机械毕业设计英文外文翻译586注塑模的温度调节系统

- 格式:docx

- 大小:25.02 KB

- 文档页数:17

外文翻译及原文(文档含英文原文和中文翻译)【原文一】CONCURRENT DESIGN OF PLASTICS INJECTION MOULDS AbstractThe plastic product manufacturing industry has been growing rapidly in recent years. One of the most popular processes for making plastic parts is injection moulding. The design of injection mould is critically important to product quality and efficient product processing.Mould-making companies, who wish to maintain the competitive edge, desire to shorten both design and manufacturing leading times of the by applying a systematic mould design process. The mould industry is an important support industry during the product development process, serving as an important link between the product designer and manufacturer. Product development has changed from the traditional serial process of design, followed by manufacture, to a more organized concurrent process where design and manufacture are considered at a very early stage of design. The concept of concurrent engineering (CE) is no longer new and yet it is still applicable and relevant in today’s manuf acturing environment. Team working spirit, management involvement, total design process and integration of IT tools are still the essence of CE. The application of The CE process to the design of an injection process involves the simultaneous consideration of plastic part design, mould design and injection moulding machine selection, production scheduling and cost as early as possible in the design stage.This paper presents the basic structure of an injection mould design. The basis of this system arises from an analysis of the injection mould design process for mould design companies. This injection mould design system covers both the mould design process and mould knowledge management. Finally the principle of concurrent engineering process is outlined and then its principle is applied to the design of a plastic injection mould.Keywords :Plastic injection mould design, Concurrent engineering, Computer aided engineering, Moulding conditions, Plastic injection moulding, Flow simulation1.IntroductionInjection moulds are always expensive to make, unfortunately without a mould it can not be possible ho have a moulded product. Every mould maker has his/her own approach to design a mould and there are many different ways of designing and building a mould. Surely one of the most critical parameters to be considered in the design stage of the mould is the number of cavities, methods of injection, types of runners, methods of gating, methods of ejection, capacity and features of the injection moulding machines. Mould cost, mould quality and cost of mould product are inseparableIn today’s completive environment, computer aided mould filling simulation packages can accurately predict the fill patterns of any part. This allows for quick simulations of gate placements and helps finding the optimal location. Engineers can perform moulding trials on the computer before the part design is completed. Process engineers can systematically predict a design and process window, and can obtain information about the cumulative effect of the process variables that influence part performance, cost, and appearance.2.Injection MouldingInjection moulding is one of the most effective ways to bring out the best in plastics. It is universally used to make complex, finished parts, often in a single step, economically, precisely and with little waste. Mass production of plastic parts mostly utilizes moulds. The manufacturing process and involving moulds must be designed after passing through the appearance evaluation and the structure optimization of the product design. Designers face a hugenumber of options when they create injection-moulded components. Concurrent engineering requires an engineer to consider the manufacturing process of the designed product in the development phase. A good design of the product is unable to go to the market if its manufacturing process is impossible or too expensive. Integration of process simulation, rapid prototyping and manufacturing can reduce the risk associated with moving from CAD to CAM and further enhance the validity of the product development.3. Importance of Computer Aided Injection Mould DesignThe injection moulding design task can be highly complex. Computer Aided Engineering (CAE) analysis tools provide enormous advantages of enabling design engineers to consider virtually and part, mould and injection parameters without the real use of any manufacturing and time. The possibility of trying alternative designs or concepts on the computer screen gives the engineers the opportunity to eliminate potential problems before beginning the real production. Moreover, in virtual environment, designers can quickly and easily asses the sensitivity of specific moulding parameters on the quality and manufacturability of the final product. All theseCAE tools enable all these analysis to be completed in a meter of days or even hours, rather than weeks or months needed for the real experimental trial and error cycles. As CAE is used in the early design of part, mould and moulding parameters, the cost savings are substantial not only because of best functioning part and time savings but also the shortens the time needed to launch the product to the market.The need to meet set tolerances of plastic part ties in to all aspects of the moulding process, including part size and shape, resin chemical structure, the fillers used, mould cavity layout, gating, mould cooling and the release mechanisms used. Given this complexity, designers often use computer design tools, such as finite element analysis (FEA) and mould filling analysis (MFA), to reduce development time and cost. FEA determines strain, stress and deflection in a part by dividing the structure into small elements where these parameters can be well defined. MFA evaluates gate position and size to optimize resin flow. It also defines placement of weld lines, areas of excessive stress, and how wall and rib thickness affect flow. Other finite element design tools include mould cooling analysis for temperature distribution, and cycle time and shrinkage analysis for dimensional control and prediction of frozen stress and warpage.The CAE analysis of compression moulded parts is shown in Figure 1. The analysis cycle starts with the creation of a CAD model and a finite element mesh of the mould cavity. After the injection conditions are specified, mould filling, fiber orientation, curing and thermal history, shrinkage and warpage can be simulated. The material properties calculated by the simulation can be used to model the structural behaviour of the part. If required, part design, gate location and processing conditions can be modified in the computer until an acceptable part is obtained. After the analysis is finished an optimized part can be produced with reduced weldline (known also knitline), optimized strength, controlled temperatures and curing, minimized shrinkage and warpage.Machining of the moulds was formerly done manually, with a toolmaker checking each cut. This process became more automated with the growth and widespread use of computer numerically controlled or CNC machining centres. Setup time has also been significantly reduced through the use of special software capable of generating cutter paths directly from a CAD data file. Spindle speeds as high as 100,000 rpm provide further advances in high speed machining. Cutting materials have demonstrated phenomenal performance without the use of any cutting/coolant fluid whatsoever. As a result, the process of machining complex cores and cavities has been accelerated. It is good news that the time it takes to generate a mould is constantly being reduced. The bad news, on the other hand, is that even with all these advances, designing and manufacturing of the mould can still take a long time and can be extremely expensive.Figure 1 CAE analysis of injection moulded partsMany company executives now realize how vital it is to deploy new products to market rapidly. New products are the key to corporate prosperity. They drive corporate revenues, market shares, bottom lines and share prices. A company able to launch good quality products with reasonable prices ahead of their competition not only realizes 100% of the market before rival products arrive but also tends to maintain a dominant position for a few years even after competitive products have finally been announced (Smith, 1991). For most products, these two advantages are dramatic. Rapid product development is now a key aspect of competitive success. Figure 2 shows that only 3–7% of the product mix from the average industrial or electronics company is less than 5 years old. For companies in the top quartile, the number increases to 15–25%. For world-class firms, it is 60–80% (Thompson, 1996). The best companies continuously develop new products. AtHewlett-Packard, over 80% of the profits result from products less than 2 years old! (Neel, 1997)Figure 2. Importance of new product (Jacobs, 2000)With the advances in computer technology and artificial intelligence, efforts have been directed to reduce the cost and lead time in the design and manufacture of an injection mould. Injection mould design has been the main area of interest since it is a complex process involving several sub-designs related to various components of the mould, each requiring expert knowledge and experience. Lee et. al. (1997) proposed a systematic methodology and knowledge base for injection mould design in a concurrent engineering environment.4.Concurrent Engineering in Mould DesignConcurrent Engineering (CE) is a systematic approach to integrated product development process. It represents team values of co-operation, trust and sharing in such a manner that decision making is by consensus, involving all per spectives in parallel, from the very beginning of the productlife-cycle (Evans, 1998). Essentially, CE provides a collaborative, co-operative, collective and simultaneous engineering working environment. A concurrent engineering approach is based on five key elements:1. process2. multidisciplinary team3. integrated design model4. facility5. software infrastructureFigure 3 Methodologies in plastic injection mould design, a) Serial engineering b) Concurrent engineeringIn the plastics and mould industry, CE is very important due to the high cost tooling and long lead times. Typically, CE is utilized by manufacturing prototype tooling early in the design phase to analyze and adjust the design. Production tooling is manufactured as the final step. The manufacturing process and involving moulds must be designed after passing through the appearance evaluation and the structure optimization of the product design. CE requires an engineer to consider the manufacturing process of the designed product in the development phase.A good design of the product is unable to go to the market if its manufacturing process is impossible. Integration of process simulation and rapid prototyping and manufacturing can reduce the risk associated with moving from CAD to CAM and further enhance the validity of the product development.For years, designers have been restricted in what they can produce as they generally have todesign for manufacture (DFM) – that is, adjust their design intent to enable the component (or assembly) to be manufactured using a particular process or processes. In addition, if a mould is used to produce an item, there are therefore automatically inherent restrictions to the design imposed at the very beginning. Taking injection moulding as an example, in order to process a component successfully, at a minimum, the following design elements need to be taken into account:1. . geometry;. draft angles,. Non re-entrants shapes,. near constant wall thickness,. complexity,. split line location, and. surface finish,2. material choice;3. rationalisation of components (reducing assemblies);4. cost.In injection moulding, the manufacture of the mould to produce the injection-moulded components is usually the longest part of the product development process. When utilising rapid modelling, the CAD takes the longer time and therefore becomes the bottleneck.The process design and injection moulding of plastics involves rather complicated and time consuming activities including part design, mould design, injection moulding machine selection, production scheduling, tooling and cost estimation. Traditionally all these activities are done by part designers and mould making personnel in a sequential manner after completing injection moulded plastic part design. Obviously these sequential stages could lead to long product development time. However with the implementation of concurrent engineering process in the all parameters effecting product design, mould design, machine selection, production scheduling,tooling and processing cost are considered as early as possible in the design of the plastic part. When used effectively, CAE methods provide enormous cost and time savings for the part design and manufacturing. These tools allow engineers to virtually test how the part will be processed and how it performs during its normal operating life. The material supplier, designer, moulder and manufacturer should apply these tools concurrently early in the design stage of the plastic parts in order to exploit the cost benefit of CAE. CAE makes it possible to replace traditional, sequential decision-making procedures with a concurrent design process, in which all parties can interact and share information, Figure 3. For plastic injection moulding, CAE and related design data provide an integrated environment that facilitates concurrent engineering for the design and manufacture of the part and mould, as well as material selection and simulation of optimal process control parameters.Qualitative expense comparison associated with the part design changes is shown in Figure 4 , showing the fact that when design changes are done at an early stages on the computer screen, the cost associated with is an order of 10.000 times lower than that if the part is in production. These modifications in plastic parts could arise fr om mould modifications, such as gate location, thickness changes, production delays, quality costs, machine setup times, or design change in plastic parts.Figure 4 Cost of design changes during part product development cycle (Rios et.al, 2001)At the early design stage, part designers and moulders have to finalise part design based on their experiences with similar parts. However as the parts become more complex, it gets rather difficult to predict processing and part performance without the use of CAE tools. Thus for even relatively complex parts, the use of CAE tools to prevent the late and expensive design changesand problems that can arise during and after injection. For the successful implementation of concurrent engineering, there must be buy-in from everyone involved.5.Case StudyFigure 5 shows the initial CAD design of plastics part used for the sprinkler irrigation hydrant leg. One of the essential features of the part is that the part has to remain flat after injection; any warping during the injection causes operating problems.Another important feature the plastic part has to have is a high bending stiffness. A number of feeders in different orientation were added to the part as shown in Figure 5b. These feeders should be designed in a way that it has to contribute the weight of the part as minimum aspossible.Before the design of the mould, the flow analysis of the plastic part was carried out with Moldflow software to enable the selection of the best gate location Figure 6a. The figure indicates that the best point for the gate location is the middle feeder at the centre of the part. As the distortion and warpage of the part after injection was vital from the functionality point of view and it has to be kept at a minimum level, the same software was also utilised to yiled the warpage analysis. Figure 5 b shows the results implying the fact that the warpage well after injection remains within the predefined dimensional tolerances.6. ConclusionsIn the plastic injection moulding, the CAD model of the plastic part obtained from commercial 3D programs could be used for the part performance and injection process analyses. With the aid ofCEA technology and the use of concurrent engineering methodology, not only the injection mould can be designed and manufactured in a very short of period of time with a minimised cost but also all potential problems which may arise from part design, mould design and processing parameters could be eliminated at the very beginning of the mould design. These two tools help part designers and mould makers to develop a good product with a better delivery and faster tooling with less time and money.References1. Smith P, Reinertsen D, The time-to-market race, In: Developing Products in Half the Time. New York, Van Nostrand Reinhold, pp. 3–13, 19912.Thompson J, The total product development organization. Proceedings of the SecondAsia–Pacific Rapid Product Development Conference, Brisbane, 19963.Neel R, Don’t stop after the prototype, Seventh International Conference on Rapid Prototyping, San Francisco, 19974.Jacobs PF, “Chapter 3: Rapid Product Development” in Rapid Tooling: Technologies and Industrial Applications , Ed. Peter D. Hilton; Paul F. Jacobs, Marcel Decker, 20005.Lee R-S, Chen, Y-M, and Lee, C-Z, “Development of a concurrent mould design system: a knowledge based approach”, Computer Integrated Manufacturing Systems, 10(4), 287-307, 19976.Evans B., “Simultaneous Engineering”, Mechanical Engi neering , V ol.110, No.2, pp.38-39, 19987.Rios A, Gramann, PJ and Davis B, “Computer Aided Engineering in Compression Molding”, Composites Fabricators Association Annual Conference , Tampa Bay, 2001【译文一】塑料注塑模具并行设计塑料制品制造业近年迅速成长。

