膏: SOLDER PASTE原料: DIRECT MATERIAL氧化: OXIDE锡炉: SOLDER-POT 辅料: INDIRECTMATERIAL额定电源: RATEDPOWER浸锡:DIG-SOLDER 试产: PILOT PRODUCTION 量产: MASS PRODUCTION焊点: SOLDERING JOINTS X 光测试: X RAY TEST焊盘: PAD/LAND 跌打测试: DROP TEST焊接: WELDING老化测试: BURN-IN TEST 超声波焊接: ULTRASONIC WELDING回流焊接: REFLOW SOLDERING波峰焊接: WAVE SOLDERING 线路板; PCB(Printed Circuit Board)回焊前: PRE-REFLOW 线路板装配: PCBA( PRINTED CIRCUIT BOARD ASSEMBLY)回焊后: POST-REFLOW 集成电路:IC( INTERGRATED CIRCUIT)回流炉: REFLOW OVEN ESD: ELECTROSTATIC DISCHARGE: 静电放电虚焊: DEWETTING ESD PREVENTION&DAMAGE: 静电防护与损坏假焊: SHORT SOLDER FMEA: FAILURE MODE AND EFFECT ANALYSIS(失效模式分析)少锡: INSUFFICENT SOLDER SPC: STASTICAL PROCESS CONTROL(统计过程控制)偏位: MISALIGNMENT IPC: INSTITUTE OF PACKING AND INTERCONNECTS(电子电路互连与封装协会)阻焊剂:SOLDER-THIEF/MASK 注塑: INJECTION MOLDING层分: DELAMINATION线路: TRACE裂: CRACKED 浮起: LIFTING回路: CIRCUIT内翘: WARPED 静电防护: STATIC SHIELDING短路: BRIGING/SHORT 翘起: LIFT 散静电: STATIC DISSIPATIVE线路开路: BROKEN TRACE 弯: BOW 防静电: ANTISTATIC。

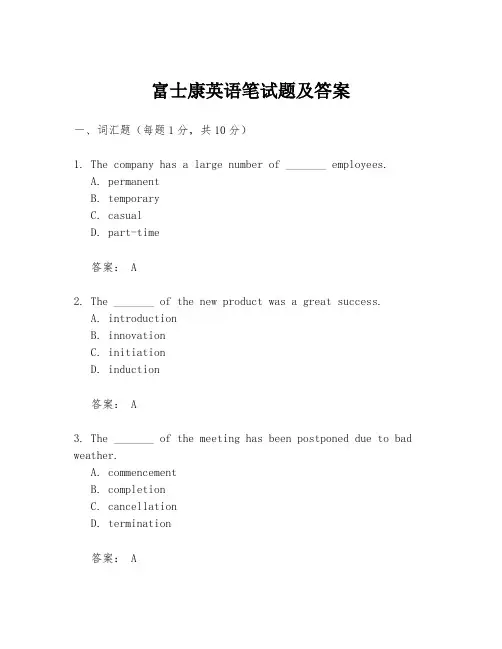

富士康英语笔试题及答案一、词汇题(每题1分,共10分)1. The company has a large number of _______ employees.A. permanentB. temporaryC. casualD. part-time答案: A2. The _______ of the new product was a great success.A. introductionB. innovationC. initiationD. induction答案: A3. The _______ of the meeting has been postponed due to bad weather.A. commencementB. completionC. cancellationD. termination答案: A4. She has a _______ knowledge of the subject.A. superficialB. profoundC. elementaryD. rudimentary答案: B5. The _______ of the old building was a difficult task.A. renovationB. demolitionC. constructionD. destruction答案: B6. The _______ of the company's profits has been steady over the past decade.A. fluctuationB. stabilityC. increaseD. decrease答案: B7. The _______ of the new policy was met with mixed reactions.A. implementationB. enforcementC. initiationD. establishment答案: A8. The _______ of the project was completed on schedule.A. executionB. performanceC. operationD. function答案: A9. The _______ of the company's assets is a complex process.A. evaluationB. valuationC. assessmentD. estimation答案: B10. The _______ of the new CEO was announced at the annual meeting.A. appointmentB. nominationC. electionD. designation答案: A二、阅读理解题(每题2分,共20分)Passage 1In recent years, the rise of e-commerce has significantly impacted the retail industry. Traditional brick-and-mortar stores are facing challenges as online shopping becomes more popular. However, some companies have adapted to thesechanges by integrating their online and offline presence to create a seamless shopping experience for customers.Questions:11. What has been the impact of e-commerce on the retail industry?A. It has led to the decline of online shopping.B. It has caused an increase in the popularity ofphysical stores.C. It has significantly impacted the way people shop.D. It has resulted in the closure of all physical stores.答案: C12. How have some companies adapted to the rise of e-commerce?A. By closing their physical stores.B. By focusing solely on online sales.C. By integrating their online and offline presence.D. By ignoring the changes in consumer behavior.答案: CPassage 2The development of renewable energy sources is crucial for reducing our reliance on fossil fuels and combating climatechange. Solar and wind power are two of the most promising renewable energy sources, offering clean and sustainable alternatives to traditional energy production methods.Questions:13. Why is the development of renewable energy sources important?A. To increase our reliance on fossil fuels.B. To reduce the cost of energy production.C. To combat climate change and reduce reliance on fossil fuels.D. To make energy production more difficult.答案: C14. Which two renewable energy sources are mentioned in the passage?A. Solar and nuclear power.B. Wind and hydro power.C. Solar and wind power.D. Fossil fuels and hydro power.答案: C三、完形填空题(每题1.5分,共15分)In the modern world, technology plays a vital role in our daily lives. It has transformed the way we communicate, work, and learn. However, with the rapid advancement of technology, there are also concerns about its impact on society.15. Technology has made our lives _______ easier.A. muchB. littleC. notD. no答案: A16. The _______ of technology is not without its drawbacks.A. progressB. developmentC. advancementD. growth答案: C17. People are increasingly _______ about the effects of technology on privacy.A. concernedB. informedC. interestedD. curious答案: A18. Despite。

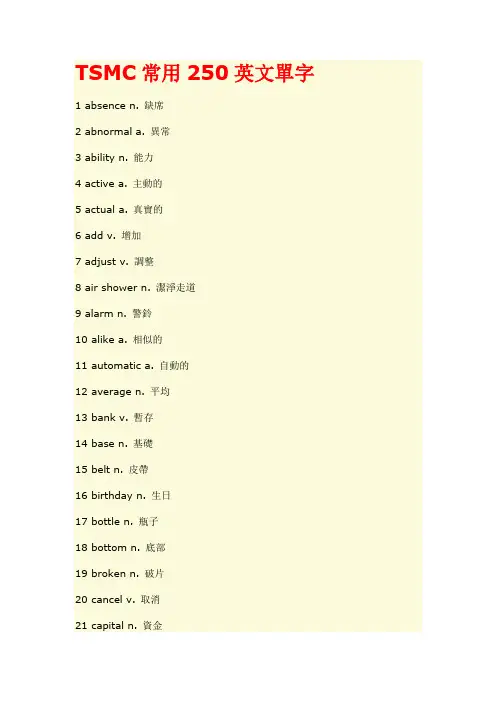

TSMC常用250英文單字1 absence n. 缺席2 abnormal a. 異常3 ability n. 能力4 active a. 主動的5 actual a. 真實的6 add v. 增加7 adjust v. 調整8 air shower n. 潔淨走道9 alarm n. 警鈴10 alike a. 相似的11 automatic a. 自動的12 average n. 平均13 bank v. 暫存14 base n. 基礎15 belt n. 皮帶16 birthday n. 生日17 bottle n. 瓶子18 bottom n. 底部19 broken n. 破片20 cancel v. 取消21 capital n. 資金22 card n. 卡片23 cart n. 手推車24 center n. 中心25 certify v. 技能確認26 change v. 更換27 change acid n. 換酸28 chart n. 圖表29 check v. 檢查30 chemical n. 化學31 choose v. 挑選32 claim v. 宣告33 clean v. 清潔34 clear v. 清除35 color n. 顏色36 collect v. 蒐集37 comment n. 註解38 complete a. 完成的39 computer n. 電腦40 confidential a. 機密41 confirm v. 確認42 contamination n. 污染43 control n. 控制44 copy n. 拷貝45 count v. 計算46 customer n. 客戶47 cycle n. 週期48 cycle time n. 生產週期49 daily monitor n. 每日檢測50 data n. 資料51 date n. 日期52 defect n. 缺陷53 delay v. 延遲54 delete v. 刪除55 depth n. 厚度56 dictionary n. 字典57 document n. 文件58 driver n. 駕駛59 dry a. 乾60 economy n. 經濟61 emergency n. 緊急情況62 emergency stop n. 緊急停止63 engineer n. 工程師64 enter v. 進入65 equipment n. 設備66 execute v. 執行67 exit n. 退出68 fault n. 錯誤69 find v. 發現70 floor n. 地板71 focus n. 焦點72 freeze v. 凍結73 full a. 滿的74 function n. 功能75 gas n. 瓦斯76 glass n. 眼鏡77 grade n. 等級78 green a. 綠色79 group n. 群組80 handle v. 處理81 heavy a. 重的82 helmet n. 安全帽83 help v. 幫助84 hold v. 暫停﹝扣留﹞85 hole n. 缺陷86 honest a. 誠實的87 hot a. 熱的88 import v. 移進89 improve v. 改善90 inform v. 通知91 information n. 資訊92 input n. 輸入93 inspection n. 檢驗94 instant a. 即時的95 insurance n. 保險96 international a. 國際97 Internet n. 網際網路98 interview n. 面試99 issue v. 更新資訊100 job n. 工作101 keyboard n. 鍵盤102 label n. 標籤103 leader n. 組長104 learn v. 學習105 level n. 程度106 lift v. 掀起107 light n. 光108 line n. 直線109 link n. 聯結110 liquid n. 液體111 list n. 清單112 load v. 下貨﹝裝載﹞113 loading n. 負擔114 location n. 區域115 lock v. 鎖住116 logsheet n. 工作紀錄117 lose v. 遺失118 lot-ID n. 批號119 machine n. 機器120 magnet n. 磁鐵121 maintain v. 維護122 manual a. 手動123 manufacture v. 製造124 mark n. 記號125 mask n. 光罩126 material n. 原料127 measure v. 量測128 mechanical a. 機械的129 merge v. 合併130 message n. 訊息131 metal n. 金屬132 monitor n. 監視器,測機133 more a. 多的134 move v. 移動135 new a. 新的136 normal a. 正常的137 note n. 註解138 notice n. 通知139 novel n. 小說140 number n. 號碼141 off-line a. 不與電腦連線142 office n. 辦公室143 on-line a. 與電腦連線144 operation n. 操作145 output n. 輸出146 oven n. 爐子147 overlook v. 忽略148 page n. 頁數149 paper n. 紙張150 parameter n. 參數151 particle n. 微粒152 pass v. 合格153 password n. 密碼154 perfect a. 完美155 personal a. 個人的156 photo n. 照相157 plan n. 計劃158 plus prep. 加159 point n. 點160 position n. 位置161 positive a. 確實162 postpone v. 延期163 power n. 力量164 practice n. 練習165 prepare v. 準備166 press v. 按下167 preview n. 預覽168 price n. 價格169 print n. 列印170 priority n. 優先權171 process n. 過程172 protect v. 保護173 push v. 推進174 quality n. 品質175 quantity n. 數量176 rate n. 比率177 recertify v. 再檢定178 recipe n. 程式179 record n. 記錄180 refer v. 參考181 release v. 釋放182 remove v. 移開183 repair v. 修理184 report n. 報告185 reset v. 重設186 rework v. 重做187 right away ad. 立刻188 route n. 途程189 rule n. 規則190 run v. 跑191 runcard n. 流程卡192 safe a. 安全193 same a. 相同194 save v. 儲存195 scrap n. 報廢196 screen n. 螢幕197 select v. 選擇198 service n. 服務199 sheet n. 表單200 show v. 顯示201 skip v. 跳過202 sorter n. 排序機台203 source n. 來源204 speech n. 演講205 speed n. 速度206 split n. 分帳,分批207 stage n. 階段208 stamp n. 郵票209 standard n. 標準210 standby n. 等待211 start n. 起動212 status n. 狀況213 step n. 步驟214 stocker n. 儲存櫃215 success n. 成功216 super a. 超級217 super hot run n. 超級急件218 supervisor n. 監督者﹝課長﹞219 support n. 支援221 system n. 系統222 tag n. 標籤223 tape n. 膠帶224 target n. 目標225 technician n. 技術員226 telephone n. 電話227 temperature n. 溫度228 thickness n. 厚度229 time n. 時間230 title n. 標題231 top a. 上部232 training n. 訓練233 travel n. 旅行234 trend n. 趨勢235 turn rate n. 晶片週轉率236 use v. 使用237 username n. 使用者名稱238 vendor n. 廠商239 view v. 查看240 wafer n. 晶片241 wafer out n. 晶片產出量243 warning n. 警告244 watch out n. 小心245 wet a 濕246 whole n. 全部247 window n. 視窗248 write v. 寫出249 yield n. 良率250 zero n. 零。

