MAVERIC An Autonomous Balloon System for Mars Exploration

- 格式:pdf

- 大小:158.74 KB

- 文档页数:5

DEVELOPMENT OF AN AUTONOMOUS AERIAL RECONNAISSANCE SYSTEM AT GEORGIA TECHEric N. Johnson*, Mathew G. Hart, Henrik B. ChristophersenSchool of Aerospace EngineeringGeorgia Institute of TechnologyAtlanta, GA 30332-0150/labs/gtarA BSTRACTThe Georgia Tech Aerial Robotics (GTAR) team has developed a system to compete in the International Aerial Robotics Competition, organized by the Association for Unmanned Vehicle Systems, International. The contest mission is divided into four levels. Level 1 is characterized by the need to fly an air vehicle under autonomous control for a distance of 3 kilometers. Level 2 requires an autonomous system to identify a building and open portals. Level 3 requires an autonomous system to enter a building and return a picture. Level 4 requires all levels to be completed by an autonomous system within 15 minutes. Each mission level must be completed before moving on to the next. In 2001, the team completed the first level of the overall mission, outperforming all other entrants and taking the lead in the contest, described here. In addition the GTAR approach to all levels of the contest mission is described.________________*Lockheed Martin Assistant Professor of Avionics Integration, Member AIAA.E-mail: Eric.Johnson@Copyright © 2002 by the authors, Published by the American Instituteof Aeronautics and Astronautics, Inc., with permissionI NTRODUCTIONThe Georgia Tech Aerial Robotics (GTAR) team consists of a multi-disciplinary group of students, from Electrical and Computer Engineering, Aerospace Engineering, and College of Computing, including both graduate and undergraduate students. The GTAR team has developed a system to compete in the International Aerial Robotics Competition, organized by the Association for Unmanned Vehicle Systems, International. The contest mission is divided into four levels. Level 1 is characterized by the need to fly an air vehicle under autonomous control for a distance of 3 kilometers. Level 2 requires an autonomous system to identify a building and open portals (windows and doors) by visual reference. Level 3 requires an autonomous system (not necessarily the same one used for Levels 1 or 2) to enter the building and return a picture of a required object from the building interior. Level 4 requires all levels to be completed by an autonomous system, possibly consisting of sub-vehicles, in 15 minutes. Each mission level must be completed before moving on to the next. The team has developed a multi-year strategy to complete all levels and the overall mission. This paper summarizes the approach taken, past results, and the current status of the project.A PPROACHAn initial assessment of the mission and the associated levels brings out the conflicting requirements on the autonomous system. It must travel long distances and be small enough to enter a 1 m by 1 m portal. One solution is a multiple component system, consisting of a primary air vehicle and one or moresecondary, possibly multi-mode (travel both on ground and through the air) vehicles. Here, the overall approach to the final mission consists of three stages:•Flight to designated site and identification of the building and an open portal•Delivery of sub-vehicle(s) through the portal •Search operations inside building to locate the required objectTwo options are being kept open for the overall mission: (1) a two-component system with a primary air vehicle and a secondary multi-mode vehicle that enters the building, and (2) a multi-component system with a primary air vehicle and secondary (redundant) multi-mode vehicles, which attempt to enter the building. These approaches are shown schematically in Figure 1.Inside BuildingFigure 1. Schematic of level 4 missionapproachA primary vehicle for the mission should have a reasonably high forward speed in order to cover the 3 km distance with the maximum possible time left to accomplish other objectives. For example, a 60 km/hr speed would require 3 minutes to complete the straight-line distance, and is considered a desirable minimum speed. At the same time, a vehicle that could hover or even land near the building would be well suited for delivering a sub-vehicle. A trade-off exists between complexity of the vehicle and complexity of the delivery process. Irrespective of the vehicle choice, it must have a considerable useful payload capability in order to carry a sub-vehicle to its delivery point. A fixed-wing aircraft offering superior speed and payload capabilities, with its inherent stability and simplicity has been chosen over a rotary-wing craft as the primary air vehicle. The added complexity of attaining an autonomous hover would be greater than the complexity of delivering a gliding sub-vehicle into an open window or door.The mode of the sub-vehicle delivery into the building is under consideration. The primary air vehicle system will provide estimated locations for building portals, and the sub-vehicle guidance is anticipated to be optical. Components of the sub-vehicle must then fly and/or drive within the building to obtain the required images. The option of deploying multiple sub-vehicles may be desirable for redundancy, to achieve an acceptable probability of completing the mission on a given attempt.P RIMARY A IR V EHICLEThe primary air vehicle is decomposed into: the basic air vehicle (including structural, aerodynamic, and propulsion elements); a guidance, navigation, and control subsystem; an image processing subsystem; a mission manager; and a power distribution subsystem. These subsystems are motivated and described below. This component of the overall system has been built and operated.A IR V EHICLEOur primary air vehicle is based on a commercial-off-the-shelf (COTS) quarter-scale Piper Cub kit donated by Sig Manufacturing, Figure 2. The large interior, inherent stability, and large wing area makes it desirable, maximizing reliability and minimizing the necessary effort to achieve autonomous flight. The large interior meets our requirements for carrying the necessary electronics. A Zenoah G-23 two-stroke gasoline engine powers the plane. Because the plane is a scale kit, designed to look and fly like the full-scale airplane, a few modifications were made during its construction.•Load bearing members of the wing werereinforced in consideration of futureheavy payloads. The plane will eventuallycarry its own autopilot as well as a subvehicle with video equipment.•Wing dihedral was increased slightly foradded stability.•Hardpoints were installed in the wing tomount the sub vehicle.•Solid fuselage formers were hollowed outto increase interior payload volume.•Material was added in several places inthe fuselage for mounting of electronics.•Copper foil was added to isolate theelectronics from the engine’s ignition.•Fuselage paneling was converted intoaccess hatches for installed electronics.•The superfluous cowling was discarded.Figure 2. Quarter scale Piper J-3 Cub,equipment installedG UIDANCE, N AVIGATION, AND C ONTROLTo accomplish the mission objectives, for levels 1, 2, and 4, our primary vehicle must perform autonomous Guidance, Navigation, and Control (GN&C) functions, for flight distances of more than 3 km. In addition, position and attitude estimates available for image processing functions must be sufficiently accurate and updated with sufficient frequency to accomplish the level 2 and 4 missions. We have also derived a requirement that manual control of the vehicle must be available, to: (1) support a flight test program of the vehicle, (2) to enable manual take-off and landing of the vehicle during any normal mission, and (3) as a backup in case of failure of the autonomous GN&C subsystem. The GN&C subsystem must be able to fly to a flight plan consisting of waypoints. This flight plan must be updateable in flight, from a ground controller (Level 1 and to support flight test) or from an image processing and mission planning subsystem (Levels 2 and 4).To meet these requirements, we utilize a MicroPilot MP20002 autopilot and sensors onboard the vehicle, a Freewave wireless modem link to the ground, NovAtel GPS reference station (the reference station has not yet been implemented), and a laptop computer on the ground. This architecture is illustrated in Figure 3, where onboard and ground-based components have been delineated.Figure 3. Autonomous guidance,navigation, and control architecturefor primary air vehicleThe MP2000 is a miniature, low cost autopilot. Its capabilities include airspeed hold, altitude hold, turn coordination, and GPS navigation. Data logging and manual overrides are supported. All feedback loop gains and flight parameters are user programmable. Our MP2000 is configured with a GPS receiver, 3 rate gyros, a single-axis magnetometer/compass, a static pressure sensor, and a total pressure (i.e., airspeed) sensor. The MP2000 utilizes a 68332 processor2.I MAGE P ROCESSINGFor the level 2 and 4 missions, the image processing and mission management subsystems will receive input from the onboard processor, giving estimates for primary air vehicle position and attitude. We anticipate that some of these functions may be located on the ground, where inputs of vehicle position and attitude (and perhaps other information) will be received from the ground control laptop computer.To accomplish level 2 and 4 missions, the primary air vehicle vision systems are responsible for locating the building and the open portals. In order to fix thelocation, vision systems interface with GN&C to obtain air vehicle co-ordinates. After the acquired image is tagged with the necessary vehicle state information, it is passed on to the Target Acquisition Module (TAM). TAM is composed of three sub-modules: edge detector, morphing, and statistical pattern matching. The template used determines which target is currently being acquired.The primary air vehicle flies a pattern around the building determined by the mission management subsystem. The TAM is now operating in the “Portal Identification” mode. The template is now a rectangle with sides greater than one meter. The co-ordinates of any positive matches are recorded and also passed on to the mission management module.S UB-V EHICLEThe Level 3 and 4 missions require the collection of visual information from within a building structure. An autonomous vehicle must be able to navigate inside the building, capture images of desired objects and transmit these images to monitoring personnel at the launch site up to 3 km away. Work on an initial prototype has been initiated. A general strategy for the development sub-vehicle is described below.1. Build a multi-mode (ground and air) robot, whichcan perform the required tasks without beingoverly concerned with the problems of deliverywithin the building.2. Optimize the sub-vehicle for minimum cost, size,and weight.3. Develop a system for delivering the robot into thebuilding.4. Modify the primary air vehicle for delivery thesub-vehicle(s).RESULTS FROM LEVEL 1(2001)Our team was formed on February 19, 2001 with a kickoff meeting at Georgia Tech. The team set of goal of achieving Level 1 for the 2001 contest year. The contest itself for the 2001 year occurred July 22, at Webster Field in Maryland. Also at this meeting, the team selected a fixed wing vehicle to accomplish this objective. The team was able to coordinate sponsors for the engine, airplane kit, and our onboard computer and sensors. A considerable amount of equipment was also available from previous GTAR teams, most notably batteries and a wireless serial modem pair.The first flight of the equipped aircraft took place in early July, with all equipment installed. This was the first flight of a new aircraft, so no attempt was made to even power the installed autopilot.Flight #2 took place July 12. This was the first flight with all avionics powered, but not given control of the aircraft. Raw sensor data was evaluated. However, the aircraft was damaged on landing.Flight #3 took place July 15, and was the first flight in which the autopilot was given control of the aircraft. Unfortunately, the aircraft suffered damage once again.Flights #4-6 took place July 21. In these flights the attitude hold autopilot was tuned. However, a bug was found in the barometric altimeter decoding, which made the data unusable. As a result, not further testing was possible until an update was made to the MP2000 software.Fight #7 took place July 22 during the International Aerial Robotics Competition. On this flight, altitude hold and heading hold modes were tested, and no tuning was necessary.Flight #8 also took place July 22 during the competition. This flight was our first attempt of the Level 1 mission. However, the flight plan was notproperly loaded on the attempt.Figure 4. A picture of the GTAR UAVapproaching for landing after flight #8Flight #9 also took place July 22 during the competition. This flight tested the waypoint followingmode of the autopilot. The switch was made to the autopilot after takeoff. We returned to manual flight after the Level 1 mission was accomplished. A 3-D plot of the recorded GPS position data from the flight is illustrated in Figure 5. Note that the 3km course cuts back on itself, ending near where it starts. Also, the level 1 mission ends by flying in a circle around the final waypoint, seen in the Figure. Some statistics about the portion of the flight that was under automatic control (autopilot on):• Distance Traveled: 3.1 mi or 4.9 km • Time: 3 min 9 sec• Average Speed: 58 mph or 93 kph• Maximum Distance from Ground Station: ½ mi or 0.8 km• Average Altitude: 397 ft or 121 m38.L a t i tu d eA l t i t u d eAutomatic Flight Manual Takeoff/LandingUnder Automatic Flight:Distance Traveled: 3.1 mi / 4.9 km Time: 3 min 9 secAverage Speed: 58 mph / 93 kphMax Distance from Ground Station: ½ mi / 0.8 km Average Altitude: 397 ft / 121 mFigure 5. Plot of Flight #9, completing the Level 1 international aerial roboticscompetition missionP LANS FOR 2002The team has set the goal of achieving the Level 2 mission in 2002. Current work includes add a Video Camera, Video Link, and Image Processor to our aircraft. We are also addressing a switch from a single-antenna GPS to a differential-GPS unit, to achieve position accuracies necessary for the Level 2 mission. A considerable effort is currently going into the image processing subsystem, and the design of a delivery system, to deliver a sub-vehicle into an entry point of the building.ACKNOWLEDGEMENTSThe authors would like to acknowledge the generous financial and technical assistance of our sponsors: Sig Manufacturing Co., Inc., The Lockheed Martin Corporation, MicroPilot (a division of Loewen Aviation Ltd.), Bahr Avionics, NovAtel Inc, and Texas Instruments. We also acknowledge other contributing team members, including: Manuj Dhingra, Richard Giuly, Jin Cheol Ha, Nikolaos Vasiloglou, and the many new members for 2002.R EFERENCES1Michelson, R., Rules For The AD2001 International Aerial Robotics Competition Qualifier , /AUVS/CurrentIARC/Future EventInfo.html, 2001. 2MP1000/MP2000 Installation and Operation , MicroPilot, 2001.。

