二氧化硅水热合成纳米硅

- 格式:pdf

- 大小:1.89 MB

- 文档页数:8

硅溶胶的鉴定方法-概述说明以及解释1.引言1.1 概述硅溶胶是一种由二氧化硅(SiO2)颗粒所组成的多孔材料。

它具有高表面积、大孔径和良好的化学稳定性等特点,因此在吸附、催化、分离等领域具有广泛的应用前景。

本文的主要目的是介绍硅溶胶的鉴定方法。

通过对硅溶胶的鉴定,我们可以了解其粒径分布、比表面积、孔径大小和孔结构等信息,从而更好地掌握硅溶胶的性质和应用特点。

文章将分为三个部分进行介绍。

首先,我们将概述硅溶胶的定义和特点,包括其制备方法、物理性质和化学性质等方面的内容;其次,我们将介绍硅溶胶的制备方法,包括溶胶-凝胶法、水热法、超临界干燥法等常用的制备方法,并对每种方法的优缺点进行讨论;最后,我们将重点介绍硅溶胶的鉴定方法,包括比表面积测定、孔径分布测定、孔结构表征等常用的鉴定方法,并对每种方法的原理和适用范围进行详细的分析。

硅溶胶的鉴定方法具有重要的意义。

通过准确、可靠的鉴定方法,我们可以了解硅溶胶的基本特性,为其在材料科学、环境工程、能源领域等的应用提供科学依据和技术支持。

同时,了解硅溶胶的鉴定方法的发展趋势,可以为今后的研究提供指导和方向,促进硅溶胶研究领域的进一步发展。

在接下来的章节中,我们将详细介绍硅溶胶的制备方法和鉴定方法,并对其应用前景和发展方向进行探讨。

希望通过本文的介绍,读者能够更全面地了解硅溶胶及其在科学研究和工程技术中的重要性。

1.2文章结构1.2 文章结构本文将从以下几个方面对硅溶胶的鉴定方法进行详细介绍和讨论。

首先,我们将在引言部分对硅溶胶的概述进行阐述,包括其定义、特点以及制备方法。

在正文部分,我们将深入探讨硅溶胶的物理和化学性质,以帮助读者更好地理解硅溶胶的特点和鉴定方法的必要性。

接下来,我们将进一步强调硅溶胶鉴定方法的重要性,包括其在科学研究和工业应用中的应用。

通过对常用的硅溶胶鉴定方法的介绍和比较分析,我们将为读者提供一种选择适合自己研究领域和实际需求的方法的指导。

二氧化硅纳米球的制备及性能研究二氧化硅纳米球是一种具有广泛应用前景的新材料,具有很好的机械性能、化学性能和热稳定性。

它可以用于制备高效催化剂、高分子复合材料、更先进的光学、电学器件、纳米传感器、医药、环境保护等领域。

因此,二氧化硅纳米球的研究具有重要的科学价值和应用前景。

一、制备方法1. 溶胶-凝胶法溶胶-凝胶法是制备二氧化硅纳米球的一种常用方法,通常包括三个步骤:溶胶的制备、凝胶的制备和热处理。

其中,溶胶的制备是将硅酸乙酯或硅酸正丁酯等有机硅溶液加入乙醇和水混合溶液中,形成胶体,随后加入引发剂,使胶体逐渐凝胶。

凝胶制备后,通过热处理,将有机物去除,形成无机物,最终得到纳米硅球。

2. 水热法水热法也是制备二氧化硅纳米球的一种常用方法。

它的制备流程如下:首先,在强碱条件下加入硅酸钠或硼酸钠等硅源,反应一定时间后,将反应体系置于高温高压的条件下,使反应体系处于水热自发反应的状态。

反应完成后,将产生的固体物质进行洗涤、干燥和处理,即可得到纳米硅球。

二、性能研究1. 结构特征二氧化硅纳米球的结构特征对其性能和应用具有重要影响。

通过透射电镜、扫描电镜和X射线衍射等实验手段,可以对其形貌和晶体结构进行表征。

实验结果表明,制备好的二氧化硅纳米球形貌为球状或半球状,平均粒径在10-50 nm之间;晶体结构为立方相(cubic phase)和六方相(hexagonal phase)。

2. 表面性质二氧化硅纳米球的表面性质对其吸附能力和催化性能具有重要影响。

通过测量比表面积和孔隙度等参数,可以对其表面性质进行表征。

实验结果表明,制备好的二氧化硅纳米球具有很高的比表面积,达到了300 m2/g左右;孔隙度也较高,主要分布在10-50 nm这一范围内。

3. 催化性能二氧化硅纳米球作为一种具有广泛应用的新材料,其催化性能是研究的重点之一。

通过测量二氧化硅纳米球在化学反应中的催化效果,可以对其催化性能进行评价。

实验结果表明,二氧化硅纳米球在催化乙醇脱水、异丙醇脱氢和酯交换等反应中均表现出优异的催化性能,说明其在催化领域具有很好的应用前景。

纳米硅的制备及其应用研究随着科技的不断进步和发展,人类对材料的需求也在不断地增加。

近年来,纳米技术得到了广泛的关注和研究,纳米硅因其特殊的物理化学性质和潜在的应用价值,成为了研究的热点之一。

本文将着重探讨纳米硅的制备方法以及在不同领域的应用研究。

一、纳米硅的制备方法1. 等离子体化学气相沉积法等离子体化学气相沉积法是一种常用的制备纳米硅的方法,它利用高温等离子体反应室中的化学反应,沉积在基板上。

该方法可以制备出单晶纳米硅。

它的优点是产量高,纯度高,但是制备过程需要高温和高真空环境。

2. 溶胶凝胶法溶胶凝胶法是一种将有机或无机前驱体在溶液中进行水解缩聚,形成胶体体系并进行热处理制备纳米硅的方法。

该方法制备出来的纳米硅具有较高的度规整和纯度,但是制备时间长,部分溶剂可能对环境不利。

3. 水热合成法水热合成法是一种利用热量和压力条件下特定化学反应生成纳米硅的方法。

该方法对操作条件要求不高,制备速度较快,但是制备的纳米硅容易受到杂质的污染,产物不容易控制。

二、纳米硅的应用研究1. 生物医学应用纳米硅因其特殊的物理化学性质和生物相容性,在生物医学领域中得到了广泛的应用。

例如,将纳米硅导入生物体内,可以在细胞膜上显示出强烈的荧光信号,并成为生物荧光探针的发展方向。

纳米硅还可以作为抗菌剂、药物载体用于生物医学材料中。

2. 电子信息领域纳米硅在电子信息领域中也具有潜在的应用价值。

如在显示器材料中加入纳米硅,可以优化显示器的性能,提高显示质量。

还可以将纳米硅作为纳米级的半导体材料用于微电子学器件加工中。

3. 能源材料纳米硅在能源领域应用较广。

在太阳能电池中,纳米硅可以作为光敏剂,通过光电转化将光能转化为电能。

同样在储能领域,纳米硅也可以作为超级电容器和锂离子电池等高性能电池的材料。

三、结论纳米技术是时下研究的热点之一,而纳米硅作为其中的一员,在不同领域拥有着广泛的应用前景。

本文对纳米硅制备和应用方面的研究进行了探讨,并简单介绍了纳米硅在生物医学、电子信息和能源材料等领域中的应用,但是纳米材料的研究需要付出大量的时间和金钱代价,因此我们也需要进行精益求精、保持谨慎的态度,更好地实现其应用价值。

疏水气相纳米二氧化硅疏水气相纳米二氧化硅是一种具有疏水性质的气相合成的纳米材料。

它具有独特的表面性质和广泛的应用潜力。

本文将介绍疏水气相纳米二氧化硅的合成方法、表面性质及其在不同领域的应用。

疏水气相纳米二氧化硅的合成方法多种多样,常见的方法包括溶胶-凝胶法、水热法、气相法等。

其中,溶胶-凝胶法是一种常用且较为简便的方法。

通过控制溶胶中硅源的浓度、酸催化剂的种类和浓度、水解和缩合反应的温度和时间等条件,可以合成出具有不同形貌和尺寸的纳米二氧化硅。

此外,还可以通过添加表面活性剂、功能化修饰剂等手段来调控疏水性能。

疏水气相纳米二氧化硅具有优异的表面性质,主要表现在两个方面:一是具有较大的比表面积和丰富的表面官能团,这使得其具有良好的吸附性能和催化活性;二是具有疏水性能,即其表面对水有较强的排斥作用。

