双金属氢化物络合催化剂MMC

- 格式:pdf

- 大小:123.22 KB

- 文档页数:5

关于过柱得实验方法与技巧(注意:有机溶剂对身体特有害别就是心肺;肝脏等所有过柱操作都要在通风橱里进行!!常说得过柱子应该叫柱层析分离,也叫柱色谱。

我们常用得就是以硅胶或氧化铝作固定相得吸附柱。

由于柱分得经验成分太多,所以下面我就几年来过柱得体会写些心得,希望能有所帮助。

1、柱子可以分为:加压,常压,减压压力可以增加淋洗剂得流动速度,减少产品收集得时间,但就是会减低柱子得塔板数、所以其她条件相同得时候,常压柱就是效率最高得,但就是时间也最长,比如天然化合物得分离,一个柱子几个月也就是有得。

减压柱能够减少硅胶得使用量,感觉能够节省一半甚至更多,但就是由于大量得空气通过硅胶会使溶剂挥发(有时在柱子外面有水汽凝结),以及有些比较易分解得东西可能得不到,而且还必须同时使用水泵抽气(很大得噪音,而且时间长)。

以前曾经大量得过减压柱,对它有比较深厚得感情,但就是自从尝试了加压后,就几乎再也没动过减压得念头了。

加压柱就是一种比较好得方法,与常压柱类似,只不过外加压力使淋洗剂走得快些。

压力得提供可以就是压缩空气,双连球或者小气泵(给鱼缸供气得就行)。

特别就是在容易分解得样品得分离中适用。

压力不可过大,不然溶剂走得太快就会减低分离效果。

个人觉得加压柱在普通得有机化合物得分离中就是比较适用得。

ﻫ2、关于柱子得尺寸,应该就是粗长得最好柱子长了,相应得塔板数就高。

柱子粗了,上样后样品得原点就小(反映在柱子上就就是样品层比较薄),这样相对得减小了分离得难度。

试想如果柱子十厘米,而样品就有二厘米,那么分离得难度可想而知,恐怕要用很低极性得溶剂慢慢冲了、而如果样品层只有0.5厘米,那么各组分就比较容易得到完全分离了。

当然采用粗大得柱子要牺牲比较多得硅胶与溶剂了,不过这些成本相对于产品来说也许就不算什么了(有些不环保得说,不过溶剂回收重蒸后也就减小了部分浪费)。

现在见到得柱子径高比一般在1:5~10,书中写硅胶量就是样品量得30~40倍,具体得选择要具体分析。

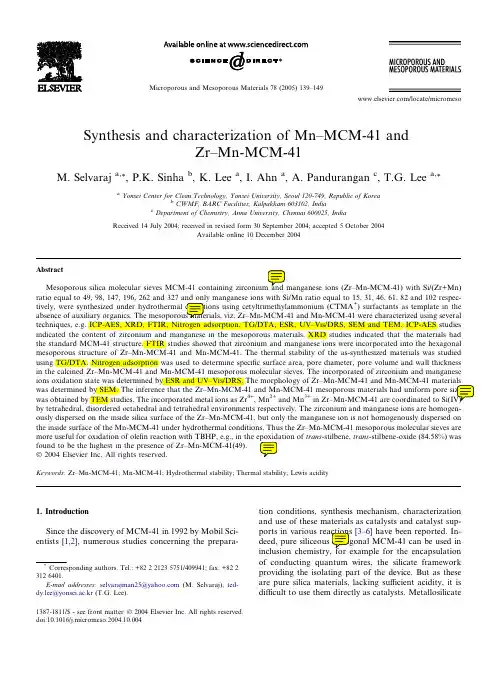

Synthesis and characterization of Mn–MCM-41andZr–Mn-MCM-41M.Selvaraja,*,P.K.Sinha b ,K.L ee a ,I.Ahn a ,A.Pandurangan c ,T.G.Leea,*aYonsei Center for Clean Technology,Yonsei University,Seoul 120-749,Republic of KoreabCWMF,BARC Facilities,Kalpakkam 603102,IndiacDepartment of Chemistry,Anna University,Chennai 600025,IndiaReceived 14July 2004;received in revised form 30September 2004;accepted 5October 2004Available online 10December 2004AbstractMesoporous silica molecular sieves MCM-41containingmanganese ions (Zr–Mn-MCM-41)with Si/(Zr+Mn)ratio equal to 49,98,147,196,262and 327manganese ions with Si/Mnratio equal to 15,31,46,61,82and 102respec-tively,were synthesized under hydrothermal using cetyltrimethylammonium (CTMA +)surfactants as template in the absence of auxiliary organics.The viz.Zr–Mn-MCM-41and Mn-MCM-41were characterized using several techniques,e.g.ICP-AES,XRD,FTIR,Nitrogen adsorption,TG/DTA,ESR,UV–Vis/DRS,SEM and TEM.ICP-AES studies indicated the content of zirconium and manganese in the mesoporous materials.XRD studies indicated that the materials had the standard MCM-41structure.FTIR studies showed that zirconium and manganese ions were incorporated into the hexagonal mesoporous structure of Zr–Mn-MCM-41and Mn-MCM-41.The thermal stability of the as-synthesized materials was studied using TG/DTA.Nitrogen adsorption was used to determine specific surface area,pore diameter,pore volume and wall thickness in the calcined Zr–Mn-MCM-41and Mn-MCM-41mesoporous molecular sieves.The incorporated of zirconium and ions oxidation state was determined by ESR and UV–Vis/DRS.The morphology of Zr–Mn-MCM-41and Mn-MCM-41was determined by SEM.The inference that the Zr–Mn-MCM-41and Mn-MCM-41mesoporous materials had uniform pore was obtained by TEM studies.The incorporated metal ions as Zr 4+,Mn 2+and Mn 3+in Zr–Mn-MCM-41are coordinated to by tetrahedral,disordered octahedral and tetrahedral environments respectively.The zirconium and manganese ions are homogen-ously dispersed on the inside silica surface of the Zr–Mn-MCM-41,but only the manganese ion is not homogenously dispersed on the inside surface of the Mn-MCM-41under hydrothermal conditions.Thus the Zr–Mn-MCM-41mesoporous molecular sieves are more useful for oxidation of olefin reaction with TBHP,e.g.,in the of trans -stilbene,trans -stilbene-oxide (84.58%)was found to be the highest in the presence of Zr–Mn-MCM-41(49).Ó2004Elsevier Inc.All rights reserved.Keywords:Zr–Mn-MCM-41;Mn-MCM-41;Hydrothermal stability;Thermal stability;Lewis acidity1.IntroductionSince the discovery of MCM-41in 1992by Mobil Sci-entists [1,2],numerous studies concerning the prepara-tion conditions,synthesis mechanism,characterization and use of these materials as catalysts and catalyst sup-ports in various [3–6]have been reported.In-deed,pure siliceous MCM-41can be used in inclusion for the encapsulation of conducting quantum wires,the silicate framework providing the isolating part of the device.But as these are pure silica materials,lacking sufficient acidity,it is difficult to use them directly as catalysts.Metallosilicate1387-1811/$-see front matter Ó2004Elsevier Inc.All rights reserved.doi:10.1016/j.micromeso.2004.10.004*Corresponding authors.Tel.:+82221235751/409941;fax:+8223126401.E-mail addresses:selvarajman25@ (M.Selvaraj),ted-dy.lee@yonsei.ac.kr (T.G.Lee)./locate/micromesoMicroporous and Mesoporous Materials 78(2005)139–149molecular sieves,obtained by isomorphous substitution of Si by metal ions in silicate structures,exhibit catalytic activity in selective oxidation reactions using hydrogen peroxide and alkylhydroperoxides at mild conditions.In recent years,attention has increasingly been directed towards the study of metal-containing mesoporousM41S type molecular sieves with large pores (20–100A˚diameter)suitable for the transformation of bulky or-ganic compounds [1,2,7–13].Metal ions such as Al [14–17],Ti [6,18],Fe[20–25],V [26,27],and Ga[28–30]have been incorporatedinto the MCM-41et al.[31–33]reported the details of synthesis and characterization of bimetal-lic as Zn-Al-MCM-41mesoporous materials.How-ever,hydrothermal stability,hydrophobicity,thermal stability and acid strength in the mesoporous materials increased by the introduction of the incorporation of zinc.Manganese are well known catalysts for epoxidation reactions [34].Recently,many research groups worked on the immobilization of Mn complexes onto the mesoporous material.Although ion-exchange method was applied to Al-MCM-41[35],only lower loading amount can be obtained by this method.Caps and Tsang [36]prepared Mn-MCM-41with a molecular organic chemical vapor deposition (MOCVD)method.Burch et al.[37]prepared surface-grafted manganese–oxo species on the walls of MCM-41channels.Yonemi-tsu et al.[38]firstly developed the template ion-exchange (TIE)method for the synthesis of Mn-MCM-41,and they argued that manganese was highly dispersed in the mesopore of MCM-41and only existed as Mn 2+.But,when the other transition metal ions are incorporated in Mn-MCM-41,the environment struc-ture,morphology and distribution of the Mn in the framework and also hydrothermal stability have not established.In the present study,Zr–Mn-MCM-41and Mn-MCM-41materials with different silicon to metal/metals ratio have been synthesized using hydrother-mal method.The materials characterized by ICP-AES,XRD,FTIR,Nitrogen adsorption,TG/DTA,DR/UV–Vis spectroscopy,ESR,SEM and TEM.Mesostructure,metal incorporation,morphology of Zr–Mn-MCM-41,the site geometry,coordination and distribution of Mn in Zr–Mn-MCM-41when the Zr-ions incorporated in Mn-MCM-41are subsequently investigated.2.Experimental 2.1.MaterialsThe syntheses of Zr–Mn-MCM-41and Mn-MCM-41materials were carried out by hydrothermal method using sodium metasilicate (Na 2SiO 3Á5H 2O),Zirconiumtetraisopropoxide ((Zr–(O–CH–(CH 3)2)4),Manganese (II)acetate ((CH3COO)2Mn),cetyltrimethylammo-niumbromide (C 3)3N +Br)and sulfuric acid (H 2SO 4).The all were purchased from M/s Aldrich &Co.,2.2.Synthesis of Zr–Mn-MCM-41and Mn-MCM-412.2.1.Synthesis of Zr–Mn-MCM-41The Zr–Mn-MCM-41was synthesized according to the