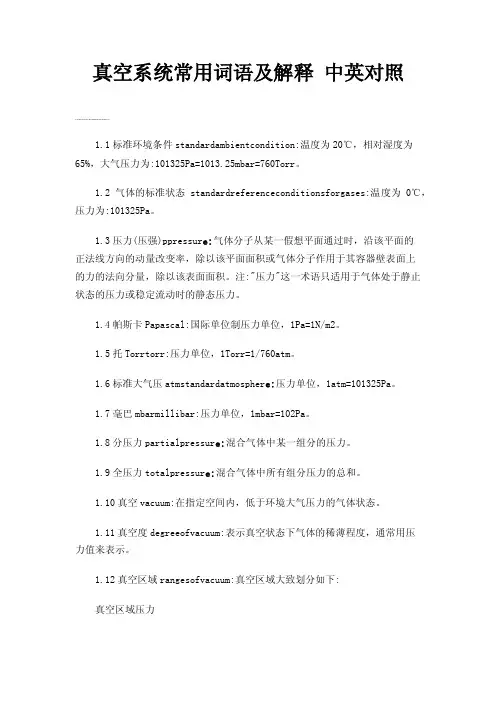

真空系统常用词语及解释中英对照0001.1标准环境条件standardambientcondition:温度为20℃,相对湿度为65%,大气压力为:101325Pa=1013.25mbar=760Torr。

1.2气体的标准状态standardreferenceconditionsforgases:温度为0℃,压力为:101325Pa。

1.3压力(压强)ppressur e:气体分子从某一假想平面通过时,沿该平面的正法线方向的动量改变率,除以该平面面积或气体分子作用于其容器壁表面上的力的法向分量,除以该表面面积。

注:"压力"这一术语只适用于气体处于静止状态的压力或稳定流动时的静态压力。

1.4帕斯卡Papascal:国际单位制压力单位,1Pa=1N/m2。

1.5托Torrtorr:压力单位,1Torr=1/760atm。

1.6标准大气压atmstandardatmospher e:压力单位,1atm=101325Pa。

1.7毫巴mbarmillibar:压力单位,1mbar=102Pa。

1.8分压力partialpressur e:混合气体中某一组分的压力。

1.9全压力totalpressur e:混合气体中所有组分压力的总和。

1.10真空vacuum:在指定空间内,低于环境大气压力的气体状态。

1.11真空度degreeofvacuum:表示真空状态下气体的稀薄程度,通常用压力值来表示。

1.12真空区域rangesofvacuum:真空区域大致划分如下:真空区域压力PaTorr低真空105~102760~1中真空102~10-11~10-3高真空10-1~10-510-3~10-7超高真空〈10-5〈10-71.13气体gas:不受分子间相互作用力的约束且能自由地占据任意空间的物质。

汪:在真空技术中,"气体"一词不严格地应用于非可凝气体和蒸汽。

1.14非可凝气体non-condensablegas:在临界温度以上的气体,即单纯增加压力不能使其液化的气体。

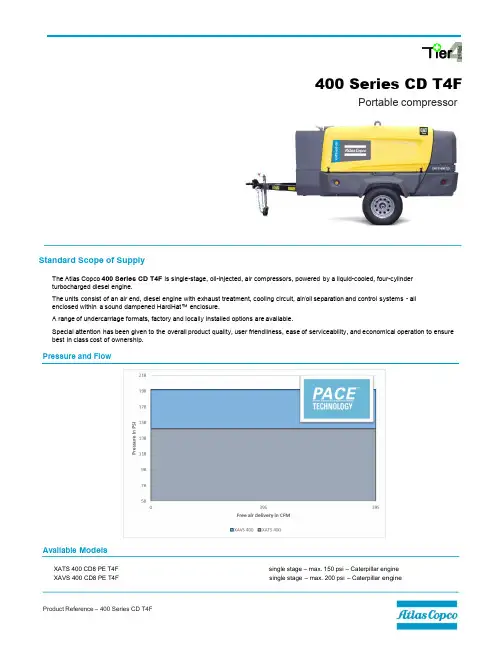

400 Series CD T4FPortable compressorStandard Scope of SupplyThe Atlas Copco 400 Series CD T4F is single-stage, oil-injected, air compressors, powered by a liquid-cooled, four-cylinder turbocharged diesel engine.The units consist of an air end, diesel engine with exhaust treatment, cooling circuit, air/oil separation and control systems - all enclosed within a sound dampened HardHat™ enclosure.A range of undercarriage formats, factory and locally installed options are available.Special attention has been given to the overall product quality, user friendliness, ease of serviceability, and economical operation to ensure best in class cost of ownership.Pressure and FlowAvailable ModelsXATS 400 CD8 PE T4F single stage – max. 150 psi – Caterpillar engine XAVS 400 CD8 PE T4F single stage – max. 200 psi – Caterpillar engi neCaterpillar T4F engine Meets all current T4F emission regulations.Integrated exhaust aftertreatment makes T4F integration easyExtended warranty available through Caterpillar dealerAtlas Copco Controller XC2003 PACEPressure Adjusted through Cognitive Electronics Proven controller for easy operation and diagnostics of the compressor and engine.Allows operator to view compressor parameters including:Pressure setting, reading engine codes, two programmable service timers, all temperatures and pressures of compressor, fuel levels and consumptions, and load/unload compressor.Cold Weather Package Improved cold weather starting, includes synthetic compressoroil &Spillage Free Containment Frame(Standard XAVS, Optional XATS)Protects environment, avoids costly clean up liabilityLow Fuel Shutdown Reduces downtime on site when operator runs out of fuel asthere is no longer a need to “re-prime” the fuel systemHeavy Duty Single Axle Trailer w/ 15" tires Well balanced for safer towing or moving around siteHigh ground clearance for rough site and road conditionsHardHat TM heavy duty ¼” polyethelene enclosure Dent and UV ResistantKeeps looking new for longer and adds to resale valueClick here to watch our HardHat video onlineAftercooler, water separator w/ filters (Standard XAVS) Provides cool, dry, clean air for applications where instrument quality air is required.Optional Features BenefitsSpecial color doors (white only) Alternative to standard yellow door color schemeTechnical Data1 According to ISO 1217 ed.3 1996 annex D2 Measured in accordance with ISO 2151 under free field conditions @ 7m distance3 Consult Atlas Copco for proper de-rating instructions for operation beyond ambient limitations4 According to DIN 72311Support mountedWeight (Wet - Ready-to-operate)XATS 400 CD8 PE T4FXAVS 400 CD8 PE T4F Trailer mounted lb (Kg) 4620 (2095) Support mounted lb (Kg) 4528 (2053)DimensionsXATS 400 CD8 PE T4FXAVS 400 CD8 PE T4F Trailer mounted (Inches) L x W x H 158 ¾ x 72 x 77 ¾ Support mounted (Inches) L x W x H 113 x 72 x 72Caterpillar C4.4 T4F turbo charged four-cylinder, liquid-cooled diesel engine provides ample power to operate the compressor continuously at full-load.Meets all US EPA and Environment Canada exhaust legislations with Final Tier 4 compliance.US EPA engine family is “HPKXL04.4MT1” and rated at 148hp at 2200 rpm, in accordance to SAE Standard for the XATS 400 CD8 PE T4F. US EPA engine family is “HPKXL04.4MT1” and rated at 148hp at 2200 rpm, in accordance to SAE Standard for the XAVS 400 CD8 PE T4F.Engine starting capacity at 14°F (-10°C) without the addition of cold start options. Cold start options are available up to -4°F (-20°C).The 52Gal (192L) fuel tank enables operation for over 8 hours at full load and comes standard with a low fuel shutdown at 5%.Emissions TreatmentCaterpillar C4.4 T4F engine after treatment consists of a Diesel Oxidization Catalyst (DOC) and Selective Catalytic Reduction (SCR).Electrical SystemThe 400 Series CD T4F is equipped with a 12 Volt negative ground electrical starting syste m .InstrumentationThe instrument control panel is located on the back, curbside of the compressor canopy with easy access.Standard instrument package includes fully diagnostic ECU controller with large 3.5” display. The intuitive Atlas Copco XC2003 controller is easy to operate with all functions conveniently at your fingertips. The controller also manages the engine ECU operating system, and a number of safety warnings, shut downs on various parameters (listed below) and full digital pressure control with PACE.XC2003 Controller Functionality:Displayed while running - Hours - Fuel level - RPM - Outlet pressure Operational Buttons- Start and stop of the unit - View measurements, settings and alarms - Multi position cursor to navigate menus - PACE digital pressure controlCompressor measurements displayed- Running hours - Fuel level - Clock - Battery voltage - Running hours - Regulating pressure - Emergency stop count - Average fuel consumption - Minor/major service counters in hours and daysEngine measurements displayed- Fuel consumption per hour tally - Engine coolant temperature - Engine oil pressure - Engine RPMWarnings and Shutdowns- High temperature engine coolant - High temperature compressor oil - Engine oil pressure - Low fuel level - Low coolantAlarms- View current & historical alarms present- History of last 20 alarms and events with timeand date stamps- DM1 & DM2: View current engine codes(SPN/FMI)Settings- Reset service timers - Diagnostics for engine ECU - Language settings - Unit of measure changes - Electronic pressure adjustment (PACE ) - Presetting two (high/low) pressure settingBodywor kHardHat™: Our HardHat™ version comes standard with dual wall, ¼” thick, Polyethylene material providing superior corrosion, and UV protection against fading and discoloration. As well as unmatched dent and damage resistance. The canopy is sound attenuated to meet the most current legal noise requirements. A clamshell style hood offers easy service access to all co mponents. Undercarriage & FrameThe 400 Series CD T4F compressors are available with two undercarriage alternatives, providing utmost flexibility in installation or towing require m ents.Single axle trailer setup with:DOT approved light packageAdjustable height pintle hitch (3” lunette)5,200 lbs torsional axle15” Rims w/ ST225/75D15 8 Ply Tires (weight rating 2,540 lbs @ 65psi)Electric trailer brakes as standard (with 7 pin flat blade connector)750lbs jack leg stand, with wheelSupport mo unted version, on steel frame, less undercarriage is availableFactory Options AvailableSkid mountedLoose Ball Couplings 2” or 2-5/16” and Loose Bulldog 2” couplingOSHA ¾” valveAftercooler & Water Separator (optional XATS only)Aftercooler & Water Separator & DD/PD coalescing & high efficiency filters (Standard XAVS, optional XATS only)Special color canopy doorsLojack anti-theft deviceManufacturing & Environmental StandardsThe 400 Series CD T4F are manufactured following stringent ISO 9001 regulations, and a fully implemented Environmental Management System fulfilling ISO 14001 require m ents.Attention has been given to ensure minimum negative impact to the environ ment.The 400 Series CD T4F meets all current EPA and Environment Canada exhaust and noise emission dir ectives.Supplied Do cu men t ationThe unit is delivered with documentation regarding:Hard copies of the Atlas Copco Operators Safety and Instruction Manual, Caterpillar Engine Operators Manual, as well as electronic copies, available upon request.Warranty Registration card for Caterpillar Engine and Atlas Copco Compressor (Units must be registered upon receipt).Test certificate for air delivery pressure and capacity, acc. ISO 1217 (Upon request only).Certificate for air/oil separator vessel and safety valve approval, ASME (Upon request only).Warranty Co verag eCaterpillar Engine: Caterpillar Diesel engines are warranted to be free from defects with regard to materials and workmanship for the period of twelve (12) months from the date of initial startup without limitation in running hours or for the period of thirty six (36) months from the date of initial startup prior to the accumulation of 4000 running hours.Atlas Copco Compressor: Warrantied to be free from defects with regard to material and workmanship for the period of eighteen (18) months from date of shipment from the factory, or twelve (12) months from date of initial start-up, whichever occurs first, withoutlimitation of running hours.Air compressor element assemblies used in Atlas Copco portable air compressors, is warranted to be free from defects with regard to materials and workmanship for the period of thirty (30) months from date of shipment from the factory, or twenty four (24) months from date of initial start up, whichever occurs first, without limitation of running hours. Atlas Copco service kits including parts and oils (PAR Oil’s) must be used to maintain warranty. Failure to register warranty upon initial start-up may cause warranty claim delays or rejection of claims.。

