工业管道sch壁厚等级对照表

- 格式:doc

- 大小:1.58 MB

- 文档页数:54

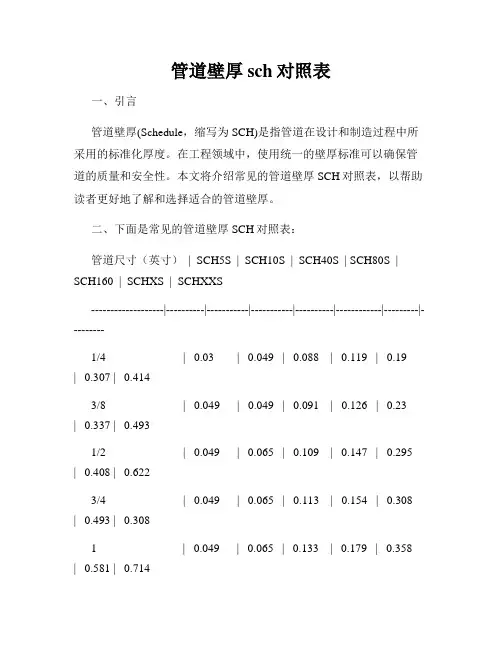

管道壁厚sch对照表一、引言管道壁厚(Schedule,缩写为SCH)是指管道在设计和制造过程中所采用的标准化厚度。

在工程领域中,使用统一的壁厚标准可以确保管道的质量和安全性。

本文将介绍常见的管道壁厚SCH对照表,以帮助读者更好地了解和选择适合的管道壁厚。

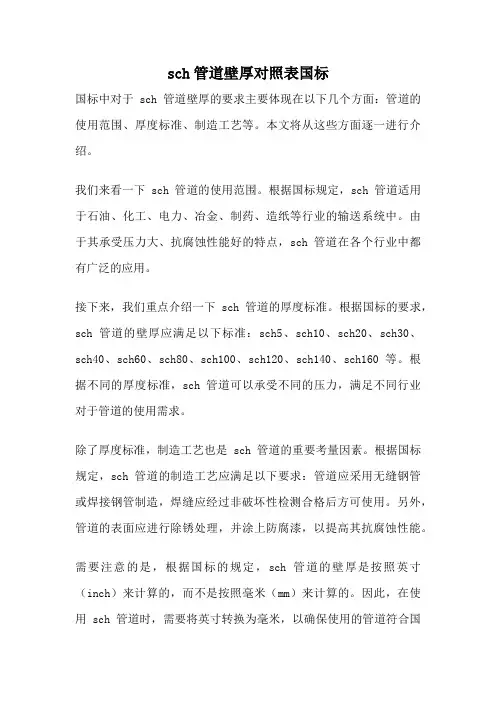

二、下面是常见的管道壁厚SCH对照表:管道尺寸(英寸) | SCH5S | SCH10S | SCH40S | SCH80S | SCH160 | SCHXS | SCHXXS-------------------|----------|-----------|-----------|----------|------------|---------|---------1/4 | 0.03 | 0.049 | 0.088 | 0.119 | 0.19 | 0.307 | 0.4143/8 | 0.049 | 0.049 | 0.091 | 0.126 | 0.23 | 0.337 | 0.4931/2 | 0.049 | 0.065 | 0.109 | 0.147 | 0.295 | 0.408 | 0.6223/4 | 0.049 | 0.065 | 0.113 | 0.154 | 0.308 | 0.493 | 0.3081 | 0.049 | 0.065 | 0.133 | 0.179 | 0.358 | 0.581 | 0.7141 1/4 | 0.049 | 0.065 | 0.14 | 0.191 | 0.382 | 0.61 | 0.8571 1/2 | 0.049 | 0.065 | 0.145 | 0.2 | 0.4 | 0.631 | 1.012 | 0.065 | 0.065 | 0.154 | 0.218 | 0.436 | 0.682 | 1.222 1/2 | 0.083 | 0.083 | 0.203 | 0.276 | 0.552 | 0.815 | 1.943 | 0.083 | 0.083 | 0.216 | 0.3 | 0.6 | 0.908 | 2.53 1/2 | 0.083 | 0.083 | 0.226 | 0.318 | 0.636 | 0.965 | 2.974 | 0.083 | 0.083 | 0.237 | 0.337 | 0.674 | 1.02 | 3.385 | 0.109 | 0.109 | 0.258 | 0.375 | 0.75 | 1.16 | 4.326 | 0.109 | 0.109 | 0.28 | 0.432 | 0.864 | 1.34 | 5.49三、结论通过以上的管道壁厚SCH对照表,我们可以清晰地了解到不同尺寸管道的标准壁厚。

