国家标准《GBT_9439-2009_灰铸铁件》修订说明

- 格式:pdf

- 大小:809.00 KB

- 文档页数:14

蠕墨铸铁标准蠕墨铸铁是一种特殊的铸铁材料,其独特的微观结构使其具有较高的抗蠕变性能。

在工业领域中,蠕墨铸铁广泛应用于高温、高压和长时间作业的设备和零件制造中。

为了确保蠕墨铸铁产品的质量,各个国家和地区都制定了相应的标准。

本文将介绍蠕墨铸铁的标准以及其主要内容。

一、蠕墨铸铁标准的概述蠕墨铸铁标准是对该材料的性能、化学成分、组织结构、机械性能等方面进行规定的依据,以确保生产出符合要求的蠕墨铸铁产品。

不同国家和地区的标准可能略有差异,但基本内容是相似的。

主要的蠕墨铸铁标准有:中国国家标准GB/T 9439-2010《蠕墨铸铁》、美国标准ASTM A439/A439M-83(2018)《蠕墨铸铁铸件化学成分、机械性能标准要求》、欧洲标准EN 1563-2018《球墨铸铁》等。

二、蠕墨铸铁标准的主要内容1. 化学成分蠕墨铸铁标准对其化学成分进行了严格的规定。

包括铁素体含量、碳含量、硅含量、锰含量、磷含量、硫含量等。

这些元素的含量对于蠕墨铸铁的性能起到关键影响,合理的化学成分能够确保蠕墨铸铁具有良好的耐蠕变性能。

2. 组织结构蠕墨铸铁标准对其组织结构进行了要求。

通常要求铸件具有均匀的铁素体和蠕墨体分布,并规定了蠕墨体的形态、尺寸和数量。

良好的组织结构可以提高蠕墨铸铁的强度和韧性,降低其蠕变倾向。

3. 机械性能对于蠕墨铸铁产品的机械性能,标准中通常规定其强度、硬度、延伸率、抗压强度等指标。

这些机械性能指标是判断蠕墨铸铁产品质量的重要标准,也是应用于实际工程中的关键参数。

4. 缺陷和疵点蠕墨铸铁标准还对铸件的缺陷和疵点进行了详细的要求,如气孔、夹杂物、砂眼等。

这些缺陷和疵点对蠕墨铸铁产品的使用寿命和安全性会带来不良影响,因此标准中需要明确规定这些缺陷的类型、数量和允许程度。

5. 检测方法标准中通常还包括蠕墨铸铁产品的检测方法。

针对化学成分、组织结构和机械性能等方面,标准会指定相应的检测方法和试验规程,以确保产品可以准确地满足标准的要求。

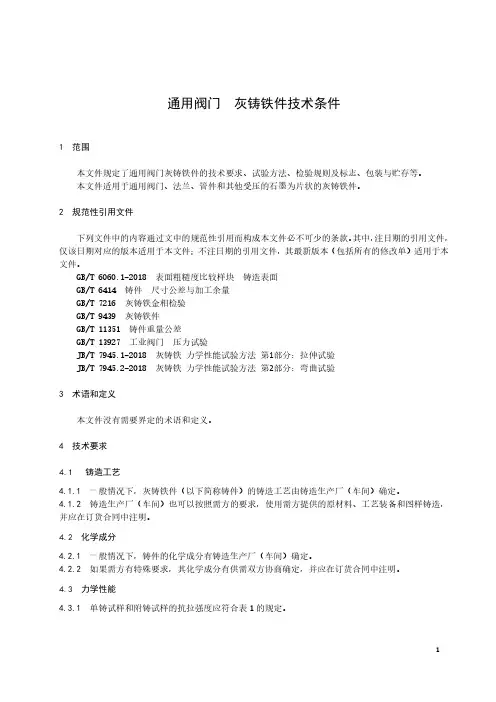

通用阀门灰铸铁件技术条件1 范围本文件规定了通用阀门灰铸铁件的技术要求、试验方法、检验规则及标志、包装与贮存等。

本文件适用于通用阀门、法兰、管件和其他受压的石墨为片状的灰铸铁件。

2 规范性引用文件下列文件中的内容通过文中的规范性引用而构成本文件必不可少的条款。

其中,注日期的引用文件,仅该日期对应的版本适用于本文件;不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。

GB/T 6060.1-2018 表面粗糙度比较样块铸造表面GB/T 6414 铸件尺寸公差与加工余量GB/T 7216 灰铸铁金相检验GB/T 9439 灰铸铁件GB/T 11351 铸件重量公差GB/T 13927 工业阀门压力试验JB/T 7945.1-2018 灰铸铁力学性能试验方法第1部分:拉伸试验JB/T 7945.2-2018灰铸铁力学性能试验方法第2部分:弯曲试验3 术语和定义本文件没有需要界定的术语和定义。