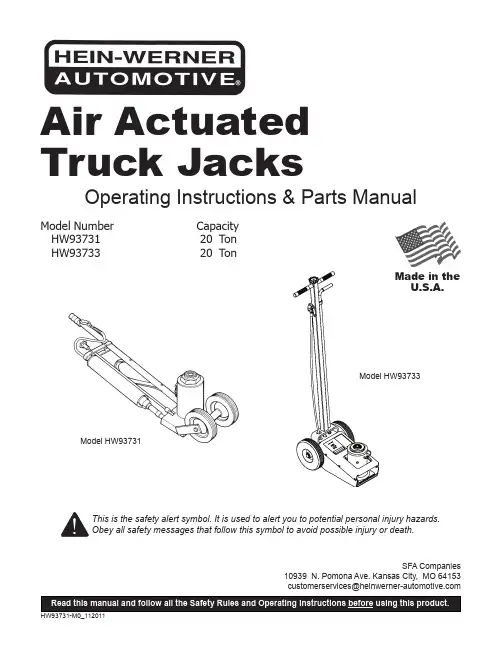

Operating Instructions & Parts ManualSFA Companies10939 N. Pomona Ave. Kansas City, MO 64153******************************************Model Number HW93731 HW93733Air Actuated Truck JacksCapacity 20 Ton 20 TonThis is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death.Model HW93731Model HW93733Made in the U.S.A.SAFETY AND GENERAL INFORMATIONSave these instructions. For your safety, read, understand, and follow the information provided with and on this jack. The owner and operator shall have an understanding of this jack and safe operating procedures before attempting to use. The owner and operator shall be aware that use and repair of this product may require special skills and knowledge. Instructions and safety information shall be conveyed in the operator's native language before use of this jack is authorized. If any doubt exists as to the safe and proper use of this jack, remove from service immediately.Inspect before each use. Do not use if broken, bent, cracked, or damaged parts (including labels) are noted. Any jack that appears damaged in any way, operates abnormally or is missing parts, shall be removed from service immediately and the manufacturer notified. If you suspect that the jack was subjected to a shock load (a load dropped suddenly, unexpectedly upon it), immediately discontinue use until the jack has been checked by a Hein-Werner authorized service center (contact distributor or manufacturer for list of Authorized Service Centers). It is recommended that an annual inspection be done by qualified personnel. Replace worn or damaged parts and assemblies with Hein-Werner authorized replacement parts only (see Replacement Parts, pages 6 thru 11).PRODUCT DESCRIPTIONHein-Werner Air Actuated Hydraulic Truck Jacks are designed to lift, but not support, rated capacity loads. They are designed to be used vertically. Immediately after lifting, loads must be supported by appropriate mechanical means (as opposed to hydraulic means), such as a pair of appropriately rated jack stands.WARNING: NEVER use a hydraulic jack as a stand-alone device. After lifting, immediately support the vehiclewith a pair of appropriately rated stands.! CAUTION! WARNINGNOTICESIGNAL WORDSIndicates situation which, if not avoided, will result in death or serious injury Indicates situation which, if not avoided, could result in death or serious injury Indicates situation which, if not avoided, could result in minor or moderate injuryIndicates situation which, if not avoided, could result in damage to propertySPECIFICATIONSFigure 1 - Model HW93731 NomenclatureModel HW93731Rated Load Capacity 20 tons (40,000 lbs)Low Pick Up Height 9-1/2"High Lifting Point 17-1/2"Power Raise 5-1/2"Screw Extension 2-1/2"Base Size 8" x 5-1/2"Ram Diameter 2-3/16"Handle Length 50"Wheel Diameter 6"Max. Air Pressure Supply 150 psiRequired Air Pressure For Lifting Loads140 psi for 40,000 lb.125 psi for 35,400 lb.100 psi for 27,900 lb.75 psi for 19,700 lb.Model HW93733Rated Load Capacity20 tons (40,000lbs)Low Height9"High Height With Extension 19-3/4"Screw Extension 4 3/4"Lift Cap Diameter 2"Wheel Diameter 8"Chassis Overall Length 20"Width at Wheels 13-1/4"Handle Length 45"Base Size8" x 17"Max. Air Pressure Supply 150 psi Typical Operating Pressure 125 - 150 psi Typical Lift Time - Full Raise (20 ton, 150 psi)2 min. 15 secFigure 2 - Model HW93733 NomenclatureHydraulic UnitValve KnobSaddleLift Control ValvePREPARATION1. Verify that the product and the application are compatible, if in doubt contact Hein-Werner Technical Service (816) 891-6390.2. Read the operator's manual completely and familiarize yourself thoroughly with the product and its components, and recognize the potential hazards associated with its use before using this product.3. To familiarize yourself with the basic operation of the jack, locate and turn the release valve knob:a. Clockwise until firm resistance is felt to further turning.This is the ‘CLOSED’ release valve position used to raise the load.b. Counter-clockwise, but no more than 1/2 full turn fromthe closed position. This is the ‘OPEN’ release valve position used to lower the load. The more you turn the release valve knob counter-clockwise, the faster the load descends.4. Locate and remove the oil filler screw (ref. part #13 for Model HW93731, part #24 for Model HW93733, in replacement parts section) with ram fully retracted. This will help release any pressurized air which may be trapped within the reservoir. Check oil level. Proper oil level should be just below the rim of oil filler hole.Model HW93731 A ir Bleeding - A rrow indicates approximate Air Vent Screw location.5. Reinstall oil filler screw.6. For Model HW93733, remove the shipping plug and install with air line elbow to reservoir (ref. part #47 in replacement parts section).7. Remove the plastic plug from air supply inlet and install a 1/4” PT air coupler (not provided). To ensure dependable, trouble free operation, an inline air dryer and oiler is recommended.NOTICE:Ensure that thread tape or compound is used when servicing connections.8. Pour a teaspoon of good quality air tool lubricant, such as #630-AAA Lubriplate, into the air supply inlet of the lift control valve. Connect to adequate air source and operate for 3 seconds to evenly distribute lubricant.9. Ensure that jack rolls freely. Raise and lower the unloaded saddle throughout the lifting range before putting into service to ensure the pump operates smoothly. Replace worn or damaged parts with Hein-Werner replacement parts only. Lubricate as instructed in Maintenance Section.OPERATIONLiftingNOTICE:Loosen the filler screw before use.1. Connect air source to the air supply inlet.2. Follow the vehicle manufacturer’s recommended guidelines for lifting. Engage the emergency brake and chock each unlifted wheel in both directions to prevent inadvertent vehicle movement.3. Locate and close the release valve by turning the release valve knob clockwise until firm resistance is felt.4. Refer to the vehicle manufacturer owner’s manual to locate approved lifting points on the vehicle. Center jack saddle under lift point.5. Verify lift point, squeeze the lift control valve until saddle contacts load. To lift, continue squeezing the lift control. Release the grip on the lift control valve when load reaches desired height.6. Immediately transfer the load to appropriately rated jack stands.WARNING: Overloading may cause hydraulicsystem failure.LoweringWARNING: Clear all tools and personnel beforelowering vehicle. Open the release valve slowly.Maintain control of speed at which the loaddecends at all times.1. Raise load high enough to clear the jack stands; then remove jack stands.2. Slowly turn release valve knob counter-clockwise, but no more than 1/2 turn. If the load fails to lower:a. Use another jack to raise the vehicle high enough toreinstall jack stands.b. Remove the malfunctioning jack and then jackstands.c. Using the non-malfunctioning jack, lower the load.3. After removing jack from under load, push saddle down to reduce ram exposure to rust and contamination.MAINTENANCENOTICE: Use only quality hydraulic jack fluid. Avoid mixing different types of fluid and never use brake fluid, turbine oil, transmission fluid, motor oil or glycerin. Improper fluid can cause failure of the jack and the potential for sudden and immediate loss of load. Hein-Werner hydraulic jack oil HW93291 or equivalent is recommended.Adding Fluid1. With saddle fully lowered, set jack in its upright, level position. Locate