冷藏车说明书

- 格式:pdf

- 大小:2.91 MB

- 文档页数:24

冷藏车使用操作指南

1.预先针对存储品种检查和确认温控区间,并按要求设置或调整温控区间;

2.夏季冷藏车制冷机开机45分钟后达到温控要求方可进行药品装车;冬季冷藏车制冷机开机10分钟后达到温控要求方可进行药品装车;

5.不得随意移动传感器的位置,每年检查和测试温控器连接的温度传感器的精度,确保其精度符合标准;

6.按年度对温湿度测点终端进行校准;提前进行充值,保证预警短信能及时发出;按月拨打短信卡电话,判断是否欠费;

7.开门装卸货物操作建议在温度低点开门,夏季最长开门作业时间控制在5分钟内完成,两次开门的间隔时间要在30分钟以上;冬季最长开门作业控制在19分钟内完成,两次开门的间隔时间要在10分钟以上;

8.装车时关闭制冷机组,并尽快完成药品装车。

邯郸利达医药有限公司

2016年10月。

冷藏车制冷操作方法

冷藏车制冷操作方法如下:

1. 开启车辆电源,插上冷藏车插头。

2. 按下冷藏车的“启动”按钮,等待压缩机启动。

3. 调节冷藏车的温度控制器,设置需要的温度。

4. 等待冷藏车内部温度降低到设定值,即可开始装载货物。

5. 装载后,记得及时关闭车门,保持车内温度稳定。

6. 行驶途中,注意车速不要过快,避免货物摇晃,影响运输效果。

7. 到达目的地后,先关闭车门,再关掉压缩机和电源。

8. 开始卸货前,等待冷藏车内部温度升高到室温,以免对货物造成冻害。

9. 卸货完成后,对冷藏车内部进行清洁和消毒,准备下一次使用。

需要注意的是,冷藏车在使用过程中,应及时检查冷藏车的制冷效果和温度控制器的运行状态,确保货物的安全运输。

同时,定期对冷藏车进行保养和维修,延长使用寿命。

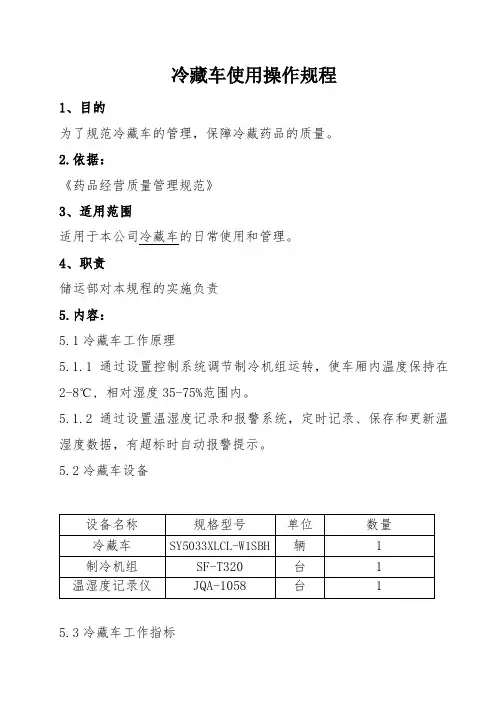

冷藏车使用操作规程1、目的为了规范冷藏车的管理,保障冷藏药品的质量。

2.依据:《药品经营质量管理规范》3、适用范围适用于本公司冷藏车的日常使用和管理。

4、职责储运部对本规程的实施负责5.内容:5.1冷藏车工作原理5.1.1通过设置控制系统调节制冷机组运转,使车厢内温度保持在2-8℃, 相对湿度35-75%范围内。