这种疏水性质使得疏水气相纳米二氧化硅在油水分离、催化反应、生物医药等领域具有广泛的应用前景。

在油水分离领域,疏水气相纳米二氧化硅可以作为吸附材料用于油污水处理。

其疏水性质可以使其选择性吸附油类物质,从而实现油水分离。

此外,疏水气相纳米二氧化硅还可以作为油水分离膜材料的添加剂,改善膜材料的疏水性能和抗污染性能。

在催化反应领域,疏水气相纳米二氧化硅可作为载体用于催化剂的负载。

其大比表面积和丰富的表面官能团可以提供更多的活性位点,从而增强催化剂的催化活性。

此外,疏水性质可以使其在液相催化反应中具有良好的稳定性和选择性。

在生物医药领域,疏水气相纳米二氧化硅可以用于药物传递和生物成像。

由于其疏水性质和良好的生物相容性,可以将药物包载在纳米二氧化硅上,以提高药物的溶解度和稳定性,并实现靶向输送。

此外,疏水气相纳米二氧化硅还可以作为荧光探针用于生物成像,通过修饰不同的荧光染料或靶向分子,实现对生物样品的高灵敏度检测和显影。

疏水气相纳米二氧化硅是一种具有独特表面性质和广泛应用潜力的纳米材料。

通过合适的合成方法和调控手段,可以制备出具有不同形貌和尺寸的疏水气相纳米二氧化硅。

1.纳米二氧化硅的制备方法到目前为止,纳米二氧化硅的生产方法主要可以分为干法和湿法两种。

干法包括气相法和电弧法,湿法有沉淀法、溶胶-凝胶法、微乳液法、超重力反应法和水热合成法等。

1.1 气相法气相法多以四氯化硅为原料,采用四氯化硅气体在氢氧气流高温下水解制得烟雾状的二氧化硅。

2H2+ O2→2H2OSiCl4+ 2H2O →SiO2+4HCl2H2+ O2+SiCl4 →SiO2+4HCl1.2 沉淀法1.2.1沉淀法是硅酸盐通过酸化获得疏松、细分散的、以絮状结构沉淀出来的SiO2晶体。

Na2SiO3+HCl →H2SO3+NaClH2SO3 →SiO2+ H2O该法原料易得,生产流程简单,能耗低,投资少,但是产品质量不如采用气相法和凝胶法的产品好。

目前,沉淀法制备二氧化硅技术包括以下几类:(1)在有机溶剂中制备高分散性能的二氧化硅;(2)酸化剂与硅酸盐水溶液反应,沉降物经分离、干燥制备二氧化硅;(3)碱金属硅酸盐与无机酸混和形成二氧化硅水溶胶,再转变为凝胶颗粒,经干燥、热水洗涤、再干燥,锻烧制得二氧化硅;(4)水玻璃的碳酸化制备二氧化硅;(5)通过喷雾造粒制备边缘平滑非球形二氧化硅。

1.2.2实验部分以Na2SiO3·9H2O为原料“浓H2SO4”为酸试剂"采用化学沉淀法制备纳米二氧化硅。

(1)原料与试剂:水合硅酸钠,分析纯,无锡市亚盛化工有限公司;浓硫酸,分析纯,国药集团化学试剂有限公司;无水硫酸钠,分析纯,无锡市亚盛化工有限公司;聚乙二醇(PEG)6000,分析纯,无锡市亚盛化工有限公司。

(2)设备与分析仪器:Avatar360型傅立叶变换红外光谱(FT-IR)仪,KBr压片,美国;D/Max型X射线粉末衍射仪,日本理学公司;TEM-2010型高分辨率透射电镜(TEM),日本日立公司;HPPS5001激光粒度分析仪,英国Malvern公司;S-570型扫描电镜(SEM),日本日立公司;紫外可见光吸收仪(UV-Vis),日本日立公司;WDT-20,KCS-20型万能试验机,深圳凯强利试验仪器有限公司;磁力搅拌器、分析天平、抽滤瓶、烘箱、马弗炉。

二氧化硅纳米颗粒的制备及其应用研究随着科学技术的不断发展,纳米科技越来越受到人们的关注。

纳米颗粒是一种基础性的纳米材料,其尺寸通常在1-100纳米之间。

二氧化硅(SiO2)是一种广泛使用的材料之一,它在医药、电子、纳米材料等领域都有广泛的应用。

在本文中,我们将探讨二氧化硅纳米颗粒的制备及其应用研究。

一、二氧化硅纳米颗粒的制备方法1. 溶胶-凝胶法溶胶-凝胶法是制备二氧化硅纳米颗粒的一种常见方法。

它涉及将硅酸醇溶液放置在高温高压条件下进行反应,反应产物是一种凝胶物质。

这种方法可以制备出高纯度、相对稳定的SiO2纳米颗粒,这是由于过程中无需引入外部气体或官能团,因此可以减少杂质的产生。

2. 水热法水热法是一种基于高温高压水或水-有机混合物反应的方法。

二氧化硅纳米颗粒的制备通常涉及硅源的预处理,并将其与其他试剂一起溶解。

在溶液中进行恒定的加热和搅拌,最终以水热形式结晶。

这种方法可以优化纳米颗粒的粒径和形状,并能够选择特定的硅源和其他试剂以获得所需的纳米颗粒。

3. 微乳液法微乳液法是一种分散功率环创利用垂直旋向顺序的动力学因素,来控制单氯化硅(SiCl4)的水解和聚合过程。

在这个过程中,SiCl4毒性很大,使用醇和表面活性剂可以改善它的稳定性。

然后,聚合反应在表面活性剂分子内部进行,反应产物直径约为15-100纳米。

二、二氧化硅纳米颗粒的应用研究1. 医疗用途在医学领域,二氧化硅纳米颗粒在癌症治疗和疫苗开发中具有潜在用途。

这是因为SiO2具有良好的生物相容性和低毒性,可以作为药物载体,靶向输送药物到肿瘤组织或免疫系统。

此外,在慢性肺疾病等治疗中,SiO2也用于改善药物的吸附、分布和释放特性。

2. 环保用途二氧化硅纳米颗粒在环境污染治理方面具有潜在的应用价值:其中,纳米颗粒可以利用其高比表面积和表面反应性来改进催化反应、分离和吸附,从而提高其处理吸附物的效率和选择性。