页眉内容页眉内容页眉内容页眉内容页眉内容650 700 750 262830660.4711.2762.0---------------6.4------7.97.97.97.912.712.712.7---15.915.9------9.59.59.59.5---------------------------12.712.712.7------------------------------------------------------800 850 900 323436812.8863.6914.4---------------------------7.97.97.912.712.712.715.915.915.9---------9.59.59.517.517.519.0------------------12.712.712.7---------------承插焊管件(一)Socket Welding FittingsGB/T 14383、SH 3410、HG/T 21634、ASME B16.11、JIS B2316页眉内容页眉内容65 80 100 21/2341616198.910.010.012.513.8------------4157675764------------2932413235------------·本表列出的为承插焊管件各相同部分尺寸,不同标准规定的接管尺寸及承插孔径d1、流通孔径d2尺寸见承插焊管件的接管外径、承插孔径及流通孔尺寸表。

·当产品为异径时,流通孔d2的尺寸用异径公称通径相对的d2尺寸、中心至承插孔底的尺寸A与同径管件相同。

·The above list shows sizes of the same parts of SW fittings.The sizes of different codes pipes,socket diameter d1 and bore diameter d2 refer tothe list of the pipe outside diameter,socket diameter and bore diameter of SW fittings.·As to the reducing fittings,size of the bore diameter d2 applies to the relevant size d2 of the reducing norminal pipe size,size of center to thebottom of socket A issame to the straight fittings,页眉内容承插焊和螺纹活接头Unions of Socket-Welding&ThreadedHG/T 21634、MSS SP-83页眉内容承插焊管件的接管外径、承插孔径及流通孔径尺寸表List of The Pipe Outside Diameter,Socket Diameter and Bore Diameter fo SW Fittings页眉内容页眉内容页眉内容页眉内容页眉内容6000螺纹Threaded --- XXS3000 承插焊Socket-Welding 80 XS6000 承插焊Socket-Welding 160 ---9000 承插焊Socket-Welding --- XXS ·本表并未限制使用较薄或较厚壁厚的管子和管件。