and remove oil filler screw. It may be necessary to remove cover plate on model HW93733.2. Fill with hydraulic fluid until just below the rim of the oil filler hole. Reinstall oil filler screw.Changing FluidNOTICE: For best performance and longest life, completely replace fluid supply annually.1. With saddle fully lowered, and pump piston fully depressed, remove oil filler screw. It may be necessary to remove cover plate on model HW93733.2. Lay the jack on its side and drain the fluid into a suitable container.NOTICE: Dispose of hydraulic fluid in accordance with local environmental regulations.3. Set jack in its level, upright position and fill with fluiduntil just below the rim of the oil filler hole. Reinstall the oil filler screw.Lubrication1. A periodic coating of light lubricating oil to pivot points,axles and hinges will help to prevent rust and assure that wheels move freely and the pump functions smoothly.2. When used on a daily basis, air pump should beinternally lubricated before each use. Use only good quality air tool lubricant such as #630 - AAA Lubriplate.If no inline oiler is used, pour a teaspoon of air tool oil into the inlet of the air control valve. Simply operate the jack using the air feature in order to fully distribute the oil.CleaningPeriodically inspect the ram for signs of rust or corrosion. Clean as needed and wipe with an oily cloth.NOTICE: Never use sandpaper or abrasive material on these surfaces.StorageWhen not in use, store the jack with ram fully retracted. REPLACEMENT PARTS(refer to page 6 thru 11)Not all components of the jack are replacement items, but are illustrated as a convenient reference of location and position in the assembly sequence. When ordering parts, give model number, part number and part description. Call or write for current pricing: Hein-Werner Customer Support, 10939 N. Pomona Ave., Kansas City, MO 64153. Phone: (816) 891-6390; E-mail: customerservices@ TROUBLESHOOTINGSymptom Possible Causes Corrective ActionJack will not lift load • Release valve not tightly closed• Overload condition• Air supply inadequate• Ensure release valve tightly closed•Remedy overload condition• Ensure adequate air supplyJack will lift, but not maintain pressure •Release valve not tightly closed•Overload condition•Hydraulic unit malfunction•Ensure release valve tightly closed•Remedy overload condition•Contact Tech. ServiceJack will not lower after unloading• Reservoir overfilled• Linkage binding • Ensure load is removed, then drain fluid to proper level• Clean and lubricate moving partsPoor lift performance • Fluid level low•Air trapped in system• Ensure proper fluid level•With saddle fully lowered, removeoil filler plug to let pressurized airescape, then reinstall oil filler plugJack will not lift to full extension • Fluid level low•Ensure proper fluid levelFigure 3 - Parts Illustration for Model HW93731 - Main13962632616028192743348395, 14593149544115642917492097832125616571826582431335237434447343930252242231135Apply Never-Seez (or equivalent) to threads and face at both ends of Ram Cylinder (ref part #44)before assembling. Assemble to Base (part #59) and tighten to crush fit.Lubricate O-rings (part #37 & 47), Tank Nut (part #43), and upper & lower of Oil Tank (part #58)with lubriplate (or comparable lubricant) before assembling. Tighten to a crush fit.A B AA B B B BAir-Hydraulic Pump Assembly(refer to Fig. 5)Ram Assembly(refer to Fig. 4)Figure 4 - Parts Illustration for Model HW93731 -Ram Assembly55531746505145386402110Figure 5 - Parts Illustration for Model HW93731 -Air Hydraulic Pump AssemblyFigure 6 - Parts Illustration for Model HW93731 -Pump Piston Assembly779579727794938865879882708684858092691018366698996}76Piston Assembly(refer to Fig. 6)7381786775991006871907491}97Apply Loctite #242 (color blue) to threads before assemblingThread into Piston todimensions shown0.060"0.080"Replacement Parts List For Model HW93731 - ref pages 6 & 7 for parts drawing(*) indicates items included in Repair Kit 240579(#) indicates items included in Repair Kit 240564Item Part No.Description Qty148230Washer 2250062Bolt 23*200003Gasket24201733ExpansionPlug15201787Lockwasher 16*203199Ball 17*203202Ball 38204446Cotter Pin 29210311Pipe Plug 110210411Washer 111211737Lockwasher112212227PoppetReleaseValve113212540Filler Screw 114212566Bolt 115213728Spacer 116*214555O-ring 117216647Spring 218217649Roll Pin 219217898Roll Pin 120222533Screen 121223166Screen 122223172Hose Clip 123351000Air Valve124212562Air VentScrew125224081Screw 126224164Adapter 127224165Rod 128224166Hand Knob 129224180Spacer 130224182Air Hose 131224472Spacer 132224475Wheel 233224521Handle134224640BalanceStrap135224641Handle Grip 136224644Bolt 337*224648O-ring 138225483Pin 139226019Hex Locknut 540226331Spring1Item Part No.Description Qty41226401Spring 242226483Pipe nipple 143227136Tank Nut144227533RamCylinder145228090Cross pin 146228091Cross pin 147228099O-ring148228929Air-hydraulicPump Assy.149229131Pipe Plug 250230125Heel Plate151230126U-cupPacking 152230134RamAssembly153245958Ram 154231102Axle155232618ExtensionScrew Assy.156*233917PlasticSpring 157233922ReleaseStem158234933Oil tank 159234935Base 160234990Strap261234999SupportBracket162236717Screw 163236718Nut 164242876Bushing 165203202Ball 166*#219861O-ring167*#221013U-cupPacking168221377Roll Pin169221820RetainingRing270222202Elbow 171*#222288O-ring172223173ReturnSpring173223183Plug1Item Part No.Description Qty 74223184Spring 175#223187Valve &Plunger 176223194Spring &Rubber Cushing177223203Trip Washer 278223678PumpPacking & Piston179223680Screen 180224034Air Cylinder 181224038Pump Rod 182224156Spring 183224469Washer 184225371Grommet 185225384Trip Spring 186226153Spring 187226373AdjustingScrew188N/A End Block 189226451Set Screw 290228235Cotter Pin 191228813Washer 192228814Gland Unit 193*#228815U-cupPacking194228816Washer 195228930PistonAssembly 196228933PumpCylinder197231347Piston & RollPin Assembly198N/A Cylinder Cap 199236684Piston 1100236685Sealing Ring 1101242877Bushing 1(*)240579Repair Kit -(#)240564Air Hyd. Pump Repair Kit-TWO YEARS LIMITED WARRANTYFor a period of two (2) years from date of purchase, SFA Companies will repair or replace, at its option, without charge, any of its products which fails due to a defect in material or workmanship under normal usage. This limited warranty is a consumer's exclusive remedy.Performance of any obligation under this warranty may be obtained by returning the warranted product, freight prepaid, to SFA Companies Warranty Service Department, 10939 N. Pomona Ave., Kansas City, MO 64153.Except where such limitations and exclusions are specifically prohibited by applicable law:(1) THE CONSUMER'S SOLE AND EXCLUSIVE REMEDY SHALL BE THE REPAIR OR REPLACEMENT OF DEFECTIVEPRODUCTS AS DESCRIBED ABOVE(2)SFA COMPANIES SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGE OR LOSSWHATSOEVER.(3) ANY IMPLIED WARRANTIES, INCLUDING WITHOUT LIMITATION THE IMPLIED WARRANTIES OFMERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, SHALL BE LIMITED TO TWO YEARS, OTHERWISE THE REPAIR, REPLACEMENT OR REFUND AS PROVIDED UNDER THIS EXPRESS LIMITED WARRANTY IS THE EXCLUSIVE REMEDY OF THE CONSUMER, AND IS PROVIDED IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.(4) ANY MODIFICATION, ALTERATION, ABUSE, UNAUTHORIZED SERVICE OR ORNAMENTAL DESIGN VOIDSTHIS WARRANTY AND IS NOT COVERED BY THIS WARRANTY.Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.SFA Companies10939 N. Pomona Ave. Kansas City, MO 64153816-891-6390******************************************。