5.1.2通过设置温湿度记录和报警系统,定时记录、保存和更新温湿度数据,有超标时自动报警提示。

5.2冷藏车设备5.3冷藏车工作指标厢内温度: 2-8℃,湿度35-75%。

5.4操作程序5.4.1启动车辆,打开电源控制箱,推上电源供电开关,开启温控系统和温湿度记录仪。

5.4.2设置5.4.2.1在温控系统设置制冷机组启动温席7.0℃,停机温度3.0℃。

5.4.2.2在温湿度记录仪中设置报警参数:温度上限7.5℃,下限2.5℃;相对湿度上限75%,下限35%。

5.4.2.3在温湿度记录仪中设置每2分钟记录一次温湿度,每1分钟更新一次温湿度数据。

5.4.3检查:启动前检查和确认车车厢的卫生条件,车厢内部必须保持洁净,无碎片、碎屑等杂物。

5.4.4及制冷机组,预冷至3℃,关闭制冷机组。

5.4.5将药品装至车厢中,装载货物时须注意:5.4.5.1货物必须放在垫板上,保持地面通风。

5.4.5.2药品码放高度不得超过制冷机组出风口下沿。

5.4.5.3在药品与车厢之间留有足够通风空间。

药品与厢内前板距离不小于15厘米的通风距离,与后板、侧板、底板间应当保持不小于5厘米的导流距离。

5.4.6装载完毕,关闭车厢,检查车厢门密闭情况,启动制冷机组。

5.4.7出车前检查5.4.7.1检查内外风机运转是否正常,制冷是否正常。

5.4.7.2检查门封是否严密,车厢是否保温。

5.4.7.3检查温湿度记录仪是否正常记录。

5.4.7.4到达温度下限时,制冷机组自动停止工作。

达到温度上限时,制冷机组自动开始工作。

5.4.8当温度达到2-8℃范围时,检查合格后,放行出车。

开利C700冷机使用说明书1、货物预冷:装货前需确认货物温度,运输冷机组只能维持货物温度,如果用它有限的冷量给货物降温,不仅很难做到,而且会耗费大量燃油。

2、车厢预冷:装货前应用冷机对车厢进行预冷,这样可以排出箱体内的热量,以保证货物的品质。

厢体预冷时手动化霜,厢时进行一次手动化霜,用来去除聚集在蒸发器盘管上的霜,提高制冷效果,加快预冷速度。

3、装货时冷机需要关闭,避免冷机压力因素外界热气进入保温箱内。

4、封闭式月台装货;应通过封闭式月台快速装车,避免货物与外部环境接触,导致冷链的断链。

车门也不要大敞四开的,一定要开到最小,建议使用门帘或风幕,尽量阻止环境温度热量传递。

5、货物的包装要正确,鲜货和冻货对包装的要求是不一样的,鲜货的包装要保证通风。

并且不同的货物要分开装,不要将冻货和干货混装在同一个厢体内。

6、留出足够的冷风通道;装货时要确保货物与冷厢的内壁之间有足够的间隙,确保冷风通畅的循环,使冷风能够包装每一个角落的货物,不致造成局部温升化货。

7、冻货采用回风闻到控制,而鲜货需要采用送风温度控制。

8、装货后再次手动化霜;装货完毕后,关闭厢门开机,半小时左右进行一次手动除霜。

9、停冷机,再开厢门;开厢门前,机组必须停机。

如果不关闭冷机,会大量吸入外部湿热空气,造成厢内温升及盘管结霜,给后期打冷造成困难,浪费燃油。

10、清洁保温厢内及制冷机组;防止污染货物或堵塞冷机的蒸发器,保证制冷效果,确保货物安全。

蒸发器和冷凝器主要是通过跟空气进行热交换去改变周边环境,为了更好的跟空气接触,表面保持干净尤为重要。

由于蒸发器风扇的作用,空气会在车厢内循环,导致地面的碎削或脏东西被蒸发器风机吸入。

长时间的作用,会使大量的杂质吸入到蒸发器盘管内,从而影响制冷机组的制冷效果。

因为盘管会被杂质一点点的包围起来,导致盘管的热交换率下降。

所以冷藏车使用几年后大家会感觉制冷效果不如开始,除本身故障原因外,就是因为盘管太脏所致。

东风天龙9米6冷藏车箱内温度控制器按

键使用说明

冷藏车或药品冷藏车在驾驶室内都会安装一个控制器,这个控制器看起来不显眼,却起着至关重要的作用哦,为什么要这样说呢,因为这个控制器掌管着货箱内的温度,制冷机全靠它来开机,关机,操作和设置,控制器的显示屏上也随时显现着货箱里的实时温度。

在装货之前,我们要先设定温度,将温控器设定在所需温度上,预冷车箱1小时左右以排走滞留在车箱内的热量;装货时将冷冻机组关闭,迅速装货。

大家一定要切记:冷冻机组是用来保持货物的温度,而非用以降低货物温度的。

许多冷藏车的使用者都有一个错误的概念,总认为冷藏车上的冷冻车机组是可以随意将装入车厢内的货物冷冻或加热至其所需要的温度。

因为冷藏车的制冷机组不是降低货物温度的,而是维持货物温度的,他就象我们过去卖冷饮时用的棉被,将货物包起来。

当外界的冷(热)源通过辐射、传导、对流到厢体内,被制冷机组吹出的冷气带走,隔绝热源进入货物。

许多人在装卸货物时都是不关闭制冷机组,其实这是一种非常错误的操作。

这是因为当我们把车厢预冷后,如果不关机,打开车厢门时,由于冷冻机组蒸发器的风扇是在工作,风扇的正面是正压,而其背面是负压,因此冷气从车厢上部吹出,而下部会将外面的热空气快速吸进来,从而导致车厢内的温度快速上升;如果关机后再装卸货物,由于风机处于停止状态,空气流动停止,车厢内外风