知识就昱力量一、常用术语Chain conveyor 链条传送 Solder iron 烙铁 Flux 助焊剂3CComputer 电脑类产品 Con sumer electr onics 消费性电子产品 Communi catio n 通讯类产品FOUR CONTROL SY STEM 四大管制系统Engin eeri ng con trol system 工程管制系统 Quality control system 品质管制系统Manu facturi ng con trol system 生产管制系统 Man ageme nt control system 经营管制系统PDCA Pla n Do Check Acti on计划执行检查总结 面SMT Surface mounting tech no logy 表面贴装技术SMD Surface moun ti ng device 表面贴装设备SMC Surface moun ti ng comp onents 表贴装元件 MIMAmanual in sert手工插件machi ne assembly机器组装 Scree n prin ter 电子印刷机 Reflow回流焊Pilot ru n试生产Ove n烤箱,烤炉 Solder 焊接Solder wett ing 焊剂润湿Profile剖面外形轮廓Chain链条7SClassification 整理(sorting, organization )-seiriRegulati on 整顿(arran geme nt, tid in ess)-seit on Cleanliness 清扫(sweeping, purity)-seiso Conservation 清洁(cleaning, cleanliness)-seiktsu Culture 教养(discipline)-shitsuke……★… 知识就昱力量Save节约Safety安全二、英文缩写品质人员名称类QC quality con trol 品质管理人员FQC final quality con trol 终点品质管制人员IPQC in process quality control 制程中的品质管制人员OQC output quality control 最终出货品质管制人员IQC incoming quality con trol 进料品质官制人员TQC total quality con trol 全面质量管理QA quality assura nee 质量保证人员OQA output quality con trol 出货质量保证人员QE quality engineering 品质工程人员品质保证类FAI first article in specti on 新品首件检查FAA first article assura nee 首件确认SSQA sta ndardized supplier quality audit 合格供应商品质评估FQC运作类AQL Acceptable Quality Level 允收品质水准ACC Accept 允收REE Reject 拒收CR Critical 极严重的MAJ Major 主要的MIN Min or 轻微的P/N Part Number 料号L/N Lot Number 批号UAI Use As It 特采FPIR First Piece In specti on Report 首件检查报告DPPM Defective Perce nt Per Millio n 白力分之缺陷制程统计品管类SPC Statistical Process Con trol 统计制程管制SQC Statistical Quality Con trol 统计品质管制DIM Dime nsio n 尺寸DIA Diameter 直径其它品质术语类ZD Zero Defect 零缺陷QP Quality Policy 品质方针TQM Total Quality Man ageme nt 全面品质管理RMA Return Material Audit 退货认可7QCTools 7 Quality Control Tools 品管七大手法……★… 知识就昱力量通用文件类ECN Engin eeri ng Change Notice 工程变更通知(供应商)ECO Engin eeri ng Change Order 工程改动要求(客户)PCN Process Change Notice 工序改动通知PMP Product Man ageme nt Pla n 生产管制计划SIP Stan dard In specti on Procedure 制程检验标准程序SOP Sta ndard Operati on Procedure 制造作业规范BOM Bill of Material 物料清单SPEC Specificati on 规格DWG Drawi ng 图面系统文件类ISO Intern ati onal Stan dard Orga ni zation 国际标准化组织部类QE Quality Engin eeri ng 品质工程QA Quality Assura nee 品质保证LAB Laboratory 实验室IE In dustrial Engin eeri ng 工业工程R&D Research&Design设计开发部生产类PCs Pieces 个(根、块等)CTN Carton 卡通箱PAL Pallet/skid 栈板PO Purchas ing Order 采购订单MO Manufacture Or de r生产单D/C Date Code 生产日期码ID/C Ide ntificatio n Order (供应商)识别码L/N Lot Number 批号P/N Part Number 料号OEM Origi nal Equipme nt Manu facture 原设备制造QTY Qua ntity 数量NG Not Good 不行,不合格C=0 Critical=0 极严重不允许APP Approve 核准,认可,承认CHK Check 确认ASSY Assembly 装配,组装LRR Lot Reject Rate 批退率PCB Prin ted Circuit Board 印刷电路板CAR Correcti on Acti on Report 改善报告TBA To Be Assured 待疋,疋缺AVL Approved Ven dor List 许可供应商清单EOL End of Life三、专业词汇知识就昱力量组装类Assembly lineLayoutConveyorScrew driverElectric screw driverAutomati onConveying beltLove is not a maybe thing. You know whe n you love some one.组装线布置图流水线运输带起子电动起子自动化输送带。

生产类1、BOM Bill Of Material 物料清单2、PS Package Specification 包装规范3、SPEC Specification 规格4、PCS Pieces 个(根,块等)5、PRS Pairs 双(对等)6、CTN Carton 卡通箱7、PAL Pallet/skid 栈板8、PO Purchasing Order 采购订单9、MO Manufacture Order 生产单10、D/C Date Code 生产日期码11、ID/C Identification Code (供货商)标识符12、SWR Special Work Request 特殊工作需求13、L/N Lot Number 批号14、P/N Part Number 料号15、其它16、OEM Original Equipment Manufacture 原设备制造17、PCE Personal Computer Enclosure 个人计算机外设18、PC Personal Computer 个人计算机19、CPU Central Processing Unit 中央处理器20、SECC SECC` 电解片21、SGCC SGCC 热浸镀锌材料22、U.S.A the United States of America 美国23、A.S.A.P As Soon As Possible 尽可能快的24、E-MAIL Electrical-Mail 电子邮件25、N/A Not Applicable 不适用26、QTY Quantity 数量27、vs. versus 以及.28、REV Revision 版本29、JIT Just In Time 零库存30、I/O Input/Output 输入/输出31、OK OK 好32、NG Not Good 不行,不合格33、C=0 Critical=0 极严重不允许34、ESD Electro Static Discharge 静电排放35、5S 希腊语 整理,整顿,清扫,清洁,教养36、ATIN Attention 知会37、CC Carbon Copy 副本复印相关人员38、APP Approve 核准,认可,承认39、CHK Check 确认40、AM Ante Meridian 上午41、PM Post Meridian 下午42、CD Compact Disk 光盘43、CD-ROM Compact Disk Read-Only Memory 只读光盘44、FDD Floppy Disk Drive 软盘驱动器45、HDD Hard Disk Drive 碟碟机46、REF Reference 仅供参考47、CONN Connector 连接器48、CAV Cavity 模穴49、CAD Computer Aid Design 计算器辅助设计50、ASS Y Assembly 装配,组装51、MAT S Material 材料52、IC Integrated Circuit 集成电路53、T/P True Position 真位度54、TYP Type 类型55、WDR Weekly Delivery Requirement 周出货需求56、C?T Cycle Time 制程周期57、L/T Lead Time 前置时间(生产前准备时间)58、S/T Standard Time 标准时间59、P/M Product Market 产品市场60、3C Computer, Communication, Consumer electronics’ 消费性电子61、5W2H When, Where, Who, What, Why, How,How many62、5M Man, Machine, Material, Method, Measurement人员、机器、材料、方法、测量63、4M1E Man, Machine, Material, Method, Environment64、4MIH Man, Material, Money, Method, Time 人力,物力,财务,技术,时间(资源)65、SQA Strategy Quality Assurance 策略质量保证66、DQA Design Quality Assurance 设计质量保证67、MQA Manufacture Quality Assurance 制造质量保证68、SSQA Sales and service Quality Assurance 销售及服务质量保证69、LRR Lot Reject Rate 批退率70、BS Brain storming 脑力激荡71、EMI Electronic Magnetron Inspect 高磁测试72、FMI Frequency Modulator Inspect 高频测试73、B/M Board/Molding (flat cable)扁平导线电缆74、SPS Switching power supply 电源箱75、DT Desk Top 卧式(机箱)76、MT Mini-Tower 立式(机箱)77、LCD Liquid Crystal Display 液晶显示器78、CAD Computer AID Design 计算机辅助设计79、CAM Computer AID Manufacturing 计算机辅助制造80、CAE Computer AID Engineering 计算机辅助工程81、BIOS Advanced Basic in put/output system 先进的基本输入/输出系统82、CMOS Complementary Metal Oxide Semiconductor 互补金属氧化物半导体83、PDA Personal Digital Assistant 个人数字助理84、ISA Industry Standard Architecture 工业标准体制结构85、MCA Micro Channel Architecture 微信道结构86、EISA Extended Industry Standard Architecture 扩充的工业标准结构87、SIMM Single in-line memory module 单项导通汇流组件88、DIMM Dual in-line Memory Module 双项导通汇流组件89、LED Light-Emitting Diode 发光二级管90、FMEA Failure Mode Effectiveness 失效模式分析91、W/H Wire Harness 金属线绪束集组件92、F/C Flat Cable 扁平电缆93、PCB Printed Circuit Board 印刷电路板94、CAR Correction Action Report 改善报告95、NG Not Good 不良96、WPR Weekly Delivery Requirement 周出货要求97、PPM Parts Per Million 百万分之一98、TPM Total Production Maintenance 全面生产保养99、MRP Material Requirement Planning 物料需计划100、OC Operation System 操作系统101、TBA To Be Design 待定,定缺102、D/C Drawing Change 图纸变更/设计变更103、EMI Electrical-Music Industry 电子音乐工业104、RFI Read Frequency Input 读频输入。

公司英語一:常用術語組織類Hon Hai 鴻海Foxconn 富士康PCEG Personal Computer Enclosure group 個人電腦週邊事業群DT(I) Desk top I 制一處DT(II) Desk top II 制二處DT(III) Desk top III 制三處NWE Net Work Enclosure NWENFE Network flexible enclosure NFEPrototype workshop 樣品中心NSE Network system enclosure NSEMGE Magnesium alloy enclosure 鎂合金MPE mobile phone enclosure MPEStamping tool shop I 沖模一廠Stamping tool shop II 沖模二廠molding tooling workshop I 塑模一廠molding tooling workshop II 塑模二廠molding tooling workshop III 塑模三廠Surface processing developing division 表面處理發展處Equipment development DEPT 設備開發部Product design center 産品設計中心Die casting tooling factory 壓鑄模具廠Cost management Division 經營管理處Human resources division 人力資源處Material purchasing Division 資財採購處Central logistics 中央物流Plant engineering 工務處System information 系統資訊處Hua Nan testing and measurement center 華南檢測中心Engineering standard division 工標處CCBG Connector & cable business groupCPBG Consumer Product Business GroupESBG Enterprise system business group 鴻富錦事業群SABG system assembly business group 系統組裝事業群NSG Network system groupCOME Contract Optical Mechanical ElectronicsNWING Network Intern connection GroupOPCG Optical Passive Components GroupOACG Optical Active Components GroupFoxcavity Hong Zhun 鴻准Steel factory 