previous report [39]using hydrothermal method.For the synthesis of the Zr–Mn-MCM-41(Si/Zr +Mn =49),21.2g (1mol)of sodium metasilicate (44–47%SiO 2)dissolved in 50g of deionised water was with 0.54g (0.015mol)of zirconium (IV)isoprop-and 0.4g (0.015mol)of manganese (II)acetate (dissolved in 10g of deionized water)solution.This mix-ture was stirred for 30min using a mechanical stirrer at a speed of about 250rpm and in order to reduce the pH to 10.8,1N of sulphuric acid was added with continuous stirring for another 30min at a speed of about 250rpm until the gel formation.After that,9.1g (0.25mol)of cetyltrimethylammonium bromide was added drop by drop (30ml h À1)through the dual syringe pump so that the gel was changed into suspension.After further stirring for 1h the resulting synthesis gel of composition 1SiO 2:0.015ZrO 2:0.015MnO:0.25CTMABr:100H 2O,was transferred into Teflon-lined steel autoclave and heated to 165°C for 48h.After cooling to room temper-ature,the material was recovered by filtration,washed with deionised water and ethanol and finally calcined in flowing air at 540°C for 6h.The different Zr–Mn-MCM-41catalysts (Si/Zr +Mn =98,147,196,262and 327)were also synthe-sized in a above similar manner wherein only the ratio of sodium metasilicate,zirconium (IV)isopropoxide and manganese (II)acetate was adjusted and the input in gel molar compositions 1SiO 2:x ZrO2:y MnO:0.25CT-MABr:100H 2O;(x =0.008–0.0025,y =0.008–0.0025).2.2.2.Synthesis of Mn-MCM-41The Mn-MCM-41catalysts (Si/Mn =15,31,46,61,82and 102)were also synthesized in a above similar manner wherein only the ratio of sodium metasilicate and manganese (II)acetate was adjusted without zirco-nium source and the input in gel molar compositions 1SiO 2:x MnO:0.25CTMABr:100H 2O;(x =0.033–0.005).2.3.Characterization2.3.1.ICP-AESThe zirconium and manganese content in Zr–Mn-MCM-41and Mn-MCM-41were recorded using ICP-AES with allied analytical ICAP 9000.140M.Selvaraj et al./Microporous and Mesoporous Materials 78(2005)139–1492.3.2.XRDThe crystalline phase identification and phase purity determination of the calcined Zr–Mn-MCM-41and Mn-MCM-41samples were carried out by XRD(Phi-lips,Holland)using nickelfiltered Cu K a radiation (k=1.5406A˚).The samples were scanned from0.5°to 5°(2h)angle in steps of0.5°,with a count of5s at each point.In order to protect the detector from the high en-ergy of the incident and diffracted beam,slits were used in this work.2.3.3.FTIRInfrared spectra were recorded with a Nicolet Impact 410FTIR Spectrometer in KBr pellet(0.005g sample with0.1g KBr)scan number36,resolution2cmÀ1. The data was treated with Omnic Software.2.3.4.N2-AdsorptionThe surface areas and pore properties of Zr–Mn-MCM-41and Mn-MCM-41samples before and after hydrothermal treatments were analyzed using a NOVA-1000(QUANTACHROME,version5.01)sorp-tometer.The calcined samples were dried at130°C and evacuated overnight for8h inflowing arogn atflow rate of60ml minÀ1at200°C under vacuum.Surface area, pore size,pore volume and wall thickness was obtained from these isotherms using the conventional BET and BJH equations.2.3.5.TG-DTAThe weight loss,dehydration and dehyoxylation for as-synthesized Zr–Mn-MCM-41and Mn-MCM-41 samples was evaluated by a Thermogravimetric-Differ-ential Thermal Analysis(TG-DTA)in a Rheometric scientific(STA15H+)thermobalance.10–15mg of as-synthesized MCM-41was placed in a platinum pan and heated from room temperature to1273K at a heat-ing rate of2K/min in air withflow rate of50ml/min. For comparison experiments,samples were dried at 323K for the same period.The data were collected at 30-s intervals using on-line PC.2.3.6.ESRFor ESR measurements,Zr–Mn-MCM-41and Mn-MCM-41samples were loaded into2mm i.d x150mm length suprasil quartz tubes.ESR spectra were recorded at X-band at either293or77K on a Bruker ESP300 spectrometer.The magneticfield was calibrated with a Varian E-500gaussmeter.The microwave frequency was measured by a Hewlett Packard HP5342A fre-quency counter.2.3.7.UV–visible/Diffuse reflectance spectroscopyThe diffuse reflectance UV–visible spectra were meas-ured with a Perkin-Elmer330Spectrometer equipped with a60mm Hitachi integrating sphere accessory.Powder samples were loaded in a quartz cell with Supra-sil windows,and spectra were collected in the200–800nm wavelength range against quartz standard.2.3.8.SEMThe SEM microscope of a typical sample of MCM-41 materials were obtained on a JEOL2010microscope operated at200KV from a thinfilm dispersed on a holly carbon grid in ethanol solvent.2.3.9.TEMTEM images were recorded using a JEOLJEM-200CX electron microscope operating at200KV with modified spectrum stage with objective lens parameters C s=0.41mm and C c=0.95mm,giving an interpretable point resolution of Ca.0.185nm.Samples for analysis were prepared by crushing the particles between two glass slides and spreading them on a holly carbonfilm supported on a Cu grid.The samples were briefly heated under tungstenfilament light bulb in air before transfer into the specimen chamber.The images were recorded at magnifications of100000·.3.Results and discussion3.1.ICP-AESThe zirconium and manganese ions content in Mn-MCM-41and Zr–Mn-MCM-41have been observed using ICP-AES.The observed zirconium and manga-nese ions content in the samples have been presented in Table1.3.2.XRDFig.1a and b show the X-ray powder diffraction pat-terns of calcined Mn-MCM-41and Zr–Mn-MCM-41 samples having different ratio of Si/Mn and Si/Zr+Mn respectively.The X-ray diffractograms of Zr–Mn-MCM-41and Mn-MCM-41after calcinations in air at540°C for6h, contain,a sharp d100reflection line in the range 2h=2.15–2.30°and 2.03–2.22°respectively.Physico-chemical properties of these mesoporous materials are summarized in Table1.For example,the pore-to-pore distance of Zr–Mn-MCM-41could be determined by the XRD patterns.The XRD patterns of calcined Zr–Mn-MCM-41(49)with characteristic peaks of hexago-nal(p6mm)symmetry and with d100of41.090are shown in Fig.1b.The repeating distance(a0)between pore cen-ters was47.440.The hexagonal unit cell parameter(a0) was calculated using the formula as a0=2d100/p3from d100,which was obtained from the peak in the XRD pat-tern by BraggÕs equation(2d sin h¼k,where k=1.54060for the Cu K a line).The value of a0wasM.Selvaraj et al./Microporous and Mesoporous Materials78(2005)139–149141equal to the internal pore diameter plus one pore wall thickness.These peaks reflections were indexed based on the hexagonal unit cell as described by Beck et al.