此外,通过表面修饰和功能化,可以引入目标物的特异性,以增强环境污染处理的选择性。

二氧化硅纳米线制备方法二氧化硅纳米线是一种具有很高应用潜力的纳米材料,它在电子器件、传感器、催化剂等领域都具有广阔的应用前景。

本文将介绍几种常见的二氧化硅纳米线制备方法。

一、气相法制备二氧化硅纳米线气相法是制备二氧化硅纳米线的常用方法之一。

该方法通过控制反应温度、气氛和反应时间等条件,使气相中的硅源在催化剂的作用下发生化学反应,生成纳米线。

常用的气相法包括化学气相沉积法(CVD)和热蒸发法。

化学气相沉积法是一种将气态前驱物转化为固态纳米线的方法。

在CVD过程中,通常使用有机硅化合物作为硅源,如三氯硅烷(SiCl3H)。

该方法需要在高温下进行,反应温度一般在800-1100摄氏度之间。

通过调节反应条件和催化剂的选择,可以控制二氧化硅纳米线的尺寸和形貌。

热蒸发法是一种将固态硅源通过升温蒸发的方法制备二氧化硅纳米线。

在热蒸发过程中,硅源被加热至高温,然后在惰性气氛中蒸发,并在基底上沉积形成纳米线。

这种方法操作简单,但对硅源的纯度要求较高。

二、溶液法制备二氧化硅纳米线溶液法是一种简单易行的制备二氧化硅纳米线的方法。

该方法通常使用硅源溶液,在适当的条件下,通过溶剂挥发或溶液中其他物质的作用,使硅源逐渐沉淀形成纳米线。

常见的溶液法包括溶胶-凝胶法、水热法和电化学沉积法。

溶胶-凝胶法是一种将溶胶转化为凝胶的方法。

在溶胶-凝胶过程中,硅源以溶胶的形式存在于溶液中,通过加热、干燥和煅烧等步骤,使溶胶逐渐凝胶化生成纳米线。

这种方法制备的纳米线具有较高的纯度和均一的尺寸分布。

水热法是一种利用高温高压水溶液制备纳米线的方法。

在水热法中,硅源在水热反应条件下与其他溶液中的成分发生反应,生成纳米线。

这种方法具有简单、环保的特点,但对反应条件的控制较为严格。

电化学沉积法是一种利用电化学方法在电极表面沉积纳米线的方法。

在电化学沉积过程中,通过控制电极电势和电解液成分,使硅源在电极表面沉积形成纳米线。

这种方法可以实现对纳米线尺寸和形貌的精确控制。

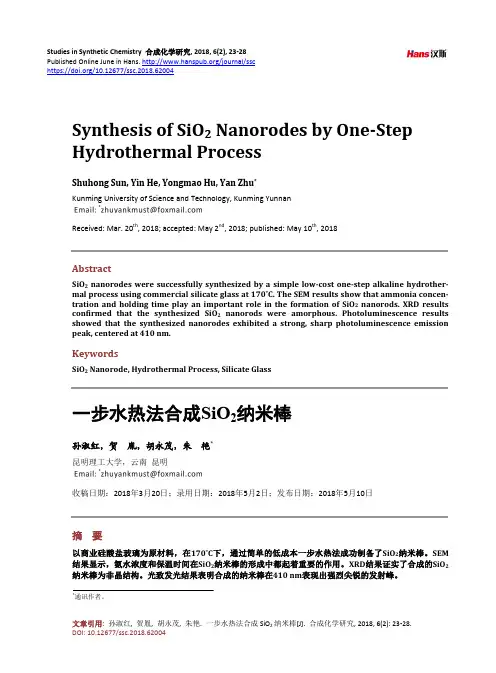

Studies in Synthetic Chemistry 合成化学研究, 2018, 6(2), 23-28Published Online June in Hans. /journal/sschttps:///10.12677/ssc.2018.62004Synthesis of SiO2 Nanorodes by One-StepHydrothermal ProcessShuhong Sun, Yin He, Yongmao Hu, Yan Zhu*Kunming University of Science and Technology, Kunming YunnanReceived: Mar. 20th, 2018; accepted: May 2nd, 2018; published: May 10th, 2018AbstractSiO2 nanorodes were successfully synthesized by a simple low-cost one-step alkaline hydrother-mal process using commercial silicate glass at 170˚C. The SEM results show that ammonia concen-tration and holding time play an important role in the formation of SiO2nanorods. XRD results confirmed that the synthesized SiO2nanorods were amorphous. Photoluminescence results showed that the synthesized nanorodes exhibited a strong, sharp photoluminescence emission peak, centered at 410 nm.KeywordsSiO2 Nanorode, Hydrothermal Process, Silicate Glass一步水热法合成SiO2纳米棒孙淑红,贺胤,胡永茂,朱艳*昆明理工大学,云南昆明收稿日期:2018年3月20日;录用日期:2018年5月2日;发布日期:2018年5月10日摘要以商业硅酸盐玻璃为原材料,在170˚C下,通过简单的低成本一步水热法成功制备了SiO2纳米棒。

水热法是一种常用的合成纳米材料的方法,其中二氧化硅(SiO2)是一种广泛使用的纳米材料。

在水热合成过程中,SiO2 纳米粒子可能会聚集在一起,形成较大的团聚体,这会影响其性能和应用。

为了抑制SiO2 纳米粒子的聚集,可以采取以下措施:

1. 添加表面活性剂:表面活性剂可以在SiO2 纳米粒子表面形成一层保护层,防止它们聚集在一起。

常用的表面活性剂包括十二烷基苯磺酸钠(SDBS)、十六烷基三甲基溴化铵(CTAB)等。

2. 控制反应条件:水热合成的反应条件,如温度、时间、压力等,也会影响SiO2 纳米粒子的聚集。

通过控制这些条件,可以减少SiO2 纳米粒子的聚集。

3. 采用模板法:模板法是一种有效的抑制SiO2 纳米粒子聚集的方法。

模板可以提供一个受限的空间,使SiO2 纳米粒子在其中生长,从而减少它们的聚集。

4. 选择合适的前驱体:前驱体的选择也会影响SiO2 纳米粒子的聚集。

选择合适的前驱体可以减少SiO2 纳米粒子的聚集。

综上所述,通过添加表面活性剂、控制反应条件、采用模板法和选择合适的前驱体等方法,可以有效地抑制SiO2 纳米粒子的聚集。

气相纳米二氧化硅气相纳米二氧化硅概述气相纳米二氧化硅是指通过气相法制备的纳米级二氧化硅材料,其粒径通常在1-100纳米之间。

由于其具有较高的比表面积、独特的光学、电学、磁学和力学性质,因此被广泛应用于催化剂、传感器、光电器件等领域。

制备方法气相纳米二氧化硅的制备方法主要包括溶胶-凝胶法、水热法、微乳液法、水热合成法等。

其中,溶胶-凝胶法是最常用的一种方法,其具体步骤为:首先将硅源和表面活性剂混合,在适当条件下使其形成凝胶;然后将凝胶进行干燥和焙烧处理,得到纳米二氧化硅。

性质与应用物理性质气相纳米二氧化硅具有较高的比表面积和孔隙度,同时具有较好的分散性和可控性。

此外,由于其尺寸效应和表面效应的影响,其晶体结构和光学、电学、磁学等性质也与传统的二氧化硅材料不同。

应用领域1. 催化剂气相纳米二氧化硅在催化剂领域具有广泛的应用。

例如,将其作为载体材料,可以制备出高效的金属催化剂;将其作为反应物参与反应,则可制备出具有特殊结构和性能的功能性材料。

2. 传感器气相纳米二氧化硅在传感器领域也有着广泛的应用。

例如,将其作为敏感元件,可以制备出高灵敏度、高选择性和快速响应的气体传感器;将其作为电极材料,则可制备出高效率、长寿命和稳定性能的生物传感器。

3. 光电器件由于气相纳米二氧化硅具有良好的光学和电学性质,因此在光电器件领域也有着广泛的应用。

例如,将其作为太阳能电池中的电子传输层,可以提高太阳能转换效率;将其作为光催化剂,则可实现光解水产生氢气等环保型能源。

4. 其他领域此外,气相纳米二氧化硅还可以应用于涂料、垃圾处理、生物医学等领域。

例如,将其作为涂料中的填充材料,则可提高涂层的耐磨性和防腐性;将其作为生物医学材料,则可制备出具有良好生物相容性和生物活性的人工骨骼、人工血管等。

结论气相纳米二氧化硅是一种具有广泛应用前景的新型材料,其制备方法简单、成本低廉、性能优异。

在未来的研究中,需要进一步探究其结构与性能之间的关系,并开发出更多适用于不同领域的新型应用。

sio2纳米球的合成

SiO2纳米球的合成一般有以下几种方法:

1.溶胶-凝胶法:该方法是将硅烷类原料在水、醇或有机溶剂中加催

化剂,形成溶胶,然后通过水解-缩合反应形成凝胶,最终经过热处理制

备成SiO2纳米球。

2.气相法:这种方法是将硅烷或氯化硅气体在惰性气体载气下通过高

温热解或化学气相沉积法形成SiO2纳米球。

3.模板法:该方法是将SiO2纳米球通过模板(如多孔聚合物、球形

颗粒等)的形态进行制备。

这种方法的优点是可以调控SiO2纳米球的大小、形态和结构等。

4.微乳液制备法:该方法是将硅烷或硅醇类化合物溶解于微乳中,然

后通过水解缩合反应生成SiO2纳米球。

5.水热法:该方法是将硅源材料和NaOH等碱性物质在高温高压下进

行水热处理,生成SiO2纳米球。

以上几种方法各有特点,可以根据实际需要选择合适的方法进行制备。

SiO2和TiO2纳米材料的合成与应用纳米科技是近年来在科学研究和产业领域取得了广泛关注和快速发展的领域之一。

在众多纳米材料中,以硅氧化物和钛氧化物为代表的纳米材料,具有良好的光电性、化学稳定性、生物相容性和可控性等优异性能,是目前研究领域中的热点之一。

本文将介绍SiO2和TiO2纳米材料的合成方法和应用领域。

一、SiO2纳米材料的合成与应用1.合成方法SiO2纳米材料的合成方法各异,但通常涉及控制SiO2的核形成和生长。

目前市场上大量的SiO2纳米材料是通过溶胶-凝胶法合成的。

这种方法通常涉及使用硅烷前体(RO)3SiX或RO2Si(OR')2等,其中R表示有机基,X表示卤素。

在这种方法中,硅烷分子逐渐氢化,产生硅氧聚合物,最终形成SiO2纳米颗粒。

其中,溶剂的类型和配比,以及温度和反应时间等因素,都可能影响SiO2纳米材料的形貌、粒径和性质。

2.应用领域SiO2纳米材料具有广泛的应用领域。

例如,在生物医学领域,SiO2纳米颗粒被广泛用于制备药物载体、细胞成像和生物探针等方面。

在环境污染治理领域,SiO2纳米材料可以作为水中污染物的吸附剂和光催化剂,以提高水质安全和处理效率。

此外,SiO2纳米材料还可以用于玻璃制品、塑料制品和建筑材料等生产中,以改善材料性能、增加机械强度和表面润滑性等。

二、TiO2纳米材料的合成与应用1.合成方法TiO2纳米材料可以通过溶胶-凝胶法、水热法、微乳法、水相合成法和气相合成法等多种方法合成。

其中,以溶胶-凝胶法合成的TiO2纳米材料较为常见。

在这种方法中,通常需要在硫酸的作用下,将金属钛或钛酸四丁酯等钛源加热至某一温度,形成硫酸钛酸铁胶体;然后,再经过水解、凝胶化和高温煅烧等过程,得到TiO2纳米材料。

其中,热处理条件、pH值、表面改性剂和配比等因素,都会对TiO2纳米材料的形态、晶型和光催化活性等产生影响。

2.应用领域TiO2纳米材料的应用领域非常广泛。

二氧化硅纳米材料制备及在生物医用材料中的应用一、引言随着纳米科技的发展,纳米材料在生物医学领域中的应用越来越受到关注。

其中,二氧化硅纳米材料因其优异的化学和物理特性,在生物医学材料中有广泛的应用前景。

本文将介绍二氧化硅纳米材料的制备方法及其在生物医用材料中的应用。

二、二氧化硅纳米材料的基本特性二氧化硅纳米材料的化学成分为SiO2,是一种无机非金属化合物。

其具有高度透明、优异的热稳定性、低热膨胀系数、高硬度和耐磨性等优异物理性能。

此外,二氧化硅纳米材料还具有良好的生物相容性和生物安全性能。

三、二氧化硅纳米材料的制备方法1. 溶胶-凝胶法溶胶-凝胶法是制备二氧化硅纳米材料的一种常用方法。

其主要步骤包括:先将硅烷预处理成溶胶状态,然后通过水解凝胶化反应生成凝胶,最后将凝胶进行热处理得到二氧化硅纳米材料。

2. 水热法水热法是另一种制备二氧化硅纳米材料的方法。

其基本原理是在高温、高压的条件下,使硅酸盐在溶液中发生水解反应,生成二氧化硅,并形成纳米颗粒。

该方法制备的二氧化硅纳米材料粒径均匀、形状规则,并且有良好的分散性。

3. 气相合成法气相合成法是利用气相化学反应制备二氧化硅纳米材料的方法。

该方法制备的二氧化硅纳米材料粒径小、分散性好,并且制备过程容易控制。

但是,该方法的制备条件较为严格,需要高温高压的反应条件,且所用的原料成本较高。

四、二氧化硅纳米材料在生物医用材料中的应用1. 生物传感器二氧化硅纳米材料具有高比表面积、优异的生化活性和生物相容性,可用于制备高灵敏的生物传感器。

例如,在荧光探针上包覆一层纳米二氧化硅材料可提高传感器对生物分子的检测灵敏度,并保持分子的稳定性。

2. 药物传递系统二氧化硅纳米材料还可用于制备药物传递系统。

将药物包载在二氧化硅纳米材料表面或内部,可实现对药物的保护和控制释放,提高药物的生物利用度和疗效,降低药物对身体的毒副作用。

3. 骨修复材料二氧化硅纳米材料还可用于制备骨修复材料。

二氧化硅纳米结构的制备及应用二氧化硅纳米结构是一种具有广泛应用前景的材料,其制备和应用已引起了越来越多的关注。

本文将从制备和应用两个方面进行讨论。

一、制备1. 溶胶-凝胶法溶胶-凝胶法是制备二氧化硅纳米结构的常用方法。

这种方法将硅源(如硅酸酯)和氧源(如乙酸铝)在水或有机溶剂中混合,并在适当的温度下加热,形成胶体溶胶。

然后将溶胶进行凝胶处理,即使其被固化,形成类似于琥珀状的固体。

最后,将其煅烧,生成具有不同形态的二氧化硅纳米结构。

2. 水热法水热法是一种将硅源和氧源在水溶液中反应制备硅纳米晶体的方法。

例如,可以将氯硅烷和乙酸铝在水中加热,形成类似于蚕茧的凝胶物质。

然后,将凝胶物质在高温下水热处理,产生纳米结晶。

该方法简单易行,制备出来的纳米结构具有优异的形貌和性能。

3. 气相沉积法气相沉积法是一种将气体、液体或固体的前驱体在高温下使之在基底上沉积成薄膜的方法。

在气相沉积法制备二氧化硅纳米结构时,可以使用化学气相沉积法、物理气相沉积法和打火机氧化沉积法等。

二、应用1. 电子学二氧化硅纳米结构具有优良的光学和电学性能,因此在光子器件和电子器件中有广泛的应用。

例如,可以将二氧化硅纳米线集成在光学器件中,用于制造更小、更高效的光学计算机处理器。

2. 吸附材料二氧化硅纳米结构的大比表面积和高比表面积,使其成为优良的吸附材料。

例如,二氧化硅纳米粒子可以应用于吸附有机污染物,清除废水中的有害物质。

3. 生物医学二氧化硅纳米结构在生物医学领域中拥有广泛的应用。

例如,可以制造出具有生物相容性和药物释放功能的二氧化硅纳米粒子,用于治疗癌症、心血管疾病等。

总之,二氧化硅纳米结构制备技术和应用是当前研究热点之一。

未来,随着技术的不断发展,二氧化硅纳米结构在更广泛的领域中将发挥重要作用。

亲水型纳米二氧化硅亲水型纳米二氧化硅是一种具有优异表面活性和水相分散能力的纳米材料。

其制备方法直接影响了其性质和应用领域。

下面将分别从定义、制备方法、性质与应用等方面进行介绍。

一、定义纳米二氧化硅是指粒径小于100纳米的二氧化硅微粒,其颗粒大小的减小使其光学、电学、力学和热学等性质得到了显著的改变。

亲水型纳米二氧化硅是表面经过改性处理,能够在水相中稳定分散的纳米材料。

其表面含有亲水基团,具有良好的水相分散性能。

二、制备方法亲水型纳米二氧化硅的制备方法主要包括溶胶-凝胶法、微乳液法、水热法等。

其中微乳液法是目前应用最广泛的制备方法。

微乳液法是将表面活性剂、油相、水相混合,在适当的条件下形成均匀无定形的微胶束,存在于水和油相之间。

然后通过向微胶束中加入硅酸四酯等硅源,在碱性条件下形成二氧化硅。

最后,将合成的二氧化硅制备为亲水型纳米二氧化硅。

三、性质1. 良好的水相分散性:亲水型纳米二氧化硅表面含有亲水性基团,具有良好的水相分散性能,能够均匀地分散在水环境中,不易形成团聚。

2. 优异的表面活性:亲水型纳米二氧化硅表面活性高,可作为表面活性剂,与水中的污染物发生作用,可以使水中的污染物有效分散,从而达到净化水质的目的。

3. 大比表面积:亲水型纳米二氧化硅颗粒细小,比表面积大,有更好的吸附性能和反应性能,可应用于吸附、催化等领域。

4. 生物相容性高:亲水型纳米二氧化硅表面活性基团的引入,使其表面具有亲水性,有良好的生物相容性。

四、应用1. 水处理领域:亲水型纳米二氧化硅可作为水处理剂,能够吸附水中的污染物,达到净化水质的效果。

2. 催化剂:亲水型纳米二氧化硅由于表面积大,具有良好的催化性能。

可以用作高效催化剂,应用于化工、石化等方面。

3. 纳米材料制备:亲水型纳米二氧化硅制备方便,能够与其他材料共同制备成功能性复合材料,可应用于医疗、生物等领域。

4. 玻璃材料:亲水型纳米二氧化硅可作为玻璃材料的添加剂,可改善玻璃材料的透明性和强度,应用于玻璃行业。

介孔sio2纳米棒的制备及其表面

锚接金纳米粒子

介孔sio2纳米棒的制备:

