大豆食品最新研究进展Recent Progress in Research and Technology on Soybeans

- 格式:pdf

- 大小:472.31 KB

- 文档页数:9

大豆膳食纤维研究报告

大豆是一种常见的植物性食材,以其丰富的蛋白质和纤维素而被广泛应用于食品加工中。

大豆膳食纤维是大豆中的一种重要成分,对人体健康有着许多益处。

本文将就大豆膳食纤维的研究进行探讨。

第一部分,大豆膳食纤维的基本特性。

大豆膳食纤维主要由大豆的种皮、胚乳和胚被组成,其主要成分包括纤维素、半纤维素和胶质等。

大豆膳食纤维具有很强的水溶性和吸水性,能够在胃肠道中形成胶体状物质,增加粪便体积,缩短粪便通过时间,促进肠道蠕动。

此外,大豆膳食纤维还能够通过与肠道内的胆汁酸结合,降低血液中的胆固醇含量,有利于心血管健康。

第二部分,大豆膳食纤维与肠道健康的关系。

研究表明,大豆膳食纤维可以促进益生菌的生长,抑制有害菌的繁殖,维持肠道微生态平衡。

大豆膳食纤维具有调节肠道功能的作用,解决便秘问题。

此外,大豆膳食纤维还可以降低结肠癌的发病风险,预防肠道疾病的发生。

第三部分,大豆膳食纤维的应用价值。

由于大豆膳食纤维具有多种益处,目前已经广泛应用于食品工业中,如面包、饼干、方便面等。

此外,大豆膳食纤维还可以作为功能性食品添加剂,用于调节血糖、降低胆固醇、控制体重等方面。

综上所述,大豆膳食纤维是一种健康、功能多样的食品成分。

通过促进消化道蠕动、调节肠道微生态和降低胆固醇等多种方式,大豆膳食纤维对于肠道健康和心血管健康具有积极的影响。

随着人们对健康饮食需求的增加,大豆膳食纤维的应用前景将愈发广阔。

4.大豆蛋白的研究进展4.1大豆蛋白乳化性大豆蛋白质具有较高的营养价值及功能特性,是某些食品加工中的重要原料。

大豆分离蛋白是表面活性剂,它既能降低水和油的表面张力,又能降低水和空气的表面张力。

易于形成稳定的乳状液。

在烤制食品、冷冻食品及汤类食品的制作中,加入大豆分离蛋白作乳化剂可使制品状态稳定。

4.2大豆蛋白 - 壳聚糖通过对大豆蛋白-壳聚糖共价化合物的乳化性及乳化稳定性、起泡性(FC)与泡沫稳定性(FS)、热稳定性测定,得出结论:大豆蛋白 - 壳聚糖共价复合物在等电点和较高盐浓度条件下的溶解性较大豆蛋白有很大改善.在测定的 pH 和盐浓度范围内,大豆蛋白 -壳聚糖共价复合物的乳化性和乳化稳定性都有所提高。

大豆蛋白 - 壳聚糖共价复合物在等电点范围内的发泡性和泡沫稳定性较大豆蛋白有很大提高。

大豆蛋白 - 壳聚糖共价复合在70℃以上受温度升高影响较小,热稳定性提高。

另外,结合红外分析和扫描电镜技术研究大豆蛋白复合膜的释放特性和表面形态,其结果表明复合膜中大豆蛋白和壳聚糖之间存在交联作用;这种复合膜在胃肠液均呈溶胀状态,在模拟胃液中溶胀度较低,且在模拟肠液中降解速率较快。

复合膜在模拟胃液中的释药速率相对模拟肠液要快,而且随着蛋白含量的增加复合膜的溶胀度和释放率都随之降低,所有的复合膜对于茶碱的保护能保持至少7 h,因此壳聚糖-大豆蛋白复合膜可以用作控缓载体。

4.3大豆蛋白水解物利用化学限定培养基对酸奶乳酸菌进行增殖作用研究,结果表明必需氨基酸只能满足乳酸菌生长的基本氮源需要。

通过化学限定培养基应用大豆蛋白水解物对保加利亚乳杆菌和嗜热链球菌进行增殖作用研究,结果表明含有寡肽和氨基酸的大豆蛋白水解物对乳酸菌的生长具有明显的促进作用,可以用来作为乳酸菌高密度细胞培养体系的生长促进剂。

通过研究大豆蛋白复合蛋白酶水解物对酿酒酵母生长和发酵性能的影响,表明: 不同水解度及不同分子量肽段的大豆蛋白酶解物对酿酒酵母的促生长效果不同,其中水解度为 19. 98% 的酶解物 SP9 具有最强的促生长活性,且具有显著促生长活性的肽段主要集中在 3 ku 以下; 该部分肽段可使菌体增长量提高 27%,稳定期活性达到 90. 3%,并且能够加快酵母代谢糖的速率,使发酵度和乙醇产量分别提高 15. 3%和 25. 8%。

大豆蛋白提取技术研究进展系别:食品工程系专业:食品科学与工程班级:食科13-2班学号:************姓名:***摘要大豆蛋白产品分为三类,即大豆蛋白粉、大豆浓缩蛋白和大豆分离蛋白。

大豆分离蛋白含有人体所必需的八种氨基酸,不含胆固醇,具有许多优良的食品性能,添加在食品中可以改善食品的品质和性能,提高食品营养价值。

是一种重要的植物蛋白,在食品工业中得到了广泛的应用,是近年来的研究重点。

其中,大豆浓缩蛋白的提取方法有稀酸浸提法、酒精浸提法和湿热浸提法。

大豆分离蛋白有碱溶酸沉法、离子交换法、超滤膜分离法等。

本文以研究方向和工艺改进方面为着力点解释大豆浓缩蛋白和分离蛋白这两种主要的提取方法的发展脉络。

关键词大豆浓缩蛋白;大豆分离蛋白;稀酸浸提法;酒精浸提法;碱溶酸沉法;离子交换法;超过滤法;湿热浸提法大豆分离蛋白(soy protein isolate,SPI )是把脱皮大豆中的除蛋白质以外的可能性物质和纤维素、半纤维素物质都除掉,得到的蛋白质含量不低于90% 的制品,又称等电点蛋白。

与大豆浓缩蛋白相比,生产大豆分离蛋白不仅要从低温脱溶豆粕中除去低分子可溶性糖等成分,而且还要去除不溶性纤维素、半纤维素等成分。

其生产方法主要有碱溶酸沉法、超过滤法和离子交换法。

一、碱溶酸沉法1. 提取原理低温豆粕中的蛋白质大部分能溶于稀碱溶液。

将低温豆粕用稀碱溶液浸提后,用离心分离法除去原料中的不溶性物质,然后用酸把浸出物的PH调至4.5左右,蛋白质由于处于等电点状态而凝聚沉淀,经分离可得到蛋白质沉淀,再经洗涤、中和、干燥得到大豆分离蛋白。