汽车英语缩写大全汽车英语缩写大全————————————————————————————————作者:————————————————————————————————日期:汽车英语缩写大全进口汽车维修技术缩略语词典??*C DegreesCelsius摄氏度?*F ?Deg rees Fahrenheit华氏度?*D* Drive 驱动,驾驶,行驶,行车?*N* Neutral Position 空档?*P*?*PARK*Position P档,停车档*P**PARK*Position P(驻车)档位置O2 ?Oxygen 氧气2WD ?Two-WheelDrive两轮驱动4WD Four-Wheel Drive四轮驱动4WS?Four-Wheel Steering四轮转向A ?A A-post, A-pillar A柱?A?Amperes 安培, 电流A?*Amper*Ammeter *Advance*安培*电流表*提前A.I.R. Air Injection Reactor 空气喷射反作用器A.M.Above-Mentioned上述的A/C AirConditioning空调?A/CA/C Amplifie空调放大器A/CCLTCH. A/C Clutch空调离合器A/CL Air Cleaner 空气滤清器?A/CL-BM AirCleaner BimetalSensor空气滤清器双金属传感器?A/CL-CWMAir Cleaner ColdWeather Modulator 空气滤清器低温调节器A/CL-DVAir Cleaner Duct Valve Vacuum Motor 空气滤清器导管阀真空马达A/CL-TSOV Air Cleaner TemperatureSensor Ove rride Valve ?空气滤清器温度传感器超压阀?A/CL-VCDAir CleanerVacuumControl Delay 空气滤清器真空延迟控制?A/CL-VCV Air CleanerVacuum ControlValve空气滤清器真空控制阀A/CL-VMAir Cleaner Vacuum Motor空气滤清器真空马达A/F Air-Fuel Ratio空燃比A/T Automatic Transaxle Or Transmission 自动变速箱?AA Automobile Association (UK)英国汽车协会?AA AAmericanAutomobile Association美国汽车协会AACAuxiliary AirControl辅助空气控制?AACAutomatic Amplitude Co ntrol自动振幅控制AACV Auxiliary Air Control Valve辅助空气控制阀?AADAuxiliary AirControl Device 辅助空气装置AAEAmericaAssociation of Engineers 美国工程师协会AAMVMAmericanAssociation of Motor Vehicle Manufacturers ??美国汽车制造者协会?AAP AuxiliaryAccelerator Pump辅助加速器泵?AAP Auxiliary Accelerating Pum p辅助加速泵AAPAmbient AbsolutePressure外界绝对压力?AAS Aspirator Air System吸气(真空)控制系统AAS Auto Adjust Suspension 自动调节悬挂?AAS Air Adjust Screw空气调整螺丝AAS American Astronautical Society 美国宇宙航行学会AAS Air Adjust Screw空气调节螺钉?AASHTO AmericanAssociation of S tate Highways and Transportation Off icials??美国各州公路及运输公务员协会?AAVAnti Afterburn V alve 防止后燃阀?AB AirBleed空气泄放ABA Air Bleed Actuator空气排放执行器(电磁阀)ABCV Air Bleed ControlValve空气泄放控制阀ABDC After Bottom DeadCenter在下止点后?ABGAlcohol BlendedGasoline掺酒精的汽油?ABNAirborne Noise 空气传播的噪音ABP Air BrakeProportioing(valves)空气制动比例分配( 阀)ABRS AirBag Restraint System 安全气囊?ABSAltitude Barometric Switch 高度(海拔)气压开关?ABS Anti-Lock Brake System防锁刹车系统,防抱刹车系统,反锁定刹车系统ABSAmerican Bureau ofStandards 美国标准局Abs Absolute绝对的ABSVisc Absolute Viscosity绝对粘度?ABSV Air Bypass S olenoid Valve空气旁通电磁阀ABV*AntiBackfire Valve *Air Bypass Valve*防止逆火阀*空气旁通阀?ABVAir Bypass Valve 空气旁通阀ABV Anti-BackfireValve防回火阀AC Air Condition 空调?AC Alternating Current Gener ator交流发电机?AC*Alternating Current *AfterContro *交流电*后段调整式?A CACAuxiliary Fan Relay空调辅助风扇继电器?AC AC Compressor Safety Switch空调压缩机安全开关?AC ACCondenser BlowerMotorRelay空调冷凝器鼓风马达继电器?AC AC Control Unit 空调电脑盒AC AC Diode空调二极管AC ACEvaporator Motor Relay空调蒸发马达继电器?ACAC Evaporat or Pump LineFuse空调蒸发泵保险丝AC AC HighPressure SafetySwitch空调高压安全开关AC ACIdle Boost Valve空调怠速加压阀?AC Alternating Current 交流电AC AnteChristum 公元前?AC Accumulator 蓄电池,储压器AC Acid酸ACAnalogue Computer模拟计算机?ACAutomaticControl 自动控制AC Air-Cooled 空冷AC ArmoredCar装甲汽车AC Adaptive Control自适应调节AC Aerodynamic Center空气动力中心ACAirCooling 风冷,空气冷却,气冷?AC Air Cycle 空气循环?AC Automatic Clutch自动离合器ACCA/CClutch Compressor 空调压缩机ACC Air Conditioning Clutch 空调离合器ACC Air ConditioningClutch Switch空调离合器开关ACC?Automatic Climate Control电脑恒温控制?ACC *Accessary*AltitudeCompensation Carb *附件*高度补偿化油器Accel?Accelerator油门,加速踏板,加速泵?ACCS?A/C ClutchCycling Switch 空调离合器循环开关ACCS?Air Conditoning CyclingSwitch空调循环开关?Accum Accumulat or蓄压器?ACCWM Air Cleaner Cold Weather Modulator 空气滤清器低温调节器?AccyAccessory 附件?ACD Auxiliary Control Device辅助控制装置?ACDAirConditioning Demand 空调作用指令ACD ?Air Conditioning Demand Switch 空调需求开关?A CDV Air Cleaner DiverterValve 空气滤清器分流阀?ACE ?Air Conditioning Equipment空气调节设备?ACE ?Automatic Check Equipment 自动检测设备?ACE ?Automatic Computing Equipment自动计算装置ACE Air Conditioning Equipment 空调设备?ACG ?A lternatingCurrentGenerator交流发电机?ACG Automatic Control Gear自动控制变速?ACID TEST CYC-LEAcceleration,Cruise, Idle,DecelerationTest Cycl e加速.稳速.怠速.减速试验循环ACIS ?Acoustic Control Iduction System 声控进气系统Ack Acknowledge承认ACKV?Air Check Valve 空气止回阀ACL?Air Clearner空气滤清器ACLAutomatic Chassis Lubrication自动底盘润滑系统ACM Advanced Composite Materials高级复合材料ACON ?AirConditioningOn 空调起动?ACP?AirConditioning Pressure空调压力ACP AuxiliaryControlPanel辅助操纵仪表板ACRS Air Cushion Restraint System气垫型保护装置ACS ?AirConditioning System 空调系统ACS-O?Access Opening检修孔?ACT AirCharge Tem perature进气温度ACT Air Charge TemperatureSensor进气温度传感器ACTE Automatic Checkout Test Equipment 自动检测装置ActuActuator执行器?Actv Active活动的?ACV Air Con trol Valve 空气控制阀?ACVAir Cut Valve 断气阀ACVArmored Command Vehicle装甲指挥车ACV Air ControlValve 二次空气喷射量控制阀?AD Anno Domini 公元?AD AerodynamicDecelerator气动减速器ADCAnalog-DigitalConverter模-数转换器?ADD Addition*添加*补充ADECS AutomotiveDiesel ElectronicControlSystem 汽车柴油机电子控制系统?ADFAerodynamic Drag Factor 空气阻力系数Adj Adjust or Adjustable调整或可调整ADL Automatic DoorLock自动门锁ADPAir-DrivenHydraulic Pump气动液压泵?ADS AdaptiveDampe rSystem 可变阻尼力避震系统ADV Wiper Pressure Control雨刷片压力控制装置Adv Advance提前的?AE AccelerationEnrichment 化油器加速时混合气浓度?AE Acoustic Emission 有害声响排放?AEA Automotive ElectricalAssociation (US) 美国汽车电气协会?AEC AutomotiveEmissionControl汽车排气控制AECD Auxiliary Emission Control Device 辅助排放控制装置AEI After End of Injection 喷射结束后AERAAutomotive Engine Rebuilders Association(US) 美国汽车引擎修护协会?AESC American Engineering Standards Committee美国工程标准委员会?AETS AutomaticEngine Test System发动机自动测试系统AF Air-Fuel Ratio混合气的空气燃油比?AF Auxiliary Fu el辅助燃料?AFC Airflow Controlled空气流量控制?AFC AirflowControlled FuelI njection 空气流量控制燃料喷射AFC AirFuel Control空气燃油混合比调节装置?AFCAutomatic Frequ ency Control 自动频率调节?AFC Airflow Control空气流量控制AFCOAutomatic Fuel Cutoff自动断油装置?AFCV Air Fuel RatioControl Valv e空燃比控制阀AFE Automobile Fuel Economy 汽车燃油经济性AFER Air-Fuel Equivalence Ratio燃油过量系数AFRAir-Fuel Ratio空气燃油混合比?AFS AirflowSensor空气流量传感器AFSAuxiliary Fuel Supply System 辅助供油系统?AG Air Guard空气护罩?AGO Automotive Gas Oil 汽车用油AGTAutomotiveGas Turbines 汽车用燃气轮机AGV AutomaticGuided Vehicle自动导向车辆AGVS Automatic Guided Vehicle System 车辆自动导向系统AHAmper Hour 安培小时?AHFSS AirConditionig /Heat er Function Select Switch空调/暖气功能选择开关?AI Air Injection 空气喷射?AICV Air Injection Check Valve空气喷射单向阀?AID AirInjection Dual双空气喷射?AIR AirInjectionReaction二次喷气装置?AIR Air Injector Reactor二次空气喷射器AIR BPV AirBypassValve 空气旁通阀?AIR COND RLY Air Conditioner Relay 空调继电器?AIR COND SIGAir Conditioner Singnal空调信号Air Sel Air Selector空气选择器AIR-CHVAIR Check Valve 空气单向阀?AIR-DVLV AIR DiverterValve空气分流阀AIR-IVV AIRIdleVacuum Valve进气怠速真空阀AIS AirInjection Single单空气喷射AIS AirInjection System二次喷气装置AISAutomatic Idle Speed自动怠速AIV AirInjection Valve 空气喷射阀?AIVVAIR Idle Vacuum Valve空气怠速真空阀?AKI Anti-KnockIndex抗爆震指数?AL Acceleratio nLevel 加速度级ALC Automatic LevelControl汽车后悬挂自动高度控制?ALCL Assembl yLine Communication Link诊断总线?ALDL AssemblyLine Diagnostic Link自我诊断接线总成ALDL Assembly Line Data Link 自我诊断线?Ali Alignment校正,定位AlmAlarm警报器?ALRAutomaticLocking Retractor 安全带自动锁定装置ALRAutomaticLength Adjusting and Locking Retra ctor?