1、经过二氧化硅热解法制备出单一纯净的SiO2材料。

2、在高温下,将SiO2材料受热至500℃以上,使其水解成介孔状SiO2材料。

3、将介孔状SiO2材料经过溶剂热浸沉积法制备出SiO2纳米棒材料。

表面锚接金纳米粒子:

1、先在SiO2纳米棒表面放置聚乙二醇 (PEG) 桥键分子,将其用作接枝基质,以实现金纳米粒子的有效锚定;

2、将金纳米粒子悬浮液滴入SiO2纳米棒表面,其中金纳米粒子被PEG桥键分子吸附,从而形成金纳米粒子

/SiO2纳米棒复合体;

3、将经过金纳米粒子锚接的SiO2纳米棒置入特定的溶液中,在溶液中,金纳米粒子会结合溶液中的特定分子,以实现最终的金纳米粒子锚接。

二氧化硅纳米材料的合成及其应用前景随着纳米科技的快速发展,纳米材料在各个领域展现出了巨大的应用潜力。

其中,二氧化硅纳米材料作为一种重要的纳米材料,在材料科学、生物医学、能源储存等领域具有广泛的应用前景。

本文将重点探讨二氧化硅纳米材料的合成方法以及其在不同领域的应用前景。

一、二氧化硅纳米材料的合成方法1. 溶胶-凝胶法溶胶-凝胶法是一种常用的合成二氧化硅纳米材料的方法。

该方法通过溶胶的形成和凝胶的固化过程,得到具有高比表面积和孔隙结构的二氧化硅纳米材料。

溶胶-凝胶法具有简单、成本低、可控性强等优点,因此在实际应用中得到了广泛的应用。

2. 热解法热解法是另一种常用的合成二氧化硅纳米材料的方法。

该方法通过高温热解硅源,使其分解并形成二氧化硅纳米颗粒。

热解法具有合成过程简单、可大规模生产等优点,适用于工业化生产。

3. 水热法水热法是一种利用高温高压水环境合成二氧化硅纳米材料的方法。

通过调控水热条件,可以控制二氧化硅纳米材料的形貌和尺寸。

水热法具有合成过程简单、可控性强等优点,因此在纳米材料的合成中得到了广泛的应用。

二、二氧化硅纳米材料在材料科学中的应用前景1. 传感器二氧化硅纳米材料具有较大的比表面积和优良的光学性能,因此在传感器领域具有广泛的应用前景。

通过将二氧化硅纳米材料与特定的功能材料结合,可以制备出高灵敏度、高选择性的传感器。

这些传感器可以应用于环境监测、生物传感等领域。

2. 光催化二氧化硅纳米材料具有优异的光催化性能,可以将光能转化为化学能,从而实现光催化反应。

利用二氧化硅纳米材料的光催化性能,可以实现水的分解产氢、有机废水的处理等重要应用。

因此,二氧化硅纳米材料在能源储存和环境保护领域具有重要的应用前景。

三、二氧化硅纳米材料在生物医学中的应用前景1. 生物传感二氧化硅纳米材料具有较大的比表面积和优良的生物相容性,因此在生物传感领域具有广泛的应用前景。

通过将二氧化硅纳米材料与特定的生物分子结合,可以制备出高灵敏度、高选择性的生物传感器。

Hydrothermal synthesis of nano-silicon from a silica sol and its use in lithium ion batteriesJianwen Liang, Xiaona Li, Yongchun Zhu (✉), Cong Guo, and Yitai Qian (✉)Hefei National Laboratory for Physical Science at Microscale and Department of Chemistry, University of Science and Technology of China, Hefei 230026, ChinaReceived: 11 September 2014 Revised: 31 October 2014 Accepted: 3 November 2014© Tsinghua University Press and Springer-Verlag Berlin Heidelberg 2014KEYWORDS silicon,hydrothermal synthesis, nanomaterials,silicon sol,energy storage ABSTRACTThere have been few reports concerning the hydrothermal synthesis of silicon anode materials. In this manuscript, starting from the very cheap silica sol, we hydrothermally prepared porous silicon nanospheres in an autoclave at 180 °C.As anode materials for lithium-ion batteries (LIBs), the as-prepared nano-silicon anode without any carbon coating delivers a high reversible specific capacity of 2,650 mAh·g–1 at 0.36 A·g–1 and a significant cycling stability of about 950 mAh·g–1 at 3.6 A·g–1 during 500 cycles.1IntroductionSilicon has been considered as a promising anode candidate material for advanced lithium-ion batteries (LIBs) due to its high theoretical capacity (3,579 mAh·g–1) and relatively low discharge potential (<0.5 V versus Li/Li+) [1]. However, Si exhibits serious volume changes (>270%) during lithiation–delithiation, which leads to a rapid reduction in capacity [2, 3]. Similar to otherelectrode materials, using Si materials with a nano-structure is one of means to relieve this problem [4–9].Various methods have been developed to produce nano-silicon anode materials in order to improve LIBs performance. One of these methods is chemical vapour deposition (CVD) of silanes, by which silicon nanotubes were prepared. After subsequent SiO2 surface-coating, the Si/SiO2 nanotubes were shown to have long cycle life (6,000 cycles with 88% capacity retention), high specific charge capacity (~2,971/1,780 mAh·g–1 at 0.4 A·g–1, and ~940/600 mAh·g–1 at 24 A·g–1) [10]. Nano-silicon anode materials are also prepared by the typical magnesiothermic reduction reaction [11–16]. For example, magnesiothermic reduction of SiO2 at 650 °C was used to synthesize Si nanotubes, which showed a capacity of about 1,900 mAh·g–1 at 0.4 A·g–1, with a reten-tion of ~50% after 90 cycles after carbon coating [11].Nano Research 2015, 8(5): 1497–1504DOI 10.1007/s12274-014-0633-6Address correspondence to Yitai Qian, ytqian@; Yongchun Zhu, ychzhu@With regard to wet chemical synthesis of nano-silicon anode materials, much attention has been paid to the preparation in organic solvents [17–19]. For example, nest-like silicon nanospheres were prepared via reaction of sodium silicide and NH 4Br in a mixed solvent of pyridine and dimethoxyethane in an autoclave at 80 °C for 24 h, and exhibited a reversible specific capacity of 1,095 mAh ·g –1 at 2 A·g –1 after 50 cycles. Si nanoparticles were produced by reduction of SiCl 4 with naphthalene sodium in anhydrous tetrahydrofuran at 380 °C in a Hastelloy Parr reactor, and showed a specific charge capacity of 3,535 mAh ·g –1 at 0.9 A·g –1 and retention as high as 96% after 40 cycles after carbon coating [17]. Si nanoparticles were synthesized via reduction of anhydrous SiCl 4 with sodium–potassium alloy (NaK) in toluene solution under reflux for 4 h, followed by oxidation; the resulting sample of Si/SiO x /SiO 2 showed an initial charge capacity of 610 mAh·g –1 at 0.2 A·g –1 and good cycling stability (maintained at ~600 mAh ·g –1 after 350 cycles) [20]. Recently, an aqueous synthesis of hydrophilic silicon nanoparticles (~2.2 nm) based on the reaction of (3-aminopropyl)trimethoxysilane (C 6H 17NO 3Si) and trisodium citrate dihydrate undermicrowave irradiation at 140°C was reported [21]. Silicon nanowires have also been grown in an aqueous solution [22]. Previously, we have fabricated silicon micromaterials by reducing crystalline Na 2SiO 3·9H 2O with Mg in an autoclave at 200 °C [23]. After being combined with graphene, the as-prepared anode showed a reversible capacity of ~600 mAh ·g –1 at a current density of 3.6 A·g –1 after 360 cycles.In this study, we hydrothermally prepared porous silicon nanospheres by reducing silica sol with metallic magnesium in an autoclave at 180 °C. Moreover, besides silica sol, this hydrothermal reduction reaction can be extended to the reduction of solid silica powders such as silica aerogel and silicic acid (hydrated silica). The as-prepared nano-silicon anode delivers a high reversible specific capacity of 2,650 mAh ·g –1 at 0.36 A·g –1 and cycling stability about 950 mAh ·g –1 at 3.6 A·g –1 after 500 cycles.2 Experimental2.1 Materials30% alkaline silica sol (industrial, pH = 13) waspurchased from Guangzhou Sui Ze Environmental Protection Technology Co., Ltd (China, http:// /company/shop1383670764546/ index.aspx). Mg (99%, 100–200 mesh powder), HCl (37%) and hydrofluoric acid (≥ 40%) were purchased from Sinopharm Chemical Reagent Co., Ltd (China). 2.2 Hydrothermal synthesis of nano-silicon The porous silicon nanospheres were prepared by reduction of industrial silica sol with magnesium using a hydrothermal reduction reaction in a stainless autoclave. Silica sol (2.2 g) and Mg (1.5 g) powder were mixed and added into a 20 mL stainless autoclave which was then sealed. Subsequently, the autoclave was maintained at 180 °C for 10 h and then cooled to room temperature. Here, the temperature as 180 °C is the lowest temperature in such reaction of silica sol and Mg. The samples were immersed in hydrochloric acid (1 mol·L –1) for several hours to remove MgO. The resulting solution was washed with distilled water and centrifuged (5,000 rpm, 5 min) to collect silicon. The obtained silicon was dissolved in 10 wt.