2. 提取工艺豆粕的质量直接影响大豆分离蛋白的功能特性和提取率,只有高质量的豆粕才能获得高质量和高得率的大豆分离。

要求原料无霉变,豆皮含量低,残留溶剂少,蛋白质含量高(45沖上),脂肪含量低,NSI高(不低于80%。

豆粕粉碎后过40-60目筛。

首先利用弱碱溶液浸泡低温豆粕,使可溶性蛋白质、糖类等溶解出来,利用离心机除去溶液中不溶性的纤维素和残渣。

大豆肽的制备及其营养功能研究进展Advancement of preparation of soybean peptide and its nutritional function摘要:大豆肽是大豆蛋白水解后,由3~6个氨基酸残基组成的低肽混合物,分子量在1000 U 以下。

为了提高大豆蛋白资源的利用率,降低大豆肽的成本,本文综述了以豆粕为原料制备大豆肽的两种方法,发酵法和酶解法。

同时也阐述了其功能特性及其在食品工业的应用。

由于它具有很多优良的理化特性和生理活性,具有极高的利用价值和广阔的发展前景。

关键词:大豆肽豆粕营养功能制备Abstract: Soybean peptides are a mixture of many small peptides which have 3 to 6 amino acids and molecular weight is below of 1000 U. In order to improve the utilization rate of soybean protein and reduce the cost of soybean peptide, the two methods, fermentation and enzymatic method of soybean peptides being made from soybean meal were reviewed in this paper. Also, the function characteristics and the application in the food industry of soybean peptides were described. Soybean peptides have high utilization value and broad prospects because of its excellent physical-chemical properties and biological activity.Key words: soybean peptides soybean meal nutritional function preparation大豆肽就是由大豆蛋白经水解所得到的由3~6个氨基酸组成的低分子量肽。

大豆蛋白提取技术研究进展系别:食品工程系专业:食品科学与工程班级:食科13-2班学号:************姓名:***摘要大豆蛋白产品分为三类,即大豆蛋白粉、大豆浓缩蛋白和大豆分离蛋白。

大豆分离蛋白含有人体所必需的八种氨基酸,不含胆固醇,具有许多优良的食品性能,添加在食品中可以改善食品的品质和性能,提高食品营养价值。

是一种重要的植物蛋白,在食品工业中得到了广泛的应用,是近年来的研究重点。

其中,大豆浓缩蛋白的提取方法有稀酸浸提法、酒精浸提法和湿热浸提法。

大豆分离蛋白有碱溶酸沉法、离子交换法、超滤膜分离法等。

本文以研究方向和工艺改进方面为着力点解释大豆浓缩蛋白和分离蛋白这两种主要的提取方法的发展脉络。

关键词大豆浓缩蛋白;大豆分离蛋白;稀酸浸提法;酒精浸提法;碱溶酸沉法;离子交换法;超过滤法;湿热浸提法大豆分离蛋白(soy protein isolate,SPI)是把脱皮大豆中的除蛋白质以外的可能性物质和纤维素、半纤维素物质都除掉,得到的蛋白质含量不低于 90%的制品,又称等电点蛋白。

与大豆浓缩蛋白相比,生产大豆分离蛋白不仅要从低温脱溶豆粕中除去低分子可溶性糖等成分,而且还要去除不溶性纤维素、半纤维素等成分。

其生产方法主要有碱溶酸沉法、超过滤法和离子交换法。

一、碱溶酸沉法1.提取原理低温豆粕中的蛋白质大部分能溶于稀碱溶液。

将低温豆粕用稀碱溶液浸提后,用离心分离法除去原料中的不溶性物质,然后用酸把浸出物的PH调至4.5左右,蛋白质由于处于等电点状态而凝聚沉淀,经分离可得到蛋白质沉淀,再经洗涤、中和、干燥得到大豆分离蛋白。

2.提取工艺豆粕的质量直接影响大豆分离蛋白的功能特性和提取率,只有高质量的豆粕才能获得高质量和高得率的大豆分离。

要求原料无霉变,豆皮含量低,残留溶剂少,蛋白质含量高(45%以上),脂肪含量低,NSI高(不低于80%)。

豆粕粉碎后过40-60目筛。

首先利用弱碱溶液浸泡低温豆粕,使可溶性蛋白质、糖类等溶解出来,利用离心机除去溶液中不溶性的纤维素和残渣。

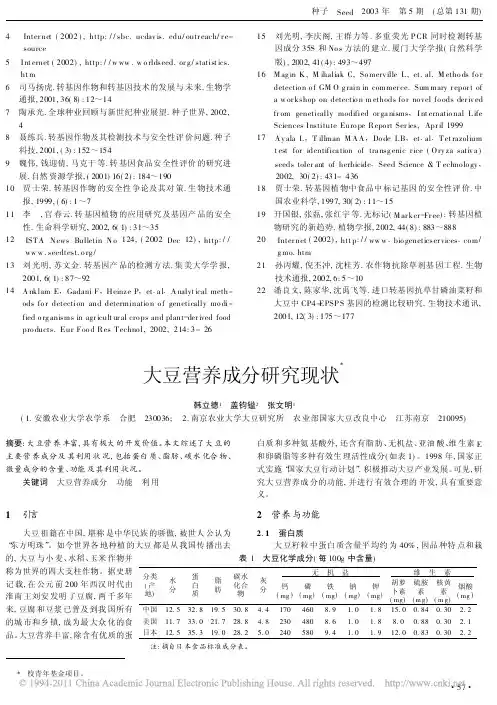

4 Inter net (2002),http://sbc.ucdav /outr each/r e-source 5 I nt ernet (2002),http://w ww.w o rldseed.or g /statist ics.ht m 6 司马扬虎.转基因作物和转基因技术的发展与未来.生物学通报,2001,36(8):12~147 陶承光.全球种业回顾与新世纪种业展望.种子世界,2002,48 聂练兵.转基因作物及其检测技术与安全性评价问题.种子科技,2001,(3):152~1549 魏伟,钱迎倩,马克干等.转基因食品安全性评价的研究进展.自然资源学报,(2001)16(2):184~19010 贾士荣.转基因作物的安全性争论及其对策.生物技术通报,1999,(6):1~711 李 ,官春云.转基因植物的应用研究及基因产品的安全性.生命科学研究,2002,6(1):31~3512 IST A N ews Bulletin N o 124,(2002Dec 12),http ://ww w.seedtest.o rg /13 刘光明,苏文金.转基因产品的检测方法.集美大学学报,2001,6(1):87~9214 A nklam E ,Gadani F ,Heinze P ,et .a l .A nalyt ical meth-ods fo r detection and determinatio n o f genetically mo di-fied o rg anisms in agr icult ur al cro ps and plant -der ived foodpro ducts.Eur F oo d R es T echno l,2002,214:3-2615 刘光明,李庆阁,王群力等.多重荧光P CR 同时检测转基因成分35S 和No s 方法的建立.厦门大学学报(自然科学版),2002,41(4):493~49716 M ag in K ,M ihaliak C,So merv ille L ,et.al.M etho ds fo rdetectio n o f GM O g rain in commer ce.Sum mary r epor t of a w or kshop on detectio n m ethods fo r no vel fo ods der iv ed fr om genetically modified or ga nisms ,I nt ernatio nal L ife Sciences I nstitute Euro pe R epo rt Ser ies,Apr il 199917 A y ala L ,T illman M A A ,Do de L B ,et .al .T et razoliumt est for identifica tion of tra nsg enic r ice (O ry za sativ a )seeds toler ant of herbicide .Seed Science &T echno lo gy ,2002,30(2):431-43618 贾士荣.转基因植物中食品中标记基因的安全性评价.中国农业科学,1997,30(2):11~1519 开国银,张磊,张红宇等.无标记(M ar ker -Fr ee ):转基因植物研究的新趋势.植物学报,2002,44(8):883~88820 Inter net (2002),htt p ://ww w .bio geneticser vices .co m /g mo.htm21 孙丙耀,倪丕冲,沈桂芳.农作物抗除草剂基因工程.生物技术通报,2002,6:5~1022 潘良文,陈家华,沈禹飞等.进口转基因抗草甘磷油菜籽和大豆中CP4-EPSP S 基因的检测比较研究.生物技术通讯,2001,12(3):175~177表1 大豆化学成分(每100g 中含量)分类(产地)水分蛋白质脂肪碳水化合物灰分 无 机 盐 维 生 素 钙(mg )磷(mg )铁(mg )钠(mg )钾(mg )胡萝卜素(mg)硫胺素(m g)核黄素(m g)烟酸(mg )中国12.532.819.530.8 4.41704608.9 1.0 1.815.00.840.30 2.2美国11.733.021.728.8 4.82304808.6 1.0 1.88.00.880.30 2.1日本12.535.319.028.25.02405809.41.01.912.00.830.302.2 注:摘自日本食品标准成分表。