裁剪廠(康富興)活動類CMM Component module move 機動元件整合CEM Contract Electronic Manufacture 合約委託代工IBSC Internet Business Solution Center 國際互聯網應用中心SDQ Speed Dragon to Compaq 龍捷克專案ERP Enterprise Resource planningSCM Supplier Chain ManagementSAP System Application ProductionBS Brain Storming 腦力激蕩QCC Quality Control Circle 品質圈PDCA Plan Do Check Action 計劃執行檢查總結Document center (database center) 資料中心Education and Training 教育訓練proposal improvement/creative suggestion 提案改善Technological exchange and study 技術交流研習會Technology and Development Committee 技術發展委員會3CComputer 電腦産品Consumer electronics 消費性電子産品Communication 通訊類産品Core value (核心價值)Love 愛心Confidence 信心Decision 決心Corporate culture (公司文化)Harmony 融合Responsibility 責任Progress 進步3T STRATEGYTime to market 及時切入生産Time to volume 及時大量生産Time to money 及時大量交貨FOUR CONTROL SYSTEM 四大管制系統Engineering control system 工程管制系統Quality control system 品質管制系統Manufacturing control system 生産管制系統Cost management control system 經營管制系統7SClassification --seiri 整理Location --seiton 整頓Cleaning --seiso 清掃Conservation --seiktsu 清潔Convention --shitsuke 教養Save 節約Safety 安全二:英文縮寫品質類QC quality control 品質管理人員FQC final quality control 終點品質管制人員IPQC in process quality control 制程中的品質管制人員OQC output quality control 最終出貨品質管制人員IQC incoming quality control 進料品質管制人員QA quality assurance 質量保證人員QE quality engineering 品質工程人員FAI first article inspection 新品首件檢查FAA first article assurance 首件確認CPK capability process index 模具制程能力參數FMEA failure modes & effects analysis 失效模式分析TVR Tool verification report 模具檢驗報告P/N Part Number 料號L/N Lot Number 批號PPM Parts Per Million 百萬分之一QIT Quality Improvement Team 品質改善小組ZD Zero Defect 零缺點通用文件類ECN Engineering Change Notes 工程變更通知(供應商)PMP Product Management Plan 生産管制計劃SIP Standard Inspection Procedure 制程檢驗標準程式SOP Standard Operation Procedure 製造作業規範A VL Approved vendor listPOP Procedure of packagingBOM Bill Of Material 物料清單DWG Drawing 圖面ES Engineering Standard 工程標準ISO International Standardization Organization 國際標準化組織生産類PMC Production & Material Control 生産和物料控制PCC Product control center 生産管制中心PPC Production Plan Control 生産計劃控制MC Material Control 物料控制IE Industry Engineering 工業工程R&D Research & Design 設計開發部PO Purchasing Order 採購訂單OEM Original Equipment Manufacture 原設備製造CPU Central Processing Unit 中央處理器5W2 When, Where, Who, What, Why, How to, How much6M Man, Machine, Material, Method, Measurement, Mother mature4M1T1H Man, Material, Money, Method, Time, HowLRR Lot Reject Rate 批退率SPS Switching power supply 電源箱DT Desk Top 臥式(機箱)MT Mini-Tower 立式(機箱) DVD Digital Video DiskVCD Video Compact DiskLCD Liquid Crystal DisplayCAD Computer Aided DesignCAM Computer Aided ManufacturingCAE Computer Aided EngineeringCAR Correction Action Report 改善報告MRP Material Requirement Planning 物料需計劃B2C Business to customerB2B Business to businessDCC Delivery control center 交貨管制中心三:專業辭彙通用類president 董事長operator 作業員position 職務general manager 總經理special assistant 特助deputy manager |'depjuti| 副理=vice managerdeputy supervisor 副課長=vice supervisor group leader 組長line leader 線長supervisor 課長Assembly facto 組裝(廠) Stamping factory 衝壓(廠) painting factory 烤漆廠molding factory 成型廠responsible department 負責單位Head count 人頭數production department 生産部門planning department 企劃部QC Section 品管課meeting minutes 會議記錄description 品名specification 規格model 機種work order 工令revision 版次remark 備註cosmetic inspection standard 外觀檢驗規範personal computer enclosure 電腦機箱産品front plate 前板rear plate 後板chassis |'∫æsi| 基座Hood 上蓋 Bezel 面板riser card 擴充卡flat cable 排線TOP driver cage 上磁架bottom driver cage 下磁架raw materials 原料roll/coil material 卷料spare parts =buffer 備品plastic parts 塑膠件sheet metal parts/stamping parts 沖件finished product 成品semi-finished product 半成品good product/accepted goods 良品defective product/non-good parts 不良品disposed goods 處理品warehouse/hub 倉庫packing material 包材flow chart 流程表單production tempo 生産進度liaison 聯絡單die worker 模工beacon 警示燈coolant 冷卻液crusher 破碎機club car 高爾夫車forklift 叉車Workshop traveler 天車trailer =long vehicle 拖板車Hydraulic trolley 手壓車hydraulic hand jack 油壓板車work cell/work shop 工作間sub-line 支線bottleneck 瓶頸progressive die 連續模stage die 工程模feature die 公母模male die 公模female die 母模cavity 型控母模core 模心公模parameter 參數efficiency 係數driller 鑽床engraving 刻印stamping 油印staking 鉚合gauge(or jig) 治具punch, press 衝床punching machine 衝床hydraulic machine 油壓機jack 升降機Uncoiler and strengthener 整平機Feeder 送料機rack, shelf, stack 料架taker 取料機flowing line 流水線Assembly line 組裝線Layout 佈置圖Conveyer 流水線運輸帶Rivet machine 拉釘機Rivet gun 拉釘槍Screw driver 起子Electric screw driver 電動起子Pneumatic screw driver 氣動起子Automation 自動化staking, riveting 鉚合robot 機械手conveying belt 輸送帶bolt 螺栓nut 螺母screw 螺絲identification tag 標示單staker = riveting machine 鉚合機fasten 鎖緊(螺絲) barcode scanner 條碼掃描器fuse machine/heat stake 熱熔機tox machine/rollover 自鉚機sand blasting 噴沙grit maker 抽粒機poor processing 制程不良poor incoming part 來件不良critical defect 極嚴重缺陷major defect 主要缺陷minor defect 次要缺陷cosmetic defect 外觀不良oxidation 氧化defective threading 抽芽不良poor staking 鉚合不良deficient purchase 來料不良deficient manufacturing procedure 制程不良cosmetic inspection 外觀檢查blister 氣泡dent 壓痕scratch 刮傷deformation 變形filings 鐵削defective label 不良標簽abrasion 磨損Breaking. (be)broken,(be)cracked 斷裂Short 射料不足Nick 缺口burr(金屬)flash(塑件) 毛邊poor staking 鉚合不良excessive gap 間隙過大grease/oil stains 油污shrinkage 縮水water spots 水漬impurity 雜質rust 生銹peel 脫漆Contamination 髒汙Streak 條紋Stains 污點Inclusion 雜質slug mark 壓痕sink `` 下凹Hickey 漏漆labels and logos 貼紙與商標。

富士康企業集團常用理念名詞解釋富士康企業集團常用理念名詞解釋富士康企業集團常用理念名詞解釋富士康企業集團常用理念名詞解釋富士康企業集團常用理念名詞解釋富士康企業集團常用理念名詞解釋富士康企業集團常用理念名詞解釋公司英語一常用術語組織類Hon Hai 鴻海Foxconn 富士康PCEG Personal Computer Enclosure Group 個人電腦外設事業群DT(I) Desk top I 制一處DT(II) Desk top II 制二處DT(III) Desk top III 制三處NWE Net Work Enclosure NWENFE Network Flexible Enclosure NFEPrototype Workshop 樣品中心NSE Network System Enclosure NSEMGE Magnesium Alloy Enclosure 鎂合金MPE Mobile Phone Enclosure MPEStamping Tool Shop I 沖模一廠Stamping Tool Shop II 沖模二廠Molding Tooling Workshop I 塑模一廠Molding Tooling Workshop II 塑模二廠Molding Tooling Workshop III 塑模三廠Surface Processing Developing Division 表面處理發展處Equipment Development Department 設備開發部Product Design Center 產品設計中心Die Casting Tooling Factory 壓鑄模具廠Cost Management Division 經營管理處Human Resource Division 人力資源處Material Purchasing Division 資財采購處Central Logistics 中央物流Plant Engineering 工務處System Information 系統資訊處Hua Nan Testing and Measurement Center 華南撿測中心Engineering Standard Division 工標處CCBG Connector &Cable Business GroupCPBG Consumer Product Business GroupESBG Enterprise System Business Group 鴻富錦事業群SABG System Assemble Business Group 系統組裝事業群NSG Network System GroupCOME Contract Optical Mechanical ElectronicsNWING Network Intern Connection GroupOPCG Optical Passive Components GroupOACG Optical Active Components GroupFoxcavity Hong Zhun 鴻準Steel factory 裁剪廠(康富興)活動類CMM Component Module Move 機動元件整合CEM Contract Electronic Manufacture 合約委托代工IBSC Internet Business Solution Center 國際互聯網應用中心SDQ Speed Dragon to Compaq 龍捷克專案ERP Enterprise Resource PlanningSCM Supplier Chain ManagementSAP System Application ProductionBS Brain Storming 腦力激蕩QCC Quality Control Circle 品質圈PDCA Plan Do Check Action 計劃執行檢查總結Document Center(Database Center) 資料中心Education and Training 教育訓練Proposal improvement/creative suggestion 提案改善Technological exchange and study 技術交流研習會Technology and Development Committee 技術發展委員會3CComputer 電腦類產品Consumer electronics 消費性電子產品Communication 通訊類產品Core value (核心價值) Love 愛心Confidence 信心Decision 決心Corporate culture (公司文化) Harmony 融合Responsibility 責任Progress 進步3T STRATEGYTime to market 及時切入生產Time to volume 及時大量生產Time to money 及時大量交貨FOUR CONTROL SYSTEM 四大管制系統Engineering control system 工程管制系統Quality control system 品質管制系統Manufacturing control system 生產管制系統Cost management control system 經營管制系統7Sclassification --seiri 整理Location --seiton 整頓Cleaning --seiso 清掃Conservation --seiktsu 清洁Convention --shitsuke 教養Save 節約Safety 安全二英文縮寫品質類QC quality control品質管理人員FQC final quality control終點品質管制人員IPQC in process quality control制程中的品質管制人員OQC output quality control最終出貨品質管制人員IQC incoming quality control進料品質管制人員QA quality assurance質量保證人員QE quality engineering品質工程人員FAI first article