Settlements induced by tunneling in Soft Ground

- 格式:pdf

- 大小:1.61 MB

- 文档页数:31

Effects of twin tunnels construction beneath existing shield-driven twintunnelsQian Fang a ,⇑,Dingli Zhang a ,QianQian Li a ,Louis Ngai Yuen Wong ba School of Civil Engineering,Beijing Jiaotong University,Beijing 100044,ChinabSchool of Civil and Environmental Engineering,Nanyang Technological University,Singapore 639798,Singaporea r t i c l e i n f o Article history:Received 16December 2013Received in revised form 14August 2014Accepted 7October 2014Available online 28October 2014Keywords:Tunnelling Settlement Ground lossSoil/structure interactiona b s t r a c tThis paper presents a case of closely spaced twin tunnels excavated beneath other closely spaced existing twin tunnels in Beijing,China.The existing twin tunnels were previously built by the shield method while the new twin tunnels were excavated by the shallow tunnelling method.The settlements of the existing tunnels and the ground surfaces associated with the new tunnels construction were systematically mon-itored.A superposition method is adopted to describe the settlement profiles of both the existing tunnels and the ground surfaces under the influence of the new twin tunnels construction below.A satisfactory match between the proposed fitting curves and the measured settlement data of both the existing tun-nels and the ground surfaces is obtained.As shown in a particular monitoring cross-section,the settle-ment profile shapes for the existing tunnel and the ground surface are different.The settlement profile of the existing structure displays a ‘‘W’’shape while the ground surface settlement profile displays a ‘‘U’’shape.It is also found that due to the flexibility of the segmental lining,the ground losses obtained from the existing tunnel level and the ground surface level in the same monitoring cross-section are nearly the same.Ó2014Elsevier Ltd.All rights reserved.1.IntroductionUrban underground areas are congested with infrastructures ranging from small pipelines and cables to large tunnels and foun-dations of high-rise buildings.With the increasing number of sub-ways constructed in urban areas,cases of tunnelling adjacent to existing structures are common.Due to the inherent complexities of the existing structure–ground–tunnel interactions,it is very challenging to ensure both the serviceability of existing structures and the safety of new tunnels construction.A significant amount of research has been performed to study the ground movements induced by the construction of twin tun-nels or more (e.g.,Addenbrooke and Potts,2001;Chapman et al.,2003;Hunt,2005;Ahn et al.,2006;Chapman et al.,2007;Laver,2011;Divall et al.,2012;Garner and Coffman,2013;Divall,2013;Do et al.,2014;Ocak,2014).The additional movements caused by the interaction between tunnels may result in asymmet-ric settlement troughs.The behaviours of existing structures induced by adjacent tunnelling have also been extensively studied,most of which focus on the influences on existing buildings (e.g.,Boscardin and Cording,1989;Burland,1995;Boone,1996;Burd et al.,2000;Mroueh and Shahrour,2003;Zhang et al.,2013)or pipelines (e.g.,Klar et al.,2005;Vorster et al.,2005;Fang et al.,2011;Zhang et al.,2012).Relatively speaking,there are only lim-ited published data related to the response of existing tunnels to new tunnels construction nearby.Cooper et al.(2002)presented extensive monitoring records taken from the interior of two exist-ing 3.8m internal diameter tunnels during the construction of three 9.1m external diameter running tunnels below in London clay (on the Heathrow Express).The vertical clearance between the new and existing tunnels is 7m and there is a skew of 69°between them.Both the new and existing tunnels were con-structed by using the shield method.Mohamad et al.(2010)adopted a distributed strain sensing technique to examine the per-formance of an approximate 8.5m diameter old masonry tunnel during the construction of a 6.5m external diameter tunnel beneath it.The minimum vertical clearance between the new and existing tunnels is about 3.6m.The new and the existing tun-nels were constructed using the shield method and the cut and cover method respectively.Li and Yuan (2012)presented data for the construction of two 6m external diameter shield-driven tun-nels below an existing 13.6m high double-deck tunnel.The verti-cal clearances from the right tunnel and the left tunnel to the existing tunnel are about 2.76m and 1.78m respectively.Ng et al.(2013)investigated the response of an existing tunnel to/10.1016/j.tust.2014.10.0010886-7798/Ó2014Elsevier Ltd.All rights reserved.⇑Corresponding author.Tel.:+861051688115;fax:+861051688111.E-mail address:qfang@ (Q.Fang).the excavation of a new tunnel perpendicularly below it by using three-dimensional centrifuge tests and numerical modelling.According to the literature,there is very limited knowledge on the response of an existing shield-driven tunnel to later tunnel-ling-induced disturbances.The data related to the relationship between the existing tunnel settlement and ground surface settle-ment are even less.In this paper,a case of two closely spaced tun-nels excavated beneath two other existing closely spaced tunnels in Beijing,China is presented.The response of existing tunnels to new tunnels construction is investigated based on the monitoring data.The deformation characteristics of the existing tunnels and the ground surfaces in two monitoring cross-sections are com-pared respectively.2.Project overviewA plan view and cross-sectional view of the existing and the new tunnels at the Ping’anli station in Beijing are shown in Figs.1and 2respectively.The existing circular shaped twin tunnels,run-ning north–south,are parts of the Beijing subway Line 4.They are horizontally parallel and are referred to as the ‘‘west tunnel’’and the ‘‘east tunnel’’.The clearance between them is 9.0m.They were driven by the earth pressure balance shield.The external and the internal radius of the precast segmental lining are 3.0m and 2.7m respectively.The segmental lining consists of five segments with a key segment (Fig.3).The length of each segment is 1.2m.The segments are rotated from ring to ring so that the joints do not line up along the longitudinal axis of the tunnel.The overbur-den depth of the existing tunnels is about 12.4m.The new horseshoe shaped twin tunnels,running east–west,are parts of the Beijing subway Line 6.The clearance between them is approximately 9.5m,which slightly decreases from west to east.The new twin tunnels are referred to as the ‘‘north tunnel’’and the ‘‘south tunnel’’,respectively.They were excavated by using the shallow tunnelling method.The shallow tunnelling method relying on manpower-excavation is particularly designed for shal-lowly-buried tunnels constructed in a densely built urban area (Fang et al.,2012).The thicknesses of the primary lining and sec-ondary lining are 250mm and 300mm respectively.A waterproof-ing system is sandwiched between the primary and the secondarylinings.The new twin tunnels were excavated perpendicularly beneath the existing twin tunnels.The vertical clearance between the new and existing tunnels is only 2.6m.The top heading (with support core and temporary invert)-bench-invert excavation approach was adopted for the new twin tunnels excavation (Fig.4).A typical geological profile of the project is shown in Fig.5.The profile reveals that the existing tunnels are located mainly in gravel,while the new tunnels are located in interbedded silty clay,silt,fine sand and gravel.Some mean values of the physical and mechanical parameters of the soils retrieved from the site investi-gation report are shown in Table 1.According to the project design,a rectangular vertical shaft was first excavated.Then a horseshoe shaped cross adit with flat walls and invert was excavated horizontally from the shaft sheeting.After that,the new twin tunnels were excavated perpendicularly from the adit wall.The north tunnel was first excavated followed by the south tunnel with a certain lag.In order to safeguard the existing twin tunnels and facilitate the new twin tunnels construc-tion,grouting into and above the new twin tunnels was performed.A total of eight grout holes,each of which about 30m long,were drilled horizontally from the cross adit wall.The grouting was achieved through a sleeve pipe known as a tube àmanchette (TAM).A grout mixture composed of ordinary Portland cement and sodium silicate was selected.The cross section and the longi-tudinal section of the long-span pre-grouting are shown in Fig.6.During the new twin tunnels construction,forepolings and footing reinforcement piles were adopted as the auxiliary measures (Fig.4).3.Monitoringyout of monitoring pointsDuring the new twin tunnels construction,the deformation of the existing tunnels and the ground surfaces were monitored.The layout of the monitoring points along the existing west tunnel and the east tunnel is shown in Fig.7.The parenthesised texts in Fig.7indicate those for the east tunnel section.The first letter ‘‘W’’or ‘‘E’’of the monitoring point label indicates the ‘‘west tun-nel’’or the ‘‘east tunnel’’.The second letter ‘‘e’’or ‘‘s’’indicatesQ.Fang et al./Tunnelling and Underground Space Technology 45(2015)128–137129the ‘‘existing tunnel’’or the ‘‘surface’’.The ground surface settle-ment monitoring points were installed from the road surface into the backfill ground to represent the ‘‘real’’ground surface settle-ment,which were monitored with total station.The settlement monitoring points of the existing twin tunnels were set up along the invert of each line,and monitored by a hydrostatic level system (Li et al.,2013).At each point of the existing tunnels to be moni-tored,hydrostatic level cells were fastened.The signals observed were sent back to the central monitoring system and recorded at 30min intervals.It is worth noting that the monitored deformation nearby the portal can also be affected by the shaft and cross adit excavation.In order to study the deformation induced bythe130Q.Fang et al./Tunnelling and Underground Space Technology 45(2015)128–137new twin tunnels construction alone,the deformation readings were taken only after the long-span pre-grouting had been performed.3.2.Monitoring dataThe development of the settlements for some typical points of the existing west and east tunnels is shown in Fig.8.The development of the ground surface settlements for some typical points above the existing west and east tunnels is shown in Fig.9.The north tunnel construction was performed under the existing west tunnel on August 8th and under the east tunnel on September 11th.In this part of the project,the south tunnel face was about 5m behind the north tunnel face and the distance between the top heading and the bench of each tunnel varied from 3m to 6m.Due to the short distance between the twintunnels,Q.Fang et al./Tunnelling and Underground Space Technology 45(2015)128–137131the settlements associated with a single tunnel construction can-not be obtained directly from the monitoring data.It is noted that the hydrostatic level system was very sensitive to the ambient interferences,such as the passage of a train nearby a monitoring point.As such,representative data relatively free of interferences, which were obtained during the non-service time of Line4after midnight,are selected from the huge volume of automatically recorded data to represent the daily settlement magnitudes of the existing tunnels due to the construction of the new twin tunnels.4.Analysis of monitoring data4.1.Superposition methodAccording to the monitoring data,we can construct the trans-verse settlement profiles of both the existing tunnels and the ground surfaces.The magnitude and shape of a settlement profile are influenced by tunnelling method,ground conditions,as well as tunnel dimensions and buried depth,etc.It is widely reported that the settlement profile for a single tunnel takes the shape ofTable1Physical and mechanical properties of soils.ID Group Bulk density(kg/m3)Water content(%)Standard(dynamic)penetration test N63.5Cohesion(kPa)Friction angle(°) t Silt197020.85129.429.3 t1Silty clay198024.581823.816.0 u Fine sand200010.6347032.0 u1Medium sand2030–53038.0 v Gravel2120–78(dynamic)045.0 w Silty clay198025.151230.917.9 w2Silt198020.921616.727.3 x1Fine sand203010.9058032.0 x Gravel2150–101(dynamic)045.0132Q.Fang et al./Tunnelling and Underground Space Technology45(2015)128–137an inverted Gaussian distribution curve symmetrical to the tunnel axis at right ing a Gaussian distribution curve to describe ground settlement profile wasfirst proposed by Peck(1969)and later verified byfield and laboratory tests(Mair et al.,1993).The shape of the settlement trough can be described by using the fol-lowing equation:S¼S max expÀx2 2i2¼AViffiffiffiffiffiffiffi2pp expÀx22i2ð1Þwhere x is the distance from the central line of a tunnel,i(or trough width)is the distance from the tunnel centre line to the inflection of the trough,S max is the maximum settlement,A is the tunnel cross-sectional area.V is the percentage of ground loss assuming the ground is incompressible.i.e.,V=V s/A and V s is the volume loss due to tunnelling.i can be calculated by a simple method proposed by Mair et al.