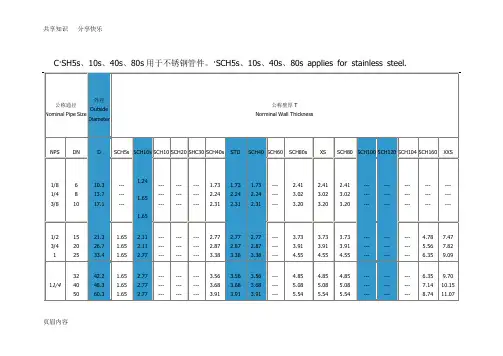

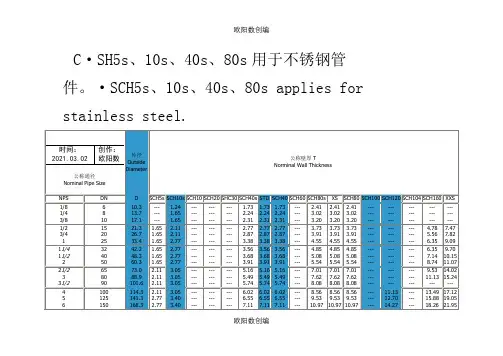

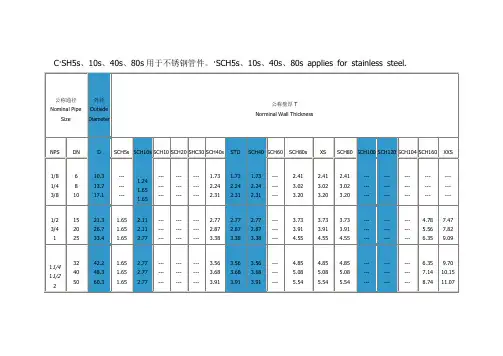

C·SH5s、10s、40s、80s用于不锈钢管件。

·SCH5s、10s、40s、80s applies for欧阳数创编欧阳数创编100125150456114.3139.8165.24.54.55.02.12.82.83.03.43.4---------------------------6.06.67.16.06.67.16.06.67.1---------8.69.511.08.69.511.08.69.511.0---------11.112.714.3---------13.515.918.217.119.021.9 20025030081012216.3267.4318.55.86.66.92.83.44.04.04.04.5---------6.46.46.47.07.88.48.29.39.58.29.39.58.29.310.310.312.714.312.712.712.712.712.712.712.715.117.415.118.321.418.221.425.420.625.428.623.028.633.322.225.425.4 350400450141618355.6406.4457.27.97.97.94.04.24.24.84.84.86.46.46.47.97.97.99.59.511.19.59.59.59.59.59.511.112.714.315.116.719.0---------12.712.712.719.021.423.823.826.229.427.830.934.931.836.539.735.740.545.2--------- 500550600202224508.0558.8609.67.9------4.84.85.55.55.56.46.46.46.49.59.59.512.712.714.39.59.59.59.59.59.515.1---17.520.622.224.6---------12.712.712.726.228.631.032.534.938.938.141.346.044.447.652.450.054.059.5---------650700750262830660.4711.2762.0---------------6.4------7.97.97.97.912.712.712.7---15.915.9------9.59.59.59.5---------------------------12.712.712.7------------------------------------------------------800850900323436812.8863.6914.4---------------------------7.97.97.912.712.712.715.915.915.9---------9.59.59.517.517.519.0------------------12.712.712.7---------------公称通径Nominal PipeSize承插孔深度Depth of Socket壁厚Wall Thickness中心至承插孔底Center to Bottom of SocketA欧阳数创编欧阳数创编公称通径Nominal PipeSize外径End DIA壁厚WallThickness螺母厚度Nut螺帽每英寸的螺纹扣数Threads Perinch球面凸缘厚度MaleFlange定位口高度Bearin公称装配长度Length AssemNominat结构尺寸Laying Length流通孔径Bore D min C minG min H F min h min LE d2DN NPS 承插焊Socket螺纹Thread承插焊Socket螺纹Thread承插焊Socket螺纹Thread6 8 10 1/81/43/821.821.825.914.719.122.93.23.33.52.53.13.23.23.23.51616143.23.23.51.51.51.54141462121247.410.913.915 20 25 1/23/4131.237.145.527.733.541.44.14.35.03.84.04.63.74.14.51411113.74.14.61.51.81.949576224293017.522.228.432 40 50 11/411/2254.961.575.250.657.270.15.35.66.14.95.15.65.25.66.41010105.45.96.62.22.32.771778637383936.542.453.9欧阳数创编欧阳数创编欧阳数创编class designation fo FittingType of Fitting Pipe Used for Ratin Basis管子表号Schedule NO.管壁代号Wall Designation2000 螺纹 Threaded 80 XS3000 螺纹 Threaded 160 ---6000 螺纹 Threaded --- XXS3000 承插焊 Socket-Welding 80 XS6000 承插焊 Socket-Welding 160 ---9000 承插焊 Socket-Welding --- XXS·本表并未限制使用较薄或较厚壁厚的管子和管件。

500 550 600 202224508.0558.8609.67.9------4.84.85.55.55.56.46.46.46.49.59.59.512.712.714.39.59.59.59.59.59.515.1---17.520.622.224.6---------12.712.712.726.228.631.032.534.938.938.141.346.044.447.652.450.054.059.5---------650 700 750 262830660.4711.2762.0---------------6.4------7.97.97.97.912.712.712.7---15.915.9------9.59.59.59.5---------------------------12.712.712.7------------------------------------------------------800850 900 323436812.8863.6914.4---------------------------7.97.97.912.712.712.715.915.915.9---------9.59.59.517.517.519.0------------------12.712.712.7---------------承插焊管件(一)Socket Welding FittingsGB/T 14383、SH 3410、HG/T 21634、ASME B16.11、JIS B2316承插焊和螺纹活接头Unions of Socket-Welding&ThreadedHG/T 21634、MSS SP-83公称通径Nominal Pipe Size外径End DIA壁厚Wall Thickness螺母厚度Nut螺帽每英寸的螺纹扣数Threads Perinch球面凸缘厚度MaleFlange定位口高度Bearin公称装配长度Length AssemNominat结构尺寸LayingLength流通孔径Bore D min C min G min H F min h min L E d2承插焊管件的接管外径、承插孔径及流通孔径尺寸表List of The Pipe Outside Diameter,Socket Diameter and Bore Diameter fo SW Fittings6000 螺纹Threaded --- XXS3000 承插焊Socket-Welding 80 XS6000 承插焊Socket-Welding 160 ---9000 承插焊Socket-Welding --- XXS·本表并未限制使用较薄或较厚壁厚的管子和管件。

sch管道壁厚对照表国标国标中对于sch管道壁厚的要求主要体现在以下几个方面:管道的使用范围、厚度标准、制造工艺等。

本文将从这些方面逐一进行介绍。

我们来看一下sch管道的使用范围。

根据国标规定,sch管道适用于石油、化工、电力、冶金、制药、造纸等行业的输送系统中。

由于其承受压力大、抗腐蚀性能好的特点,sch管道在各个行业中都有广泛的应用。

接下来,我们重点介绍一下sch管道的厚度标准。

根据国标的要求,sch管道的壁厚应满足以下标准:sch5、sch10、sch20、sch30、sch40、sch60、sch80、sch100、sch120、sch140、sch160等。