毕业设计论文翻译中英文对照对注塑机的控制现代塑料注塑机是一个典型的系统集机械,电气和流体,此设备已形成了复杂的产品,少的后处理,加工各种塑料的特性,自成立以来发展迅速,目前全过世界上的产品80%用于加工塑料注塑成型机。

传统的注塑机一般采用简单的开环控制,即按照预先设定值的控制。

在设备制造过程中,预先设定的参数值,如从机器的锁模力,循环时间,温度等,在生产过程中予以保留。

例如,通过控制模具温度可以维持加热流体的温度,塑料温度可控制电源,以保持外加热装置。

这种结构简单的控制方法,然而,穷人的抗干扰能力,控制温度也比较低。

目前,更多的注塑机采用闭环控制,即根据上线的测量值和设定值的偏差控制。

闭环控制系统采用了负反馈回路,抗干扰能力强,当注射速度,注射压力,模腔温度,模腔压力,熔体温度和压力油,由于干扰,在生产过程中通过机器的偏差自适应控制系统的干扰进行自动修正。

这一控制方法抗干扰能力强,控制精度高。

更先进的控制方法是应用计算机控制,就是建立一个闭环实时计算机控制系统。

它包括直接数字控制系统(DDC),监督计算机控制系统(SCC),分布式控制系统(DCS)和多层次的几种类型的控制。

常用的注塑机控制系统有三种,即传统的基于继电器,可编程控制器和基于计算机的控制类型。

近年来,可编程逻辑控制器(简称为PLC)以其高可靠性,高性能的特点在注塑机控制系统已被广泛使用。

为了提高注塑机控制系统和质量水平更高的水平,比PLC控制系统的设计专门为中小型可编程计算机控制器(PCC)的应运而生。

政协集成了一个标准的PLC和工业控制计算机的功能,多任务分时操作系统,数据计算和处理能力比PLC更强大。

政协形成了注塑机控制系统,以实现包括位置控制,速度控制,温度控制,故障控制和实时显示整个过程中,如注塑成型的各种控制,可以大大提高塑料制品的质量有利于提高经济效益。

控制注塑机的内容注塑机过程控制系统主要由两部分组成:一是温度控制系统,为了权利桶,熔体和模具的温度控制;第二项议案注射压力,速度和位移的多级交换过程的控制系统。

机械设计毕业设计外文文献翻译中英文对照:塑料模具CAD集成技术毕业设计外文文献翻译毕业设计题目摇控器面板注塑模设计翻译题目The molding tool CAD gathers the technique专业机械设计制造及其自动化姓名班级机械A0731学号指导教师机械与材料工程学院二O一O年十一月[K.P. Rao and K. Sivaram: J. Mater. Proc. Technol., 1993, vol. 37, pp.295-318.]毕业论文(设计)外文翻译课题名称:塑料模具CAD集成技术内容提要:通过分析计算机辅助注射模设计和制造的各个环节中共享的技术和信息,本文揭示了注射模CAD的集成技术的根本内涵,并提出了它的研究热点和趋势。

引言模具CAD集成技术是一项重要的模具先进制造技术, 是一项用高技术改造模具传统技术的重要关键技术。

从六五计划开始,我国有许多模具企业采用CAD 技术, 特别是近年, CAD技术的应用越来越普遍和深入, 大大缩短了模具设计周期,提高了制模质量和复杂模具的制造能力。

然而, 由于许多企业对模具CAD集成技术认识不足, 投资带有盲目性, 不能很好地发挥作用,造成了很大的浪费。

本文就塑料模具CAD集成技术及其应用发表一些观点, 供大家参考。

1、塑料模具CAD集成技术塑料模具的制造, 包括塑料产品的造型设计、模具的结构设计及分析、模具的数控加工铣削、电加工、线切割等、抛光和配试模以及快速成形制造等。

各个环节所涉及的CAD单元技术有:造型和结构设计CAD、产品外形的快速反求RE、结构分析与优化设计CAE、辅助制造CAM、加工过程虚拟仿真SIMULATION、产品及模具的快速成形RP、辅助工艺过程CAPP和产品数据管理技术PDM等。

塑料模具CAD集成技术,? 就是把塑料模具制造过程所涉及的各项单元技术集成起来, 统一数据库和文件传输格式, 实现信息集成和数据资源共享, 从而大大缩短模具的设计制造周期, 提高制模质量。

毕业设计(论文)外文资料翻译及原文(2012届)题目电话机三维造型与注塑模具设计指导教师院系工学院班级学号姓名二〇一一年十二月六日【译文一】塑料注塑模具并行设计Assist.Prof.Dr. A. Y AYLA /Prof.Dr. Paş a YAYLA摘要塑料制品制造业近年迅速成长。