currentresearchinfoodscience文献您好!以下是一些关于当前食品科学研究的文献,包括正文和拓展:1. "Current perspectives on food science and technology" by K. B. Lettinga, F. G. M. ter Haar, and J. A. M. van der Star. This book covers a wide range of topics including food chemistry, nutrition, processing, and safety.拓展:这本书是食品科学领域最新和最全面的著作之一,涵盖了食品化学、营养、加工和安全等各个方面。

作者们来自不同的国家和领域,他们的论文反映了当前食品科学研究的最新进展。

2. "Food science and technology: An overview" by H. F. Dannert. This book provides a general introduction to food science and technology, including topics such as food chemistry, nutrition, processing, and safety.拓展:这本书是一本介绍食品科学和技术的入门读物,涵盖了食品化学、营养、加工和安全等各个方面。

作者们都是食品科学的知名专家,他们的文章提供了对食品科学研究的全面认识。

3. "Enzymology: A practical approach" by W. A. F. Idso. This book focuses on the biochemistry of enzymes and their role in metabolism and digestion.拓展:这本书是一本介绍酶学理论和实践的经典之作。

大豆起源与进化的研究进展摘要:只有了解大豆的起源问题,才能更科学地指导大豆种质的搜集、分类、研究和利用。

此外,研究大豆的进化,可以更加清楚地了解大豆遗传特性的演替规律,为改良和培育大豆新品种提供理论依据。

栽培大豆起源于中国,但是起源的时间及在我国的发源地是一个历史久远的问题,本文就大豆起源的假说及大豆进化的研究进展加以论述。

关键词:大豆;起源;进化中国自古就栽培大豆,商朝甲骨文中有菽的象形文字。

我国最古老的、记述史前文化的、著于元前六世纪的《诗经》,便记载有“蓺之荏菽、荏菽旆旆”。

由此推断我国大豆种植历史约在5 000年上下。

世界其它国家的大豆,都是直接或间接从我国传播去的。

公元前三世纪大豆由我国传入朝鲜,六世纪传至日本。

约在300年前,大豆传入菲律宾、印度尼西亚。

欧美认识大豆则在18 世纪以后[1,2]。

国际学者均认同栽培大豆起源于中国,但在中国何处有多种假说。

瓦维洛夫在作物八大起源中心学说中认为大豆为温带物种,起源于中国中西部山地及毗邻低地[3]。

Hymowitz[4]提出栽培大豆起源于黄河流域并得到许多研究者的支持。

Fukuda[5]认为栽培大豆起源于中国东北。

王金陵[6,7]则推测大豆起源于华南或印度附近。

吕世霖[8]认为大豆可能有多个起源中心。

近期一些研究支持后两种假说[9~12]。

还有一些日本学者则认为有些日本栽培大豆可能不是从中、朝传播过去而是直接由日本本地野生大豆群体驯化的[12~14]。

研究一个古老作物的起源应该回答5个方面的问题:出自何物种何种群、何地、何时、由何人群驯化以及演化的经过。

这是一个难题,因史前文化难以确切追踪取得实据,但又是一个重要命题,这对了解一个古国的文化,民族的历史,物种的进化,科学的发展都至关重要。

笔者将对以上多种大豆起源假说作一评述,从大豆属物种的系统进化和栽培大豆起源研究的方法等方面分析栽培大豆起源的多种假设及依据,并提出进一步研究的问题和意见。

1 大豆起源1.1 东北起源学说日本学者福田[15]认为大豆起源于中国东北,其理由一是中国东北广泛分布有半野生大豆,中国其它地方则不多。

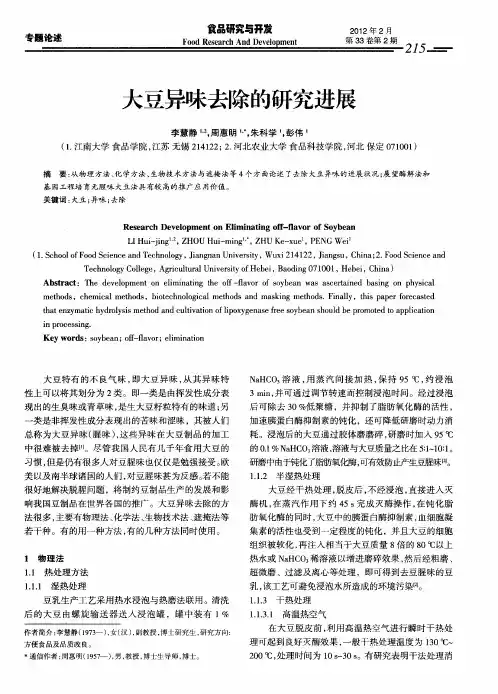

转基因大豆检测技术研究进展[摘要]大豆的转基因研究是国内外植物分子生物学研究的热点之一。

转基因大豆已成为世界大豆主产国大豆产业发展的主要动力。

由于转基因产品的安全性在世界范围内引起广泛关注,对转基因检测技术的要求也越来越高,因此,对转基因大豆检测技术的研究成为近年来研究的热点。

重点介绍以蛋白质和核酸为目标的检测技术,如EI。

ISA、PCR和基因芯片技术的最新进展,并对不同方法的优缺点进行比较,为转基因大豆快速检测方法的选择、改进和后续研究提供参考。

[关键词]转基因大豆;检测技术;蛋白质;核酸Abstract:Soybean transformation research is a/hot spot0in the area of plant molecular genetics. Transgenic soybean has become the important power of soybeans industry development in the worlds' major producers of soybean. The different points on potential ecological risks and the impact of transgenic products on human health attracted worldwide attention. With the increase of transgenic products, the transgenic detection technology requirements should be established and perfected. The advance in detection techniques of transgenic soybean were summarized focusing on the protein and nucleic acid for target detection technology,such as new research on ELISA,PCR and gene chip techn0109y,and their characteristic were compared to provide references for transgenic soybean fast detection selection,improvement and subsequent research.Key words:transgenosis soybean;detection technology;protein;nucleic acid.转基因大豆,是指利用转基因技术,通过基因工程方法导入外源基因所培育的具有特定性状的大豆品种。