压一致,因而使得外部热空气传递进入车厢内的速度相对减缓,一定要记住。

6.8冷藏车操作方法

1. 装载:在冷藏车装载货物前,要确保车厢内部卫生和温度适宜。

将货物放置在车厢内并用绑带固定好,注意不要挤压过度,同时确保货物周围留有适当的空间以便空气循环。

2. 开机:启动冷藏车前必须检查车辆电池是否充足、制冷机是否清洁、水位是否充足等等,确保有足够的电力和冷却能力支撑车辆的长途运输。

随后启动冷藏车并将舱门关闭,选择适当的温度档位、风速、运行模式等。

3. 运输:在运输途中,要确保车辆的稳定、速度适中,避免路况不平、加/减速过快、过弯过大等能够造成货物振动、温度波动等问题的行为。

同时要时刻监测运行状态,确保冷藏车正常工作,如发现异常情况应立即停车检查。

4. 卸载:卸载货物时要将货物从车厢内取出,并将绑带拆除。

同时应注意货物在运输过程中是否有受损、变质、漏损等问题,并及时采取措施,确保货物质量不受影响。

5. 清洁:卸载完货物后,要对冷藏车进行彻底清洁,包括车厢内的卫生和制冷机的清洁。

清洁完成后,将舱门关闭并拔掉电源插头,以便下次使用。

冷藏车正确操作方法

下面是冷藏车的正确操作方法:

1. 准备工作:在使用冷藏车之前,确保车载冷藏设备已经接通电源并且正常运转。

检查温度计是否准确,是否有足够的冷藏空间和货运设备(如冷藏货架)。

2. 装载货物:将冷藏货物放置于冷藏车的冷藏空间中。

确保货物被正确地摆放和固定,以防止在行驶中发生滑动或损坏。

3. 控制温度:根据货物的要求和运输距离,设置冷藏车的温度。

确保温度设定在货物的适宜储存温度范围内。

4. 监测温度:在车辆运行过程中,定期监测冷藏车的内部温度。

确保温度保持在所需的范围内。

如果温度超出范围或出现异常,及时进行调整或修理。

5. 排放热气:冷藏车在运行过程中会产生热气。

确保车辆周围有足够的空间和通风,以便排放热气,防止过热。

6. 避免频繁开启冷藏车:尽量避免频繁开启冷藏车的车门,以减少冷空气流失。

7. 保持车内清洁:冷藏车应保持干净整洁。

定期清洁冷藏车的货物空间和冷藏设备,以确保其正常运行。

8. 维护保养:定期检查冷藏车的电气设备和冷藏系统,确保其正常运转。

定期更换冷藏液体或气体,保持设备的有效性。

9. 安全驾驶:冷藏车的驾驶员要遵守交通规则,并且以安全的速度和方式行驶。

及时处理任何突发状况,确保货物安全和冷藏车的可靠性。

总之,正确操作冷藏车需要对设备的正常运行和货物的储存要求有清晰的认识,并严格遵守操作规程和安全要求。

冷藏车4.2米操作规程

《冷藏车4.2米操作规程》

一、冷藏车的准备工作

1. 确认车辆冷藏系统及温度记录仪工作正常。

2. 确保冷藏车内部清洁卫生,无异味。

3. 检查制动系统、轮胎、灯光等车辆主要部件是否正常。

4. 确认所载货物符合冷藏车的温度要求。

二、冷藏车的启动与运行

1. 启动车辆前,应确保冷藏系统已开启并达到所需温度。

2. 行驶过程中,严禁在急刹车、急转弯等情况下产生过大的冷藏车内部震动。

3. 车辆停放时,应选择平整稳固的场地,并避免长时间停留在阳光直射的地方。

三、冷藏车的停车与故障处理

1. 车辆停放时,应关闭冷藏系统并将车辆锁好,防止货物遭到盗窃或变质。

2. 如遇冷藏系统故障或温度上升异常,应立即停车并联系维修人员进行处理,不得私自修理或延误时间。

四、冷藏车的清洁与维护

1. 每次运输结束后,应对冷藏车内部进行清洁,清除残留物和异味。

2. 定期对冷藏车进行例行检查和保养,保证冷藏系统及车辆主要部件正常运作。

以上即为《冷藏车4.2米操作规程》,请所有驾驶员和运输工作人员严格遵守,以确保所载货物的安全和质量。

大运4.2米冷藏车温控器说明书

大运4.2米冷藏车温控器的主要功能为:

1、设置压缩机工作温度范围,即上限和下限。

2、设置化霜电加热的时间。

3、设置化霜周期。

4、设置化霜终止温度。

5、设置化霜后滴水时间。

设置过程详解:

一、开始设置时,按住设定键三秒钟,即左上方第一个圆点亮时,表示可以进行开机温度值设定,此值为压缩机开机温度值。

二、接着按设定键一下,第二个圆点亮时,表示可以设定停机温度值,此值为压缩机的停机温度值,温度值设定按上下键进行调整。

三、依次按下设定键进入下一个菜单项的设置,当显示屏显示字母P时,为化霜时间设定,1——60分钟范围内可调,一般设置在15分钟左右,可根据经验及风机结霜的实际情况来设定。

四、当显示屏显示字母H时,为化霜周期设置,大运4.2米冷藏车温控器的化霜周期计算方式为压缩机工作累计时间,在0——12小时范围可调,一般设定6小时,化霜一次,也可根据风机除霜情况调整。