其中最受欢迎的制作过程是注塑塑料零件。

注塑模具的设计对产品质量和效率的产品加工非常重要。

模具公司想保持竞争优势,就必须缩短模具设计和制造的周期。

模具是工业的一个重要支持行业,在产品开发过程中作为一个重要产品设计师和制造商之间的联系。

产品开发经历了从传统的串行开发设计制造到有组织的并行设计和制造过程中,被认为是在非常早期的阶段的设计。

并行工程的概念(CE)不再是新的,但它仍然是适用于当今的相关环境。

团队合作精神、管理参与、总体设计过程和整合IT工具仍然是并行工程的本质。

CE过程的应用设计的注射过程包括同时考虑塑件设计、模具设计和注塑成型机的选择、生产调度和成本中尽快设计阶段。

介绍了注射模具的基本结构设计。

在该系统的基础上,模具设计公司分析注塑模具设计过程。

该注射模设计系统包括模具设计过程及模具知识管理。

最后的原则概述了塑料注射模并行工程过程并对其原理应用到设计。

关键词:塑料注射模设计、并行工程、计算机辅助工程、成型条件、塑料注塑、流动模拟1、简介注塑模具总是昂贵的,不幸的是没有模具就不可能生产模具制品。

每一个模具制造商都有他/她自己的方法来设计模具,有许多不同的设计与建造模具。

当然最关键的参数之一,要考虑到模具设计阶段是大量的计算、注射的方法,浇注的的方法、研究注射成型机容量和特点。

模具的成本、模具的质量和制件质量是分不开的在针对今天的计算机辅助充型模拟软件包能准确地预测任何部分充填模式环境中。

这允许快速模拟实习,帮助找到模具的最佳位置。

工程师可以在电脑上执行成型试验前完成零件设计。

工程师可以预测过程系统设计和加工窗口,并能获得信息累积所带来的影响,如部分过程变量影响性能、成本、外观等。

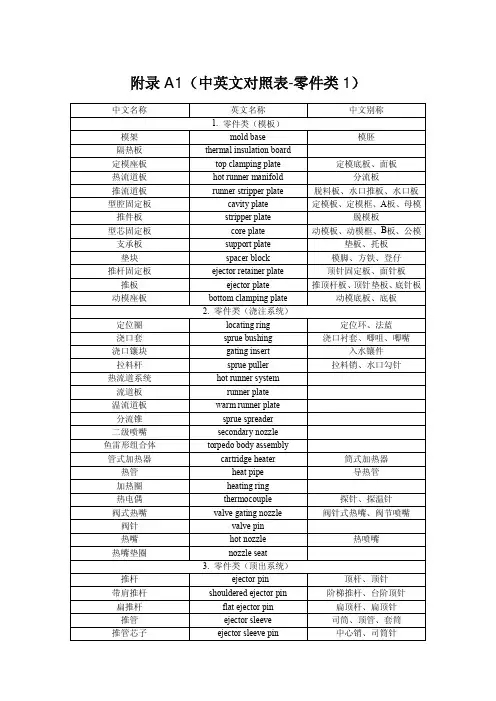

附录A1(中英文对照表-零件类1)中文名称英文名称中文别称1. 零件类(模板)模架mold base 模胚隔热板thermal insulation board定模座板top clamping plate 定模底板、面板热流道板hot runner manifold 分流板推流道板runner stripper plate 脱料板、水口推板、水口板型腔固定板cavity plate 定模板、定模框、A板、母模推件板stripper plate 脱模板型芯固定板core plate 动模板、动模框、B板、公模支承板support plate 垫板、托板垫块spacer block 模脚、方铁、登仔推杆固定板ejector retainer plate 顶针固定板、面针板推板ejector plate 推顶杆板、顶针垫板、底针板动模座板bottom clamping plate 动模底板、底板2. 零件类(浇注系统)定位圈locating ring 定位环、法蓝浇口套sprue bushing 浇口衬套、唧咀、唧嘴浇口镶块gating insert 入水镶件拉料杆sprue puller 拉料销、水口勾针热流道系统hot runner system流道板runner plate温流道板warm runner plate分流锥sprue spreader二级喷嘴secondary nozzle鱼雷形组合体torpedo body assembly管式加热器cartridge heater 筒式加热器热管heat pipe 导热管加热圈heating ring热电偶thermocouple 探针、探温针阀式热嘴valve gating nozzle 阀针式热嘴、阀节喷嘴阀针valve pin热嘴hot nozzle 热喷嘴热嘴垫圈nozzle seat3. 零件类(顶出系统)推杆ejector pin 顶杆、顶针带肩推杆shouldered ejector pin 阶梯推杆、台阶顶针扁推杆flat ejector pin 扁顶杆、扁顶针推管ejector sleeve 司筒、顶管、套筒推管芯子ejector sleeve pin 中心销、司筒针中文名称英文名称中文别称3. 零件类(顶出系统)推块ejector pad 顶块推件环stripper ring 脱模圈斜顶杆angle ejector rod 斜导杆斜顶lifter自润滑活型芯组件slide core guide unit 斜顶滑座导滑座slide base斜导杆固定座angle ejector rod fixed seat自润滑板guide plate挡块baffle block挡块固定螺钉baffle block set screw复位杆return pin 回程销、回针限位块stop block 止动件限位钉stop pin 垃圾钉4. 零件类(成型零部件)型腔cavity 母模仁型芯core 公模仁、模芯侧型芯side core 侧模芯镶件mould insert 镶块型腔镶件cavity insert 上内模、母模入子型芯镶件core insert 下内模、公模入子活动镶件movable insert拼块split螺纹型芯threaded core螺纹型环threaded cavity嵌件insert镶针insert pin5. 零件类(温度调节系统)快速接头jiffy quick connector管接头hose nippler三通接头three way cock四通接头four-way connection弯管接头pipe bend水嘴water nozzle 水接头油嘴oil nozzle 油接头软管hose 喉管水管water tube油管oil tube气管air tube中文名称英文名称中文别称5. 零件类(温度调节系统)管夹hose clip 软管卡子丝堵pipe plug 螺塞、喉塞冷却管cooling pipe隔水片baffle 挡水板O形圈o-ring 密封圈、O形环止水栓stopcock 导流塞流量计flow meter集水器siamese 集水块集油器oil collector 集油块节流阀throttle valve 截流阀流量分配器flow divider 分流器6. 零件类(侧向分型与抽芯机构)滑块slide 行位斜导柱angle pin 斜销、斜导边弯销clog-leg cam锁紧块locking block 楔紧块、铲鸡滑块导板slide glide strip 滑块导轨、压条耐磨板wear plate 硬片、油板球头顶丝ball plunger 波子螺丝、波子弹弓限位块stop block 止动件滑块定位器slide retainer 行位管位7. 零件类(导向、定位系统)导柱guide pin 边钉、导边直身导柱straight leader pins 直导柱带肩导柱shoulder leader pin 台阶导柱推板导柱ejector guide pin 中托边方型导柱guide square 方导柱三板模导柱support pins 细水口导边、水口边三板模导套runner stripper plate bushing 水口板导套、水口套导向条gib block 导向块导套guide bushing 边司直导套straight bushing带肩导套shoulder bushing 有托导套推板导套ejector guide bush 中托司套定位销dowel pin 销钉、管钉定位块locating block直身锁side lock 边锁、侧锁扣、直身定位块斜度锁taper lock 斜度定位块中文名称英文名称中文别称8. 零件类(开关模控制)定距拉杆puller bolt 拉杆螺丝、拉杆定距拉板puller plate 拉板止动螺钉stop bolt 限动螺栓锁模板safety bar 安全杆、锁模扣、安全扣阻尼销parting locks 尼龙拉钩、树脂开闭器、拉模扣分型面锁模装置parting lock set 分型拉钩、扣鸡、扣机顶出预复位机构early ejector return 早回机构、先复位机构9. 零件类(其他功能件)螺钉screw 螺丝螺帽screw cap 螺丝帽内六角螺钉shcs 杯头螺丝内六角沉头螺钉fhcs 平头螺丝无头螺丝grub screw弹簧spring 弹弓圆线弹簧wire spring扁弹簧flat spring氮气弹簧gas spring齿轮gear wheel轴承bearing马达motor止动键locking key卡簧clamp spring油缸hydraulic cylinder 液压缸气缸air cylinder排气阀air evacuation valve支撑柱support pillar 支承柱、撑头承压块pressure block吊模块lifting bars for mold 模具起吊块吊环lifting eye bolts 吊环螺钉挤紧块clamping block 锁定块垫圈washer 垫片弹簧垫圈spring washer 弹垫标牌nameplate 铭牌保护盖protective cover 防护罩顶模块ejector rod 顶出杆、顶棍行程开关position limit switch 限位开关计数器counters中文名称英文名称中文别称9. 零件类(其他功能件)压力传感器pressure transducer日期章date markers 日期标记电源插座power socket公插male connector母插female connector电线electric wire接线盒connection box 接线箱保护盒protection box保护柱stand off调整板adjustment plate压板stopper plate中文名称英文名称中文别称10. 相关术语类(设计系统)模具工程mold engineering工程力学engineering mechanics工程热力学engineering thermodynamics流变学rheology塑料成形模具mould for plastics 塑料模、塑胶模注射模injection mould 注塑模注射模设计design of injection mould热塑性塑料注射模injection mould forthermoplastics热固性塑料注射模injection mould for thermoses双色模double-color mould叠层模stack injection mould热流道模hot runner mould绝热流道模insulated runner mould 温流道模二板模two plate mold 大水口模三板模three plates mold 细水口模浇注系统feed system冷流道系统cold runner system主流道sprue 注入口、注道分流道runner浇口gate 入水浇口形式gate type 入水形式浇口大小gate size 入水大小浇口位置gate location 入水位置直接浇口direct gate 大水口环形浇口ring gate 环型浇口盘形浇口dish gate轮辐浇口spoke gate点浇口pin-point gate 细水口、针点式浇口侧浇口edge gate 边缘浇口潜伏浇口submarine gate 潜水口隧道式浇口tunnel gate 月牙形浇口、牛角形浇口、香蕉形浇口冷料穴cold-slug well 冷料井溢料槽flash groove 跑胶道、流胶沟排气槽air vent 排气道、排气孔、疏气位分型面parting surface 分模面分型线parting line 分模线中文名称英文名称中文别称10. 相关术语类(设计系统)水平分型面(线)horizontal parting line垂直分型面(线)vertical parting line定模fixed half 固定侧动模moving half 可动侧排气系统vent system顶出系统ejection system 脱模系统顶出机构ejection mechanisms 脱模机构成型零部件molding parts冷却系统cooling system冷却通道cooling channel加热系统heating system 供热系统收缩率shrinkage 缩水抽芯力core-pulling force抽芯距core-pulling distance投影面积projected area脱模斜度draft 拔模斜度模具寿命die life模腔数cavity number11. 