inspection新品首件檢查FAA first article assurance首件確認CPK capability process index模具制程能力參數FMEA Failure modes & effects analysis失效模式分析TVR tool verification report模具檢驗報告P/N Part Number料號L/N Lot Number批號PPM Parts Per Million百萬分之一QIT Quality Improvement Team品質改善小組ZD Zero Defect零缺點通用文件類ECN Engineering Change Note工程變更通知(供應商)PMP Product Management Plan生產管制計劃SIP Standard Inspection Procedure製程檢驗標準程序SOP Standard Operation Procedure製造作業規範A VL Approved Vendor ListPOP Procedure of PackagingBOM Bill of Material物料清單DWG Drawing圖面ES Engineering Standard工程標準ISO International Standardization Organization國際標準化組織生產類PMC Production & Material Control生產和物料控制PCC Product Control Center生產管制中心PPC Production Plan Control生產計劃控制MC Material Control物料控制IE Industry Engineering工業工程R&D Research & Design設計開發部PO Purchasing Order採購訂單OEM Original Equipment Manufacture原設備製造CPU Central Processing Unit中央處理器` 5W2H When,Where,Who,What,Why ,How to,How much6M Man,Machine,Material,Method,Measurement,Mother,mature4M1T1H Man,Material,Money ,Method,Time,HowLRR Lot Reject Rate批退率SPS Switching power supply電源箱DT Desk Top臥式(機箱)MT Mini-Tower立式(機箱) DVD Digital Video DiskVCD Video Compact DiskLCD Liquid Crystal DisplayCAD Computer Aided DesignCAM Computer Aided ManufacturingCAE Computer Aided EngineeringCAR Correction Action Report改善報告MRP Material Requirement Planning物料需計劃B2C Business to CustomerB2B Business to Business三專業詞匯通用類president 董事長position 職務operator 作業員general manager 總經理special assistant 特助sheet metal parts/stamping parts 衝件deputy manager\`depjuti\副理finished product 成品=vice managerdequty supervisor副課長semi-finished product 半成品=vice supervisorgroup leader 組長good product/accepted goods 良品line leader 線長defective product/non-good part 不良品supervisor 課長disposed goods 處理品assembly factory 組裝(廠) warehouse/hub 倉庫stamping factory 衝壓(廠) packing material 包材painting factory 烤漆廠flow chart 流程表單molding factory 成型廠production tempo 生產進度responsible department 負責單位liaison 聯絡單head count 人頭數die worker 模工production department 生產部門beacon 警示燈planning department 企劃部coolant 冷卻液QC section 品管課crusher 破碎機DCC Delivery control center 交貨管制中心club car 高爾夫車meeting minutes 會議記錄forklift 叉車description 品名workshop traveler 天車specification 規格trailer=long vehicle 拖板車model 機种hydraulic trolley 手壓車work order 工令hydraulic hand jack 油壓板車revision 版次work cell/work shop 工作間remark 備注sub-line 支線cosmetic inspection standard 外觀檢驗規範bottleneck 瓶頸personal computer enclosure 電腦機箱產品progressive die 連續模front plate 前板stage die 工程模rear plate 后板feature die 公母模Chassis\'∂e si\基座male die 公模Hood 上蓋female die 母模Bezel 面板cavity 型控母模riser card 擴充卡core 模心公模flat cable 排線parameter 參數TOP driver cage 上磁架efficiency 系數bottom driver cage 下磁架driller 鉆床raw material 原料engraving 刻印roll/coil material 捲料stamping 油印spare part 備品staking 鉚合plastic part 塑膠件gauge(or jig) 治具hydraulic machine 油壓機punch,press 衝`床jack 升降機punching machine 衝床uncoiler and strengthener 整平機deficient manufacturing procedure 制程不良feeder 送料機cosmetic inspection 外觀檢查rack,shelf,stack 料架blister 氣泡taker 取料機dent 壓痕flowing line 流水線scratch 刮傷assembly line 組裝線deformation 變形layout 布置圖filings 鐵削conveyer 流水線運輸帶defective label 不良標簽rivet machine 拉釘機abrasion 磨損rivet gun 拉釘槍breaking(be)broken,(be)cracked 斷裂screw driver 起子short 射料不足electric screw driver 電動起子nick 缺口pneumatic screw driver 氣動起子burr(金屬)flash(塑件) 毛邊automation 自動化poor staking 鉚合不良staking,riveting 鉚合excessive gap 間隙過大robot 機械手grease/oil stains 油污conveying belt 輸送帶shrinkage 縮水bolt 螺栓water spots 水漬nut 螺母impurity 雜質screw 螺絲rust 生銹identification tag 標示單peel 脫漆staker=riveting machine 鉚合機contamination 臟污fasten 鎖緊(螺絲) streak 條紋barcode scanner 條碼掃描器stains 污點fuse machine/heat stake 熱熔機inclusion 雜質tox machine/rollover 自鉚機slug mark 壓痕sand blasting 噴沙sink 下凹grit maker 抽粒機hickey 漏漆poor processing 制程不良labels and logos 貼紙與商標poor incoming part 來件不良critical defect 极嚴重缺陷major defect 主要缺陷minor defect 次要缺陷cosmetic defect 外觀不良oxidation 氧化defective threading 抽芽不良poor staking 鉚合不良deficient purchase 來料不良。

制造业常用英语词汇总经理办公室General manager's office模具部Tooling department项目部Project department品质部Quality department计划部 Plan department制造部Manufacture departmentKeypad产品部Keypad departmentIMD 产品部 IMD department五金部 Metal stamping department设计科 Design section冲压车间 Stamping workshop电镀车间 Plating workshop物控科 Production material control section 计划科 Plan section仓务科 Warehouse section商务科 Business section品质规划科 quality plan sectionIQC科 IQC sectionIPQC科 IPQC sectionOQC科 OQC section检测中心 measurement center项目规划科 Project plan section项目XX科 Project section XX试模科 Mold test section成本科 Cost section设备科 Facility section采购科 Purchase section综合办 General affairs office编程科 Programming section模具工程科 Tooling engineering section模具装配车间Mold assembly workshop文控中心 Document control center (DCC)注塑车间Injection workshop喷涂车间 Spray painting workshop装配车间Assembly workshop总经理General manager (GM)经理managerXX部门经理Manager of XX department原料库 Raw material warehouse半成品库 Semi-finished product warehouse 成品库 Finished product warehouse科长 section chief主任 chief部门主管 department head主管,线长supervisor组长Foreman, forelady秘书secretary文员clerk操作员operator助理assistant职员staff二、产品超声波焊接ultrasonic welding 塑胶件 Plastic parts塑材 Raw parts喷涂件 Painted parts装配件 Assembly parts零件 Component原料 Raw material油漆 Paint稀释剂 Thinner油墨 Ink物料编号part number三、模具注塑模具injection mold冲压模具Stamping tool模架mold base定模座板Fixed clamp plateA板A plateB板B plate支承板 support plate方铁 spacer plate回位销 Return pin导柱 Guide pin动模座板Moving clamp plate 顶针ejector pin单腔模具single cavity mold 多腔模具multi-cavity mold浇口gate合模力clamping force锁模力locking force开裂crack循环时间cycle time老化aging螺杆screw镶件 Insert主流道 sprue分流道runner浇口gate直浇口 direct gate点浇口pin—point gate测浇口edge gate潜伏浇口submarine gate浇口套sprue bush流道板runner plate排气槽vent分型线(面)parting line定模Fixed mold动模movable mold型腔cavity凹模cavity plate,凸模core plate斜销angle pin滑块slide拉料杆sprue puller定位环locating ring脱模斜度draft滑动型芯slide core螺纹型芯threaded core热流道模具hot—runner mold熔合纹weld line三板式模具three plate mold脱模ejection脱模剂release agent注射能力shot capacity注射速率injection rate注射压力injection pressure保压时间holding time闭模时间closing time电加工设备Electron Discharge Machining数控加工中心CNC machine center万能铁床Universal milling machine平面磨床Surface grinding machine万能摇臂钻床Universal radial movable driller 立式钻床Vertical driller倒角chamfer键Key键槽keyway间距pitch快速成型模Rapid prototype tool (RPT)四、品管SPC statistic process control品质保证Quality Assurance(QA)品质控制Quality control(QC)来料检验IQC Incoming quality control巡检IPQC In-process quality control校对calibration环境试验Environmental test光泽gloss拉伸强度tensile strength盐雾实验salt spray test翘曲warp比重specific gravity疲劳fatigue撕裂强度tear strength缩痕sink mark耐久性durability抽样sampling样品数量sample sizeAQL Acceptable Quality level批量lot size抽样计划sampling plan抗张强度 Tensile Strength抗折强度 Flexural Strength硬度 Rigidity色差 Color Difference涂镀层厚度 Coating Thickness导电性能 Electric Conductivity粘度 viscosity附着力 adhesion耐磨 Abrasion resistance尺寸 Dimension(喷涂)外观问题 Cosmetic issue不合格品 Non—conforming product限度样板 Limit sample五、生产注塑机injection machine冲床Punch machine嵌件注塑 Insert molding双色注塑 Double injection molding薄壁注塑 Thin wall molding膜内注塑 IMD molding ( In—mold decoration)移印 Tampo printing丝印 Silk screen printing热熔 Heat staking超声熔接 Ultrasonic welding (USW)尼龙nylon黄铜 brass青铜 bronze紫(纯)铜 copper料斗hopper麻点pit配料compounding涂层coating飞边flash缺料 Short mold烧焦 Burn mark缩水 Sink mark气泡 Bubbles破裂 Crack熔合线 Welding line流痕 Flow mark银条 Silver streak黑条 Black streak表面光泽不良Lusterless表面剥离Pelling翘曲变形Deformation脏圬 Stain mark油污 Oil mark蓝黑点 Blue-black mark顶白 Pin mark拉伤 Scratch限度样品 Limit sample最佳样品 Golden sample预热preheating再生料recycle material机械手 Robot机器人 Servo robot试生产 Trial run; Pilot run (PR)量产 mass production切料头 Degate产能 Capacity能力 Capability参数 Parameter二次加工 Secondary process六.