4 技术要求铸造工艺4.1.1 一般情况下,灰铸铁件(以下简称铸件)的铸造工艺由铸造生产厂(车间)确定。

4.1.2 铸造生产厂(车间)也可以按照需方的要求,使用需方提供的原材料、工艺装备和图样铸造,并应在订货合同中注明。

化学成分4.2.1 一般情况下,铸件的化学成分有铸造生产厂(车间)确定。

4.2.2 如果需方有特殊要求,其化学成分有供需双方协商确定,并应在订货合同中注明。

力学性能4.3.1 单铸试样和附铸试样的抗拉强度应符合表1的规定。

表1 抗拉强度4.3.2 如果需方以硬度要求作为检验铸件材质力学性能时,应在订货合同中注明。

质量要求4.4.1 铸件的尺寸和偏差应符合GB/T 6414的规定,也可按需方订货时的图样、模样所要求尺寸和偏差。

4.4.2 按照GB/T 6414或需方铸造图样、模样的规定,在铸件的必要部位应留出切削加工余。

;4.4.3 铸件的重量偏差应符合GB/T 11351的规定。

4.4.4 铸件表面的粘砂、浇口、冒口、夹砂、结疤、毛刺等,均应清除干净。

铸铁铸件技术标准及接收准则 ***/***—20**1.目的为确保公司铸铁铸件生产、检验、接收时有所依循并适合公司质量方针。

2.适用范围本标准适用于本公司生产的顾客没有提供或没有提供全部(有明确要求的及时纳入《顾客要求—材质》记录表中)技术标准和接受准则的灰铸铁铸件的检验和接收。

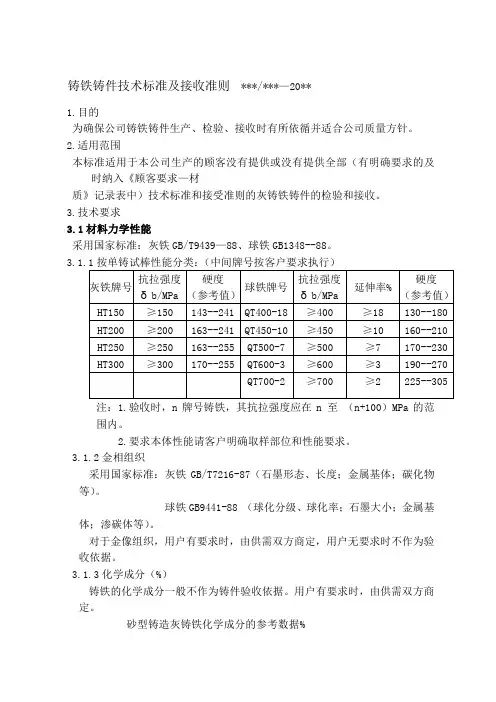

3.技术要求3.1材料力学性能采用国家标准:灰铁GB/T9439—88、球铁GB1348--88。

注:1.验收时,n牌号铸铁,其抗拉强度应在n 至(n+100)MPa的范围内。

2.要求本体性能请客户明确取样部位和性能要求。

3.1.2金相组织采用国家标准:灰铁GB/T7216-87(石墨形态、长度;金属基体;碳化物等)。

球铁GB9441-88 (球化分级、球化率;石墨大小;金属基体;渗碳体等)。

对于金像组织,用户有要求时,由供需双方商定,用户无要求时不作为验收依据。

3.1.3化学成分(%)铸铁的化学成分一般不作为铸件验收依据。

用户有要求时,由供需双方商定。

砂型铸造灰铸铁化学成分的参考数据%在保证抗拉强度、硬度及金相组织的前提下,上列各元素允许在如下范围内波动: C±0.050% Si±0.050% Mn±0.030% 。

3.1.4根据铸件性能要求,针对铸件重量、壁厚、冷却条件等不同对我公司生产的材质做如下分类:3.2铸件外观质量要求3.2.1铸字(包括铸造日期代码、生产厂家标志、模具编号、铸件号等)要清晰可辩并符合图纸要求或用户要求。

3.2.2铸件必须质地均匀、无裂纹以及影响产品性能的缺陷。

3.2.3铸件加工表面上,允许存在加工余量范围内的砂眼、气孔、渣眼等孔洞类铸造缺陷。

3.2.4铸件非加工表面上允许存在以下规定范围内的表面缺陷:在ф50mm范围内,允许存在3处—ф2mm×1.5mm的孔洞类缺陷,允许用铸造修补胶对其填塞修补,修补处刷硝基黑漆(按规定配比稀释后使用),然后防锈处理。