相关术语类(注塑成型)注射机injection molding machine 注塑机、射出成型机、啤机注射能力shot capacity 注塑容量、注塑能力注射压力injection pressure 注塑压力、射胶压力锁模力clamping force 合模力成型压力moulding pressure 成形压力模内压力internal mould pressure 型腔压力开模力mould opening force脱模力ejection force 顶出力闭合高度mould-shut height最大开距maximum daylight 模板开距脱模距stripper distance最大容模厚度max mold height 最大模厚最小容模厚度min. mould thickness 最小模厚拉杆内距space between tie bars 拉杆间距、导柱内距注射装置injection unit 射胶系统预塑化装置preplasticator合模装置clamping unit 锁模系统控制装置control unit 控制系统机械手mechanical arm 机械臂中文名称英文名称中文别称11. 相关术语类(注塑成型)快速换模系统quick die change system 快速换模装置顺序阀sequence valve喷嘴直径nozzle diameter喷嘴球半径nozzle radius成型周期molding cycle 模塑周期注射时间injection time 射出时间保压时间packing time冷却时间cooling time顶出时间ejection time 脱模时间开、合模时间time of mold open & close塑料Plastics 塑胶塑件plastic parts 塑胶件项目名称project name产品名称product name 品名外观件appearance part总产量total product电镀plating 喷镀油漆paint蚀纹texture 咬花光面shiny side热板焊hot plate welding超声波焊ultrasonic welding 超声焊摩擦焊friction welding振动焊vibration welding壁厚wall thickness加强筋rib圆角fillet尖角sharp corner 锐角、利角凸台convex plate文字text孔位hole location工艺分析process analysis 过程分析流动分析flow analysis 充填分析顶白ejected mark 顶痕毛刺burr 毛边缩痕sink mark 凹痕水波痕water wave effect表面光泽度不良gloss ng中文名称英文名称中文别称11. 相关术语类(注塑成型)银丝纹silver streak 银条纹、银丝气泡bubble黑条纹dark streak烧焦burn 烧伤、烧黑黑点black spots 黑色斑翘曲warpage熔接线weld lines 熔合线熔接痕welding mark 溶合痕尺寸不稳定dimensional instability裂痕flaw 裂缝变色discoloration 褪色困气air trapping缺胶short shot 充填不足、欠注、短射试模mold trial注射速度injection rate 注射速率干燥温度drying temperature 烘干温度干燥时间drying time 烘干时间成型温度injection temperature 注塑温度、喷射温度模具温度mould temperature12. 相关术语类(材料)模板mould plate标准件standard parts电极electrode铜电极copper electrode 铜公石墨电极graphite electrode钨电极tungsten electrode钢steel 钢铁、钢材热作钢hot work tool steel 热锻模具钢冷作钢cold work steel预硬钢prehardened steel碳素钢carbon steel 碳钢碳素工具钢carbon tool steel不锈钢stainless steel铬钼钢chrome molybdenum steel合金工具钢alloy tool steel高速工具钢high speed tool steel硬质合金钢hard alloy steel弹簧钢spring steel中文名称英文名称中文别称12. 相关术语类(材料)灰口铸铁grey cast iron 灰铸铁、灰口铁紫铜copper黄铜brass青铜bronze铍铜BeCu铍青铜beryllium bronze铝aluminum13. 相关术语类(技术参数)结晶性crystallinity 结晶度透明性transparency 透明度耐热性heat resistance 抗热性熔融指数melt index 熔体流动指数剪切速率shear rate 剪切率剪切应力shear stress摩擦系数frictional coefficient布氏硬度brinell hardness HB洛氏硬度rockwell hardness HRC肖氏硬度shore hardness Hs维氏硬度vickers hardness HV金属疲劳metal fatigue疲劳寿命fatigue life密度density重量weight重心centre of gravity面积area体积volume承压面积bearing area 支承面积雷诺数reynolds number导热性thermal conductivity 导热率、导热系数比热容specific heat 比热热量heat quantity温差temperature difference弹性模量modulus of elasticity 弹性模数、杨氏模量截面惯性矩second moment of area 截面二次轴矩截面模量section modulus 截面系数泊松比poisson ratio 横向变形系数拉伸强度tensile strength 抗拉强度压缩强度compressive strength 抗压强度中文名称英文名称中文别称13. 相关术语类(技术参数)屈服强度yield strength剪切强度shear strength 抗剪强度冲击强度impact strength 抗冲强度扭曲强度torsional strength 抗扭强度、扭转强度弯曲强度bending strength 抗弯强度、抗挠强度屈服应力yield stress延展率elongation 延伸率载荷load弹性变形elastic deformation 弹性形变热膨胀系数thermal expansion coefficient14. 相关术语类(表面处理)热处理heat treatment调质thermal refining TR渗碳carburizing退火annealing回火tempering氮化nitriding NT、渗氮真空氮化vacuum nitriding 真空渗氮真空渗碳氮化vacuum carbonitriding 真空碳氮化离子氮化plasma nitriding离子渗碳氮化ion carbonitriding淬火quenching hardening QH高频淬火high frequency hardening真空淬火vacuum hardening化学电镀chemical plating 化学镀阳极氧化处理anodizing 阳极氧化发黑blackening 染黑法喷砂处理sand blast时效处理seasoning15. 相关术语类(加工)加工中心机床machine centers 加工中心CNC铣床cnc milling machine 数控铣床高速铣床high speed milling machine仿形铣床profiling milling machine 靠模铣床仿形车床copy lathe 靠模车床锯床saw machine刨床planing machines磨床grinding machines中文名称英文名称中文别称15. 相关术语类(加工)车床lathe摇臂钻床radial drilling machine 旋臂钻床钻床drilling machine 钻孔机雕刻机engraving machines电火花机electric discharge machines 火花机线切割放电机wire E.D.M. 线割放电加工机测量机measuring machines三座标测量仪three-coordinates measuringmachine合模机die spotting machine机加工machining 切削加工锻造forging铸造casting精密压铸accurate die casting电铸electroforming热轧hot rolling HR冷轧cold rolling 冷压延拉拔draw out挤压extrusion 挤制加工锯削sawing雕削carving-and-scraping铣削milling镗削boring锉削加工filing车削turning钻孔drilling铰孔reaming 铰孔修润拉削broaching刮削scraping磨削grinding研磨加工lapping切削cutting砂纸加工coated abrasive machining抛光加工polishing 抛亮光电火花加工electrical discharge machining 放电加工、EDM 线切割加工spark-erosion wire cutting WEDM电解研磨electrochemical lapping化学研磨chemical polishing中文名称英文名称中文别称15. 相关术语类(制图)技术制图technical drawing 工程制图技术参数technical parameter表面粗糙度surface finish 表面光洁度公差与配合common difference &cooperation形位公差geometric tolerance 几何公差尺寸公差dimension tolerance公差范围tolerance limits 容差极限基孔制basic hole system基轴制basic shaft system三角函数trigonometric function装配图assembly drawing 组装图、总装图、组合图模具排位图die layout 结构草图零件图part drawing 散件图工艺图process drawing 工艺过程图件号no.名称designation实际尺寸actual size标准尺寸stock size材质material 材料、物料数量quantity订货号order no. 订单号备注remarks 附注供应商supplier 供货商模号mold no设计design审核checked by 核对批准approve 审批比例scale单位unit张次sheet版本revision 版次图纸大小drawing sheet size模具公差mold tolerance日期date客户customer技术要求technical requirement 技术条件、技术规定使用说明书operation specifications 操作规范中文名称英文名称中文别称16. 相关术语类(流程、商务)流程优化process optimization 过程优化时间计划表time schedule 工作进度表、时间安排表设计优化design optimization产品分析报告product analysis report流动分析报告flow analysis report结构分析报告structural analysis report模具性能与寿命分析analysis of performance andlife of mold行政部administrative department 行政司营销部marketing department 市场部、市场销售部项目部project department工程部engineering department技术部technical department 技术研发部制造部manufacture department 生产部质检部quality inspection department 品保部采购部purchasing department财务科finance section客服部customer service department 客户服务部董事长board chairman 董事局主席总经理general manager技术总监technical director工程部经理engineering manager制造部经理manufacturing manager 生产部经理模具项目经理mold project manager模具设计师mould designer模具分析师mould analyst项目工程师project engineer钳工fitter模具成本mold cost 模具费用利润profit报价单quotation设计成本design cost 设计费制造成本manufacturing cost 生产成本材料成本material cost 物料成本调试成本debugging cost 调试费用管理成本administration cost 管理费税收revenue交期delivery time 发货期、交货期。