物控保质期shelf lifeABC分类法ABC Classification装配Assembly平均库存Average Inventory批号Batch Number批量生产Mass Production提货单Bill of Lading物料清单Bill of Material采购员Buyer检查点Check Point有效日期Date Available修改日期Date Changed结束日期Date Closed截止日期Date Due生产日期Date in Produced库存调整日期Date Inventory Adjust作废日期D ate Obsolete收到日期Date Received交付日期Date Released需求日期Date Required需求管理Demand Management需求Demand工程变更生效日期Engineering Change Effect Date 呆滞材料分析Excess Material Analysis完全跟踪Full Pegging在制品库存In Process Inventory投入/产出控制Input/ Output Control检验标识Inspection ID库存周转率Inventory Carry Rate准时制生产Just-in—time (JIT)看板Kanban人工工时Labor Hour最后运输日期Last Shipment Date提前期Lead Time负荷Loading仓位代码Location Code仓位状况Location Status批量标识Lot ID批量编号Lot Number批量Lot Size机器能力Machine Capacity机器加载Machine Loading制造周期时间Manufacturing Cycle Time制造资源计划Manufacturing Resource Planning (MRP II)物料成本Material Cost物料发送和接收Material Issues and Receipts物料需求计划Material Requirements Planning现有库存量On—hand Balance订单输入Order Entry零件批次Part Lot零件编号Part Number (P/N)零件Part领料单Picking List领料/提货Picking产品控制Product Control产品线Production Line采购订单跟踪Purchase Order Tracking需求量Quantity Demand毛需求量Quantity Gross安全库存量Safety Stock在制品Work in Process零库存Zero Inventories七.QS—9000中的术语APQP Advanced Product Quality Planning and Control Plan,产品质量先期策划和控制计划PPAP Production Part Approval Process,生产件批准程序FMEA Potential Failure Mode and Effects Analysis,潜在失效模式及后果分析MSA Measure System Analysis,测量系统分析SPC Statistical Process Control,统计过程控制审核 Audit能力 Capability能力指数 Capability Indices控制计划 Control Plans纠正措施 Corrective Action文件 Documentation作业指导书 Standard operation procedure (SOP); Work instruction不合格品 Nonconformance不合格 Nonconformity每百万零件不合格数 Defective Parts Per Million, DPPM预防措施 Preventive Action程序Procedures过程流程图 Process Flow Diagram, Process Flow Chart质量手册Quality Manual质量计划 Quality Plan质量策划 Quality Planning质量记录Quality Records原始数据Raw Data反应计划Reaction Plan返修Repair返工Rework现场Site分承包方Subcontractors产品product质量quality质量要求quality requirement顾客满意customer satisfaction质量管理体系quality management system质量方针quality policy质量目标quality objective质量管理quality management质量控制quality control质量保证quality assurance组织organization顾客customer供方supplier过程process服务service设计与开发design and development:特性characteristic可追溯性trace ability合格conformity缺陷defect纠正correction让步concession放行release报废scrap规范specification检验inspection试验test验证verification评审review测量measurement普通原因Common Cause均值Mean极差Range稳定性Stability计量型数据Variables Data变差Variation重复性Repeatability再现性Reproducibility稳定性Stability分辨率Resolution过程更改Process change质量功能展开QFD外观项目Appearance Item初始过程能力Preliminary Process Capability材料清单Bill of Material设计确认Design Validation设计验证Design Verification八.常用缩略词语OEM Original Equipment ManufacturerANOVA 方差分析法 Analysis of VarianceDFMEA 设计失效模式及后果分析 Design Failure Mode and Effects Analysis DOE 试验设计 Design of ExperimentGR&R 量具的重复性和再现性Gage Repeatability and Reproducibility PFMEA 过程失效模式及后果分析Process Failure Mode and Effect Analysis QSR 质量体系要求Quality System RequirementQFD 质量功能展开 Quality Function DeploymentBOM 物料清单 Bill of MaterialCpk 稳定过程的能力指数 Capability for stable processLCL 下控制限 Lower Control LimitUCL 上控制限 Upper Control LimitLSL 工程规范下限 Lower Specification LimitX(—)--R图均值一极差图 Average-Range Chart防错(POKA—YOKE)Mistake ProofingETA 预计到达 Estimate to be arrivePO 定单 Purchase orderM/C 机器 machineRFQ 报价需求 Request for quotationMFI 熔融流动指数 Melt flow indexFAI 全尺寸检测报告 First article inspectionCOC 材质证明 Certificate of complianceALT 加速老化试验 Accelerated life testCRR 承认书 Component review reportOT 加班 Over timeCAP 矫正计划 Corrective action planR&D 研发 Research and DevelopmentASAP 尽快 As soon as possibleECN工程更改通知Engineering change noticeDCN 设计更改通知 Design change noticeOTD 准时交货 On time delivery九.通用词语确保 ensure构想 construct会签 con-sign功能 Function机构 organization外观 appearance适用 apply to作业流程 Operation flow附件 attachment商务人员 business personnel汇总 summarize指定相关人员 designated personnel新产品开发说明会 new product development explanation meeting拟定 Prepare委托 entrust认证 qualify电子档 Soft copy3D文件 3D database移转 Transfer执行 ConductXXX申请单 XXX Application form客户要求 Customer requirement启动 Kick off评估 Evaluation作业员 Operator批准,承认 Approval合同评审 Contract review可靠性 Reliability相关的 Relevant程序 Procedure制程 Process流程图 Flow chart产品 Product生产 Production资材 Logistics责任 Responsibility跟进 Follow-up交付 Delivery汇总 Summarize外协加工 subcontract指定相关人员 designated personnel 编号 number附件 attachment产品名称 Description周期循环时间 Cycle time模具号 Mold No,数量 quantity ( Qt’y )备注 remarkSAP号 SAP No.客户 Customer表单 Form初步的 Preliminary版本 Version根本原因 Root cause(喷漆)夹具 Fixture(设备)小夹具 Jig设备 Equipment设施 Facility送,提交(样品)Submit责任部门,责任人 Responsible by (大的)目标 Objective(小的,具体的)目标 Target格式 Format上岗证 Qualification card需求 Requirement现场 On site查检表 Checklist试产 pilot增值税 VAT—--value-added tax品质专业英语大全零件材料类的专有名词CPU: central processing unit(中央处理器)IC: Integrated circuit(集成电路)Memory IC: Memory Integrated circuit(记忆集成电路)RAM: Random Access Memory(随机存取存储器)DRAM: Dynamic Random Access Memory(动态随机存取存储器)SRAM: Staic Random Access Memory(静态随机存储器)ROM: Read-only Memory(只读存储器)EPROM:Electrical Programmable Read—only Memory(电可抹只读存诸器)EEPROM: Electrical Erasbale Programmable Read-only Memory(电可抹可编程只读存储器)CMOS: Complementary Metal-Oxide—Semiconductor(互补金属氧化物半导体)BIOS: Basic Input Output System(基本输入输出系统)Transistor:电晶体LED:发光二极体Resistor:电阻Variator:可变电阻Capacitor:电容Capacitor array:排容Diode:二极体Transistor:三极体Transformer:变压器(ADP)Oscillator:频率振荡器(0sc)Crystal:石英振荡器XTAL/OSC:振荡产生器(X)Relay:延时器Sensor:感应器Bead core:磁珠Filter:滤波器Flat Cable:排线Inductor:电感Buzzer:蜂鸣器Socket:插座Slot:插槽Fuse:熔断器Current:电流表Solder iron:电烙铁Magnifying glass:放大镜Caliper:游标卡尺Driver:螺丝起子Oven:烤箱TFT:液晶显示器Oscilloscope:示波器Connector:连接器PCB:printed circuit board(印刷电路板)PCBA: printed circuit board assembly(电路板成品)PP:并行接口HDD:硬盘FDD:软盘PSU:power supply unit(电源供应器)SPEC:规格Attach:附件Case: 机箱,盖子Cover:上盖Base:下盖Bazel:面板(panel)Bracket:支架,铁片Lable:贴纸Guide:手册Manual:手册,指南Card:网卡Switch:交换机Hub:集线器Router:路由器Sample:样品Gap:间隙Sponge:海绵Pallet:栈板Foam:保利龙Fiber:光纤Disk:磁盘片PROG:程序Barcode:条码System:系统System Barcode:系统条码M/B:mother board:主板CD—ROM:光驱FAN:风扇Cable:线材Audio:音效K/B:Keyboard(键盘)Mouse:鼠标Riser card:转接卡Card reader:读卡器Screw:螺丝Thermal pad:散热垫Heat sink:散热片Rubber:橡胶垫Rubber foot:脚垫Bag:袋子Washer:垫圈Sleeve:袖套Config:机构Label hi-pot:高压标签Firmware label:烧录标签Metal cover:金属盖子Plastic cover:塑胶盖子Tape for packing:包装带Bar code:条码Tray:托盘Collecto:集线夹Holder:固定器,L铁Connecter:连接器IDE:集成电路设备,智能磁盘设备SCSI:小型计算机系统接口Gasket:导电泡棉AGP:加速图形接口PCI:周边组件扩展接口LAN:局域网USB:通用串形总线架构Slim:小型化COM:串型通讯端口LPT:打印口,并行口Power cord:电源线I/O:输入,输出Speaker:扬声器EPE:泡棉Carton:纸箱Button:按键,按钮Foot stand:脚架部门名称的专有名词QS:Quality system品质系统CS:Coutomer Sevice 客户服务QC:Quality control品质管理IQC:Incoming quality control 进料检验LQC:Line Quality Control 生产线品质控制IPQC:In process quality control 制程检验FQC:Final quality control 最终检验OQC:Outgoing quality control 出货检验QA:Quality assurance 品质保证SQA:Source(supplier) Quality Assurance 供应商品质保证(VQA)CQA:Customer Quality Assurance客户质量保证PQA rocess Quality Assurance 制程品质保证QE:Quality engineer 品质工程CE:component engineering零件工程EE:equipment engineering设备工程ME:manufacturing engineering制造工程TE:testing engineering测试工程PPE roduct Engineer 产品工程IE:Industrial engineer 工业工程ADM: Administration Department行政部RMA:客户退回维修CSDI:检修PC:producing control生管MC:mater control物管GAD: General Affairs Dept总务部A/D: Accountant /Finance Dept会计LAB: Laboratory实验室DOE:实验设计HR:人资PMC:企划RD:研发W/H:仓库SI:客验PD: Product Department生产部PA:采购(PUR: Purchaing Dept)SMT:Surface mount technology 表面粘着技术MFG:Manufacturing 制造MIS:Management information system 资迅管理系统DCC:document control center 文件管制中心厂内作业中的专有名词QT:Quality target品质目标QP:Quality policy目标方针QI:Quality improvement品质改善CRITICAL DEFECT:严重缺点(CR)MAJOR DEFECT:主要缺点(MA)MINOR DEFECT:次要缺点(MI)MAX:Maximum最大值MIN:Minimum最小值DIA iameter直径DIM imension尺寸LCL:Lower control limit管制下限UCL:Upper control limit管制上限EMI:电磁干扰ESD:静电防护EPA:静电保护区域ECN:工程变更ECO:Engineering change order工程改动要求(客户)ECR:工程变更需求单CPI:Continuous Process Improvement 连续工序改善Compatibility:兼容性Marking:标记DWG rawing图面Standardization:标准化Consensus:一致Code:代码ZD:Zero defect零缺点Tolerance:公差Subject matter:主要事项Auditor:审核员BOM:Bill of material物料清单Rework:重工ID:identification识别,鉴别,证明PILOT RUN: (试投产)FAI:首件检查FPIR:First Piece Inspection Report首件检查报告FAA:首件确认SPC:统计制程管制CP: capability index(准确度)CPK: capability index of process(制程能力) PMP:制程管理计划(生产管制计划)MPI:制程分析DAS efects Analysis System 缺陷分析系统PPB:十亿分之一Flux:助焊剂P/N:料号L/N:Lot Number批号Version:版本Quantity:数量Valid date:有效日期MIL—STD:Military-Standard军用标准ICT: In Circuit Test (线路测试)ATE:Automatic Test Equipment自动测试设备MO: Manafacture Order生产单T/U: Touch Up (锡面修补)I/N:手插件P/T:初测F/T: Function Test (功能测试—终测)AS 组立P/K:包装TQM:Total quality control全面品质管理MDA:manufacturing defect analysis制程不良分析(ICT) RUN—IN:老化实验HI-pot:高压测试FMI:Frequency Modulation Inspect高频测试DPPM: Defect Part Per Million(不良率的一种表达方式:百万分之一) 1000PPM即为0。

