中英文中英文文献翻译-环缝自动焊机

- 格式:doc

- 大小:548.00 KB

- 文档页数:10

Original text:X-RAY DETECTS WELDS AND MECHANICALSTRUCTURE DAMAGE MATHoDSfUMMARIZEThe moving small object detection in image is always a difficult problem in field of image processing, which applies in many fields, such as industrial detection and medical detection. The defects, such as blowholes and incomplete penetration, occasionally appear in the welding process. These defects can affect the quality and the security of products. Therefore, defects detection in welding seam is extremely important. Now, the on-line detection of defects in the weld is still done by human interpreter. However, this process is subjective, inconsistent, labor intensive and fatigue of interpreter. It is desirable to find an effective automatic defects detection method to assist human interpreter in evaluating the quality of weld and to make the on-line detection objective, standard and intelligent. Our research is based on this.We have studied the automatic defects detection in the weld seam and mainly done the following research :(1) There is much redundant background information for the defects detection in the image. Therefore we use an automatically abstracting method of weld area based on the auto- adapted threshold segmentation. This method can reduce the computation and increase the precision. (2) The SUSAN algorithm hasgood anti-noise ability, which can recognize the image edge very well. So we have studied a defects detection method based on SUSAN algorithm, which associated with the morphology operation. The results indicate that this method is effective.(3) Wavelet analysis method has a very good localization characteristic, which can focus on the arbitrary detail of the analyzed object. Therefore, we studied a method using wavelet decomposition to get the shape and position information of the defects. Then we use the wiener filter and morphology method to complete the detection.The automatic flaw detection of welded tubes is one of the most important steps to ensure the quality of the tubes. Nondestructive inspection on welding seam of tube is required in the tube production, and real time X-Rayradiography inspection is an effective means. Along with continuous improvement of the productive ratio, the demand for the automatic inspection to the welding seam becomes more and more pressing, so implementation of the automatic inspection possesses important significance on both theory and reality. Wavelet transform is a powerful tool in the signal and image processing, and its fundamental theory has been formed. From the view of engineering applications, however, the wavelet transform is still in the elementary stage, the further Researches are required for the practical uses. In this thesis, we concentrate mainly on using wavelet analysis for welding seam imageprocessing and recognition, and some related techniques are developed.For constructing welding seam positioning and detection control system, the multiple computers configuration for weld seam image recognition is proposed. The system adopts the architecture in which multiple CPUs process parallels under the control of the master IPC computer. The system can perform storing the weld seam images, positioning, flaws recognizing and quality prejudging. The Watch-Dog interface card is successfully developed; it can improve the system reliability by redundancies technique of saving breakpoint data and restoring them.The hardware supporting the system makes use of the high speed digital signal processor TMS320C30 from Tax ax Instruments Company. The frame grabber can capture 25 frames of welding seam image per second continuously and make it possible to fulfill the real time welding seam image processing Andre cognition. The one kind of improved FWT (Fast Wavelet Transform) algorithm for a finite sequence is proposed after studying theory of mustier solution analysisand analyzing technical characteristics of DSP. The implementation of the periodic extension of the FWT on DSP is described in detail and the corresponding FWT assembly code is described for the DSPTMS320C3X series.This dissertation suggests scheme of image demonizing based ontwo-dimensional discrete wavelet transform. The demonizing algorithm is described with some operators. By threshold the wavelet transform coefficients9of noisy images, the original image can be reconstructed correctly. Different threshold selections and threshold methods are discussed. The new robust local threshold scheme is proposed. Quantifying the performance of image demonizing schemes by using the mean square error, the performance of the robust local threshold scheme is demonstrated and is compared with the universal threshold scheme. The experiment shows that image demonizing using the robust local threshold performs better than that using the universal threshold.In order to improve the accuracy and the real time performance of edge detection, a method need to be found to match the detection of low contrast blurred welding seam image. This dissertation analyzed the main sources of noise as well as the different characteristics of noise and signal under wavelet transform, and proposed a Moultrie solution edge detection method based on wavelet transform.The experimental results show the effect of this algorithm is advantageous over that of traditional edge detection algorithm.The geometrical relation of elliptic imaging is studied for welding seam image of the butt welds in straight tubes. The region model of welding seam image is proposed, It furnishes a evidence theory to further process to welding seam image. Combining with the region model, amodel-based adaptive target segmentation algorithm is proposed. One basis of the algorithm is Otsu's discriminates criterion. The adaptive target segmentation of welding seam image is realized. The effect of target image segmentation is quite well.The difficult problem of target flaw automatic recognition in welding seam image is analyzed. Using for reference the consciousness organizing process of the human vision system, a knowledge-based target recognition algorithm with mufti-feature fusion, mufti-window architecture and mustier solution is presented. With the help of certain prior knowledge, criteria and means of artificial intelligence, target flaws are extracted and recognized quite well. It is a Prospecting intelligent recognition algorithm.The fast feature extraction algorithm for target geometrical feature is proposed. This algorithm is different from usual feature extraction methods which first need to change a gray image into binary image. The algorithms proposed get the feature of a image in the gray image directly. Using this algorithm can fast extract features of target flaws in welding seam image.All kinds of mechanical devices and structure tend to become large-scale and high efficient with the industry developing and progress of science and technology. The mechanical devices and structure become very complex to meet the need of industry. The structure or devices aredamaged is couldn,t avoided during working under complex load and working for a long time. The loss caused by crash, fatigue, eroding and wear is about 6%一8% of GDP of USA and Japan. In our country, accident number of structural damage is 10 times as many as that in, intense industrialization country in eighties of last century. In 1986, the loss is 12 hundred million $ caused by the space shuttle named ,v challengerπ of U.S.A, crashed. In 1985, the accident cause of joint of electromotor set of Datong power plane crashed, In 1988, the accident cause of main beam of electromotor set of Qianlong power plane crashed, those accident cause of loss near 1 hundred million RMB. In our country, 6 serious accidents ware been caused by rotor of over 50Mw electromotor set damaged badly during 1984 to 1991 .Therefore, the study the theory and technique about large scale and complex mechanical devices and structure online inspect and early fault diagnosis is urgent task. Especially, how to detect the fault of structure as early as possible is engineers most want to do. But it is very difficult that faint signal produced by early fault is recognized.The research reports of our country and overseas show that at present the study of structure damage inspect by vibration characteristics carry out most on the simple and symmetry structure just as beam and frame etc. and result is given based on finite element numeric calculation. But the structure and join of practical device is quite complex, it isimpossible modeling the practical device reliably by FE. So that realizing complex industrial device inspect online and early fault diagnosis by using vibrate testing technique is a problem that wants to be solved urgently.Fault diagnosis technique is intercross subject. Especially, the base in theory of fault diagnosis of complex system is provided based on modern control theory, signal processing, pattern recognition, optimum method, decision-making and manual intelligent are developed rapidly.Structure damage detection is a research project that has wide background of industrial application. But realizing large-scale and complex structure damage inspect online is depend on techniques such as development of accurate testing technique and signal processing method, based on getting to the best advantage mix model of structure damage detection, the sensors escape placed on structure reasonably and optimally The large-scale vibrating device as a researched object, the method structure damage detection is studied. In general NDT technique such ultrasonic test, ray test, magnetism applied in modeling offline mostly. The project test and scheme pervade test etc. are vibrate properties and structure damage characteristics from platitudinous: offline tests and analysis to structure as impotent information of online automatic fault diagnosis database. Then the method of few-testing, points modeling togetting structure damage information has beer researched. Placing sensors reasonably and realizing large-scale an Complex structure damage inspect online are targets of this project.The large-scale vibrating screen has been applied widely in coax industry and other industrial areas as a kind of important device. A: vibration mechanical device, it works very hardly and works in verb wretched environment so that the beam of screen is damaged easily Therefore, it is very important how to detect the fault of beam as early a possible to make the repair schedule reasonably and economically and to avoid the body hurt and device damage.In this thesis, how can locate a damaged beam of screen is studied serially. The regulation of beam vibration characteristics change depend on damage degree of beam is found. Also the regulation of whole screen vibration characteristics change depend on damage degree of beam is found too. Based on deep research about beam vibration characteristics change regulation and whole screen vibration characteristics change regulation in series, we can get the optimum place to placed sensors for location which beam is damaged.The target of the thesis is combine the on-line dynamically inspect screen for structure damage with accurately locate fault by acoustic emission technique.The main content of this thesis consist of (1) Based on modalparameters recognition of whole screen, get location of damaged substructure. (2) Locate fault of substructure accurately by acoustic emission technique. (3)Carry on research about finding a efficient way we can inspect screen for structure damage on-line.These projects are done step by step. At first, free-free beam vibration characteristics are studied deeply. The first rank and second rank bending vibration modal shape of beam are abstracted as research objects. The study result is shown that the frequencies of FRF peak value drift toward lower frequency and the amplitudes of FRF peak value increase with the damage degree of beam. Then the first rank and second rank bending vibration characteristics of beam fixed on screen are studied. The change regulations of characteristics of FRF with beam damage are agreement to that of free-free beam. Therefore the damage information of beam can be gotten from FRE The wavelet packet analysis method and spectral analysis calculation method are employed in frequency response and transmissibility processing. The fault characteristics are abstracted. After then, the damaged beam has an effect on whole screen vibration characteristics are researched. From above work, the damaged beam of screen could be located from whole screen. Then the acoustic emission technique is used to locate fault of the damaged beam accurately. Because the too many sensors couldn't place on the working screen so that we must find limited positions to place sensors getting enough structuredamage information. At last, the method of the finding optimum places to placed sensors for location which beam is damaged is studied. The efficient way of optimum place to placed sensors is found.In this thesis, the different spectral analysis calculation methods are employed in vibration signal processing to abstract fault characteristics. The processing result indicates that methods of vibration signal procession are efficiently.This thesis provides some realizable ways to realize the on-line dynamically inspect screen for structure damage.Translation:χ射线探测焊缝及机械损伤方法概述图像中运动小目标的检测一直是图像处理与分析领域中的难题,它涉及到很多领域,具有很广泛的研究价值和应用价值。

AAW——Air-Acetylene Welding——空气乙炔焊AB——Adhesive Bonding——粘接ABW——Arc Braze Welding——电弧钎焊AC——ARC CUTTING——电弧切割Acetylene 乙炔 Ampere 电流安培Acid-Resistant Water Purifier抗酸化机能水制造装置Acoustic Emission Testing声发射检测Actual Throat焊缝实际厚度Actual Weld-Throat Thick-Ness焊缝厚度AHW——Atomic Hydrogen Welding——原子氢焊Air Tight Test气密性检验Air-Acetylene Welding空气-乙炔焊接Aircomatic Welding自动调弧氩弧焊, 惰性气体保护金属极弧焊All-Around Weld (整周焊缝)环焊缝All-Around Weld整周焊缝All-Welded Construction全焊结构All-Welded全焊接Aluminothermic Welding 铸焊, 铝热剂焊接Analyzer,Particle Size Distribution Laser Diffraction Device回折/散乱式粒度分布测定装置Angle Beam Method斜射法超声波探伤Angle Butt Weld斜对接焊Angle Welding 角焊 Arc 电弧Angle Weld角焊Angular Distortion角变形Appearance Of Weld焊缝成形Aqueous Ultrasonic Cleaning Systems大型超声波清洗机Arc Scratch电弧擦伤Arc Welding Robot弧焊机器人Arc-Seam Weld电弧缝焊Arc-Spot Weld电弧点焊Arc-Welded Pipe弧焊管Arc-Welded Steel Pipe电弧焊接钢管Arc-Weld电弧焊Argon Arc Welding 氩弧焊Argon Shielded Arc Welding 氩护电弧焊Around Openings For Welded Attachments环绕焊接附件孔口Artificial Atmospheric Phenomena Simulator人工气候室As Welded焊态ASP——Arc Spraying——电弧喷涂Aspect Ratio Of Weld焊缝成形系数Aspirators, Pumps, Compressors送液。