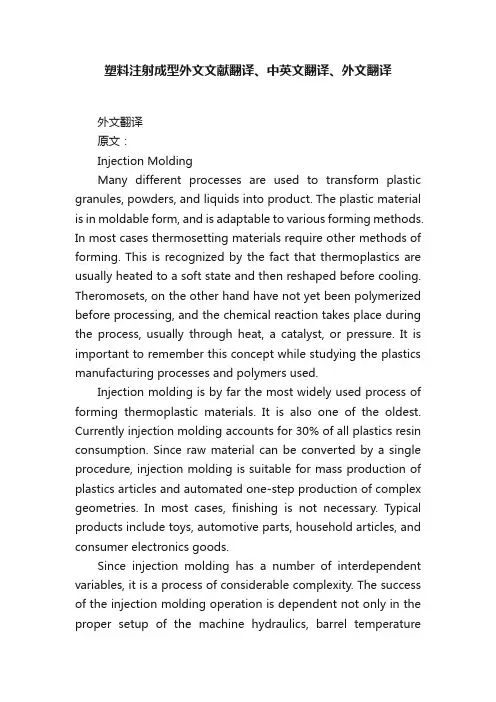

塑料注射成型外文文献翻译、中英文翻译、外文翻译外文翻译原文:Injection MoldingMany different processes are used to transform plastic granules, powders, and liquids into product. The plastic material is in moldable form, and is adaptable to various forming methods. In most cases thermosetting materials require other methods of forming. This is recognized by the fact that thermoplastics are usually heated to a soft state and then reshaped before cooling. Theromosets, on the other hand have not yet been polymerized before processing, and the chemical reaction takes place during the process, usually through heat, a catalyst, or pressure. It is important to remember this concept while studying the plastics manufacturing processes and polymers used.Injection molding is by far the most widely used process of forming thermoplastic materials. It is also one of the oldest. Currently injection molding accounts for 30% of all plastics resin consumption. Since raw material can be converted by a single procedure, injection molding is suitable for mass production of plastics articles and automated one-step production of complex geometries. In most cases, finishing is not necessary. Typical products include toys, automotive parts, household articles, and consumer electronics goods.Since injection molding has a number of interdependent variables, it is a process of considerable complexity. The success of the injection molding operation is dependent not only in the proper setup of the machine hydraulics, barrel temperaturevariations, and changes in material viscosity. Increasing shot-to-shot repeatability of machine variables helps produce parts with tighter tolerance, lowers the level of rejects, and increases product quality (i.e., appearance and serviceability).The principal objective of any molding operation is the manufacture of products: to a specific quality level, in the shortest time, and using repeatable and fully automaticcycle. Molders strive to reduce or eliminate rejected parts in molding production. For injection molding of high precision optical parts, or parts with a high added value such as appliance cases, the payoff of reduced rejects is high.A typical injection molding cycle or sequence consists of five phases;1. Injection or mold filling2. Packing or compression3. Holding4. Cooling5. Part ejectionPlastic granules are fed into the hopper and through an in the injection cylinder where they are carried forward by the rotating screw. The rotation of the screw forces the granules under high pressure against the heated walls of the cylinder causing them to melt. As the pressure building up, the rotating screw is forced backward until enough plastic has accumulated to make the shot. The injection ram (or screw) forces molten plastic from the barrel, through the nozzle, sprue and runner system, and finally into the mold cavities. During injection, the mold cavity is filled volumetrically. When the plastic contacts the cold mold surfaces, it solidifies (freezes) rapidly to produce theskin layer. Since the core remains in the molten state, plastic follows through the core to complete mold filling. Typically, the cavity is filled to 95%~98% during injection. Then the molding process is switched over to the packing phase.Even as the cavity is filled, the molten plastic begins to cool. Since the cooling plastic contracts or shrinks, it gives rise to defects such as sink marks, voids, and dimensional instabilities. To compensate for shrinkage, addition plastic is forced into the cavity. Once the cavity is packed, pressure applied to the melt prevents molten plastic inside the cavity from back flowing out through the gate. The pressure must be applied until the gate solidifies. The process can be divided into two steps (packing and holding) or may be encompassed in one step(holding or second stage). During packing, melt forced into the cavity by the packing pressure compensates for shrinkage. With holding, the pressure merely prevents back flow of the polymer malt.After the holding stage is completed, the cooling phase starts. During, the part is held in the mold for specified period. The duration of the cooling phase depends primarily on the material properties and the part thickness. Typically, the part temperature must cool below the material’s ejection temperature. While cooling the part, the machine plasticates melt for the next cycle.The polymer is subjected to shearing action as well as the condition of the energy from the heater bands. Once the short is made, plastication ceases. This should occur immediately before the end of the cooling phase. Then the mold opens and the part is ejected.When polymers are fabricated into useful articles they are referred to as plastics, rubbers, and fibers. Some polymers, forexample, cotton and wool, occur naturally, but the great majority of commercial products are synthetic in origin. A list of the names of the better known materials would include Bakelite, Dacron, Nylon, Celanese, Orlon, and Styron.Previous to 1930 the use of synthetic polymers was not widespread. However, they should not be classified as new materials for many of them were known in the latter half of the nineteenth century. The failure to develop them during this period was due, in part, to a lack of understanding of their properties, in particular, the problem of the structure of polymers was the subject of much fruitless controversy.Two events of the twentieth century catapulted polymers into a position of worldwide importance. The first of these was the successful commercial production of the plastic now known as Bakelite. Its industrial usefulness was demonstrated in1912 and in the next succeeding years. T oday Bakelite is high on the list of important synthetic products. Before 1912 materials made from cellulose were available, but their manufacture never provided the incentive for new work in the polymer field such as occurred after the advent of Bakelite. The second event was concerned with fundamental studies of the nature polymers by Staudinger in Europe and by Carohers, who worked with the Du Pont company in Delaware. A greater part of the studies were made during the 1920’s. Staudinger’s work was primarily fundamental. Carother’s achievements led t o the development of our present huge plastics industry by causing an awakening of interest in polymer chemistry, an interest which is still strongly apparent today.The Nature of ThermodynamicsThermodynamics is one of the most important areas ofengineering science used to explain how most things work, why some things do not the way that they were intended, and why others things just cannot possibly work at all. It is a key part of the science engineers use to design automotive engines, heat pumps, rocket motors, power stations, gas turbines, air conditioners, super-conducting transmission lines, solar heating systems, etc.Thermodynamics centers about the notions of energy, the idea that energy is conserved is the first low of thermodynamics. It is starting point for the science of thermodynamics is entropy; entropy provides a means for determining if a process is possible.This idea is the basis for the second low of thermodynamics. It also provides the basis for an engineering analysis in which one calculates the maximum amount of useful that can be obtained from a given energy source, or the minimum amount of power input required to do a certain task.A clear understanding of the ideas of entropy is essential for one who needs to use thermodynamics in engineering analysis. Scientists are interested in using thermodynamics to predict and relate the properties of matter; engineers are interested in using this data, together with the basic ideas of energy conservation and entropy production, to analyze the behavior of complex technological systems.There is an example of the sort of system of interest to engineers, a large central power stations. In this particular plant the energy source is petroleum in one of several forms, or sometimes natural gas, and the plant is to convert as much of this energy as possible to electric energy and to send this energy down the transmission line.Simply expressed, the plant does this by boiling water andusing the steam to turn a turbine which turns an electric generator.The simplest such power plants are able to convert only about 25 percent of the fuel energy to electric energy. But this particular plant converts approximately 40 percent;it has been ingeniously designed through careful application of the basic principles of thermodynamics to the hundreds of components in the system.The design engineers who made these calculations used data on the properties of steam developed by physical chemists who in turn used experimental measurements in concert with thermodynamics theory to develop the property data.Plants presently being studied could convert as much as 55 percent of the fuel energy to electric energy, if they indeed perform as predicted by thermodynamics analysis.The rule that the spontaneous flow of heat is always from hotter to cooler objects is a new physical idea. There is noting in the energy conservation principle or in any other law of nature that specifies for us the direction of heat flow. If energy were to flow spontaneously from a block of ice to a surrounding volume of water, this could occur in complete accord with energy conservation. But such a process never happens. This idea is the substance of the second law of thermodynamics.Clear, a refrigerator, which is a physical system used in kitchen refrigerators, freezers, and air-conditioning units must obey not only the first law (energy conservation) but the second law as well.To see why the second law is not violated by a refrigerator, we must be careful in our statement of law. The second law of thermodynamics says, in effect, that heat never flowsspontaneously from a cooler to a hotter object.Or, alternatively, heat can flow from a cooler to a hotter object only as a result of work done by an external agency. We now see the distinction between an everyday spontaneous process, such as the flow of heat from the inside to the outside of a refrigerator.In the water-ice system, the exchange of energy takes place spontaneously and the flow of heat always proceeds from the water to the ice. The water gives up energy and becomes cooler while the ice receives energy and melts.In a refrigerator, on the other hand, the exchange of energy is not spontaneous. Work provided by an external agency is necessary to reverse the natural flow of heat and cool the interior at the expense of further heating the warmer surroundings.译文:塑料注射成型许多不同的加工过程习惯于把塑料颗粒、粉末和液体转化成最终产品。

