JCB推出新型Loadall系列叉装机

- 格式:pdf

- 大小:63.70 KB

- 文档页数:1

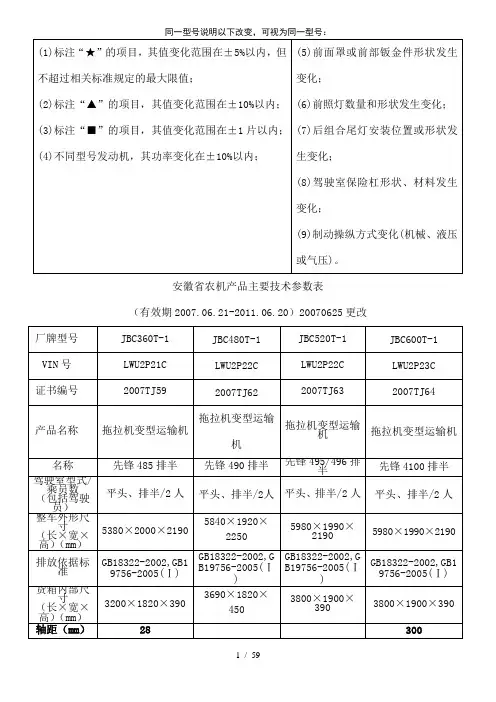

第7期 I…B Vozquezl et a1.压力拉丝模的设计 443 表3 采用传统拉丝模和压力拉丝模时 电机的温度 ℃

道次 压力拉丝模 传统拉丝模 差值

模相比,全部采用压力拉丝模,磷酸盐涂层及润滑 剂总残留物的量和钢丝产量相差不大,生产效率 略有下降。

(3)使用Hspeed 20型拉丝机,采用3道传统 拉丝模和6道压力拉丝模,润滑模和拉拔模的角 度均为10。,且润滑模直径与入口钢丝直径比为 30 时,磷酸盐涂层及润滑剂总残留物的量和钢 丝产量最大,生产效率最高。 (4)试验及实际生产表明,采用传统拉丝模和 压力拉丝模组合的拉拔工艺生产的高碳钢丝性能 优异。在高速拉拔过程中,适当的润滑很重要,可 以防止钢丝温度过高,避免钢丝因应变失效而脆 断,确保钢丝的物理性能持续满足要求。 (江苏兴达钢帘线股份有限公司 刘湘慧摘译) 译自美国“Wire Journal International”, 39厂10],82~84(2006)

北院将形成从小型到巨型全钢工程机械 子午线轮胎的全套生产技术 中图分类号:TQ336.1 文献标识码:D 北京橡胶工业研究设计院(以下简称北院)独 立研发、具有完全自主知识产权的全钢工程机械 子午线轮胎生产技术在山东万达宝通轮胎公司实 施后,目前顺利完成了第二期产品的试制。 该项目从2006年5月开始开发了23.5R25 和20.5R25两个规格的产品,并投放南非、澳大 利亚和加拿大等市场,用户反映良好。目前开发 的产品覆盖了l6.00R25,18.00R25,17.5R25, 26.5R25,29.5R25,29.5R29,18.00R33 和 24.00R35等系列规格,最高行驶速度达到70 km・h。为使产品能够满足各种使用条件的要 求,还开发了适应恶劣作业环境的抗刺扎、耐磨耗 胎面胶配方以及适应良好路面的高速胎面胶配 方,同时针对不同路面开发了9种花纹形式,其中 深花纹深度达到95 mm。 北院转让的巨型全钢工程机械子午线轮胎生 产技术即将在福建省海安橡胶有限公司完成产品 试制,轮胎规格从27.00R49到40.00R57。届 时,北院将形成从小型到巨型全钢工程机械子午 线轮胎的全套生产技术。 (北京橡胶工业研究设计院 樊文茹 阙元元) 东洋推出新规格轮胎产品 中图分类号:F27;TQ336.1 1 文献标识码:D 美国《现代轮胎经销商》(www.moderntire dealer.com)2008年5月2日报道: 东洋轮胎美国公司宣布将推出.41款新规格 轮胎产品,其中包括Proxes RIR,Proxes 4,Prox— e8 T1R,Versado LX和其它系列产品。 Proxes R1R推出9款新规格。Proxes 4推 出1款新规格(275/25R28)。 Proxes TIR推出4款新规格:235/45ZR18, 255/30ZR20,275/35R20和265/3ozR22。 全天候的Versado LX推出3款新规格: 235/55R17,225/45R17和245/45R17。 东洋轮胎公司还推出不同种类的轻型载重/ SUV新规格轮胎产品,其中包括Proxes S/T,Open Country H/T和Open Country A/T系列产品。 (双钱集团股份有限公司 上海轮胎研究所 苏 博摘译)

