SPEEDQUEEN美国速比坤下洗上烘设备

- 格式:doc

- 大小:39.50 KB

- 文档页数:4

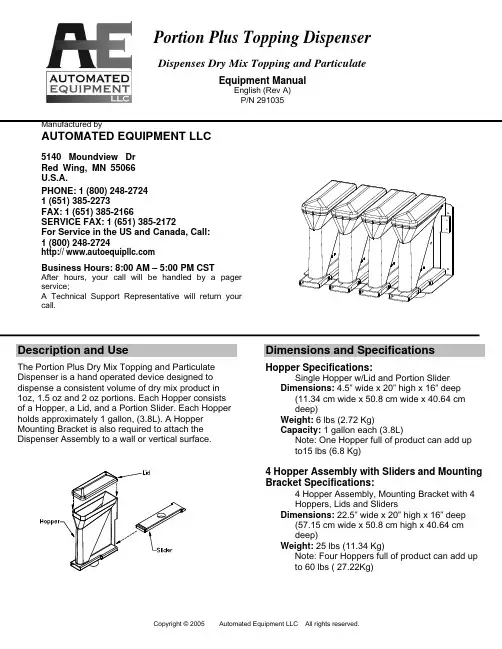

Portion Plus Topping DispenserDispenses Dry Mix Topping and ParticulateEquipment ManualEnglish (Rev A) P/N 291035Manufactured byAUTOMATED EQUIPMENT LLC5140 Moundview Dr Red Wing, MN 55066 U.S.A.PHONE: 1 (800) 248-2724 1 (651) 385-2273FAX: 1 (651) 385-2166SERVICE FAX: 1 (651) 385-2172For Service in the US and Canada, Call: 1 (800) 248-2724http:// Business Hours: 8:00 AM – 5:00 PM CSTAfter hours, your call will be handled by a pager service;A Technical Support Representative will return your call.Description and UseThe Portion Plus Dry Mix Topping and Particulate Dispenser is a hand operated device designed to dispense a consistent volume of dry mix product in 1oz, 1.5 oz and 2 oz portions. Each Hopper consists of a Hopper, a Lid, and a Portion Slider. Each Hopper holds approximately 1 gallon, (3.8L). A Hopper Mounting Bracket is also required to attach the Dispenser Assembly to a wall or vertical surface.Dimensions and SpecificationsHopper Specifications:Single Hopper w/Lid and Portion SliderDimensions: 4.5” wide x 20” high x 16” deep(11.34 cm wide x 50.8 cm wide x 40.64 cm deep)Weight: 6 lbs (2.72 Kg)Capacity: 1 gallon each (3.8L)Note: One Hopper full of product can add up to15 lbs (6.8 Kg)4 Hopper Assembly with Sliders and Mounting Bracket Specifications:4 Hopper Assembly, Mounting Bracket with 4 Hoppers, Lids and SlidersDimensions: 22.5” wide x 20” high x 16” deep(57.15 cm wide x 50.8 cm high x 40.64 cm deep)Weight: 25 lbs (11.34 Kg)Note: Four Hoppers full of product can add up to 60 lbs ( 27.22Kg)CleaningWarranty InformationThe Hopper, Lid, Slide, and Mounting Bracket are warranted to be free from manufacturing defects in material or workmanship for one (1) year. The warranty period commences on the shipping date and applies only to the original purchaser. Except as otherwise provided herein, Automated Equipment LLC, makes no other warranties, expressed or implied, and specifically disclaims any warranty of merchantability or fitness forparticular purpose. Automated Equipment LLC, shall not be liable for any direct, indirect, consequential damages (including damages for loss ofbusiness profits, business interruption, loss of business information and the like) arising out of the use of or inability to use this product. This warranty is void if the product is not functioning correctly due to abuse or neglect by the purchaser, its employees, agents, or other representatives either by breaking, bending, misuse, abuse, dropping, alteration, improper installation or maintenance, or any other form of neglect or improper usage. This warranty does not cover damage to the product caused by natural causes such as lightning, flood, fire, tornadoes, or other acts of God. This warranty is governed by the substantive laws of Minnesota, USA, without giving effect to the conflict of law provisions.• Use water, a soft brush and mild detergent tothoroughly clean all parts of the Dispenser.• Do not use abrasive cleaning pads or cleansers. • Frequent cleaning will prevent food buildup on thesliding parts and ensure proper operation.Warning!• Do not use a dishwasher to clean the Dispensercomponents. Hand wash only.• Do not use excessive force to operate the Sliders. • Dispense dry products only. Do not attempt todispense frozen or liquid products.• Do not attach or hang other material or equipmenton the Mounting Bracket or Hopper Assembly .The information in this manual is subject to change without notice. In no event will Automated Equipment LLC, be liable for technical or editorial omissions made herein; nor for direct, special, incidental, or consequential damages resulting from the furnishing, performance, or use of this material.。

洗涤服务行业融资租赁分析报告洗涤服务行业是城市消费融资租赁行业的子行业,一方面洗涤服务行业受经济波动较小,有利于公司的稳定发展,另外行业客户主要面对中小微企业,符合宜信的发展策略,这是我们在融资租赁行业差异化发展的策略,服务于中小微企业也是目前国家的政策导向。

【2012年6月,商务部新闻发言人沈丹阳明确表示,民营商业企业占经营单位总数的比重达到93%,在引导生产、拉动消费、保障和改善民生等方面发挥着日益重要的作用,商务部近日出台文件明确提出,鼓励民间资本发展连锁连经营、特许经营,鼓励发展商贸物流、鼓励发展电子商务;支持民间资本进入商贸流通领域的特种行业。

】本篇先分析洗涤服务行业现状和行业特点,针对融资租赁的要点和行业特点,确定其做融资租赁的长远性发展,然后将在行内人对做融资租赁的看法做一个总结,最后做个简单的开展项目的计划。