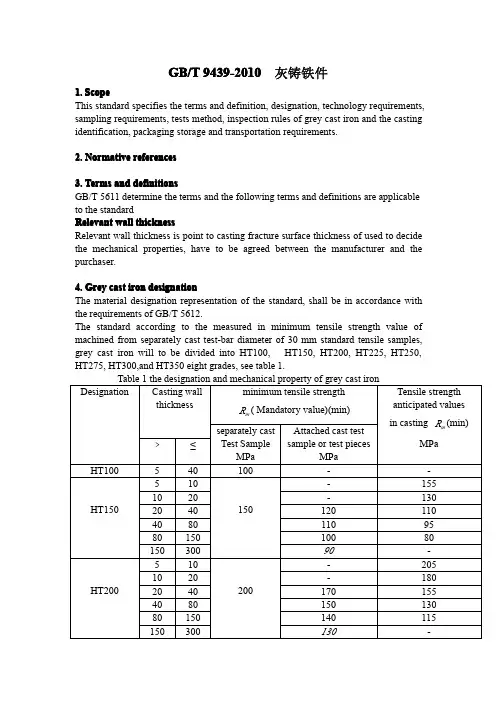

GB/T 9439-2010灰铸铁件1.ScopeThis standard specifies the terms and definition,designation,technology requirements,sampling requirements,tests method,inspection rules of grey cast iron and the casting identification,packaging storage and transportation requirements.2.Normative references3.Terms and definitionsGB/T 5611determine the terms and the following terms and definitions are applicable to the standardRelevant wall thicknessRelevant wall thickness is point to casting fracture surface thickness of used to decide the mechanical properties,have to be agreed between the manufacturer and the purchaser.4.Grey cast iron designationThe material designation representation of the standard,shall be in accordance with the requirements of GB/T 5612.The standard according to the measured in minimum tensile strength value of machined from separately cast test-bar diameter of 30mm standard tensile samples,grey cast iron will to be divided into HT100,HT150,HT200,HT225,HT250,HT275,HT300,and HT350eight grades,see table 1.Table 1the designation and mechanical property of grey cast ironDesignation Casting wall thickness minimum tensile strength m R (Mandatory value)(min)Tensile strengthanticipated values in casting m R (min)MPa separately cast Test Sample MPa Attached cast testsample or test pieces MPa﹥≤HT100540100--HT150510150-1551020-1302040120110408011095801501008015030090-HT200510200-2051020-1802040170155408015013080150140115150300130-HT225510225-230 1020-200 2040190170 4080170150 80150155135 150300145-HT250510250-250 1020-225 2040210195 4080190170 80150170155 150300160-HT2751020275-250 2040230220 4080205190 80150190175 150300175-HT3001020300-270 2040250240 4080220210 80150210195 150300190-HT3501020350-315 2040290280 4080260250 80150230225 150300210-Note1:when casting wall thickness exceeding30mm,the mechanical property have to be agreed between the manufacturer and the purchaser.Note2:This column gives guidance only about the likely variation in tensile strength for different casting wall thicknesses when a casting of simple shape and uniform wall thickness is cast in a given grey cast-iron material.For castings of non-uniform wall thickness,or castings containing cored holes,the table values are only an approximate guide to the likely tensile strength in different sections,and casting design should be based on the measured tensile strength in critical parts of the casting.Note3:The italics numerical values are guideline values,the others tensile strength are mandatory, tensile strength anticipated values in casting are not mandatory.5.Order requirementsThe following information shall be supplied by the purchaser:a)The complete designation of the material;b)Any special requirements which have to be agreed between the manufacturer andthe purchaser.6.The method of producing chemical composition6.1The method of producingThe moulding sand or thermal conductivity and moulding the relative sand produce gray cast iron pieces.The method of producing grey cast iron shall be left to the discretion of the supplier,if purchaser has any special requirements(other moulding way or heat treatment and so on)which have to be agreed between the manufacturer and the purchaser.6.2Chemical compositionWhen if the technology requirements of purchaser include the acceptance requirement of chemical composition,according to the provision of supplier carry out.When purchaser has no requirements about chemical composition,the chemical composition decided by supplier,the chemical composition is not as the basis of acceptance of casting.But the select of chemical composition must be ensured casting material meeting the requirement of mechanical property and metallographic structure in provision of the standard.7.Technology requirement7.1Mechanical propertieswhether the mechanical properties measured on separately cast samples or on the casting,whether tensile strength or Brinell hardness as the acceptance indexes,all must be specify,in an unambiguous manner in the order or the technology requirement of supplier.The mechanical properties acceptance indexes of casting shall explicitly stipulated in order.The mechanical properties and physical properties of grey cast iron test samples see appendix AThe standard specified mechanical properties indexes and metallographic structure is main indexes of the casting acceptance.7.1.1Tensile strength7.1.1.1The tensile strength of separately cast samplesThe standard according to the measured in minimum tensile strength value of machined from separately cast test-bar diameter of30mm standard tensile samples, grey cast iron will to be divided into eight grades,the minimum tensile strength of each grade shall be in accordance with the requirements of Table1.7.1.1.2The tensile strength of attached cast test sample(test pieces)The tensile strength of attached cast test sample(test pieces)shall meet the provision of table1.7.1.1.3The tensile strength of casting itselfTable1gives each different grades of wall thickness of grey cast iron itself tensile strength references7.1.1.4Sampling position of casting itselfThe sampling position,sample size and tensile strength of casting itself have to beagreed between the manufacturer and the purchaser,if when the purchaser has theexplicitly provision.When purchaser request sampling from casting itself,but unspecified the samplingposition of casting itself,the supplier can decide the sampling position according tocasting structure and loading condition,the size of the casting itself see table5.The frequency of inspection and quantity of tensile