% dilute HF solution for 10 min to remove unreacted silica and other impurities formed during reduction. The brown-black precipitate was collected by centrifugation, washed with deionized water and ethanol and dried for overnight at 60 °C in a vacuum oven to evaporate residual solvent. We also tested the synthesis of silicon materials by using other kinds of silicon precursors such as silica aerogel and silicic acid (hydrated silica). Experimental details are shown in the Electronic Supplementary Material (ESM). 2.3 Materials characterizationThe morphologies of the reaction products were characterized by scanning electron microscopy (SEM, JEOL-JSM-6700F), transmission electron microscopy (TEM, Hitachi H7650 and HRTEM, JEOL 2010). X-ray diffraction (XRD) was performed on a Philips X’ Pert Super diffractometer with Cu K α radiation (λ = 1.54178 Å). The Brunauer–Emmett–Teller (BET) surface area and Barrett–Joyner–Halenda (BJH) pore distri-bution plots were measured on a Micromeritics ASAP 2020 accelerated surface area and porosimetry system. Before analysis, the samples were allowed to dryunder vacuum and degas at 300 °C for 0.5 h undervacuum (10–5 bar).2.4 Electrochemical measurements The electrochemical properties of nano-silicon electrodeswere measured with coin-type half cells (2016 R-type)which were assembled in an argon-filled glove box (H 2O, O 2 < 1 ppm). The working electrode was preparedby mixing the nano-silicon material, super P carbonblack and sodium alginate (SA) binder in a weight ratio of 60:20:20 in water as solvent. The slurry waspasted onto a Cu foil and then dried in a vacuum ovenat 80 °C for 12 h. The active material density of eachcell was determined to be 0.5–1.0 mg·cm –2. Metallic Lisheet was used as the counter electrode, and 1 M LiPF 6in a mixture of ethylene carbonate/dimethylcarbonate(EC/DMC; 1:1 by volume) and 10 wt.% fluoroethylenecarbonate (FEC) was used as the electrolyte (ZhuhaiSmoothway Electronic Materials Co., Ltd. (China)). Galvanostatic measurements were made using a LAND-CT2001A instrument at room temperature thatwas cycled between 0.005 V and 1.50 V versus Li +/Liat a rate of 0.36–18 A·g –1.3 Results and discussionSilica sol was converted into H 2/Si by the hydrothermalreduction process with Mg in a stainless steel autoclave.X-ray powder diffraction (XRD) analysis (Fig. S1, in the ESM) confirmed the main components to be MgOand Si. Trace amounts of Mg(OH)2 and Mg 2SiO 4 werealso detected in the XRD pattern. The composite reacted specimens were then immersed in a 1 M HCl solution for several hours to remove MgO andMg(OH)2 (Fig. S2, in the ESM) and further treatedwith HF solution to remove unreacted silica and other impurities formed during reduction.The XRD pattern of the resulting silicon-basedproduct is shown in Fig. 1(a). All the peaks can be indexed to the standard pattern of cubic silicon (JPCDS 27-1402) with calculated lattice constants of a = 5.408 Å,which is close to the reported value of 5.430 Å. The yield of this Si material is above 25%. Moreover, the 2p Si XPS (X-ray photoelectron spectroscopy) spectrumof the as-prepared sample (Fig. 1(b)) shows—in addition to the strong peak of silicon at 99 eV—a weak peak at 103.5 eV , indicating the existence of small amount of amorphous SiO 2 [24]. Figure 2 shows the scanning electron microscopy (SEM) and transmission electron microscopy (TEM) images of the as-prepared nano-silicon. From the SEM image (Fig. 2(a)), one can see that the as-prepared silicon is composed of uniform sphere-like nano-particles with average diameter of 80 nm. The TEMimage in Fig. 2(b) shows the presence of pores in the spherical nanostructures, which is further confirmed by the enlarged TEM image of Fig. 2(c). It is obvious that the primary pores with a size of several nano-meters are homogeneously distributed. A HRTEMimage (Fig. 2(d)) taken on the edge of an individual nanosphere shows that the porous nanospheres are composed of many nanocrystallites and the pore size is 2–5nm. The interplanar spacing is about 3.1 Å, corresponding to the (111) planes of the crystalline Si. Nitrogen adsorption measurements (Fig. S3, in the ESM) indicated that the specific surface area of nano- silicon was about 11 m 2·g –1. BJH analyses (Fig. S4, inthe ESM) of the nitrogen desorption curves indicatedFigure 1 (a) XRD pattern and (b) XPS spectrum of the porous Si nanospheres after hydrothermal reduction silica sol process.Figure 2 The morphology, size, and structure of the resulting porous Si nanospheres. (a) SEM and (b) and (c) TEM image of the spherical porous silicon; (d) HRTEM image taken on the edge of an individual nanosphere.that the porous Si nanosphere possessed a large amount of nanopores (~4 nm and ~10 nm) and a small amount of macropores.Moreover, we also synthesized silicon materials by using other kinds of silicon precursor, such as silica aerogel and silicic acid (hydrated silica). Experimental details are shown in the ESM (Extension experiments 1 and 2). XRD, SEM and TEM analysis (Figs. S5–S8) clearly reveals that the crystalline phase of nano-silicon can be hydrothermally synthesized by using other kinds of silicon precursor at relatively low temperature (~200 °C).In contrast to previous reports, hydrothermal reduction of the silica sol proceeds through the formation of active H intermediates. First, the reaction of H 2O and Mg according to the equation H 2O + Mg = MgO + H 2 (ΔH θ = –316 kJ· mol –1) produces a large amount of heat in a short time which promotes the subsequent reaction leading to the production of silicon. On the other hand, based on the standard electrode potentials E θ(H/H 2O) = –0.93 V , E θ(Mg/Mg 2+) = –2.36 V and E θ(Si/SiO 2) = –0.86 V, reactions such as (1) Mg + H 2O = MgO + 2H, (2) H + SiO 2 = Si + H 2O and (3) Mg + SiO 2 = MgO + Si are thermodynamically spontaneous. It is proposed that the generation of active H intermediates will promote the reaction, which is similar to the Clemmensen reaction in traditional organic synthesis [25]. In the Clemmensen reaction, active H intermediates generated from Zn and HCltransform carbonyl groups into methylene groups. Moreover, such a hydrothermal reduction of silica sol can be carried out at even lower temperatures than 180 °C through activating the formation of active H intermediates by adding acid, which provides direct proof that the formation of active H intermediates should facilitate the formation of silicon. An extension experiment involving adjusting the pH of the reaction system is given in the ESM (Extension experiment 3 and Fig. S9).The electrochemical performance of the spherical porous Si nanostructures as an anode was investigated in CR2016 coin cells with lithium foil as a counter electrode. Figure 3(a) shows typical voltage curves during the first five cycles in the voltage window of 0.005–1.50 V versus Li/Li + at a current density of 0.36 A·g –1. In the first discharge curve, a discharge plateau at around 0.8 V can be assigned to the for-mation of a solid electrolyte interface (SEI) layer, which disappears in the following cycle and is related