机床的论文中英文资料外文翻译文献引言机床是制造业中重要的设备,用于加工各种零部件和制造产品。

本文汇总了关于机床的论文中英文资料的外文翻译文献,以供参考和研究使用。

外文翻译文献列表Author: John Smith John SmithYear: 2015 20152. Title: Advanced Techniques for Machine Tool Analysis Title: Advanced Techniques for Machine Tool AnalysisAuthor: Jennifer Lee Jennifer LeeYear: 2016 20163. Title: Intelligent Control Systems for Precision Machining Title: Intelligent Control Systems for Precision MachiningAuthor: David Wang David WangYear: 2018 2018Abstract: This paper focuses on intelligent control systems for precision machining. It discusses the integration of artificial intelligence and control algorithms to enhance the precision and performance of machine tools. The paper presents case studies on the application of intelligent control systems in precision machining processes. This paper focuses on intelligent control systems for precision machining. It discusses the integration of artificial intelligence and control algorithms to enhance the precision and performance of machine tools. The paper presents case studies on the application of intelligent control systems in precision machining processes.4. Title: Advances in Machining Processes for Hard-to-Machine Materials Title: Advances in Machining Processes for Hard-to-Machine MaterialsAuthor: Emily Chen Emily ChenYear: 2019 2019Abstract: This paper reviews recent advances in machining processes for hard-to-machine materials. It discusses the challenges associated with machining materials such as titanium, nickel-basedalloys, and ceramics. The paper highlights the development of new cutting tools, machining strategies, and technologies to improve the machinability of these materials. This paper reviews recent advances in machining processes for hard-to-machine materials. It discusses the challenges associated with machining materials such as titanium, nickel-based alloys, and ceramics. The paper highlights the development of new cutting tools, machining strategies, and technologies to improve the machinability of these materials.5. Title: Optimization of Machining Parameters for Energy Efficiency Title: Optimization of Machining Parameters for Energy EfficiencyAuthor: Michael Liu Michael LiuYear: 2020 2020Abstract: This paper explores the optimization of machining parameters for energy efficiency. It discusses the impact of machining parameters, such as cutting speed, feed rate, and depth of cut, on energy consumption in machining processes. The paper presents optimization techniques and case studies on reducing energy consumption in machining operations. This paper explores theoptimization of machining parameters for energy efficiency. It discusses the impact of machining parameters, such as cutting speed, feed rate, and depth of cut, on energy consumption in machining processes. The paper presents optimization techniques and case studies on reducing energy consumption in machining operations.结论以上是关于机床的论文中英文资料的外文翻译文献,希望对研究和了解机床技术的人员有所帮助。

