机壳类2D图纸标注参考规范模板PPT课件

- 格式:ppt

- 大小:881.00 KB

- 文档页数:46

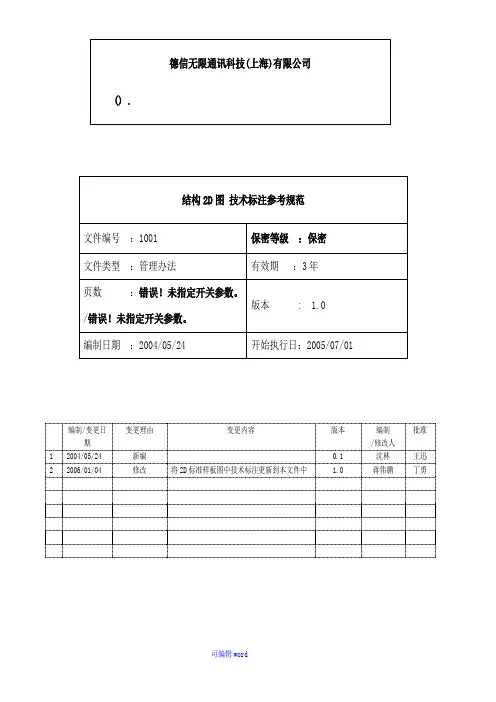

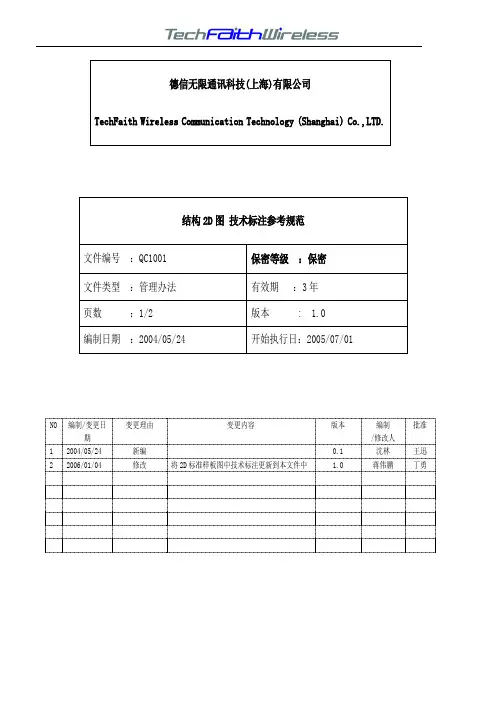

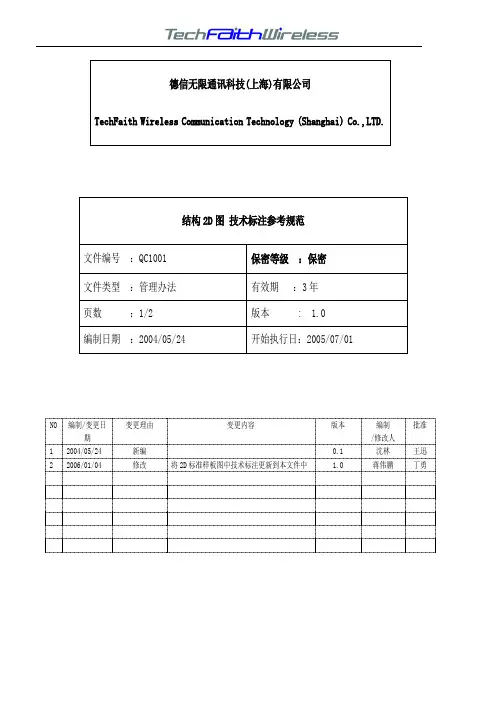

编制/变更日期变更理由变更内容版本编制/修改人批准1 2004/05/24 新编0.1 沈林王迅2 2006/01/04 修改将2D标准样板图中技术标注更新到本文件中 1.0 蒋伟鹏丁勇目录索引01.02.03.103.204.05.1 (注塑)05.2 ()06.106.207.107.207.308.09.10.11.12.1 金属装饰件12.212.312.413.1 双面胶13.2 泡棉13.3 铜箔13.4 绝缘片14.114.214.3 电镀键帽14.4 数字键15.1 外观漆喷漆图15.2 导电漆喷漆图16.17.18.01.技术要求():1. 材料: 500, 用100%原材料;: 500 100% .2. 尺寸: 图面尺寸用于检验零件外形、功能和装配;未注圆角R0.05,未注脱模斜度1度,未注尺寸依照 3D ;标有环形圈:每批次出货均需检查;时需要做;: , ;: R0.05; : 1;3D ;, , .3. 公差:未注公差依照图面公差表;: ;4. 外观:成品清洁、无杂质、无划伤、缩水及其它瑕疵;飞边及分型线段差≤0.03;顶杆痕≤0.05;浇口凸出≤0.10;穴号应刻在模具上,标志不得高于表面;外观皮纹: 24;: , , ;0.03; 0.05; 0.10;. 24.5. 检测须满足德信质量标准:《部品检验标准_注塑件》:《部品检验标准_注塑件》02.1. 材料:见图,用100%原材料;1: , 100% .2.尺寸:图面尺寸用于检验零件外形、功能和装配;未注圆角R0.05,未注脱模斜度1度,未注尺寸依照 3D ;标有环形圈的是重点尺寸,每批次出货均需检查时需要做;2: , ;返回索引目录 : R0.05; : 1°; 3D ;, , .3.公差:未注公差依照图面公差表;3. : ;4.外观: 成品清洁、无杂质、无划伤、缩水及其它瑕疵;飞边及分型线段差≤0.03,顶杆痕≤0.05;浇口凸出≤0.05;穴号应刻在模具上,标志不得高于表面;外观皮纹:抛光4: , , ;0.03, 0.05, 0.05 . . 5.电气性能依照规格书:1 05-02-18。

NO 编制/变更日期变更理由变更内容版本编制/修改人批准1 2004/05/24 新编0.1 沈林王迅2 2006/01/04 修改将2D标准样板图中技术标注更新到本文件中 1.0 蒋伟鹏丁勇目录索引01. Latch02. Antenna03.1 PCBA limited drawing03.2 PCBA outline drawing04. Battery05.1 Lens(注塑)05.2 Lens(CNC)06.1 Audio cover06.2 RF_switch_cover07.1 Shielding cover07.2 Shielding frame07.3 Spring08. Metal dome09. Stop TPU10. Light guide11. Fpcba12.1 金属装饰件12.2 Logo12.3 Plating plastic12.4 Electroform13.1 双面胶13.2 泡棉13.3 铜箔13.4 绝缘片14.1 Keypad asm14.2 keypad rubber14.3 Keypad 电镀键帽14.4 Keypad 数字键15.1 外观漆喷漆图15.2 导电漆喷漆图16. Housing part drawing17. Housing Assembly18. Explode01. Latch技术要求(Notes):1. 材料:POM Dupont500, 用100%原材料;Material: POM Dupont500,use 100% raw material .2. 