大豆功能因子的研究进展卢义伯,潘超(南京雨润集团技术中心,江苏 南京210041)摘要:大豆营养成分丰富,而且其含有的功能因子具有多种保健作用,在食品、医药、养殖等行业中均发挥着重要的作用。

本文从功能、提取和应用的角度,综述了大豆主要功能因子的研究进展。

关键词:大豆;功能因子;进展中图分类号:TS214.2;文献标识码:A;文章篇号:1007-2764(2007)02-0105-04Research Progress of Soybean Functional FactorsLU Yi-bo, PAN Chao(Technical Center of Nanjing Y urun Group, Nanjing 210041, China)Abstract: Soybean is rich in nutrients and good for health especially for its functional factors. So, it is widely used in food, medicine and livestock breeding industries. The functions, extraction methods and applications of soybean functional factors are reviewed in this thesis.Keywords:soybean; functional factor; development大豆包括黄豆、青豆和黑豆,营养成分含量丰富,而且具有良好的保健功效,这些保健功效源于大豆中的多种功能因子,主要包括大豆蛋白、大豆皂苷、大豆低聚糖、大豆异黄酮、大豆卵磷脂、大豆膳食纤维等。

大豆功能因子的保健功效已得到科学实验证实。

在这些因子的提取方面,我国已经研制出具有国际先进水平和独立知识产权的连续提取技术,并且已经实现了工业化生产。

学术篇■

No.1.2010收稿日期:2009-12-28*专家介绍:郭顺堂教授,中国农业大学食品科学与营养工程学院副院长。主要从事植物蛋白、乳蛋白的食品化学、营养化学和功能性成分的生理活性研究,开发大豆食品、植物蛋白加工和应用新技术以及乳成分分离加工新技术研究。

大豆食品原料与加工技术问题研究进展

郭顺堂*徐婧婷(中国农业大学食品科学与营养工程学院,北京100083)

大豆是重要的食品原料,也是世界贸易中重要的战略物资。大豆的丰富营养价值和作为可开发利用的优质蛋白质资源得到了世界各国的广泛重视。2009年8月,在北京举行的第八届世界大豆研究大会对大豆种质资源、遗传育种、基因组学、大豆病害及防治、大豆营养与健康、现代加工技术及产品应用等领域的科学问题进行了广泛的交流,与会大豆科学家报道了最新研究进展。根据与会者的报告内容,本文对大豆食品原料学和现代加工技术中的一些研究进展进行了总结,力求为我国的大豆研究和产业研究发展提供参考依据。1贮藏条件与大豆原料品质大豆从采收后到加工,因市场消费地点的不同要进行一定时间的贮藏和运输。当大豆暴露在不同的温度和湿度条件下时,随着时间的延长,大豆成分的一些性质,如蛋白质高级结构、溶解性等会发生变化,从而影响大豆的加工品质。CarlJ.Bern教授(IowaStateUniversity)对大豆品种、收获方式和环境湿度对大豆品质的影响进行了研究。指出,从高湿度人工收获,低湿度机械收获,低湿度人工收获,到高湿度机械收获,大豆的受损程度依次增加。尽管贮藏期间不同品种间自由氨基酸(FFA)的生成速度不同,但CO2生成速度却相同。将大豆于27℃条件下贮藏时,水分含量为14%的大豆氮溶解指数(NSI)比9%的下降快。Kow-Ching(Sam)Chang教授(NorthDakotaStateUniversity)与其科研团队长期研究贮藏大豆的品质问题。他们总结到,高湿和高温环境可使大豆在感官上色泽变深,大豆贮藏蛋白被糖基化,二硫键增加而表面疏水性减少,二级结构发生改变。由于疏水性相互作用和二硫键作用,蛋白溶解性降低,大豆蛋白形成不溶性聚合体。在恶劣的条件下贮藏的大豆,其制备豆腐的产量和品质明显下降。此外,高温高湿贮藏还会使大豆的可滴定酸度增加,植酸和蛋白质溶解度降低。共轭丙二酰异黄酮转化为糖苷和苷元。贮藏条件也会影响大豆种子的活力。为使种用大豆在生产期时能达到生产标准要求,大豆不但要避开高温高湿贮藏环境,还要对种子进行适当的包衣处理,提高种子质量。N.K.Biradar-Patil(UniversityofAgriculturalsciences,Dharwad)报道,大豆经聚合物涂层(5mL/kg)和杀菌(福美双(2g/