strength of casting itself has to beagreed between the manufacturer and the purchaser.7.1.2Hardness grades and casting hardnessThe Brinell hardness values of the six grades of grey cast iron specified by hardness,see Table2.The hardness of each hardness grades is the maximum hardness value ofmain wall thickness t>40mm and t≤80mm.Table2the hardness grades and casting hardness of grey cast ironHardness grades The main wall thickness ofcasting/mmThe hardness range of casting/HBW>≤min maxH155510-185 1020-170 2040-160 4080-155H175510140225 1020125205 2040110185 4080100175H19545190275 510170260 1020150230 2040125210 4080120195H215510200275 1020180255 2040160235 4080145215H2351020200275 2040180255 4080165235H25520402002754080185255Note1:Information on the relationship between Brinell hardness and tensile strength is indicated in Annex B,and on the relationship between Brinell hardness and relevant wall thickness is indicatedin Annex C.Note2:The figures given in bold indicate the minimum and maximum Brinell hardness.Note3:By agreement between the manufacturer and the purchaser,a narrower hardness range may be adopted at the agreed position on the casting,provided that this is not less than40Brinell hardness unitsWhen purchaser request the hardness as the acceptance indexes,the frequency ofinspection and quantity of hardness has to be agreed between the manufacturer andthe purchaser,and choose one of the following the acceptance rules:a)The hardness of casting itself shall be in accordance with the requirements of Table2.b)When measure the hardness of machined from separately cast test-bar,shall be in accordance with the requirements of Table3.When purchaser has the specific provision to inspection position and hardness value,shall be in accordance with the requirements of purchaser drawing and technology requirements.Note1:This classification is applicable principally where machinability or wearresistance of importance.Note2:For a relevant wall thickness t>80mm,grades are not classified by hardness.7.2Metallographic structureThe inspection method and inspection items of grey cast iron metallographic structureshall be in accordance with the requirements of GB/T7216.When purchaser has thespecific provision to the quantity,distribution,grades and sampling of each inspectionitems,shall be in accordance with the requirements of purchaser drawing and technology requirements.7.3Geometrical dimensionThe geometrical dimension of casting shall be in accordance with the requirements ofpurchaser drawing and technology requirements.7.4Dimensional toleranceThe casting dimensional tolerance shall be in accordance with the requirements ofpurchaser drawing and technology requirements.If purchaser has no special requirements,shall be in accordance with the requirements of GB/T6414.7.5Working allowanceThe working allowance of casting shall be in accordance with the requirements ofpurchaser drawing and technology requirements.If purchaser has no special requirements,shall be in accordance with the requirements of GB/T6414.7.6Weight deviationThe weight deviation of casting shall be in accordance with the requirements ofpurchaser drawing and technology requirements.If purchaser has no specialrequirements,shall be in accordance with the requirements of GB/T11351.7.7Surface qualityThe surface quality of casting include outside surface and internal surface.7.7.1The surface roughness of the casting shall be shall be in accordance with the requirements of GB/T6060.1or the requirements of purchaser drawing and technology requirements.7.1.2Casting should clean up,finishing the spare parts,removing feeding residual, core bar,adhering sand and entocoele residues etc.the feeding residual,joint flash, Flying Spur residual entocoele cleanness etc.of Casting allowed,shall be in accordance with the requirements of purchaser drawing and technology requirements or the order agreement of between supplier and purchaser.7.7.3Unless otherwise specified,the castings are in as-cast delivery.7.7.4The delivery process of Casting shall be in accordance with the protection, packaging and storage and transportation regulations of purchaser.7.8Casting defects7.8.1Not allow the defects of effect casting operating property exiting existing,such as cracks,cold shut,shrinkage cavity etc.7.8.2Casting machining surface allowance the existence defects in machining allowance range7.8.3Casting non-processing surface and internal casting allowance the variety,scope, quantity,shall be in accordance with the requirements of purchaser drawing and technology requirements or the order agreement of between supplier and purchaser.7.8.4Casting machining surface may not welding,repair in principle,but by the authority of purchaser,on condition that not affected mechanical processing conditions,Defects which not affect the structure property can welding,repair7.9Special requirementsWhen purchaser has request for MT,UT,RT etc.shall be agreed between the manufacturer and the purchaser8.Sampling requirements8.1GeneralIf heat treatment is used to modify the properties of the material,then the samples shall be heat-treated in the same way as the castings they represent.8.2Tensile test8.2.1Separately cast samplesThe separately cast samples used to establish the material grade shall be cast vertically as the castings they represent in similar cooling conditions and thermal conductivity moulding sand(see figure1).The moulds may be made for casting more than three pieces samples simultaneously,the minimum distance among the moulds are not less than50mm,the length of samples L shall be determined