一.洗涤服务行业的现状、优势及发展趋势1.行业现状随着城市化进程,洗衣店产业为中国服务业带来的产值以每年20%的速度递增,而目前已有每年近100亿元以上的产值。

在发达国家,人均5,000人拥有一家洗衣店;而我国目前人均25,000拥有一家洗衣店,随着经济的迅猛发展,要达到发达国家的水平还有相当长的路要走;因此以超前的眼光进入洗衣业,必将带来丰厚的回报。

干洗行业在大城市已经形成了较完善的市场,但对于我国的中小城市、乡镇来说,干洗行业还有很大的市场和发展空间。

在我国政策指向城镇的时期,城镇市场将成为干洗品牌大力争夺的蓝海。

从投资者的关注度角度看,中国加盟网数据研究院数据显示:7月份新增关注干洗行业的创业投资者占总比例的42.86%,8月份下降了将近20个百分点,9月份比例又上升至33.33%。

行业专家分析说,夏季是干洗的旺季,7月份关注干洗的新增创业投资者迎来了增长高峰。

8月份,关注干洗的创业投资者,都已经转为了准店家,纷纷都已经开始着手开店,所以关注干洗的创业投资者有所下降。

而接下来的9月,10月,换季时节将又会迎来干洗旺季。

PT 8257PT 8337PT 8407PT 8507PT 8807为避免对机器造成意外损坏,在进行安装和首次使用之前仔细阅读此使用与安装说明书。

燃气加热电器如闻见煤气味请采取下列安全防护措施立即关闭煤气紧急控制阀。

控制阀通常位于燃气表附近。

安全排除所有点火隐患。

请勿吸烟、点燃打火机或火柴。

请勿操作电灯或开关,即请勿“打开”或“关闭”它们。

打开所有门窗使房间通风。

如果煤气味持续不散,请从房屋撤离。

请遵照国内有关燃气的具体做法。

2目录________________________________________________________________________________________________________________________________注意事项及安全说明 (4)环境保护 (6)电器结构示意图 (7)控制元件 (8)烘干 (10)衣物分类 (10)首次使用前 (11)接通电源将衣物装入滚筒 (11)选择程序 (12)卡片操作/硬币机制 (15)卡片访问操作 (15)用硬币机制C 4060 / C 4065 / C 4070烘干 (15)附加选项 (16)启动日期与时间 (16)停止程序 (17)取消程序 (17)改变程序顺序 (17)程序信息 (17)程序概述 (18)标准程序 (18)羽绒服 (20)拖把(房屋保洁) (20)消防服务 (21)专业清洁程序 (21)家用专业清洁程序 (23)可选模块 (26)操作数据 (26)峰载切断 (27)故障排除指南 (28)出错信息 (28)售后服务 (29)清洁与保养 (30)绒毛过滤器 (30)安装与连接 (31)放平电器 (32)安装在抬高底座上 (32)硬币机制 (32)通信模块XKM RS232 (32)电气连接 (33)进气与排气连接 (33)蒸汽连接 (33)燃气连接 (33)技术数据 (34)数据牌符号说明 (35)简要操作说明PT 8257 / 8337 / 8407 / 8507 / 8807 (37)3安装和首次使用之前,注意事项及安全说明______________________________________________________________________________________________________________________________________________电器与电源完全隔离。

合格品,3C认证标志为:产品型号EHGS100MATE7SU1目 录1.使用前须知2.安全注意事项3.干衣前准备4.操作步骤正面5.操作面板说明6.故障排除7.清洁/维护8.技术参数9.保修说明反面智能家电操控智慧场景定制智家商城购物家电报装报修滚筒干衣机使用说明书2)将附件中的外接排水管与拔下的排水管通过接头连接在一起。

1)外接排水管两端应插接、固定牢靠,以防止其脱落漏水;2)连接后,外接排水管请勿扭结或弯折,以防止排水不畅;3)如果外接排水管过长可以剪掉。

··0701805015442速 烘智慧烘浴 巾大 物除菌螨晒 被羊 毛羽 绒丝 绸干燥度预 约出现以下情况时,有时未必是故障。

委托修理前,请先按照以下列表检查确认。

如果确属故障,请与 机器在运行过程中,由于产品特性,当出现以下声音时,是正常的,请放心使用:E ”显示屏剩余时间停止或清洗后,请将线屑过滤器及内过滤网重新安装到位,不要用尖锐的工具清理过滤网,以免破坏网布。

取下海绵,用湿毛巾清理线屑勾住内过滤网,向外拨动,再按照斜向上45°的方向拿出4.• 清理内过滤网按照斜向下45°的方向放入,再向内拨动,如图所示7.• 重新安装到位6.取下海绵,用湿毛巾清理线屑, 清洗干净后重新组装到位注:选定程序时,根据程序特性,有些参数已经选定为默认值,为不可选状态,无需用户自己设置。