自动长度调节和锁紧式伸缩装置ALR Automatic Locking Retractor自动锁紧式伸缩装置?AltAlternatoror Altitude发电机,高度Alt Alternator交流发电机?ALU Arithmeticand Logical Unit算术及逻辑单位AM Amplitude Modulation 调幅Amb Ambient周围的?AMC American Motors Corporation 美国汽车公司?AMG V AirManagementValve空气控制阀Amm Ammeter电流表Amp Amplifier放大器?AmpAmpere安培AN Above-Named上述的?ANAnnual年度的AN Anode 阳极?ANCActiveNoise Control System活性噪音控制系统?ANLAutomatic Noise Limiter噪声自动限制器ANS Answer答案ANSI AmericanNational Standards Institute美国国家标准局Ant Antenna天线?ANTBV Anti-Backfire Valve防回火阀?Anti-Dsl Anti-Diesel防止後燃(熄火後)?AO Air Operated 气动的?AOC Air Oil Cooler机油空气冷却器?AOC Automatic OverloadControl自动超载控制?AODAutomatic Overdrive 自动超速?AOQ AverageOutgoing Quality平均产品质量AOT AutomaticOverdrive Transmission超速式自动变速器APAir Pump 气泵?APC AutomaticPhase Control自动相位调整?APC Automatic Power Control自动功率调整?AP CAutomatic ProgramControl 自动程序控制APC Armored PersonnelCarrier 装甲人员输送车?AP CAutomaticPerformance Control自动性能控制系统?APCV Air Pump Control Valve 空气泵控制阀?APDV Air Pump Diverter Valve空气泵分流阀API AmericanPetrol Institude美国石油协会AppApparatus仪表.器件. 设备?App Appendix附录App Approved by经...批准,批准人Approx Approximation近似.略计?Apr Apprentice学徒,徒工?APRA AutomotiveParts Rebuilders Associati on(US)美国汽车零件再制协会APREVLVAirPump Relief Valve空气泵减压阀APU Auxiliary Power Unit辅助动力设备?AQ Aqua(Wate r)*水*水柱?AR Air Regulator空气流量调节器?ARAxleRatio 驱动轴减速比?ARC Acceleration Signal加速信号ARQ AutomaticError Request Equipement自动误差校正装置ARV ArmoredRecovery Vehicle装甲抢救车AS AirflowSensor空气流量传感器AS American Standard美国标准AS AirSuction进气AS Automatic Synchronizer自动同步器?ASAAmericanSta ndard(s)Association美国标准化协会?ASA Acoustical Society of America美国声学学会ASCAutomatic StabilityControl 电脑控制稳定装置ASCD Auto Speed Control Device 自动速度调节装置ASCPS AirSwitch CanisterPurgeSolenoid 空气切换碳罐塞电磁阀ASCPTAir Switch Canister Purge Timer空气切换碳罐塞定时器ASD AutoShutDown 自动切断?ASDM Air BagSystemDiagnosticModule安全气囊系统诊断模块ASDV AirSwitching Diverter Valve 空气转换分流阀ASE Automatic StabilizationEquipment自动稳定装置ASIS Abort Sensing and Implementation System 紧急故障传感及处理系统ASIS American Societyfor IndustrialSecurity美国工业安全协会ASL Above Sea Level 海拔高度Asm Assembly 总成ASME AmericanSociety of Mechanical Engineers美国机械工程师协会?ASQC AmericanSocietyfor Quality Control 美国品管协会?ASRV Air Switching ReliefValve 空气转换减压阀?ASS Air SwitchingSolenoid 空气转换电磁阀ASS Air Suction System进气装置Ass Assembly总成,装配,机组?Ass Assistant辅助的,助手,帮手?As sAssociation 学会,协会.公司?AssyAssembly总成?ASTM America nSociety forTestingandMaterials美国材料试验协会ASVAir Switching Valve 空气转换阀?ASVAirSuction Valve 进气阀ASVAirSwitchingValve空气转换阀,空气开关阀?ASVSAir Switch ingVacuum Solenoid空气转换真空电磁阀?ATAc ceptanceTest验收试验AT Air Temperature空气温度?ATAmpere Turn安培匝数?ATAngle of Train方位角.方向角.传导方位ATAutomaticTransmission自动变速器?AT. Air Tight气密的,密封的At.Atmosphere大气.周围情况.Barometric 气压(计)BBattBattery电瓶电池BAV Bleed AirValve 泄气阀?BB Babbit Metal巴氏合金BBDC Before BottomDeadCenter在下止点前?BBL.Barrel 筒?BBSBuilding Block System积木式系统BC Befor Control前段控制?BCCBatteryChargerCont rol电瓶充电控制BCDD BoosterControlDecelerate Device 倍力控制减速装置BCM Body Control Module 车体控制模块(车体电脑)?BCV Boost ControlValve 真空控制阀溢油控制阀(三菱)减速节气阀(铃木)BCV Booster Control Valve倍力控制阀?BCV BoostControl Valve强制怠速时节气门开度控制阀?BCVBoost Contr ol Valve(铃木,三菱)强制怠速工况进气管真空控制阀?BDC BottomDead Center下止点.下死点BDVBreakdownVoltage击穿电压BE Banchelorof Engineering工学士?BEBaume 玻美度BEBooster Engine 助推发动机?BE Best Economy 最佳经济性BEI Breakerless ElectronicIgnition 无白金式电子点火?BESA British EngineeringStandardAssociation英国工程标准协会BFCBrake ForceCoefficient 制动力系数BFLI Brake Fluid LevelIndicator 制动液液面指示器BHPBrake Horsepower制动马力?BHS BimetalHeat Sensor 双金属热传感器?Bi Met BiMetallic Air T emperature Control Sensor双金属进气温控传感器BICERIBritish InternalCombustionEngineResearch Institute英国内燃机研究所BIT BestInjection Timing最佳喷油正时?BK Brake Swit ch 刹车开关?Bk Back 背部,後面,倒退,衬里Bk Rest Back Rest 椅背,後支架?BLKBlack黑色?BLRBlower 鼓风机BLRBeyond Local Repair本地不能修理?Blst Ballast稳压(电阻)BLU Blue 蓝色Blwr Blower鼓风机?BM BenchMark 基准点BM Breakdown Maintenance 故障维修?BM BreakeElec tromagnet制动电磁铁?BM BrakdownMaintenance 故障维修?BMAPBarometric and MainfoldAbsolute Pressure大气进气歧管绝对压力?BMEPBrake MeanEffective Pers sure 平均制动有效压力BNH Burnish抛光.精加工.烧蓝BOCBuick,Oldsmobile, Cadillac Group别克-奥兹莫比尔-凯迪莱克集团BOO BrakeOn-Off Switch制动开关BP Back Pressure 背压.反压BP Barometric Pressure气压?BPBoiling Point 沸点BPBestPower 最佳功率BPA BypassAir旁通空气BPCBack PressureControl背压控制BPO Bypass Orifice旁通口BPS Barometric Pressure Sensor 大气压力传感器BPTBackpressure Transducer 背压转换器BPVBy-PassValve 旁通阀Br Bromine溴?Br Brass 黄铜?Brkr Breaker 断电器BRN Brown 棕色?BS BarometricSwitch大气压力开关BSBimetalSensor 双金属传感器?BSBachelor of Science 理工学士BSBinary Scale二进位?BS Both Sides 两边.两侧?BS Briti sh Standards英国(工业)标准BSAUBritish StandardsAutomotive 英国汽车标准?BSC ENGBachlor of Science in Engineering工学士BSFC Brake Specific Fuel Consumption 制动油耗率, 制动单位油耗量?BSI British Standards Institute 英国标准局?BTC British Technical Council of the Motorand Petroleum Industries英国汽车及石油工业技术中心BTDCBeforeTopDeadCenter 在上止点前BTHEBrakeThermalEfficiency制动热效率BTRY Battery 蓄电池BTU British Thermal Units英国热量单位?BTV Below theThrottleValve 在节气门下方BUDC BoforeUpperDeadCentre 上死点前?BULKHD. Bulkhead隔壁?Buz B uzzer 蜂鸣器?BV Bowl VentPort浮桶室通风孔?BV Breakdowm Voltage击穿电压BV Balanced Voltage 平衡电压BVSV BimetallicVacuumSwitchingValve 双金属式真空转换阀?BVT BackPressure VariableTransducer负压可变传感器?BVV Bowl Vent Valve 浮筒室防溢油通气阀?BYP Bypass 旁路,支线?BYPA BypassAir(IdleSpeed Control) 旁通空气(怠速控制)CC Celcius 摄氏C C-Piller C柱CCall 呼叫C Candle烛光?CCapacitance 电容?C Car汽车CCarbon碳C Cathode 阴极?CCelsiusScale 摄氏温标?CCoulomb 库仑?C*Celcius 摄氏度?C&M Careand Maintenance 维修及保养C-4 Computer Controlled CatalyticConverter电脑控制触媒转换器C.CANI Charcoal Canister 碳罐C.E.Check Engine 引擎故障灯C.G. Center of Gravity 重心C/O Checkout 检查,调整,测试?C/O Choke Openner阻风门强制开启阀?C3IComputerControlledCoil Ignition 电脑控制线圈点火C4 Computer Controled Catalytic Converter 电脑控制触媒转换器?CA Calcium 钙?CA Compressed Air压缩空气?CA CrankAngle曲轴转角?CABRCabriolet 敞蓬车CAC ChargeAir Cooler 进气冷却器CACS Comprehensive Automobile Control System汽车综合控制系统CACV Combined AirControl Valve组合空气控制阀CADComputer-Aided Design 计算机辅助设计?CAEComputer Aided Enginering 电脑辅助工程?CAFECorporate AverageFuel Economy 美国汽车制造厂采用的平均油耗?CAL Calorie卡路里?CAL Calculated Average Life(汽车等的)平均计算寿命CALCaliber 口径CAL Calibrate 校定,校正?CAL Collision Avoidance Light 防撞灯CAL-PAC Calibration Package 校正用套装软体?CalibCalibration 校正,修正,定位?CalifCalifornia加州规格车?Calif California加州CALSEL Calibration Select校正选择?CAMCamber外倾角?CAM Camshaft 凸轮轴CAMComputerAided Manufacturing 电脑辅助制造?Can Canaba加拿大?Can Canister碳罐Can Prg Canister Purge碳罐塞Can.Prg Canister Purge 碳罐净化?Canc.Cancel 取消CanCV Canister ControlValve 碳罐控制阀?CANP Canister Purge solenoid碳罐清除电磁阀CANPCanisterPurge碳罐净化, 滤筒净化CAP Capacity *容量*能力CAP Cleaner AirPackage净化空气装置Cap Capacitor or Capacity 电容器或电容量?CARB California AirResource sBoard加州空气资源协会?Carb Carburetor化油器?CAS Caster 后倾角CAS ClearAirSystem净化空气系统?CAT Carburetor Air Temperature 化油器空气温度?CAT Catalogue目录CAT Catalyst 催化剂CATCategory种类.