(1981):i¼Kðz0ÀzÞð2Þwhere z0is the depth to the new tunnel axis and z is a concerned depth,K is an empirically determined trough width parameter.For multiple tunnels,it is not always possible to represent a transverse settlement profile by a single Gaussian curve.A common practice is to superpose the independent transverse settlement profiles calcu-lated for each individual excavation to obtain thefinal accumulative settlement profile.New and O’ReilIy(1991)provided a method of calculating surface settlement for twin tunnels driven simulta-neously.The same method had been reported by GCG(1992). Hunt(2005)provided a method for predicting ground movements above twin tunnels construction based on modifying the ground movements above the second tunnel in the‘‘overlapping zone’’where the soil is assumed to have been previously disturbed by thefirst tunnel.This modified method is validated against a number of case studies(Hunt,2005)and is also proved to be applicable to the laboratory model test data(Chapman et al.,2007).However, additional parameters are required in this method.In this research, in order to describe the settlement profiles of both the existing tun-nels and the surfaces induced by the separately constructedtwin Q.Fang et al./Tunnelling and Underground Space Technology45(2015)128–137133tunnels,a superposition method is introduced to separate the accu-mulated settlement profile into settlement profiles attributed by each tunnel.Although this method is not directly applicable to cases where plastic deformation occurs,similar method has been exten-sively adopted by many researchers(e.g.,Peck,1969;Suwansawat and Einstein2007).That is:S¼S max1expÀxþL=2ðÞ22i21"#þS max2expÀxÀL=2ðÞ22i22"#¼A1V1ffiffiffiffiffiffiffi2ppi1expÀxþL=2ðÞ22i21"#þA2V2ffiffiffiffiffiffiffi2ppi2expÀxÀL=2ðÞ22i22"#ð3Þwhere the subscript numbers1and2stand for thefirst tunnel exca-vated and the second tunnel excavated,L is the horizontal distance between the centre lines of the twin tunnels.4.2.Settlement profile of existing tunnels and ground surfacesUpon reviewing the recorded settlements for this project,they were found to be influenced by the top heading,bench and invert excavation of each tunnel.However,since the lag maintained between the top heading and the bench(and invert)of each of the twin tunnels was only3–6m and the distance between the leading faces of the twin tunnels varied(the north tunnel was about5m ahead of the south tunnel),it is unjustified to separate the settlement profile into profiles due to different construction stages of each tunnel.Therefore we only use the proposed superpo-sition method to estimate thefinal settlement profiles of the exist-ing tunnels and the ground surfaces.Thefinal settlement data of the existing tunnels and the ground surfaces of the two sections, along with thefitting curves obtained by the proposed method are shown in Fig.10.Four parameters,V1,V2,K1and K2,arefitted 134Q.Fang et al./Tunnelling and Underground Space Technology45(2015)128–137simultaneously to each set of data.The values of i 1and i 2can be calculated by Eq.(2)and the values of S max1and S max2can be cal-culated by Eq.(3).A summary of the data obtained by fitting and calculation is shown in Table 2.The adjusted coefficient of deter-mination (Adj.R -Square)indicates how well the data points match the proposed fitting curve.The closer the fit,the closer the adjusted R 2will be to the value of 1.The adjusted coefficients of determina-tion shown in Table 1are all above 0.9,indicating that the data points are appropriately fitted by the proposed method.A comparison of the total settlement profiles of the existing tunnel and the ground surface at each monitored cross-section reveals that the existing tunnel settlement profile displays a dou-ble-trough ‘‘W’’shape,while the ground surface settlement profile displays a single-trough ‘‘U’’shape.This phenomenon is mainly ascribable to their different overburden depth.As the buried depth increases,the more pronounced the double-trough shape of the settlement profile will be.The double-trough deformation pattern of the existing tunnels also indicates the flexibility of the segmen-tal lining,which means the existing tunnels follow the green field deformation.Due to the flexibility of the existing tunnels,the ground above the new tunnels is able to deform continuously.Therefore the total percentages of ground loss (V 1+V 2)obtained from different levels above the new tunnels in one monitoring cross-section,such as the existing tunnel level and the ground sur-face level,are nearly the same only with a slight increase from sur-face to subsurface.According to the monitoring results shown in Fig.10,we can observe that larger settlements both at surface and subsurface are reported above the north tunnel,which was first excavated.According to the fitting results shown in Table 2,it is foundthatQ.Fang et al./Tunnelling and Underground Space Technology 45(2015)128–137135the ground losses and the trough width parameters associated with the second tunnel excavation are larger than those due to thefirst tunnel at different depths.Similar results have been reported by other researchers(e.g.,Hunt,2005;Chapman et al., 2007;Divall,2013).Referring to the two Gaussian curves simply superimposed to represent the monitored total settlements,we can observe an interesting phenomenon that larger maximum settlement of a Gaussian curve is reported above thefirst tunnel excavated(S max1) at the existing tunnel level,while larger maximum settlement of a Gaussian curve is found above the second tunnel excavated(S max2) at the surface level.A similar trend that the maximum settlement of the Gaussian curvefitted for the second tunnel is larger than that for thefirst tunnel at the surface level can also be found in the laboratory model tests performed by Chapman et al.(2007). However,the mismatching phenomenon at different depths is rarely mentioned.We believe that with the development of settle-ment from the tunnel crown to the surface,the larger volume loss associated with the second tunnel at the subsurface level may increase the magnitude of the maximum settlementfitted for the second tunnel at the surface level.Therefore the larger maximum settlementfitted for a single tunnel may be revealed above thefirst tunnel at subsurface and above the second tunnel at surface.5.ConclusionsThis paper presents a case of closely spaced twin tunnels con-structed beneath two other existing closely spaced tunnels.The measures taken in this project and related monitoring data are elaborated.The key results obtained in this study can be summa-rised as follows:(1)A superposition method is proposed to describe the settle-ment profile due to the construction of twin tunnels below.A satisfactory match between the proposedfitting curvesand the measured settlement readings is obtained.(2)The settlement profile of the existing structure displays adouble trough‘‘W’’shape while the ground surface settle-ment profile displays a single trough‘‘U’’shape.This phe-nomenon is mainly ascribed to their different overburden depth.As the depth increases,the more pronounced the double-trough shape of the settlement profile will be for a twin tunnels project.(3)The ground losses obtained from the existing tunnel leveland the ground surface level in the same monitoring cross-section were nearly the same.It implies that the segmental lining has a sufficientflexibility to deform in a manner that matched the deformation of the surrounding ground. AcknowledgmentsThe authors gratefully acknowledge thefinancial support by the Science and Technology Project of Ministry of Transport of the People’s Republic of China under Grant2013318Q03030and the National Natural Science Foundation of China under Grant 51108020.ReferencesAddenbrooke,T.I.,Potts, D.M.,2001.Twin tunnel interaction–surface and subsurface effects.Int.J.Geomech.1(2),249–271.Ahn,S.K.,Chapman, D.N.,Chan, A.H.,Hunt, D.V.L.,2006.Model Tests for Investigating Ground Movements cause by Multiple Tunnelling in Soft Ground.Taylor and Francis,pp.1133–1137.Boone,S.J.,1996.Ground-movement-related building damage.J.Geotech.Geoenviron.Eng.122(11),886–896.Boscardin,M.D.,Cording, E.J.,1989.Building response to excavation-induced settlement.J.Geotech.Eng.115(1),1–21.Burd,H.J.,Houlsby,G.T.,Augarde,C.E.,Lui,G.,2000.Modeling tunnelling-induced settlement of masonry buildings.ICE Proc.:Geotech.Eng.143,17–29. Burland,J.B.,1995.Assessment of risk of damage to buildings due to tunnelling and excavation.In:Proc.1st Int.Conf.on Earthquake Geotechnical Engineering,IS, Tokyo,pp.155–162.Chapman,D.N.,Rogers,C.D.F.,Hunt,D.V.L.,2003.Investigating the settlement above closely spaced multiple tunnel constructions in soft ground.In:Proc.of World Tunnel Congress2003,vol.2,Amsterdam,pp.629–635.Chapman,N.D.,Ahn,S.K.,Hunt, D.V.L.,2007.Investigating ground movements caused by the construction of multiple tunnels in soft ground using laboratory model tests.Can.Geotech.J.44(6),631–643.Cooper,M.L.,Chapman,D.N.,Rogers,C.D.F.,Chan,A.H.C.,2002.Movements in the piccadilly line tunnels due to the heathrow express construction.Géotechnique 52(4),243–257.Divall,S.,2013.Ground Movements associated with Twin-Tunnel Construction in Clay.PhD Thesis,City University London,UK.Divall,S.,Goodey,R.J.,Taylor,R.N.,2012.Ground movements generated by sequential twin-tunnelling in over-consolidated clay.In:2nd European Conference on Physical Modelling in Geotechnics,Delft,The Netherlands. Do,N.A.,Dias,D.,Oreste,P.,Djeran-Maigre,I.,2014.Three-dimensional numerical simulation of a mechanized twin tunnels in soft ground.Tunn.Undergr.Space Technol.42,40–51.Fang,Q.,Zhang,D.L.,Wong,L.N.Y.,2011.Environmental risk management for a cross interchange subway station construction in China.Tunn.Undergr.Space Technol.26(6),750–763.Fang,Q.,Zhang,D.L.,Wong,L.N.Y.,2012.Shallow tunnelling method(STM)for subway station construction in soft ground.Tunn.Undergr.Space Technol.29, 10–30.Garner,C.D.,Coffman,R.A.,2013.Subway tunnel design using a ground surface settlement profile to characterize an acceptable configuration.Tunn.Undergr.Space Technol.35,219–226.(GCG)Crossrail Project,1992.Prediction of Ground Movements and Associated Buildings Damage due to Bored Tunnelling.Geotechnical Consulting Group, London.Hunt, D.V.L.,2005.Predicting the Ground Movements above Twin Tunnels constructed in London Clay.PhD Thesis,University of Birmingham,UK.Klar, A.,Vorster,T.E.B.,Soga,K.,Mair,R.J.,2005.Soil–pipe interaction due to tunnelling:comparison between Winkler and elastic continuum solutions.Géotechnique55(6),461–466.Laver,R.G.,2011.Long-term Behaviour of Twin Tunnels in London Clay.PhD Thesis, University of Cambridge,UK.Li,X.G.,Yuan,D.J.,2012.Response of a double-decked metro tunnel to shield driving of twin closely under-crossing tunnels.Tunn.Undergr.Space Technol.28,18–30.Li,X.G.,Zhang,C.P.,Yuan,D.J.,2013.An in-tunnel jacking above tunnel protection methodology for excavating a tunnel under a tunnel in service.Tunn.Undergr.Space Technol.34,22–37.Mair,R.J.,Gunn,M.J.,O’Reilly,M.P.,1981.Ground movements around shallow tunnels in soft clay.In:Proceedings of the Tenth ICSMFE,Stockholm,pp.323–328.Mair,R.J.,Taylor,R.N.,Bracegirdle,A.,1993.Subsurface settlement profiles above tunnels in clays.Géotechnique43(2),315–320.Mohamad,H.,Bennett,P.J.,Soga,K.,Mair,R.J.,Bowers,K.,2010.Behaviour of an old masonry tunnel due to tunnelling-induced ground settlement.Géotechnique60(12),927–938.Table2Settlement parameters of the existing tunnels and ground surfaces.Monitoring points Monitored maximumsettlement(mm)Fitted maximumsettlement(mm)Percentage of groundloss(%)Trough widthparameterTrough width(m)Adjusted coefficientof determination(Adj.R-Square)S max1S max2V1V2K1K2i1i2West tunnel7.00 6.19 5.920.240.320.87 1.22 5.127.140.92 East tunnel 6.60 6.01 5.550.220.290.83 1.18 4.84 6.900.91 Surface above west tunnel 5.17 3.38 3.720.210.310.340.458.2111.000.98 Surface above east tunnel 4.95 3.22 3.630.200.280.340.428.2010.190.91 136Q.Fang et al./Tunnelling and Underground Space Technology45(2015)128–137Mroueh,H.,Shahrour,I.,2003.A full3-Dfinite element analysis of tunnelling-adjacent structures put.Geotech.30(3),245–253.New,B.M.,O’ReilIy,M.P.,1991.Tunnelling induced ground movements:predicting their magnitude and effects(invited review paper).In:Proc.4th Int.Conf.on Ground Movements and Structures.Pentech Press,Cardiff,pp.671–697.Ng, C.W.W.,Boonyarak,T.,Mašín, D.,2013.Three-dimensional centrifuge and numerical modeling of the interaction between perpendicularly crossing tunnels.Can.Geotech.J.50(9),935–946.Ocak,I.,2014.A new approach for estimating the transverse surface settlement curve for twin tunnels in shallow and soft soils.Environ.Earth Sci.,1–11. Peck,R.B.,1969.Deep excavation and tunneling in soft ground.state of the art report.In:7th International Conference on Soil Mechanics and Foundation Engineering,Mexico City,pp.225–290.Suwansawat,S.,Einstein,H.H.,2007.Describing settlement troughs over twin tunnels using a superposition technique.J.Geotech.Geoenviron.Eng.133(4), 445–468.Vorster,T.,Klar,A.,Soga,K.,Mair,R.,2005.Estimating the effects of tunneling on existing pipelines.J.Geotech.Geoenviron.Eng.131(11),1399–1410. Zhang,C.,Yu,J.,Huang,M.,2012.Effects of tunnelling on existing pipelines in layered put.Geotech.43,12–25.Zhang,D.L.,Fang,Q.,Hou,Y.J.,Li,P.F.,Wong,L.N.Y.,2013.Protection of buildings against damages as a result of adjacent large-span tunneling in shallowly buried soft ground.J.Geotech.Geoenviron.Eng.139(6),903–913.Q.Fang et al./Tunnelling and Underground Space Technology45(2015)128–137137。