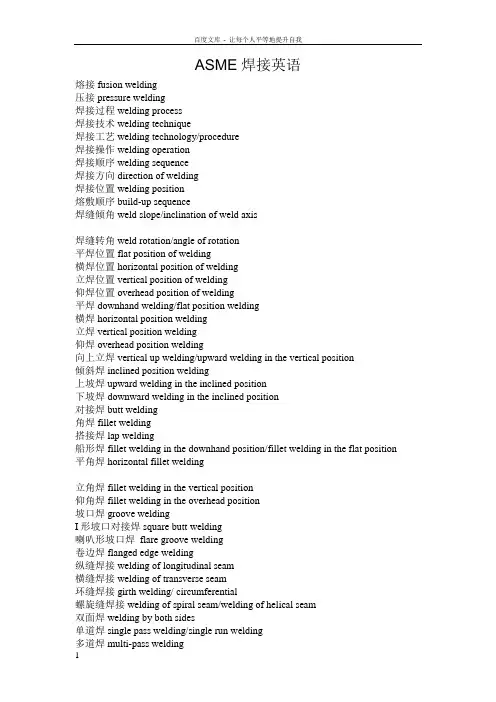

ASME焊接英语熔接fusion welding压接pressure welding焊接过程welding process焊接技术welding technique焊接工艺welding technology/procedure焊接操作welding operation焊接顺序welding sequence焊接方向direction of welding焊接位置welding position熔敷顺序build-up sequence焊缝倾角weld slope/inclination of weld axis焊缝转角weld rotation/angle of rotation平焊位置flat position of welding横焊位置horizontal position of welding立焊位置vertical position of welding仰焊位置overhead position of welding平焊downhand welding/flat position welding横焊horizontal position welding立焊vertical position welding仰焊overhead position welding向上立焊vertical up welding/upward welding in the vertical position倾斜焊inclined position welding上坡焊upward welding in the inclined position下坡焊downward welding in the inclined position对接焊butt welding角焊fillet welding搭接焊lap welding船形焊fillet welding in the downhand position/fillet welding in the flat position 平角焊horizontal fillet welding立角焊fillet welding in the vertical position仰角焊fillet welding in the overhead position坡口焊groove weldingI形坡口对接焊square butt welding喇叭形坡口焊flare groove welding卷边焊flanged edge welding纵缝焊接welding of longitudinal seam横缝焊接welding of transverse seam环缝焊接girth welding/ circumferential螺旋缝焊接welding of spiral seam/welding of helical seam双面焊welding by both sides单道焊single pass welding/single run welding多道焊multi-pass welding单层焊single layer welding多层焊multi-layer welding分段多层焊block sequence/ block welding分层多道焊multi-layer and multi-pass welding连续焊continuous welding断续焊intermittent welding打底焊backing weld封底焊back sealing weld盖面焊cosmetic welding深熔焊deep penetration welding摆动焊welding with weaving/weave bead welding前倾焊foreward welding (英国)/ forehand welding (美国) 后倾焊backward welding(英国)/ backhand welding(美国) 分段退焊backstep welding跳焊skip welding对称焊balanced welding/ balanced welding sequence左焊法leftward welding forehand welding右焊法rightward welding/backhand welding挑弧焊whipping method自动焊automatic welding手工焊manual welding/hand welding车间焊接shop welding工地焊接site welding(英国)/ field welding (美国)拘束焊接restraint welding堆焊surfacing/building up/overlaying隔离层堆焊buttering端部周边焊boxing/end return返修焊rewelding补焊repair welding塞焊plug welding槽焊slot welding衬垫焊welding with backing焊剂垫焊welding with flux backing窄间隙焊narrow-gap welding强制成形焊enclosed welding脉冲电弧焊pulsed are welding电弧点焊arc spot welding螺柱焊stud welding热风焊hot gas welding高能焊high grade energy welding单面焊双面成形one-side welding with back formation焊接条件welding condition焊接工艺参数welding parameter极性polarity正接electrode negative/straight polarity反接electrode positive/reversed polarity运条方式manipulation of electrode焊接电流welding current焊接电流增加时间welding current upslope time焊接电流衰减时间welding current downslope time电流密度current density短路电流short circuit current脉冲电流pulse level/pulse current level脉冲电流幅值pulse current amplitude基值电流background level脉冲频率pulse frequency脉冲焊接电流占空比duty cycle of pulse duration电弧电压arc voltage再引弧电压reignition voltage焊接速度welding speed行走速度rate of travel/travel speed送丝速度wire feed rate线能量heat input/energy input热输入heat input预热preheat后热postheat焊后热处理posweld heat treatment/postheat treatment预热温度preheat temperature层间温度interpass temperature焊接终了温度finishing temperature后热温度postheating temperature焊丝伸出长度wire extension弧长arc length熔化速度melting rate熔化时间melting time熔化系数melting coefficient熔敷速度rate of deposition/deposition rate熔敷系数deposition coefficient熔敷效率deposition efficiency损失系数loss coefficient飞spatter飞溅率spatter loss coefficient融合比fusion ratio稀释dilution稀释率rate of dilution合金过度系数transfer efficiency/recovery (of an element) 坡口groove坡口面groove face坡口面角度angle of bevel (英国)/ bevel angle (美国)坡口角度included angle(英国)/groove angle(美国)坡口高度groove depth钝边root face钝边高度thickness of root face/width of root face根部间隙root gap(英国)/root opening (美国)根部半径root radius/groove radius根部锐边root edge卷边高度height of flange卷边半径radius of flange单面坡口single groove双面坡口double groove坡口形式groove typeI形坡口square grooveV形坡口single V grooveY形坡口single V groove with root face带钝边U形坡口single U groove带钝边双U形坡口double U grooveVY形坡口single compound angle groove带钝边J形坡口single J groove带钝边双J形坡口double J groove单边V形坡口single bevel groove双V形坡口double V groove不对称双V形坡口asymmetric double V groove双单边V形坡口double bevel groove/K groove带垫板V形坡口V groove with backing/ single V groove with backing 喇叭形坡口flare groove锁底坡口single bevel groove with backing locked坡形板边tapered edge焊缝weld接逢seam焊缝符号welding symbol焊缝金属weld metal填充金属filler metal熔敷金属deposited metal焊缝表面weld face/ face of weld焊缝背面back of weld焊缝轴线axis of weld焊缝尺寸size of weld焊缝宽度weld width/ width of weld焊缝长度weld length/ length of weld焊缝有效长度effective length of weld焊缝厚度throat depth/ throat thickness焊缝计算厚度theoretical throat焊缝实际厚度actual throat熔深penetration/ depth of penetration焊缝成形appearance of weld焊缝成形系数form factor of weld余高reinforcement/ excess weld metal背面余高root reinforcement削平焊缝flush weld/ weld machined flush对接焊缝butt weld角焊缝fillet焊脚leg/ fillet weld leg角焊缝断面形状profile of fillet weld平形角焊缝flat fillet凸形角焊缝convex fillet weld凹形角焊缝concave fillet weld角焊缝凹度concavity侧面角焊缝side fillet weld/ fillet weld in parallel shear正面角焊缝front fillet weld/ fillet weld in normal shear立角焊缝fillet weld in the vertical position横角焊缝fillet weld in the horizontal position平角焊缝fillet weld in the flat position斜角焊缝oblique fillet weld连续焊缝continuous weld断续焊缝intermittent weld连续角焊缝continuous fillet weld断续角焊缝intermittent fillet weld交错断续角焊缝staggered intermittent fillet weld并列断续角焊缝chain intermittent fillet weld端接焊缝edge weld卷边焊缝flanged edge weld塞焊焊缝plug weld纵向焊缝longitudinal weld横向焊缝transverse weld环行焊缝girth weld/ circumferential weld螺旋形焊缝spiral weld/ helical weld密封焊缝seal weld承载焊缝strength weld联系焊缝connective weld定位焊缝tack weld焊道bead/ run/ pass焊波ripple焊根weld root/ root of weld焊趾weld toe/ toe封底焊道sealing run (after making main weld)/ back weld打底焊道backing weld (before making main weld)/ back weld 根部焊道root pass/ root run填充焊道filling bead盖面焊道cosmetic bead/ cover pass回火焊道temper bead/ annealing bead熔透焊道penetration bead焊层layer焊接接头welded joint接头形状joint geometry等强匹配接头equalmatching weld joint低强匹配接头undermatching weld joint超强匹配接头overmatching weld joint接头根部root of joint对接接头butt jointI形对接接头square butt jointV形对接接头single V butt jointU形对接接头single U butt jointJ形坡口接头single J butt joint双V形对接接头double V butt joint双单边V形对接接头double bevel butt joint/ K groove butt joint 带钝边U形对接接头double U butt joint带钝边J形坡口接头double J joint角接接头corner jointT形接头T joint斜T形接头inclined T joint十字接头cruciform joint/ cross-shaped joint三联接头joint among three members搭接接头lap joint套管接头muff joint/ sleeve joint双盖板接头double strapped joint盖板接头strapped joint端接接头edge joint卷边接头flanged edge joint锁底对接接头lock butt joint斜对接接头oblique butt joint混合接头mixed joint/ composite joint有间隙接头open joint无间隙接头closed joint焊接电弧welding arc电弧形态arc shape电弧物理行为arc physics behaviour引弧striking arc引弧电压striking voltage电弧气氛arc atmosphere阴极cathode热阴极hot cathode冷阴极cold cathode阴极斑点cathode spot阴极区cathode region阴极区电场强度intensity of the electric field in the cathode region 阴极压降cathode drop阳极anode阳极斑点anode spot斑点压力spot pressure阳极区anode region阳极区电场强度intensity of the electric field in the anode region 阳极压降anode drop弧柱arc column/ arc stream弧柱压降voltage drop in arc column弧柱电位梯度potential gradient in the arc column弧焰arc flame弧心arc core硬电弧forceful arc/ hard arc软电弧soft arc旋转电弧rotating arc脉冲电弧pulsed arc脉冲喷射电弧pulsed spray arc起皱现象puckering phenomena起皱电弧puckering arc起皱临界电流puckering critical current间接电弧indirect arc压缩电弧compressive arc磁控电弧magnetic controlling arc电弧力arc force电磁力electromagnectic force电磁收缩效应pinch effect电弧飘移wandering of arc电弧稳定性arc stability电弧静特性static characteristic of arc电弧动特性dynamic characteristic of arc最小电压原理principle of minimum voltage电弧挺度arc stiffness电弧偏吹arc blow磁偏吹magnetic blow阴极清理作用cleaning action of the cathode电弧自身调节arc self-regulation挖掘作用digging action极性效应polarity effect熔滴droplet熔滴比表面积specific surface of droplet熔滴过渡metal transfer过度频率transition frequency粗滴过渡globular transfer; drop transfer短路过渡short circuiting transfer喷射过渡spray transfer旋转喷射过渡rotating spray transfer脉冲喷射过渡pulsed spray transfer爆炸过渡explosive transfer渣壁过渡flux wall guided transfer熔池molten pool沸腾状熔池boiling molten pool熔渣slag渣系slag system渣系相图slag system diagram碱性渣basic slag酸性渣acid slag碱度basicity酸度acidity长渣long slag短渣short slag粘性熔渣viscous slag氧化物型熔渣oxide melting slag盐型熔渣salt melting slag盐-氧化物型熔渣salt-oxide melting slag熔渣流动性fluidity of the slag; slag fluidity熔渣solidified slag多孔焊渣porous slag玻璃状焊渣vitreous slag自动脱落焊渣self-releasing slag脱渣性slag detachability电焊机electric welding machine; electric welder 焊接电源welding power source焊接欠缺与检验焊接欠缺welding imperfection焊接缺陷weld defect气孔blowhole/ gas pore针尖状气孔pinhole密集气孔porosity条虫状气孔wormhole裂纹crack表面裂纹surface crack咬边undercut焊瘤overlap凹坑pit烧穿burn through塌陷excessive penetration未焊透incomplete penetration/ lack of penetration 未熔合lack of fusion/ incomplete fusion未焊满incompletely filled weld根部凹陷root concavity电弧擦伤arc scratch夹渣slag inclusion夹杂物inclusion夹钨tungsten inclusion白点fish eye/ flake错边misalignment/ dislocation试件test piece试样test specimen无损检验nondestructive test破坏检验destructive test外观检查visual examination超声波探伤ultrasonic inspection直射法超声波探伤straight beam method斜射法超声波探伤angle beam method液浸法超声波探伤immersion method射线探伤radiographic inspection/ radiographyX射线探伤X-ray radiographic inspectionγ射线探伤gamma-ray inspectionX射线工业电视探伤X-ray industrial television inspection 磁粉探伤magnetic particle inspection电磁探伤electromagnetic inspection/ eddy current test探伤灵敏度flaw detection sensitivity渗透探伤penetration inspection荧光探伤flurescent penetrant inspection着色探伤dye penetrant inspection密封性检验leak test气密性检验air tight test枕形气密检验pillow test耐压检验pressure test水压检验hydraulic test气压检验pneumatic test液晶检验liquid crystal test声发射检测acoustic emission testing面弯试验face bend testing背弯试验root bend test侧弯试验side bend test横弯试验horizontal bend test纵弯试验axial bend test压扁试验squeezing testactual weld-throat thick-ness焊缝厚度all-around weld整周焊缝all-around weld (整周焊缝)环焊缝angle butt weld斜对接焊angle weld角焊appearance of weld焊缝成形arc-seam weld电弧缝焊arc-spot weld电弧点焊arc-weld电弧焊aspect ratio of weld焊缝成形系数at weld edge在焊缝边上attachment weld连接焊缝automatic spot weld自动点焊法automatic weld自动焊接axis of a weld焊缝中心线; 焊接轴线axis of weld焊缝轴线; 焊接轴线back of weld焊缝背面backing groove of weld焊缝反面坡口backing weld底焊; 底焊焊缝bare metal arc weld裸焊条电弧焊bead weld珠焊; 堆焊bead-on-plate weld堆焊焊缝beading weld凸焊beam-to-beam weld梁间焊接; 梁式引线焊接block sequence weld分段多层焊bond weld钢轨接头焊接bridge seam weld桥缝焊接; 桥线焊brize weld硬焊butt weld对接焊缝butt weld ends对头焊接端butt-weld碰焊; 平式焊接; 对头焊接butt-weld in the downhand position对接平焊butt-weld joint对头焊接butt-weld pipe mill对焊管轧机button spot weld按电钮点焊cap weld最后焊层; 盖面焊缝carbon content of weld materials焊接材料的碳含量cast-weld construction铸焊结构caulk weld填缝焊caulking weld密实焊缝chain intermittent fillet weld链式分段角焊; 并列间断角焊缝chain intermittent weld并列焊接circular weld环形焊缝circumferential weld环缝; 环焊缝cleft weld裂口焊closed weld底边无缝焊; 无间隙焊缝closed-chamber fusion weld闭室熔焊cluster weld丛聚焊缝coil weld卷板对接焊; 卷板对接焊; 板卷焊cold weld冷压接commutator-controlled weld换向控制焊接complete penetration butt weld贯穿对焊composite weld紧密焊缝; 强度密封焊缝concave filled weld凹形角焊缝concave filler weld凹角焊concave fillet weld凹面填角焊concave weld凹焊缝; 凹面焊; 凹形焊缝; 轻型焊connective weld联系焊缝continuous butt-weld mill连续式炉焊管机组continuous fillet weld连续(填)角焊缝; 连续角焊缝; 连续贴角焊continuous weld连续焊缝continuous weld process连续式炉焊管法contour weld特形焊接convex fillet weld凸角焊缝; 凸形角焊缝convex weld凸焊缝; 凸形焊缝copper weld wire包铜钢丝corner flange weld单卷边角焊缝corner weld角焊corner-flange weld卷边角焊缝; 卷边角焊缝crack of weld焊部裂纹cross weld十字交叉焊缝; 横向焊缝cross-wire weld十字焊crotch weld楔接锻接; 楔接焊接cup weld带盖板焊缝depth of weld焊接深度dissimilar weld metal不同的焊接金属; 不同金属的焊接distance between the toes of a weld焊缝宽度double groove weld双面坡口焊缝double-bevel groove weld双斜边坡口焊缝; 双斜坡口焊double-flanged butt weld双弯边对接焊缝double-V groove weld双斜边坡口焊缝; 双斜坡口焊downhand weld平焊缝duplex spot weld双点点焊接头edge joint weld边缘焊edge weld端接焊; 端接焊缝; 端面焊缝; 对边焊electric resistance weld mill电阻焊管机electric weld-pipe mill电焊管机焊接专业英语词汇(通用部分)acetylene 乙炔ampere 电流安培angle welding 角焊arc 电弧argon arc welding 氩弧焊接bare electrode 光熔接条butt welding 对接焊接camber 电弧弯曲cascade 阶叠熔接法clad weld 被覆熔接crator 焊疤excess metal 多余金属filler rod 焊条fillet weld 填角焊接gas shield 气体遮蔽groove welding 起槽熔接hand face shield 手握面罩hard facing 硬表面堆焊jig welding 工模焊接laser beam welding 雷射光焊接metal electrode insert gas welding MIG熔接nugget 点焊熔核overlaying 堆焊peening of welding 珠击熔接法plug welding 塞孔熔接positioned welding 正向熔接pressure welding 压焊propane gas cutting 丙烷气切割pure nickel electrode 纯镍熔接条reinforcement of weld 加强焊接resist 抗蚀护膜root running 背面熔接seam 焊缝seaming 接合seam welding 流缝熔接series seam welding 串联缝熔接skip welding process 跳焊法spark 火花spot welding 点焊接stitch welding 针角焊接stud arc welding 电弧焊接under laying 下部焊层void 焊接空隙weld flow mark 焊接流痕weld flush 焊缝凸起weld line 焊接纹weld mark 焊接痕weld penetration 熔接透入weld zone 焊接区welding 焊接welding bead 焊接泡welding direction 焊接方向welding distortion 焊接变形welding flux 焊剂welding ground 电熔接地welding interval 焊接周期welding stress 熔接应变welding torch 熔接气炬welding electrode production line 电焊条生产线welding electrode 焊条welding fixture 焊接夹具welding generator 电焊机welding goggles 焊工护目镜welding gun 焊枪welding helmet 电焊帽welding inspection ruler 焊接检验尺welding machine 焊接机welding mill 焊管机welding motor generator 电动焊接发电机welding nozzle 焊嘴welding paste 焊接药膏welding pipe 焊接管welding powder 焊粉welding rectifier 焊接整流器welding robot 焊接机器人welding rod extrusion press 焊条挤压机welding rod with acidic coating 酸性焊条welding rod with alkaline coating 碱性焊条welding rod 焊条welding simulator 焊接模拟器welding stainless electrode 不锈电焊条welding steel tube 焊接钢管welding tin billet 焊锡棒料welding tongs 焊接夹钳welding torch 焊炬welding transformer 电焊变压器welding unit 焊机welding wire machine 焊线机welding wire 焊丝welding-cutting hose 熔焊及切割胶管welding-cutting tool 焊割具welding-rod core 焊条芯welding-seam cleaner 焊缝清理机weldless pipe 无缝管weldless steel tube 无缝钢管well borer 凿井机well counter 井式计数器well deck vessel 井形甲板船well drill 钻井机well platform 钻井平台well rig 钻井机well testing truck 试井车well thermometer 井温计well tube filter 井管滤管well type tempering electric furnace 井式回火电炉well winch 矿井绞车well-logging probe 测井探头well-type counter 井型计数器Wella Balsam Conditioner 威娜宝护发素Wella Balsam shampoo 威娜宝香波Wellene 韦纶聚酯短纤维wellhead acid preventer 井口防酸器wellington 惠灵顿防雨呢Wellingtons 长筒皮靴Welltite 韦纶泰特聚丙烯和聚乙烯单丝Welsbach's alloy 韦尔斯巴赫发火合金Welsh flannel 威尔士法兰绒Welsh wool 威尔士粗羊毛welsh-onion stalk 葱白welsh-onion 葱welt cementing machine 贴边粘合机welt coloring machine 贴边染色机welt cutting machine 切沿条机welt fitting machine 贴边机welt footwear 加贴边的鞋welter screen 翻滚筛welter 镶边机Wepsin 三唑磷胺Werlisa 威里沙牌照相机Werner 维尔纳牌手表weskit 紧身背心Wessel silver 韦塞尔铜镍锌合金West cigarette 威狮牌香烟West ginseng 西洋参West Lake Dragon Well tea 西湖龙井茶West Lake silk umbrella 西湖绸伞West Lake silk 西湖丝绸West Lake water shield 西湖莼菜Westeeco 韦斯蒂科镍铬铁耐热合金Western king prawn 宽沟对虾Western saddle pants 西式马裤Western sand cherry 沙樱桃Western shirt 西式衬衫western style bed sheet 西式床单Western style hat 西式呢帽Western style pajamas 西式睡衣裤Western style pants 西裤Western style shirt 西式衬衫Western style shirt-waist blouse 西式衬衫上衣Western style suit 西服western tie 西式领带Western wool 美国西部羊毛Western-made shirt in plaid gingham 长方格贞咸布西式衬衫Westinghouse alloy 西屋镍铜热磁补偿合金wet spinning frame 湿纺细纱机wet air compressor 湿空气压缩机wet air pump 湿空气泵wet and dry bulb hygrometer 干湿球湿度计wet and dry bulb recording hygrometer 干湿球自记湿度计wet and dry bulb thermometer 干湿球温度计wet ball mill 湿式球磨机wet blue goat leather 山羊蓝湿革wet blue goat skin 蓝湿山羊皮wet board machine 湿式纸板机wet brush 湿刷wet chrome goat skin 铬湿山羊皮wet cleaner 湿法清洗器wet cloth 湿光布wet clutch 湿式离合器wet collector 湿式除尘器wet condenser 湿式冷凝器wet crude 含水原油wet crushing mill 湿粉碎机wet cylinder liner 湿式气缸套wet drill 湿式风钻wet dust collector 湿式收尘器wet dust separator 湿式除尘器wet electro-magnet 湿式电磁铁wet electrolytic capacitor 电解液电容器wet feeder 湿式给料机wet fiber filter 湿式纤维过滤器wet filter 湿式过滤器wet fourdrinier board machine 长网湿抄机wet frame 湿纺机wet furfural condenser 含水糖醛冷凝器wet gas meter 湿式气量计wet gas scrubber 湿法气体洗涤质量合格证书certification of fitness原材料rawmaterial底板bottom plate垫层cushion侧壁sidewall中心线center line条形基础strip footing附件accessories型钢profile steel钢板steel plate熔渣slag飞溅welding spatter定位焊tacking引弧generating of arc熄弧quenching of arc焊道welding bead坡口beveled edges外观检查visual inspection重皮doubleskin水平方向弧度radian in horizontal direction成型molding直线度straightness accuracy焊缝角变形welding line angular distortion水平度levelness铅垂度verticality翘曲变形buckling deformation角尺angle square对接焊缝butt weld母材parent metal法兰密封面flange sealing surface夹层interlayer表面锈蚀浓度surface corrosion concentration挠曲变bending deformation超声波探伤ultrasonic testing/ ultrasonic examination 压力容器pressure vessel预制下料prefabrication baiting排版直径set-type diameter焊缝welding line中幅板? center plate测量方法measuring method基准点datum mark跳焊skip welding允许偏差allowable variation补强板stiffening plate开孔tapping对接接头banjo fixing butt jointing角钢angle iron安装基准圆installation fundamental circle吊装立柱hoisting upright column焊接钢管welded steel pipe向心斜拉筋centripetal canting pull rope带板band plate槽钢胀圈channel steel expansion ring环口collar extension局部变形local distortion环缝circumferential weld顶板top plate拱顶vault顶板加强肋stiffening rib对接butt joint胎具clamping fixture卷板机plate bending rolls中心支架center bearing bracket椭圆度ovality等分线bisectrix搭接宽度lap width点焊spot welding搭接焊overlap welding对称:symmetrically螺旋爬梯cockle stairs放料阀baiting valve液位计content gauge充水试验filling water test错边量unfitness of butt joint底圈foundation ring真空度检漏vacuum degree leak test丁字焊缝tee welding渗透探伤oil whiting test充水试验filling water test内侧角焊缝接头interior angle welding line joint foundation settlement 基础沉降测量基准点datum mark稳定性试验stability test排气阀outlet valve角钢angle steel构件component part机械损伤mechanical damage缩孔shrinkage cavityenfoldment 折迭碳钢管carbon steel tube公称直径nominal diameter预埋件embedded part轴测图axonometric drawing布置图arrangement diagram氧乙炔气割oxyacetylene gas cutting低合金钢管low alloy steel热影响区heat affected area修磨polish砂轮片grinding wheel等离子plasma panel重皮coldlap凹凸unevenness缩口necking down端面head face倾斜偏差dip deviation外径external diameter砂轮grinding wheel管件pipe casting单线图single line drawing平齐parallel and level两端two terminals满扣buckle螺栓紧固bolton周边periphery附加应力additional stress同轴度axiality平行度parallelism随机stochastic允许偏差allowable variation重直度verticality水平度levelness隔离盲板blind plate氩弧焊argon arc welding压盖螺栓gland bolt间距spacing有效期period of validity担任take charge of ;undertake焊条welding rod碳钢焊条carbon steel焊丝welding wire熔化焊melting钢丝steel wire气体保护焊gas shielded arc welding 烘干drying清洗ablution制度system焊接工艺welding procedure相应corresponding手工电弧焊manual electric arc welding手工钨极manual tungsten electrode打底render电源power source交流alternating current焊件weldment管壁厚度pipe thickness对接焊缝butt weld工件壁厚workpiece飞溅物splash沾污smirch油污oil stain细锉smooth file铣刀milling cutter氧化膜oxide film脱脂处理ungrease treatment]棉质纤维cotton fibre丙酮acetone硫sulfur焊剂welding flux钢板steel plate纵向焊缝longitudinal weld longitudinal seam 筒节shell ring封头end socket卷管reelpipe强度试验strength test起弧arc starting穿堂风draught熔合fusion反面reverse side整体integral封堵block up焊口weld bond医用胶布medical proof fabric高频high frequency焊炬welding torch送气air supply焊接专业英语词汇(熔化焊)熔接fusion welding压接pressure welding焊接过程welding process焊接技术welding technique焊接工艺welding technology/procedure焊接操作welding operation焊接顺序welding sequence焊接方向direction of welding焊接位置welding position熔敷顺序build-up sequencedeposition sequence焊缝倾角weld slope/inclination of weld axis焊缝转角weld rotation/angle of rotation平焊位置flat position of welding横焊位置horizontal position of welding立焊位置vertical position of welding仰焊位置overhead position of welding平焊downhand welding/flat position welding横焊horizontal position welding立焊vertical position welding仰焊overhead position welding全位置焊all position welding:熔焊时,焊件接逢所处空间位置包括平焊、横焊、仰焊等位置所进行的焊接。