范畴?CATCarburator Air Temproture 化油器空气温度Cat Catalytic Converter 触媒转换器?CAV ConstructionAssistanceVehicle 建筑辅助运输车辆CAV Coasting AirVa lve 强制怠速空燃比控制阀?CBCircuit Breaker 电路断电器?CB ChokeBreaker 阻风门限制器CBContactBreaker 断电器CBE Cab Behind Engine 驾驶舱在引擎后方式?CBVVCarburetorBowl Vent Valve 化油器浮子室通气阀CCCubic Centimeters立方厘米?CC Cruise Control 定速控制,巡行控制CC Catalytic Converter触媒转化器CC Converter Clutch 扭力转换器离合器?CCCComputer Command Control 电脑指令控制CCCS ComputerControlled Cooling System 电脑控制冷却系统?CCD Computer Control Dwell 电脑控制点火闭角?CCEGRCoolant Controlled Exhaust Gas?Recirculation冷却剂控制废气再循环CCEVS Coolant Control Engine Vacuum Switch冷却水温控制引擎真空开关?CCEVV Coolant Control EngineVacuum Valve 冷却水温控制引擎真空阀?CCIVCoolant Control Idle EnrichmentValve 却水温控制怠速增浓阀?CCM CentralControlModule 中央控制模块(中央电脑)?CCOCatalytic Converter forOxidation氧化触媒转换器CCOT Cycling Clutch Orifice Tube 循环离合器限流孔?CCOT Cy cling Clutch (Orifice) Turbo 循环离合器涡轮增压CCPControlled Canister Purge控制碳罐净化CCP Charcoal CanisterPurge活性碳罐净化CCRCatalytic ConverterReduction还原催化废气净化器?CCRMConstant Control Relay Module定控制继电器模组CCROCatalytic Converter for Reductionand Oxidation三元触媒转换器CCRO CatalyticConverter Rhodium氧化,还原催化废气净化器?CCS Control led Combustion System 燃烧控制系统CCU Cruise Control Unit定速控制电脑盒CCWCounterclockwise 逆时针方向?CDComputer AidedDesign电脑辅助设计CD Candera 烛光?CDCapacity Discharge (electronic ignition)电容放电式电子点火?CDCompact Disc光盘?CD CapacitorDischarge(ignition)电容器放电(点火_)?CD Cofficientof Drag 空气阻力系数CD-REGVLVCrankcase DepressionRegulator Valve 曲轴箱真空调节器阀?CD-ROM CompactDisc ReadOnly Memory CD只读存储器CDI Capacitive Discharge Ignition电容放电式点系统?CDI Controlled Direc tInjection(system) 可控直喷系统CDY Chassis Dynamometer底盘测功计?CEAB Cold Eng ine Air Bleed 冷引擎空气排放CEC Computerized EmissionControl 电脑废气控制?CEC Combined Emission control(Valve)组合废气控制阀?CEC C omputerized Engine Control 电脑引擎控制CEC CoordinatingEuropean Council (standards)欧洲标准协会CELO ColdEngineLock-Out 冷机锁定CEMComposite Electro-Chemical Material复合电化学材料CENT Center中心CES Clutch EngagedSwitch 离合器啮合开关?CES Coast ingEnricherSystem 减速浓化系统?CESSCold Engine Sensor Switch 冷引擎传感器开关?CF C enter of Floatation浮心CFCentrifugal Force离心力?CF Conversion Factor 转换系数CFCutting Fluid切削液?CF Confer比较.对照?CF Cubic Feet立方英尺?CFCounter Fire 逆火?CFI Central FuelInjection 中央喷射系统?CFI CrossFi re Injection 多缸同时点火喷油?CFICentrolFuelInjection 节气门上方燃油喷射系统?CFI Continuous(throttle body)Fuel Injection 连续燃油喷射系统?CFRP Carbon Fiber Reinforced Plastics 碳纤维强化塑料CFSCoastingFuel Cut System 强制怠速工况燃油切断系统CH.O ChokeOpenner自动阻风门CHACharge 充电?CHBChoke Braker 阻风门开度限制器?CH G.Charge 进气或充电?CHK Check 核对,检查?Chk.Eng. Chec kEigine 检查引擎(灯)CHNGChange 交换CHO Choke Opener 阻风门开启器?CHRG Charging 进气,充电?CHT Cylinder HeadTemperature汽缸盖温度CHU CentigradeHeat Unit 热量单位?Ch Vlv CheckValve单向阀?CI Cubi cInches立方英寸CICompression Ignition压缩式点火CICompression Ignition Engine 压缩点火引擎CI CubicInches 立方英寸CI Cast Iron 铸铁CI Compression Ignition压燃?CIDCubic Inch Displacement 立方英寸排气量CID CylinderIdentification Sensor 气缸识别传感器?CID Cylinder Identification 汽缸识别?Cig Cigarette 香烟?Cig Ltr Cigarette Lighter点烟器Circ Circuit电路?Circ Brkr Circuit Breaker 电路断电器CIS Continuous Injection System 连续喷射系统CIS-E Continuous Injection System Electronic 电子控制连续喷射CK-VLV Check Valve 止回阀,单向阀CKD Completely Knocked Down完全拆散的,全解体的CKDL-VLV CheckDelayValve单向延迟阀?CKP Cran kshaft Position 曲轴位置?CKPS Crankshaft Position Se nsor曲轴位置传感器?Ckt. Circuit 电路,回路CLClosed Loop 闭环,闭路?CLCentral Line 中心线?CL CarLoad车辆载荷CLClass 等级. 种类CL Clearance 间隙CL CraneLoad 吊车起重量CL Chlorine 氯CLA Chemilumineceut Analyzer 光化学分析仪?CLC ConverterLocking Clutc h转换器锁定离合器CLCC Closed LoopCarburetor Control 闭环式化油器控制?Clch Clutch离合器CLD, CLA Chemiluminecent Detector(Analyzer)光化学分析仪?CLEC Closed Loop Emission Control 闭路废气控制CLKClock 时钟CLRC Clearance 间隙,空隙, 游隙Clmn. Coloumn 柱Clmt.Climate气候CLR Clear清除?CLR Current-Limiting Resistor限流电阻器CLS Closed Loop反馈控制?Clstr.Cluster 群,组CLTBI Closed Loop Throttle Body Injection 闭路回馈式单点喷射?CMCentimeter 厘米CMCenter of Mass 质量中心?CM Control Motor 控制马达CMET Coated Metal镀层金属CMH ColdMixtureHeater 冷车混合汽加热器?CMO Conventi onal Mineral Oil 常规矿物润滑油?CMPCamshaft Position 凸轮轴位置?CMPS Camshaft Positi on Sensor凸轮轴位置传感器Cmpnstr. Compensator 补偿器?Cmptr.Computer电脑CMVSS Canadian Motor Vehicle Safety Standard加拿大车辆安全标准CN ChangeNotice更改通知?CNCLD Concealed 隐藏式?CNG Compressed Natural Gas Automobile 天然气燃料汽车CNGCompressedNatural Gas 压缩天然气?CNT Constant 常数,恒量.恒定的?Cntr. Central orCenter 中心,中央?CNTRL Control 控制Cnvnc.Convenience便利,方便?CO Carbon Monoxide 一氧化碳CO ChokeOpener 阻风门助开器?Co-Ax. Co-Axial 同轴?CO2 Carbon Dioxide 二氧化碳?COC Conventional Oxidation Catalyst 普通氧化触媒COD Cash On Delivery 交货付款CODChemical Oxygen Demand化学耗氧量COE Cab Over Engine驾驶舱在引擎上?Colng.Coolng 冷却?Colnt. Coolant冷却液?Comb.Combination综合,组合?COMPCompressoror Compartme nt 压缩机或舱、室Comp.Compressor 压缩机Compens Compensation补偿Compt. Compartment 室?CON. ROD Connecting Rod连杆Cond.Condenser 电容器,冷凝器?Conn.Connector orConnection 连接器或接头CONT Continued连续?CONT. Control 控制?CONVConverter转换器CONV Convertible 敞蓬车Convs.Conversion 换算CORP Corporation 协会,社团,公司,企业Count. Counter 计数器(转数表)COV ControlValve 控制阀?CP Candera Power烛光CP Canister Purge 碳罐净化?CP Centre ofPressure压力中心?CP Crankshaf tPosition曲轴位置?CP CondensationProduct 冷凝物,浓缩物CP Carriage Paid 运费已付CP Chemical Pure 化学纯CP CircularPitch (齿轮)分度圆周节?CP ConstantPressure 等压,常压,恒压,稳定压力CPCV CanisterPurge Control Valve 碳罐净化控制阀?CPMCycles Per Minute 每分钟转数?CPPS Clutch Padel Position Switch离合器踏板位置开关CPRV Canister PurgeRegulator Valve 滤筒净化调节阀?CPS Canister PurgeSolenoid碳罐净化电磁阀?CPS Central Power Supply 集中电源供应CPSCrankPosition Sensor 曲轴位置传感器?CPS Cent ral Power Supply 中央电源?CPS Crankshaft Position Sensor 曲轴位置传感器?CPS Cycle Per Second 每秒周期数?CP SControl Pressure System 压力控制系统CPT Convertible PowerTrain 可变式传动系?CPU Cen tral ProcessingUnit 中央控制单元?CPUComputer 电脑CPV CanisterPurge Valve碳罐净化阀?CPV Constant Pre ssure Valve 定压阀CPVVV Choke PulldownVacuum Vent Valve阻风门真空强制通风阀?CRCrossroad 交叉路,十字路CRContraction Ratio压缩比CRECorrosionResistant防腐的,耐蚀的CRES CorrosionResistant Steel 耐蚀钢?CRK CrankingSignal 曲轴起动信号Crnr. Corner 角?CRNRNG Cornering 转向?CRO Cathode-RayOscilloscope 阴极射线示波器?CRS C hoke Return System 阻风门回位系统?CRS ChildRestraint System 儿童专用安全装置CRSCoasting Richer System 强迫怠速工况混合气加浓系统CRS Coolant Recovery System 密闭式冷却系统CRT Cathode Ray Tube阴极射线管CRTC Cathode Ray Tube Controller阴极射线管控制器CRVCoasting Richer Valve惯性(怠速)加浓(补偿)阀?CSA Cold Start Advance冷机起动提前装置CSC Coolant SpakConrol 冷却水点火控制?CSCSColdStartControl Solenoid冷车起动控制电磁阀?CSD Constant Speed Drive 等速传动?CSE GND Case Ground外壳接地CSPM Cold StartProgram Modifier 冷起动程序修正器?CSSCalibration Select Switch 校正选择开关CSSACold StartSpark Advance 冷车起动点火提前?CSSH ColdStart Spark Advance Hold(system) (福特)冷起动点火提前控制系统?CSU Crank Angle SelectingUnit曲轴转角自动调节装置?CT Cold Temperature冷车温度?CT Conventional Ther mactor 传统热反应器CT Cam-Train凸轮系?CT Closed Throttle关闭的节气门CTA Computer-Aided Test计算机辅助测试CTA Constant Temperatuer HotWire Anemometer常温热线风速计?CTAV Cold Temperature