当设置时间为00时,表示停止自动化霜。

五、当显示屏显示字母C时,为化霜终止温度,当风机蒸发器铜管翅片周边的温度超过该设定值时,停止电加热除霜,以防止加热器出现故障和作为一种安全防护措施。

该设定值5——40°C范围内可调,一般选择10°C。

六、当显示屏显示字母E时,为化霜后滴水时间,3——20分钟范围内调整,可观察冷风机底板融霜水是否流干净来设置,一般设定5-7分钟为宜。

冷藏车操作规程

《冷藏车操作规程》

一、冷藏车的开启与关闭

1. 确认环境温度:在开启冷藏车前,需要确认环境温度是否符合所需的冷藏温度要求,若环境温度过高,则需进行调整。

2. 开启冷藏车:按照冷藏车制造商提供的操作手册,正确地开启冷藏车,并将温度调整为所需的冷藏温度。

3. 关闭冷藏车:在使用完毕后,需要将冷藏车正确地关闭,确保冷藏车内的温度不会受到外部因素影响。

二、冷藏车内货物的装载与装卸

1. 货物装载:将需要冷藏的货物正确地装载进冷藏车内,避免堆放过高、过密,确保冷藏车内空气流通。

2. 货物装卸:在装卸货物时,需要注意避免将冷藏车的门打开时间过长,以免影响冷藏温度。

三、温度监控与维护

1. 温度监控:定期监控冷藏车内的温度,一旦发现温度异常,需要及时进行调整,确保货物的质量。

2. 冷藏车维护:定期对冷藏车进行清洁、检查与维护,保证冷

藏车内的设备正常运转,避免因设备故障影响货物质量。

以上是关于冷藏车操作规程的一些基本流程与注意事项,操作人员需要严格按照规程进行操作,确保冷藏车内货物的质量和安全。

Série de RV comunidade de veículoDesign personalizado para caminhões refrigerados leves e médiosSérie-RVRV - Rapid cooling/Reliable/Revolution Vehicle, (Veículo com Resfriamento Rápido/Confiável/Revolucionário) - como o próprio significado da sigla diz, foi especialmente projetado para refrigeração de transporte na faixa de veículos de distribuição leve e média. Esta nova plataforma RV está equipada com um sistema otimizado de refrigeração, um robusto compressor TK e outros componentes comprovados, o que garante alta capacidade de resfriamento, tração rápida, controle preciso da temperatura, alta confiabilidade, facilidade de uso e baixo custo de manutenção.Modelos de produtosRecursos ChaveMaior capacidade e maior eficiênciaDesign compacto e instalação flexívelMaior confiabilidade para mais tempo de atividade Fácil uso e manutenção •RV-200 (Montado na frente e no teto) •RV-300 (Montado na frente e no teto) • RV-380• RV-580•Serpentina do condensador / evaporadora maior para troca de calor mais rápida • Pré-resfriamento rápido para maior eficiência • Maior capacidade de refrigeração para melhor proteção de carga •Leve e compacta para fácil instalação, esp. para veículo leve e mini • Opção de veículo montado na frente e no teto (RV-200/RV-300)• Melhor sistema elétrico • Menos carga de refrigerante para o ambientes delicados • Design de relé removível para melhor manutenção• Compressor robusto TK • Novo sistema de controle elétrico com alta confiabilidadeNota: A carga de refrigerante mencionada é para referência. As configurações de veículo e tubulação determinam os pesos de carga corretos.Dimensões (mm)EspecificaçõesCondensador RV-200 / RV-300(Montado da frente/teto)Condensador RV-380Condensador RV-380Evaporador RV-300Evaporador RV-200Condensador RV-580Evaporador RV-58082082050010031881883163852356226275854901876081809852204901080108013764351023。

冷藏车使用操作规程一、装车前准备内容:1、对冷藏车的动力系统等汽车相关系统进行检查,确定汽车系统能正常启动行驶。

2、检查冷藏车上温度记录仪的时间设定。

3、检查车厢的内部和外部应无损坏。

4、确保车厢门和密封条状态良好,门必须牢靠锁紧,密封条必须密封良好。

5、对冷藏车的车厢进行预冷,车厢内要求温度为2-8℃:(1)在司机驾驶室内,启动冷藏车的制冷机组和温度监测报警系统,具体操作见“冷藏车制冷系统使用操作规程”,冷藏车温度监测报警系统操作规程”。