[2].The XRD peaks shifted to lower 2h values for the rest of the samples.The higher d -spacing and unit cell parameter values observed with increasing metal content suggest an incorporation of metal in the framework locations [40]because of its (Zr–O ($1.71160)and Mn–O ($1.73080))longer bonding length with oxygen than Si–O ($1.5090).However,there is no regular rule in MCM-41as it has an amorphous structure where both bond length and angle may be change.The pertur-bation of d-spacing and unit cell parameter is hypothe-sized to be dependent on the metal substitution stateresulting from the sample preparation method,i.e.,coordination number of metal with OH groups and also along with bond length and bond angle of metal ion on the silica surface.3.3.FTIRInfrared spectroscopy had been used extensively for the characterization of transition-metal cation modified zeolites.The as-synthesized Zr–Mn-MCM-41and Mn-MCM-41samples exhibit absorption bands around 2921and 2851cm À1corresponding to n -C–H and d -C–H vibrations of the surfactant molecules.The broad bands around 3500cm À1may be attributed surfaceTable 1Physicochemical characterization of Zr–Mn-MCM-41and Mn-MCM-41Catalysts Zr content d (wt%)Mn content d (wt%)d -spacing a (A˚)Unit cell parameter aa 0(A ˚)Surface areab (m 2/g)Pore size bD (A ˚)Pore volume b (cm 3/g)Wallthickness c (A ˚)Zr–Mn-MCM-41(49)0.1650.16641.0947.4483530.30.8117.14Zr–Mn-MCM-41(98)0.0830.08240.5646.8386330.20.7916.63Zr–Mn-MCM-41(147)0.0520.05540.1546.3689030.10.7516.26Zr–Mn-MCM-41(197)0.0410.04139.4345.5292429.90.7015.62Zr–Mn-MCM-41(261)0.0320.03138.4044.3494329.80.6914.54Zr–Mn-MCM-41(327)0.0230.02536.8142.50102529.40.6813.1Mn-MCM-41(15)–0.33043.5150.2486332.70.9917.54Mn-MCM-41(31)–0.16542.6149.2088432.60.9816.60Mn-MCM-41(46)–0.11142.2648.7990332.50.9716.29Mn-MCM-41(61)–0.08241.6148.1194532.40.9415.71Mn-MCM-41(82)–0.06240.7147.0099932.30.9114.7Mn-MCM-41(102)–0.05039.7945.94103432.20.8913.74a Values obtained from XRD studies.b Values obtained from N 2-adsorption results.c Wall thickness (t )=Unit cell parameter(a 0)pore size(D ).dThe results obtained from ICP-AES.142M.Selvaraj et al./Microporous and Mesoporous Materials 78(2005)139–149silanols and adsorbed water molecules,while deforma-tional vibrations of adsorbed molecules cause the absorption bands at1623–1640cmÀ1[41](the results of peaks have not shown infigures).The substitution of silicon by zirconium and manganese causes shifts of the lattice vibration bands to lower -pared to the Si-MCM-41,the wave number of the anti-symmetric Si–O–Si vibration band of Mn-MCM-41and Zr–Mn-MCM-41samples decreases to1086and 1080cmÀ1,receptively(Fig.2a and b).Theses shifts should be due to the increase of the mean Si–O distance in the walls caused by the substitution of the small sili-con(radius40pm)by the larger size of Mn2+(radius 83pm)and Zr4+(radius59pm)[42].The observed shifts, which depend as well on the change in the ionic radii as on the degree of substitution,are comparatively small. Therefore,only a low degree of substitution is sug-gested.Interestingly,the wavenumber shifts decrease in the series Zr–Mn-MCM-41>Mn-MCM-41, although the ionic radius of zirconium is smaller than those of manganese.While the wave number of the anti-symmetric Si–O–Zr and Si–O–Mn vibration bands of Zr–Mn-MCM-41and Mn-MCM-41samples de-creases to957and962cmÀ1,receptively(Fig.2a and b).The absorption band at1057and1223cmÀ1are due to asymmetric stretching vibrations of Si–O–Si bridges,while the960to965cmÀ1bands are due to Si–OÀM+(M=Mn and Zr)vibrations in metal incorporated silanols.By the disappearing peaks at 2851and2921cmÀ1,one could conclude that calcination of the original framework was complete and the identity of organic molecule completely disappeared from the calcined M-MCM-41.Upon introduction of higher metal content,most of the bands shifted to higher wave numbers,consistent with their incorporation in lattice positions.Addition-ally,an absorption band in the range962–967cmÀ1as-signed to a stretching vibration of Si–OÀM+linkage was observed.This is generally considered to be a proof of the incorporation of the heteroatom into the frame-work.Cambler et al.[43]have reported similar stretch-ing vibrations of Si–OH groups present at defect sites.3.4.N2-adsorption isothermFig.3a and b show the isotherm of nitrogen adsorp-tion by calcined Mn-MCM-41and Zr–Mn-MCM-41 measured at liquid nitrogen temperature(77K).Three well-defined stages may be identified:(1)A slow increase in nitrogen uptake at low relative pressure,correspond-ing to monolayer-multilayer adsorption on the pore walls;(2)a sharp step at intermediate relative pressures indicative of capillary condensation within mesopores; and(3)a plateau with a slight inclination at high relative pressures associated with multilayer adsorption on the external surface of the crystals[44].A fourth stage,M.Selvaraj et al./Microporous and Mesoporous Materials78(2005)139–149143characterized by a sharp rise in N2uptakefilling all other available pores as the pressure reaches saturation (p/p0=1.0),may be identified in some isotherms.Each isotherm showed type IV character,which is a typical shape for mesoporous MCM-41.The third stage of the isotherm shifts slightly toward higher relative pressure with the incorporation of transition metal(Zr+Mn and Mn).The hysteresis loop broadened with an in-crease in the metal content suggesting some disorder in the pore system arising from metal incorporation.Incor-poration of metal in MCM-41has significant effect on these parameters.The surface area values decreased with increasing metal content.The pore diameter,pore vol-ume and wall thickness increased in Zr–Mn-MCM-41144M.Selvaraj et al./Microporous and Mesoporous Materials78(2005)139–149and Mn-MCM-41with increasing metal content.and are listed in Table1.In the crystalline zeolites,metal incorporation slightly increases the pore size because of its longer bonding length with oxygen than Si–O. However,there is no regular rule in MCM-41as it has an amorphous structure where both bond length and angle may ually,it has been observed that the pore size of MCM-41is decreased after metal incor-poration,but there is no clear explanation for this obser-vation.MCM-41has thin pore walls relative to zeolites so that the incorporated metal cannot be substituted into the silica framework completely.That is,a part of the metal will be exposed on the pore wall surface so that it might have properties similar to impregnated metal complexes on the MCM-41walls.The incorpo-rated metal may interact with surface hydroxyl groups and may contract the pore wall when combined with two or three hydroxyl groups,so that the pore size will be de-creased[45,46].If these metals are incorporated deep within the silica framework,this pore shrinkage might not occur as with condensed surface hydroxyl groups, and the pore size might be increased instead by the in-creased metal-oxygen bond length,as for zeolites.In this study,we obtained an increased pore size after both metal as Zr and Mn,and alone Mn incorporation as shown in Fig.2a and b respectively.This is an unusual result, and strongly suggests that Zr and Mn are incorporated into silica framework according to the above hypothesis. This can be confirmed indirectly by the ease of metal reduction,and such a result has been reported[47].The remarkable improvement of hydrothermal stabil-ity due to the higher metal incorporation is further evi-denced by the measurement of N2adsorption.The surface areas of all the MCM-41materials were mea-sured after they had been treated in boiling water for1 week.The surface areas