干燥度按键用于烘干程度选择,分为3个等级。

重要:某些程序中“干燥度”轻触此键可选择防皱功能,再次具体设置详见右侧“特殊功能”。

TIVALavadoras de alto desempeño para ladecontaminación de instrumentos complejosMédico2 | La línea de lavadoras-desinfectadoras TIVALa línea de lavadoras-desinfectadoras TIVALas cirugías son el núcleo de los hospitales. El suministro a tiempo de materiales esterilizados es crucial para el funcionamiento de los hospitales. Los instrumentos quirúrgicos deben ser sometidos a procesos de limpieza, desinfección y esterilización estrictos e estandarizados antes de que puedan ser utilizados nuevamente. Estar a ala atura de la alta demanda de los quirófanos, suministrando rápidamente los instrumentos y, al mismo tiempo, garantizar la seguridad de los pacientes exige soluciones avanzadas. Las lavadoras-desinfectadoras Tiva de T uttnauer dan respuesta a estos desafíos al simplificar la misión de los trabajadores y reduciendo el tiempo y los costes del línea Tiva presenta un excelente desempeño que:- Minimiza el consumo y los costes operacionales mientras maximiza la sostenibilidad - Mejora la experiencia del usuario con un sistema de control avanzado y una interfaz de fácil utilización- Utiliza materiales de la más alta calidad, ofreciendo un proceso seguro y eficienteLas lavadoras-desinfectadoras Tiva ofrecen una solución lista flexible para el lavado, desinfección y secado de diversos instrumentos médicos para un ciclo de decontaminación completo.Ciclo de decontaminación:01En el quirófanoContaminantes tenaces y otros residuos son removidos02Con destino al Departamento central de servicios deesterilización, transporte para la unidad de reprocesamientoSon utilizados sistemas autónomos03En el Departamento central de servicios de esterilización - Limpieza manual de la zona sucia:Los productos químicos, con o sin efecto antimicrobiano y con o sin utilización de enzimas04En los procesos automatizados delimpieza y desinfección del Departamento central de servicios de esterilizaciónProceso estandarizado. Limpieza, desinfección, secado a través de lavadora-desinfectadora05En la inspección visual del Departamento central de servicios de esterilizaciónLos instrumentos soninspeccionados visualmente para garantizar una limpieza suficiente.06Esterilización a travésde AutoclaveEfectuada con vapor saturado normalmentea 134 / 132 ºC07AlmacenamientoLos paquetes esterilizados son mantenidos en la sala de Almacenamiento hastasu utilizaciónLa línea de lavadoras-desinfectadoras TIVA | 3Configuraciones disponibles:Armario para almacenamiento de detergentes / Depósito deprecalentamiento para reducción deltiempo del ciclo + Armario de detergentes y conexión de agua desmineralizada- 3 resistencias de calentamiento - U SB / impresora para Cámara de la lavadora fabricada en AISI 316 litros de alta calidad Ciclo de velocidadOpcional- Mediciones de conductividad para verificar la calidad del agua de aclarado antes de la fase de desinfección - Semicaldera de agua (apenas para la versión HS)- Iluminación LED de la cámara: opera durante la carga, descarga y ejecución del programa- Reconocimiento del tipo de carga del carro550550TIVA 10-M PUERTA(A) BATIENTE MANUALTIVA10-1M / TIVA10-2MCámara de 265 litrosDimensiones (AxPxA) 650 x 700 x 1850HASTA 6 niveles de lavado de una capacidad total de 12 cestos DIN, cámara de 265 litrosLa lavadora TIVA 10 está equipada con puerta(s) batiente manual de vidrio y es más adecuada para departamentos quirúrgicos y de esterilización. Puede ser cargada con hasta 6 niveles de lavado de un total de 12 cestos DIN con una gran variedad de carros y accesorios de lavado. Carros disponibles para instrumentos quirúrgicos, tubulares, laparoscopia, ofatlmológicos, recipientes, zapatos, anestesia y más.CaracterísticasPuerta(s) de vidrio manual ámara de la lavadora fabricada en AISI 316 litros de alta calidadPanel táctil con pantalla gráfica de colores n total de 40 programas: predeterminados y programablesPrefiltro de secado de aire + filtro HEPA H14Caldera para agua purificada bombas de dosificación con flujómetro para detergentesLa línea de lavadoras-desinfectadoras TIVA | 7Opcional- M ediciones de conductividad para verificar la calidad del agua de aclarado antes de la fase de desinfección (si la máquina está equipada con conexiones de agua desmineralizada)- Iluminación LED de la cámara: iluminada durante la carga, descarga y ejecución del programa - Reconocimiento del carro de lavado - M onitorización continua del brazo de pulverizado del sistema de agua para garantizar que la carga está actualmente lavada- Cierre de la estructura para configuración del paso - Bomba de drenaje de agua- Conexión del servicio de vapor / calentamiento híbrido: vapor y eléctrico- Conexión de agua para la versión normal: ablandador de agua fría, agua purificada- Conexión de agua