ZW-6series311 hp232 kWEngine Output, Max, Gross (ISO 14396)Tier 4 Final Certified58,158 lbs26,380 kgOperating weight302 hp225 kWEngine Output, Max, Net (ISO 9249)6.3 yd³ 4.8 m³Bucket capacityZW330‑6ZW330‑6NO COMPROMISEExceptionally durable and reliable, theZW330‑6 is ideal for working in toughconditions. Designed and built usingpioneering technology, it incorporates high‑quality and robust components that canwithstand the challenges of busy job sites.Thanks to low levels of fuel consumptionand greater traction force, the new ZW‑6wheel loader can deliver high levels ofperformance without compromising onefficiency.6. COMPLETE RELIABILITY8. BUILT FOR DURABILITY4. DEMAND PERFECTION10. OUTSTANDING VERSATILITY212. THE HIGHEST QUALITY14. DRIVEN BY TECHNOLOGY4DEMAND PERFECTIONHitachi has developed the ZW330‑6 to perfection, using unique technology and a focus on durability, operator comfort and safety. Robust materials and strengthened components ensure a reliable performance. It is designed and built todeliver exceptional productivity at the lowest possible cost of ownership.Superior comfortSpacious cab with several storage compartments.Smooth operationRide control minimizes machine pitching.Easy to operateMultifunctional monitor shows information at a glance.Industry-leading safety360° visibility from the cab.Easy loading operation26% improved traction force for easier loading.Powerful performanceQuick power switch increases engine output when required.ZW330‑65Convenient accessEasy-to-open wide engine covers.Low emissionsSCR system without DPF reduces NO x from exhaust gas.Reduced running costs7% fuel saving in V-shaped loading.User-friendlyEffortless control with E-Stick Steering.Improved fuel efficiencyLock-up transmission and Tier 4 Final compliant engine.Excellent visibilityLED rearconventional lights.Enhanced designExcellent rear view thanks to the curved engine hood.6ZW330‑6COMPLETE RELIABILITYBuilt using decades of experience in manufacturing reliable construction machinery, the ZW330‑6 has been developed by Hitachi to perform efficiently. Its designincludes several easy maintenance features to ensure minimal downtime and high levels of accessibility.Easy access to the engine compartment.Quick accessThe engine covers open fully for the convenience of technical support. The urea tank is also located for safe and easy access from ground level. These help to ensure routine maintenance is completed quickly to ensure a reliable performance.Improved fuel efficiencyThe lock‑up transmission has improved the fuel efficiency of the ZW330‑6 while travelling, which reduces running costs.Easy maintenanceFor safer and easier maintenance, the battery disconnect switch is standard. This helps to avoid electrical accidentsand retain battery energy during long‑term storage.Reduced costsThe new Tier 4 Final certified engine does not require a diesel particulate filter, which further reduces fuel consumption and maintenance costs.Reliable performanceThe lift arm contributes to the reliable performance of the ZW330‑6. Its speed has been improved and it stops smoothly thanks to the flow control system forincreased productivity. It is easy to control using the auto leveller.The battery is easy to maintain.New engine reduces fuel consumption.Machine representative of global product.Options may not be available in all markets.7New rear grille protects radiator compartment.Durable radiators are corrosion resistant.ZW330‑6Hitachi wheel loadersare tested extensivelyin job site conditionsaround the world, inextreme temperatures.BUILT FORDURABILITYUltimate durability is required from Hitachi ZW‑6 wheel loaders. The ZW330‑6 is equipped with reinforced parts, strengthened components and robust features to ensure it meets the needs of customers working in demanding conditions. It hasbeen designed and engineered to withstand the toughest environments.Increased protectionThe newly designed rear grille prevents raw material from the job site enteringthe radiator compartment. This provides greater protection for this durable component.Durable materialsHigh‑quality radiators improve