according to the sample and the length of clamping device,see Figure1.Figure1—Separately cast samplesThe length of samples L shall be determined according to the length of the test piece A or B(see9.2)and the length of clamping device.Other dimensions of the samples shall meet the dimensional requirements of Figure1.The dimension of the samples made from separately cast samples,see Table4.When purchaser has special request for separately cast samples and machining samples dimension,shall be in accordance with the requirements of purchaser.Samples must be pouring from the same liquid,and at the later period of the batch pouring liquid pour samples.The frequency of casting the separately cast samples shall be in accordance with the requirement of the10.3.The samples shall be removed from the mould at a temperature≤500°C.If the castings need heat treatment,the samples with the represent castings shall be handled; when the castings carry out the ageing treatment of eliminate stress,the samples may not be handled.NOTE:By agreement between the manufacturer and the purchaser,samples may be removed from the mould at a temperature≥500°C,if the castings are also to be removed from the moulds at this higher temperature.8.2.2Attached cast samples(pieces)When a casting is more than20mm thick and the mass is less than2000kg,the test pieces used for the tests shall be machined from a attached cast samples(see figure2) or attached cast pieces(see figure3).The type of sample shall be chosen in such a way as to provide approximately the same cooling conditions as for the casting.The sample used to determination of tensile strength,the measured result is more approximate to the property of casting than the tensile strength of separately cast samples.The type of sample(pieces),and the location of the sample(pieces)on the casting, shall be agreed between the manufacturer and the purchaser.If there is no such agreement,the manufacturer shall decide on the type of sample and it shall be located at a representative position on the casting.The length of test bar or test pieces L shall be determined according to the length of the samples and the length of clamping device.The numeral in bracket apply to the test bar of diameter50mm and the test pieces of radius25mm separately.If the castings need heat treatment,attached cast samples(pieces)shall be cut from a casting after heat treatment.The length of test bar or test pieces L(see Figures2and3)shall be determined according to the length of the samples and the length of clamping device.Note:the test bar of diameter30mm and the test pieces of radius15mm used for castings less than80mm wall thickness,the test bar of diameter50mm and the test pieces of radius25mm used for castings more than80mm wall thickness.8.2.3Casting itself samplesThe sampling of casting itself samples have to be agreed between the manufacturer and the purchaser.The processing size of casting itself samples see Table5.Figure2—Cast-on test barFigure3—Cast-on test block8.3Hardness test blocksWhen purchaser will regard hardness as the acceptance indexes,hardness shall be in accordance with the requirements of7.1.2.Measuring hardness will on separately cast samples.The hardness value see Table3. Table3the tensile strength and hardness value of separately cast samplesDesingnationMinimum tensile strengthm R (min)MPa Brinell Hardness HBW HT100100≤170HT150150125~205HT200200150~230HT225225170~240HT250250180~250HT275275190~260HT300300200~275HT350350220~290The position of the Brinell knob,and its size and shape,shall be agreed between the manufacturer and purchaser,or on a test piece (“Brinell knob”)which is cast-on to the casting as shown in Figure 4.The test piece used for a casting is more than 20mm thick,test piece shall be cut from a casting.If the casting is heat-treated,the Brinell knob shall not be detached from the casting until the heat-treatment process has been concluded.Figure4Figure4——Brinell Hardness test blocks 9.Test methods10.Inspection rules11.Casting identification identification,,packaging storage and transportation requirementsAnnex A(informative)Mechanical and physical properties of Gray cast ironInformation on mechanical properties of separately and attached cast test pieces with diameter30is given in Table A.1Information on phisical properties of separately and attached cast test pieces with diameter30is given in Table A.2Table A.1-mechanical properties of separately and attached cast test pieces with diameter30characteristicaMaterial designationHT150HT200HT225HT250HT275HT300HT350Basic structureFerrite/pearlitepearliteTensile strength Rm/Mpa 150~25200~30225~325250~35275~375300~40350~45Yield strength Rp0.1/Mpa 98~165130~195150~21165~228180~245195~26228~285ElongationA/%0.3~0.80.3~0.80.3~0.80.3~0.80.3~0.80.3~0.80.3~0.8 Compression strength/ db Mpaσ6007207808409009601080 Compression1952602903253603904550.1/d Mpa σBending strength/bB Mpa σ250290315340365390490Shear strength/aB Mpa σ170230260290320345400Torsionalb Stength /tB Mpaτ170230260290320345400Modulus of celasticity /E kMpa 78~10388~11395~115103~118105~128108~137123~143Poisson's ratio (υ)0.260.260.260.260.260.260.26Bending fatigue d Strength /bW Mpa σ7090105120130140145Fatigue limit under reversedtensioncompression estresses zdW /MPa σ40505560687585Fracture toughness3/4/IC K MPa 320400440480520560650a When there are special requirements relating to machinability or magnetic properties,then HT 100is used.The required properties can be obtained by means of a structure-changing heat-treatment process.HT 100is not cited here.b Torsional fatigue strength tW m a 