电子工厂专业英语词汇大全冲压、喷漆等专业词汇Assembly line组装线Layout布置图Conveyer流水线物料板Rivet table拉钉机Rivet gun拉钉枪Screw driver起子Electric screw driver电动起子Pneumatic screw driver气动起子worktable 工作桌OOBA开箱检查fit together组装在一起fasten锁紧(螺丝)fixture 夹具(治具)pallet栈板barcode条形码barcode scanner条形码扫描仪fuse together熔合fuse machine热熔机repair修理operator作业员QC品管supervisor 课长ME制造工程师MT制造生技cosmetic inspect外观检查inner parts inspect内部检查thumb screw大头螺丝lbs.inch镑、英寸EMI gasket导电条front plate前板rear plate后板chassis |'∫?si| 基座bezel panel面板power button电源按键reset button重置键Hi-pot test of SPS高源高压测试V oltage switch of SPS 电源电压接柆键sheet metal parts 冲件plastic parts塑料件SOP制造作业程序material check list物料检查表work cell工作间trolley台车carton纸箱sub-line支线left fork叉车Personnel resource department人力资源部production department生产部门planning department企划部QC Section品管科stamping factory冲压厂painting factory烤漆厂molding factory成型厂common equipment常用设备uncoiler and straightener整平机punching machine 冲床robot机械手hydraulic machine油压机lathe车床planer |'plein|刨床miller铣床grinder磨床driller钻床linear cutting线切割electrical sparkle电火花welder电焊机staker=reviting machine铆合机position职务president董事长general manager总经理special assistant manager特助factory director厂长department director部长deputy manager |'depjuti| =vice manager副理section supervisor课长deputy section supervisor =vice section supervisor副课长group leader/supervisor组长line supervisor线长assistant manager助理to move, to carry, to handle搬运be put in storage入库pack packing包装to apply oil擦油to file burr 锉毛刺final inspection终检to connect material接料to reverse material 翻料wet station沾湿台Tiana天那水cleaning cloth抹布to load material上料to unload material卸料to return material/stock to退料scraped |'skr?pid|报废scrape ..v.刮;削deficient purchase来料不良manufacture procedure制程deficient manufacturing procedure制程不良oxidation |' ksi'dei n|氧化scratch刮伤dents压痕defective upsiding down抽芽不良defective to staking铆合不良embeded lump|in'bed| |l mp|镶块feeding is not in place送料不到位stamping-missing漏冲production capacity生产力education and training教育与训练proposal improvement提案改善spare parts=buffer备件forklift叉车trailer=long vehicle拖板车compound die合模die locker锁模器pressure plate=plate pinch压板bolt螺栓name of a department部门名称administration/generalaffairs dept总务部automatic screwdriver电动启子thickness gauge厚薄规gauge(or jig)治具power wire电源线buzzer蜂鸣器defective product label不良标签identifying sheet list标示单screwdriver holder起子插座pedal踩踏板stopper阻挡器flow board流水板hydraulic handjack油压板车forklift叉车pallet栈板glove(s)手套glove(s) with exposed fingers割手套thumb大拇指forefinger食指midfinger中指ring finger无名指little finger小指band-aid创可贴industrial alcohol工业酒精alcohol container沾湿台head of screwdriver起子头sweeper扫把mop拖把vacuum cleaner吸尘器rag 抹布garbage container灰箕garbage can垃圾箱garbage bag垃圾袋chain链条jack升降机production line流水线chain链条槽magnetizer加磁器lamp holder灯架to mop the floor拖地to clean the floor扫地to clean a table擦桌子air pipe 气管packaging tool打包机packaging打包missing part漏件wrong part错件excessive defects过多的缺陷critical defect极严重缺陷major defect主要缺陷minor defect次要缺陷not up to standard不合规格dimension/size is a little bigger尺寸偏大(小)cosmetic defect外观不良slipped screwhead / slippery screw head螺丝滑头slipped screwhead / shippery screw thread滑手speckle斑点mildewed=moldy=mouldy发霉rust生锈deformation变形burr(金属)flash(塑件)毛边poor staking铆合不良excessive gap间隙过大grease/oil stains油污inclusion杂质painting peel off脏污shrinking/shrinkage缩水mixed color杂色scratch划伤poor processing 制程不良poor incoming part事件不良fold of packaging belt打包带折皱painting make-up补漆discoloration羿色water spots水渍polishing/surface processing表面处理exposed metal/bare metal金属裸露lack of painting烤漆不到位safety安全quality品质delivery deadline交货期cost成本engineering工程die repair模修enterprise plan = enterprise expansion projects企划QC品管die worker模工production, to produce生产equipment设备to start a press开机stop/switch off a press关机classification整理regulation整顿cleanness清扫conservation清洁culture教养qualified products, up-to-gradeproducts良品defective products, not up-to-gradeproducts不良品waste废料board广告牌feeder送料机sliding rack滑料架defective product box不良品箱die change 换模to fix a die装模to take apart a die拆模to repair a die修模packing material包材basket蝴蝶竺plastic basket胶筐isolating plate baffle plate; barricade隔板carton box纸箱to pull and stretch拉深to put material in place, to cut material, to input落料to impose lines压线to compress, compressing压缩character die字模to feed, feeding送料transportation运输(be)qualified, up to grade合格not up to grade, not qualified不合格material change, stockchange材料变更feature change 特性变更evaluation评估prepare for, make preparations for 准备parameters参数rotating speed, revolution转速manufacture management制造管理abnormal handling异常处理production unit生产单位lots of production生产批量steel plate钢板roll material卷料manufacture procedure制程operation procedure作业流程to revise, modify修订to switch over to, switch---tothrow--over switching over切换engineering, project difficulty工程瓶颈stage die工程模automation自动化to stake, staking, riveting铆合add lubricating oil加润滑油shut die架模shut height of a die架模高度analog-mode device类模器die lifter举模器argon welding氩焊Vocabulary for stamping冲压常词汇stamping, press冲压punch press, dieing out press冲床uncoiler & strainghtener整平机feeder送料机rack, shelf, stack料架cylinder油缸robot机械手taker取料机conveyer belt输送带transmission rack输送架top stop上死点bottom stop下死点one stroke一行程inch寸动to continue, cont.连动to grip(material)吸料location lump, locating piece, block stop 定位块reset复位smoothly顺利dent压痕scratch刮伤deformation变形filings铁削to draw holes抽孔inquiry, search for查寻to stock, storage, in stock库存receive领取approval examine and verify审核processing, to process加工delivery, to deliver 交货To return/delivery to. to send delivery back to return of goods退货registration登记registration card登记卡to control管制to put forward and hand in提报safe stock安全库存acceptance = receive验收to notice通知application form for purchase请购单consume, consumption消耗to fill in填写abrasion磨损reverse angle = chamfer倒角character die字模to collect, to gather收集failure, trouble故障statistics统计demand and supply需求career card履历卡to take apart a die卸下模具to load a die装上模具to tight a bolt拧紧螺栓to looser a bolt拧松螺栓to move away a die plate移走模板easily damaged parts易损件standard parts标准件breaking.(be)broken,(be)cracked 断裂to lubricate润滑common vocabulary for die engineering模具工程常用词汇die 模具figure file, chart file图档cutting die, blanking die冲裁模progressive die, follow (-on)die连续模compound die复合模punched hole冲孔panel board镶块to cut edges=side cut=side scrap切边to bending折弯to pull, to stretch拉伸Line stretching, line pulling线拉伸engraving, to engrave刻印upsiding down edges翻边to stake铆合designing, to design设计design modification设计变化die block模块folded block折弯块sliding block滑块location pin定位销lifting pin顶料销die plate, front board模板padding block垫块stepping bar垫条upper die base上模座lower die base下模座upper supporting blank上承板upper padding plate blank上垫板spare dies模具备品spring 弹簧bolt螺栓document folder活页夹file folder资料夹to put file in order整理资料spare tools location手工备品仓first count初盘人first check初盘复棹人second count 复盘人second check复盘复核人equipment设备waste materials废料work in progress product在制品casing = containerization装箱quantity of physical inventory second count 复盘点数量Quantity of customs count会计师盘,点数量the first page第一联filed by accounting department for reference会计部存查end-user/using unit(department)使用单位Summary of year-end physicalinventory bills年终盘点截止单据汇总表bill name单据名称This sheet and physical inventory listwill be sent to accounting departmenttogether (Those of NHK will be sent tofinancial department)本表请与盘点清册一起送会计部-(NHK厂区送财会部)Application status records of year-endphysical inventory List and physicalinventory card 年终盘点卡与清册使用-状况明细表Blank and waste sheet NO.