中文5351字出处:Environmental Earth Sciences, 2011, 62(2): 357-365外文原文Surface settlement predictions for Istanbul Metrotunnels excavated by EPB-TBMS. G. Ercelebi • H. Copur • I. OcakAbstract In this study, short-term surface settlements are predicted for twin tunnels, which are to be excavated in the chainage of 0 ? 850 to 0 ? 900 m between the Esenler and Kirazlı stations of the Istanbul Metro line, which is 4 km in length. The total length of the excavation line is 21.2 km between Esenler and Basaksehir. Tunnels are excavated by employing two earth pressure balance (EPB) tunnel boring machines (TBMs) that have twin tubes of 6.5 m diameter and with 14 m distance from center to center. The TBM in the right tube follows about 100 m behind the other tube. Segmental lining of 1.4 m length is currently employed as the final support. Settlement predictions are performed with finite element method by using Plaxis finite element program. Excavation, ground support and face support steps in FEM analyses are simulated as applied in the field. Predictions are performed for a typicalgeological zone, which is considered as critical in terms of surface settlement. Geology in the study area is composed of fill, very stiff clay, dense sand, very dense sand and hard clay, respectively, starting from the surface. In addition to finite element modeling, the surface settlements are also predicted by using semi-theoretical (semi-empirical) and analytical methods. The results indicate that the FE model predicts well the short-term surface settlements for a given volume loss value. The results of semi-theoretical and analytical methods are found to be in good agreement with the FE model. The results of predictions are compared and verified by field measurements. It is suggested that grouting of the excavation void should be performed as fast as possible after excavation of a section as a precaution against surface settlements during excavation. Face pressure of the TBMs should be closely monitored and adjusted for different zones.Keywords Surface settlement prediction _ Finite element method _ Analytical method _ Semi-theoretical method _ EPB-TBM tunneling _Istanbul MetroIntroductionIncreasing demand on infrastructures increases attention to shallow soft ground tunneling methods in urbanized areas. Many surface and sub-surface structures make underground construction works very delicate due to the influence of grounddeformation, which should be definitely limited/controlled to acceptable levels. Independent of theexcavation method, the short- and long-term surface and sub-surface ground deformations should be predicted and remedial precautions against any damage to existing structures planned prior to construction. Tunneling cost substantially increases due to damages to structures resulting from surface settlements, which are above tolerable limits (Bilgin et al. 2009).Basic parameters affecting the ground deformations are ground conditions, technical/environmental parameters and tunneling or construction methods (O’Reilly an d New 1982; Arioglu 1992; Karakus and Fowell 2003; Tan and Ranjit 2003; Minguez et al. 2005; Ellis 2005; Suwansawat and Einstein 2006). A thorough study of the ground by site investigations should be performed to find out the physical and mechanical properties of the ground and existence ofunderground water, as well as deformation characteristics, especially the stiffness. Technical parameters include tunnel depth and geometry, tunnel diameter–line–grade, single or double track lines and neighboring structures. The construction method, which should lead to a safe and economic project, is selected based on site characteristics and technical project constraints and should be planned so that the ground movements are limited to an acceptablelevel. Excavation method, face support pressure, advance (excavation) rate, stiffness of support system, excavation sequence and ground treatment/improvement have dramatic effects on the ground deformations occurring due to tunneling operations. The primary reason for ground movements above the tunnel, also known as surface settlements, is convergence of the ground into the tunnel after excavation, which changes the in situ stress state of the ground and results in stress relief. Convergence of the ground is also known as ground loss or volume loss. The volume of the settlement on the surface is usually assumed to be equal to the ground (volume) loss inside the tunnel (O’Reilly and New 1982).Ground loss can be classified as radial loss around the tunnel periphery and axial (face) loss at the excavation face (Attewell et al. 1986; Schmidt 1974). The exact ratio of radial and axial volume losses is not fully demonstrated or generalized in any study. However, it is possible to diminish or minimize the face loss in full-face mechanized excavations by applying a face pressure as a slurry of bentonite–water mixture or foam-processed muck. The ground loss is usually more in granular soils than in cohesive soils for similar construction conditions. The width of the settlement trough on both sides of the tunnel axis is wider in the case of cohesive soils, which means lower maximum settlement for the same amount of ground loss.Time dependency of ground behavior and existence of underground water distinguish short- and long-term settlements (Attewell et al. 1986). Short-term settlements occur during or after a few days (mostly a few weeks) of excavation, assuming that undrained soil conditions are dominant. Long-term settlements are mostly due to creep, stress redistribution and consolidation of soil after drainageof the underground water and elimination of pore water pressure inside the soil, and it may take a few months to a few years to reach a stabilized level. In dry soilconditions, the long-term settlements may be considered as very limited.There are mainly three settlement prediction approaches for mechanized tunnel excavations: (1) numerical analysis such as finite element method, (2) analytical method and (3) semi-theoretical (semi-empirical) method. Among them, the numerical approaches are the most reliable ones. However, the results of all methods should be used carefully by an experienced field engineer in designing the stage of an excavation project.In this study, all three prediction methods are employed for a critical zone to predict the short-term maximum surface settlements above the twin tunnels of the chainage between 0 ? 850 and 0 ? 900 m between Esenler and Kirazlıstations of Istanbul Metro line, which is 4 km in length. Plaxis finite element modeling program is used fornumerical modeling; the method suggested by Loganathan and Poulos (1998) is used for the analytical solution. A few different semi-theoretical models are also used for predictions. The results are compared and validated by field measurements. Description of the project, site and construction methodThe first construction phase of Istanbul Metro line was started in 1992 and opened to public in 2000. This line is being extended gradually, as well as new lines are being constructed in other locations. One of these metro lines is the twin line between Esenler and Basaksehir, which is 21.2 km. The excavation of this section has been started in May 2006. Currently, around 1,400 m of excavationhas already been completed. The region is highly populated including several story buildings, industrial zones and heavy traffic. Alignment and stations of the metro line between Esenler and Basaksehir is presented in Fig. 1.Totally four earth pressure balance (EPB) tunnel boring machines (TBM) are used for excavation of the tunnels. The metro lines in the study area are excavated by a Herrenknecht EPB-TBM in the right tube and a Lovat EPB-TBM in the left tube. Right tube excavationfollows around 100 m behind the left tube. Some of the technical features of the machines are summarized in Table 1.Excavated material is removed by auger (screw conveyor) through the machine to a belt conveyor and than loaded to rail cars for transporting to the portal. Since the excavated ground bears water and includes stability problems, the excavation chamber is pressurized by 300 kPa and conditioned by applying water, foam, bentonite and polymers through the injection ports. Chamber pressure is continuously monitored by pressure sensors inside thechamber and auger. Installation of a segment ring with 1.4-m length (inner diameter of 5.7 m and outer diameter of 6.3 m) and 30-cm thickness is realized by a wing-type vacuum erector. The ring is configured as five segments plus a key segment. After installation of the ring, the excavation restarts and the void between the segment outer perimeter and excavated tunnel perimeter is grouted by300 kPa of pressure through the grout cannels in the trailing shield. This method of construction has beenproven to minimize the surface settlements.The study area includes the twin tunnels of the chainage between 0 + 850 and 0 + 900 m, between Esenler and Kirazlı stations. Gungoren Formation of th e Miosen age is found in the study area. Laboratory and in situ tests are applied to define the geotechnical features of theformations that the tunnels pass through. The name, thickness and some of the geotechnical properties of the layers are summarized in Table 2 (Ayson 2005). Fill layer of 2.5-m thick consists of sand, clay, gravel and some pieces of masonry. The very stiff clay layer of 4 m is grayish green in color, consisting of gravel and sand. The dense sand layer of 5 m is brown at the upper levels and greenish yellow at the lower levels, consisting of clay, silt and mica. Dense sand of 3 m is greenish yellow and consists of mica. The base layer of the tunnel is hard clay, which is dark green, consisting of shell. The underground water table starts at 4.5 m below the surface. The tunnel axis is 14.5 m below the surface, close to the contact between very dense sand and hard clay. This depth isquite uniform in the chainage between 0 + 850 and 0 + 900 m.Surface settlement prediction with finite element modelingPlaxis finite element code for soil and rock analysis is used to predict the surface settlement. First, the right tube is constructed, and then the left tube 100 m behind the right tube is excavated. This is based on the assumption that ground deformations caused by the excavation of the right tube are stabilized before the excavation of the left tube. The