resistance to corrosion and enhance the overall durability of the ZW330‑6 wheel loader.Robust designThe lift arm, front and rear frame of the ZW330‑6 have been designed to be able to handle the rigours of heavy applications. Efficient coolingThe reversible cooling fan, activated manually or automatically every 30 minutes, ensures that the radiator stays clean during operation.9ZW330‑6Enhanced rear visibilityThe muffler and air intake have been moved further away from the cab to improve visibility through the rear window. Greater traction forceThe traction force has improved by 26% compared to the previous model. The result is a more efficient loading operation. Efficient flexibilityThe quick power switch increases engine output when more power is instantly required, or when driving uphill.Effective controlTo ensure a smooth drive on all kinds of terrain, the ride control feature prevents unnecessary pitching via the movement of lift arm cylinders.High productivityThe simultaneous movement of the bucket and lift arm ensures a smooth digging operation. The Hitachi flow control system ensures smooth lift arm starts and stops.OUTSTANDINGVERSATILITYThe versatility of the ZW330‑6 is enhanced by its smooth operation anduser‑friendly features. It demonstrates speed and precision on a wide rangeof applications, and the all‑around visibility from the cab ensures industry‑leading safety for a variety of busy job sites.Rear visibility has been enhanced by10The ride control feature ensures a smoothperformance.11The standard LED work lights enhancevisibility in low light conditions.12ZW330‑6 Reduced emissionsA selective catalytic reduction (SCR) system injects urea into exhaust gas to reduce nitrous oxide from emissions. This cutting‑edge technology not only helps the environment, but also complies with Tier 4 Final emission regulations. Increased safetyTo enhance visibility in low light conditions, the ZW330‑6 is fitted with LED tail lights and standard LED work lights at the front and rear.Excellent visibilityThe 360° panoramic view of the spacious cab creates a comfortable working environment, and helps to increase safety and productivity. The rear‑view camera,in combination with the unique two‑piece counterweight, also contributes to excellent all‑round visibility and safety on the job site. Low-noise performanceTo significantly reduce noise levels in the cab, sound insulation has been improved. As a result of this and the low‑noise engine, operators can enjoy a quieter working environment.User-friendly operationThe E‑Stick Steering enables operatorsto reach high levels of productivity with effortless steering, and incorporates a number of useful functions.The final pre‑deliveryinspection procedure foreach Hitachi wheel loader istypical of Hitachi’s dedicationto manufacturing products ofunfailing quality in responseto customer needs.THE HIGHESTQUALITYThe inherent quality of a Hitachi ZW‑6 wheel loader is one of the reasons why it remainsat the forefront of the industry in terms of comfort and safety. With first‑rate designelements and superior components, it also offers exceptional visibility from the cab anda low‑noise performance that ensures it’s one of the quietest on the market.The E‑Stick Steering providesexceptional control.1314ZW330‑6Reduced maintenanceA new Tier 4 Final certified engine contains a high‑volume cooled exhaust gas recirculation (EGR) system, a common rail‑type fuel injection system and a diesel oxidation catalyst (DOC) without DPF . This helps to reduce fuel costs and maintenance requirements.Fewer emissionsThe after‑treatment device consists of a diesel oxidation catalyst (DOC), urea mixing pipe, SCR system and silencer. This advanced technology is designed to reduce emissions as well as noise levels.Optimum performanceHitachi ZW‑6 wheel loaders are fitted with a multifunctional LCD color monitor that shows useful information at a glance, such as fuel and urea levels, oil temperature and power modes. It ensures an optimum performance and easy maintenance. It also includes the display for the easy‑to‑use rear‑view camera, which enhances