根据不同的厚度标准,sch管道可以承受不同的压力,满足不同行业对于管道的使用需求。

除了厚度标准,制造工艺也是sch管道的重要考量因素。

根据国标规定,sch管道的制造工艺应满足以下要求:管道应采用无缝钢管或焊接钢管制造,焊缝应经过非破坏性检测合格后方可使用。

另外,管道的表面应进行除锈处理,并涂上防腐漆,以提高其抗腐蚀性能。

需要注意的是,根据国标的规定,sch管道的壁厚是按照英寸(inch)来计算的,而不是按照毫米(mm)来计算的。

因此,在使用sch管道时,需要将英寸转换为毫米,以确保使用的管道符合国标的要求。

总结起来,sch管道壁厚对照表国标规定了管道的使用范围、厚度标准和制造工艺。

在选择和使用sch管道时,需要根据具体的行业需求和国标要求进行选择和验收。

只有满足国标要求的管道才能够确保其使用的安全性和可靠性。

希望通过本文的介绍,读者对于sch管道壁厚的国标规定有了更加清晰的了解。

在实际使用中,我们应严格按照国标要求进行选用和验收,以确保管道的质量和安全。

承插焊管件(一)Socket Welding FittingsGB/T 14383、SH 3410、HG/T 21634、ASME B16.11、JIS B2316公称通径Nominal Pipe Size 承插孔深度Depth ofSocket壁厚Wall Thickness中心至承插孔底Center to Bottom of SocketAC min90°弯头、三通、四通90°Elbow、Tee、Cross45°弯头45°ElbowDN NPS J min SCH803000SCH1606000XXS9000SCH803000SCH1606000XXS9000SCH803000SCH1606000XXS90006 8 10 1/81/43/81010103.23.34.03.54.04.4---------111114111416---------8888811---------15 20 25 1/23/411013134.55.05.66.07.08.09.510.011.516192219222725283211131413141816192132 40 50 11/411/221313166.36.47.08.09.011.012.013.014.027323832384135385418212521252922252865 80 100 21/2341616198.910.010.012.513.8------------4157675764------------2932413235------------·本表列出的为承插焊管件各相同部分尺寸,不同标准规定的接管尺寸及承插孔径d1、流通孔径d2尺寸见承插焊管件的接管外径、承插孔径及流通孔尺寸表。