finite element mesh is shown in Fig. 2 using 15 stress point triangular elements. The FEM model consists of 1,838 elements and 15,121 nodes. In FE modeling, the Mohr–Coulomb failure criterion is applied.Staged construction is used in the FE model. Excavation of the soil and the construction of the tunnel lining are carried out in different phases. In the first phase, the soil in front of TBM is excavated, and a support pressure of 300 kPa is applied at the tunnel face to prevent failure at the face. In the first phase, TBM is modeled as shell elements. In the second phase, the tunnel lining is constructedusing prefabricated concrete ring segments, which are bolted together within the tunnel boring machine. During the erection of the lining, TBM remains stationary. Once a lining ring has been bolted, excavation is resumed until sufficient soil excavation is carried out for the next lining. The tunnel lining is modeled using volume elements. In the second phase, the lining is activated and TBM shell elements are deactivated.When applying finite element models, volume loss values are usually assumed prior to excavation. In this study, the FEM model is run with the assumption of 0.5, 0.75, 1 and 1.5% volume loss caused by the convergence of the ground into the tunnel after excavation. Figures 3 and 4 show total and vertical deformations after both tubes are constructed. The vertical ground settlement profile after theright tube construction is given in Fig. 5, which is in theshape of a Gaussian curve, and that after construction of both tubes is given in Fig. 6. Figure 7 shows the total deformation vectors.The maximum ground deformations under different volume loss assumptions are summarized in Table 3.Surface settlement prediction with semi-theoretical and analytical methodsSemi-theoretical predictions for short-term maximum settlement are performed using the Gaussian curve approach, which is a classical and conventional method. The settlement parameters used in semi-theoretical estimations and notations are presented in Fig. 8.The theoretical settlement (Gaussian) curve is presented as in Eq. 1 (O’Reilly and New 1982):)2(m a x 22i x e S S -= (1)where, S is the theoretical settlement (Gauss error function, normal probability curve), Smax is the maximum short-term (initial, undrained) settlement at the tunnel centerline (m), x is the transverse horizontal distance from the tunnel center line (m), and i is the point of inflexion (m). To determine the shape of a settlement curve, it is necessary to predict i and Smax values.There are several suggested methods for prediction of the point of inflexion (i). Estimation of i value in this studyis based on averages of some empirical approaches given in Eqs. 2–6:where, Z0 is the tunnel axis depth (m), 14.5 m in this study, and R is the radius of tunnel, 3.25 m in this study. Equation 3 was suggested by Glossop (O’Reilly and New 1982) for mostly cohesive grounds; Eq. 4 was suggested by O’Reilly and New (1982) for excavation of cohesive grounds by shielded machines; Eq. 5 was suggested by Schmidt (1969) for excavation of clays by shielded machines; Eq. 6 was suggested by Arioglu (1992) for excavation of all types of soils by shielded machines. As a result, the average i value is estimated to be 6.6 m in this study.There are several suggested empirical methods for the prediction of the maximum surface settlement (Smax).Schmidt suggested a model for the estimation of Smax value for a single tunnel in 1969 as given in Eq. 7 (through Arioglu 1992):where, K is the volume loss (%). Arioglu (1992), based on field data, found a good relationship between K and N (stability ratio) for face-pressurized TBM cases as in Eq. 8:where cn is the natural unit weight of the soil (kN/m3), the weighted averages for all the layers, which is 19 kN/m3 in this study; rS is the total surcharge pressure (kPa), assumed to be 20 kPa in this study; rT is TBM face pressure (kPa), which is 300 kPa in this study; and CU is the undrained cohesion of the soil (kPa), the weightedaverages for all the layers, which is 50 kPa in this study assuming that CU is equal to SU (undrained shear strength of the soil). Allaverages are estimated up to very dense sand, excluding hard clay, since the tunnel axis passes around the contact between very dense sand and hard clay. The model yields 17.1 mm of initial maximum surface settlement.Herzog suggested a model for the estimation of Smax value in 1985 as given in Eq. 9 for a single tunnel and Eq. 10 for twin tunnels (through Arioglu 1992):where, E is the elasticity modulus of formation (kPa), the weighted averages for all the layers, which is 30,000 kPa in this study, and a is the distance between the tunnel axes, which is 14 m in this study. The model yields 49.9 and 58.7 mm of initial maximum surface settlements for the right and the left tube tunnel, which is 100 mm behind the right tube, respectively.There are several analytical models for the prediction of short-term maximum surface settlements for shielded tunneling operations (Lee et al. 1992; Loganathan and Poulos 1998; Chi et al. 2001; Chou and Bobet 2002; Park 2004). The method suggested by Loganathan and Poulos (1998) is used in this study. In this method, a theoretical gapparameter (g) is defined based on physical gap in the void, face losses and workmanship value, and then the gap parameter is incorporated to a closed form solution to predict elastoplastic ground deformations. The undrained gap parameter (g) is estimated by Eq. 12:where Gp is the physical gap representing the geometric clearance between the outer skin of the shield and the liner, is the thickness of the tail shield, d is the clearance required for erection of the liner, U*3D is the equivalent 3D elastoplastic deformation at the tunnel face, and w is a value that takes into account the quality of workmanship.Maximum short-term surface settlement is predicted by theoretical Eq. 13 (Loganathan and Poulos 1998):where, t is undrained Poisson’s ratio, assumed to be of maximum 0.5; g is the gap parameter (m), which is estimated to be 0.0128 m in this study; and x is transversedistance from the tunnel centerline (m) and it is assumed to be 0 m for the maximum surface settlement. The model yields 23.0 mm of undrained maximum surface settlement.Other parameters of settlement such as maximum slope, maximum curvature and so on are not mentioned in this study.Verification of predictions by field measurements and discussionThe results of measurements performed on the surface monitoring points, by Istanbul Metropolitan Municipality, are presented in Table 4 for the left and right tubes. As seen, the average maximum surface settlements are around 9.6 mm for the right tube and 14.4 mm for the left tube, which excavates 100 m behind the right tube. Themaximum surface settlements measured around 15.2 mm for the right tube and 26.3 mm for the left tube. Higher settlements are expected in the left tube since the previous TBM excavation activities on the right tube overlaps the previous deformation. The effect of the left tube excavation on deformations of the right tube is presented in Fig. 9. As seen, after Lovat TBM in the right tube excavates nearby the surface monitoring point 25, maximum surface settlement reaches at around 9 mm; however, while Herrenknecht TBM in the left tube passes the same point, maximum surface settlement reaches at around 29 mm (Fig. 10).If the construction method applied to the site is considered, long-term (consolidation) settlements are expected to be low, since the tail void is grouted immediately after excavation. The results of predictions mentioned above and observed maximum surface settlements are summarized in Table 5.The methods suggested by Loganathan and Poulos (1998) and Schmidt (1969) connected with Arioglu’s suggestion (1992) can predict the maximum short-term surface settlements only for a single tunnel. Plaxis finite element and Herzog (1985) models can predict deformations for twin tubes.Herzog’s model (1985) yields higher maximum surface settlements than the observed ones. The reason for that is that the database of the model includes both shielded tunnels and NATM (New Austrian Tunneling Method) tunnels, of which surfacesettlements are usually higher compared to shielded tunnels. Schmidt (1969), along withArioglu’s suggestion (1992), yields predictions close to observed.Plaxis finite element modeling gives the most realistic results, provided there is correct assumption of volume loss parameter, which is usually difficult to predict. The model provides simulation of excavation, lining, grouting and face pressure in a realistic manner to predict surface and sub-surface settlements. The volume loss parameter is usually assumed to be \1% for excavation with facepressure-balanced tunnel boring machines. The realized volume loss in the site is around 1% for this study.Currently, there is difficulty yet in modeling the deformation behavior of twin tunnels. One of the most impressive studies on this issue was performed by Chapman et al. (2004). However, Chapman’s semi-theoretical method still requires enlargement of the database to improve the suggested model in his paper.ConclusionsIn this study, three surface settlement prediction methods for mechanized twin tunnel excavations be tween Esenler and Kirazlı stations of Istanbul Metro Line are applied. Tunnels of 6.5-m diameters with 14-m distance between their centers are excavated by EPM tunnel boring machines. The geologic structure of the area can be classified as soft ground.Settlement predictions are performed by using FE modeling, and semi-theoretical (semi-empirical) and analytical methods. The measured results after tunneling are compared to predicted results. These indicate that the FE model predicts well the short time surface settlements for a given volume loss value. The results of some semi-theoretical and analytical methods are found to be in goodagreement with the FE model, whereas some methods overestimate the measured settlements. The FE model predicted the maximum surface settlement as 15.89 mm (1% volume loss) for the right tube, while the measured maximum settlement was 15.20 mm. For the left tube (opened after the right), FE prediction was 24.34 mm, while measured maximum settlement was 26.30 mm.中文翻译基于盾构法的Istanbul地铁施工引起的地面沉降预测摘要在这项研究中,研究的是双线隧道的短期地面沉降,选取线路里程总长为4km的Istanbul地铁从Esenler站到Kirazl站方向850到900m区间为研究对象。