to an initial irreversible capacity loss [12, 26, 27]. The discharge plateau located at around 0.2 V is related to the alloy formation process between Li and crystal Si [28, 29]. Subsequent discharge and charge cycles curves had the voltage profiles characteristic of amorphous Si [30, 31].The porous silicon nanospheres anode delivers initial discharge and charge capacities of 4,055 and 3,015 mAh·g –1 at 0.36 A·g –1, respectively , corresponding to a first cycle coulombic efficiency (CE) of 74%. The irreversible capacity loss can be mainly attributed to the formation of the SEI layer on the electrode surface and presumably arises partly from electrolyte decomposition, partly from electrically disconnected particles due to the large volume changes [10], and perhaps also from Li atoms “trapped” in the electri-cally connected particles [32, 33]. Meanwhile, after cycling up to 40 cycles at 0.36 A·g –1, the porous silicon nanospheres anode retained a charge capacity of 2,650 mAh·g –1 (Fig. 3(b)), corresponding to about 89% of its initial charge capacity (3,015 mAh·g –1). Further-more, the coulombic efficiency remains near 100% after the first cycle, which means that the porous silicon nanospheres structure can enhance the coulombic efficiency of the electrode due to the increased number of active sites for reversible electrochemical Li storage[14]. A capacity of 950 mAh·g –1 after 500 cycles at a higher current density of 3.6 A·g –1 and good capacity retention were also attained, with the first three cycles activated at 0.72 A·g –1 (Fig. 3(e)). Some oscillations in the specific capacity values over several cycle periods could sometimes be observed (Fig. 3(e)), although neither the average value of the specific capacities, nor the ability for long cycling were affected. Such oscillations have sometime been observed in previous reports for not only Si anodes [34–36] but also for other kinds of electrode materials [37, 38]. The slight capacity oscillations might result from the temperature difference (between the inside of the cell and themeasurement environment—see Figs. S10 and S11 (inFigure 3 Electrochemical performances of spherical porous silicon anode. (a) Typical galvanastatic discharge–charge curves of the cellwith spherical porous silicon in the potential region of 0.005–1.5 V versus Li +/Li at a current density of 0.36 A·g –1. (b) Cycling property and coulombic efficiency of the cell with spherical porous silicon at the constant current density of 0.36 A·g –1. ■ as discharge capacity (Q d ), ● as charge capacity (Q c ) and ◆ as coulombic efficiency (Q c /Q d ). (c) The typical galvanastatic discharge–charge curves of spherical porous silicon at different current densities, and (d) the rate performance of a spherical porous silicon anode. (e) Cycling property at 3.6 A·g –1 for 500 cycles.the ESM) for temperature difference measurements), the surface conditions, the active sites of the sample and the SEI layer thickness [39]. The rate capability of the spherical porous Si anode was evaluated using galvanostatic charge–discharge measurements by increasing the current density froma low value of 0.36 A·g –1 to a high value of 18 A·g –1 and then back to 1.8 A·g –1 and 0.72 A·g –1 (shown in Figs. 3(c) and 3(d)). The discharge specific capacities were ~2,900, 2,600, 2,000, 1,500, 800 and 350 mAh·g –1 and the coulombic efficiencies were almost 100% at current densities of 0.36, 0.72, 1.8, 3.6, 7.2, and 18 A·g –1, respectively. It is worthwhile to note that the specific capacity reversibly recovers to approximately 1,800 mAh·g –1 once the current density goes back to 1.8 A·g –1 and then go back to about 2,450 mAh·g –1when the current density back to 0.72 A·g –1. The specific capacity is almost recovered, indicating an excellent rate performance of the silicon anode. The high electrochemical performance of the silicon may beattributed to its porous nanostructure [12, 40, 41] aswell as the presence of amorphous SiO 2 [10, 42, 43].The porous nanostructure offers a pathway for theefficient access of electrons and electrolytes, increasednumber of active sites and enhances the contact surfacebetween the electrode material and electrolyte. Fur-thermore, the presence of pores and amorphous SiO 2may effectively accommodate the volume changes ofsilicon and allow for facile strain relaxation without large mechanical stress during cycling. This should provide a new avenue for large-scale production of anode materials with high electrochemical performance. 4 ConclusionsPorous Si nanospheres have been hydrothermally synthesized based on the reduction of silica sol by magnesium metal in an autoclave at 180 °C. Moreover, besides silica sol, this hydrothermal process can be extended to the reduction of solid silica powders such as silica aerogel and silicic acid (hydrated silica). The porous Si nanospheres without any carbon coating exhibit excellent lithium-storage capacity, high-rate capability and long cycling performance, which may be attributed to the porous nanostructure as well asthe presence of amorphous SiO 2. Since the reactant is cheap, and the reaction conditions are relatively mild, this study should provide a new avenue for the large- scale production of silicon anode materials. AcknowledgementsThis work was supported by the 973 Project of China (No. 2011CB935901), and the National Natural Science Fund of China (Nos. 91022033, 21201158). Electronic Supplementary Material: Supplementary material is available in the online version of this article at /10.1007/s12274-014-0633-6. References[1] Su, X.; Wu, Q.L.; Li, J.C.; Xiao, X.C.; Lott, A.; Lu, W.Q.; Sheldon, B. W.; Wu, J. Silicon-based nanomaterials forlithium-ion batteries: A review. Adv. Energy Mater. 2014, 4, 1–23. [2] McDowell, M. T.; Lee, S. W.; Nix, W. D.; Cui, Y. Understanding the lithiation of silicon and other alloying anodes for lithium-ion batteries. Adv. Mater. 2013, 25, 4966–4985.[3] McDowell, M. T.; Ryu, I.; Lee, S.; Wang, W. C.; Nix, W. D.;Cui, Y. Studying the kinetics of crystalline silicon nanoparticlelithiation with in situ transmission electron microscopy. Adv.Mater. 2012, 24, 6034–6041.[4] Szczech, J. R.; Jin, S. Nanostructured silicon for high capacity lithium battery anodes. Energy Envir. Sci. 2011, 4, 56–72. [5] Armstrong, M. J.; O’Dwyer, C.; Macklin, W. J.; Holmes, J.D. Evaluating the performance of nanostructured materials as lithium-ion battery electrodes. Nano Res . 2014, 7, 1–62. [6] Li, S.; Li, A.; Zhang, R.; He, Y.; Zhai, Y.; Xu, L.Hierarchical porous metal ferrite ball-in-ball hollow spheres: General synthesis, formation mechanism, and high per-formance as anode materials for Li-ion batteries. Nano Res. 2014, 7, 1116–1127.[7] Cheng, J.; Che, R.; Liang, C.; Liu, J.; Wang, M.; Xu, J.Hierarchical hollow Li 4Ti 5O 12 urchin-like microspheres with ultra-high specific surface area for high rate lithium ion batteries. Nano Res. 2014, 7, 1043–1053.[8] Su, D.; Dou, S.; Wang, G. Mesocrystal Co 3O 4 nanoplateletsas high capacity anode materials for Li-ion batteries. Nano Res. 2014, 7, 794–803.