·当产品为异径时,流通孔d2的尺寸用异径公称通径相对的d2尺寸、中心至承插孔底的尺寸A与同径管件相同。

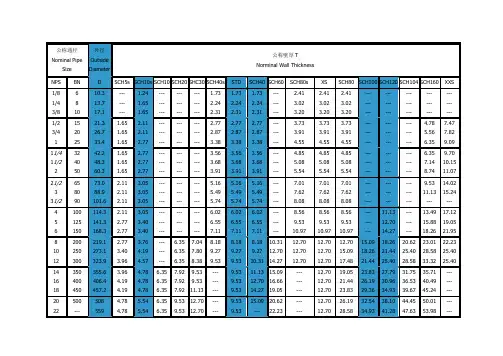

ASME B36.10M-2015焊接和无缝轧制钢管英制米制英制NPS DN in.ASME ISO 国标焊管国标无缝mm kg/m mm kg/m mm kg/m mm kg/m mm kg/m mm kg/m mm kg/m mm kg/m mm kg/m mm kg/m mm kg/m mm kg/m mm kg/m mm kg/m 1/860.40510.310.210.210…… 1.240.28…… 1.450.32 1.730.37…… 2.410.47…………………… 1.730.37 2.410.47……1/480.54013.713.713.513.5…… 1.650.49…… 1.850.54 2.240.63…… 3.020.80…………………… 2.240.63 3.020.80……3/8100.67517.117.217.217…… 1.650.63…… 1.850.70 2.310.84…… 3.20 1.10…………………… 2.310.84 3.20 1.10……1/2150.84021.321.321.321 1.650.80 2.11 1.00…… 2.41 1.12 2.77 1.27…… 3.73 1.62……………… 4.78 1.95 2.77 1.27 3.73 1.627.47 2.553/420 1.05026.726.926.927 1.65 1.03 2.11 1.28…… 2.41 1.44 2.87 1.69…… 3.91 2.20……………… 5.56 2.90 2.87 1.69 3.91 2.207.82 3.64125 1.31533.433.733.734 1.65 1.29 2.77 2.09…… 2.90 2.18 3.38 2.50…… 4.55 3.24……………… 6.35 4.24 3.38 2.50 4.55 3.249.09 5.451¼32 1.66042.242.442.442 1.65 1.65 2.77 2.69…… 2.97 2.87 3.56 3.39…… 4.85 4.47……………… 6.35 5.61 3.56 3.39 4.85 4.479.707.771½40 1.90048.348.348.348 1.65 1.90 2.77 3.11…… 3.18 3.53 3.68 4.05…… 5.08 5.41………………7.147.25 3.68 4.05 5.08 5.4110.159.55250 2.37560.360.360.360 1.65 2.39 2.77 3.93…… 3.18 4.48 3.91 5.44…… 5.547.48………………8.7411.11 3.91 5.44 5.547.4811.0713.442½65 2.87573.076.176.176 2.11 3.69 3.05 5.26…… 4.788.04 5.168.63……7.0111.41………………9.5314.92 5.168.637.0111.4114.0220.39380 3.50088.988.988.989 2.11 4.52 3.05 6.46…… 4.789.92 5.4911.29……7.6215.27………………11.1321.35 5.4911.297.6215.2715.2427.683½90 4.000101.6101.6101.6102 2.11 5.18 3.057.41…… 4.7811.41 5.7413.57……8.0818.64…………………… 5.7413.578.0818.64……4100 4.500114.3114.3114.3114 2.11 5.84 3.058.37…… 4.7812.91 6.0216.08……8.5622.32……11.1328.32……13.4933.54 6.0216.088.5622.3217.1241.035125 5.563141.3139.7139.7140 2.779.46 3.4011.56………… 6.5521.77……9.5330.97……12.7040.28……15.8849.12 6.5521.779.5330.9719.0557.436150 6.625168.3168.3168.3168 2.7711.31 3.4013.83…………7.1128.26……10.9742.56……14.2754.21……18.2667.577.1128.2610.9742.5621.9579.2282008.625219.1219.1219.1219 2.7714.78 3.7619.97 6.3533.327.0436.828.1842.5510.3153.0912.7064.6415.0975.9218.2690.4420.62100.9323.01111.278.1842.5512.7064.6422.23107.931025010.750273.0273.0273.0273 3.4022.61 4.1927.78 6.3541.767.8051.019.2760.2912.7081.5315.0995.9818.26114.7121.44133.0125.40155.1028.58172.279.2760.2912.7081.5325.40155.101230012.750323.8323.9323.9324 3.9631.24 4.5735.98 6.3549.718.3865.1910.3179.7114.27108.9317.48132.0521.44159.8725.40186.9228.58208.0833.32238.699.5373.8612.7097.4425.40186.921435014.000355.6355.6355.6356 3.9634.34 6.3554.697.9267.919.5381.3311.1394.5515.09126.7219.05158.1123.83194.9827.79224.6631.75253.5835.71281.729.5381.3312.70107.40……1640016.000406.4406.4406.4406 4.1941.56 6.3562.657.9277.839.5393.2712.70123.3116.66160.1321.44203.5426.19245.5730.96286.6636.53333.2140.49365.389.5393.2712.70123.31……1845018.000457457457457 4.1946.79 6.3570.577.9287.7111.13122.3814.27155.8119.05205.7523.83254.5729.36309.6434.93363.5839.67408.2845.24459.399.53105.1712.70139.16……2050020.000508508508508 4.7859.32 6.3578.569.53117.1512.70155.1315.09183.4320.62247.8426.19311.1932.54381.5538.10441.5244.45508.1550.01564.859.53117.1512.70155.13……2255022.000559559559559 4.7865.33 6.3586.559.53129.1412.70171.10……22.23294.2728.58373.8534.93451.4541.28527.0547.63600.6753.98672.309.53129.1412.70171.10……2460024.000610610610610 5.5482.58 6.3594.539.53141.1214.27209.3617.48255.4324.61355.2830.96442.1138.89547.7446.02640.0752.37720.1959.54808.279.53141.1212.70187.07……2665026.000660660660660……7.92127.3612.70202.74…………………………………………9.53152.8812.70202.74……2870028.000711711711711……7.92137.3212.70218.7115.88272.23……………………………………9.53164.8612.70218.71……3075030.000762762762762 6.35118.347.92147.2912.70234.6815.88292.20……………………………………9.53176.8512.70234.68……3280032.000813813813813……7.92157.2512.70250.6515.88312.1717.48342.94………………………………9.53188.8312.70250.65……3485034.000864864864864……7.92167.2112.70266.6315.88332.1417.48364.92………………………………9.53200.8212.70266.63……3690036.000914914914914……7.92176.9712.70282.2915.88351.7319.05420.45………………………………9.53212.5712.70282.29……3895038.000965965965965…………………………………………………………9.53224.5612.70298.26……40100040.0001016101610161016…………………………………………………………9.53236.5412.70314.23……42105042.0001067106710671067…………………………………………………………9.53248.5312.70330.21……44110044.0001118111811181118…………………………………………………………9.53260.5212.70346.18……46115046.0001168116811681168…………………………………………………………9.53272.2712.70361.84……48120048.0001219121912191219…………………………………………………………9.53284.2512.70377.81……注:表中…表示无此规格;质量为ASME 供货平端管的理论质量。