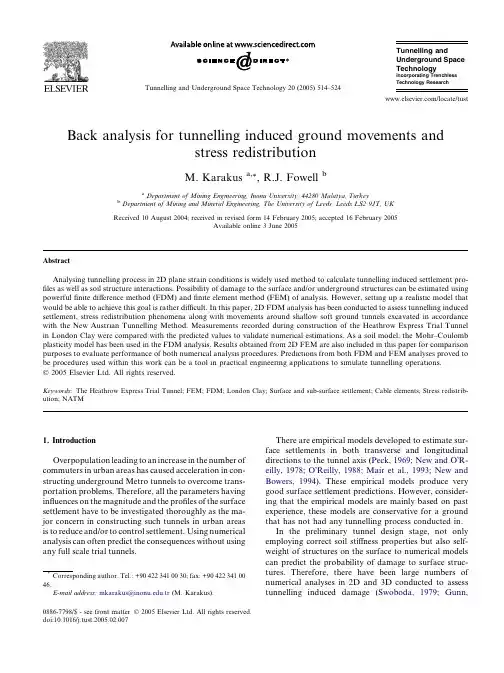

Back analysis for tunnelling induced ground movements andstress redistributionM.Karakusa,*,R.J.FowellbaDepartment of Mining Engineering,Inonu University,44280Malatya,TurkeybDepartment of Mining and Mineral Engineering,The University of Leeds,Leeds LS29JT,UKReceived 10August 2004;received in revised form 14February 2005;accepted 16February 2005Available online 3June 2005AbstractAnalysing tunnelling process in 2D plane strain conditions is widely used method to calculate tunnelling induced settlement pro-files as well as soil structure interactions.Possibility of damage to the surface and/or underground structures can be estimated using powerful finite difference method (FDM)and finite element method (FEM)of analysis.However,setting up a realistic model that would be able to achieve this goal is rather difficult.In this paper,2D FDM analysis has been conducted to assess tunnelling induced settlement,stress redistribution phenomena along with movements around shallow soft ground tunnels excavated in accordance with the New Austrian Tunnelling Method.Measurements recorded during construction of the Heathrow Express Trial Tunnel in London Clay were compared with the predicted values to validate numerical estimations.As a soil model,the Mohr–Coulomb plasticity model has been used in the FDM analysis.Results obtained from 2D FEM are also included in this paper for comparison purposes to evaluate performance of both numerical analysis procedures.Predictions from both FDM and FEM analyses proved to be procedures used within this work can be a tool in practical engineering applications to simulate tunnelling operations.Ó2005Elsevier Ltd.All rights reserved.Keywords:The Heathrow Express Trial Tunnel;FEM;FDM;London Clay;Surface and sub-surface settlement;Cable elements;Stress redistrib-ution;NATM1.IntroductionOverpopulation leading to an increase in the number of commuters in urban areas has caused acceleration in con-structing underground Metro tunnels to overcome trans-portation problems.Therefore,all the parameters having influences on the magnitude and the profiles of the surface settlement have to be investigated thoroughly as the ma-jor concern in constructing such tunnels in urban areas is to reduce and/or to control ing numerical analysis can often predict the consequences without using any full scale trial tunnels.There are empirical models developed to estimate sur-face settlements in both transverse and longitudinal directions to the tunnel axis (Peck,1969;New and O ÕR-eilly,1978;O ÕReilly,1988;Mair et al.,1993;New and Bowers,1994).These empirical models produce very good surface settlement predictions.However,consider-ing that the empirical models are mainly based on past experience,these models are conservative for a ground that has not had any tunnelling process conducted in.In the preliminary tunnel design stage,not only employing correct soil stiffness properties but also self-weight of structures on the surface to numerical models can predict the probability of damage to surface struc-tures.Therefore,there have been large numbers of numerical analyses in 2D and 3D conducted to assess tunnelling induced damage (Swoboda,1979;Gunn,0886-7798/$-see front matter Ó2005Elsevier Ltd.All rights reserved.doi:10.1016/j.tust.2005.02.007*Corresponding author.Tel.:+904223410030;fax:+904223410046.E-mail address:mkarakus@.tr (M.Karakus)./locate/tustTunnelling and Underground Space Technology 20(2005)514–524Tunnelling andUnderground Space Technologyincorporating Trenchless Technology Research1992;Shohrour and Ghorbanbeigi,1994;Swoboda et al.,1994;Dasari,1996;Swoboda et al.,1999;Mroueh and Shahrour,2003;Karakus and Fowell,2003).In the present work,2D plane strain Finite Difference analyses have been conducted to investigate ground movement profiles and stress redistribution around a NATM tunnel.Fast Lagrangian analysis of continua (FLAC)(Itasca,1993)program has been utilized to sim-ulate tunnel construction.Tunnel Excavation process has been modelled using the hypothetical modulus of elasticity(HME)soft lining approach(Powell et al., 1997).Mroueh and Shahrour(2003)has studied interac-tions of buildings with tunnels using3Dfinite element analysis.They concluded that self weight of buildings on the surface has a major role on determination of ini-tial stresses in the ground and neglecting this results in underestimation of tunnelling induced forces leading to less settlement predictions.Therefore,surcharge of 80kPa(Bowers,1997)due to existing car park over the Heathrow Trial Tunnel excavation has been in-cluded within the analysis.Surface and subsurface transverse settlement troughs, along with horizontal stress distributions measured dur-ing the Heathrow Trial Tunnel construction in1992have been compared with the predicted results(Bowers,1997).2.Geology at the site and construction processesMaterials encountered at the site consist of Thames gravel,made ground and London Clay.The London Clay is clearly dominant at the site and is found belowa depth of4.2m.This is overlain by coarse gravel,with0.3m of cement-stabilised material and above this a bitumen covered car park(Ryley and Carder,1995). Dean and Basset(1995)reported that London Clay is generally homogenous with very few major discontinu-ities and it has a good stand up time of at least18h. Trial tunnel construction was carried out approximately 16.8m crown depth.The analyses were carried out in terms of effective stress parameters,in other words, drained analyses were conducted.Therefore,London Clay properties were expressed in terms of equivalent effective stress values effective Young modulus(E0)and effective poissonÕs ratio(v0)(Burland and Kalra,1986). Made ground and Terrace gravel(Thames gravel)were modelled using the drained material properties.Proper-ties adopted for the numerical analysis are given in Table1.Grose and Eddie(1996)suggested that the cohesion of the London Clay is10kPa and earth pres-sure at rest,K0=1when analysing the Heathrow Trans-fer Baggage System tunnel.On the other hand,it was found by Atzl and Mayr(1994)and Ryley and Carder (1995)that the cohesion of the London Clay varies be-tween0and30kPa.Earth pressure at rest(K0)value for made ground and Thames gravel was predicted using well known JakyÕs formula(K onc=1Àsin/0)and adopted in the FDM analysis(see Fig.1).According to the data derived from different sites in London,Burland and Kalra(1986)proposed a relation for the drained Young Modulus of London Clay in both vertical and horizontal directions.These relationships show that stiffness of the London Clay varies with depth (z).E0m¼7.5þ3.9zðMN=m2Þ;ð1ÞE0h¼1.6E0mðMN=m2Þ.ð2ÞTable1Drained material properties at the site(Powell et al.,1997;Burland and Kalra,1986)Parameters,units and symbols London Clay Thames Gravel Bulk unit weight,kN/m3,c2019 Cohesion,MPa,c0100Earth pressure at rest,K0 1.150.43Internal friction angle,/0(°)25°35°Dilation angle,u0(°)12.5°17.5°PoissonÕs ratio,m00.1250.3Effective bulk modulus,MPa,K0See Fig.123.8E3Effective shear modulus,MPa,G0See Fig.119.23E3Effective YoungÕs modulus(in vertical),MPa,E0m See Fig.150E3M.Karakus,R.J.Fowell/Tunnelling and Underground Space Technology20(2005)514–524515Construction of the trial tunnel started in February1992 with the Type-1(TS1)method of advance,a double side drift sequence,followed by Type-2(TS2),single side drift sequence,and Type-3(TS3),crown,bench,and in-vert face excavation(Fig.2).This work was completed by16June1992.Measurement and monitoring of the construction process was conducted by the Transport Research Laboratory(TRL).The project provided information on ground movements in the London Clay to tunnel designers.Each trial section progressed for at least30m in or-der to obtain adequate and meaningful data over each section.Trial tunnel construction was carried out at 16.8m crown depth below the surface with having 7.9m height and9.2m width,producing a100-metre long running tunnel.From thefield observations, Type-2(TS2)produced the minimum transverse surface settlement profile among the Trial tunnels and TS2was subjected to the FDM analysis in this research.The shotcrete has been represented by elastic beam elements in the analysis.The elasticity modulus of the beam elements was divided by(1Àm2)in order to take account the plane strain conditions since beam element formulation is a plane stress formulation implemented in the FLAC.Beam elements attached to the ground and cable elements were used to simulate rock bolts.Properties of these structural elements are given in Table2.Cable elements are1D axial structural elements an-chored at a specific point in the grid or grouted so that the cable element develops forces along its length as the grid deforms.Cable elements are used to model rock bolts,cable bolts.Cable element formulation in FLAC considers deformations along entire length of bolts rather than a specific point and thus it is useful model-ling such reinforcement systems as rock bolts where grout material may fail in shear in some length of the reinforcement(Itasca,1993).Fig.3illustrates the cable element behaviour implemented in FLAC.As the input parameters for cable elements,grout stiff-ness(K bond),grout shear strength(S bond),and area(A), YoungÕs Modulus(E),diameter(D),length(L)and ulti-mate strength of cable are required.A1D constitutive model is used to model axial behavior of the reinforcing element in FLAC.The axial stiffness is described in terms of the reinforcement cross-sectional area,A,and YoungÕs modulus,E(w),the incremental axial force,D F t,is calcu-lated from the incremental axial displacement byD F t¼ÀEALD u t;ð3Þwhere D u t¼ðu½b1Àu½a1Þt1þðu½b2Àu½a2Þt2.The super-scripts[a],[b]refer to the nodes in the grid.The cosines t1,t2are the tangential(axial)direction of the cable.As a consequence of relative shear displacement,u t,be-tween the tendon surface and the borehole surface,the shear force,F t,mobilized per length of cable is related to the grout stiffness,K bond–i.e.(Itasca,1993),F t¼K bond u t.