visibility for safe operation.Smaller environmental impactThe standard auto idle shutdown feature helps to prevent fuel waste, as well asreduce noise levels, exhaust emissions and NOx levels of the ZW330‑6 wheel loader.Remote monitoringGlobal e‑Service allows ZW330‑6 owners to monitor their Hitachi machines remotely via Owner’s Site (24/7 online access) and ConSite (an automatic monthlyreport). These help to maximize efficiency, minimize downtime and improve overall performance.Unique technology is at the heart of the design of Hitachi ZW‑6 wheel loaders. As a result, they are state‑of‑the‑art machines that incorporate the most advanced features and components. They are engineered to satisfy the demands of American or North American construction industry for equipment that not only offers high productivity, but also the lowest possible cost of ownership.DRIVEN BY TECHNOLOGYCovers open fully to give easy access for maintenance.Remote monitoring with Globale‑Service helps to maximize efficiency.The LCD monitor shows the machine’sstatus and settings.15ZW330‑6 Global e-ServiceHitachi has developed two remote monitoring systems as part of its Global e‑Service online application. Owner’s Site and ConSite are an integral part of the wheel loader, which sends operational data daily via GMS to . This allows immediate access to the Owner’s Site,and the vital information that is requiredfor support on job sites.Comparing the ratio of operating and non‑operating hours helps to enhance efficiency. Effective management of maintenance programs helps to maximize availability. Running costs can also be managed byanalyzing the fuel consumption. The locationand movements of each machine are clearlydisplayed for essential planning.An automatic service report — ConSite —sends a monthly email summarizing theinformation from Global e‑Service for eachmachine. This includes: daily working hoursand fuel consumption data; statistics on theoperating mode ratio, plus a comparisonfor fuel consumption/efficiency, and CO2emissions.Technical supportEach Hitachi service technician receives fulltechnical training from Hitachi ConstructionMachinery Loaders America Inc. (HCMA)in the USA. These sessions provideaccess to the same technical knowledgeavailable within the Hitachi qualityassurance departments and design centers.Technicians combine this global expertisewith the local language and culture of thecustomer to provide the highest level ofafter‑sales support.REDUCING THE TOTAL COST OF OWNERSHIPHitachi has created the Support Chain after‑sales program toensure optimum efficiency, as well as minimal downtime, reduced running costs and high resale values.16Extended warranty and service contractsEvery new Hitachi ZW‑6 model is covered by a full manufacturer’s warranty. Forextra protection – due to severe working conditions or to minimize equipment repair costs – Hitachi dealers offer a unique extended warranty called HELP (Hitachi Extended Life Program) and comprehensive service contracts. These can help to optimize the performance of each machine, reduce downtime and ensure higher resale values.PartsHitachi offers a wide range and a highavailability of parts provided by HCMA’s USparts warehouse.• H itachi Genuine Parts: allow machinesto work longer, with lower runningand maintenance costs.• H itachi Select Parts and Genuine Parts:are of proven quality and come with themanufacturer’s warranty.• P erformance Parts: to cope with highlydemanding conditions, they have beenengineered for greater durability, betterperformance or longer life.