SCH壁厚等级对照表SCH是钢管壁厚的标准,通常用于管道系统的设计和构建。

在管道系统中,SCH等级决定了钢管的壁厚,因此,正确选择适当的SCH等级非常重要。

在本文档中,我们提供了一张SCH壁厚等级对照表,帮助您选择正确的SCH等级。

SCH等级和壁厚在管道系统中,要选择正确的SCH等级,需要了解每个SCH等级所表示的壁厚。

通常来讲,SCH等级越高,钢管的壁厚越厚,因此,能够承受更高强度和更大压力的管道也会更加坚固。

下面是SCH等级和壁厚的对应关系:SCH等级壁厚(英寸)壁厚(毫米)5 0.109 2.7710 0.134 3.4020 0.187 4.7830 0.250 6.3540 0.281 7.1460 0.437 11.1380 0.500 12.70100 0.594 15.09120 0.687 17.48140 0.781 19.89160 0.875 22.23XXS 0.875 22.23XXS 1.000 25.40XXS 1.125 28.58XXS 1.312 33.32XXS 1.500 38.10如何选择SCH等级选择正确的SCH等级对于管道系统的设计和构建来说非常重要,如果选择了错误的SCH等级,可能会导致管道系统的不稳定,甚至会引起管道破裂。

在选择SCH等级时,需要考虑以下因素:工作压力工作压力是决定选择SCH等级的重要因素之一。

如果管道系统中的工作压力较高,那么应该选择具有更高SCH等级的钢管,以保证稳定性和安全性。

管道直径管道直径也是选择SCH等级的重要因素之一。

如果管道直径较小,那么可以选择低SCH等级的钢管,不会影响管道系统的安全性。

管道材料管道材料也会影响选择SCH等级的决策。

一般来说,选择与管道材料相匹配的SCH等级可以最大程度地保证管道稳定性和安全性。

本文提供了一张SCH壁厚等级对照表,帮助读者选择正确的SCH等级。

在选择SCH等级时,需要考虑管道系统中的工作压力,管道直径和管道材料等因素。

C·SH5s、10s、40s、80s用于不锈钢管欧阳道创编 2021.03.06欧阳道创编 2021.03.0690 31/2101.6 4.2 2.1 3.0 --- --- --- 5.7 5.7 5.7 --- 8.1 8.1 8.1 --- --- --- --- ---100 125 150 456114.3139.8165.24.54.55.02.12.82.83.03.43.4---------------------------6.06.67.16.06.67.16.06.67.1---------8.69.511.08.69.511.08.69.511.0---------11.112.714.3---------13.515.918.217.119.021.9200 250 300 81012216.3267.4318.55.86.66.92.83.44.04.04.04.5---------6.46.46.47.07.88.48.29.39.58.29.39.58.29.310.310.312.714.312.712.712.712.712.712.712.715.117.415.118.321.418.221.425.420.625.428.623.028.633.322.225.425.4350 400 450 141618355.6406.4457.27.97.97.94.04.24.24.84.84.86.46.46.47.97.97.99.59.511.19.59.59.59.59.59.511.112.714.315.116.719.0---------12.712.712.719.021.423.823.826.229.427.830.934.931.836.539.735.740.545.2---------500 550 600 202224508.0558.8609.67.9------4.84.85.55.55.56.46.46.46.49.59.59.512.712.714.39.59.59.59.59.59.515.1---17.520.622.224.6---------12.712.712.726.228.631.032.534.938.938.141.346.044.447.652.450.054.059.5---------650 700 750 262830660.4711.2762.0---------------6.4------7.97.97.97.912.712.712.7---15.915.9------9.59.59.59.5---------------------------12.712.712.7------------------------------------------------------800 850 900 323436812.8863.6914.4---------------------------7.97.97.912.712.712.715.915.915.9---------9.59.59.517.517.519.0------------------12.712.712.7--------------- 承插焊管件(一) Socket Welding FittingsGB/T 14383、SH 3410、HG/T 21634、ASME B16.11、JIS B2316欧阳道创编 2021.03.06欧阳道创编 2021.03.06欧阳道创编2021.03.06公称通径 Nominal Pipe Size外径 End DIA 壁厚 Wall Thickness 螺母厚度 Nut 螺帽每英寸的螺纹扣数 Threads Per inch球面凸缘厚度Male Flange 定位口高度 Bearin 公称装配长度Length Assem Nominat结构尺寸 Laying Length流通孔径 BoreD minC minG min H F min h min L E d2 DN NPS 承插焊 Socket 螺纹 Thread 承插焊 Socket 螺纹Thread 承插焊 Socket 螺纹 Thread 6 8 10 1/8 1/4 3/8 21.8 21.8 25.9 14.7 19.1 22.9 3.2 3.3 3.5 2.5 3.1 3.2 3.2 3.2 3.5 16 16 14 3.2 3.2 3.5 1.5 1.5 1.5 41 41 46 21 21 24 7.4 10.9 13.9 15 20 25 1/2 3/4 1 31.2 37.1 45.5 27.7 33.5 41.4 4.1 4.3 5.0 3.8 4.0 4.6 3.7 4.1 4.5 14 11 11 3.7 4.1 4.6 1.5 1.8 1.9 49 57 62 24 29 30 17.5 22.2 28.4 32 11/454.950.65.34.95.2105.42.2713736.5欧阳道创编 2021.03.06欧阳道创编 2021.03.06·Since ASME B36.10M does not include Schedule 160 nor include double Extra Strong thickness for DN6,8,and 10,the values in table may beused as the nominal wall thincknessesof the pipe for rating purposes.管件级代号与管子壁厚代号的关系Relevance of Fittings Class with Schedule Nunber or Wall Designation of pipe for Calculation of Ratings管件级别代号class designation fo Fitting 管件连生产建设形式Type of Fitting用作额定计算依据的管子Pipe Used for Ratin Basis管子表号Schedule NO.管壁代号Wall Designation2000 螺纹 Threaded 80 XS3000 螺纹 Threaded 160 ---6000 螺纹 Threaded --- XXS3000 承插焊 Socket-Welding 80 XS6000 承插焊 Socket-Welding 160 ---9000 承插焊 Socket-Welding --- XXS·本表并未限制使用较薄或较厚壁厚的管子和管件。