para la versión HS: ablandador de agua fría, segunda caldera para agua caliente - Reporte gráfico de las fases de lavado incluyendo el tiempo y la temperaturaA Conexión de agua caliente - 3/4” g (tubo 1/2” g)B Conexión de agua fría - 3/4” g (tubo 1/2” g)C2Drenaje dn 40 - conexión de manguera de 25 mm (en el suelo)D2Drenaje dn 40 - conexión de manguera de 25 mm (en la pared)G Conexión eléctricaOConexión de agua desmineralizada - 1/2” gQ Conexión de vapor 1/2” g (entrada)RConexión de vapor 1/2” g (salida)C2560408553501950D2D2CICLO DE VELOCIDAD DE LA CALDERA (opcional)300900A O BR QGC26358580068067070063585800C2QR2300TIVA10-1M / TIVA10-2M TIVA10-1M / TIVA10-2M Dibujos:Dimensiones (AxPxA) 680 x 700 x 1950Dimensiones (AxPxA) 680 x 700 x 2300 Características- Puerta(s) batiente de vidrio automática- Cámara de la lavadora fabricada en AISI 316 litros de alta calidad- Panel táctil con pantalla gráfica de colores- U n total de 40 programas: predeterminados y programables- Prefiltro de secado de aire + filtro HEPA H14- Caldera para agua purificada- 2 bombas de dosificación con flujómetro para detergentes ácidos y alcalinos (opción de 2 bombas adicionales)- 3 resistencias de calentamiento- USB / impresora para documentos de datos - Condensador de vapor integrado- A rmario de almacenamiento para cuatro detergentes de 5 litrosLa línea de lavadoras-desinfectadoras TIVA | 9- M ediciones de conductividad para verificar la calidad del agua de aclarado antes de la fase de desinfección (si la máquina está equipada con conexiones de agua desmineralizada)- Iluminación LED de la cámara: iluminada durante la carga, descarga y ejecución del programa - Reconocimiento del carro de lavado - M onitorización continua del brazo de pulverizado del sistema de agua para garantizar que la carga está actualmente lavada- Cierre de la estructura para configuración del paso - Bomba de drenaje de agua- Conexión del servicio de vapor / calentamiento híbrido: vapor y eléctrico- Conexión de agua para la versión normal: ablandador de agua fría, agua purificada- Conexión de agua para la versión HS: ablandador de agua fría, segunda caldera para agua caliente - Reporte gráfico de las fases de lavado incluyendo el tiempo y la temperaturaOpcionalC2560408553501950D2D2CICLO DE VELOCIDADDE LA CALDERA (opcional)300900A O BR QGC26358580068067070063585800C2QR2300TIVA10-1V / TIVA10-2V TIVA10-1V-HS / TIVA10-2V-HSA Conexión de agua caliente - 3/4” g (tubo 1/2” g)B Conexión de agua fría - 3/4” g (tubo 1/2” g)C2Drenaje dn 40 - conexión de manguera de 25 mm (en el suelo)D2Drenaje dn 40 - conexión de manguera de 25 mm (en la pared)G Conexión eléctricaOConexión de agua desmineralizada - 1/2” gQ Conexión de vapor 1/2” g (entrada)RSalida de la conexión de vapor 1/2” g (salida)Dibujos:Ciclo develocidadCaracterísticasPuerta(s) de vidrio manualCámara de la lavadora fabricada en AISI 316 litros dealta calidadPaneles táctiles con pantalla gráfica de colores- U n total de 40 programas: predeterminados y programablesPrefiltro de secado de aire + filtro HEPA H14Caldera para agua purificada (apenas para la versión HS)2 bombas de dosificación con flujómetro para detergentesácidos y alcalinos (opción de 3 bombas adicionales paraLa línea de lavadoras-desinfectadoras TIVA | 11Opcional- M ediciones de conductividad para verificar la calidad del agua de aclarado antes de la fase de desinfección (si la máquina está equipada con conexiones de agua desmineralizada)- Iluminación LED de la cámara: iluminada durante la carga, descarga y ejecución del programa - Reconocimiento del carro de lavado- M onitorización continua del brazo de pulverizado del sistema de agua para garantizar que la carga está actualmente lavada- Cierre de la estructura para configuración del paso- Bomba de drenaje de agua- Conexión del servicio de vapor / calentamiento híbrido: vapor y eléctrico- Conexión de agua para la versión normal: ablandador de agua fría, agua purificada- C onexión de agua para la versión HS: ablandador de agua fría, segunda caldera para agua caliente, tercera caldera para agua fría- Reporte gráfico de las fases de lavado incluyendo el tiempo y la temperaturaDibujos:TIVA15-1V / TIVA15-2V TIVA15-1V-HS / TIVA15-2V-HS A Conexión de agua caliente - 3/4” g (tubo 1/2” g)B Conexión de agua fría - 3/4” g (tubo 1/2” g)C2Drenaje dn 40 - conexión de manguera de 25 mm (en el suelo)D2Drenaje dn 40 - conexión de manguera de 25 mm (en la pared)G Conexión eléctrica O Conexión de agua desmineralizada - 1/2” gQ Conexión de vapor 1/2” g (entrada)R Salida de la conexión de vapor 1/2” g (salida)C2680408554001900C2GQR B O A 73090D2D2CICLO DE VELOCIDAD DE LA CALDERA (opcional)300900A OB R Q G C290730100087090081081ElaraAutoclaves de mesa PlazMax Esterilización a baja HSG Prevacío y posvacío - Línea T-Max de grandes。