(2)对冷藏车车厢进行预冷时,车厢门要确定是关闭的,防止外面的空气影响制冷,延长冷藏车预冷所需时间。

(3)冷藏车制冷机开机15分钟,当温度达到2-8℃范围内,关闭制冷系统。

(4)停止制冷系统后方可将冷藏药品装车,装车要快,防止冷气外流。

二、装车操作:1、当冷藏车预冷温度达到2-8度范围之内,开始装车,装车前先启动温度记录监测系统,记录仪的具体操作详见“冷藏车温度监测报警系统操作规程”。

2、冷藏车车厢内药品的码放要求,药品与厢内前板距离大于10厘米,与后板、侧板、底板间距大于5厘米,药品码放高度不得超过制冷机组出风口下沿。

3、冷藏车装上药品后关好车厢门,确定车门严密无任何泄漏,同时确保货厢门牢靠锁好。

4、药品装好车并锁好车厢的门,此时启动制冷机组。

5、再次检查冷藏车的制冷系统控制面板显示的温度(2-8℃)、温度监测报警系统显示的温度(2-8℃)和温度记录仪运行情况,全部运行正常后可启运。

6、装车时间必须在5分钟内完成,再次开门的间隔时间在10分钟以上。

7、以门的中心点为圆心,以20cm为半径的圆弧内不得放置药品,方便出入库作业。

三、运输过程中:1、冷藏车运输途中,无异常情况不得随意打开车厢门,如必须开门应限定在3分钟之内完成开关门。

2、运输员和送货员要注意查看驾驶室内的冷藏车温控系统和报警系统的控制面板,确保在运输过程中车厢的温度情况符合药品储存条件(2-8℃范围内)。

F a l l 2012A publication for the over-the-road transport temperature control industry.IntroducIng Precedent ™ MultIteMP.The mosT environmenTally-sensiTive diesel UniT we’ve ever made.Engineered to be Thermo King’s most fuel-efficient platform ever, Precedent™ is simply designed to put money back into our customers’ pockets. Like its single temperature counterparts, the Precedent S-600M MultiTemp unit is state-of-the-art … in design, in architecture, in reliability , in efficiency . Featuring a greater-than-25 HP evergreen engine, the S-600M offers double-digit fuel savings, a lower lifecycle cost, and confidence in future compliance requirements. It’s themost environmentally-sensitive unit we’ve ever manufactured.Three years in the making, the Precedent S-600M is a leap forward for the food distribution industry , providing smarter temperature control, stronger efficiencies and increased profits with each pallet.Page 2-3 NFI Intermodal - Innovating the Temperature- Controlled Supply Chain via the RailwaysPage 4-5 Introducing Precedent MultiT emp (continued)Page 6-7 Maximizing its (Minority) Strengths: Tribe Transportation Has Made Its MarkPage 8 Save Fuel and Save Money on Smooth AirBlower!continued on page 4 ...N FI Intermodal is a division of the diversifiedNFI Industries, a privately owned internationaltransportation and logistics company that takes pride in delivering completely customized supply chain solutions that are fast, smart and responsible.Since 2005, NFI Intermodal has played an instrumental role in successfully meeting evolving customer needs for reliable capacity, consistent service and low costs when moving goods from factories or import distribution centers to regional distribution centers via rail. The company expanded in 2010, entering the refrigerated container business for the first time and making an immediate impact on the industry. In short, the company has providedthe technology and service that has both modernized and strengthened the rail transport industry.Why Temperature Controlled Intermodal?With intermodal being the fastest growing mode of transportation, NFI Intermodal wanted to grow its offerings to better address rising customer needs for consistent capacity, good service and low costs in the quickly growing temperature controlled supply chain. And they wanted to do it the rightway … with updated, dependable technology that was both environmentally responsible and efficient.“We realized that the old way of operating the refrigerated intermodal business utilized antiquated and inefficient traileron flatcar (TOFC) intermodal technology,” said Ike Brown,one of NFI’s owners. “In the 1990s and early 2000s, all of the major railroads made a major leap forward in dry van domestic intermodal technology through the proliferation of domestic 53-foot double stack containers on flatcars (COFC). COFC technology revolutionized the domestic intermodal business by enabling trains to handle almost twice as many shipments per train as the old TOFC technology. This substantially drove down costs for railroads, intermodal carriers and shippers.“We wanted to bring the same technological and cost advantages that COFC technology brought to the dry supply chain to the temperature controlled supply chain.”And that’s exactly what Brown and his NFI Intermodal team did.NFI INTeRmOdAL INNOvATINg The TemPeRATURe CONTROLLed SUPPLy ChAIN vIA The RAILWAyS2 A Matter of DegreesTechnological PartnershipNFI Intermodal worked with its equipment partners Hyundai and Thermo King to overcome technical and economic hurdles and became the first carrier to launch domestic temperature controlled containers in the United States. And today, just two years since it entered the market, NFI Intermodal boasts a fleet of 120 state-of-the-art refrigerated containers, all with Thermo King SB-RR units capable of cooling to -20 degrees F, a 120 gallon front mounted fuel tank, TracKing™ telematics for 24-hour monitoring, and Thermo King SVC guaranteed maintenance coverage to keep the units tuned and in top performance as they roll across North America.Reliable Refrigeration is Key“We chose Thermo King as our refrigerated partner fromthe beginning,” says Scott Webb, senior vice president NFI Intermodal. “We believed that the lessons learned from Thermo King’s extensive refrigerated boxcar experience would result in the best overall experience for us in the refrigerated container segment. And we have not been disappointed.