slightly decreased from863–1034to830–980m2/g in the Mn-MCM-41samples and also slightly decreased from1025-890to967–1002m2/g in Si/(Zr+Mn)ratios of147–327in Zr–Mn-MCM-41 samples,but the surface area does not decrease in other Zr–Mn-MCM-41samples.The Si–O–Zr and Si–O–Mn bonds are relatively stable to further attack from boiling water[39,48];the presence of Mn2+and Zr4+creates a negative charge on the surface of the pore walls,repel-ling OHÀions and therefore preventing the hydrolysis of siloxane bonds and also resulting in an increase in the number of acid sites.The surface area in the Mn-MCM-41and Zr–Mn-MCM-41(Si/Zr+Mn=147–327) samples decreased due to low metal incorporation/non-framework as it does not create sufficient negative charges on the surface of the pore walls.But the surface area of other Zr–Mn-MCM-41samples does not decrease due to repelling OHÀions higher on the pore walls.Hence,it is concluded that Zr is irreversibly incor-porated into the structure of Zr–Mn-MCM-41samples. Thus,the hydrothermal stability is higher in Zr–Mn-MCM-41(49)than that in other Zr–Mn-MCM-41and Mn-MCM-41samples.3.5.Thermal analysisThermogravimetric analysis of the catalysts show dis-tinct weight losses that depend on framework composi-tion.Representative thermograms are given in Fig.4a (Mn-MCM-41)and Fig.4b(Zr–Mn-MCM-41).Gene-rally,when the metal content increases,there is a de-crease in organic content and increase in water content.Three distinct regions of weight loss are noted in the temperature range50–150°C,150–350°C and 350–550°C.Thefirst weight loss($4.6–16.61%)corre-sponds to the desorption and removal of the water and/or ethanol molecules physisorbed on the external surface of the crystallites or occluded in the macropores and mesopores present between the crystallites aggre-gates.A second weight loss($38.58–40.5%),between 150°C and350°C is attributed to the removal of the or-ganic template.Finally,a third weight loss($1.51–1.9%) between350°C and550°C is related to water loss from the condensation of adjacent silanol groups to form siloxane bond[49].The total weight loss at1000°C of the Mn-MCM-41and Zr–Mn-MCM-41samples are in the44.69–59.01%range.However,the distribution of successive weight loss depends on the framework or sub-stituted silicon to metal ratio[50].Thus,weight loss was higher in the low metal contents of MCM-41materials than that in the high metal contents of MCM-41 materials.3.6.ESRThe Q-band ESR spectrum of synthesized Mn-MCM-41at150°C in the presence of suphuric acid exhibits a typical Mn2+spectrum,sextet lines with a hyperfine coupling(A)of81G and g=2.00,as shown in Fig.5a.Low intensity forbidden transitions are evi-dent in room temperature spectra,indicating that the Mn2+ions are rather incorporated.The greater incorpo-ration of the Mn2+species in as-synthesized Mn-MCM-41at150°C can be attributed either to its location within the wall or in the interface region of the polar head groups of the template and the silica walls.How-ever,their high mobility indicates that they are not located within the inorganic walls but are within the pores.This indicates that the Mn2+is more mobile after calcination.The same spectrum was obtained from cal-cined Mn-MCM-41that did not exhibit Mn2+ESR sig-nals prior to calcinations.From the above results,it is inferred that the Mn2+is coordinated to Si(IV)by dis-torted octahedral environments.The preliminary EPR analysis was carried out for the Zr–Mn-MCM-41.A strong resonance at g=2.01with a hyperfine coupling of91g was observed(Fig.5b)whichM.Selvaraj et al./Microporous and Mesoporous Materials78(2005)139–149145could be easily attributed to a distorted octahedral Mn2+species.The hyperfine lines are slightly broader for Zr–Mn-MCM-41than for Zr-MCM-41.The spin Hamilton parameters are also similar to those reported by Piaggio et al.[51]for the homogeneous Mn(II)-salen complex,suggesting the incorporation of the Zr and Mn in the MCM-41materials.3.7.Diffuse reflectance UV/visible spectroscopyThe calcined Mn-MCM-41samples are characterized by reflectance UV–Visible spectroscopy.Two bands at 270and500nm were observed for these samples.The A1g!T2g crystalfiled transitions of Mn2+in Mn2O3 or MnO showed a band at500nm[52].Thus the band at500nm was assigned to Mn2+probably existing on the surface of MCM-41.However,the band at270nm with such a high intensity was not reported in the liter-ature.The charge transfer transition of O2À!Mn2+in Mn3O4in which Mn was disordered octahedrally coor-dinated with oxygen exhibited a band at320nm[52]. We thus tentatively assigned the intense band observed at lower wavelength(270nm)to the charge transfer transition of O2À!Mn3+tetrahedral coordination,i.e in the framework of MCM-41.From the above results, it is inferred that the Mn2+and Mn3+ions may be coor-dinated with Si(IV)by disordered octahedral and tetra-hedral environments respectively.The DR UV–Vis spectra of Zr–Mn-MCM-41were found to be similar for those of Zr-MCM-41[39]and Mn-MCM-41in that the peaks were in the same position and the Zr4+and Mn2+are coordinated to Si(IV)by tet-rahedral and disordered octahedral environments respectively.From the ESR and UV–Vis/DRS results, theoretically,we conclude that the Lewis acidity in Zr–Mn-MCM-41materials are higher than that that in Mn-MCM-41due to the higher electron-pair donated to the inner side silica surface.3.8.SEMAll Mn-MCM-41and Zr–Mn-MCM-41materials are having micellar rod-like shape hexagonal or spherical edges,as shown in the Fig.6a(Mn-MCM-41(31))and Fig.6b(Zr–Mn-MCM-41(49)).Each rod,itself trans-formed into the MCM-41hexagonal-phase mesostruc-ture.Because all materials have been synthesized using cetyltrimethyammonium bromide as surfactant in the liquid crystal template mechanism,Steel et al.[53]pos-tulated that CTMABr surfactant molecules assembled directly into the hexagonal liquid crystal phase upon addition of the silicate species,based on14NMR spectro-scopy.The size of micellar rod like shape and hexagonal phase in Zr–Mn-MCM-41materials are slightly smaller than those in Mn-MCM-41.3.9.TEMThe TEM image of all Mn-MCM-41and Zr–Mn-MCM-41samples(Fig.7a(Mn-MCM-41(31))and Fig.7b(Zr–Mn-MCM-41(49))exhibit ordered hexago-nal arrays of mesopores with uniform pore size[1]. The corresponding electron diffraction pattern also shows reflections contrast in the TEM image of the sam-ple,the distance between mesopores are estimated,in good agreement with the value determined from XRD and N2-adsorption measurements values.Both pore channels and hexagonal symmetry can be clearly identified in the TEM image for the Mn-MCM-41and Zr–Mn-MCM-41samples which indicates that the MCM-41materials have only one uniform phase as inferred from the XRD results.Interestingly,the TEM image viewed down the d110direction shows that pore channels are not straight,they are arc-like.In con-trast,the TEM image recorded along the d110direction of MCM-41showshorizontal.Fig.6.(a)SEM image of Mn-MCM-41(31).(b)SEM image of Mn-MCM-41(49).M.Selvaraj et al./Microporous and Mesoporous Materials78(2005)139–149147。