Nozzles includedTABLE OF CONTENTSIntroduction .......................................................................................................................................... Operation .............................................................................................................................................. Specifications ........................................................................................................................................Important Safety Instructions ...............................................................................................................Grounding Instructions ......................................................................................................................... Parts List ............................................................................................................................................... Maintenance ......................................................................................................................................... Warranty / Service ................................................................................................................................ Warranty Registration Form ................................................................................................................. 1 2 2 3 4 5 6 7 9INTRODUCTIONThank you for purchasing an XPOWER B-8S professional force dryer. Featuring advanced BRUSHLESS technology, the B-8S will outlast standard brush motor dryers with its 7,000+ hour motor. Enjoy full control when drying or styling with variable heat and speed controls. Add a stand and stationary styling arm (sold separately) for convenient hands-free drying.- 1 -Special Features:• 4 HP BRUSHLESS DC Motor • Powerful and Energy-Efficient • Super Lightweight and Compact • Remarkably QUIET Motor• 8' Flexible Heat Protected PU Hose • Thermally Protected• Variable Heat and Speed Control Switches • Digital temp and speed LCD display • Durable & Rugged ABS Housing • 1 Year Limited Warranty• 3 Nozzle Attachments (included)1. Place the dryer on a flat surface. Plug the electrical cord into a 3-prong outlet.2. Connect the hose to the front hose connector and attach the desired nozzle.3. Turn variable speed switch to desired speed.4. To use heating element, choose desired heat setting or leave on off setting.5. To reduce the risk of injury, close supervision is necessary when the unit is used near children. Do not allow children to play with or around the unit.- 2 -OPERATIONSPECIFICATIONSSAFETY INSTRUCTIONSWARNING: IMPORTANT SAFETY PRECAUTIONS!When using electrical appliances, especially when children or animals are present, basic safety precautions should always be followed to reduce the risk of fire, electric shock, and personal injury, including, but not limited to the following:• Do not leave the dryer and animal unattended while the product is in use.• Unplug dryer when not in use.• Do not use extension cords with the product.• Do not unplug unit by pulling on cord.• Do not expose dryer to rain or water.• Unplug unit before attempting any maintenance or service.• Do not let air-intake get clogged.• Do not direct dryer air towards eyes or ears of people or pets.• Never use dryer with a damaged cord/plug or when unit has been dropped, damaged, orexposed to rain/water. Please call our Technical Department for service or repair.• Do not use any other nozzles not intended for use with the dryer.• Do not operate without filter in place. Keep filter clean, as a dirty filter limits air intake and may damage the motor or cause overheating.• Plug only into a properly grounded receptacle. Always confirm that the amperage rating of theelectrical outlet complies with the Dryer rating.• Do not use product for anything other than its intended purpose.• Do not attempt to perform any service or maintenance not outlined in the instruction manual.- 3 -- 7 -XPOWER’s Limited Warranty covers the unit (excludes POWER CORD) from defects in material and craftsmanship. The Warranty covers normal use for a term of one year from the original date of purchase including parts, labor, and one way shipping. Non-contiguous states must pay for roundtrip freight. A purchase receipt must be provided.Important!This warranty does not cover or apply to defects due directly or indirectly to misuse, abuse, disassembly, alteration, corrosive chemicals, improper voltage, fire, flood, negligence, accident, improperly or incorrectly performed maintenance or repair, or failure to perform necessary maintenance or repair, or if the use of this product is not in compliance with the instructions and specifications for its useFor Warranty service and parts replacement (US customer only), you must:A. Call 1-855-855-8868 for a RMA (Return-Merchandise-Authorization) number.B. Have original proof of purchase.C. Use the original undamaged packaging or an industrial certified packaging method.End user will be responsible for shipping the unit (with RMA Number showing on theshipping label) to the XPOWER Service Department. XPOWER will inspect, assess and advise the repairs needed and the applicable cost, if any.For users outside the US, please contact an XPOWER Distributor in your country or region for Warranty service and parts replacement.SERVICEXPOWER LIMITED WARRANTY (USA)XPOWER PET PRODUCTS FOR PROFESSIONAL GROOMING INDUSTRYForce DryersB-3 (2 HP / 8 Amps / 130 CFM) - with vacuuming feature Stand DryersB-16 (1/4 HP / 12 Amps / 300 CFM)B-16S (1/4 HP / 15 Amps / 300 CFM)Cage DryersX -430TF w/ 430MDK (1/3 HP / 3.8 Am ps / 2000 CFM)X -800TF w/ 800MDK (3/4 HP / 7.5 Amps / 3200 CFM)B-4 (3 HP / 10 Amps / 150 CFM) -with vacuuming featureB-8 (4 HP / 12 Amps / 150 CFM) - brushless DC motor with heater B-25 (4 HP / 12 Amps / 160 CFM) - double motor B-24 (3 HP / 12 Amps / 150 CFM) - with heater B-27 (6 HP / 19 Amps / 180 CFM) - double motor Air Purification:APDS-1 - Air Purification & Drying SystemX-3300 / X-3500 - Air ScrubbersTO:XPOWER MANUFACTURE, INC.220 Clary AvenueSan Gabriel, CA 91776, USATel: 626-285-3301, Fax: 626-285-3302。