“Thermo King’s team, led by Doug Moore (rail business development/applications manager), Rick Boily (rail service manager), Frank Pryzwara (district sales manager), Freddy Munoz (district service manager) and Ed Brown (sales manager for Thermo King dealer CSTK), has brought tremendous rail knowledge, experience and service, enabling NFI Intermodal to create an industry-changing refrigerated container product.”Thermo King’s Rail Ready units were specifically engineered to stand up to tough, unattended rail environments, and come in the COFC double-stack packaging NFI Intermodal was seeking.“The SB-RR units are reliable, offer industry-leadingfuel economy and are backed by Thermo King’s extensive dealer network for all maintenance work. The SR-2 and SR-3 controllers are easy to use, and coupled with OptiSet™ Plus,are unbeatable when it comes to optimizing unit performance,” continues Webb.Thermo King’s OptiSet Plus is a controller interface program that helps reduce shipper and operator error by providing commodity profile settings. Developed with food and agriculture experts, the settings are customizable to meet individual customer needs and parameters.Remote Monitoring and Streamlined ProcessesA dependable satellite tracking system was another key feature that NFI Intermodal wanted as part of its refrigerated container offering for customers. Thermo King’s TracKing system was the perfect fit.“The telematics package is a critical component to our success and commitment to customer service excellence,” says Webb. “It’s a much more streamlined process when the telematics comes from the same vendor partner who manufactures the actual refrigeration unit. Updates can be made remotely, saving both time and labor expenses. It also allows one contact for any issue or question that comes up … whether it is associated with telematics, maintenance or invoicing; it can all be addressed through one Thermo King contact. This makes life much easier for us and our customers.”With cross country routes from California to the upper Midwest and Northeast, as well as the Pacific Northwest and Texas and Florida, effective tracking during each trip is essential. Especially when the typical products hauled include frozen and chilled food, food ingredients, beverages, and temperature-sensitive ice cream.NFI Intermodal takes both its remote monitoring with TracKing and its manual checks very seriously throughout each trip. Pre-trip monitoring and precooling are conducted, as well as manual fuel and temperature verifications at rail terminal in-gate checks. In addition to the automatic alarms programmed into TracKing, the system is manually monitored twice-daily while the product is being transported.“It’s NFI Intermodal’s commitment to superior service that makes the company so successful,” says Doug Moore, Thermo King rail business development/applications manager. “They understand that intermodal success is based on relationships– with vendors, customers and carriers. They understand their customer needs and the environmental benefits of rail transport, and they’ve invested in the right technologies that truly deliver. They are a phenomenal partner and innovator in the world of intermodal transport.”Together with its unique container design and its rail partners, Union Pacific and CSX, NFI Intermodal has drastically decreased the cost of domestic temperature controlled transportation while providing excellent service and consistent capacity. As a result, NFI has experienced rapid revenue and profit growth since launching refrigerated intermodal service. In fact, it has become the company’s fastest growing segment, continuing NFI’s legacy as a product innovation leader.More information on NFI Intermodal can be found at /services/nfi-intermodal.Learn more about Thermo King’s Rail Ready products at .Thermo King Corporation 3IntroducIngPrecedent MultIteMP.The mosT environmenTally-sensiTivediesel UniT we’ve ever made.... continued from page 1ArcHItecturedoUBle-diGiT Gains in FUel eFFiCienCyengIneredUCed emissions:90% redUCTion in Pm 37% redUCTion in noxShhh … the Precedent S-600the evergreen engine is so quiet. A small displacement turbo is used to control particulate matter emissions within the combustion chamber. A simple air-to-air intercooler provides maintenance-free operation for the 25,000-hour design life of the unit.The greater-than-25 HP engine utilizes a high-pressure common rail to elevate fuel pressure to approximately 20,000 psi, minimizing particulate matter residues and emissions within the cylinder itself. As a result, the S-600M engine runs cleaner and avoids the costs and complexities of a high maintenance after treatment system. That’s right; no DPF!This customized EGR Light solution exceeds government nitrogen oxide, particulate matter and carbon dioxide emission standards without compromising fuel efficiency and performance.visit for more details on the entire Precedent platform.relIAbIlIty ArcHItecture tHe engIne6 A Matter of DegreesGeorgia-based Tribe Transportation may be a mere seven years old, but the company has more than proved itself as a progressive industry leader within refrigerated transport. Touting its minority roots through Owner Carla Joy Cain, a Native American woman who grew up in the industry , the company has become one of the most respected transportation companies in the Southeast. And the company did it during one of the most difficult economic periods in American history .