第四章生产规模及产品方案用途主要软泡:海绵;弹性体胶棒防水跑道1000D用作防水底板,地板材料,密封胶,粘合剂,DG330N与POP混用,汽车摩托车自行车坐垫,仪表盘扶手方向盘DG4110(硬泡)冰箱冰柜保温,夹心板材,管道保温,墙体保温DG5631K 大型块状泡沫,对助剂,发泡剂宽容度高,N45 高回弹泡沫,块状泡沫,汽车坐垫靠背,家具,床垫C45 本类产品用于制造高硬度块状泡沫,热模塑高回弹泡沫,能与普通聚醚共用,可增加泡沫制品的承载能力,并可增加泡沫的开孔性DG2000D 聚氨酯涂料,弹性体,粘合剂和密封剂等,其制品有更好的物理机械性能DG3050D 软质泡沫,涂料,弹性体,粘合剂和密封剂聚醚多元醇的主要应用领域是聚氨酯高分子材料,其消耗量占聚醚多元醇总量80%左右。

主要用于生产聚氨酯软泡、聚氨酯硬泡及涂料、胶粘剂、密封胶、弹性体(CASE)制品。

此外,聚醚多元醇也用于生产泡沫稳定剂、造纸工业消泡剂、原油破乳剂、高效低泡洗涤剂、润滑剂、淬火剂、乳胶发泡剂、橡胶润滑剂及表面活性剂等。

聚醚多元醇(简称PPG)成品根据用途可以分为以下六种:1、普通块状软泡15万吨,即DG-5631K;2、普通弹性体塑模软泡5万吨,即DG-330N;3、高回弹体软泡,包括DG-1000D、DG-2000D、DG-3050D;4、用于POP生产的中间体PPG,包括DG-551C、DG-331 5万吨;5、普通硬泡,即DG-4110 A。

一.生产规模第五章工艺技术方案5.1 聚醚多元醇生产工艺聚醚多元醇的发展是由20世纪30年代开始的,它最初应用于非离子表面活性剂领域。

1939年,美国Scretle和Wotter合成出烷醇聚醚非离子表面活性剂。

1940年又合成出烷基酚聚氧乙烯醚非离子表面活性剂。

1953年Du Pont公司首次把聚醚多元醇应用于聚氨酯软泡,接着美国怀安多特化学公司于1954年提出以氧化丙烯一氧化乙烯嵌段共聚醚制备聚氨酯泡沫塑料,并于1957年将聚醚型聚氨酯泡沫塑实现工业化。

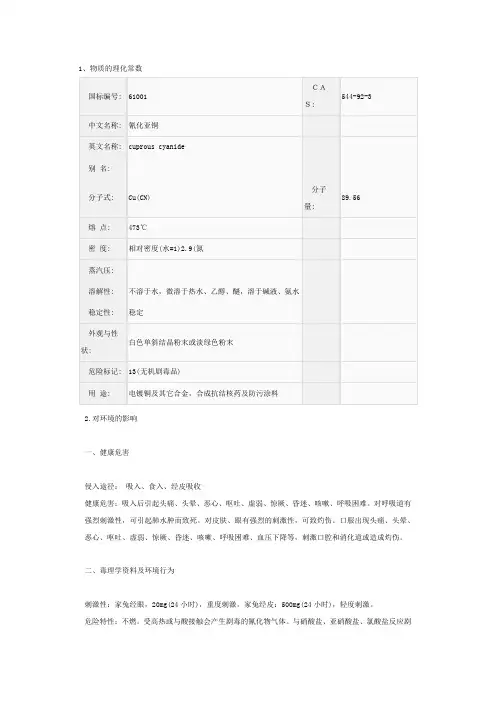

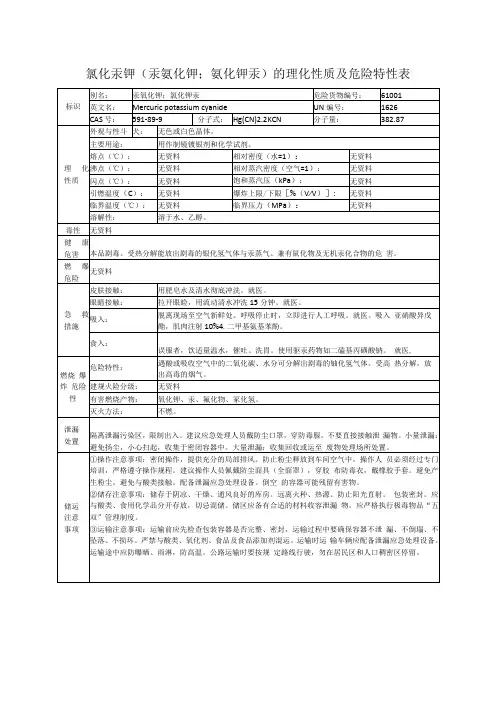

1、物质的理化常数2.对环境的影响一、健康危害侵入途径:吸入、食入、经皮吸收健康危害:吸入后引起头痛、头晕、恶心、呕吐、虚弱、惊厥、昏迷、咳嗽、呼吸困难。

对呼吸道有强烈刺激性,可引起肺水肿而致死。

对皮肤、眼有强烈的刺激性,可致灼伤。

口服出现头痛、头晕、恶心、呕吐、虚弱、惊厥、昏迷、咳嗽、呼吸困难、血压下降等,刺激口腔和消化道或造成灼伤。

二、毒理学资料及环境行为刺激性:家兔经眼,20mg(24小时),重度刺激。

家兔经皮:500mg(24小时),轻度刺激。

危险特性:不燃。

受高热或与酸接触会产生剧毒的氰化物气体。

与硝酸盐、亚硝酸盐、氯酸盐反应剧烈,有发生爆炸的危险。

遇酸或露置空气中能吸收水分和二氧化碳,分解出剧毒的氰化氢气体。

燃烧(分解)产物:氰化氢、氧化氮。

3. 现场应急监测方法试纸法;速测管法;化学试剂测试组法;分光光度法;离子选择电极法《突发性环境污染事故应急监测与处理处置技术》万本太主编(氰化物)4.实验室监测方法比色法(GB7486-87,GB7487-87)(氰化物)5.环境标准中国(TJ36-79)车间空气中有害物质的最高容许浓度 0.3mg/m3(HCN)[皮]6.应急处理处置方法一、泄漏应急处理对泄漏物处理必须戴好防毒面具与手套,扫起,倒至大量水中。

加入过量NaClO或漂白粉,放置24小时,确认氰化物全部分解,稀释后放入废水系统。

污染区用NaClO溶液或漂白粉浸光24小时后,用大量水冲洗,洗水放入废水系统统一处理。

对HCN则应将气体送至通风橱或将气体导入碳酸钠溶液中,加等量的NaClO,以6mol/L NaOH中和,污水放入废水系统做统一处理。

二、防护措施呼吸系统防护:可能接触毒物时,必须佩戴头罩型电动送风过滤式防尘呼吸器。

紧急事态抢救或撤离时,建议佩戴自给式呼吸器。

眼睛防护:呼吸系统防护中已作防护。

身体防护:穿连衣胶布防毒衣。

手防护:戴橡胶手套。

其它:工作现场禁止吸烟、进食和饮水。

一些常见物质地安托因常数公司内部档案编码:[OPPTR-OPPT28-OPPTL98-OPPNN08]一些常见物质的Antoine(安托万)常数(修正)2007-11-09 09:22不同物质的蒸气压(摘自)在表10中给出了采用Antoine公式计算不同物质在不同温度下蒸气压的常数A、B、C。