• Genuine Hitachi rebuilt components areavailable from HCMA’s in‑house rebuildcenter and are offered with a standardwarranty.Whatever the choice, the renownedquality of Hitachi construction machineryis assured.Global e‑Service Technical support Hitachi Parts17Hitachi Construction MachineryBUILDING ABETTER FUTUREHitachi Construction Machinery Co., Ltd. (HCM) was founded in 1970 as as ubsidiary of Hitachi, Ltd. and has become one of the world’s largest construction equipment suppliers.Incorporating advanced technology, Hitachi construction machinery has a reputation for the highest quality standards. Suitable for a wide range of industries, it is always hard at work around the world – helpingto c reate infrastructure for a safe and comfortable way of living, developing natural resources and supporting disaster relief efforts.Hitachi ZW wheel loaders are renowned for being reliable, durable and versatile – c apable of delivering the highest levels of productivity under the most challenging of conditions. They are designed to provide owners with a reduced total cost of ownership, and operators with the ultimate level of comfort and safety.Established in 1910, Hitachi, Ltd. was built upon a founding philosophy of making a positivecontribution to society through technology. This is still the inspiration behind the Hitachi group’sreliable solutions that answer today’s challenges and help to create a better world.Hitachi, Ltd. is now one of the world’s largest corporations, with a vast range of innovative productsand services. These have been created to challenge convention, improve social infrastructure and contribute to a sustainable society.1920* Measured in accordance with SAE J732CModel Name: ZW330-6, EPA Tier 4 Final/EU Stage IV CertifiedTORQUE CONVERTER AND TRANSMISSIONAXLE SYSTEMBRAKE SYSTEMRemarks• M aterials and specifications are subject to change without notice and without any obligation on the part of the manufacturer.• T his information, while believed to be completely reliable, is not to be taken as warranty for which we assume legal responsibility.• D umping clearance and reach are measured from bucket edge in accordance with SAE J732C.• C ounterweight should not be used with tire ballast.• T his specification sheet may contain attachments and optional equipment not available in your area.Please contact your local HCMA dealer for additional information.SPECIFICATIONSNote: All dimensions, weight and performance data based on ISO 6746‑1:1987,ISO 7131:2009 and ISO 7546:1983*: Static tipping load and operating weight marked with* include 26.5 R25 (L‑3) tires (No ballast) with lubricants, full fuel tank and operator.Machine stability and operating weight depend on counterweight, tire size and other attachments.2122Standard and optional equipment may vary by country, so please consult your Hitachi dealer for details.115%100%95%%=Bucket Fill Factor lb / yd 3 (kg / m³)Material Densityyd 3 (m³)General purpose 6.3 (4.8)Light material6.8 (5.2)(1,100)(1,200)(1,300)(1 400)(1,500)(1,600)(1,700)(1,800)(1,900)(2,000)(2,100)SPECIFICATIONSBucket positioner (horizontal)Control lever, dual, pilot-assistedControl lever lock (electric)Control valve, 2-function, parallel and tandem control E‑stick steeringPump, variable displacement, load-sensingRide control w/load sensing valve and automatic shut-offSteering, pilotSystem; open-center, high-pressure, load-sensing Valve, anti-driftBelly guard, transmission (rear)CounterweightDrawbarFenders, front, w/mudflapGlobal e‑service, telematic monitoring systemLadders, inclinedLifting eyesLinkage pins, HN bushingNeutral safety startRear grill, hingedSteps, rearZ‑bar loader linkageALARMS, GAUGES, INDICATORSAlarms(visual &audible)Aftertreatment deviceAir cleaner elementAxle oil temperatureBattery discharge warningBrake oil low pressureCAN network systemDEF/AdBlue tank level/quality/systemEngine coolant tempEngine oil low pressureEngine troubleEngine warningFuel filter (water in fuel)Hydraulic oil levelHydraulic oil temperatureMain pump oil pressureTransmission oil tempTransmission warningGauges DEF/AdBlue tank levelEngine coolant temperatureFuel gaugeSpeedometerTachometerTransmission oil temperatureIndicators Aftertreatment deviceAir conditioner displayBoom kick‑out, dualCold startControl lever lockDeclutchECO‑Operating StatusFan reverse rotationF‑N‑R SelectionF‑N‑R Switch enableHigh beamParking brakeShift holdTime/Operating hour/ODOTransmission mode and statusTurn signal w/4‑way flashers/MarkerWork lightWork mode (Normal, Power)OPTIONAL EQUIPMENTHigh mount in‑cab monitorLoadrite scaleSatellite Telematic monitoringSingle lever hydraulic control w/multifunction gripEQUIPMENT DATA23。