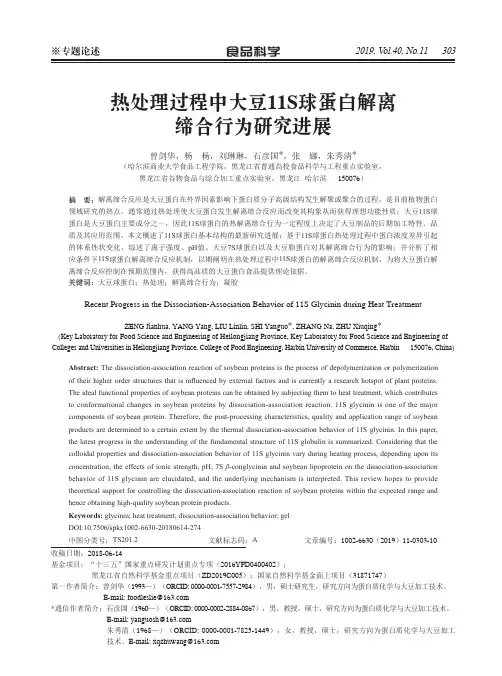

Food Sci. Technol. Res., 7 (1), 8–16, 2001ReviewRecent Progress in Research and Technology on SoybeansDanji F UKUSHIMAKikkoman Corporation, Noda, Chiba 278-0037, JapanReceived December 12, 2000, Accepted January 11, 2001For a long time, it had been considered that soybean storage proteins play only a role as traditional nutrients and other soybean minor constituents such as isoflavones, saponins, trypsin inhibitors, phytic acid, lectin, etc., act as anti-nutrient factors. At present, however, these substances have all been recognized to have exciting roles in the prevention of heart disease, cancer, osteoporosis, etc. Besides these physiological effects, soybean storage proteins exhibit excellent functional properties physicochemically in food systems, such as gelation, bind ing, emulsification, fat and water absorption, etc. On the other hand, there are some substances having undesirable properties in soybeans, such as off-flavors, allergens, etc. Recently, there was a great progress in the research of a molecular basis on these functionalities, off-flavors, and allergenicities. By applying these results for soybean breeding, the creation of the new cultivars or lines having more improved properties is in progress. Another highlight in soybean research is the success of the crystalliza-tion of -conglycinin and glycinin and the subsequent complete determination of their three-dimensional molecular structures through X-ray crystallographic analysis. This paper overviews these recent investgations.Keywords: soybean, b-conglycinin, glycinin, physiological function, three-dimensional structure, isoflavone, lypoxygenase-free, allergen-less1. IntroductionFor more than 2000 years have people throughout East Asia consumed soybeans in the form of traditional soy foods, such as nimame (cooked whole soy), edamame (green fresh soy; Fuku-shima, 2000a), soy milk (Fukushima, 1994), tofu (Fukushima, 1981), kori-tofu (freeze-denatured and dry tofu; Fukushima, 1980 and 1994), abura-age (deep-fat-fried tofu; Fukushima, 1981), sufu or tofu-yo (fermented tofu; Fukushima, 1981 and 1985), soy sauce (Fukushima, 1985 and 1989), miso (Fukushi-ma, 1985), natto (Fukushima, 1985), tempeh (Fukushima & Hashimoto, 1980), etc. In Western countries, soybeans had be-come to draw people’s attention in 1960s as an economical and high quality vegetable protein source for humans. In the United States, new soy protein products were developed, such as soy flour, soy protein concentrates, soy protein isolates, and their tex-turized products. These soy products were introduced into Japan at the end of 1960s, but their consumption remains only 40,000 metric tons as products (see Table 1). The consumption of soy-beans as foods in Japan is mostly to the traditional soy foods, for which about one million metric tons of soybeans and soybean meal are used, as shown in Table 1. The manufacturing tech-niques and equipments of these traditional soy foods had made a great progress through the technical innovations after the World War II and the modernization of the manufacturing had almost been achieved, until the end of 1980.In Western countries, the history of soybeans for human con-sumption is only several decades, where the non-traditional pro-tein products described above are mainly used as ingredients in formulated foods for their functional properties, such as water and fat absorption, emulsification, foaming, gelation, binding, etc. These soy foods have penetrated steadily into Western coun-tries as healthy foods, but the growth is not so high as they expected, perhaps owing to their strong off-flavors associated with their products. However, the consumption of soy foods in the United States has begun to increase abruptly with a turning point in 1997 (Liu, 2000). Undoubtedly, this increase is due to the penetration of the recognition that soybeans possess the excit-ing physiological functions. Namely, numerous investigations during the 1990s put soybeans in the spotlight, where soybean storage proteins and soybean minor components traditionally considered to be antinutritional factors have been recognized to have exciting roles in the prevention of chronic disease. Further-more, FDA authorized “Soy Protein Health Claim” on October 26, 1999, that 25 grams of soy protein a day may reduce the risk of heart disease. Since the market is very much responsive to this Health Claim, soy foods will penetrate rapidly into Western cul-tures and diets.In the processing and utilization of soybeans, the following four points are very important. One is the nutritional and physio-logical aspects, the second is the functional properties working in food systems, the third is the unfavorable substances such as off-flavors, allergens, etc., and the forth is the creation of the benefi-cial cultivars and lines. This paper deals with the review on the recent progress in these subjects.2. Physiological Functions of Soybeans and Soy Food Prod-uctsReevaluation of nutritive value of soyb ean storage pro-teins The quality of soybean proteins has actually been under-valued until recently, because the protein efficiency ratio was based upon the growth of laboratory rats. Growing rats not only possess a much higher requirement for proteins than infants, but also a much higher need for certain amino acids than humans (Steinke, 1979). Particularly, the rat requirement for methionineE-mail: danjif@ka 2.so-net.ne.jpRecent Progress in Research and Technology on Soybeans9is about 50% higher (Sarwar, 1985). According to the Report of a Joint FAO/WHO/UNU Expert Consultation in 1985, the amino acid requirements are different depending upon human age and methionine is not a limiting amino acid for soybean proteins, except infants (see Table 2; Fukushima, 1991a). Both the World Health Organization (WHO) and the United States Food and Drug Administration (FDA) adopted the protein digestibility cor-rected amino acid score (PDCAAS) as the official assay for eval-uating protein quality. Soybean proteins have a PDCAAS of 1.0, indicating that it is able to meet the protein needs of children and adults when consumed as the sole source of protein at the recom-mended level protein intake of 0.6 g/kg body wt. (Y oung, 1991). It is now concluded that the quality of soybean proteins is com-parable to that of animal protein sources such as milk and beef.Physiological functions of soybean storage proteinsFormerly, soybean proteins had been considered to play only arole as traditional nutrients. In the latter half of 1970s, however, itwas found that soybean proteins have a hypocholesterolemiceffect. As shown in Fig. 1 (Descovich et al., 1980), the animalproteins in the diet are exchanged with soybean proteins, theserum cholesterol is lowered markedly. Since then, numerousinvestigations on the hypocholesterolemic effect of soybean pro-teins have been carried out. According to a meta-analysis of 38separate studies involving 743 subjects, the consumption of soyprotein resulted in significant reduction in total cholesterol Fig. 1.Total cholesterol levels in type II patients treated with soy proteindiets. Mark (*) indicates highly significant difference from mean plasmalipid levels during the term before soy protein diets. Source: Descovich etal. (1980).Table 1.Consumption of traditional soy food products in 1998 in Japan.Soybeans a)Soybean meal b)Total Tofu and its derivatives496,0000496,000Kori-tofu28,000028,000Natto128,0000128,000Miso162,0000162,000Soy sauce26,300157,600183,900Soy milk4,20004,200Major traditional products (Total above)844,500157,6001,002,100Non-traditional products (Soy proteins)4,000 (as product)4,000 (as product)Food use total1,032,000401,000c)1,433,000c)Source: a)Shokuhin Sangyou Shinbunsha and b)Ministry of