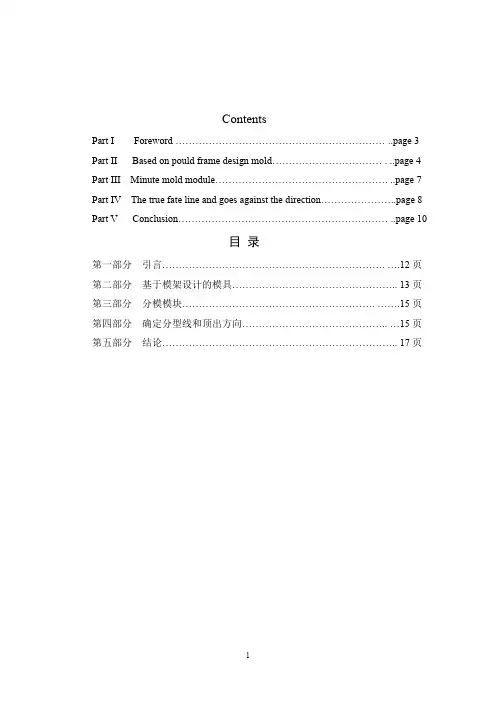

ContentsPart I Foreword ……………………………………………………… ..page 3 Part II Based on pould frame design mold…………………………… . ..page 4 Part III Minute mold module……………………………………………. ..page 7 Part IV The true fate line and goes against the direction…………………..page 8 Part V Conclusion……………………………………………………… ..page 10目录第一部分引言…………………………………………………………. ….12页第二部分基于模架设计的模具………………………………………….. 13页第三部分分模模块…………………………………………………. …….15页第四部分确定分型线和顶出方向…………………………………….. …15页第五部分结论…………………………………………………………….. 17页Plastic injection mold design system1.AbstractThe primary object of the first editeon of this book was to provide a information book on students studying in university, In addition to fulfilling this function, this book has been used increasingly by the novice as an introductory guide, because it progresses in simple stages from the consoderation of basic principles and components to mote detailed ewplanation of themore complex types of special purpose mould。