尺寸: 图面尺寸用于检验零件外形、功能和装配;未注圆角R0.05,未注脱模斜度1度,未注尺寸依照Pro/e 3D Data;标有环形圈:每批次出货均需检查;Qualify时需要做CP/CPK;Dimension: Specified dimensions in the drawing are used to check outside shape, function and assembly;Unspecified round: R0.05mm; Unspecified draft angle: 1%%d;Unspecified dimensions refer to Pro/e 3D model data;Specified dimensions with marked ring are critical dimensions, need to be checked every shipment, and must do CP/CPK check in the Qualification stage.3. 公差:未注公差依照图面公差表;Tolerance: Unspecified tolerance should comply with tolerance table in the drawing; 4. 外观:成品清洁、无杂质、无划伤、缩水及其它瑕疵;飞边及分型线段差≤0.03mm;顶杆痕≤0.05mm;浇口凸出≤0.10mm;穴号应刻在模具上,标志不得高于表面;外观皮纹:VDI 24;Appearance:Product should be tidy and purity, no nick, no shrinkage and other blemish; Galling should be less than 0.03mm;Ejector rod mark should be less than 0.05mm; gate trim should be less than 0.10mm;Cavity number shall be located low on the surface. Appearance require:VDI 24.5. 检测须满足德信质量标准:《部品检验标准_注塑件_x.x_xxxxxx》Product should be satisfied with quality standard of Techfaith Wireless:《部品检验标准_注塑件_x.x_xxxxxx》02. Antenna1. 材料:见图,用100%原材料;1.Material: Refer to the drawing table, in original color and with 100% raw material.2.尺寸:图面尺寸用于检验零件外形、功能和装配;未注圆角R0.05,未注脱模斜度1度,未注尺寸依照Pro/e 3D Data;标有环形圈的是重点尺寸,每批次出货均需检查,Qualify时需要做CP/CPK;2.Dimension: Specified dimensions in the drawing are used to check outside shape, function and assembly;返回索引目录Unspecified round: R0.05mm; Unspecified draft angle: 1°; Unspecified dimensions refer to Pro/e 3D model data;Specified dimensions with marked ring are critical dimensions, need to be checked every shipment, and must do CP/CPK check in the Qualification stage.3.公差:未注公差依照图面公差表;3. Tolerance: Unspecified tolerance should comply with tolerance table in the drawing;4.外观: 成品清洁、无杂质、无划伤、缩水及其它瑕疵;飞边及分型线段差≤0.03mm,顶杆痕≤0.05mm;浇口凸出≤0.05mm;穴号应刻在模具上,标志不得高于表面;外观皮纹:抛光4.Appearance:Product should be tidy and purity, no nick, no shrinkage and other blemish;Galling shall be less than 0.03mm, ejector rod mark shall be less than 0.05mm, gate trim shall be less than 0.05mm.Cavity number shall be located low on the surface. Surface shall be smooth.5.电气性能依照规格书:violet1-Antenna SPEA-05-02-18.pdf。