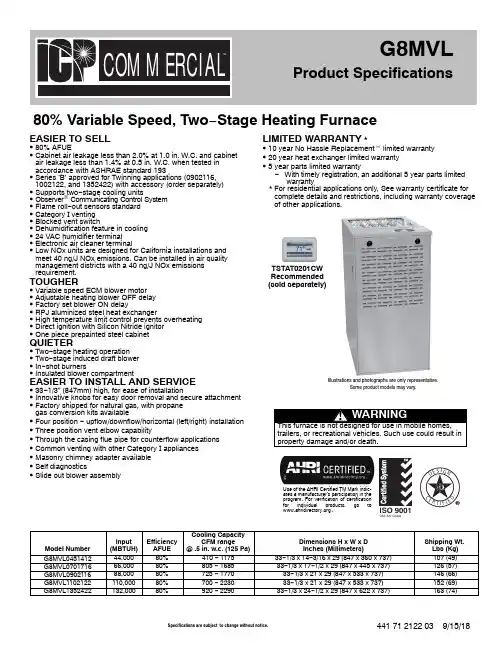

80% Variable Speed, Two −Stage Heating FurnaceEASIER TO SELLS 80% AFUES Cabinet air leakage less than 2.0% at 1.0 in. W.C. and cabinetair leakage less than 1.4% at 0.5 in. W.C. when tested in accordance with ASHRAE standard 193S Series ’B’ approved for Twinning applications (0902116, 1002122, and 1352422) with accessory (order separately)S Supports two −stage cooling unitsS Observer â Communicating Control System S Flame roll −out sensors standard S Category I venting S Blocked vent switchS Dehumidification feature in cooling S 24 VAC humidifier terminal S Electronic air cleaner terminalS Low NOx units are designed for California installations and meet 40 ng/J NOx emissions. Can be installed in air quality management districts with a 40 ng/J NOx emissions requirement.TOUGHERS Variable speed ECM blower motor S Adjustable heating blower OFF delay S Factory set blower ON delayS RPJ aluminized steel heat exchangerS High temperature limit control prevents overheating S Direct ignition with Silicon Nitride ignitor S One piece prepainted steel cabinetQUIETERS Two −stage heating operation S Two −stage induced draft blower S In −shot burnersS Insulated blower compartmentEASIER TO INSTALL AND SERVICES 33−1/3” (847mm) high, for ease of installationS Innovative knobs for easy door removal and secure attachment S Factory shipped for natural gas, with propanegas conversion kits availableS Four position − upflow/downflow/horizontal (left/right) installation S Three position vent elbow capabilityS Through the casing flue pipe for counterflow applications S Common venting with other Category I appliances S Masonry chimney adapter available S Self diagnosticsS Slide out blower assemblyLIMITED WARRANTY *S 10 year No Hassle Replacement t limited warranty S 20 year heat exchanger limited warranty S 5 year parts limited warranty−With timely registration, an additional 5 year parts limited warranty*For residential applications only, See warranty certificate for complete details and restrictions, including warranty coverage of other applications.Illustrations and photographs are only representative.Some product models may vary.Use of the AHRI Certified TM Mark indic-ates a manufacturer’s participation in the program. For verification of certification for individual products, go to .ISO 9001QMI-SAI GlobalD ES I G NCE RT I F I EDModel Number Input (MBTUH)Efficiency AFUE Cooling Capacity CFM range@ .5 in. w.c. (125 Pa)Dimensions H x W x D Inches (Millimeters)Shipping Wt. Lbs (Kg)G8MVL045141244,00080%410 − 117533−1/3 x 14−3/16 x 29 (847 x 360 x 737)107 (49)G8MVL070171666,00080%805 − 168533−1/3 x 17−1/2 x 29 (847 x 445 x 737)126 (57)G8MVL090211688,00080%725 − 177033−1/3 x 21 x 29 (847 x 533 x 737)146 (66)G8MVL1102122110,00080%700 − 223033−1/3 x 21 x 29 (847 x 533 x 737)152 (69)G8MVL1352422132,00080%920 − 229033−1/3 x 24−1/2 x 29 (847 x 622 x 737)163 (74)G8MVLProduct SpecificationsTSTAT0201CW Recommended (sold separately)MODEL NUMBER IDENTIFICATION GUIDEDIGIT POSITION 123456,7,89,1011,121314G = Mainline G8M V L0451412B2N = Entry8 = 80% AFUE EFFICIENCYM = Multiposition POSITIONV = Variable Speed Blower Motor − ECMX = ECM Blower MotorS = Single−stageT = Two−stage TYPEN = StandardL = Low NOx FEATURE045 = 44,000 BTU/hr070 = 66,000 BTU/hr090 = 88,000 BTU/hr110 = 110,000 BTU/hr135 = 132,000 BTU/hr HEAT INPUT14 = 14−3/16”17 = 17−1/2”21 = 21”24 = 24−1/2”CABINET WIDTH08 = 800 CFM12 = 1200 CFM14 = 1400 CFM16 = 1600 CFM20 = 2000 CFM22 = 2200 CFM NOMINAL MAXIMUM COOLING AIRFLOW @ .5 IN. W.C.SALES (MAJOR) REVISION DIGITENGINEERING (MINOR) REVISION DIGITECM-Electronically Commutated MotorACCESSORIES PART NUMBER IDENTIFICATION GUIDEDIGIT POSITION12345, 6, 78, 910, 11N A H A00101DH N = Non−Branded BRANDINGA = Accessory PRODUCT GROUPH = Heating KIT USAGEA = OriginalB = 2nd Generation MAJOR SERIESProduct Identifier NumberPackage QuantityType of Kit (Example: DH = Draft Hood − Chimney Adapter)For California Residents:For installation in SCAQMD only: This furnace does not meet the SCAQMD Rule 1111 14 ng/J NOx emission limit, and thus is subject to a mitigation fee of up to $450. This furnace is not eligible for the Clean Air Furnace Rebate Program: PHYSICAL DATANATURAL GAS04514120701716090211611021221352422OUTPUT CAPACITY BTUH* (Nonweatherized ICS) †UpflowHigh35,00053,00071,00089,000107,000Low23,00035,00047,00059,00070,000 Downflow/HorizontalHigh34,00051,00068,00085,000102,000Low23,00035,00047,00059,00070,000INPUT BTUH*UpflowHigh44,00066,00088,000110,000132,000Low29,00043,50058,00072,50087,000 Downflow/HorizontalHigh42,00063,00084,000105,000126,000Low29,00043,50058,00072,50087,000TRANSFORMER (24 volt)40 VACERTIFIED TEMP RISE RANGE −_F (_C)High30−60(17−33)25−55(14−31)30−60(17−33)30−60(17−33)40−70(22−39)Low20−50(11−28)15−45(8−25)25−55(14−31)20−50(11−28)25−55(14−30)CERTIFIED EXT STATIC PRESSURE(in. w.c.)Heating/Cooling0.10/0.500.12/0.500.15/0.500.20/0.500.20/.050AIRFLOW CFM‡Heating−High/Low820/7251570/10451265/10301555/12951865/1640 Cooling11751685177022302290AFUE%*Nonweatherized ICS80.080.080.080.080.0 LIMIT CONTROL SPSTHEATING BLOWER CONTROL Solid-State Time OperationBURNERS (Monoport)23456 GAS CONNECTION SIZE1/2 inch NPTGAS VALVE (Redundant) Manufacturer White-Rodgers tMinimum Inlet Pressure (in. w.c.) 4.5 (Natural Gas)Maximum Inlet Pressure (in. w.c.)13.6 (Natural Gas)IGNITION DEVICE Hot SurfaceFACTORY−INSTALLED ORIFICE Size 43*Gas input ratings are certified for elevations to 2000 ft. (610 M). In USA, for elevations above 2000 ft. (610 M), reduce ratings 4 percent for each 1000 ft. (305 M) above sea level. Refer to National Fuel Gas Code NFPA 54/ANSI Z223.1-2012 T able F.4 or furnace Installation Instructions.†Capacity in accordance with U.S. Government DOE test procedures.