ActuatedVacuum 冷车温度动作真空?CTD Contrlolled Traction Differential 可控制(调整)牵引力差速器CTOCoolantTemperatureOverride 冷却水温过热控制CTPS Closed ThrottlePosition Switch 关闭节气门位置开关CTR Critical Temperature Resistance临界温度电阻?Ctrl. Control控制,控制器?Ctrlld Controlled 控制CTS Coolant Temperature Sensor冷却水温传感器?CTSCoolant TemperatureSwitch 水温开关?CTSWH Closed T hrottle Switch 节气门关闭开关?CTSY Courtesy门控灯?CTSY. C ourtesy 副, 反,对?CTTS CoolantTemperature Thermo Switch水温温控开关CTVS Choke Thermal Vacuum Switch 阻风门热控真空开关?CU Control unit电脑盒,控制器?Cu.In. CubicInches 立方英寸?CUBCubic立方?CURR Current电流CV ConstantVelocity 定速,等速CV CheckValve 单向阀?CVCheck Valve止回阀CV CoastingValve 滑行阀?CVConstant Velocity 定速, 等速CV ConstantVelocityJoint等速接头CV Control Valve 控制阀CV Calorific Valve 热值?CVCombat Vehicle 战斗车辆?C VCommercial Vehicle商用车辆,营运车辆CV Convertible 活动顶篷小客车CVConstant Volume Specific Heat 等容比热CVCritical Viscosity 临界粘度CVCConstant Vacuum Control 真空恒定控制CVC ConstantVoltageControl定电压控制?CVCCCompound Vertex ControlledCombussion 复合涡流控制式燃烧?CVCC ConstantVolume CombustionChamber等容燃烧室?CVRTContinuously Variable Ratio Transmission无级调速变速器?CVSConstant Volume Sampling定容量取样?CVS3PCold Vacuum Spark,3-Port冷车起动真空点火3孔式?CVSCC CoolantVa cuumSwitch Cold Closed 水温温控真空开关冷车关闭?CVSCO Coolant VacuumSwitch Cold Open水温温控真空开关冷车打开CVT Contiuously Variable Transmission无级变速器CVU Continuously-Variable Unit 无级变速器?CWClockwise顺时针方向CW Continuous Wave连续波,等幅波?CYCopy 副本,复制品?CYL Cylinder 气缸,油缸,圆柱?CYL Cylindrical圆柱形的D ?DDrive 驱动,行驶D Drive前进档?D *Diameter*Discharge*Drive*Dual *Double *直径*放电*驱动*双重*复式D&MDriving and Maintenance 驾驶与维修?D/O DeliveryOrder 提货单?Dam pDamper 阻尼器,缓冲器DAR Drive Axle Ratio驱动桥减速比?DASDistributor A dvanceSolenoid分电盘点火提前电磁阀?DASS Diesel Additive Supply System 柴油添加剂自动加添系统?DATA+DataPositive正线(自诊)DATA- Data Negative负线(自诊)DB Decibel 分贝DBCDual Bed Catalytic 双层触媒转换?DBP Drawbar Pull 拉杆拉力?DBW Drive-by-Wire索控式DC Direct Current直流电DC Digital Control 数位控制?DC DropCenter Rim深底钢圈?DC DeadCenter 死点DCELDirectCurrentLuminescence电流直接照明?DCHDual-Circuit Hydraulic System 双管路液压制动系统DCI Direct CylinderInjection直接喷入气缸(汽油喷射)?DCL Data Communications Link 数据交换连线DCLVDecelerationValve 减速阀DCM DirectCurrent Motor直流马达DCM/C-VLV DecelerationMixture Control Valve减速混合比控制阀?DCS Deceleration Control System 减速控制系统?DCTO Dual Coolant Temperature Override 双水温过热控制?DCV DecelerationControl Valve 减速控制阀?DCV Downdraft ConstantVacuum Carburettor 下吸式等真空化油器DD DualDistributors 双分电盘?DD Direct Drive 直接驱动?DDC Direct Digital Control 直接数字控制?Dual Diaphragm Distributor双膜片分油盘?DDV DistributorDecel Valve 分电盘减速阀De-Ice De-Icer 除冰装置?De-ice.De-Ice除冰DEC Digital Engine Control 数位引擎控制Decel Deceleration减速?DECS Daihatsu Economical Clean-Up System(大发)汽车经济式净化系统?DEEDi gital Engine Electronic发动机数字式电子控制单元?DEFDefrost er除雾器?DEFDieselExhaustFilter 柴油机的排气过滤器?Def Defrost er除霜器?DEF.DefoggerorDefroster除雾或除霜?DEFI Digital Electronic Fuel Injection数字式电子燃油喷射系统Defog Defogger除雾器?DegDegree度Del Delay 延迟DELO Diesel EngineLubricating Oil柴油机润滑油DERM Diagnostic Energy Reserve Module 自诊备用电源模块DesigDesignation 指明,标明,目标DET Detached 拆开的,分开的DET Detail零件.细目.详图.详细?DETDetection 检波.检测DET Dtector 检波器.探测仪Deton. Detonation 爆震,敲缸?DETRNT. Deterrent制止?DF Design Formula设计公式DF Direction Finding 测向.定向?DF Defogging去雾DFDrive Fit推入配合?DFF Direct Fuel Feed(injector)直接供油DFI Digital Fuel Injection 数字式汽油喷射?DFIP/D Diesel Distribution-Type Fuel Injection Pump柴油机分配式燃油喷射泵DftDefeat缺点,不良,损坏DG DoubleGlass双层玻璃?DG Double Groove双槽DI DecelerationIdle减低怠速?DI DirectInjection直接喷射DI Defense Industry 国防工业DI Deicing 防冻.去冰?DI Direction Indicator 方向指示器DI DieselIndex 柴油指数?DI.B Disk Brake 盘式制动器?DiagDiagnostic 诊断DIC Driver Information Center 行车电脑中心DIDVDual Ignition Delay Valve 双点火延迟阀?Diff Differential 差速器,差动的Dig. Digital 数字式?DIGRO DigitalReadout数字读出Dim Dimmer变光器?DINDeutsch Industrial德国工业标准规格?Dir Direction orDirectional 方向,定向,引导DIRSIDeposit Induced RunawaySurfaceIgnition表面点火方式DIS DirectIgnition System 直接点火系统?DIS Discharge放电DIS Distribution IgnitionSystem分电盘式点火系统DIS Doppler Inertial System多普勒惯性系统DISDigital Idling Stabilization数字式怠速稳定系统?DIS DistributorlessIgnition System无分电器点火系统?DIS Dual Induction System 双进气系统DispDisplay 显示DISTDistribution分配?DISTDistributor 分电器,分油盘?DITDirect Injection Turbocharged直喷式涡轮增压柴油机DITA Direct Injection Turbocharged Aftercooled 直喷式涡轮增压后冷柴油机?DIX. Deluxe豪华型?DIY Do-It-Yourself 自己动手维修车辆?DKBLU DarkBlue深蓝色DK GRN Dark Green深绿色DLDatumLevel 基准面DL Dead Load静载荷,静重,自重?DL Drawing List图纸清单?D LCData Link Connector自诊接头?DLI Distributorless Ignition无分电盘式电子点火DLL Design Limit Load 设计极限载荷?DLR Driving LampsR elay 行驶灯继电器DLSDigitalIdling Stabilization(unit) 数字式怠速稳定装置DLV DeflectionLimitin Volume 变形极限区?Dlx Deluxe 豪华型(高级的)Dly Delay延迟DM Diesel Moderate 柴油机用中级润滑油DMDehydrogenatedMixture 脱氢混合物?DM DesignManual设计手册DMDevelopment Milestone 发展里程碑DM Differential Motor差绕电动机?DM DriveMagnet 驱(启)动磁铁?DMEDigital MotorElectronics 数字电子引擎DMS Dual Manifold System 双歧管系统?DMS DistributorModulator System 分电盘调节系统Dn.Down 下,向下Dnshft Downshift 低档位,降档?DOCDirectOperating Cost 直接操作费用?DOD Departmentof Defense (美国)国防部?DOHC Double OverheadCams haft 双顶置凸轮轴?DOL DataOutput Line数据输出线DOT Department ofTransportation(US) 美国运输局?DP Dashpot 减速缓冲器DPDevelopment Prototype 开发原型.研制原型?DP DampProofing 防潮的,不透水的DP Data Processing数据处理?DP Dead Point死点.止点?DPDew Point露点?DP Diametral Pitch (齿轮)径节DP. CHAMBERDepression Chamber (三菱)化油器车滑轮增压控制装置?DPA DelayedPort Admission(system)延迟气口进气系统?DPADistributor PumpAssembly 分配式喷油泵总成DPBDual Power Brake 双管路助力制动DPCData ProcessingCenter数据处理中心DPDDual PointDistributor双白金分电盘DPDT Double-PoleDouble-Throw 双刀双掷(开关)?DPF DieselParticulate Filter 柴油机微粒过滤器?DPI Dual Plug Inhibit双塞抑制装置?DPSTDouble-Pole Single-Throw双刀单掷(开关)?DPTDepartment部.科.系.车间?DRDrive Ran ge 前进级DRDouble Reduction 两级减速?Dr Door门DR.B Drum Regulation Braker鼓式制动器DRB-II Diagnostic Readout Box诊断专用机?DRCV D istributorRetard Con trol Valve 分电盘延迟控制阀DRL Daytime Running Lmps 日间运转灯?DropDropping 电压降,降落,滴油DRS Distributor RetardSolenoid 分电盘迟滞电磁阀?DrvrDriver 驾驶员DS Distributor Spark 分电盘点火DS Detonation Sensor 爆震感知器DS Diesel Severe柴油机用高级润滑油DS Data Set数据组DSDesignSpecification 设计参数.设计说明书DS DrawingSummary 图纸一览表?DS-II Duraspark II 电子点火(第二代)DSC Doctor of Science理学博士?DSCC DigitalSpark ControlComputer 数字式点火控制计算机?Dsl Diesel柴油Dsl Diesel 柴油车DSM Design StandardsManual设计标准手册DstncDistance 距离DTDate日期?DTDescrepancy Tag误差标签DTDoubling Time 双倍时间?DT DoubleTire双轮胎?DTC Diagnostic TroubleCo de故障码?DTM Decel Throttle Modulator节流门减速调制器DTM Diagnostic TestMode 诊断测试模式?DTMS Diagnostic TestMode Selector 诊断测试模式选择器?DTP Department of Transport(UK)英国运输局?DTR DutyType Rat ing 负载型定额?DTS Detailed Test Specification详细试验说明书?DTVSDistributorThermal VacuumSwitch 分电盘温控真空开关?DV Decel Valve 减速阀DV Delay Valve 延迟阀DV Diverter Valve 分流阀?DVDevice装置.设备DV-TW DelayValve-Two Way二段式延迟阀?DVAC Distributor Vacuum Advanc eControl Valve分电盘真空提前控制阀DVAS Distributor Vacuum Advance Solenoid分电盘真空提前电磁阀?DVB Delay Vacuum Bypass System (福特)点火延迟。