SCH表示壁厚等级;S表示外径。

备注:①SCH**s指奥氏不锈钢,壁厚超过SCH80S按碳钢管选用②带括号者不推荐使用美标 ASTM A182 Gr F22 对应中国在美标材质中,A182开头的材质都是不锈钢,GR:等级(GRADE )F22:锻件,具体是 12Cr1MoV 25Cr2MoV 20Cr1Mo1VAPIPE,SMLS,:pipe seamless(无缝管)BE, : beveled (坡口)S-20, : sch20管件的壁厚CS : cast steel 铸铁ASTM : American Society of Testing Materials 美国材料试验协会,SA106 :美标的一个标准GR.B, : grade b B 等级ASME:ASME 是 American Society of Mechanical Engineers (美国机械工程师协会)的英文缩写ASME-B36.10M:这里的意思--boiler and pressure vessel code(气压标准)by the way:B36.10 壁厚等级:Sch10 Sch20 Sch30、Sch40 Sch60、Sch80 Sch1O0 Sch120 Sch140 Sch160 十个等级;这里就是指 SCH20办公室卫生管理制度一、主要内容与适用范围1•本制度规定了办公室卫生管理的工作内容和要求及检查与考核。

2•此管理制度适用于本公司所有办公室卫生的管理二、定义1 •公共区域:包括办公室走道、会议室、卫生间,每天由行政文员进行清扫;2•个人区域:包括个人办公桌及办公区域由各部门工作人员每天自行清扫。

1.公共区域环境卫生应做到以下几点:1)保持公共区域及个人区域地面干净清洁、无污物、污水、浮土,无死角。

2)保持门窗干净、无尘土、玻璃清洁、透明。

3)保持墙壁清洁,表面无灰尘、污迹。

4 )保持挂件、画框及其他装饰品表面干净整洁。

承插焊管件(一)Socket Welding FittingsGB/T 14383、SH 3410、HG/T 21634、ASME B16.11、JIS B2316公称通径Nominal Pipe Size 承插孔深度Depth ofSocket壁厚Wall Thickness中心至承插孔底Center to Bottom of SocketAC min90°弯头、三通、四通90°Elbow、Tee、Cross45°弯头45°ElbowDN NPS J minSCH803000SCH1606000XXS9000SCH803000SCH1606000XXS9000SCH803000SCH1606000XXS9000承插焊和螺纹活接头Unions of Socket-Welding&ThreadedHG/T 21634、MSS SP-83公称通径Nominal Pipe Size外径End DIA壁厚Wall Thickness螺母厚度Nut螺帽每英寸的螺纹扣数Threads Perinch球面凸缘厚度MaleFlange定位口高度Bearin公称装配长度Length AssemNominat结构尺寸LayingLength流通孔径Bore D min C min G min H F min h min L E d2承插焊管件的接管外径、承插孔径及流通孔径尺寸表List of The Pipe Outside Diameter,Socket Diameter and Bore Diameter fo SW Fittings螺纹管件Threaded Fittings GB/T 1426、ASME B16.11公称通径Nominal Pipe Size90°弯头、三通、四通90°Elbows、Tees、Crosses45°弯头45°Elbows所有管件All Fittings中心至端面Center to End中心至端面Center to End端部外径Outside Diameter of Band 最小壁厚Minimum Wall Thickness螺纹长度Length of Thread MinA G D CDN NPS SCH802000SCH1603000XXS6000SCH802000SCH1603000XXS6000SCH802000SCH1603000XXS6000SCH802000SCH1603000XXS6000B L2螺纹管件Threaded Fittings GB/T 1426、ASME B16.11公称通径Nominal Pipe Size 管箍、半管接头Couplings、Boss管帽Caps所有管件All Fittings端面至端面End to End端面至端面End to End底部壁厚End Wall Thickness外径Outside Diameter 螺纹长度Length of Thread MinE F C min DDN NPS SCH160、XXS3000、6000SCH1603000 XXS SCH1603000XXS6000SCH1603000XXS6000B L2螺纹管件Threaded Fittings GB/T 1426、ASME B16.11公称通径Nominal Pipe Size长度Length方头管塞Square Head Plugs圆头管塞Round Head Plugs六角头管塞和内外螺纹接头Hex Plugs and Bushings方头高度Height of Square 对边宽度Width Flats头部直径NominalDiameter ofHead长度Length对边宽度Width Flats(Nominal)六角头高度Hex HeighDN NPS L2 min B min C min D L min S K min H min25-50 1-2 ±2.0 ±2.0 ±1.0 65-100 21/2-4 ±2.5六角头双丝头Hexagonal Nipples六角头双丝头Hexagonal Nipples公称通径Nominal Pipe Size 尺寸SizeDN NPS C E1 E2 WD螺纹短节Nipples公称通径Nominal Pipe Size管子外径Outside Diameter of Pipe螺纹长度Length of Thread Min长度End to End管子壁厚Wall Thickness of PipeDN NPS D L2 min L T6 8 10 1/81/43/810.313.717.19.511.012.575、100、150 SCH80、SCH16015 20 1/23/421.326.714.516.0材料的化学成分和力学性是指标会因为某项条件的规定而有所改变,使用时请查阅原标准。