在本使用手册中,我们将尽力叙述各种与该数控系统操作相关的事项。

限于篇幅限制及产品具体使用等原因,不可能对数控系统中所有不必做或不能做的操作进行详细的叙述。

因此,本使用手册中没有特别指明的事项均视为“不可能”或“不允许”进行的操作。

本使用手册的版权,归广州数控设备有限公司所有,任何单位与个人进行出版或复印均属于非法行为,广州数控设备有限公司将保留追究其法律责任的权利。

IGSK25iMc/GSK25iTc 系列总线式铣削/车削中心数控系统安装调试手册II前言尊敬的客户对您惠顾选用广州数控设备有限公司全新开发及设计制造的GSK 25iMc/GSK25iTc 系列总线式铣削/车削中心数控系统,我们深感荣幸并深表感谢。

本手册详细介绍了GSK 25iMc/GSK25iTc 系列总线式铣削/车削中心数控系统的连接调试等有关事项。

操作不当将引起意外事故,必须要具有相应资格的人员才能操作本系统。

操作之前请务必仔细阅读本使用手册!特别提示:安装在机箱上(内)的系统电源,是仅为本公司制造的数控系统提供的专用电源。

禁止用户将这个电源作其他用途使用。

否则,将产生极大的危险!前言、安全及注意事项安全警告在对本产品进行安装连接、编程和操作等之前,必须详细阅读本产品使用手册及机床制造厂的使用说明书,严格按手册与机床使用说明书等的要求进行相关的操作。

本手册包含保护用户和防止机床损坏的安全预防措施,这些预防措施根据安全性质分为警告和注意,补充的信息作为注释叙述,在操作机床之前请仔细地阅读警告、注意和注释。

警告如果不遵守指定的操作方法或步骤,有可能使用户受伤害或损坏设备。

注意如果不遵守指定的操作方法或步骤,有可能使设备损坏。

注释注释用于指出除警告和注意之外的补充信息。

IIIGSK25iMc/GSK25iTc系列总线式铣削/车削中心数控系统安装调试手册IV声明●本手册尽可能对各种不同的内容进行了说明,但是,由于涉及到的可能性太多,无法将所有可以或不可以进行的操作一一予以说明。

【利器】利勃海尔推全新SX臂杆系统,750吨级起重机秒变千吨级2017年4月21日,利勃海尔开发出一款全新的SX臂杆系统,采用了SX臂杆系统的750吨级LR 1750/2和LG 1750履带起重机适用于最新一代风电机组的安装。

采用SX系统的LR 1750/2和LG 1750履带起重机能够安装轮毂高度165米、部件重量120吨的风电机组。

目前,该级别风电机组只有千吨级及以上吨级起重机才能安装。

目前,全新SX系统已完成测试,并已投放市场。

不同于之前的臂杆系统,全新SX系统采用3.5米宽桁架臂标准节,之前的桁架臂则采用3米宽标准节。

桁架臂标准节宽度加大,进一步提升了臂杆横向稳定性,荷载能力得以进一步提高。

同时,桁架臂标准节重量减轻,主臂加上固定桁架副臂的臂杆总长度可达165米。

起重能力的另一方面提升是通过在SX系统中增添的另一项创新技术实现的:在主臂的最下部区域,不使用3.5米宽的桁架臂标准节,取而代之安装宽度为6米、长度为14米的两节(即SX2系统)或三节(即SX3系统)桁架臂结构,进一步提升了臂杆系统的强度,从而提升荷载能力。

为了实现6米宽桁架臂结构的安装,从3米到6米臂节两端采用了用于转换的臂节拓展适配装置,从6米宽臂节到3.5米宽臂节则通过第二个臂架拓展适配装置连接。

在这款臂杆系统升级时,利勃海尔的设计力求保证系统的经济实用,在SX系统的基础上,起重机操机手只需添置6米宽桁架臂节和适配机构即可实现升级。

另外,开发6米宽桁架臂结构的另一个挑战是如何更加经济地进行公路运输的问题。

利勃海尔开创了解决这个问题的全新方法:宽臂架是由螺栓连接在一起并可以快速拆分的两半网格结构拼装而成。

在运输过程中,每半网格结构可实现如牙齿一样的相互纵向咬合,从而实现了3.5米实际运输宽度。

全新的SX系统能够在LR 1750/2履带起重机和LG 1750移动式起重机之间互换使用。

为了实现SX系统在使用过程中更高的起重能力,利勃海尔还专为提升该系统开发了一款全新的固定副臂。