[9] Nan, C.; Lu, J.; Li, L.; Li, L.; Peng, Q.; Li, Y. Size and shapecontrol of LiFePO 4 nanocrystals for better lithium ion battery cathode materials. Nano Res. 2013, 6, 469–477.[10] Wu, H.; Chan, G.; Choi, J. W.; Ryu, I.; Yao, Y.; McDowell,M. T.; Lee, S. W.; Jackson, A.; Yang, Y.; Hu, L.; Cui, Y. Stable cycling of double-walled silicon nanotube battery anodes through solid-electrolyte interphase control. Nat. Nanotechnol. 2012, 7, 310–315.[11] Yoo, J. K.; Kim, J.; Jung, Y. S.; Kang, K. Scalable fabricationof silicon nanotubes and their application to energy storage. Adv. Mater. 2012, 24, 5452–5456. [12] Jia, H.; Gao, P.; Yang, J.; Wang, J.; Nuli, Y.; Yang, Z.Novel three-dimensional mesoporous silicon for high power lithium-ion battery anode material. Adv. Energy Mater. 2011, 1, 1036–1039.[13] Xing, A.; Zhang, J.; Bao, Z. H.; Mei, Y. F.; Gordin, A. S.;Sandhage, K. H. A magnesiothermic reaction process for the scalable production of mesoporous silicon for rechargeable lithium batteries. Chem. Commun. 2013, 49, 6743–6745. [14] Lee, J. -I.; Lee, K. T.; Cho, J.; Kim, J.; Choi, N.-S.; Park, S.Chemical-assisted thermal disproportionation of porous silicon monoxide into silicon-based multicomponent systems. Angew. Chem. Int. Ed. 2012, 51, 2767–2771.[15] Yi, R.; Dai, F.; Gordin, M. L.; Chen, S.; Wang, D. Micro-sized Si-C composite with interconnected nanoscale building blocks as high-performance anodes for practical application in lithium-ion batteries. Adv. Energy Mater. 2013, 3, 295–300. [16] Chen, S. Q.; Bao, P. T.; Huang, X. D.; Sun,, B.; Wang, G.X. Hierarchical 3D mesoporous silicon@graphene nano-architectures for lithium ion batteries with superior per-formance. Nano Res . 2014, 7, 85–94.[17] Kim, H.; Seo, M.; Park, M. H.; Cho, J. A critical size ofsilicon nano-anodes for lithium rechargeable batteries. Angew. Chem. Int. Ed. 2010, 49, 2146–2149.[18] Ma, H.; Cheng, F. Y.; Chen, J.; Zhao, J. Z.; Li, C. S.; Tao, Z.L.; Liang, J. Nest-like silicon nanospheres for high-capacity lithium storage. Adv. Mater. 2007, 19, 4067–4070.[19] Chan, C. K.; Patel, R. N.; O’Connell, M. J.; Korgel, B. A.;Cui, Y. Solution-grown silicon nanowires for lithium-ion battery anodes. ACS Nano 2010, 4, 1443–1450.[20] Dai, F.; Yi R.; Gordin, M. L.; Chen, S.; Wang, D. AmorphousSi/SiO x /SiO 2 nanocomposites via facile scalable synthesis as anode materials for Li-ion batteries with long cycling life. RSC Adv. 2012, 2, 12710–12713.[21] Zhong, Y.; Peng, F.; Bao, F.; Wang, S.; Ji, X.; Yang, L.; Su,Y.; Lee, S.-T.; He, Y. Large-scale aqueous synthesis of fluorescent and biocompatible silicon nanoparticles and their use as highly photostable biological probes. J. Am. Chem. Soc. 2013, 135, 8350–8356.[22] Park, N. M.; Choi, C. J. Growth of silicon nanowires inaqueous solution under atmospheric pressure. Nano Res . 2014, 7, 898–902. [23] Liang, J. W.; Wei, D. H.; Lin, N.; Zhu, Y. C.; Li, X. N.;Zhang, J. J.; Fan, L.; Qian, Y. T. Low temperature chemical reduction of fusional sodium metasilicate nonahydrate into a honeycomb porous silicon nanostructure. Chem. Commun. 2014, 50, 6856–6859.[24] Alexander, M. R.; Short, R. D.; Jones, F. R.; Michaeli, W.;Blomfield, C. J. A study of HMDSO/O 2 plasma deposits using a high-sensitivity and -energy resolution XPS instrument: curve fitting of the Si 2p core level. ACS Appl. Surf. Sci. 1999, 137, 179–183. [25] Di Vona, M. L., Rosnati, V. Zinc-promoted reactions.Mechanism of the clemmensen reaction reduction of benzophenone in glacial acetic acid. J. Org. Chem. 1991, 56, 4269–4273.[26] Zhou, Y.; Jiang, X.; Chen, L.; Yue, J.; Xu, H.; Yang, J.;Qian, Y. Novel mesoporous silicon nanorod as an anode material for lithium ion batteries. Electrochim. Acta 2014, 127, 252–258.[27] Yen, Y.; Chao, S.; Wu, H.; Wu, N. Study on solid- electrolyte-interphase of Si and C-coated Si electrodes in lithium cells. J. Electrochem. Soc. 2009, 156, A95–A102.[28] Li, J.; Dahn, J. R.; An in situ X-ray diffraction study of thereaction of Li with crystalline S. J. Electrochem. Soc. 2007, 154, A156–A161.[29] Chan, C. K.; Peng, H.; Liu, G.; McIlwrath, K.; Zhang, X.;Huggins, R. A.; Cui, Y. High-performance lithium battery anodes using silicon nanowires. Nat. Nanotechnol. 2008, 3, 31–35.[30] Maranchi, J. P.; Hepp, A. F.; Kumta, P. N. High capacity,reversible silicon thin-film anodes for lithium-ion batteries. Electrochem. Solid-State Lett. 2003, 6, A198–A201.[31] Netz, A.; Huggins, R. A.; Weppner, W. The formation andproperties of amorphous silicon as negative electrode reactant in lithium systems. J. Power Sources, 2003, 119, 95–100. [32] Lu, J.; Nan, C.; Li, L.; Peng, Q.; Li, Y. Flexible SnS nano-belts: Facile synthesis, formation mechanism and application in Li-ion batteries. Nano Res. 2013, 6, 55–64.[33] Song, T.; Han, H.; Choi, H.; Lee, J; Park, H.; Lee, S.; Paek,W; Kim, S; Liu, L; Paik, U. TiO 2 nanotube branched tree on a carbon nanofiber nanostructure as an anode for high energy and power lithium ion batteries. Nano Res. 2014, 7, 1–11. [34] Cho, J. H.; Picraux, S. T. Enhanced lithium ion batterycycling of silicon nanowire anodes by template growth to eliminate silicon underlayer islands. Nano Lett. 2013, 13, 5740–5747.[35] Wang, B.; Li, X.; Qiu, T.; Luo, B.; Ning, J.; Li, J.; Zhang, X.;Liang, M.; Zhi, L. High volumetric capacity silicon-based lithium battery anodes by nanoscale system engineering. Nano Lett. 2013, 13, 5578–5584.[36] Wu, H.; Yu, G.; Pan, L.; Mctthew, M. T.; Bao, Z.; Cui, Y.;Stable Li-ion battery anodes by in-situ polymerization of conducting hydrogel to conformally coat silicon nanoparticles. Nat. Commun. 2013, 4, 1943.[37] Sun, Y.; Hu, X.; Luo, W.; Xia, F.; Huang, Y. Reconstructionof conformal nanoscale MnO on graphene as a high -capacity and long -life anode material for lithium ion batteries. Adv. Funct. Mater. 2013, 23, 2436–2444.[38] Liang, J.; Wei, D.; Cheng, Q.; Zhu, Y. Li, X.; Zhang, J.;Fan, L.; Qian, Y. Stable cycling of Fe 2O 3 nanorice as an anode through electrochemical porousness and the solid- electrolyte interphase thermolysis approach. ChemPlusChem 2014, 79, 143–150.[39] Cho, J. H.; Picraux, S. T. Silicon nanowire degradation andstabilization during lithium cycling by SEI layer formation. Nano Lett. 2014, 14, 3088–3095.[40] Zhou, X. S.; Cao, A. M.; Wan, L. J.; Guo, Y. G. Spin-coatedsilicon nanoparticle/graphene electrode as a binder-free anode for high-performance lithium-ion batteries. Nano Res. 2012, 5, 845–853.[41] Wang, X.; Liu, B.; Hou, X.; Wang, Q.; Li, W.; Chen, D;Shen, G. Ultralong-life and high-rate web-like Li 4Ti 5O 12 anode for high-performance flexible lithium-ion batteries. Nano Res., 2014, 7, 1073–1082.[42] Sim, S.; Oh, P.; Park, S.; Cho, J. Critical thickness of SiO 2coating Layer on Core@Shell Bulk@Nanowire Si anode materials for li-ion batteries. Adv. Mater. 2013, 25, 4498– 4503.[43] Nara, H.; Yokoshima, T.; Momma, T.; Osaka, T. Highlydurable SiOC composite anode prepared by electrodeposition for lithium secondary batteries. Energy Environ. Sci. 2012, 5, 6500–6505.。