ð4ÞFig.2.The Heathrow Express Trial Tunnel,Type-2(Bowers,1997).Table2Structural element properties used in the FDM analysis(Itasca,1993;Bowers,1997)Parameters,symbols and units Beam elements Cable elementsInner lining Outer liningArea,A,m20.150.250.0005 PoissonÕs ratio,m0.150.15–YoungÕs modulus,E,MPa5000500040000 Moment of inertia,I,m40.0002810.0013–Cable diameter,D,m n/a0.025Cable length,L,m n/a3Ultimate strength of cable(force),MN n/a0.225Bond stiffness of grout,K bond,MN/m/m n/a6000Bond strength of grout,S bond,MN/m n/a0.320n/a:not applicable.516M.Karakus,R.J.Fowell/Tunnelling and Underground Space Technology20(2005)514–524If laboratory pull-out tests are available,K bond can bemeasured directly,else the stiffness can be calculated from a numerical estimate for the elastic shear stress,s G ,obtained from an equation describing the shear stress at the grout/rock interface (Itasca,1993):s G ¼G ðD =2þt ÞD uln ð1þ2t =D Þ;ð5Þwhere D u is relative displacement between the element and the surrounding material;G w is grout shear modu-lus;D w is reinforcing diameter;and t w is the annulus thickness.Consequently,the grout shear stiffness,K bond w (N/m/m ‘w ,is simply given byK bond ¼2p Gln ð1þ2t =D Þ.ð6ÞOther important parameter which has to be defined is S bond .This may also be deduced from the following expressions when ignoring frictional confinement effects (Itasca,1993):S bond ¼p ðD þ2t Þs peak ;ð7Þs peak ¼s I Q B ;ð8Þwhere s peak is the maximum shear force per cable length in the grout,s I is about 50%of the uniaxial compressive strength of the weaker of the rock and grout,and Q B is the quality of the bond in between grout and rock (Q B =1is for perfect bonding)(Itasca,1993).2.1.The Heathrow Express Trial Tunnel Type-2and instrumentation methodologySub-surface measuring equipment consists of extens-ometers,inclinometers and push-in pressure cells and piezometers.Magnetic probe extensometers were used to measure vertical displacement.Horizontal soil stresswas measured using spade cells and push-in soil stress cells that were inserted near to the tunnel crown and at axis level.To measure the horizontal total stresses,these cells were incorporated with the pneumatic piez-ometers to record pore water pressures.Pneumatic piez-ometers were installed in sand cells within the spade cell boreholes with bentonite plugs above and below.Three extensometers were placed over the axis perpendicular to the Tunnel Type-2and one on the tunnel centreline.The magnetic rings located at various depths,which were ranged from 3to 27m depth.Biaxial inclinometers with automatic loggers were used to record the horizon-tal movements using techniques developed by TRL (Bowers,1997).A detailed location drawing for the inclinometers are given in Fig.4.As in-tunnel instrumentation,convergence-measuring pins were used to measure horizontal and vertical move-ments of the shotcrete with time.These were installed on the tunnel periphery when the shotcrete was installed.2.2.General numerical analysis procedureMohr–Coulomb plasticity model has been adopted throughout the FLAC analysis to represent stress–strain behaviour of not only London Clay but also Thames gravel and made ground.Mohr–Coulomb criterion has a linear failure surface corresponding to shear failure as described in the follow-ing equations:f s ¼r 1Àr 3N /þ2c ffiffiffiffiffiffiffiN /p ;ð9ÞN /¼ð1þsin /Þ=ð1Àsin /Þ;ð10Þwhere r 1is major principal stress;r 3is minor principal stress;/is friction angle and c is the cohesion.Shear yield is detected if f s <0(Itasca,1993).For modelling of the tunnelling process in 2D,an ap-proach has to be adopted to take into account the defor-mation occurring prior to shotcrete installation andtheFig.3.Cable element behaviour in FLAC (Itasca,1993).Fig.4.Surface,subsurface and in-tunnel instrumentation around the Heathrow Trial Tunnel Type-2(Bowers,1997).M.Karakus,R.J.Fowell /Tunnelling and Underground Space Technology 20(2005)514–5245173D tunnelling problem.There are different approaches to consider aforementioned deformations such as the convergence confinement method(Panet and Guenot, 1982),the progressive softening method(Swoboda, 1979),volume loss control method(Potts and Zdravko-vic,2001).The hypothetical modulus of elasticity (HME)soft lining approach,a relatively new technique developed for the simulation of Heathrow Express tun-nel at Terminal4by Powell et al.(1997),has been em-ployed in the analysis.Essential to this approach is to introduce a lower elasticity modulus for the shotcrete to represent the excavation process and subsequently in-crease it to the assumed short-term modulus of elasticity for the shotcrete.The approach is believed to model the shotcrete behaviour until it gains strength.More de-tailed explanation of this approach is given by Karakus (2000)and Karakus and Fowell(2003).The model grid used in the analysis is shown in Fig.5. The model wasfixed in the horizontal direction at each side,which means that vertical movement was allowed,and the bottom part of the boundary was pinned,so nei-ther vertical nor horizontal movements were allowed.As can be seen in Fig.5,the top surface of the model was free in both directions.The construction process of the Trial Tunnel Type-2consists of a left hand heading, bench and invert excavation.This was followed by the excavation of the right hand heading,bench andfinally closing the ring of support.In order to imitate the same construction process in FLAC analysis,sequential exca-vation model(SEM)was employed(Karakus and Fo-well,2003).The SEM excavation process was modelled with the following main stages:1.Establishing the equilibrium condition for the modelbody by setting up a gravitational stressfield and introducing80kPa surcharges owing to the carpark.518M.Karakus,R.J.Fowell/Tunnelling and Underground Space Technology20(2005)514–524M.Karakus,R.J.Fowell/Tunnelling and Underground Space Technology20(2005)514–5245192.Having reached equilibrium conditions,elements in the left hand heading were removed,followed by acti-vation of the beam elements in this section with a lower elasticity modulus of 0.40GPa assigned which was found from the back analysis.3.Removing elements in the left hand bench and invert and activating the beam elements for this section with an elasticity modulus of 0.40GPa.At the same time the HME value of the left heading beam elements was increased to 5GPa,assumed to be the short-term modulus of the shotcrete.4.The same procedures in stage 2,and stage 3have been applied to the right hand heading,bench and invert excavations.5.Removing the inner wall was the final step of the FDM analysis.0.40GPa of HME value found from back analysis.According to Karakus and Fowell (2003),HME value can be found from the following expression which is similar to the progressive softening method (Swoboda,1979):HME ¼d E Shorttermð11Þwhere d is the reduction factor as percentage and the E Short term is the Short term Young Õs modulus of shot-crete.Total amount of reduction in stiffness of shotcrete is (1Àd )which is 92%in this case.This value indicates that beam elements used to represent shotcrete behaves in a very stiffmanner as supported by Augarde and Burd (2001)who reported that structural elements such as shell elements to model liner may behave in an over-stiffmanner when embedded in a mesh of continuum element.520M.Karakus,R.J.Fowell /Tunnelling and Underground Space Technology 20(2005)514–5243.Evaluation of the results3.1.Transverse surface settlement analysisResults of the analyses have been shown in three main parts as surface settlement profiles,sub-surface set-tlement profiles and stress redistribution around tunnel.Surface settlement analysis has been carried out in accordance with thefield measurements corresponding to the completion of the left sidewall excavation and the enlargement of the tunnel as illustrated in Fig.6.Karakus and Fowell(2003)reported that0.40GPa of HME value produced the best results for sequential excavation model.Thus,for this analysis,0.40GPa va-lue was taken as HME value.As can be seen from Fig.6, surface settlement profiles for both sidewall excavation and enlargement of the tunnel are in very close agree-ment with thefield measurements.Maximum surface settlement predicted by the SEM model for sidewall excavation and enlargement are 15.3and27.6mm,respectively.Including cable elements during numerical analysis prevented excessive settlement at the either side of the tunnel headings as shown in Fig.7. Cable elements included in the analysis and assumed to be fully grouted.The material properties adopted for the cable elements and beam elements are summarised in Table2.Fig.7illustrates the effects of cable elements on the surface settlement.The settlement profiles were not af-fected1.5-diameter away from either side of the tunnel centreline in both including and excluding cable ele-ments in the numerical analysis.However,the settle-ment profiles for the sidewall and the enlargement of the tunnel are greatly influenced within1.5D of either side of the tunnel when no cable elements were present. Therefore,the use of cable elements reduced the ground movements within1.5D of either side of the tunnel. Without cable elements,approximately2and4mm more surface settlements have been predicted for side-wall and enlargement,respectively.Hence,the use of cable elements for NATM analysis is considered important.3.2.Subsurface settlement analysisThe horizontal movements and subsurface settlement predictions from the FLAC are compared with the cor-responding inclinometers measurements and magnetic ring measurements,respectively.Thus,these compari-sons provide a verification of the predictions obtained from thefinite difference analysis.Fig.8illustrates the calculated horizontal movements towards the tunnel.Although calculated movements for the IB3was two times greater than the measured values, predicted horizontal movements are in good agreement with the inclinometer measurements IB1,IB2,and IB4.Besides,predictions corresponding to IB1and IB2became greater initiating from a depth of15m to the ground surface.On the other hand,predicted sub-surface settlements for all magnetic measurements are in very good agreement with the