Agriculture, Forestry, and Fishery. c)Including non-food meal other than feeds.Table 2.Patterns of amino acid requirements and soybean amino acid composition.Amino acid(mg/g protein)Pattern of requirement Amino a. comp.of soybeans3–4 Mo.2–5 Yr.10–12 Yr.Adult His2619191627 Ile4628281348 Leu9366441978 Lys6658441661 Met + Cys4225221726 Phe +Tyr7263221990 Thr433428935 Trp17119513 Val5535251348 Total (Including His)460339********* Total (Minus His)434320222111399 Source: Joint FAO/WHO/UNU Expert Consultation (1985).Table 3.Meta-analysis of effects of soy protein intake.No. ofstudiesNo. ofsubjectsChange(mg/dl)95%CI a)Change(%)Total cholesterol38730–23.2–32.9~–13.5–9.3LDL cholesterol31564–21.7–31.7~–11.2–12.9HDL cholesterol30551+1.2–3.1~+5.4+2.4VLDL cholesterol20255–0.4–4.6~+3.9–2.6Triglyceride30628–13.3–25.7~–0.3–10.5a)Confidence interval. Source: Anderson et al. (1995).10D. F UKUSHIMA(9.3%), LDL cholesterol (12.9%), and triglycerides (10.5%),with a small but insignificant increase (2.4%) in HDL cholesterol (see Table 3; Anderson et al ., 1995). In linear regression analysis,the threshold level of soy intake at which the effects on blood lip-ids became significant was 25 g. Thus, soy protein represents a safe, viable, and practical nonpharmacologic approach to lower-ing cholesterol. It is clear that soybean storage proteins possess the hypocholesterolemic effect in themselves, because the plas-ma total cholesterol of the rats fed casein-cholesterol diets was reduced by 35 and 34% by the administration of purely isolate b -conglycinin and glycinin, respectively (Lovati et al., 1992). The exact mechanism of the cholesterol reduction has not been estab-lished fully. Some suggest that cholesterol absorption and/or bile acid reabsorption is impaired, when soybean proteins are fed,while others propose that changes in endocrine status, such as alteration in insulin to glucagon ratio and thyroid hormone con-centrations, are responsible (Potter, 1995).In addition to the cholesterol-lowering effects described above, soybean proteins suppress the lipogenic enzyme gene ex-pression in the livers of genetically fatty rats (Wistar fatty rats),indicating that dietary soybean proteins are useful for the reduc-tion of body fats (Iritani et al., 1996).Physiologically active fragments derived from soyb ean storage protein molecules It has been suggested that some hydrophobic polypeptides produced through proteolytic hydroly-sis of soybean proteins, which bind well to bile acids, are in-volved in the hypocholesterolemic effect of soybean proteins (Iwami et al ., 1986; Sugano et al ., 1988). Minami et al. (1990)found that the A 1a and A 2, the acidic polypeptides of the glycinin subunits A 1a B 1b and A 2B 1a , strongly combine to bile acids. Fur-ther, they obtained the peptide fraction of Ile (114)–Arg (161)with 48 amino acid residues through a tryptic digestion of A 1a peptide. This peptide has a high hydrophobicity and provides a binding site to bile acids.Besides these, there are many physiologically active peptide fragments derived from storage protein molecules, which have antioxidative activities (Chen et al., 1995), the inhibitory action for angiotensin converting enzymes (Kawamura, 1997), or the promoting action for phagocytosis (Y oshikawa et al., 1993), as shown in Table 4.Physiological functions of soy bean minor com-ponents Another importance in the physiological action of soy-beans is that soybean minor components have exciting roles in the prevention of chronic disease (see Table 5). Hitherto, these minor components, such as isoflavones, saponins, trypsin inhibi-tors, phytic acid, lectin, etc., were thought to be antinutritional factors, but now they are recognized to have preventing effects on cancer (Messina & Barnes, 1991). Among these, isoflavones (mainly genistein and daidzein) are particularly noteworthy,because soybeans are the only significant dietary source of these compounds. Isoflavones have not only anticarcinogenic activi-ties, but also the preventive effects on osteoporosis (Anderson &G arner, 1997) and the alleviation of menopausal symptoms (Albertazzi et al., 1998).Physiologically functional sub stances produced b y micro-organisms contained in fermented soy foods The physiologi-cally functional substances described above are the components originally contained in soybeans. Besides these substances, how-ever, some of the traditional fermented soy foods, such as soy sauce, miso, natto, and tempeh, have the physiologically active substances which are produced by microorganisms. Particularly,it is very interesting that HEMF (see Fig. 2), the key flavor com-ponent in Japanese-style fermented soy sauce, has quite a strong anticarcinogenic activity (Nagahara et al., 1992). HEMF is bio-synthesized through the pentose-phosphate cycle by the yeast during the fermentation (Sasaki, 1996). Therefore, it is not present at tamari-type soy sauce, because of the lack of yeast fer-mentation. HEMF is a very unique compound which is not con-tained in foods other than Japanese-style fermented soy sauce and miso (Sasaki, 1996). The HEMF content in miso is low,namely around 0–7 ppm (Sugawara, 1991; Hayasida, 1999),Table 4.Physiologically active peptide fragments from soybean storage protein.Peptide fragmentsProtein sourceVNPHQNa )b -Conglycinin LVNPHDHQN a )b -ConglycininAntioxidant activities LLPHH a )b -Conglycinin LLPHHADADY a )b -ConglycininVIPAGYP a )b -Conglycinin LQSGDALRVPSGTTYY a )b -ConglycininInhibition of angiotensin-converting enzymes FVIPAGY b )a ,a ’(b -Conglycinin subunit)ASUDTLF b )a ,a ’ (b -Conglycinin subunit)DQTPRVF b )A 5A 4B 3 (Glycinin subunit)YRILEF b )a ’(b -Conglycinin subunit)Promoting action of phagocytosis MITLAIPVNKPGRc )a ’(b -Conglycinin subunit)HCQRPR d )A 1a B 1b (Glycinin subunit)QRPR d )A 1a B 1b (Glycinin subunit)Source: a )Chen et al . (1995); b )Kawamura (1997); c )Tanaka et al . (1994); and d )Yoshikawa et al . (1993).Fig. 2.4-Hydroxy-2(or 5)-ethyl-5(or 2)-methyl-3(2H)-furanone. Abbrevi-ated as HEMF.Table 5.Physiological functions of minor components contained in soy-beans.Anticarcinogenic activities a ), prevention of cardiovascu-lar diseases b ), prevention of osteoporosis c ), antioxidant activeties d ), and alleviation of menopausal symptoms e ).IsoflavonesSaponinsAnticarcinogenic activities a ),f ),g ), hypocholesterolemic effects f ), Inhibition of platelet aggregation, HIV preventing effects (group B saponin)h ), and antioxidant activities (DDMP saponin)i ).Phytosterol Anticarcinogenic activities a ).Phytic acid Anticarcinogenic activities a ),f ).Lectin(Hemagglutinin)Activation of lymphocytes (T cell)h ) and aggregating action of tumor cells h ).Nicotianamine Inhibitor of angiotensin-converting enzymes j ), k ).Protease inhibitors Anticarcinogenic activities a ),f ).a )Hawrylewicz et al. (1995); b )Setchell and Cassidy (1999); c )Anderson and G arner (1997); d )Yoshiki and Okubo (1997); e )Albertazzi et al . (1998);f )Messina and Barnes (1991); g )Rao and Sung (1995); h )Harada (1999);i )Yoshiki and Okubo (1995); j )Kinoshita et al . (1993); and k )Kinoshita et al.