0.42R τ≈(MP ).c Depends on the quantity and form of the graphite,as well as on the loading.d The following approximately applies:(0.35~0.50)bW m R σ≈.e The following approximately applies:0.530.26zdW bW m R σσ≈≈.Table A.2-mechanical properties of separately and attached cast test pieces withCharacteristicaMaterial designation HT150HT200HT225HT250HT275HT300HT350Density 3/(/)kg mm ρ7.107.157.157.207.207.257.30Specific heat Capacity J/(kg ⋅K)Between 20°C and 200°C 460Between 20°Cand 600°C535Linear expansion Coefficient m/m µ⋅Kbetween- 100°C and + 20°C 10.0Between 20°Cand 200°C11.7Between 20°C and 400°C13.0Thermal Conductivity W/(m ⋅K)at 100°C 52.550.049.048.548.047.545.5at 200°C 51.049.048.047.547.046.044.5at 300°C50.048.047.046.546.045.043.5at 400°C 49.047.046.045.044.544.042.0at 500°C 48.546.045.044.543.543.041.5Resistivity 2/mm mΩ⋅0.800.770.750.730.720.700.67Coercivity A/m 560to 720Maximum permeability at room temperature μH/m220to 330Hysteresis losses at B =1T J/m32500to 3000a When there are special requirements relating to machinability or magnetic properties,then HT 100is used.The required properties can be obtained by means of a structure-changing heat-treatment process.HT 100is not cited here.Annex B(informative)Additional information on the relationship between hardness and tensile strengthof grey cast ironsHardness and tensile strength,as well as modulus of elasticity and the modulus of rigidity of grey cast iron of a given grade,are approximately related to each other.In most cases,an increase in the value of one property results in an increase in the values of other properties.Grey cast irons naturally divide into a family or series of grades having different relative hardness(RH)or tensile-strength-to-hardness(T/H)ratios. This Annex briefly discusses RH and T/H for grey cast irons.B.1Relative hardnessThe following empirical relationship between Brinell hardness(HBW)and tensile strength Rm exists:HBW=RH×(A+B×Rm)Commonly accepted values for the constants are:A=100B=0,44where RH is the relative hardness.RH has been found to vary between0,8and1,2 (see Figure B.1).The factor RH is influenced mainly by the raw materials,the melting process,and the metallurgical workingmethod.Within one foundry,these influences can be maintainednearly constant.Therefore,the manufacturer can indicate both hardness and the corresponding tensile strength .Figure B.1—Relative hardness (RH)relationship between Brinell hardnessand tensile strength of grey cast irons B.2Tensile-strength-to-hardness ratioTensile-strength-to-hardness (T/H)ratios are regulated by the eutectic graphite content,up to the eutectic composition shown in Figure B.2,with carbon equivalent (CE)as the graphite ing tensile strength in N/mm2,or MPa and Brinell hardness in HBW,the T/H ratios of grey cast irons range from approximately 0,8to 1,4.A decline in T/H ratio continues as CE increases above the eutectic,but at a much smaller and less predictable rate.Constant T/H lines in Figure B.2are essentially lines of constant graphite effect on mechanical properties.Properties sensitive to both graphite and matrix,such as bulk tensile strength and bulk hardness,vary in constant proportionality to each other and to their matrix counterparts (matrix tensile strength and matrix hardness)along constant T/H lines.Elastic modulus and damping capacity vary mainly only with graphite and are,therefore,highly uniform along the constant T/H lines.Since these lines are also lines of constant eutectic graphite and carbon equivalent,the most important castability parameters,they are logical grade lines for foundry control,as well as for mechanical propertycontrol.Annex C(informative)Additional information on the relationship between tensile strength,hardnessand wall thickness of grey iron castingsFigure C.1provides additional general information on the expected relationship between minimum tensile strength and relevant wall thickness.Figure C.2provides information on average Brinell hardness and relevant wall thickness of castings. This illustrates the importance of reaching an agreement between the manufacturer and the purchaser on the specification of the hardness required in castings,and also the location where a hardness test should be carried out.Figure C.1—Examples of relationship between minimum values of the tensilestrengthand the relevant wall thickness of simple shaped castingsFigure C.2—Typical relationship between average values of the Brinell hardness and the relevant wall thickness of simple shaped castingsAnnex D (informative)Penetration strengthPenetration strength test usually refers to limitation of sample size to detect a detection method for gray cast iron body strength.The sample size is usually (6x20x32)mm (minimum accuracy of 0.05mm).In the penetration device,loaded by top sword and press sword,the penetration sample truncated.The ratio of penetration pressure and the transaction area,this is Penetration strength ,is as judgment basis of the gray cast iron property.By agreement between the manufacturer and the purchaser,the penetration strength test may be applied as an alternative to the tensile test.D.1Calculation method of penetration strengthPenetration strength (Rk)calculation,is according to penetration pressure (F)and the transaction area (S).Rk =F/S D.2Conversion relationship of Penetration strength and tensile strengthConversion relationship of Penetration strength and Tensile strength,usually can use the following formula.Tensile strength 1.8664m k R R =×−Or,1.8055m k R R =×−Acting lode speed should be less than or equal to 10MPa/s during the test.。