其公式如下lgP=A-B/(t+C) (7-10)式中:P—物质的蒸气压,毫米汞柱;t—温度,℃公式(7—10)适用于大多数化合物;而对于另外一些只需常数B与C值的物质,则可采用(7—11)公式进行计算lgP=T+C (7-11)式中:P—物质的蒸气压,毫米汞柱;T—绝对温度,(t℃+).表10 不同物质的蒸气压名称分子式范围(℃) A B C银 Ag 1650~1950 公式(7-11) 250氯化银 AgCl 1255~1442 公式(7-11)三氯化铝 AlCl3 70~190 公式(7-11) 115氧化铝 Al2O3 1840~2200 公式(7-11) 540砷 As 440~815 公式(7-11) 133砷 As 800~860 公式(7-11)三氧化二砷 As2O3 100~310 公式(7-11)三氧化二砷 As2O3 315~490 公式(7-11)氩 Ar ~ 公式(7-11)金 Au 2315~2500 公式(7-11) 385 三氯化硼 BCl3 ……钡 Ba 930~1130 公式(7-11) 350 铋 Bi 1210~1420 公式(7-11) 200 溴 Br2 ……碳 C 3880~4430 公式(7-11) 540 二氧化碳 CO2 ……二硫化碳 CS2 -10~+160一氧化碳 CO -210~-160四氯化碳 CCl4 ……钙 Ca 500~700 公式(7-11) 195 钙 960~1100 公式(7-11) 370镉 Cd 150~ 公式(7-11) 109镉 500~840 公式(7-11)氯 Cl2 (240)二氧化氯 ClO2 -59~+11 公式(7-11)钴 Co 2374 公式(7-11) 309铯 Cs 200~230 公式(7-11)铜 Cu 2100~2310 公式(7-11) 468 氯化亚铜 Cu2Cl2 878~1369 公式(7-11)铁 Fe 2220~2450 公式(7-11) 309氯化亚铁 FeCl2 700~930 公式(7-11)氢 H2 ~-248氟化氢 HF -55~+105氯化氢 HCl -127~-60溴化氢 HBr -120~-87① 270溴化氢 -120~-60 250碘化氢 HI -97~-51 公式(7-11)碘化氢 -50~-34 公式(7-11)氰化氢 HCN -85~-40氰化氢 -40~+70过氧化氢 H2O2 10~90 公式(7-11)水② H2O 0~60水③ 60~150硒化氢 H2Se 66~-26 公式(7-11)硫化氢 H2S -110~83 公式(7-11)碲化氢 H2Te -46~0 公式(7-11)氦 He (290)汞 Hg 100~200汞 200~300汞 300~400汞 400~800氯化汞 HgCl2 60~130 公式(7-11)氯化汞 130~270 公式(7-11)氯化汞 HgCl2 275~309 公式(7-11)氯化亚汞 Hg2Cl2 …碘 I2 …钾 K 260~760 公式(7-11)氟化钾 KF 1278~1500 公式(7-11)氯化钾 KCl 690~1105 公式(7-11)氯化钾 1116~1418 公式(7-11)溴化钾 KBr 906~1063 公式(7-11)溴化钾 1095~1375 公式(7-11)碘化钾 KI 843~1028 公式(7-11)碘化钾 1063~1333 公式(7-11)氢氧化钾 KOH 1170~1327 公式(7-11) 136 氪 Kr ~-169 公式(7-11)氟化锂 LiF 1398~1666 公式(7-11)镁 Mg 900~1070 公式(7-11) 260锰 Mn 1510~1900 公式(7-11) 267钼 Mo 1800~2240 公式(7-11) 680氮 N2 -210~-180一氧化氮 NO -200~161 公式(7-11)一氧化氮 ~148 公式(7-11)三氧化二氮 N2O3 -25~0 公式(7-11)四氧化二氮 N2O4 -100~-40 公式(7-11)四氧化二氮 -40~-10 公式(7-11)五氧化二氮 N2O5 -30~+30 公式(7-11)氯化亚硝酰 NOCl ~ 公式(7-11)肼 N2H4 -10~+39肼 39~250钠 Na 180~883 公式(7-11)氯化钠 NaF 1562~1701 公式(7-11)氯化钠 NaCl 976~1155 公式(7-11)氯化钠 1562~1430 公式(7-11)溴化钠 NaBr 1138~1394 公式(7-11)碘化钠 NaI 1063~1307 公式(7-11)氰化钠 NaCN 800~1360 公式(7-11)氢氧化钠 NaOH 1010~1402 公式(7-11) 132 氖 Ne ……镍 Ni 2360 公式(7-11) 309四羰基镍 Ni(CO) 4 2~40 公式(7-11)氧 O2 -210~-160臭氧 O3 ……磷(白磷) P 20~ 公式(7-11)磷(紫磷) P 380~590 公式(7-11)磷化氢 PH3 ……铅 Pb 525~1325 公式(7-11)氯化铅 PbCl2 500~950 公式(7-11)铂 Pt 1425~1765 公式(7-11) 486铷 Rb 250~370 公式(7-11) 76氡 Rn (250)硫 S ……二氧化硫 SO2 ……三氧化硫 SO3 24~48 公式(7-11)锑 Sb 1070~1325 公式(7-11) 189三氯化锑 SbCl3 170~253 公式(7-11)硒 Se ……二氧化硒 SeO2 ……硅 Si 1200~1320 公式(7-11) 170四氯化硅 SiCl4 -70~+5 公式(7-11)甲硅烷 SiH4 -160~112 公式(7-11)二氧化硅 SiO2 1860~2230 公式(7-11) 506 锡 Sn 1950~2270 公式(7-11) 328四氯化锡 SnCl4 -52~-38 公式(7-11)锶 Sr 940~1140 公式(7-11) 360铊 Tl 950~1200 公式(7-11) 120钨 W 2230~2770 公式(7-11) 897氙 Ke (260)锌 Zn 250~ 公式(7-11) 133甲烷 XH4 固体③甲烷液体氯甲烷 CH3Cl -47~-10 公式(7-11)三氯甲烷 CHCl3 -30~+150二苯基甲烷 C13H12 217~283 公式(7-11)氯溴甲烷 CH2ClBr -10~+155硝基甲烷 CH3O2N 47~100 公式(7-11)乙烷 C2HS ……氯乙烷 C2H5Cl 65~+70 230溴乙烷 C2H5Br -50~+130均二氯乙烷 C2H4Cl2 ……均二溴乙烷 