‡Airflow shown is for bottom only return-air supply in comfort mode (as shipped). For air delivery above 1800 CFM, see Air Delivery T able for other options. A filter is required for each return‐air supply.ICS — Isolated Combustion SystemELECTRICAL DATAG8MVL VOLTSHERTZPHASEOPERATINGVOLTAGE RANGEMAXIMUMUNIT AMPSUNITAMPACITY #MAXIMUMWIRELENGTHFT (M)‡MAXIMUMFUSE ORCKT BKRAMPS† **MIN. WIRESIZE Maximum*Minimum*0451412115-60-11271048.010.834 (10.4)1514 0701716115-60-112710411.315.024 (7.3)1514 0902116115-60-112710410.213.427 (8.2)1514 1102122115-60-112710413.016.834 (10.4)2012 1352422115-60-112710413.016.834 (10.4)2012*Permissible limits of the voltage range at which unit operates satisfactorily.†Time-delay type is recommended.‡Length shown is as measured one way along wire path between unit and service panel for maximum 2 percent voltage drop.**Time-delay type is recommendedG8MVLA B C DCABINETWIDTHin (mm)OUTLETWIDTHin (mm)TOP AND BOTTOMFLUE COLLARin (mm)BOTTOMINLET WIDTHin (mm)FLUE COLLAR*in (mm)SHIPPING WT.LB (KG)045141214−3/16 (360)12−9/16 (319)9−5/16 (237)12−11/16 (322) 4 (102)107 (49) 070171617−1/2 (445)15−7/8 (403)11−9/16 (294)16−1/8 (410) 4 (102)126 (57) 090211621 (533)19−3/8 (492)13−5/16 (338)19−1/2 (495) 4 (102)146 (66) 110212221 (533)19−3/8 (492)13−5/16 (338)19−1/2 (495) 4 (102)152 (69) 135242224−1/2 (622)22−7/8 (581)15−1/16 (383)23 (584) 4 (102)163 (74) * 5 inch or 6 inch (127 or 152 mm) vent connector may be required in some cases.Venting Notes1.For common vent, vent connector sizing and vent material: United States−use the NFGC.2.Immediately increase to 5 inch (102 mm) or 6 inch (152 mm) vent connector outside furnace casing when 5 inch (127 mm) ventconnector is required, refer to Note 1 above.3.Side outlet vent for upflow and downflow installations must use Type B vent immediately after exiting the furnace, expect whenDownflow Vent Guard Kit is used in the downflow position.4.Type−B vent where required, refer to Note 1 above.5.A 4 inch(102 mm) single−wall (26 ga. min.) vent must be used inside furnace casing and when the NAHB00301VC DownflowVent Guard Kit is used external to the furnace.6.Accessory Downflow Vent Guard Kit is required in downflow installations with lower vent configuration.7.Chimney Adapter Kit may be required for exterior masonry chimney applications. Refer to Chimney Adapter Kit for sizing andcomplete application details.8.Secure vent connector to furnace elbow with (2) corrosion−resistant sheet metal screws, spaced approximately 180_ apart.9.Secure all other single wall vent connector joints with (3) corrosion resistant screws spaced approximately 120_ apart. SecureType−B vent connectors per vent connector manufacturer’s recommendations.MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS FOR ALL UNITSThis forced air furnace is equipped for use with natural gas at alti-tudes 0 − 10,000 ft (0 − 3,050m).An accessory kit, supplied by the manufacturer, shall be used toconvert to propane gas use or may be required for some naturalgas applications.This furnace is for indoor installation in a building constructed onsite.The furnace may be installed on combustible flooring in alcove orcloset at minimum clearance as indicated by the diagram fromcombustible material.This furnace may be used with a Type B−1 Vent and may be ven-ted in common with other gas fired appliances.This furnace is approved for UPFLOW, DOWNFLOW, and HORI-ZONTAL installations.Downflow Positions:{Installation on non−combustible floors only.For Installation on combustible flooring only when installed onspecial base or coil assembly.18 inch front clearance required for alcove.*Indicate supply or return sides when furnace is in the horizont-al position. Line contact only permissible between linesformed by intersections of the T op and two Sides of the furnacejacket, and building joists, studs or framing.BLOWER PERFORMANCE DATAMODEL SIZE G8MVL0451412G8MVL0701716G8MVL0902116G8MVL1102122G8MVL1352422 DIRECT−DRIVE MOTOR Hp(PWM)1/23/43/411MOTOR FULL LOAD AMPS 6.810.18.410.910.9RPM (Nominal)1200BLOWER WHEEL DIAMETER X WIDTHS −in(mm)10 x 6(254 x 152)11 x 8(279 x 20310 x 10(254 x 254)11 x 11(279 x 279)11 x 11(279 x 279)AIR DELIVERY − CFM (with filter)* COOLING AND HEATING AIR DELIVERY − CFM (Bottom Return with Filter)(SW1−5 and SW4−3 set to OFF. See notes 1 and 2.)Unit Size Selectable AC Switch Settiings External Static Pressure (ESP)SW2−8SW2−7SW2−60.10.20.30.40.50.60.70.80.91045−12OFF OFF OFF11901140110010651020985905800665525 OFF OFF ON620560520455410355305255See note 4 OFF ON OFF795755705670615585530490440405 OFF ON ON1020955930890840805755715645490 ON OFF OFF11901140110010651020985905800665525 ON OFF ON1455139013251255117510851000880755575 ON ON OFF1455139013251255117510851000880755575 ON ON ON1455139013251255117510851000880755575 Selectable CF Switch Settings External Static Pressure (ESP)SW2−5SW2−4SW2−30.10.20.30.40.50.60.70.80.91 OFF OFF OFF620560520455410355305255See note 4 OFF OFF ON620560520455410355305255See note 4 OFF ON OFF795755705670615585530490440405 OFF ON ON1020955930890840805755715645490 ON OFF OFF11901140110010651020985905800665525 ON OFF ON1455139013251255117510851000880755575 ON ON OFF1455139013251255117510851000880755575 ON ON ON1455139013251255117510851000880755575 Maximum Clg Airflow21455139013251255117510851000880755575 High Heat Airflow3915860825790735700650610550450 Low Heat Airflow3780730685635585545495450400370Unit SizeSelectable AC Switch Settings External Static Pressure (ESP)SW2−8SW2−7SW2−60.10.20.30.40.50.60.70.80.91070−16OFF OFF OFF1615157015301490145014051365132512801210 OFF OFF ON640See note 4OFF ON OFF840775700640See note 4OFF ON ON1045980920860805750690640See note 4 ON OFF OFF12201175112010751025970925875820775 ON OFF ON139013351290124512001155110510551015970 ON ON OFF1615157015301490145014051365132512801210 ON ON ON1890185018101750168516151545147513951275 Selectable CF Switch Settings External Static Pressure (ESP)SW2−5SW2−4SW2−30.10.20.30.40.50.60.70.80.91 OFF OFF OFF640See note 4OFF OFF ON640See note 4OFF ON OFF840775700640See note 4OFF ON ON1045980920860805750690640See note 4ON OFF OFF12201175112010751025970925875820775 ON OFF