空白与作废单号plate电镀mold成型material for engineering mold testing 工程试模材料not included in physical inventory不列入盘点sample样品incoming material to be inspected进货待验description品名steel/rolled steel钢材Material statistics sheet物料统计明细表meeting minutes会议记录meeting type 会别distribution department分发单位location地点chairman主席present members出席人员subject主题conclusion结论decision items决议事项responsible department负责单位pre-fixed finishing date预定完成日approved by / checked by / prepared by核准/审核/承办PCE assembly production schedule sheetPCE组装厂生产排配表model机锺work order工令revision版次remark备注production control confirmation生产确认checked by初审approved by核准department部门Stock age analysis sheet库存货龄分析表on-hand inventory现有库存available material良品可使用obsolete material良品已呆滞to be inspected or reworked待验或重工total合计cause description原因说明part number/ P/N 料号type形态item/group/class类别quality品质prepared by制表notes说明Year-end physical inventory difference analysis sheet年终盘点差异分析表physical inventory盘点数量physical count quantity账面数量difference quantity差异量cause analysis原因分析raw materials原料materials物料finished product成品semi-finished product半成品packing materials包材good product/accepted goods/ accepted parts/good parts 良品defective product/non-good parts不良品disposed goods处理品warehouse/hub仓库on way location在途仓oversea location海外仓spare parts physical inventory list备品盘点清单spare molds location模具备品仓skid/pallet栈板tox machine自铆机wire EDM线割EDM放电机coil stock卷料sheet stock片料tolerance工差score=groove压线cam block滑块pilot导正筒trim剪外边pierce剪内边drag form压锻差pocket for the punch head挂钩槽slug hole废料孔feature die公母模expansion dwg展开图radius半径shim(wedge)楔子torch-flame cut火焰切割set screw止付螺丝form block折刀stop pin定位销round pierce punch=die button圆冲子shape punch=die insert异形子stock locater block定位块under cut=scrap chopper清角active plate活动板baffle plate挡块cover plate盖板male die公模female die母模groove punch压线冲子air-cushion eject-rod气垫顶杆spring-box eject-plate弹簧箱顶板bushing block衬套insert 入块club car高尔夫球车capability能力parameter参数factor系数phosphate皮膜化成viscosity涂料粘度alkalidipping脱脂main manifold主集流脉bezel斜视规blanking穿落模dejecting顶固模demagnetization去磁;消磁high-speed transmission高速传递heat dissipation热传rack上料degrease脱脂rinse水洗alkaline etch龄咬desmut剥黑膜D.I. rinse纯水次Chromate铬酸处理Anodize阳性处理seal封孔revision版次part number/P/N料号good products良品scraped products报放心品defective products不良品finished products成品disposed products处理品barcode条形码flow chart流程窗体assembly组装stamping冲压molding成型spare parts=buffer备品coordinate坐标dismantle the die折模auxiliary function辅助功能poly-line多义线heater band 加热片thermocouple热电偶sand blasting喷沙derusting machine除锈机degate打浇口dryer烘干机induction感应induction light感应光response=reaction=interaction感应ram连杆edge finder巡边器concave凸convex凹short射料不足nick缺口speck瑕疪shine亮班splay 银纹gas mark焦痕delamination起鳞cold slug冷块blush 导色gouge沟槽;凿槽satin texture段面咬花witness line证示线patent专利grit沙砾granule=peuet=grain细粒grit maker抽粒机cushion缓冲magnalium镁铝合金magnesium镁金metal plate钣金mill锉plane刨grind磨drill铝boring镗blister气泡fillet镶;嵌边through-hole form通孔形式roller pin formality滚针形式cam driver铡楔shank摸柄crank shaft曲柄轴angular offset角度偏差velocity速度production tempo生产进度现状torque扭矩spline=the multiple keys花键quenching淬火tempering回火annealing退火carbonization碳化alloy合金tungsten high speed steel钨高速的moly high speed steel钼高速的organic solvent有机溶剂bracket小磁导liaison联络单volatile挥发性resistance电阻ion离子titrator滴定仪beacon警示灯coolant冷却液crusher破碎机模具工程类plain die简易模pierce die冲孔模forming die成型模progressive die连续模gang dies复合模shearing die剪边模riveting die铆合模pierce冲孔forming成型(抽凸,冲凸) draw hole抽孔bending折弯trim切边emboss凸点dome凸圆semi-shearing半剪stamp mark冲记号deburr or coin压毛边punch riveting冲压铆合side stretch侧冲压平reel stretch卷圆压平groove压线blanking下料stamp letter冲字(料号) shearing剪断tick-mark nearside正面压印tick-mark farside反面压印冲压名称类extension dwg展开图procedure dwg工程图die structure dwg模具结构图material材质material thickness料片厚度factor系数upward向上downward向下press specification冲床规格die height range适用模高die height闭模高度burr毛边gap间隙weight重量total wt.总重量punch wt.上模重量五金零件类inner guiding post内导柱inner hexagon screw内六角螺钉dowel pin固定销coil spring弹簧lifter pin顶料销eq-height sleeves=spool等高套筒pin销lifter guide pin浮升导料销guide pin导正销wire spring圆线弹簧outer guiding post外导柱stop screw止付螺丝located pin定位销outer bush外导套模板类top plate上托板(顶板)top block上垫脚punch set上模座punch pad上垫板punch holder上夹板stripper pad脱料背板up stripper上脱料板male die公模(凸模)feature die公母模female die母模(凹模)upper plate上模板lower plate下模板die pad下垫板die holder下夹板die set下模座bottom block下垫脚bottom plate下托板(底板)stripping plate内外打(脱料板)outer stripper外脱料板inner stripper内脱料板lower stripper下脱料板零件类punch冲头insert入块(嵌入件)deburring punch压毛边冲子groove punch压线冲子stamped punch字模冲子round punch圆冲子special shape punch异形冲子bending block折刀roller滚轴baffle plate挡块located block定位块supporting block for location定位支承块air cushion plate气垫板air-cushion eject-rod气垫顶杆trimming punch切边冲子stiffening rib punch = stinger 加强筋冲子ribbon punch压筋冲子reel-stretch punch卷圆压平冲子guide plate定位板sliding block滑块sliding dowel block滑块固定块active plate活动板lower sliding plate下滑块板upper holder block上压块upper mid plate上中间板spring box弹簧箱spring-box eject-rod弹簧箱顶杆spring-box eject-plate弹簧箱顶板bushing block衬套cover plate盖板guide pad导料块塑件&模具相关英文compre sion molding压缩成型flash mold溢流式模具plsitive mold挤压式模具split mold分割式模具cavity型控母模core模心公模taper锥拔leather cloak仿皮革shiver饰纹flow mark流痕welding mark溶合痕post screw insert螺纹套筒埋值self tapping screw自攻螺丝striper plate脱料板piston活塞cylinder汽缸套chip细碎物handle mold手持式模具移转成型用模具encapsulation molding低压封装成型射出成型用模具two plate两极式(模具)well type蓄料井insulated runner绝缘浇道方式hot runner热浇道runner plat浇道模块valve gate阀门浇口band heater环带状的电热器spindle阀针spear head刨尖头slag well冷料井cold slag冷料渣air vent排气道h=0.02~0.05mmw=3.2mmL=3~5mmwelding line熔合痕eject pin顶出针knock pin顶出销return pin回位销反顶针sleeve套筒stripper plate脱料板insert core放置入子runner stripper plate浇道脱料板guide pin导销eject rod (bar)(成型机)顶业捧subzero深冷处理three plate三极式模具runner system浇道系统stress crack应力电裂orientation定向sprue gate射料浇口,直浇口nozzle射嘴sprue lock pin料头钩销(拉料杆) slag well冷料井side gate侧浇口edge gate侧缘浇口tab gate搭接浇口film gate薄膜浇口flash gate闸门浇口slit gate缝隙浇口fan gate扇形浇口dish gate因盘形浇口H=F=1/2t~1/5tT=2.5~3.5mmdiaphragm gate隔膜浇口ring gate环形浇口submarine gate潜入式浇口tunnel gate隧道式浇口pin gate针点浇口Φ0.8~1.0mmRunner less无浇道(sprue less)无射料管方式long nozzle延长喷嘴方式sprue浇口;溶渣质量人员名称类QC quality control 品质管理人员FQC final quality control 终点质量管理人员IPQC in process quality control 制程中的质量管理人员OQC output quality control 最终出货质量管理人员IQC incoming quality control 进料质量管理人员TQC total quality control 全面质量管理POC passage quality control 段检人员QA quality assurance 质量保证人员OQA output quality assurance 出货质量保证人员QE quality engineering 质量工程人员质量保证类FAI first article inspection 新品首件检查FAA first article assurance 首件确认TVR tool verification report 模具确认报告3B 3B 模具正式投产前确认CP capability index 能力指数CPK capability index of process 模具制程能力参数SSQA standardized supplier quality 合格供货商质量评估OOBA out of box audit 开箱检查QFD quality function deployment 质量机能展开FMEA failure model effectiveness analysis 失效模式分析8D 8 disciplines 8项回复内容FA final audit 最后一次稽核CAR corrective action request 改正行动要求corrective action report 改正行动报告FQC运作类AQL Acceptable Quality Level 运作类允收质量水平S/S Sample size 抽样检验样本大小ACC Accept 允收REE Reject 拒收CR Critical 极严重的MAJ Major 主要的MIN Minor 轻微的AOQ Average Output Quality 平均出厂质量AOQL Average Output Quality Level 平均出厂质量Q/R/S Quality/Reliability/Service 质量/可靠度服务MIL-STD Military-Standard 军用标准S I-S IV Special I-Special IV 特殊抽样水平等级P/N Part Number 料号L/N Lot Number 特采AOD Accept On Deviation 特采UAI Use As It 首件检查报告FPIR First Piece Inspection Report 百万分之一PPM Percent Per Million 批号制程统计品管专类SPC Statistical Process Control 统计制程管制SQC Statistical Quality Control 统计质量管理R Range 全距AR Average Range 全距平均值UCL Upper Central Limit 管制上限LCL Lower Central Limit 管制下限MAX Maximum 最大值MIN Minimum 最小值GRR Gauge Reproducibility & Repeatability 量具之再制性及重测性判断量可靠与否DIM Dimension 尺寸DIA Diameter 直径FREQ Frequency 频率N Number 样品数其它质量术语类QCC Quality Control Circle 品质圈QIT Quality Improvement Team 质量改善小组PDCA Plan Do Check Action 计划执行检查总结ZD Zero Defect 零缺点QI Quality Improvement 质量改善QP Quality Policy 目标方针TQM T otal Quality Management 全面质量管理MRB Material Reject Bill 退货单LQL Limiting Quality Level 最低质量水平RMA Return Material Audit 退料认可QAN Quality Ameliorate Notice 质量改善活动ADM Absolute Dimension Measurement 全尺寸测量QT Quality Target 质量目标7QCT ools 7 Quality Control T ools 品管七大手法通用之件类ECN Engineering Change Notes 工程变更通知(供货商) ECO Engineering Change Order 工程改动要求(客户) PCN Process Change Notice 工序改动通知PMP Product Management Plan 生产管制计划SIP Specification In Process 制程检验规格SOP Standard Operation Procedure 制造作业规范IS Inspection Specification 成品检验规范BOM Bill Of Material 物料清单PS Package Specification 包装规范SPEC Specification 规格DWG Drawing 图面系统文件类QC Quality System 质量系统ES Engineering Standardization 工程标准CGOO China General PCE龙华厂文件H Huston (美国)休斯敦C Compaq (美国)康伯公司C China 中国大陆A Assembly 组装(厂)S Stamping 冲压(厂)P Painting 烤漆(厂)I Intel 英特尔公司T TAIWAN 台湾IWS International Workman Standard 工艺标准ISO International Standard Organization 国际标准化组织GS General Specification 一般规格CMCS C-China M-Manufact C-Compaq S-Stamping Compaq 产品在龙华冲压厂制造作业规范CQCA Q-Quality A-Assembly Compaq产品在龙华组装厂品管作业规范CQCP P-Painting Compaq 产品在龙华烤漆厂品管作业规范部类PMC Production & Material Control 生产和物料控制PPC Production Plan Control 生产计划控制MC Material Control 物料控制ME Manufacture Engineering 制造工程部PE Project Engineering 产品工程部A/C Accountant Dept 会计部P/A Personal & Administration 人事行政部DC Document Center 资料中心QE Quality Engineering 质量工程(部)QA Quality Assurance 质量保证(处)QC Quality Control 质量管理(课)PD Product Department 生产部LAB Library 实验室IE Industrial Engineering 工业工程R&D Research & Design 设计开发部P Painting 烤漆(厂)A Assembly 组装(厂) S Stamping 冲压(厂)。