(1994).Recent Progress in Research and Technology on Soybeans11whereas that in Japanese-style fermented soy and sauce is very high, namely around 230 ppm. HEMF is effective when it is fed to mouse at 4 mg/kg body wt./day, indicating that it is a potent anticarcinogen. As another physiological effect, fermented soy sauce has the activity to inhibit angiotensin I-converting enzyme,but this activity is mostly ascribed to nicotianamine (Kinoshita et al., 1994), which is the constituent of soybeans (see Table 5). Natto made through the fermentation by Bacillus natto has a strong fubrinolytic activity, which is due to the enzyme named nattokinase, produced by Bacillus natto (Sumi et al., 1987).Natto also has anti-tumor-promoting activity, because the extract prevented the reduction of dye transfer caused by a typical tumor promoter of 12-O-tetradecanoylphorbol-13-acetate (Takahashi et al., 1995). Besides these, natto possesses the activities to inhibit angiotensin I-converting enzyme, as soy sauce does (Okamoto et al., 1995). The substances responsible for these activities have not been elucidated yet. However, it is certain that nicotianamine does not relate to these activities, because it disappears during the fermentation of natto (Kinoshita et al., 1994).3. Physicochemical Functions of Soybean Storage Proteins Approximately 90% of the proteins in soybeans exist as stor-age proteins, which mostly consist of b -conglycinin and glyci-nin. b -Conglycinin (Koshiyama, 1965; Catsimpoolas & Eken-stam, 1969; Koshiyama & Fukushima, 1976a) has the sedimen-tation coefficients of 7S, whereas glycinin (Mitsuda et al., 1965)has that of 11S. Besides b -conglycinin, there are two kinds of globulins which have the sedimentation coefficient of 7S. They are g -conglycinin (Catsimpoolas & Ekenstam, 1969; Koshiyama & Fukushima, 1976b) and basic 7S globulin (Y amauchi et al.,1984). However, these two 7S globulins are minor components which account for less than a few percent. The major storage proteins of b -conglycinin and glycinin possess a variety of func-tional properties physicochemically for food applications as shown in the introduction. These functional properties are ascribed to the intrinsic physicochemical characteristics which are based on the molecular structures. Therefore, this chapter focuses on recent developments in the structure-function rela-tionship of b -conglycinin and glycinin.Basic structures of b -conglycinin and glycinin mole-cules b -Conglycinin is a glycoprotein and a trimer with a molecular mass of 150–200 kDa. Major subunits are a ’ (72kDa), a (68 kDa), and b (52 kDa) (Thanh & Shibasaki, 1977).Besides these, there is a minor subunit called g in b -conglycinin (Thanh & Shibasaki, 1977). The amino acid sequences of these subunits are similar each other (Hirano et al., 1987). Each of a ’and a subunits possesses one cysteine residue (-SH) near the N-termini, whereas b subunit does not possess any cysteine residue (Utsumi et al., 1997). No cystine residues (-SS-) exist in these subunits. b -Conglycinin exhibits molecular heterogeneity, where six molecular species are identified as a ’b 2, ab 2, aa ’b , a 2b ,a 2a ’, and a 3 (Thanh & Shibasaki, 1978; Y amauchi et al., 1981).In addition, Y amauchi et al. (1981) found another species of b 3.b -Conglycinin trimers cause association or dissociation depend-ing upon the pHs and ionic strengths of the solution (Thanh &Shibasaki, 1979).Glycinin is a hexamer with a molecular mass of 300–380 kDa.Each subunit is composed of acidic (~35 kDa) and basic (~20kDa) polypeptides, which are linked together by a disulfide bond(Staswick et al., 1984). In glycinin, five subunits are identified as A 1a B 1b (53.6 kDa), A 2B 1a (52.4 kDa), A 1b B 2 (52.2 kDa), A 5A 4B 3(61.2 kDa) and A 3B 4 (55.4 kDa), which are classified into group I (A 1a B 1b , A 2B 1a , A 1b B 2) and group II (A 5A 4B 3, A 3B 4) by the extent of the homology (Nielsen, 1985; Nielsen et al., 1989). Each sub-unit in group I has two cysteine and three cystine residues,whereas that in group II has two cysteine and two cystine resi-dues (Utsumi et al., 1997). Glycinin subunits exhibit polymor-phism, that is, there are some amino acid replacements in the same kind of subunit among soybean cultivars (Mori et al., 1981;Utsumi et al , 1987). Moreover, glycinin exhibits molecular heter-ogeneity, because the molecule is a hexamer with different sub-unit composition (Utsumi et al., 1981). Glycinin hexamers dis-sociate to their constituent polypeptides, subunits, and half-mole-cules, depending upon pHs, ionic strengths, and heating tempera-tures (Wolf & Briggs, 1958; Mori et al., 1982).Physicochemical functionalities and three-dimensional structures of protein molecules The difference of the function-alities on the gel formation, thermal stability, and emulsification,in soybean storage proteins and their subunits is shown in Table 6(Utsumi et al., 1997). The mechanisms on the gel formation of b -conglycinin (Nakamura et al., 1986) and glycinin (Mori et al.,1982; Nakamura et al., 1984) are studied in details. G lycinin forms a turbid, hard, and not fragile gel, whereas b -conglycinin forms a transparent, soft, but rather elastic gel, in 100˚C heating (Utsumi et al , 1997). The A 2 polypeptide of glycinin A 2B 1a sub-unit closely relates to gel turbidity, whereas the A 3 polypeptide of the A 3B 4 subunit relates to the gel hardness. The hardness of gly-cinin gel increases in proportion to the content of A 3 polypeptide.The A 5A 4B 3 subunit relates to the easiness of gel formation,because of the easy cleavage of the hydrophobic bonds between the A 5 and A 4 acidic chains during heating. b -Conglycinin is more unstable thermally than glycinin, but the emulsifying and emulsion-stabilizing abilities of b -conglycinin are much stronger than those of glycinin.The physicochemical functions of proteins depend upon their three-dimensional structures substantially. The polypeptide chains of the protein molecules are unfolded through the heat treatment of soybeans and as a result the amino acid side resi-Table 6.Functional properties of soybean storage proteins and their sub-units working physicochemically in food systems. FunctionalityProteins or subunits Property or its differenceb -ConglycininTransparent, soft, but rather elastic gel.Glycinin Turbid, hard, and not so fragile gel.Gel formationA 2B 1a subunit A 2 polypeptide relates to gelhardness.A 3B 4 subnunitA 3 polypeptide relates to gel hardness.A 5A 4B 3 subunit A 5A 4B 3 subunit relates to the easinessof gel formation.Soybean storage b -Conglycinin ϽGlycininThermal stability proteinsb -Conglycinin a Ͻa ’Ͻb subunitsSoybean storage b -Conglycinin ϾGlycininEmulsification proteinb -Conglycinin Subunitsa мa ’ӷb Source: Utsumi et al. (1997).12D. F UKUSHIMAdues buried inside a molecule are exposed on the surface. The exposed -SH or hydrophobic residues combine the protein mole-cules through -SH, -SS- interchange reaction or hydrophobic bonding, respectively. In this case, it is very important that these active residues are present at an accessible location of the mole-cules each other. Table 7 shows the numbers of -SH and -SS-groups in each subunit. The larger numbers of -SH groups and their topology in glycinin make glycinin gel much harder and more turbid in comparison with b -conglycinin gel, whereas the higher hydrophobicity and more easily unfolded structure in b -conglycinin make its emulcifying ability much stronger than that of glycinin (Utsumi et al., 1997).In order to improve these functional properties, it is necessary to know about the theoretical relations between the functional properties and the three-dimensional structures of the molecules.The research on the three-dimensional structures of soybean stor-age proteins started 35 years ago. We investigated the three-dimensional structures of b -conglycinin and glycinin molecules through optical rotatory dispersion (ORD), circular dichroism (CD), infrared absorption spectra, ultra-violet difference spectra,deutration studies, etc. (Fukushima; 1965, 1967, and 1968).However, these methods are the indirect ones for the measure-ment of three-dimensional structures. For a direct and complete analysis of three-dimensional structures, soybean proteins must be crystallized, followed by a X-ray crystallographic analysis.The complete amino acid sequence of molecular subunits of soy-bean storage proteins has been determined in early 1980s through the sequence analysis of full-length cDNA and a