C2H4Br2 ……环氧乙烷 C2H4O -70~+100偏二氯乙烷 C2H2Cl2 0~30 公式(7-11)1,1,2一三氯乙烷 C2H3Cl3 ……丙烷 C3H8 ……正氯丙烷 C3H7Cl 0~50 公式(7-11)环氧丙烷(1,2) C3H6O -35~+130 232正丁烷 C4H10 ……异丁烷 C4H10 ……正戊烷 C5H12 ……异戊烷 C5H12 ……环戊烷 C5H10 ……正己烷 C6H14 ……环已烷④ C6H12 -50~200 正庚烷 C7H16 ……正辛烷 C8H18 -20~+40 正辛烷 20~200异辛烷(2-甲基庚烷) C8H18 ……正壬烷 C9H20 -10~+60 正壬烷 60~230正癸烷 C10H22 10~80正癸烷 70~260正十一烷 C11H24 15~100 正十一烷 100~310正十二烷 C12H26 5~120 正十二烷 115~320正十三烷 C13H28 15~132 正十三烷 132~330正十四烷 C14H30 15~145 正十四烷 145~340正十五烷 C15H32 15~160 正十五烷 160~350正十六烷 C16H34 ……正十七烷 C17H36 20~190正十七烷 190~320正十八烷 C18H38 20~200正十八烷 200~350正十九烷 C19H40 20~40正十九烷 160~410正二十烷 C20H42 25~223正二十烷 223~420乙烯 C2H4 ……氯乙烯 C2H3 Cl -11~+501,1,2一三氯乙烯 C2HCl3 ……苯乙烯 C8H8 (206)丙烯 C3H6 ……丁稀-1 C4H8 ……顺-2-丁烯 C4H8 ……反-2-丁稀 C4H8 ……2-甲基丙烯-1 C4H8 ……1,2一丁二烯 C4H6 -60~+801,3一丁二烯 C4H6 -80~+652-甲基丁二稀-1,3 C5H8 -50~+95 乙炔 C2H2 -140~-82 公式(7-11)苯甲醇 C7H8O 20~113苯甲醇 113~300乙醇 C2H6O ……正丙醇 C3H8O ……异丙醇 C3H8O 0~113正丁醇 C4H10 75~ 公式(7-11)特丁醇 C4H10 ……乙二醇 C2H6O2 25~112乙二醇 112~340乙醛 C2H4 O -75~-45 250乙醛 -45~+70 230丙酮 C3H6O (224)二乙基酮 C5H10O (204)甲乙酮 C4H3O (216)甲酸 CH2O2 ……苯甲酸 C7H6O2 60~110 公式(7-11)乙酸 C2H4O2 0~36 225乙酸 36~170 211丙酸 C3H6O2 0~60 1690 210丙酸 60~185正丁酸 C4H8O2 0~82 200月硅酸 C12H24O2 164~205 公式(7-11)十四烷酸 C14H28O2 190~224 公式(7-11)乙酐 C4H6O3 100~140 公式(7-11)顺丁烯二酸酐 C4H2O3 60~160 公式(7-11)邻苯二甲酸酐 C3H4O3 160~285 公式(7-11)酷酸乙醋 C4H8 O2 -20~+150甲酸乙酯 C3H6O2 -30~+235醋酸甲酯 C3H6O2 ……苯甲酸甲酯 C8H8O2 25~100苯甲酸甲酯 100~260甲酸甲酯 C2H4O2 ……水杨酸甲酯 C8H8O3 175~215 公式(7-11)氨基甲酸乙酯 C3H7O2N ……甲醚 C2H6O ……苯甲醚 C7H8O (200)二苯醚 C12H10O 25~147⑤二苯醚 147~325甲乙醚 C3H8O 0~25 公式(7-11)乙醚 C4H10O ……甲胺 CH5N -93~-45甲胺 -45~+50二甲胺 C2H7N -80~-30二甲胺 -30~+65三甲胺 C3H9N -90~-40三甲胺 -60~+850乙胺 C2H7N -70~-20乙胺 -20~+90二乙胺 C4H11N -30~+100三乙胺 C6H15N 0~130苯胺 C6H7N (200)二甲替甲酰胺 C3H7ON 15~60二甲替酰胺 60~350二苯胺 C12H11N 278~284 公式(7-11)间硝基苯胺 C6H6O2N2 190~260 公式(7-11)邻硝基苯胺 C6H5O2N2 150~260 公式(7-11)对硝基苯胺 C6H6O2N2 190~260 公式(7-11)苯酚 C6H6O ……邻甲酚 C7H8O ……间甲酚 C7H8O ……对甲酚 C7H8O ……α-萘酚 C10H8O ……β-萘酚 C10H8O ……苯⑥ C6H6 ……氯苯 C6H5Cl 0~42氯苯 42~230邻二氯苯 C6H4Cl2 (200)乙苯 C8H10 ……氟苯 C6H5F -40~+180硝基苯 C6H6O2N 112~209 公式(7-11)甲苯 C7H8 ……邻硝基甲苯 C7H7O2N 50~225 公式(7-11)间硝基甲苯 C7H7O2N 55~235 公式(7-11)对硝基甲苯 C7H7O2N 80~240 公式(7-11)三硝基甲苯 C7H5O6N3 (160)邻二甲苯 C8H10 ……间二甲苯 C8H10对二甲苯 C8H10乙酰苯 C8H8O 30~100 公式(7-11)乙腈 C2H3N (230)丙烯腈 C3H3N -20~+140氰 C2N2 -72~-28 公式(7-11)氰 C2N2 -36~-6 公式(7-11)萘 C10H8 ……α-甲基綦 C11H10 ……β-甲基萘 C11H10 ……蓖 C14H10 100~160 公式(7-11) 72 蓖 223~342 公式(7-11)蓖醌 C14H3O2 224~286 公式(7-11)蓖醌 285~370 公式(7-11)樟脑 C10H16O 0~18 公式(7-11)咔唑 C12H9N 244~352 公式(7-11)芴 C13H10 161~300 公式(7-11)呋喃 C4H4O -35~+90吗啉 C4H9ON 0~44吗啉 44~170菲 C14H10 203~347 公式(7-11)喹啉 C9H7N 180~240 公式(7-11)噻吩 C4H4S -10~180草酸 C2H2O4 55~105 公式(7-11)光气 COCl2 -68~+68 230氨⑥ NH3 -83~+60氯化铵 NH4Cl 100~400 公式(7-11)氰化铵 NH4CN 7~17 公式(7-11)①固体②见第六章③三相点:℃,毫米汞柱.④三相点℃,毫米汞柱.⑤过冷的.⑥三相点:℃,毫米汞柱.一些常见物质的Antoine(安托万)常数(修正)2007-11-09 09:22不同物质的蒸气压(摘自)在表10中给出了采用Antoine公式计算不同物质在不同温度下蒸气压的常数A、B、C。