富士康英语测试题答案一、选择题1. The new product has been __________ a number of improvements.A) undergoneB) went throughC) subject toD) processed答案:C) subject to2. Despite the __________ weather, they decided to continue their journey.A) adverseB) averseC) diverseD) conversed答案:A) adverse3. It is __________ to discuss such a controversial topic at the dinner table.A) impoliteB) unpoliteC) impoliticD) impolitely答案:C) impolitic4. The __________ between the two cultures is quite evident.A) differenceB) differentC) differingD) differentiate答案:A) difference5. The company has been facing __________ due to the economic downturn.A) financial difficultiesB) difficulties financeC) finance difficultiesD) financial trouble答案:A) financial difficulties二、完形填空In the era of globalization, companies like Foxconn have to adapt to the ever-changing demands of the market. As a leading manufacturer, Foxconn relies heavily on its __6__ workforce to maintain __7__ and efficiency. The English proficiency test is one such measure to ensure that employees can __8__ with international clients and handle the __9__ workload that comes with global operations.The test includes various sections designed to assess different aspects of language skills. The __10__ sectionevaluates the ability to understand written English, whilethe __11__ section tests the capability to express ideasclearly and accurately. Listening and speaking are also crucial, as they facilitate __12__ and collaboration with colleagues from around the world.Foxconn recognizes the importance of continuous learning and provides __13__ for employees who wish to improve theirEnglish skills. This not only benefits the individual butalso contributes to the company's __14__ to provide the best service and products to its global clients.答案:6. skilled7. competitiveness8. communicate9. challenging10. reading11. writing12. communication13. training opportunities14. commitment三、阅读理解Foxconn Technology Group, a multinational electronics manufacturing company, is known for its role in producing products for some of the world's leading technology companies. With a workforce that spans across multiple continents, the need for a common language is essential. English serves asthis common language, facilitating communication andcollaboration among diverse teams.The English proficiency test is an integral part of the recruitment process at Foxconn. It is designed to ensure that new hires can effectively communicate in an internationalwork environment. The test covers reading, writing, listening, and speaking components, each assessing the candidate'sability to understand and use English in a professional context.In addition to the English test, Foxconn also places a strong emphasis on technical skills and the ability to work in a team. The company's commitment to quality and innovation is reflected in its hiring practices, which seek to find individuals who not only have the language skills but alsothe technical expertise to contribute to the company's success.Foxconn's approach to language training and continuous skill development underscores its dedication to staying competitive in the global market. By investing in its employees' language abilities, Foxconn ensures that it can meet the demands of an increasingly interconnected world.四、写作题根据上述阅读材料,写一篇短文,阐述富士康如何通过英语能力测试来确保员工能够适应全球化工作环境,并讨论这种测试对公司和员工个人的潜在益处。

Plskindlyreviewit请尽快回复TKS::谢start:开始时间End结束时间Target预计结束时间cut off截止时间update更新below is Failure summary以下是不良明细QAquality assurance质量保证IQA:Imcomingqualityassurance进料品质保证进料检验PQA:process quality assurance制程品质保证CQA:customerqualityassurance客户品质保证质检RQA:Recallqualityassurance回收物料品质保证OQA:outputqualityassurance出货品质保证SQA:supplier quality assurance软件质量保证LQA:laboratory quality assurance检验品质保证MQA:manufactune quality assurance制造品质保证VQA进料品质保证QC:quality control品质管控IPQC:in process quality control制程品质管控巡检OQC:out going quality control出货品质管控出货检验RQC:Recall quality control物料回收品质管控FQC:Finallqualitycontrol最终品质管控最终检验TQC:Total quality control全面质量管控TQM:Tontal quality control全面品质管理IQC:Imcomingqualitycontrol进料品质管控SQC:Statisticalqualitycontrol统计品质管控PQC:passage quality control段检品质管控QE:quality engineering质量工程SQE:Supplier quality engineering供应商品质工程师VQE:Verdor quality engineeringJQE:Joint quality engineering协力品质工程师PQE:processqualityengineering制程品质工程师PEproduction engineering制造工程TEtestengineering测试工程MEmechanical engineering机械工程IEindustrialengineering工业工程DE: Desense 拆机测试品质指数:quality index品质目标:quality target品质方针:qualitypolicy品质要求:quality requirement品质改善:qualityimprovement品质保证:qualityAssurance品质管控:quality control品质检验:quality inspcton品质管理:qualitymanagerHRhuman resoures人力资源PCproduction control生管DCCdocument control资料中心PD:product Department生产部制造部:production departmentquality control Department品质部工程部engineering departmentPM:project management专案管理MM:Material management物料管理MC:Material control物控BOMBill Of Material物料清单MLB:Main Logistic Board主板PCB板:printed circuit boardP/Npart munber料号SMT:surface mounting technology表面贴装技术S/Nseries number序列号sop:standardoperationprocedure标准作业指导书Wi:working instruction作业指导书SIP:standard instruction procedure标准检验规范O/Ioperation instuction工作指导书ECN(engineering change notice)工程变更通知FAIfirst article inspection新品首件检查FAAfirst article assurance首件确认OBA:openboxaubit开箱检验outofboxauditPCS:数量ISO:Internationalorganizationforstandardization国际标准化组织通风系统:Ventication system车间环境:working place environment车间:workshop工艺流程图:process flow diagramoperation procedure作业流程生产流程:production flowshut down关机copy复制保存:replace异常机:Abnormal UinitCTR:异常机BTR:正常机脏污:Dirtydeformation变形刮伤:surfacefinished product成品semi-finished product半成品goodproduct/acceptedgoods/acceptedparts/good parts良品defective product/non-good parts不良品WIP work in progress半成品cause analysis原因分析cosmetic inspect外检良率:yield不良率:Failure vate投入数:input quatity插入:plug in释放,流拉:release点击:click拔掉:unplug,remove弹出:display扫描:scan目检:inspect连接:connectmodel机种revision版本异常:abnormalities维修:repair生产人员:production personbel 测试人员:opratorsproduction team作业员线长:Line suppervisor领导:leader经理:manager总经理:general manager老板:boss科长课长主管:supervisor组长:team leader助理:assitand工程师:engineering副手:assitand adunct员工:personrel全技员:multi function厂长:director of a factory董事长:chairman, the board of directors总裁:president, director general customer客户purchasing采购warehouse仓库ENGengineering工程discription描述remark备注MA major主要的MIminor次要的supplier/vendor厂商material物料barcode条码board看板label标签Rivet table拉钉机power wire电源线capacitor电容case外壳washer垫片connector连接器fan风扇heatsink散热片Rivet gun拉钉枪Screw driver起子Electric screw driver风批Pneumatic screw driver电批desktop台式机fasten螺丝screwfixture夹具(治具)pallet栈板硬盘:HD,disk内存:memorry支架:bracket底盖:footbarcode scanner扫描枪IC集成电路电阻resistor开关switch噪音noise程序procedure检验员inspectortarget预计技术员technician抽检sample checkPO purchase order订单deficient purchase来料不良classification整理regulation整顿cleanness清扫conservation清洁三月march四月april五月may六月June七月JuneI will soon get used to the work我很快就会习惯这项工作的this company is our regular customer这家公司是我们的老顾客youbecamemoreandmorebeautiful你变的越来越漂亮了没问题No problemfunction test功能测试flux助焊剂fuse保险丝packing包装station工站temperature温度solder machine锡炉插座socket颜色单词红色red绿色green白色white黄色yellow黑色black蓝色blue棕色brown金色gold紫色purple(violet)银色silverJanuary一月february二月八月August九月september十月October十一月November十二月December11/ 11。