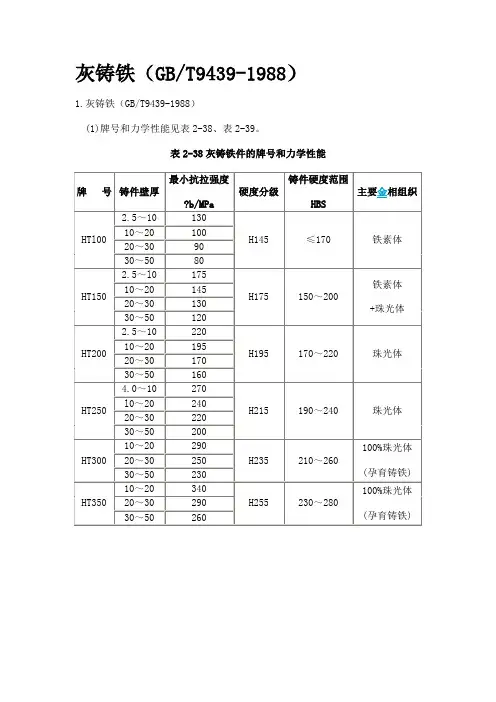

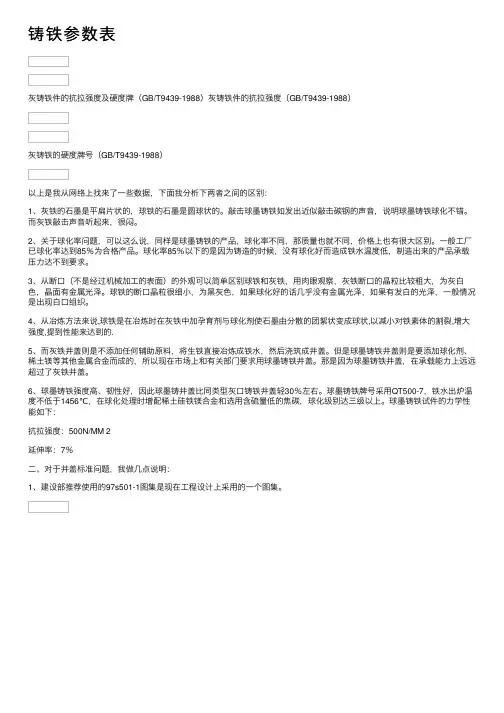

铸铁参数表灰铸铁件的抗拉强度及硬度牌(GB/T9439-1988)灰铸铁件的抗拉强度(GB/T9439-1988)灰铸铁的硬度牌号(GB/T9439-1988)以上是我从⽹络上找来了⼀些数据,下⾯我分析下两者之间的区别:1、灰铁的⽯墨是平扁⽚状的,球铁的⽯墨是圆球状的。

敲击球墨铸铁如发出近似敲击碳钢的声⾳,说明球墨铸铁球化不错。

⽽灰铁敲击声⾳听起来,很闷。

2、关于球化率问题,可以这么说,同样是球墨铸铁的产品,球化率不同,那质量也就不同,价格上也有很⼤区别。

⼀般⼯⼚已球化率达到85%为合格产品。

球化率85%以下的是因为铸造的时候,没有球化好⽽造成铁⽔温度低,制造出来的产品承载压⼒达不到要求。

3、从断⼝(不是经过机械加⼯的表⾯)的外观可以简单区别球铁和灰铁,⽤⾁眼观察,灰铁断⼝的晶粒⽐较粗⼤,为灰⽩⾊,晶⾯有⾦属光泽。

球铁的断⼝晶粒很细⼩,为⿊灰⾊,如果球化好的话⼏乎没有⾦属光泽,如果有发⽩的光泽,⼀般情况是出现⽩⼝组织。

4、从冶炼⽅法来说,球铁是在冶炼时在灰铁中加孕育剂与球化剂使⽯墨由分散的团絮状变成球状,以减⼩对铁素体的割裂,增⼤强度,提到性能来达到的.5、⽽灰铁井盖则是不添加任何辅助原料,将⽣铁直接冶炼成铁⽔,然后浇筑成井盖。