genom-ic clone (see the review of Fukushima, 1988, 1991a, and 1991b).For a long time, however, the X-ray analysis of soybean proteins have not been carried out, because the molecular heterogeneities in both b -conglycinin and glycinin obstructed their crystalliza-tion. Utsumi’s group has overcome these difficulties by using a special soybean variety, of which b -conglycinin molecules or glycinin molecules are composed of the same kinds of subunits [b homotrimer (3b ) in b -conglycinin and A 3B 4 homohexamer (6A 3B 4) in glycinin]. Thus, they have succeeded in the crystalliza-tion of both b homotrimer b -conglycinin and A 3B 4 homohexam-er glycinin (see Fig. 3) and in the subsequent X-ray crystal-lographic analysis of the three-dimensional structures of their molecules (Maruyama et al.,1999; Adachi et al., 1999). The schematic diagrams of the polypeptides are shown in Fig. 4 and 5 (Fukushima, 2000b). The success of the complete analysis of the three-dimensional structures should be mentioned to be epoch-making in knowing the mechanisms of the functionalities of soybean proteins, because most of the properties of proteins are ascribed to the conformation of the molecular surface in the three-dimensional structures of the molecules. Furthermore, theTable 7.Number of cysteine and cystine in each subunit of b -conglycinin and glycinin.SubunitCysteine (-SH)Cystine (-SS-)a ’10b -Conglycinin a10b 00A 1a B 1b 23A 2B 1a23Glycinin A 1b B 223A 3B 422A 5A 4B 322Source: Utsumi et al. (1997).(A) (B)Fig. 3.The crystals of b -conglycinin b homotrimer (A) and glycinin A 3B 4homohexamer (B) (By the courtesy of Dr. S. Utsumi).Fig. 4.Three-dimensional molecular structures of b -conglycinin b homo-trimer (By the courtesy of Dr. S. Utsumi).Fig. 5.Three-dimensional molecular structures of glycinin A 3B 4 homo-hexamer (By the courtesy of Dr. S. Utsumi).Table 8.Contents of secondary structures contained in soybean storage proteins molecules.b -Conglycinin Glycinin X-ray a )CD b )X-ray a )CD b )a -Helix 10585b -Structure 33353635Disordered structure 57605660a )Values obtained by X-ray crystallographic method. b )Values obtained by circular dichroism method.Recent Progress in Research and Technology on Soybeans13elucidation of the detailed three-dimensional structures enables us the theoretical modifications of the molecules, leading into the improvement of soybean protein properties through the protein engineering. Table 8 shows the comparison between the X-ray data of Utsumi’s group (Fukushima, 2000b) and our ORC and CD data (Fukushima; 1965, 1967, and 1968; Koshiyama &Fukushima, 1973) on the per cent of the secondary structures. It is very interesting that the results of X-ray analysis are in good accordance with the results by our indirect CD method around 30 years ago.4. Quality Improvement of Soy Food ProductsOff-flavors and allergenic proteins in soybeans The most difficult problem limiting the expanded use of soy protein prod-ucts in the Western countries is strong off-flavors associated with these products. There are two types of off-flavors. One is grassy and beany flavors and the other is bitter, astringent, and chalky flavors. The grassy-beany flavors are developed through the action of the three kinds of lipoxygenases 1, 2, and 3 present at soybeans. The bitter, astringent, and chalky flavors are caused by saponins and isoflavones (Okubo et al., 1992). The off-flavors of isoflavones are enhanced by the hydrolysis into their aglycones through the action of three kinds of b -glucosidases A, B, and C in soybeans (Matsuura & Obata, 1993). Thus, both lipoxigenases and b -glucosidases contained in soybeans play an important role in the production or enhancement of the off-flavors. Moreover,the lipid hydroperoxides produced by lipoxygenases oxidize the free -SH groups of soybean proteins, resulting into the decrease of their gel-forming ability (Fukushima, 1994). For a long time, a variety of attempts to remove or mask these off-flavors have been done through the operation during processing. However, it was impossible to remove or mask the off-flavors to a satisfactory extent by these methods.Another unbeneficial substance other than off-flavors in soy-beans is allergenic proteins. The major allergenic proteins in soy-beans are shown in Table 9 (Ogawa et al., 1991). It is noticeable that the two of the three subunits of b -conglycinin have allergen-ic proteins. It is impossible to remove all of these major allergens through usual treatments or processing.Genetic improvement of soybeans In the last two decades,the various soybean mutant genes which control the production of enzymes, allergenic proteins, storage proteins, etc. have been identified in the world soybean germplasm. Using these mutants,the commercially available soybean cultivars without having undesirable substances or with the beneficially modified compo-sition of storage proteins have been bred. As an example, there is the cultivar “Kunitz” [Illinois Agricultural Experiment Station (AES)] lacking Kunitz’s soybean trypsin inhibitor (Bernard et al.1991) or the cultivar “Ichihime” (Kyushu AES) lacking all of the lipoxygenases 1, 2, and 3 (Nishiba et al., 1995). The develop-ment of lipoxygenase-free cultivar will be beneficial for the pro-duction of non-traditional soy products, since Western people are very sensitive for beany flavors. However, the soybean cultivars lacking the b -glucosidases have not been developed yet, which are the enzymes enhancing the off-flavors by changing the isofla-vones into their aglycones.There was some progress on the removal of allergenic proteins recently. The cultivar with a high ratio of glycinin to b -conglyci-nin was developed by the group of Tohoku National AES, named Tohoku 124. This cultivar lacks the two major allergenic proteins of 28K and a subunit, while it still possesses allergenic proteins of 30K and b -subunit (Samoto, 1996). Fortunately, the 30K pro-tein can be removed easily by centrifugation, which is bound to IgE antibodies most strongly and frequently. Another group of Kyushu National AES found the wild soybean line, named QT 2,which lacks all of b -conglycinin (Hajika et al., 1998). This line grows normally and produces successive generations, indicating the possibility to breed the soybean varieties, of which storage proteins are mainly composed of glycinin without containing any b -conglycinin. Using this QT 2 line, they obtained the line lacking all the subunits of b -conglycinin by back-crossing with Fukuyu-taka. This line contains only glycinin as storage proteins and that it lacks the three major allergenic proteins of 28K, a , and b sub-units (Takahashi et al., 2000). This had so good field perfor-mance as Fukuyutaka in the on-campus experiment and was named Kyu-kei 305. Kyu-kei 305 should be mentioned to be the variety with the least quantities of allergens so far. Besides these,Table 10.Hardness of tofu gel made from soybeans with different ratio of both 11S/7S proteins and glycinin subunit compositions.Breeding lineGlycinin subunit11S/7S in soy milkBreaking stress of tofu gelGroup IA 5A 4B 3A 3B 4Enrei (control)+–+58/429,891EnB 2-111+++66/349,989EnB 2-110++–62/388,955EnB 2-101+–+57/4310,171EnB 2-100+––45/557,162EnB 2-011–+–52/486,791EnB 2-010–+–33/674,835EnB 2-001––+25/755,381EnB 2-000–––12/883,002Crops: Enrei (control), 380 kg; and others, 384–441 Kg/10 a. Protein content of seeds: Enrei (control), 42%; and others, 39.3–40.7%. Source: Yagasaki et al.(1999).Table 9.Major allergenic proteins in soybeans b ).Protein assignmentMolecular wt. (k Da)Frequency a ) (%)Gly m Bd30 k 3065.2Gly m Bd28 k 2823.2a subunit of 6823.2b -conglycinin b subunit of 4510.1b -conglycinin a )Detection frequency among 69 soybean-sensitive patients with atopic der-matitis. b )Source: Ogawa et al. (1991).。