Quality Control Plan for the Orbital Welding轨道自动焊质量控制方案1Formulation Description and Working Scope编制说明及工作范围:This plan is formulated to ensure the quality of stainless steel orbital-welding and meet the requirement of the owner.为保证不锈钢轨道自动焊的质量,达到业主要求。

特编制本方案。

Working Scope工作范围:Material for nitrogen, carbon dioxide, vacuum, compressed air systems is stainless steel 304L.氮气、二氧化碳、真空、压缩空气系统,材料材质为SS304L 。

Material for the RO water system is SS316L BA standard, for oxygen system is SS316L EP standard.RO水系统,材料材质为SS316LBA级别,氧气系统材质为SS316LEP级别。

2Welding Machine焊机In this project, AMI orbital-welding machine will be used in stainless steel auto-welding.本项目中,不锈钢自动焊的焊机采用AMI轨道自动焊机。

3Requirement of the Welder焊工要求Welders can only be allowed to start the operation of auto-welding when their welded specimens are approved by M+W. XX’s QAR can sign the coupon as acceptable if it meet the requirement.只有焊接试样被M+W美施威尔管理公司接受的焊工,才能进行不锈钢自动焊的作业。

汽车焊接夹具设计中英文对照外文翻译文献(文档含英文原文和中文翻译)汽车焊接夹具的设计1摘要依据车体焊装线夹具设计理论,对各工位焊接夹具及其焊装总线进行规划、设计,之后进行夹具建模、装配,插入焊钳确定其数量、型号及判断其可达性,最终设计出符合要求的焊接夹具。

关键词:焊接部件;基础;夹紧;位置1.介绍装配和焊接夹具在汽车车身装配和焊接生产线与生产制造优质的汽车设备息息相关。

焊装夹具,是焊接工艺的重要组成部分。

装配和焊接夹具除了是完成这个过程中零部件装配的途径和定位,同时在生产线上也作为一个测试和校准程序,完成检测焊接配件和焊接质量的任务。

因此焊装夹具的设计和制造,直接影响焊接过程中汽车的生产能力和产品质量。

汽车焊装夹具是保证其制造质量、缩短其制造周期的重要手段。

因此,正确理解焊装夹具设计要点,改善和提高焊装夹具的设计手段和设计水平,并提高夹具的调整和验证水平等三方面都是必不可少的,也是汽车制造公司在激烈的竞争中得以生存所必须解决的问题。

汽车的风格不同,焊接夹具的形状,因而有着很大的不同,但在设计、制造和调整都是共同的,可以借鉴采用。

2.焊接夹具的结构设计焊接夹具的结构设计,确保该夹具有良好的操作方便性、装夹定位的可靠性。

焊装夹具的制造商也很容易集成的调整,以保证结构各部分的表面应该允许足够的空间用于调整,以确保立体可调。

当然,在确保焊接夹具质量准确性的前提下,焊接夹具的结构应尽可能简单。

夹具设计通常是夹具上全部元件的位置都是直接根据设计基准确定的,最终保证制造出合格的焊接工装结构。

根据作业高度可初步决定夹具底板的高度,即夹具固定位置的高度。

焊接夹具设计首先要考虑夹紧方式,一般有手动和气动两种,手动夹紧一般适合于小件、外协件、小批量工件焊装,对于大型车体部件、规划于生产线内、自动化程度要求高的焊接夹具宜选用气动夹紧,汽车生产的一般采用气动夹紧,然后手工大批量夹紧可作为辅助夹紧。

这样可以相应的降低成本。

环缝焊机的功能及⽤途

环缝⾃动焊接机主要⽤于碳钢、不锈钢圆形⼯件对接,根据要求可选择单缝或双缝,与⽴式环缝焊机相⽐对,焊件的长度没有过多的限制3-4⽶的长管都可以轻松焊接,设备可⼴泛的⽤于液压油缸、汽车⽅向架、传动轴、液压⽓罐、消防器材、矿⼭及⽣产线⽤滚筒及储液筒等产品的焊接。

环缝滚焊机的主要配置及功能:

床⾝结构、焊接结构、保证⼯件旋转直径和床⾝的强度,床⾝进⾏热处理,焊枪相对固定,⼯件旋转,哈尼额位置⽔平,⼯件由三⽖卡盘夹紧随动,中间有升降⽀撑机构。

主轴箱:主轴带有间隙微调装置,以便于轴承磨损后有效调节主轴跳动,主轴径向与端⾯跳动0.15mm,尾座与主轴同轴度0.15mm。

⼯件⽀撑:采⽤直线导轨,第⼀个⼯件⼿⼯调整尾座及⾼度,调整后⾃动控制上升和下降,⼯件⽀撑机构可沿导轨纵向移动,以适应不同长度⼯件的焊接。

焊枪系统:电机驱动(⾃动/⼿动)每⼀圈上升⾼度可调,焊枪⾓度可调,焊枪微调,焊枪左右可移动。

摆动系统:焊枪要有摆动和提升功能,来实现焊接过程中焊枪的⾃动提升和摆动,以完成多层焊,填满焊道,摆动速度0-100摆动范围:0~25mm。

毕业设计(论文)外文资料翻译系部:专业:姓名:学号:外文出处:English For Electromechanical(用外文写)Engineering附件:1.外文资料翻译译文;2.外文原文。