但是球墨铸铁井盖则是要添加球化剂、稀⼟镁等其他⾦属合⾦⽽成的,所以现在市场上和有关部门要求⽤球墨铸铁井盖。

那是因为球墨铸铁井盖,在承载能⼒上远远超过了灰铁井盖。

6、球墨铸铁强度⾼、韧性好,因此球墨铸井盖⽐同类型灰⼝铸铁井盖轻30%左右。

球墨铸铁牌号采⽤QT500-7,铁⽔出炉温度不低于1456℃,在球化处理时增配稀⼟硅铁镁合⾦和选⽤含硫量低的焦碳,球化级别达三级以上。

球墨铸铁试件的⼒学性能如下:抗拉强度:500N/MM 2延伸率:7%⼆、对于井盖标准问题,我做⼏点说明:1、建设部推荐使⽤的97s501-1图集是现在⼯程设计上采⽤的⼀个图集。

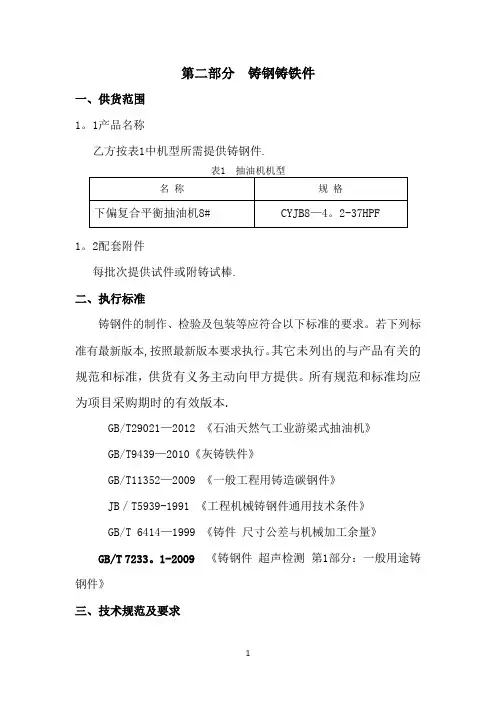

第二部分铸钢铸铁件一、供货范围1。

1产品名称乙方按表1中机型所需提供铸钢件.1。

2配套附件每批次提供试件或附铸试棒.二、执行标准铸钢件的制作、检验及包装等应符合以下标准的要求。

若下列标准有最新版本,按照最新版本要求执行。

其它未列出的与产品有关的规范和标准,供货有义务主动向甲方提供。

所有规范和标准均应为项目采购期时的有效版本.GB/T29021—2012 《石油天然气工业游梁式抽油机》GB/T9439—2010《灰铸铁件》GB/T11352—2009 《一般工程用铸造碳钢件》JB/T5939-1991 《工程机械铸钢件通用技术条件》GB/T 6414—1999 《铸件尺寸公差与机械加工余量》GB/T 7233。

1-2009 《铸钢件超声检测第1部分:一般用途铸钢件》三、技术规范及要求3。

1 抽油机配件的加工必须按照甲方提供的图纸要求进行加工制造,其中包括:设计尺寸及公差、材料规格及成份、加工的技术条件要求等。

所有组合件的焊接方式必须是手工焊接,焊缝高度执行图纸要求。

3.2材料配件材料按照图纸上标注的材质采购。

各项指标必须达到国家标准。

3.2.1牌号和化学成分铸钢件牌号和化学成分应符合表2规定。

表2 铸钢件化学成分注:①对上限减少0.01%的碳,允许增加0.04%的锰,最高至1.20%;②残余元素总量不超过1.00%。

如需方无要求,残余元素可不进行分析。

表3 灰铸铁件化学成分注:①试棒为单铸的铸钢件应从单铸试棒和本体分别取样进行金相组织分析对比,验证两者热处理状态是否一致。

3.2。

2 机械性能铸钢件的机械性能应符合表4的规定.表4 铸钢件机械性能表5 铸铁件机械性能3.3 铸件几何形状、尺寸及尺寸公差3.3。

1 铸件几何形状、尺寸、尺寸公差等级及公差,应符合由需方提供的相应图样中规定的要求.3.3。

2 如果由需方提供的图样中未注明铸件的尺寸公差及公差等级,均按照标准JB/T5939—1991《工程机械铸钢件通用技术条件》中规定CT12—CT13级尺寸公差等级执行。