measurements(Fig.9).Table3Comparison of the maximum surface settlements Numerical models used Maximum surfacesettlement at tunnelcentrelineSidewall (mm)Enlargement (mm)Field measurement14.626.8FLAC with cable elements15.327.6FLAC without cable elements17.331.4ABAQUS without cable elements11.427.4M.Karakus,R.J.Fowell/Tunnelling and Underground Space Technology20(2005)514–524521This is believed to be due to adopting variation of London clay Elasticity modulus with depth,which was suggested by Burland and Kalra(1986),in the FLAC analysis.3.3.Stress analysis around the tunnelThe locations of the spade cells are illustrated in Fig.4. The real time of construction was not considered in the analysis.However,the stresses at the end of each main excavation sequences were used for comparison with the correspondingfield measurements.Thus,only re-lated measurements were used in this analysis.Fig.10 shows the horizontal stress redistribution around the tunnel.General trend of stress changes for both FLAC pre-dictions and thefield measurements can be explained as follows:1.When thefirst heading is excavated,the horizontalstresses are decreasing sharply from the geostatic stress condition to a lower stress level.2.Then,the application of the shotcrete stabilises thestress distribution around the tunnel until a new sec-tion was excavated.This phenomenon continues until the entire tunnel construction is completed and the support ring is closed. Calculated horizontal stresses are in close agreement with the spade cells measurements,SB1,SB2,and ST1,while predictions for the spade cell SB3is greater522M.Karakus,R.J.Fowell/Tunnelling and Underground Space Technology20(2005)514–524than the measured stress.Similar predictions were found for SB3with thefinite element analysis(Karakus and Fowell,2003).This implies that the accuracy of the spade cell measurement SB3might not be as accurate as the other spade cell measurements.parison of FDM and FEM analysis resultsIn this section,overall comparison of thefinite ele-ment andfinite difference analysis,is made so that the differences between these two powerful modelling tools can be examined.In addition,this comparison will pro-vide an insight into the effects of using different plasticity models for London Clay.For the Finite element analy-sis,ABAQUS program has been utilized detailed analy-sis procedure is given elsewhere(Karakus and Fowell, 2003).During FEM analysis,London Clay stress strain behaviour was represented by Modified Cam-clay plas-ticity with porous elasticity.The Drucker–Prager plas-ticity model was used for Thames gravel and made ground.As can be seen from Fig.11and Table3,surface set-tlement predictions by FLAC and ABAQUS for the tunnel enlargement are in very close agreement with each other and withfield measurements as well.Con-versely,FDM analysis produced better settlement pre-dictions for sidewall excavation.This is believed to be due to variation of London Clay elasticity modulus with depth,which was considered in the FDM analysis.Horizontal displacements towards tunnel and subsur-face settlements profiles are illustrated in Figs.12and 13,respectively.Finite element andfinite difference pre-dictions for horizontal movement are in good agreement with each other.Nevertheless,FDM analysis failed to predict the horizontal movement 4.35m away from the tunnel centreline.Also,FDM analysis overestimated these movements for IB1and IB2from above15m depth towards the ground surface.This can be attrib-uted to the use of different soil models considered for both analyses.Subsurface settlement calculated from both models is well matched to thefield measurements.Apparently,the contradictions between surface settlement and horizon-tal movements from both analyses show that anisotropy in the London clay should be considered in the numeri-cal analysis.However,plasticity models especially the Modified Cam-clay model did not take into account anisotropy in ABAQUS program as it was originally developed for isotropic conditions.Stress redistribution around the tunnel predicted by FDM and FEM are in agreement with thefield measure-ments.However,predictions obtained from thefinite element analysis are much closer to thefield measure-ment than thefinite difference analysis predictions.Both analyses have failed to predict the horizontal stresses for the SB3spade cell measurement as can be seen from Fig.14.As explained earlier,this could be due to failure in spade cell measurements.Bowers(1997)reported thatM.Karakus,R.J.Fowell/Tunnelling and Underground Space Technology20(2005)514–524523some of the stress cells failed before tunnelling was started.According to both numerical analyses results, there would be a possibility of damage in this particular stress cell,SB3.4.ConclusionsHME approach which is used in both FDM and FEM analysis to account for volume loss during tunnel-ling operations proved to be a practical tool for numer-ical modeller.The0.40GPa of HME value found from back analysis of FEM produced very good predictions in FDM analysis as well.As different soil plasticity mod-els considered viz.Modified Cam-clay and Mohr–Cou-lomb plasticity for FEM and FDM,respectively,it can be proposed that HME approach can be used in which different plasticity models apart from above ones considered in a numerical analysis.The results of present analyses showed that both methods of analyses using the sequential excavation model could be used for the preliminary design of NATM tunnelling for the conditions used in this research.It was found that the variation of elasticity modulus of London clay with depth is very important for accu-rate numerical modelling.Thus,FDM analysis pre-dicted much closer surface settlement for the sidewall excavation than thefinite element predictions.Con-tradictions between subsurface settlement and horizon-tal displacements suggest that considering anisotropic behaviour of London clay could improve predictions in both FEM and FDM analyses.Thus,this problem should be subjected to further analysis to examine their effects on NATM tunnelling.FDM analysis has also shown the importance of cable elements adopted in the numerical analysis.With-out considering cable elements in the numerical analysis led to greater settlements.AcknowledgmentsGrateful acknowledgement is given to Inonu Univer-sity,Turkey for providingfinancial support during the research undertaken in the Department of Mining and Mineral Engineering at the University of Leeds,UK. ReferencesAugarde,C.E.,Burd,H.J.,2001.Three-dimensionalfinite element analysis of lined tunnels.Int.J.Numer.Anal.Meth.Geomech.25, 243–262.Atzl,G.V.,Mayr,J.K.,1994.FEM-analysis of Heathrow NATM trial tunnel.In:Numerical Methods in Geotechnical Engineering.Balkema,Rotterdam,pp.195–201.Bowers,K.H.,1997.An appraisal of the New Austrian Tunnelling Method in soil and weak rock.Ph.D.Thesis,The University of Leeds,240pp.Burland,J.B.,Kalra,J.C.,1986.Queen Elizabeth II Conference Centre:geotechnical aspects.Proc.Inst.Civil Eng.80(1),1479–1503.Dasari,G.R.,1996.Numerical modelling of a NATM tunnel construction in London Clay.In:International Symposium on Geotechnical Aspects of Underground Construction in Soft Ground.Balkema,Rotterdam,pp.491–496.Dean,A.P.,Basset,R.H.,1995.The Heathrow Express Trial Tunnel.Proc.Inst.Civil Eng.,Geotech.Eng.113,144–156.Grose,W.J.,Eddie,C.M.,1996.Geotechnical aspects of the construc-tion of the Heathrow Transfer Baggage System tunnel.In: International Symposium on Geotechnical Aspects of Under-ground Construction in Soft Ground.Balkema,Rotterdam,pp.269–276.Gunn,M.J.,1992.The prediction of surface settlement profiles due to tunnelling.In:Proceedings of the Wroth Memorial Symposium held at St.CatherineÕs College,Oxford,pp.304–316.Itasca Consulting Group Inc.,1993.FLAC UserÕs Manual I,Minne-apolis,MN.Karakus,M.,2000.Numerical modelling for NATM in soft ground.Ph.D.Thesis,The University of Leeds,240pp.Karakus,M.,Fowell,R.J.,2003.Effects of different tunnel face advance excavation on the settlement by FEM.Tunnelling Underground Space Technol.18(5),513–523.Mair,R.J.,Taylor,R.N.,Bracegirdle,A.,1993.Subsurface settlement profiles above tunnels in clays.Geotechnique43(2),315–320. Mroueh,H.,Shahrour,I.,2003.A full3-Dfinite element analysis of tunnelling–adjacent structures put.Geotech.30, 245–253.New,B.M.,Bowers,K.H.,1994.Ground movement model validation at the Heathrow Express trial tunnel.In:TunnellingÕ94,IMM, London,pp.301–329.New,B.M.,OÕReilly,M.P.,1978.Tunnelling induced ground move-ments;predicting their magnitude and effects.In:Proceedings of the Conference on Large Ground Movements and Structures.Pentech Press,Cardiff,pp.671–693.OÕReilly,M.P.,1988.Evaluating and predicting ground settlements caused by tunnelling in London Clay.In:TunnellingÕ88,IMM, London,1988,pp.231–241.Panet,M.,Guenot,A.,1982.Analysis of convergence behind the face of a tunnel.In:TunnellingÕ82,IMM,London,pp.197–204. Peck,R.B.,1969.Deep excavations and tunnelling in soft ground.In: Proceedings of the7th International Conference on Soil Mechanics and Foundation Engineering,Mexico,pp.225–290.Potts, D.M.,Zdravkovic,L.,2001.Finite Element Analysis in Geotechnical Engineering Application.Thomas-Telford,London, 427pp.Powell,D.B.,Sigl,O.,Beveridge,J.P.,1997.Heathrow–Express-design and performance of platform tunnels at Terminal4.In:Tunnelling Õ97,IMM,London,pp.565–593.Ryley,M.D.,Carder,D.R.,1995.The performance of push-in spade cells installed in stiffclay.Geotechnique45(3),533–539. Shohrour,I.,Ghorbanbeigi,S.,1994.Calculation of tunnels in soft ground.In:Numerical Methods in Geotechnical Engineering.Balkema,Rotterdam,pp.229–234.Swoboda,G.,1979.Finite element analysis of the New Austrian Tunneling Method(NATM).In:Proceedings of the3rd Interna-tional Conference on Numerical Methods in Geomechanics, Aachen,vol.2,pp.581–586.Swoboda,G.,Marence,M.,Mader,I.,1994.Finite element modelling of tunnel excavation.Int.J.Eng.Modell.6,51–63.Swoboda,G.,Ichikawa,Y.,Dong,Q.,Zaki,M.,1999.Back analysis of large geotechnical models.J.Numer.Anal.Meth.Geomech.23, 1455–1472.524M.Karakus,R.J.Fowell/Tunnelling and Underground Space Technology20(2005)514–524。