附件1:外文资料翻译译文机床机床是用于切削金属的机器。

工业上使用的机床要数车床、钻床和铣床最为重要。

其它类型的金属切削机床在金属切削加工方面不及这三种机床应用广泛。

车床通常被称为所有类型机床的始祖。

为了进行车削,当工件旋转经过刀具时,车床用一把单刃刀具切除金属。

用车削可以加工各种圆柱型的工件,如:轴、齿轮坯、皮带轮和丝杠轴。

镗削加工可以用来扩大和精加工定位精度很高的孔。

钻削是由旋转的钻头完成的。

大多数金属的钻削由麻花钻来完成。

用来进行钻削加工的机床称为钻床。

铰孔和攻螺纹也归类为钻削过程。

铰孔是从已经钻好的孔上再切除少量的金属。

攻螺纹是在内孔上加工出螺纹,以使螺钉或螺栓旋进孔内。

铣削由旋转的、多切削刃的铣刀来完成。

铣刀有多种类型和尺寸。

有些铣刀只有两个切削刃,而有些则有多达三十或更多的切削刃。

铣刀根据使用的刀具不同能加工平面、斜面、沟槽、齿轮轮齿和其它外形轮廓。

牛头刨床和龙门刨床用单刃刀具来加工平面。

用牛头刨床进行加工时,刀具在机床上往复运动,而工件朝向刀具自动进给。

在用龙门刨床进行加工时,工件安装在工作台上,工作台往复经过刀具而切除金属。

工作台每完成一个行程刀具自动向工件进给一个小的进给量。

磨削利用磨粒来完成切削工作。

根据加工要求,磨削可分为精密磨削和非精密磨削。

精密磨削用于公差小和非常光洁的表面,非精密磨削用于在精度要求不高的地方切除多余的金属。

车床车床是用来从圆形工件表面切除金属的机床,工件安装在车床的两个顶尖之间,并绕顶尖轴线旋转。

车削工件时,车刀沿着工件的旋转轴线平行移动或与工件的旋转轴线成一斜角移动,将工件表面的金属切除。

车刀的这种位移称为进给。

车刀装夹在刀架上,刀架则固定在溜板上。

溜板是使刀具沿所需方向进行进给的机构。

焊接工艺参数:焊接时,为保证焊接质量而选定的诸物理量(如:焊接电流、电弧电压、焊接速度、线能量等)的总称叫焊接工艺参数。

(Welding procedure parameter:The floorboard of all physical terms(as welding current, arc voltage, welding speed, energy definitions and so on)which are sel ected to ensure the welding quality when welding is taken is called welding pro cedure parameter)1、焊接电流:当其它条件不变时,增加焊接电流,则焊缝宽度和厚度都增加,而焊缝宽度几乎保持不边。

其原因是:Welding current: When the other conditions don’t change, if the weld current i s added, both the weld depth and weld reinforcement will increase, the weld wid th almost will not change. The reasons are:⑴焊接电流增加时,电弧的热量增加,因此熔池体积和弧坑深度都随电流增加,所以冷却下来后,焊缝厚度就增加。

When the welding current is added, the quality of heat of the arc will increa se, so both the volume of molten puddle and the depth of arc crater will all in crease, and the weld depth will increase when the weld is cooling.⑵焊接电流增加时,焊丝的熔化量也增加,因此焊缝的余高也随之增加。