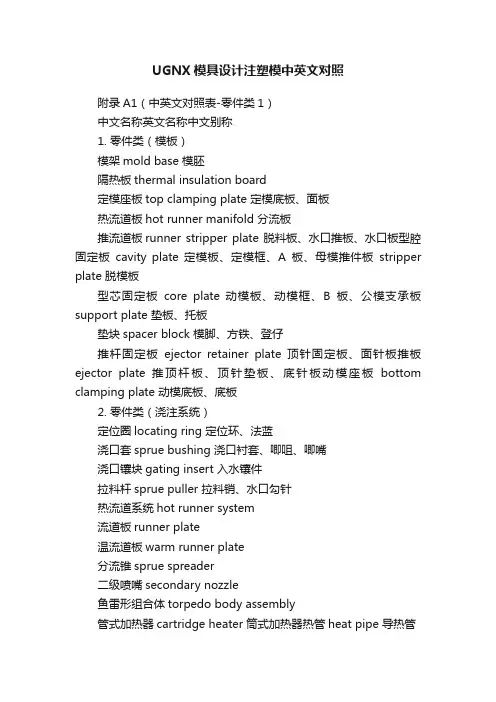

UGNX模具设计注塑模中英文对照附录A1(中英文对照表-零件类1)中文名称英文名称中文别称1. 零件类(模板)模架mold base 模胚隔热板thermal insulation board定模座板top clamping plate 定模底板、面板热流道板hot runner manifold 分流板推流道板runner stripper plate 脱料板、水口推板、水口板型腔固定板cavity plate 定模板、定模框、A板、母模推件板stripper plate 脱模板型芯固定板core plate 动模板、动模框、B板、公模支承板support plate 垫板、托板垫块spacer block 模脚、方铁、登仔推杆固定板ejector retainer plate 顶针固定板、面针板推板ejector plate 推顶杆板、顶针垫板、底针板动模座板bottom clamping plate 动模底板、底板2. 零件类(浇注系统)定位圈locating ring 定位环、法蓝浇口套sprue bushing 浇口衬套、唧咀、唧嘴浇口镶块gating insert 入水镶件拉料杆sprue puller 拉料销、水口勾针热流道系统hot runner system流道板runner plate温流道板warm runner plate分流锥sprue spreader二级喷嘴secondary nozzle鱼雷形组合体torpedo body assembly管式加热器cartridge heater 筒式加热器热管heat pipe 导热管加热圈heating ring热电偶thermocouple 探针、探温针阀式热嘴valve gating nozzle 阀针式热嘴、阀节喷嘴阀针valve pin热嘴hot nozzle 热喷嘴热嘴垫圈nozzle seat3. 零件类(顶出系统)推杆ejector pin 顶杆、顶针带肩推杆shouldered ejector pin 阶梯推杆、台阶顶针扁推杆flat ejector pin 扁顶杆、扁顶针推管ejector sleeve 司筒、顶管、套筒推管芯子ejector sleeve pin 中心销、司筒针中文名称英文名称中文别称3. 零件类(顶出系统)推块ejector pad 顶块推件环stripper ring 脱模圈斜顶杆angle ejector rod 斜导杆斜顶lifter自润滑活型芯组件slide core guide unit 斜顶滑座导滑座slide base斜导杆固定座angle ejector rod fixed seat自润滑板guide plate挡块baffle block挡块固定螺钉baffle block set screw复位杆return pin 回程销、回针限位块stop block 止动件限位钉stop pin 垃圾钉4. 零件类(成型零部件)型腔cavity 母模仁型芯core 公模仁、模芯侧型芯side core 侧模芯镶件mould insert 镶块型腔镶件cavity insert 上内模、母模入子型芯镶件core insert 下内模、公模入子活动镶件movable insert 拼块split螺纹型芯threaded core螺纹型环threaded cavity嵌件insert镶针insert pin5. 零件类(温度调节系统)快速接头jiffy quick connector管接头hose nippler三通接头three way cock四通接头four-way connection弯管接头pipe bend水嘴water nozzle 水接头油嘴oil nozzle 油接头软管hose 喉管水管water tube油管oil tube气管air tube中文名称英文名称中文别称5. 零件类(温度调节系统)管夹hose clip 软管卡子丝堵pipe plug 螺塞、喉塞冷却管cooling pipe隔水片baffle 挡水板O形圈o-ring 密封圈、O形环止水栓stopcock 导流塞流量计flow meter集水器siamese 集水块集油器oil collector 集油块节流阀throttle valve 截流阀流量分配器flow divider 分流器6. 零件类(侧向分型与抽芯机构)滑块slide 行位斜导柱angle pin 斜销、斜导边弯销clog-leg cam锁紧块locking block 楔紧块、铲鸡滑块导板slide glide strip 滑块导轨、压条耐磨板wear plate 硬片、油板球头顶丝ball plunger 波子螺丝、波子弹弓限位块stop block 止动件滑块定位器slide retainer 行位管位7. 零件类(导向、定位系统)导柱guide pin 边钉、导边直身导柱straight leader pins 直导柱带肩导柱shoulder leader pin 台阶导柱推板导柱ejector guide pin 中托边方型导柱guide square 方导柱三板模导柱support pins 细水口导边、水口边三板模导套runner stripper plate bushing 水口板导套、水口套导向条gib block 导向块导套guide bushing 边司直导套straight bushing带肩导套shoulder bushing 有托导套推板导套ejector guide bush 中托司套定位销dowel pin 销钉、管钉定位块locating block直身锁side lock 边锁、侧锁扣、直身定位块斜度锁taper lock 斜度定位块中文名称英文名称中文别称8. 零件类(开关模控制)定距拉杆puller bolt 拉杆螺丝、拉杆定距拉板puller plate 拉板止动螺钉stop bolt 限动螺栓锁模板safety bar 安全杆、锁模扣、安全扣阻尼销parting locks 尼龙拉钩、树脂开闭器、拉模扣分型面锁模装置parting lock set 分型拉钩、扣鸡、扣机顶出预复位机构early ejector return 早回机构、先复位机构9. 零件类(其他功能件)螺钉screw 螺丝螺帽screw cap 螺丝帽内六角螺钉shcs 杯头螺丝内六角沉头螺钉fhcs 平头螺丝无头螺丝grub screw弹簧spring 弹弓圆线弹簧wire spring扁弹簧flat spring氮气弹簧gas spring齿轮gear wheel轴承bearing马达motor止动键locking key卡簧clamp spring油缸hydraulic cylinder 液压缸气缸air cylinder排气阀air evacuation valve支撑柱support pillar 支承柱、撑头承压块pressure block吊模块lifting bars for mold 模具起吊块吊环lifting eye bolts 吊环螺钉挤紧块clamping block 锁定块垫圈washer 垫片弹簧垫圈spring washer 弹垫标牌nameplate铭牌保护盖protective cover 防护罩顶模块ejector rod 顶出杆、顶棍行程开关position limit switch 限位开关计数器counters中文名称英文名称中文别称9. 零件类(其他功能件)压力传感器pressure transducer日期章date markers 日期标记电源插座power socket公插male connector母插female connector电线electric wire接线盒connection box 接线箱保护盒protection box保护柱stand off调整板adjustment plate压板stopper plate中文名称英文名称中文别称10. 相关术语类(设计系统)模具工程mold engineering工程力学engineering mechanics工程热力学engineering thermodynamics流变学rheology塑料成形模具mould for plastics 塑料模、塑胶模注射模injection mould 注塑模注射模设计design of injection mould 热塑性塑料注射模injection mould forthermoplastics热固性塑料注射模injection mould for thermoses双色模double-color mould叠层模stack injection mould热流道模hot runner mould绝热流道模insulated runner mould 温流道模二板模two plate mold 大水口模三板模three plates mold 细水口模浇注系统feed system冷流道系统cold runner system主流道sprue 注入口、注道分流道runner浇口gate 入水浇口形式gate type 入水形式浇口大小gate size 入水大小浇口位置gate location 入水位置直接浇口direct gate 大水口环形浇口ring gate 环型浇口盘形浇口dish gate轮辐浇口spoke gate点浇口pin-point gate 细水口、针点式浇口侧浇口edge gate 边缘浇口潜伏浇口submarine gate 潜水口隧道式浇口tunnel gate 月牙形浇口、牛角形浇口、香蕉形浇口冷料穴cold-slug well 冷料井溢料槽flash groove 跑胶道、流胶沟排气槽air vent 排气道、排气孔、疏气位分型面parting surface 分模面分型线parting line 分模线中文名称英文名称中文别称10. 相关术语类(设计系统)水平分型面(线)horizontal parting line垂直分型面(线)vertical parting line定模fixed half 固定侧动模moving half 可动侧排气系统vent system顶出系统ejection system 脱模系统顶出机构ejection mechanisms 脱模机构成型零部件molding parts冷却系统cooling system冷却通道cooling channel加热系统heating system 供热系统收缩率shrinkage 缩水抽芯力core-pulling force抽芯距core-pulling distance投影面积projected area脱模斜度draft 拔模斜度模具寿命die life模腔数cavity number11. 相关术语类(注塑成型)注射机injection molding machine 注塑机、射出成型机、啤机注射能力shot capacity 注塑容量、注塑能力注射压力injection pressure 注塑压力、射胶压力锁模力clamping force 合模力成型压力moulding pressure 成形压力模内压力internal mould pressure 型腔压力开模力mould opening force脱模力ejection force 顶出力闭合高度mould-shut height最大开距maximum daylight 模板开距脱模距stripper distance最大容模厚度max mold height 最大模厚最小容模厚度min. mould thickness 最小模厚拉杆内距space between tie bars 拉杆间距、导柱内距注射装置injection unit 射胶系统预塑化装置preplasticator合模装置clamping unit 锁模系统控制装置control unit 控制系统机械手mechanical arm 机械臂中文名称英文名称中文别称11. 相关术语类(注塑成型)快速换模系统quick die change system 快速换模装置顺序阀sequence valve喷嘴直径nozzle diameter喷嘴球半径nozzle radius成型周期molding cycle 模塑周期注射时间injection time 射出时间保压时间packing time冷却时间cooling time顶出时间ejection time 脱模时间开、合模时间time of mold open & close塑料Plastics 塑胶塑件plastic parts 塑胶件项目名称project name产品名称product name 品名外观件appearance part总产量total product电镀plating 喷镀油漆paint蚀纹texture 咬花光面shiny side热板焊hot plate welding超声波焊ultrasonic welding 超声焊摩擦焊friction welding振动焊vibration welding壁厚wall thickness加强筋rib圆角fillet尖角sharp corner 锐角、利角凸台convex plate文字text孔位hole location工艺分析process analysis 过程分析流动分析flow analysis 充填分析顶白ejected mark 顶痕毛刺burr 毛边缩痕sink mark 凹痕水波痕water wave effect表面光泽度不良gloss ng中文名称英文名称中文别称11. 相关术语类(注塑成型)银丝纹silver streak 银条纹、银丝气泡bubble黑条纹dark streak烧焦burn 烧伤、烧黑黑点black spots 黑色斑翘曲warpage熔接线weld lines 熔合线熔接痕welding mark 溶合痕尺寸不稳定dimensional instability裂痕flaw 裂缝变色discoloration 褪色困气air trapping缺胶short shot 充填不足、欠注、短射试模mold trial注射速度injection rate 注射速率干燥温度drying temperature 烘干温度干燥时间drying time 烘干时间成型温度injection temperature 注塑温度、喷射温度模具温度mould temperature12. 相关术语类(材料)模板mould plate标准件standard parts电极electrode铜电极copper electrode 铜公石墨电极graphite electrode钨电极tungsten electrode钢steel 钢铁、钢材热作钢hot work tool steel 热锻模具钢冷作钢cold work steel预硬钢prehardened steel碳素钢carbon steel 碳钢碳素工具钢carbon tool steel不锈钢stainless steel铬钼钢chrome molybdenum steel合金工具钢alloy tool steel高速工具钢high speed tool steel硬质合金钢hard alloy steel弹簧钢spring steel中文名称英文名称中文别称12. 相关术语类(材料)灰口铸铁grey cast iron 灰铸铁、灰口铁紫铜copper黄铜brass青铜bronze铍铜BeCu铍青铜beryllium bronze铝aluminum13. 相关术语类(技术参数)结晶性crystallinity 结晶度透明性transparency 透明度耐热性heat resistance 抗热性熔融指数melt index 熔体流动指数剪切速率shear rate 剪切率剪切应力shear stress摩擦系数frictional coefficient布氏硬度brinell hardness HB洛氏硬度rockwell hardness HRC肖氏硬度shore hardness Hs维氏硬度vickers hardness HV金属疲劳metal fatigue疲劳寿命fatigue life密度density重量weight重心centre of gravity面积area体积volume承压面积bearing area 支承面积雷诺数reynolds number导热性thermal conductivity 导热率、导热系数比热容specific heat 比热热量heat quantity温差temperature difference弹性模量modulus of elasticity 弹性模数、杨氏模量截面惯性矩second moment of area 截面二次轴矩截面模量section modulus 截面系数泊松比poisson ratio 横向变形系数拉伸强度tensile strength 抗拉强度压缩强度compressive strength 抗压强度中文名称英文名称中文别称13. 相关术语类(技术参数)屈服强度yield strength剪切强度shear strength 抗剪强度冲击强度impact strength 抗冲强度扭曲强度torsional strength 抗扭强度、扭转强度弯曲强度bending strength 抗弯强度、抗挠强度屈服应力yield stress 延展率elongation 延伸率载荷load弹性变形elastic deformation 弹性形变热膨胀系数thermal expansion coefficient14. 相关术语类(表面处理)热处理heat treatment调质thermal refining TR渗碳carburizing退火annealing回火tempering氮化nitriding NT、渗氮真空氮化vacuum nitriding 真空渗氮真空渗碳氮化vacuum carbonitriding 真空碳氮化离子氮化plasma nitriding离子渗碳氮化ion carbonitriding淬火quenching hardening QH高频淬火high frequency hardening真空淬火vacuum hardening化学电镀chemical plating 化学镀阳极氧化处理anodizing 阳极氧化发黑blackening 染黑法喷砂处理sand blast时效处理seasoning15. 相关术语类(加工)加工中心机床machine centers 加工中心CNC铣床cnc milling machine 数控铣床高速铣床high speed milling machine仿形铣床profiling milling machine 靠模铣床仿形车床copy lathe 靠模车床锯床saw machine刨床planing machines磨床grinding machines中文名称英文名称中文别称15. 相关术语类(加工)车床lathe摇臂钻床radial drilling machine 旋臂钻床钻床drilling machine 钻孔机雕刻机engraving machines电火花机electric discharge machines 火花机线切割放电机wire E.D.M. 线割放电加工机测量机measuring machines三座标测量仪three-coordinates measuringmachine合模机die spotting machine机加工machining 切削加工锻造forging铸造casting精密压铸accurate die casting电铸electroforming热轧hot rolling HR冷轧cold rolling 冷压延拉拔draw out挤压extrusion 挤制加工锯削sawing雕削carving-and-scraping铣削milling镗削boring锉削加工filing车削turning钻孔drilling铰孔reaming 铰孔修润拉削broaching刮削scraping磨削grinding研磨加工lapping切削cutting砂纸加工coated abrasive machining抛光加工polishing 抛亮光电火花加工electrical discharge machining 放电加工、EDM 线切割加工spark-erosion wire cutting WEDM电解研磨electrochemical lapping化学研磨chemical polishing中文名称英文名称中文别称15. 相关术语类(制图)技术制图technical drawing 工程制图技术参数technical parameter表面粗糙度surface finish 表面光洁度公差与配合common difference &cooperation形位公差geometric tolerance 几何公差尺寸公差dimension tolerance公差范围tolerance limits 容差极限基孔制basic hole system基轴制basic shaft system三角函数trigonometric function装配图assembly drawing 组装图、总装图、组合图模具排位图die layout 结构草图零件图part drawing 散件图工艺图process drawing 工艺过程图件号no.名称designation实际尺寸actual size标准尺寸stock size材质material 材料、物料数量quantity订货号order no. 订单号备注remarks 附注供应商supplier 供货商模号mold no设计design审核checked by 核对批准approve 审批比例scale单位unit张次sheet版本revision 版次图纸大小drawing sheet size模具公差mold tolerance日期date客户customer技术要求technical requirement 技术条件、技术规定使用说明书operation specifications 操作规范中文名称英文名称中文别称16. 相关术语类(流程、商务)流程优化process optimization 过程优化时间计划表time schedule 工作进度表、时间安排表设计优化design optimization产品分析报告product analysis report流动分析报告flow analysis report结构分析报告structural analysis report模具性能与寿命分析analysis of performance andlife of mold行政部administrative department 行政司营销部marketing department 市场部、市场销售部项目部project department工程部engineering department技术部technical department 技术研发部制造部manufacture department 生产部质检部quality inspection department 品保部采购部purchasing department财务科finance section客服部customer service department 客户服务部董事长board chairman 董事局主席总经理general manager技术总监technical director工程部经理engineering manager制造部经理manufacturing manager 生产部经理模具项目经理mold project manager模具设计师mould designer模具分析师mould analyst项目工程师project engineer钳工fitter模具成本mold cost 模具费用利润profit报价单quotation设计成本design cost 设计费制造成本manufacturing cost 生产成本材料成本material cost 物料成本调试成本debugging cost 调试费用管理成本administration cost 管理费税收revenue 交期delivery time 发货期、交货期。