NO 编制/变更日期变更理由变更内容版本编制/修改人批准1 2004/05/24 新编0.1 沈林王迅2 2006/01/04 修改将2D标准样板图中技术标注更新到本文件中 1.0 蒋伟鹏丁勇目录索引01. Latch02. Antenna03.1 PCBA limited drawing03.2 PCBA outline drawing04. Battery05.1 Lens(注塑)05.2 Lens(CNC)06.1 Audio cover06.2 RF_switch_cover07.1 Shielding cover07.2 Shielding frame07.3 Spring08. Metal dome09. Stop TPU10. Light guide11. Fpcba12.1 金属装饰件12.2 Logo12.3 Plating plastic12.4 Electroform13.1 双面胶13.2 泡棉13.3 铜箔13.4 绝缘片14.1 Keypad asm14.2 keypad rubber14.3 Keypad 电镀键帽14.4 Keypad 数字键15.1 外观漆喷漆图15.2 导电漆喷漆图16. Housing part drawing17. Housing Assembly18. Explode01. Latch技术要求(Notes):1. 材料:POM Dupont500, 用100%原材料;Material: POM Dupont500,use 100% raw material .2. 尺寸: 图面尺寸用于检验零件外形、功能和装配;未注圆角R0.05,未注脱模斜度1度,未注尺寸依照Pro/e 3D Data;标有环形圈:每批次出货均需检查;Qualify时需要做CP/CPK;Dimension: Specified dimensions in the drawing are used to check outside shape, function and assembly;Unspecified round: R0.05mm; Unspecified draft angle: 1%%d;Unspecified dimensions refer to Pro/e 3D model data;Specified dimensions with marked ring are critical dimensions, need to be checked every shipment, and must do CP/CPK check in the Qualification stage.3. 公差:未注公差依照图面公差表;Tolerance: Unspecified tolerance should comply with tolerance table in the drawing; 4. 外观:成品清洁、无杂质、无划伤、缩水及其它瑕疵;飞边及分型线段差≤0.03mm;顶杆痕≤0.05mm;浇口凸出≤0.10mm;穴号应刻在模具上,标志不得高于表面;外观皮纹:VDI 24;Appearance:Product should be tidy and purity, no nick, no shrinkage and other blemish; Galling should be less than 0.03mm;Ejector rod mark should be less than 0.05mm; gate trim should be less than 0.10mm;Cavity number shall be located low on the surface. Appearance require:VDI 24.5. 检测须满足德信质量标准:《部品检验标准_注塑件_x.x_xxxxxx》Product should be satisfied with quality standard of Techfaith Wireless:《部品检验标准_注塑件_x.x_xxxxxx》02. Antenna1. 材料:见图,用100%原材料;1.Material: Refer to the drawing table, in original color and with 100% raw material.2.尺寸:图面尺寸用于检验零件外形、功能和装配;未注圆角R0.05,未注脱模斜度1度,未注尺寸依照Pro/e 3D Data;标有环形圈的是重点尺寸,每批次出货均需检查,Qualify时需要做CP/CPK;2.Dimension: Specified dimensions in the drawing are used to check outside shape, function and assembly;返回索引目录Unspecified round: R0.05mm; Unspecified draft angle: 1°; Unspecified dimensions refer to Pro/e 3D model data;Specified dimensions with marked ring are critical dimensions, need to be checked every shipment, and must do CP/CPK check in the Qualification stage.3.公差:未注公差依照图面公差表;3. Tolerance: Unspecified tolerance should comply with tolerance table in the drawing;4.外观: 成品清洁、无杂质、无划伤、缩水及其它瑕疵;飞边及分型线段差≤0.03mm,顶杆痕≤0.05mm;浇口凸出≤0.05mm;穴号应刻在模具上,标志不得高于表面;外观皮纹:抛光4.Appearance:Product should be tidy and purity, no nick, no shrinkage and other blemish;Galling shall be less than 0.03mm, ejector rod mark shall be less than 0.05mm, gate trim shall be less than 0.05mm.Cavity number shall be located low on the surface. Surface shall be smooth.5.电气性能依照规格书:violet1-Antenna SPEA-05-02-18.pdf。