·The index of material chemical composition and mechanical properties shall change as to some defined condition,and please refer to the priginal管件形位公差mm项目公称直径mm 15~100 125~200 250~300 350~400 450~600 650~750 800~1050 1100~1200 in 1/2~4 5~8 10~12 14~16 18~24 26~30 32~42 44~48倾斜度偏差角度偏移Q 1 2 3 3 4 5 5 5 平面偏移P 2 4 5 7 10 10 13 20管件坡口形式压力等级表(HG 5010.10~16-58,HGJ 514-87,SY 7510-87)mm公称直径Dg2.5MPa 4.0MPa 6.4MPa 10.0MPa 16.0MPa HG HGJ SY HG HGJ SY HG HGJ SY HG HGJ SY HG HGJ SY25 32 40333.5333.5 3.5333.5333.5 3.53.53.53.533.53.5 3.544.54.544.54.5 4.5 750 65 3.543.543.543.543.543.543.54.53.54.53.54.556565678注:表中HG为HG5010-87标准,HGJ为HGJ514-87,SY为SY7510-87标准。

管件尺寸公差壁厚分级表ANSI B36.10 & B36.19壁厚分级表GB 12459-90 GB/T 13401-92mm壁厚表 GB 12459、GB/T 13401列5s 10s 20s 20 30 40 60 80 100 120 140 16015 20 25 21.326.933.71825321.61.61.62.12.12.82.62.63.2┅┅┅┅┅┅┅┅┅┅┅┅2.92.93.2┅┅┅┅┅┅3.64.04.5┅┅┅┅┅┅┅┅┅4.55.66.332 40 50 42.448.360.33845571.61.61.62.82.82.83.23.23.6┅┅┅┅┅3.2┅┅┅┅┅┅3.63.64.0┅┅┅┅┅┅5.05.05.6┅┅┅┅┅┅┅┅┅6.37.18.865 80 90 76.1(73)88.9101.67689┅2.02.02.03.03.03.03.64.04.0┅┅┅4.54.54.5┅┅┅┅┅┅5.05.65.6┅┅┅┅┅┅7.18.08.0┅┅┅┅┅┅┅┅┅10.011.012.5100 125 150 114.3139.7168.31081331592.02.92.93.03.43.44.05.05.0┅┅┅5.05.05.6┅┅┅┅┅┅5.96.37.1┅┅┅┅┅┅8.810.011.1┅┅┅11.012.514.2┅┅┅14.216.017.5200 250 300 219.1273.0323.92192733252.93.64.04.04.04.56.36.36.3┅┅┅6.36.36.37.18.08.8┅┅┅8.08.810.010.012.514.2┅┅┅12.516.017.516.017.522.217.522.225.020.025.028.022.228.032.0350 400 450 500 355.6406.4457.2508.03774264785294.04.04.05.05.05.05.05.68.08.08.08.08.08.08.08.08.08.08.010.010.010.011.012.510.010.010.010.011.012.514.216.016.017.520.020.013.013.013.013.020.022.225.028.025.828.030.032.028.030.036.040.032.036.040.045.036.040.045.050.0550 559 ┅ 5.0 5.6 ┅8.0 ┅┅10.0 ┅┅13.0 30.0。