焊接专业网焊接英汉词典(3)requency welding 射频熔接;高频焊接d welding 轨端补焊face welding neck flange 凸面对焊法兰welding method 上升焊接法requency welding 高频焊cating welding electrode 往复焊接电极allization welding 再结晶焊接er welding machine 整流焊机er welding set 整流焊机on welding 还原焊接cing cage welding machine 钢筋骨构架焊接机(焊接网 )welding 凸焊by welding 焊接修补welding 补焊;焊补;焊修ng welding 修补焊;补焊;焊修l strain by welding 焊接残余应变l stress by welding 焊接残余应力nce butt welding 对接接触焊nce butt-seam welding 电阻对缝焊接nce butt-welding 电阻对焊nce electroslag welding 接触电渣焊nce percussion welding 接触冲击焊welding fixture 焊接夹具welding flame 焊接火焰welding flash 弧光灼伤welding flux 焊接溶剂;焊药welding flux backing 焊剂垫welding force 阻焊加压;电极力;电极压力welding from one side 单面焊welding fume 焊接烟尘welding furnace 烧结炉welding gap 焊件装配间隙welding gauge 确定焊缝尺寸用样板welding generator 焊接发电机;焊接用发电机;电焊发电机welding generator with differential excitation 差激电焊welding generator with splitting pole 裂极式电焊发电机welding glass 焊接保护玻璃;黑玻璃welding glove 焊工手套welding gloves 焊接手套;焊接用手套welding goggles 焊工保护眼镜;焊工护目镜;焊接护目镜welding grade gas 焊接级保护气体;焊接级气体welding grade shield gas 焊接级保护气体welding ground 焊接地线;电焊地线;工件引线welding gun 焊接喷枪welding gutter 焊管拉模nce percussive-welding 电阻锻接nce roller-spot-welding 电阻滚动点焊nce seam welding 电阻缝焊;电阻滚焊nce spot welding 电阻点焊nce stitch welding 电阻点缝焊接nce welding 电阻焊接nce welding machine 电阻焊机nce welding time 电阻焊通电时间nce-flash welding 电阻弧花压焊接;电阻闪光焊接nce-welding time 接触焊通电时间nt welding 约束下焊接;抑制焊接cing welding 堆焊ssion welding method 后退焊接法elding 筋状凸焊rd welding 右焊法int welding neck flange 梯形槽式密封面对焊法兰;环槽式对焊法兰lding 滚焊projection welding 波纹状凸焊elding 电铆焊elding system 自动焊接系统arm resistance welding machine 摇臂接触焊机lding 热辊压焊接ot welding 滚点焊welding handle 焊条夹welding head 焊机头;焊接机头;烙铁头;烧焊枪welding heat 焊接热;焊热welding heat input 焊接输入热量welding helmet 焊工帽罩;电焊帽welding holder 焊接握把welding hose 焊接软管welding impulse 电焊脉冲welding inspection 焊接检查welding inspection ruler 焊接检验尺welding interval 焊接时间;焊接时间间隔;焊接周期welding jig 焊接夹具;焊条夹钳welding joint 焊接接头welding laboratory 焊接试验室welding layer 焊层welding lead 电焊引线welding machine 电焊机;焊接机welding machine with power factor correction 功率因素改焊机welding manipulator 焊件支架;焊接操作机;焊接机械手welding material 焊接材料welding metal cracking 焊缝金属裂纹welding metallurgy 焊接冶金welding method 焊接方法lding 滚压焊lding (RW)滚焊spot-and-seam welding machine 辊式点缝焊机welding 轧焊type seam welding machine 辊式缝焊机welding set 旋转式焊机welding transformer 旋转式焊接变压器;可旋转焊接变压器g arc pipe welding machine 旋转电弧焊管机g arc welding 旋转电弧焊g welding machine 旋转式弧焊机welding 鞍形焊h welding 夹紧冷焊elding 两端搭接焊elding 嵌焊welding 焊接连接密封lding 密封焊接lding 线焊接;缝焊lding electrode 滚极lding machine 缝焊机justing arc welding 自动调节电弧焊;自调电弧焊gulating arc welding transformer 自调节弧焊变压器ielded arc welding 自保护电弧焊ielded welding wire 自保护焊丝tomatic arc welding 半自动弧焊welding micrometer 检验卡规welding mill 焊管机welding motor generator 旋转式直流焊机;电动焊接发电机;转式电焊机welding neck 对焊welding neck 对焊法兰welding neck flange 高颈法兰welding nozzle 焊嘴welding of tube-tubesheet 管子与管板氩弧焊接welding of tubes 炉管焊接welding on bottom 底焊welding operation 焊接操作welding operator 焊工;焊接操作者;自动焊工welding outfit 焊接机组;焊接配备welding parameter 焊接工艺参数welding paste 焊膏;焊糊;焊接涂料;焊接药膏welding performance 焊接性能welding period 焊接循环周期welding pipe 焊接管welding plant 焊接厂;焊接装置welding pool 焊接熔池welding portion 焊接部分welding position 焊接部位;焊接位置;焊位welding positioner 焊接翻转台;焊接胎架tomatic arc welding machine 半自动电弧焊机;半自动弧焊tomatic metal arc welding 半自动金属电弧焊tomatic welding 半自动焊接tomatic welding machine 半自动焊接机omatic welding 半自动焊e of welding 焊接顺序ial welding 程序焊接;连续焊arc welding 串联弧焊projection welding 单边多极凸焊seam welding 串联缝焊;单边多极滚焊;单边双电极焊缝;单滚焊spot welding 串点焊;串联点焊;单边多极点焊;单面点焊;点点焊;连续点焊submerged arc welding (SAW-S)横列双丝串联埋弧焊welding 串焊;串联焊;单边多电极焊接;系列焊接arc welding 串联电弧焊接spot welding 单面点焊elding 异形焊;成形零件堆焊;有型焊接d carbon-arc welding 气保护碳弧焊arc welding 封闭电弧焊inert gas metal arc welding 惰性气体保护金属极弧焊arc welding 掩护电孤焊接d arc welding 有保护的电弧焊;保护电弧焊welding positioner roller 焊接定位滚轮welding powder 焊粉welding power lead 焊接用输电线welding press 焊接压力机welding pressure 焊接压力welding procedure 焊接程序;焊接次序;焊接工艺;焊接工艺焊接规程;焊接施工welding procedure drawing 焊接施工图welding procedure qualification 焊接程序评定welding procedure qualification test record 焊接工艺鉴定录welding procedure sheet 焊接工艺卡welding procedure specification 焊接程序welding procedure specification (WPS)焊接工艺规程welding process 焊接方法;焊接过程welding puddle 焊接熔池welding quality 焊接质量welding rate 焊接速度welding rectifier 焊接整流器;电焊整流器;整流式焊机welding regulator 电焊调节器;焊接调节器welding requirements 焊接要求Welding Research Council 焊接研究委员会welding residual deformation 焊接残余变形welding residual stress 焊接残余应力d carbon arc welding 碳弧保护焊d metal (manual electric) arc welding 手弧焊d metal arc welding 自动保护金属极电弧焊;熔化极自动保焊d metal-arc welding 掩护电孤焊接;气保护金属极电弧焊;电弧焊ng arc welding 盾护电焊;盾护电弧焊lding 工厂焊接;车间焊接;车间中焊接rc welding 短弧焊ircuiting arc welding 短路过渡电弧焊lding 脉冲焊接welding 预应变焊接llet welding 侧面角焊p welding 侧搭焊;侧面搭接焊elding 西格玛焊接rectifier for welding 硅焊接整流器welding rectifier 硅焊接整流器impulse welding 单脉冲焊operator arc welding generator 单站电焊发动机operator arc welding machine 单站弧焊机operator arc welding set 单人电焊机operator welding machine 单工使用焊机;单站弧焊机oxyacetylene welding goggles 单玻璃焊工护目镜side welding 单面焊welding resistor 焊接电阻器welding robot 焊接机器人welding rod 焊棒;焊条;电焊条welding rod coating 焊条上的焊药welding rod core 焊条芯welding rod extrusion press 焊条挤压机;焊条压涂机;焊条抹机welding rod holder 焊把;焊条夹钳;焊条钳welding roll 焊滚;焊接滚轮welding rolls 焊接辊welding rules 焊接规则welding schedule 焊接工艺程序;焊接计划表welding screen 电焊遮光罩welding seam 焊缝welding seam No. 焊缝编号welding sequence 焊接程序;焊接次序;焊接顺序welding set 焊接机组;焊接设备;焊接装置;电焊装置welding set with a surge injector 脉冲稳弧焊机welding shop 焊接车间;焊接工场;电焊车间welding simulator 焊接模拟器welding slag 焊接熔渣;焊渣welding sleeves 焊接用套袖welding socket 焊接管套;焊接套管welding source 焊接电源spot welding 单点焊;单行点焊welding 单点点焊;单面焊impulse welding 单脉冲焊接layer welding 单层焊operator welding machine 单站焊机run welding 单道焊;单头焊side welding 单面焊接sided argon arc spot welding machine 单面氩弧点焊机lding 现场焊接;工地焊接lding 表面焊ock welding 分段多层跳焊;跳跃块焊接ock welding sequence 分段多层跳焊法quence welding 跳焊lding 跳焊lding 电渣焊ngle type welding 低角度式焊接g butt seam welding 斜对接缝焊lding 槽焊lding slotted weld 槽焊tt welding 电阻压力对焊welding 承插焊接welding fitting 焊接式管接头welding flange 承插焊接法兰hase welding 固相焊接welding spats 焊接用护脚welding speed 焊接速度welding stainless electrode 不锈电焊条welding steel tube 焊接钢管welding stick 焊棒welding strain 焊接应变welding stress 焊接应力welding structure members 焊接构件welding sub assembly 焊接部件welding symbol 焊接代号;焊接符号welding symbols 焊缝代号welding table 焊接工作台welding technique 焊接技术welding technology 焊接工艺welding temperature 焊接温度welding temperature field 焊接温度场welding terminal 焊机输出端welding thermal cycle 焊接热循环welding thermit 焊接热剂;焊接用铝热剂welding tilter 焊接翻转机welding timer 焊接定时器welding tin billet 焊锡棒料welding tip 焊接喷嘴welding tip (点焊用)电极工作端elding wire 实心焊丝hase pressure welding 固相压焊hase welding 固相压焊tate welding 固态焊;固态焊接of welding current 焊接电源elding 间隔焊接;有间隙焊接elding 火花焊automatic vacuum welding chamber 特种自动真空焊接室 build-up welding 特殊堆焊;特殊堆焊f welding 焊接速度f welding travel 焊接速度lding 旋转焊接;旋转熔接;摩擦焊welding 螺旋焊welding steel pipe 螺焊钢管d butt welding machine 点焊对焊两用机lding 点焊lding fixture (SWFX)点焊夹具lding gun 点焊枪lding point 点焊点lding electrode 点焊电极lding gun 点焊焊枪;点焊钳lding machine 点焊机lding sealer 点焊用密封材料elding 喷雾熔接welding tongs 焊接夹钳;焊钳welding tool 焊接工具;电焊工具welding torch 熔接炬;焊接吹管;焊接炬;焊接喷灯;焊炬welding torch pipe 焊枪管welding tractor 焊车;焊接小车welding transformer 焊接变压器;电焊变压器welding unit 焊接机welding variable 焊接规范参数welding variables 焊接规范参数welding voltage 电弧电压welding wheel 盘状电极welding wire 焊丝;焊条钢丝welding wire machine 焊线机welding with backing 垫板焊;衬垫焊welding with flux backing 焊剂垫焊welding with weaving 横向摆动焊接welding work 焊工工作welding zone 焊接区welding-cutting tool 焊割具welding-grade argon 焊接级用氩welding-on 焊合;焊上;镶焊welding-seam cleaner 焊缝清理机welding-wire reel 焊丝卷圈whipping welding 抖动焊elding unit 喷焊器contact arc welding 弹力焊type welding 弹力式焊接welding 弹力焊butt welding 平头对接焊welding 埋弧半自动焊;埋弧斗自动焊elding 多层接触点焊ed welding 错列焊接ss steel welding electrode 不锈钢电焊条d welding symbols 标准焊接符号ary welding machine 固定焊机;固定式焊机ire for welding electrode 焊条钢丝elding fittings 钢焊接管件step roller spot welding 步进式滚点焊step seam welding 步进式缝焊ck method of welding 分段反向焊法ck welding 逆向分段焊接;后向分段焊接-step welding 步进焊缝;跨步焊lsed welding 步进脉冲焊welding 针脚点焊法;自动点焊;连续点焊;合缝焊接;叠焊;;断续缝焊;跳焊and-seam welding 断续缝焊;断续焊缝welding 垫缝焊接energy welding 贮能焊wire-mesh welding machine 金属网焊机wrist-watch dial locating pin welding machine 表盘焊钉机Zerener welding 间接作用碳弧焊zigzag welding 交错焊zone of welding current 焊接电流调节范围all-welded 全焊接all-welded construction 全焊结构welded fissure 焊接裂纹welded fitting 焊接式管接头welded flange 焊接法兰;焊接翼缘;焊制法兰welded flat head 焊接式平盖welded frog 焊接辙叉welded gasket 焊接垫welded impeller 焊制叶轮welded installation 焊接装配welded joint 焊缝;焊接接头;焊接连接welded joint coefficient 焊接接头系数welded joints seal 焊接连接密封welded liquefied petroleum gas cylinder 焊接式液化石油气welded metal 焊接金属welded module 焊接微型组件welded oil-storage tank 焊接油类贮槽welded on head 焊制封头welded on the bottom of vessels 焊在容器底上的t bead welding 直线焊接t flash welding 直接闪光焊d welding wire 综合焊条verlay welding experiment 板极堆焊试验ral welding 结构焊接lding 螺栓焊;螺柱焊;柱极焊;电栓焊lding (SW)柱钉焊接lding gun 螺柱焊枪ed arc welding 焊剂层下焊;水下弧焊;潜弧焊;隐弧焊ed arc welding machine 埋弧焊机ed-arc welding 埋弧焊nic welding 超声波焊;超声波焊接;超声焊welding 表面焊接ng by fire cracker welding process 躺板极堆焊ng welding electrode 堆焊焊条ng welding rod 堆焊填充棒;堆焊填充焊棒;堆焊填充丝lding 点定焊;点固焊接;暂焊welding 串列多弧焊welding 多极平行弧焊lding 油罐焊接tt-seam welding machine 带状对接缝焊机t welding 丁字点焊ding 丁字焊ece for welding 焊接试板welded pipe 焊接管;焊制管welded pipe tube 焊缝接管welded plate 焊合板welded reinforcement of nozzle opening 接管开孔的焊接补welded sample 焊接试样welded seam 焊缝welded sheet condenser 焊接板式冷凝器welded shell course 焊接锅炉筒welded shell ring 焊接锅炉筒welded specimen 焊接试样welded splice 焊接接头welded stayed construction 焊接的支撑结构welded steel 焊接钢welded steel fabric 焊接钢筋网welded steel fences 钢材焊接围栏welded steel pipe 焊接钢管welded steel space frame 钢焊接空间框架welded steel tank 金属焊接油罐welded steel tube 焊接钢管welded structural shape 焊接结构型钢welded structural steel 焊接结构钢welded structure 焊接的结构;焊接结构welded tank 焊接贮油罐welded together 焊合compression welding 热压焊接pressure welding 热压焊接rail welding 钢轨热剂焊welding 铝镍焊;铝热焊;铝热剂焊;热剂焊(e) fusion welding 热剂铸焊(e) pressure welding 加压热剂焊e welding 铝热焊接ussion welding 热熔焊lastic welding strip 热塑性焊条hase arc welding 三相电弧焊o-single-phase welding transformer 三相输入的单相焊接变welding 焊透-welding 焊透c) welding 惰性气体保护钨极电弧焊raze welding 焊矩钎焊elding 气焊;吹管焊接elding 接触式焊接automatic arc welding machine 拖车式自动电焊机rse seam welding 横向缝焊rse submerged arc welding 横列双丝并联埋弧焊lding machine 焊管机lding) 惰性气体保护钨极电弧焊n arc welding 钨极电弧焊welded truss 焊接桁架welded tube 焊缝管;焊接管;电焊管welded tuff 熔结凝灰岩welded turning rolls 焊接滚轮架welded turret 焊合转搭welded unit 焊接构件welded vessel 焊接容器welded wire fabric 焊接钢丝网welded wire mesh 电焊网welded-contact rectifier 熔接整流器welded-steel plate construction 钢板焊接结构arc-welded pipe 弧焊管arc-welded steel pipe 电弧焊接钢管around openings for welded attachments 环绕焊接附件孔口as welded 焊态as-welded 焊后状态automatic arc welded tube 自动电弧焊缝管big diameter welded tube 大口径焊缝管blacksmith welded joint 煅接接头butt welded (bw)对焊机butt welded seam 对焊缝butt-welded drill 对头焊接钻头butt-welded joint 对焊接头butt-welded pipe 对缝焊接管n inert gas welding machine 钨极惰性气体保护弧焊机n-arc welding 钨弧焊c welding 双弧焊re parallel power submerged arc welding 双丝并列埋弧焊re series power submerged arc welding 双丝串联埋弧焊ad tandem arc-welding machine 双头串联电弧自焊机d automatic arc welding machine 自动双弧焊机peed welding 超高速焊接nic metal welding 超声波金属焊接nic remote welding 超声遥焊nic seam welding 超声波缝焊nic spot welding 超声波点焊nic spot welding machine 超声波点焊机nic welding 超声波焊接;超声焊nic welding inspection 超声波焊缝检查nic welding machine 超声波焊接机ater welding 水下焊ater welding 水下焊ter welding 水中焊接elt welding 埋弧自动焊c welding 磁性焊剂CO2焊;气渣联合保护电弧焊c welding 磁性焊剂二氧化碳保护焊lt welding 焊剂层下自动焊al upsetting and welding machine 万能镦锻焊接机butt-welded rail ends 对焊轨端butt-welded tube 对缝焊管;对焊钢管;对口焊接钢管butt-welded with square ends 方头对焊cast welded rail joint 铸焊钢轨接头continuous welded rail 连续焊接钢轨double fillet welded T-joint 双面丁字形焊接double-welded butt joint 双面焊对接接头double-welded lap joint 双面焊搭接接头electric welded anchor cable 电焊锚链electric welded steel pipe 电焊钢管electric-resistance-welded steel pipe 电阻焊钢管electric-welded pipe 电焊管electrically welded tube 电焊管expanded and welded tube joint 胀焊fillet welded joint 填角焊缝forge-welded (monolayered) cylinder 锻焊式单层圆筒forged and welded vessel 锻焊式容器galvanized and welded steel pipe 镀锌焊缝钢管galvanized electric welded mesh 镀锌电焊网galvanized welded tube 镀锌焊缝管galvanized welded wire mesh 镀锌电焊网gas welded joint 气焊接头guided-bend test for butt welded joint 对接接头靠模弯曲handhole with butt welded flange 对焊法兰手孔ded arc welding 无保护层电弧焊welding 仰焊welding 上坡焊utt welding 电阻对焊;电阻对接焊elding joint 对接焊缝welding in the inclined position 上坡焊welding in the vertical position 向上立焊welding electrode 低层焊条;底层焊条;打底焊条diffusion welding 真空扩散焊接electron beam welding 真空电子束焊welding 真空焊接l down welding 向下立焊l position of welding 立焊位置l up welding 向上立焊l welding 垂直焊;竖焊ng block welding 游移块焊接lding 熔面焊接ooled welding torch 水冷焊炬apour arc welding 水蒸气保护电弧焊as welding 水煤气焊;液压焊apo(u)r welding 水蒸气保护焊welding 摆动焊焊接;熔化极惰性气体保护焊;压实作用;固化allowance 焊接留量helically welded tube 螺旋焊接管helically-welded case 螺旋焊接壳体high frequency welded spiral fin tube 高频焊接螺旋翅片管high strength welded pipe 高强度焊接管high strength welded steelpipe 高强度焊接钢管high-frequency electric welded steel pipe 高频电焊钢管high-frequency straight seam welded pipe 高频直缝焊接钢holes in joints of welded vessels 焊接容器接头处的孔in welded joints 在焊缝上jump welded tube 对缝焊管;焊缝管lap welded pipe 搭焊管lap-welded 搭焊limitations on welded vessels 焊接容器的限制located in welded joint 位于焊接接头中manhole with butt welded flange对焊法兰人孔manhole with common welded flange 平焊法兰人孔notch break test for butt welded joint 对接接头缺口断裂notched and welded wide plate test 缺口焊接宽板试验on welded vessels 在焊接容器上openings through or near welded joints 通过或靠近焊缝处openings through welded joints 通过焊接连接处的开孔plate-welded spiral case 钢板焊接蜗壳pressure-welded junction 热压焊结projection welded cap 凸焊帽alloy 焊接合金and cutting combine 割焊两用机and cutting torch 焊割两用炬;焊割两用气焊枪 apron 焊工的围裙;焊工围裙arc 焊弧;焊接电弧arc analyzer 焊接电弧分析仪arc viewer 焊弧观察器arc voltage 焊弧电压;焊接电弧电压assembly 焊接部件;焊接构件atmosphere 焊接气氛backing 焊接衬垫base metal 焊条金属bead length 焊缝长度bell (焊管用)碗模bellows 焊接波纹管bench 焊接工作台;焊接台between pipe connect 管口和筒体间焊缝booth 焊接室burner 焊炬喷嘴by both sides 双面焊by forging 锻焊by one side 单面焊cable 电焊电缆;焊接电缆cam (接触对焊机的)加压凸轮projection welded joint 凸焊接头repair defects in welded vessel 修理焊接容器中的缺陷roll-welded (monolayered) cvlinder 卷焊式单层圆筒;卷焊圆筒rolled steel for welded structure 焊接结构用轧制钢材sectioning of welded joints 焊接连接的切片segmentally welded (monolayered) cylinder 瓦片式圆筒shop-welded connection 厂焊接头single fillet welded lap (joint) 单面搭焊接single fillet welded T joint 单面T形焊接single welded joint 单面焊single welded lap joint 单面焊搭接接头single-welded butt joint 单面焊的搭接接头;单面焊对接接single-welded lap joint 单面焊搭接接头;单面焊的搭接接头spiral welded pipe 螺旋焊管spiral welded steel pipe 螺旋焊接钢管spiral-welded pipe 螺旋焊接管spot-welded joint 点焊接头stamping-welded 冲压焊接的strengthening of welded seam 焊缝补强tests of welded vessels 焊接容器试验unfired fusion welded pressure vessel 非直接火焊接压力容welded 焊接的welded and expansion joint 焊接加胀接法capacity 可焊性characteristics 焊接特性circuit 焊接回路clamp 电焊钳code 焊接规程coefficient 焊接系数compound 焊药condition 焊接工艺参数;焊接工艺条件;焊接规范;焊接条conditions 焊接规范connector 电缆夹头contactor 电焊接触器crack 焊接裂纹;焊裂缝current 焊接电流cut bit 焊割工具cycle 焊接循环;焊接周期网 )defect 焊接缺陷deformations 焊接变形deposit 焊敷金属;焊着金属device 焊接设备direction 焊接方向dribble (焊接时间的)金属熔滴或飞溅dynamo 焊接发电机welded and rolled tube joint 焊胀welded armor 焊接甲板welded attachment 焊接附件welded body 焊接车身welded bond 焊接轨隙连接器welded bonnet (WB)焊接阀盖welded bridge 焊接桥梁welded cathode 焊接阴极welded chain 焊接链welded connection 焊接合;焊接联结welded construction 焊接结构welded corner joint 角焊接welded eye 焊眼welded fin tube 焊片式翅片管fabrication weldability 工艺焊接性local weldability 局部可焊性;局部可焊性operative weldability 操作工艺性;工艺可焊性overall weldability 综合可焊性;使用焊接性service weldability 使用焊接性;使用可焊性thermal weldability 热焊接性weldability 焊接性;可焊性weldability test 可焊性试验;焊接性试验high strength weldable aluminium alloy 高强度可焊铝合金non-weldable steel 不可焊接的钢electrode 焊接电极;焊条;电焊条electrode hold 焊条夹electrode production line 电焊条生产线 electrodes 焊接电极ends 焊接端engineer 焊接工程师engineering 焊接工程equipment 焊接设备experiments 焊接试验fabrication 焊接装配weldable 可焊的weldable copper 可焊复合铜板weldable steel 可焊钢;焊接钢weldless 无焊缝的weldless (seamless) steel pipe (tube) 无焊缝钢管weldless connection非焊接式接头weldless fitting 非焊接式接头weldless pipe 无缝管head fork weldment 顶叉焊接件weldment 焊件;焊接装配(焊接网 www.Hanjie.。