“Tribe Transportation was strategically founded to help fill the need for supplier diversity within the industry ,” explains Matt Handte, executive vice president. “Many larger food distribution companies are committed to support minority-run companies, recession or not. We created the company to provide a choice, but we built the company based on previous industry experience and a reputation of performance. That history , along with Carla’s leadership, has helped us earn customers such as General Mills, Land O’ Lakes, Unilever, Schwan’s, PepsiCo, and Macy’s.”The company , which has developed a strong reputation in the deep frozen category , has become one of the fastest growing, asset-based minority transportation companies in the nation providing service to the United States, Canada and Mexico.Besides impeccable customer service, Tribe Transportation prides itself in running new, top of the line equipment and technology . They do not cut corners.FleetThe company owns Volvo, Freightliner and Peterbilt tractors and is planning to double its fleet to meet anticipated customer demand. The company also has Great Dane and Utility trailers and is presently expanding their capacity with new Utility 3000R trailers. All trailers are cooled by Thermo King SB-330 refrigeration units. In addition, Tribe recently beganincorporating Thermo King TriPac™ auxiliary power units (APUs) into its tractor fleet. The APU allows the driver to shut thesystems such as air conditioning. Each APU has allowed Tribe to save up to eight gallons per day in diesel fuel.“It was a large initial capital expenditure,” says Handte, “but the payback for Tribe in terms of fuel savings and carbon emission reductions to our environment is significant.”The most recent addition to Tribe’s fleet are 30 new Peterbilts which came equipped with TriPac APUs, and the company has plans to incorporate more in the near future.“The equipment we run is vitally important,” says Handte. “It has to be reliable, efficient and technologically-forward, yet sound. I’m a firm believer that we are only as good as the vendors we choose. That’s why we choose to partner with Thermo King.”mAxImIzINg ITS(mINORITy ) STReNgThSTRIBe TRANSPORTATION hAS mAde ITS mARkThe SB-330 trailer units were selected for Tribe Transportation’s fleet because of power. “The units pre-cool fast; they can reach an ambient of -10 F in 35 minutes; and they offer excellent fuel efficiency at the lower temperatures Tribe hauls its ice cream – their biggest volume product,” says Tim Edwards of Thermo King of Atlanta, Tribe Transportation’s local dealership. “They’ve been recording 6/10 of a gallon of fuel per hour.”This industry-leading equipment not only ensures the integrity of the shipper’s product, but also aids the shipperin achieving energy savings goals that many sustainability-conscious industry leaders are adopting. RelationshipsTribe Transportation understands what equipment is needed to fill customer needs because of its strong focus on relationships. “Relationships are BIG … with customers and vendors,” explains Handte. “We work hard to keep the lines of communication open with customers. The better we understand their business, the better we can meet their needs.“The same goes with our vendors. Reliability, urgency, new ideas, and a strong network of support are essential to this Environmentally SpeakingSustainable, environmentally-conscious practices play another big role in Tribe Transportation’s planning and future vision for the industry. The company recently partnered with Unileveron an innovation study to identify more sustainable ways to ship deep frozen products. The research was focused on howto increase temperatures for long-distance transports while maintaining quality through varying altitudes. The first studyof its kind, Tribe Transportation will be at the forefront of developing effective solutions to generate fuel savingswhile reducing carbon emissions and the industry’soverall carbon footprint.The company’s environmental focus also shows in its equipment choices and even in the incentives offered to drivers. The fleet conversion to the TriPac APU is one example of how Tribe is cutting idle times and decreasing its overall fuel burn. “We are in the process of establishing incentive programs for all of our drivers participating in our fuel optimization program,” explains Handte. “We currently utilize state-of-the-art software programs to route drivers to specific stations, that tell them how much to fill the tank, and more.”Commitment to the IndustryA certified EP A Smartway Transport Partner, Tribe TransportationA Matter Of DegreesA publication for the over-the-road transport tem-perature control industry.Editor: Managing Editors/Writers: Layout and Design: For more information, *****************************Thermo King Corporation NOW JUST $285PLUS LABOR!**At participating dealer locations. SB-200/210 requires 2 hours labor, SB-300/310/400 requires 3 hours labor. ** Based on -20o F set point, 80o F ambient and 3 precools per week, 60% annual usage.TK 55598-8-MS。