Unit10:水密性浸入隧道虽然水密性是任何沉管的隧道设计的首要目标之一,设计不会亏如果(附带太小被忽略)。

隧道元素的大型外围表面上未检测到的建设缺失的混凝土或防水膜或钢焊缝中未检测到针孔的可能性不能完全为直纹的。

适当的维修方法存在和设计中,必须指定。

水压力与隧道墙系统中必须避免的。

提供适当的排水入内排水系统。

此渗漏很小,不需要额外的排水和水仓容量。

对于钢壳隧道元素,是纯粹由钢外壳本身提供的。

水密性依赖于大量的焊缝的质量。

内壳的混凝土是在压缩下的横向。

对于混凝土隧道,泄漏有关的防水膜的质量,如果使用的话,和裂缝的发展。

因此,在横向和纵向方向上的不同的结构的行为的理解是很重要的。

在横向方向上,盒形的钢筋混凝土隧道总是有经历弯曲张力在屋顶和底板的区域,即使在横向压缩。

的隧道段被设计成使得所得到的破解可以仅部分地渗透在压缩区足够厚,以避免通过缝隙泄漏,离开混凝土。

在纵向的方向,强调是多低幅度比横向方向。

基本压力是压缩。

二级影响,可能会导致局部紧张不应导致全面深度裂缝。

热收缩裂缝是典型的辅助效果。

在厚厚的混凝土构件,水化热导致大量加热的成员。

一段时间后该成员将冷却到环境温度。

稀土盛鸿现在硬化混凝土的收缩可能会受到限制。

为了保证充足,这发生在铸造到在较早阶段铸造的底板上墙。

连接到刚性底板墙的冷却收缩的结果是磁珠在底板和墙的底部部分中的纵向拉伸应变。

除非采取适当的措施,因此垂直深度的全方位的裂缝可以发生在约5米的间隔。

制定了令人满意的进程,以避免这些施工裂缝,即通过减少水化,热和使用具有相对较低的水泥含量和强迫冷却的墙壁的下半部分的混凝土。

有时这样做是与绝缘和基地合板加热相结合。

如果不过发现裂缝,补救灌浆似乎有效。

微分热发展的有效控制很大程度上取决于混凝土的热量。

这一进程,反过来,是量的行政长官发挥了其中的直接职能。

因此,典型混凝土混与高水泥因素(摘自公路结构)的使用可以在这方面的。

有关于控制混凝土隧道渗漏的两个基本概念:扩大联合概念混凝土隧道防水的扩张联合概念涉及通过避免跨韵文实现水密性混凝土的开裂。