珠海力得CWS系列双枪环缝自动焊接专机※设备用途CWS系列双枪环缝自动焊接专机主要应用于空调、冰箱压缩机和园筒型钢瓶封头及筒体间二氧化碳气体保护焊、氩弧焊、等离子焊的自动焊接。

※主要特点CWS系列双枪环缝自动焊专机采用模块化设计,整机布局合理、结构紧凑、功能齐全、操作方便、稳定及可靠性好、生产效益高。

以进口可编程控制器为核心组成自动焊接控制系统,自动进出料,自动装夹工件,自动对中,保证焊接质量,特别适合批量生产和流水线作业。

控制面板采用人机界面,彩色汉字显示终端,参数预置。

分设手动、自动模式,可正、反向旋转,可双枪或单枪操作。

焊接速度无级调节,焊缝搭接量预先设置,焊枪位置及角度可自由调整,满足焊接工艺要求。

进出料系统调整灵活,准确到位,夹具可根据一定范围的工件大小互换,方便焊接不同规格的产品。

配备冷却水循环系统,保证长时间焊接焊枪不易发热。

配备专用气阀,装夹力度随意调整。

选用进口气体配比器,采用混合气体保护。

焊缝成型优良,无气孔、夹渣、裂纹等缺陷。

※设备构成CWS系列双枪环缝自动焊专机主要由:焊接电源、送丝机构、控制系统、操作面板、主传动箱、从动箱、进出料机构、冷却系统、配气机构、焊枪调节机构、机架、排气及照明等组成。

※主要技术参数机械部分主设备尺寸:2900*1700*2100(长宽高mm)主动箱行程:100mm从动箱行程:100mm进出料架升程:75mm进出料架行程:300mm取料器行程:600mm焊枪进退行程:100mm工艺参数主轴转速范围:0.5-10RPM 按工艺要求设置焊接搭角范围: 0-300 按工艺要求设置工件长度最大L=580mm 根据工件长度调整机头位置工件直径最大=ф210 调整料架顶起气缸行程焊接电流最大500A 按工艺要求设置焊接电压最大40V 按工艺要求设置压缩空气 0.5-0.7Mpa保护气流量 CO2、Ar配比按工艺要求设置。

外文原文:An Automatic MechanotronicsHorizontal CutterDirecting towards the present situationof decentralized control by single computer in do2mestic glass industry an automatic mechanotronicshorizontal cutter was introduced based on the pre2cision and thefunctional control of the cutter .1.Say after 70's in 20 centuries the our country sun float the method glass technique invention, our country of float method glass, the industry develops quickly.Currently, the our country is the world is the biggest to float the method glass production country, 2006 our country of float method glass, the production line has more than 160s totally, adopting among them our country the sun float method glass to float method glass technically, the production line has more than 130s totally, floating the method glass total yield already more than 454,000,000, and yield annually all significant increment.But our country the LuoYang float the method glass technique material and other nations to compare automation degree still very low, has been being placed in the half auto half artificial appearance, raise completely our country the 洛sun float method glass a technique a material level, developing whole lineses allied lock follow produce the technique have already forced in the eyebrow .Currently, our country the sun float method glass a technique a material to mainly be placed in a single machine dispersion control stage(or part of llied lock control), rush through super nations float method glass a technique a material level, have to raise first our country the automation function of the single machine equipments.Horizontal slice machine conduct and actions to float method glass cold carry to produce one of the on-line important equipmentses, its automation degree and incise accuracy will influence the finished product rate that the glass produces, we introduce a kind of machine electricity integral whole to turn here full-automatic horizontal slice machine1 The equipments accuracy is in keeping with, the biggest original plank width:the 5000 mms suit glass plate thickness: the 1.5~19 mms incise a straight line degree accuracy: the ± 0.5 mms incise diagonal line accuracy:<3 m the plank is long: the ± 1 mm 3~6 m plank long:the ± 1.5 mms incise a straight line degree accuracy: the ± 0.5 mm the knife press to regulate scope: the 0~100 Ns is the biggest to return to knife speed:3000 mms/s2.Equipments function2.1 Excellent turn of incise function to operate the touch of pedestal to hold on the spot up(or control box in) can set a few in common use products and 1 kind to discard plank specification, be an usage excellent turn to incise, horizontal slice machine can according to artificial examination(or on-line examination equipments examination) of the blemish position chooses reasonable enactment specification and discards plank specification to carry on incising automatically, incising an information to pass allied the net deliver to transport a way behind.There is excellent a few the following to turn a way generally:the ① press grade excellent turn to incise, press different grade to incise, the biggest limit slices to take high-quality glass;The ②presses product specification excellent turn to incise, incise the glass of Chengkong University, medium and small different specification according to the heap circumstance of different quality and heap area; The ③ carries on according to the market sale's circumstance excellent turn to incise, can have the initiative and incise the product specification that the market needs with maximum limit2.2 The flower slices function to set several floricultures to slice a specification comparison, slicing machine with allied lock completion, produce the glass ofdifferent specification in the meantime.So can satisfy a production line to produce the request of various specificationses in the meantime, if adopt mechanization heap , the heap then canned resolve a heap of the machine problem with not enough period, can also reduce a heap of machine amount, economical investment2.3 Side department follow incise function horizontal slice machine and side department and follow control the system unite a lock, can carry out horizontal slice machine and fall the position variety that the knife order, lifts knife and orders, carry out the biggest scope and slice and cut qualified knothole function thus, increase a production line at falsely often of slicing and cutting rate, special produce at float and move quantity and change very big of time2.4 The whole lineses follow to incise function horizontal slice machine and the whole line control allied lock can carry out whole lineses' glass to different specification, different quality to follow different destination(fall the plank, heap etc.), and can record each the quality of the glass and each glass of the blemish and the position;2.5 Hint the function has an examination to lack oil and breaks spirit and breaks down hint function.2.6 Automate function and break bridge to spread the feeling machine allied lock, can lift knife automatically when the glass break plank.2.7 Periodic can the product which incise certain specification of the periodic ground.3 Equipments control(1) Adopting the high performance, high sex price compares of the GE 9030 PLCs and high performance are loose to descend numerical type intelligence's exchanges servo drive system, match with to develop specially and pass by long-term test of control software, make the system not only have very high control accuracy, and come to an intelligent and stable perfect combine.(2) All parameters can constitution in touching to hold, include plank long, the plank breadth, start order, fall knife to order, return to speed and add and subtract soon and move to adjust to try speed, diagraph round and diagonal line school quasi- and horizontal bye control parameter and limit protect a constitution etc. parameter.(3) Incise process automatically in, can operate to lift knife and fall knife at any time, make the knife have the glass that can jump to crack open by explosion to take, since the protection knife have, and then avoids appearing long glass of size to take.(4) The forerunner's speed follows function, knife head while promising to fall knife speed and glass take speed of synchronous.Moreover horizontal slice a machine design and make of choose a material, process and the standard piece buy etc. also want to control strictly.Slice machine with of its kit, horizontal bye break, bye the side transport machine etc. the equipments also needs to make a further improvement and the exaltation.4 The new century, electromechanical integration of the type widely used to be, people developed a series of products. Addition, we re-introduce some other type of reference do.4.1 ZHJ-D computer-controlled vertical and horizontal high-precision cutting machineUse: This applies to all kinds of paper, paper plastic composite categories, such as large-scale color composite category reel packaging materials-cut. Widely used in paper processing sector, the printing and packaging industries. Performance and features:(1), the use of servo motor (or stepper motor) control for long-cut. With electro-optical tracking system that in the cross section of the products can be longitudinal.(2), transmission system using pneumatic, hydraulic systems, such as photoelectric sensor centralized control, discharge system uses hydraulic lifting device. The machine set light, electricity, liquid, gas, integrated, easy to operate, high precision-cut, mechanical stability, low noise advantages.(3), the electrical VVVF, automatic counting, alarm Parking, tension figures show that functions.Technical parameters:Model parameters ZHJ-800D ZHJ-1100D ZHJ-1300D ZHJ-1600D1400m maximum diameter of raw materialsThe largest-cut width of 800 mm 1100mm 1300mm 1600mm- Cut 20-1200mm lengthThe accuracy of ± 0.2mmProductivity ≤ 80 m / minComplete machine power 5kw 5kw 6kw 8kwApplicable power 380v/50Hz (-phase 4-wire)Asked the biggest source of air pressure 5.5 kg/cm2 × 5m3/minThe device weighs about 1,000 kg of about 2000 kg of about 2500 kg of about 2800 kgDimensions (mm) 5500 ×1550 ×1200 5500 ×1850 ×1200 5500 ×2100 ×1250 6000 × 2400 × 12504.2 ZHJ-C1/C2 high-speed automatic Cutting MachineUse: This applies to all kinds of paper, paper plastic composite categories, such as large-scale color composite category reel packaging materials-cut. Widely used in paper processing sector, the printing and packaging industries.Performance and features:(1), the use of servo motor (or stepper motor) control for long-cut. Amended with electro-optical tracking system.(2), transmission system using pneumatic, pneumatic systems, such as photoelectric sensor centralized control, discharge system uses air pressure lifting equipment. The machine set light, electricity, liquid, gas, integrated, easy to operate, high precision-cut, mechanical stability, low noise advantages.(3), the electrical VVVF, automatic counting, alarm Parking, tension figures show that functions.(4), are heavy-duty cutting tool imports, product uniformity, no edges and corners. Technical parameters:Machine Model ZHJ-800C1/C2 ZHJ-1100 C1/C2 ZHJ-1300 C1/C2The largest raw materials 800 1100 mm width 1350 mmComplete machine power 5.5kw 6kw 7kwThe device weighs about 2,500 kg of 2,800 kg about 3200 kgDimensions (mm) 5500 × 1500 × 1400 5500 × 1800 × 1400 5500 × 2300 × 1400 Applicable power 380v/50Hz (-phase 4-wire)Asked the biggest source of air pressure 5.5 kg/cm2 × 5m3/minThe largest raw material Ф ≤ 14 mm in diameter.30g of raw materials / ㎡~ 500 g / m 2 (depending on the materials may be)- Cut of 5 ~ 1200mm lengthThe accuracy of ± 0.2mmFang / Recoiler paper tube diameter Ф3 "or Ф6" (or according to customers required) Crop frequency 120degree/min4.3 ZHJ-C3 high-speed automatic finishing Cutting MachineThis applies to all kinds of paper, paper plastic composite categories, such as large-scale color composite category reel packaging materials-cut. Widely used in paper processing sector, the printing and packaging industries.Performance and features:1, the use of servo motor (or stepper motor) control for long-cut. With electro-optical tracking system that in the cross section of the products can be longitudinal, and finished automatically collate.2, transmission system using pneumatic, hydraulic systems, such as photoelectric sensor centralized control, discharge system uses hydraulic lifting device. The machine set light, electricity, liquid, gas, integrated, easy to operate, high precision-cut, mechanical stability, low noise advantages.3, the electrical VVVF, automatic counting, alarm Parking, tension figures show that functions.Technical parameters:Model ZHJ-1100C3 ZHJ-1400C3 ZHJ-1600C3Raw materials maximum diameter 1400mm 1400mm 1400mmThe largest-cut width of 1100mm 1400mm 1600mm- Cut 20-1200mm length 20-1200mm 20-1200mmThe accuracy of ± 0.2mm ± 0.2mm ± 0.2mmProductivity 80m/min 80m/min 80m/minPiled material largest high 1200mm 1200mm 1200mmComplete machine power 8kw 9kw 11kwApplicable power 380v/50Hz (three-phase) 380v/50Hz (three-phase) 380v/50Hz (three-phase)Asked the biggest source of air pressure 5.5 kg/cm2 × 5m3/min largest 5.5 kg/cm2 ×5m3/min largest 5.5 kg/cm2 × 5m3/minThe device weighs about 3,200 kg of about 3800 kg of about 4300 kgDimensions 6000 × 1500 × 1700mm 6000 × 1800 × 1700mm 6000 × 2000 × 1700mm译文:机电一体化全自动横切机1、述自20世纪70年代我国洛阳浮法玻璃技术发明之后,我国的浮法玻璃工业迅速发展。