J6L说明书

解放J6L质惠版6.8米冷藏车价格及配置详细介绍

整车尺寸:9160*2600*4000(mm)

箱体尺寸:6800*2420*2500(mm)

整车出厂价格:23.8-26.8万

解放J6L质惠版6.8米冷藏车【底盘配置】

解放J6L高顶排半驾驶室,功率/马力: 179KW/245马力,5700排量,5300轴距,2020

款J6L半浮高顶排半驾驶室、电动玻璃升降、电动后视镜、驾驶员座椅为真皮通风加热座椅(腰托、扶手)、单DIN北斗兼容车载系统、中间座椅、自动空调、前下防护装置、300L钢油箱、宽保险杠、电动液压举升装置、铝合金储气筒、悬架7/7+6、VOSS接头、水壶座、定速巡航、机箱桥体现5/5/5万公里长换油周期、车身左侧带“质惠版绿通”字样、右转弯音响提示装置、限速89km/h、T-box1.5、安全带佩戴提醒、制动器衬片更换报警。

解放J6L质惠版6.8米冷藏车【厢体配置】

厢体内外面料采用玻璃钢,厢体厚度为8cm填充聚苯乙烯发泡材质,内衬骨架为武钢优质轻钢型材,厢体底部为铝合金花纹板,厢体采用不锈钢包角,铝合金包边,不锈钢后门合页及锁件,后门框为不锈钢,厢体内部采用LED照明灯。

配置-15℃国产知名制冷机组,带冷机温度显示控制调节器。

提供:合格证、上户、使用说明书、保修手册、备胎、随车工具。

冷链设备操作说明书一、引言冷链设备是现代物流运输中不可或缺的重要工具,主要用于保持货物在运输过程中的低温状态,确保货物的质量和安全。

本操作说明书旨在提供冷链设备的正确操作方法,以确保设备稳定运行和货物的安全。

二、设备概述冷链设备通常由以下组件组成:1. 制冷机组:负责制冷并调控温度。

2. 冷藏车厢:提供贮存空间,设有温度控制装置。

3. 控制面板:用于设定和监测温度,并调节制冷机组。

4. 温度传感器:感知并反馈货物和车厢内部的温度情况。

三、操作步骤1. 准备工作:a. 检查设备:确保设备处于正常工作状态,没有故障或损坏。

b. 清洁卫生:清理车厢内部,确保无异味或污垢。

2. 开机:a. 按下控制面板上的开机按钮,启动制冷机组。

b. 设置目标温度:通过控制面板设定所需的货物温度。

3. 装载货物:a. 将待运输的货物放置在冷藏车厢内。

b. 注意货物的摆放方式,确保冷空气流通并保持温度均匀。

4. 监测温度:a. 通过控制面板监测车厢内部的温度。

b. 定期检查温度传感器,确保准确度和稳定性。

5. 运输过程中的注意事项:a. 避免频繁开启车厢门,以防温度波动。

b. 防止货物受潮或受热,确保包装完好。

c. 维持车厢内的干燥环境,防止霉菌滋生。

6. 关机:a. 到达目的地后,按下控制面板上的关机按钮,停止制冷机组。

b. 将冷链设备清洁干净,确保不留渣或异物。

四、故障排除在操作冷链设备时,可能会遇到以下故障情况,需及时处理:1. 制冷机组噪音过大:a. 检查机组是否有异物卡住,清理并重新启动。

b. 如果问题仍然存在,请联系专业维修人员。

2. 控制面板无法正常调节:a. 检查面板电源是否连接。

b. 检查面板设置是否正确。

c. 如果问题仍然存在,请联系专业维修人员。

3. 温度传感器故障:a. 检查传感器连接是否正常。

b. 检查传感器是否需要更换。

c. 如果问题仍然存在,请联系专业维修人员。

五、安全注意事项在操作冷链设备时,务必遵守以下安全注意事项:1. 不得将手或其他物体伸入运行中的设备内部。

冷藏车12挡操作方法

冷藏车的12档操作方法分为启动前准备和行驶中操作两部分。

在进行操作前,需要确保车辆处于停车状态并且手刹已经拉起,然后才能进行下面的操作步骤。

启动前准备:

1. 调整座椅和方向盘:司机首先要确保座椅和方向盘调整到合适的位置,以确保舒适性和行驶的安全性。

2. 踩离合器和刹车:将离合器踩到底,脚踩刹车,以确保车辆在启动时不会滑动。

3. 挂挡:将变速杆挂到空挡,或者将自动挡变速杆拨至P档。

4. 启动汽车:插入车钥匙,启动汽车的引擎,然后将手刹松开。

启动汽车后,即可进入行驶操作部分:

1. 挂挡:将挡杆挂入一挡,并踩下离合器,缓慢松开刹车踏板。

2. 启动齿轮:首先需要将挡杆拨至一挡,然后缓慢松开离合器,同时加速踏板较缓慢的松开。

一般情况下,这个时候车辆就会开始行驶。

3. 换挡:在汽车行驶过程中,当需要加速或减速时,司机需要随时换挡。

更高档数意味着更高速度,而更低档数意味着更大的扭矩。

根据行驶的需要,推挡杆向前为换到更高的挡位,而拉挡杆向后为换到更低的挡位。

4. 减速停车:当需要减速或停车时,需要逐渐减少油门,并且踩下刹车踏板,同时换到更低的挡位。

当车速逐渐降低到可接受的范围时,可以将挡杆挂到空挡,然后再刹车减速停车。

5. 关闭车辆:当需要关闭汽车引擎时,首先将挡杆置于空档,然后踩下离合器,拉起手刹,最后关闭汽车引擎。

利用以上的步骤,司机可以更加安全且合理地操作12挡冷藏车,确保行驶安全和司机及乘客的安全。

同时在行驶过程中,需要特别注意车辆的转向、车速等情况,以确保行车安全并减少事故发生的可能。