模具外文翻译外文文献英文文献注塑模The Injection Molding1、The injection moldingInjection molding is principally used for the production of the thermoplastic parts,although some progress has been made in developing a method for injection molding some thermosetting materials.The problem of injection a method plastic into a mold cavity from a reservoir of melted material has been extremely difficult to solve for thermosetting plastic which cure and harden under such conditions within a few minutes.The principle of injection molding is quite similar to that of die-casting.The process consists of feeding a plastic compound in powered or granular form from a hopper through metering and melting stages and then injecting it into a mold.After a brief cooling period,the mold is opened and the solidified part ejected.Injection-molding machine operation.The advantage of injection molding are:(ⅰ)a high molding speed adapter for mass production is possible;(ⅱ)there is a wide choice of thermoplastic materials providing a variety of useful properties;(ⅲ)it is possible to mold threads,undercuts,side holes,and large thin section.2、The injection-molding machineSeveral methods are used to force or inject the melted plastic into the mold.The most commonly used system in the larger machines is the in-line reciprocating screw,as shown in Figure 2-1.The screw acts as a combination injection and plasticizing unit.As the plastic is fed to the rotating screw,it passes through three zones as shown:feed,compression,and metering.After the feed zone,the screw-flight depth is gradually reduced,force theplastic to compress.The work is converted to heat by conduction from the barrel surface.As the chamber in front of the screw becomes filled,it forces the screw back,tripping a limit switch that activates a hydraulic cylinder that forces the screw forward and injects the fluid plastic into the closed mold.An antiflowback valve presents plastic under pressure from escaping back into the screw flight.The clamping force that a machine is capable of exerting is part of the size designation and is measured in tons.A rule-of-thumb can be used to determine the tonnage required for a particular job.It is based on two tons of clamp force per square inch of projected area.If the flow pattern is difficult and the parts are thin,this may have to go to three or four tons.Many reciprocating-screw machines are capable of handing thermosetting plastic materials.Previously these materials were handled by compression or transfer molding.Thermosetting materials cure or polymerize in the mold and are ejected hot in the range of 375°C~410°C.T hermosetting parts must be allowed to cool in the mold in order or remove them without distortion. Thus thermosetting cycles can be faster.Of course the mold must be heated rather than chilled,as with thermoplastics.3、Basic Underfeed MouldA simple mould of this type is shown in Figure3-1,and the description of the design and the opening sequence follows.The mould consists of three basic parts,namely:the moving half,the floating cavity plate and the feed plate respectively.The moving half consists of The moving mould plate assembly,support block,backing plate,ejector assembly and the pin ejection system.Thus the moving half in this design is identical with the moving half of basic moulds.The floating cavity plate,which may be of the integer or insert-bolster design,is located on substantial guide pillars(not shown)fitted in the feed plate.These guide pillars must be of sufficient length to support the floating cavity plate over its full movement and still project to perform the function of alignment between the cavity and core when the mould is being closed.Guide bushes are fitted into the moving mould plate and the floating cavity plate respectively.The maximum movement of the floating cavity plate is controlled by stop or similar device.The moving mould plate is suitably bored to provide a clearance for the stop bolt assembly.The stop bolts must be long enough to provide sufficient space between the feed plate and the floating cavity plate for easy removal of the feed system.The minimum space provide for should be 65mm just sufficient for an operator to remove the feed system by hand if necessary.The desire operating sequence is for the first daylight to occur between the floating cavity plate.This ensures the sprue is pulled from the sprue bush immediately the mouldis opened.T o achieve this sequence,springs may be incorporated between the feed plate and the floating cavity plate.The springs should be strong enough to give an initial impetus to the floating cavity plate to ensure it moves away with the moving half.It is normal practice to mount the springs on the guide pillars(Figure3-2)and accommodate them in suitable pocket in the cavity plate.The major part of the feed system(runner and sprue)is accommodated in the feed plate to facilitate automatic operation,the runner should be of a trapezoidal form so that once it is pulled from the feed plate is can easily beextracted.Note that if a round runner is used,half the runner is formed in the floating cavity plate,where it would remain,and be prevented from falling or being wiped clear when the mould is opened.Now that we have considered the mould assembly in the some detail,we look at the cycle of operation for this type of mould.The impressions are filled via the feed system(Figure3-1(a))and after a suitable dwell period,the machine platens commence to open.A force is immediately exerted by the compression springs,which cause the floating cavity plate to move away with the moving half as previously discussed.The sprue is pulled from the sprue bush by the sprue puller.After the floating cavity plate has moved a predetermined distance,it is arrested by the stop bolts.The moving half continues to move back and the moldings,having shrunk on to the cores,are withdrawn from the cavities.The pin gate breaks at its junction with the runner(Figure3-1(b)).The sprue puller,being attached to the moving half,is pulled through the floating cavity plate and thereby release the feed system which is then free to fall between the floating cavity plate and the feed plate.The moving half continues to move back until the ejector system is operated and the moldings are ejected (Figure3-1(c)).When the mould is closed,the respective plates are returned to their molding position and the cycle is repeated.4、Feed SystemIt is necessary to provide a flow-way in the injection mould to connect the nozzle(of the injection machine)to each impression.This flow-way is termed the feed system.Normally thefeed system comprises a sprue,runner and gate.These terms applyequally to the flow-way itself,and to the molded material which is remove from the flow-way itself in the process of extracted the molding.A typical feed system for a four-impression,two plate-type mould is shown in Figure4-1.It is seen that the material passes through the sprue,main runner,branch runner and gate before entering the impression.As the temperature of molten plastic is lowered which going through the sprue and runner,the viscosity will rise;however,the viscosity is lowered by shear heat generated when going through the gate to fill the cavity.It is desirable to keep the distance that the material has to travel down to a minimum to reduce pressure and heat losses.It is for this reason that careful consideration must be given to the impression layout gate’s design.4.1.SprueA sprue is a channel through which to transfer molten plastic injected from the nozzle of the injector into the mold.It is a part of sprue bush,which is a separate part from the mold.4.2.RunnerA runner is a channel that guides molten plastic into the cavity of a mold.4.3.GateA gate is an entrance through which molten plastic enters the cavity.The gate has the following function:restricts the flow and the direction of molten plastic;simplifies cutting of a runner and moldings to simplify finishing of parts;quickly cools and solidifies to avoid backflow after molten plastic has filled up in the cavity.4.4.Cold slug wellThe purpose of the cold slug well,shown opposite the sprue,is theoretically to receive the material that has chilled at the front of nozzle during the cooling and ejection phase.Perhaps of greater importance is the fact that it provides position means whereby the sprue bush for ejection purposes.The sprue,the runner and the gate will be discarded after a part is complete.However,the runner and the gate are important items that affect the quality or the cost of parts.5、EjectionA molding is formed in mould by injecting a plastic melt,under pressure,into animpression via a feed system.It must therefore be removed manually.Furthermore,all thermoplastic materials contract as they solidify,which means that the molding will shrink on to the core which forms it.This shrinkage makes the molding difficult to remove. Facilities are provided on the injection machine for automatic actuation of an ejector system,and this is situated behind the moving platen.Because of this,the mould’s ejector system will be most effectively operated if placed in the moving half of the mould,i.e. the half attached to the moving platen.We have stated previously that we need to eject the molding from the core and it therefore follows that the core,too,will most satisfactorily be located in the moving half.The ejector system in a mould will be discussed under three headings,namely:(ⅰ)the ejector grid;(ⅱ)the ejector plate assembly; and(ⅲ)the method of ejection.5.1、Ejector gridThe ejector grid(Figure5-1)is that part of the mould which supports the mould plate and provides a space into which theejector plate assembly can be fitted and operated.The grid normally consists of a back plate on to which is mounted a number of conveniently shaped “support blocks”.The ejector plate assembly is that part of the mould to which the ejector element is attached.The assembly is contained in a pocket,formed by the ejector grid,directly behind the mould plate.The assembly(Figure5-2)consists of an ejector plate,a retaining plate and an ejector rod.One end of this latter member is threaded and it is screwed into the ejector plate.In this particular design the ejector rod function not only as an actuating member but also as a method of guiding the assembly.Note that the parallel portion of the ejector rod passes through an ejector rod bush fitted in the back plate of the mould.5.2、Ejection techniquesWhen a molding cools,it contracts by an amount depending on the material being processed.For a molding which has no internal form,for example,a solid rectangular block,the molding will shrink away from the cavity walls,thereby permitting a simple ejection technique to be adopted.However,when the molding has internal form,the molding,as it cools,will shrink onto the core and some positive type of ejection is necessary.The designer has several ejection techniques from which to choose,but in general,the choice will be restricted depending upon the shape of the molding.The basic ejection techniques are as follows:(ⅰ)pin ejection(ⅱ)sleeve ejection(ⅲ)stripper plate ejection and(Ⅳ)air ejection.Figure 2-1aFigure 2-1bFigure 3-1Figure 3-2Figure 4-1aFigure 4-1bFigure 5-1Figure 5-2注塑模1、注塑模尽管成型某些热固性材料的方法取得了一定的进步,但注塑模主要(还是)用来生产热塑性塑件。