中英文中英文文献翻译-环缝自动焊机

一定义:环缝自动焊机是一种能完成各种圆形、环形焊缝焊接的通用自动焊接

设备。可用于碳钢、低合金钢、不锈钢、铝及其合金等材料的优质焊接,并可选

择氩弧焊(填丝或不填丝)、熔化极气体保护焊,等离子焊等焊接电源组成一套

环缝自动焊接系统。可广泛地应用于液压油缸、汽车方向架、传动轴、贮气筒、

化工及医疗容器、液化气罐、消防器材、矿山及生产线用滚筒及储液筒等产品的

焊接。

根据工件形状大小不不同,可将环缝自动焊机分为以下几种:⒈a立式环缝

自动焊机b卧式环缝自动焊机⒉焊接变位机⒊焊接操作机(又名焊接中心)⒋

仿形环缝自动焊机。

下面将种焊机适用于哪种焊件,主要构造特点说明如下

⒈a立式环缝自动焊机的表示方法:HF(L)其意为环缝(立),下面举一焊接环直

径为200mm的型号技术参数如下

控制电源:单相220V,50HZ 结构形式:单立柱可倾式

倾斜调节方式:无级,蜗轮蜗杆调节

倾斜角度范围:0-±90度

可焊工件直径(mm):0~200

主轴转速:0~7rmp或0.5~14rmp

环缝焊接范围:0~1080度

焊枪气动行程:100

焊枪手动微调距离:x,y,z向60mm

集电环最大电流300A

立式环缝自动焊机是一种小巧、价廉物美、操作简单方便,能完成各种小型

的圆形、环形焊缝焊接的通用自动焊接设备。其最大特点就是适用于一些小型工

件的环缝焊接,而且工件不宜过,长如手指长短的工件较适合焊接。

主控制器采用运动控制器可编程控制器为核心控制单元,根据用户要求,可

通过修改控制软件的程序及参数来调节设备的功能,实现圆形、半圆形、分段多

段圆弧、环形焊缝的焊接,使整个设备具有很强的智能性和柔性,是一个具有较

高档次,较高性价比和可靠性的控制器。该控制器具有手动调节和自动焊接控制

功能;回转机构由直流伺服电机驱动,无级调节焊接速度,焊接速度由控制面板

上的数显显示;采用独立的调速电路,焊缝的搭接量可预先数码设定,焊后焊枪

高速复位;该控制器可根据焊接工艺要求采用多种控制输出信号选择和输出接

口,具有抗干扰强、可靠性高、调速稳定、操作方便、自动化程度高等特点,可

广泛地应用环形焊缝工件的焊接控制

b卧式环缝自动焊机

卧式环缝自动焊机与立式环缝自动焊机相比,其对焊件的长度没有过多的限

制.三、四米的长管都可轻松焊接。该设备可广泛地应用于液压油缸、汽车方向

架、传动轴、贮气筒、化工及医疗容器、液化气罐、消防器材、矿山及生产线用

滚筒及储液筒等产品的焊接。

性能特点:

床身采用卧式结构,由焊接结构件经退火后精加工而成,保证床身导轨不变

形;

回转机头采用直流电机或交流变频电机驱动,速度稳定可靠;

主轴端部安装有焊接夹具或三爪卡盘,用于装夹定位工件;

尾座可采用气动或手动顶紧方式,端部可根据工件形式的不同选用不同的焊

装夹具或活动顶尖;

尾座可在床身导轨上滑动,可调整机头尾座的距离以适应不同长度的工件;

焊枪机构可根据工件焊接位置的不同,沿导轨方向移动到相应位置。

⒉ 焊接变位机

1、HB系列焊接变位机是通过倾斜和回转动作将工件置于便于焊接位置的

工艺设备,主要用于复杂工件(如机架、机座、 法兰、球形容器、封头、三通

和顶盖等部件)的TIG、MIG/MAG或PLASMA自动焊接,也可用于PLASMA

切割

2、HB系列焊接变位机主要由工作转盘、翻转机构、减速箱、机架等构成

3、可根据焊接速度需要设定不同的转速进行焊接,对于椭圆形工件可通过

分区间进行焊接编程,满足各区段的焊接要求

4、设计精巧,转动精度高、惯性小,制动性和平稳性好,对中精度高

5、HB系列变位机配合TIG、MIG/MAG或PLASMA焊接电源和控制系统

组成自动焊接系统,此外还可以与操作机或焊接机器人联动使用,组成较为复杂

的自动焊接系统

焊枪手动三维调节机构和旋转机构可满足焊枪精确对准焊接位置时的微动

调整需要;

焊枪气动升降机构和尾座气动顶紧机构可满足自动焊接和自动装夹的要求,

提高生产效率;

根据工件焊接的要求,可选配气动升降托架,焊缝跟踪装置、焊接摆动器;

采用运动控制器可编程控制器作为主控单元,工业用触摸屏操作界面,自动

化程度高,焊接质量稳定可靠;

可通过修改控制软件的程序及参数来调节设备的功能,实现圆形、半圆形、

分段多段圆弧、环形焊缝的焊接

⒊焊接操作架

焊接操作机一般由立柱、横梁、回转机构、台车等部件组成。各部件为积木

式结构,一般立柱、横梁为其基本部件,其余部件可据用户使用要求选配。一般

适用于压力容器中锅炉汽包, 石化容器等圆筒形工件的内外缝的纵缝焊和环缝

焊焊接。

独特的横梁和立柱截面设计,导轨为45号钢,焊后去应力处理,经刨、磨

成型。重量轻、强度高、稳定性好。横梁内伸缩臂的设计,可有效增加横梁的水

平伸缩距离。

横梁升降采用交流电机恒速方式,升降平稳、均匀,安全系数高。带安全防

坠装置。

横梁伸缩、立柱电动回转、电动台车均采用交流电机变频无级调速,恒转矩

输出,速度平稳(特别是低速下),启动或 停止迅捷,速度数字显示并可预置。

立柱回转分为手动、电动两种,回转支承采用国内名牌厂家的产品,自带高

精度齿轮,转动灵活,并可气动锁紧,安全可靠。

台车采用标准铁路路轨为行走轨道,分为手动及电动两种。手动适用于轻型

及移动范围较小的操作机,电动则适用于重型或移动范围较大的操作机。

载人型操作机设有载人操作平台,随横臂一起移动。

采用手控盒、机头控制箱(焊接控制箱)构成近控与远控方式,操作灵活方

便,并在电气箱预留联动接口,可与本公司 或国内外其它厂家制造的焊接机、

滚轮架、变位机、圆形回转工作台等实现同步联动。

⒋仿形环缝自动焊机

仿形环缝自动焊机是我公司针对焊接生产过程大量的管管垂直交叉而形成

的马鞍形焊缝以及管板倾斜一定角度而成的椭圆形焊缝而开发的新型焊接设备,

适用于汽车贮气筒的筒体与螺母、汽车油箱油嘴、热水器的筒体与出水嘴、热水

器加热管与固定安装板、液压油缸的油嘴、空调压缩机的螺母等工件的焊接。焊

机由加压定位机构、床身、仿形机构、焊枪调节机构、控制系统等组成。可适应

不同大小的马鞍型接头或管板接头的焊接。焊接电源可选用熔化极气体保护焊电

源或TIG焊电源。

立式床身采用焊接结构,送丝机设置在立柱上,立柱前端设置焊枪回转机头

安装板.

主要特点:

焊枪回转机头采用直流减速电机驱动,其回转速度实现无极调速,焊接搭接

量通过数码预先设置。

数控机构为单轴或多轴数控,采用步进电机或交流伺服电机驱动,焊枪做环

缝焊接时数控机构驱动焊枪做上下做仿形运动。

焊接夹具保证工件的轴向和径向定位,通过调整焊接夹具的定位点和更换定

心轴,可以实现不同螺母工件的自动焊 接。

机头摆动装置:可实现机头摆动,增加焊缝宽度、摆动频率、摆动幅度无级

可调;

焊枪气动提升机构采用气缸推动,保证升降重复精度。

焊枪三维调节机构用于焊枪初始焊接位置的微调对中。

主控制柜采用运动控制器可编程控制控制,主控操作盒为独立部件,所有动

作调整和焊接操作均可以在此完成。

翻译成英语