氰化亚铜简介氰化亚铜是一种无机化合物,化学式为CuCN。

它是一种白色或浅蓝色的固体,具有毒性。

氰化亚铜是一种重要的铜化合物,广泛应用于催化剂、颜料、电镀和有机合成等领域。

物理性质分子结构:氰化亚铜分子由一个铜离子和一个氰根离子组成,铜离子为+1价。

外观:氰化亚铜呈白色或浅蓝色固体,晶体呈单斜晶系。

密度:氰化亚铜的密度大约为3.8 g/cm³。

溶解性:氰化亚铜在水中的溶解度较低,但可以溶解于酸性溶液中。

熔点和沸点:氰化亚铜的熔点约为460°C,沸点约为500°C。

化学性质氧化还原性:氰化亚铜可以通过与其他化合物的反应展现出一系列氧化还原反应。

例如,氰化亚铜可以被还原为金属铜,通过反应生成氰气。

酸碱性:氰化亚铜在水中的酸碱中性为弱碱性。

催化剂:氰化亚铜是一种重要的催化剂,在有机合成反应中具有重要的应用。

例如,它可以催化烯烃的加成反应、醛酮的还原反应和碳-氮键的形成反应等。

电镀:氰化亚铜可以用作电镀材料,用于在金属表面形成一层铜镀层。

应用领域有机合成:氰化亚铜在有机合成中广泛应用,特别是作为催化剂。

它可以促进一些重要的有机反应,如烯烃的加成反应和羰基化合物的还原反应等。

颜料:氰化亚铜可以用作颜料,用于制作蓝色和绿色的陶瓷和玻璃制品。

电镀:氰化亚铜可以用于电镀铜合金,改善金属表面的耐蚀性和装饰性。

金属抗氧化剂:氰化亚铜可以作为金属的抗氧化剂,可以防止金属在空气中氧化而受到损坏。

安全性氰化亚铜具有一定的毒性,接触或吸入过量的氰化亚铜可能会引起中毒。

因此,在使用氰化亚铜时必须遵循安全操作规程,并采取必要的个人防护措施。

建议在使用氰化亚铜时佩戴防护手套、口罩和防护眼镜,确保良好的通风环境。

结论氰化亚铜是一种重要的铜化合物,在催化剂、颜料、电镀和有机合成等领域具有广泛应用。

它具有一定的化学性质和物理性质,并在各个领域发挥重要的作用。

使用氰化亚铜时必须注意安全,遵循正确的操作规程,保护自己的人身安全。

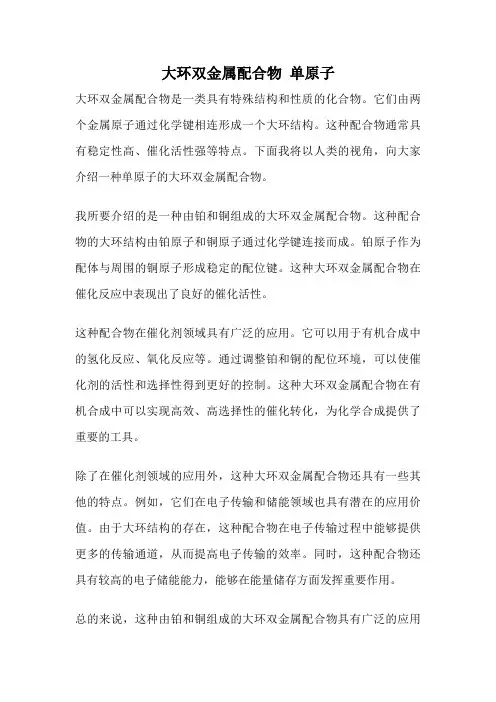

大环双金属配合物单原子

大环双金属配合物是一类具有特殊结构和性质的化合物。

它们由两个金属原子通过化学键相连形成一个大环结构。

这种配合物通常具有稳定性高、催化活性强等特点。

下面我将以人类的视角,向大家介绍一种单原子的大环双金属配合物。

我所要介绍的是一种由铂和铜组成的大环双金属配合物。

这种配合物的大环结构由铂原子和铜原子通过化学键连接而成。

铂原子作为配体与周围的铜原子形成稳定的配位键。

这种大环双金属配合物在催化反应中表现出了良好的催化活性。

这种配合物在催化剂领域具有广泛的应用。

它可以用于有机合成中的氢化反应、氧化反应等。

通过调整铂和铜的配位环境,可以使催化剂的活性和选择性得到更好的控制。

这种大环双金属配合物在有机合成中可以实现高效、高选择性的催化转化,为化学合成提供了重要的工具。

除了在催化剂领域的应用外,这种大环双金属配合物还具有一些其他的特点。

例如,它们在电子传输和储能领域也具有潜在的应用价值。

由于大环结构的存在,这种配合物在电子传输过程中能够提供更多的传输通道,从而提高电子传输的效率。

同时,这种配合物还具有较高的电子储能能力,能够在能量储存方面发挥重要作用。

总的来说,这种由铂和铜组成的大环双金属配合物具有广泛的应用

前景。

它们在催化剂和电子传输领域都具有重要的作用。

通过进一步的研究和开发,相信这种配合物将能够在更多的领域展现出其独特的性质和潜力。

我们期待着更多的科学家能够投入到这一领域的研究中,为人类的科技发展做出更大的贡献。

我国聚醚多元醇(PPG)的研究开发主要集中在低不饱和度、高相对分子量聚醚多元醇以及阻燃聚醚多元醇的研究开发上。

(1)低不饱和度、高相对分子量聚醚多元醇。

南京金陵石化公司研究院于1998年成功开发DMC催化剂制备聚醚多元醇生产技术,并于2000年完成中试生产。

金陵石化研究院与金陵石化化工二厂合作采用DMC 催化剂,配以AC-4为助催化剂,低相对分子量聚醚多元醇N-204和N-305为起始剂,成功地合成出相对分子质量大于10000的三官能团聚醚多元醇和相对分子量大于8000的三官能团聚醚多元醇。

此后,与金陵石化塑料厂研究利用DMC催化剂,采用自产的环氧丙烷和浙江兰溪化工试验厂生产的丙三醇等为原料,试制了不饱和度较低的高相对分子量聚醚多元醇,并对影响聚合的主要因素进行了考察。

随之,金陵石化公司研究院又对DMC催化剂催化合成聚醚多元醇的起始条件进行了研究。

对起始温度、催化剂用量、环氧丙烷的起始压力等因素对聚醚多元醇质量的影响进行了详细分析研究。

认为起始温度在130℃左右,催化剂质量分数为30ppm、环氧丙烷起始压力较低时,得到的聚醚多元醇物性较好。

在对提高低不饱和度聚醚多元醇的伯羟基含量的研究中,金陵石化公司研究院用DMC催化剂制备的聚

醚多元醇与传统碱催化剂制备的未经后处理的聚醚多元醇按一定比例混合,用环氧乙烷封端以提高伯羟基含量,经精制所制备的高活性聚醚二醇、聚醚三醇的不饱和度小于0.010mmol/g,伯羟基摩尔分数小于65%。

(另外,金陵石化研究院与上海高桥石化公司用酸式DMC催化剂合成出不饱和度小于0.02mmol·gI1的聚醚多元醇。

)

2007年10月,金陵石化公司研究院与金陵石化二厂和上海高桥石化公司联合在万吨级聚醚生产装置上对金陵石化研究院所研制的DMC催化剂进行了工业应用试验,并通过了中国石化股份公司组织的技术鉴定。

新工艺充分发挥了DMC催化剂活性高、转化率高、产品质量好的特点,合成的聚醚多元醇分子量分布窄、不饱和度低、产品质量稳定。

应用试验过程中,聚醚收率达到99.5%,生产周期缩短一半。

随后,金陵石化研究院在对DMC催化剂进一步研究时,一举突破非晶态催化剂的限制,在催化剂制备工艺上一改传统方法中需多次沉淀、多次过滤和多次反复混合络合的步骤,采用连续化的生产方法,通过多次配位制备出具有自主知识产权和四项专利的高活性且对晶态成分无特定要求的多组分双金属氰化物络合催化剂(MMC)。

在不改变现行反应装置的情况下,该MMC催化剂具有较高的活性,可以在极低浓度(30ppm)下合成起始剂1-6官能团的氧化烯烃聚醚多元醇,大大缩短反应时间,并在聚

醚生产过程中提高产品收率,使装置的生产能力提高数倍。

由于产品中金属离子浓度低,还可省去中和、过滤等后处理工艺,消除三废的产生。

使用MMC催化剂制备的聚醚具有不饱和度低,分子量分布窄、一元醇含量低、官能度高等优点(每摩尔羟基分子量2000以上),另外,其起始氧化分解温度高于普通聚醚。

产品应用于PU领域(弹性体、软泡、高回弹泡沫、涂料、密封胶等)时各方面性能大大改进。

近年来,我国许多科研单位、高等院校及企业加大了对双金属氰化物络合物催化剂(DMC)的开发研究,并用其催化合成高活性、高分子量、低不饱和度的聚醚多元醇。

黎明化工研究院用自制的双金属氰化物络合催化剂,制备了相对分子量高、相对分子质量分布窄、不饱和度低的低单官能度聚醚多元醇,而且还对其合成工艺进行了研究。

天津第三石化厂与中科院山西煤化所合作,研制出相对分子质量可达15000,不饱和度小于0.005mmol·g-1的聚醚多元醇,产品质量与国外同类产品相当。

研究证明DMC催化剂,在聚醚多元醇的合成中,催化剂用量少于200ppm,单体转化率为98%,反应时间小于3小时,聚醚多元醇的不饱和度最大可以达到0.003mmol/g,相对分子量最大可以达到15300。

(2)阻燃聚醚多元醇,聚氨酯泡沫或弹性体阻燃防火

技术的研究与应用一直是人们关注的难题。

我国阻燃聚醚多元醇的研究开发工作近年来也取得了一定的进展。

天津石化公司研究所于1999年成功研制出含铁系列聚醚多元醇,有明显的阻燃和抑烟作用,与含卤素的有机阻燃剂复配时,协同阻燃效果更佳。

江苏省江阴友邦化工有限公司开发的阻燃级系列聚醚多元醇,不含卤素、P、Sb等元素,对发泡设备无腐蚀作用。

用其制成的制品氧指数≥20,烟密度≤60%。

锦化化工(集团)有限责任公司以环氧丙烷为主要原料,选择复合起始剂,将阻燃元素引入聚醚多元醇键中,经小试、中试研制出JH-452R耐燃聚醚多元醇产品。

应用试验证明,该产品具有活性高、粘度低,与其他助剂相容性好,易于施工、操作等特点。

用其制成的聚氨酯制品具有明显的耐燃烧性和低发烟量,其氧指数达到20%-21%。

陕西西安近代化学研究所对3-溴甲基-3-(2-氰乙氧基)甲基氧丁烷(BMCMO)进行阳离子开环聚合,首次在聚醚多元醇分子结构中同时引入-Br(理论值为34%)和-CN(理论值为11%),制得了一种新型的端羟基聚醚多元醇PBMCMO。

用该聚醚多元醇制备的聚氨酯可同时具有阻燃、耐热以及耐油等多种特殊性能。

淮海工学院和青岛科技大学对侧链含有氯甲基的高活性氯代聚醚多元醇(CHIROL)与三溴苯酚钠盐亲核取代合成高活性阻燃聚醚多元醇(HIROL)的方法进行了研究。

制得的HIROL为透明琥珀色液体,溴含量为20%-25%,粘

度为0.75-0.88Paos,可用于制造高性能阻燃聚氨酯软泡。