ON139013351290124512001155110510551015970 ON ON OFF1615157015301490145014051365132512801210 ON ON ON1890185018101750168516151545147513951275 Maximum Clg Airflow21890185018101750168516151545147513951275 High Heat Airflow31540149014501410136513201275123511901140 Low Heat Airflow313701320127512251180113510851040995950090−16OFF OFF OFF162515801535149014451390132512151070910 OFF OFF ON555See note 4OFF ON OFF845770670595See note 4OFF ON ON1010950880790725670580See note 4ON OFF OFF1210115511051035970910850800730660 ON OFF ON14051360130512551185113010701015960875 ON ON OFF162515801535149014451390132512151070910 ON ON ON209520101935185517701675154013001120940 Selectable CF Switch Settings External Static Pressure (ESP)SW2−5SW2−4SW2−30.10.20.30.40.50.60.70.80.91 OFF OFF OFF555See note 4OFF OFF ON555See note 4OFF ON OFF845770670595See note 4OFF ON ON1010950880790725670580See note 4ON OFF OFF1210115511051035970910850800730660 ON OFF ON14051360130512551185113010701015960875 ON ON OFF162515801535149014451390132512151070910 ON ON ON209520101935185517701675154013001120940 Maximum Clg Airflow2209520101935185517701675154013001120940 High Heat Airflow3173516851630158015201455137512351085915 Low Heat Airflow31230117511251055995930875820755690Unit SizeSelectable AC Switch Settings External Static Pressure (ESP)SW2−8SW2−7SW2−60.10.20.30.40.50.60.70.80.91110−22OFF OFF OFF2055200019501900184017901740167516251565 OFF OFF ON855755See note 4OFF ON OFF1060985875800700See note 4OFF ON ON1250118010951025925860775715See note 4ON OFF OFF1445138013201235117511001035955900825 ON OFF ON1685163015601505144513751320126511951140 ON ON OFF2055200019501900184017901740167516251565 ON ON ON2465241523652305223021402045192518051655 Selectable CF Switch Settings External Static Pressure (ESP)SW2−5SW2−4SW2−30.10.20.30.40.50.60.70.80.91 OFF OFF OFF855755See note 4OFF OFF ON655550See note 4OFF ON OFF855755See note 4OFF ON ON1060985875800700See note 4ON OFF OFF1250118010951025925860775715See note 4ON OFF ON1445138013201235117511001035955900825 ON ON OFF1685163015601505144513751320126511951140 ON ON ON2055200019501900184017901740167516251565 Maximum Clg Airflow22465241523652305223021402045192518051655 High Heat Airflow32105205520051955189518501795173516651580 Low Heat Airflow31740168516201560150514401385132512601205135−22OFF OFF OFF2040198519301880183017751715166015951510 OFF OFF ON850740See note 4OFF ON OFF1040960865755See note 4OFF ON ON1245117010801005920835750See note 4ON OFF OFF1450138513051245118010851015935880805 ON OFF ON1670160515401480142513501280122011351070 ON ON OFF2040198519301880183017751715166015951510 ON ON ON2520245524052350229021952090196518151615 Selectable CF Switch Settings External Static Pressure (ESP)SW2−5SW2−4SW2−30.10.20.30.40.50.60.70.80.91 OFF OFF OFF850740See note 4OFF OFF ON640See note 4OFF ON OFF850740See note 4OFF ON ON1040960865755See note 4ON OFF OFF1245117010801005920835750See note 4ON OFF ON1450138513051245118010851015935880805 ON ON OFF1670160515401480142513501280122011351070 ON ON ON2040198519301880183017751715166015951510 Maximum Clg Airflow22520245524052350229021952090196518151615 High Heat Airflow32260220521502100204519851925185517451600 Low Heat Airflow320051950189518451790173516751620155014751. Nominal 350 CFM/ton cooling airflow is delivered with SW1−5 and SW4−3 set to OFFSet SW1−5 to ON for nominal 400CFM/ton (+15% airflow)Set SW4−3 to ON for nominal 325 CFM/ton (−7% airflow)Set both SW1−5 and SW4−3 to ON for nominal 370CFM/ton (+7% airflow)The above adjustments in airflow are subject to motor horsepower range/capacity2. Maximum cooling airflow is achieved when switches SW2−6, SW2−7, SW2−8 and SW1−5 are set to ON, and SW4−3 is set toOFF3. All heating CFM’s are when low heat rise adjustment switch SW1−3 and comfort/efficiency adjustment switch SW1−4 are both set to OFF4. Ductwork must be sized for high−heating CFM within the operational range of ESP. Operation within the blank areas of the chart is not recommended because high−heat operation will be above 1.0 ESP5. All airflows on 21” (533 mm) casing size furnaces are 5% less on side−return only installations6. Side returns for 24.5” (622 mm) casing sizes require two sides, or a side and bottom to allow sufficient airflow at the return of the furnace7. Airflows over 1800 CFM require bottom return, two−side return, or bottom and side return or excessive watt draw may result. A minimum filter size of 20x25” (508 x 635 mm) is requiredACCESSORIESPART NUMBER DESCRIPTION0451412B0701716B0902116B1102122B1352422BNAHB00501FF External Bottom Filter Rack, 14 inch(14 x 25 inch washable filter included)XNAHB00601FF External Bottom Filter Rack, 17 inch(16 x 25 inch washable filter included)XNAHB00701FF External Bottom Filter Rack, 21 inch(20 x 25 inch washable filter included)X XNAHB00801FF External Bottom Filter Rack, 24 inch(24 x 25 inch washable filter included)XNAHA00506FB†Washable filter, 1 inch 16 X 25 (6 pack)X XNAHA00706FB Washable filter, 1 inch 24 X 25 (6 pack)X X XNAHA01101SB Combustible Floor Base (Not requiredwhen evaporator coil case is used fordownflow)X X X X XNAHB00301VC Downflow Vent Guard (Not required whenvent is routed through cabinet)X X X X XNAHA00401DH Chimney Adapter Kit 4−in. vent X X X XNAHA00301DH Chimney Adapter Kit 5−in. vent X NAHB01001LP*Natural−to−Propane Conversion Kit X X X X X NAHB01001NG*Propane−to−Natural Conversion Kit X X X X X NAHA00201HL High Altitude Kit X X X X XNAHA00801WK Twinning Kit for two furnaces of samemodel and seriesX X XTSTAT0201CW Observer Control System − SelfConfiguring Communicating Control X X X X XX Accessory available†Suitable for 17 inch external bottom filter rack.*Factory authorized and field installed. Gas conversion kits are CSA recognized.Copyright 2018 International Comfort ProductsLewisburg, Tennessee 37091 USA10441 71 2122 03Specifications subject to change without notice.。

qwertON-PREMISESWasher-Extractors18 lb (8 kg)25 lb (11 kg)35 lb (16 kg)55 lb (25 kg)75 lb (34 kg)100 lb (45 kg)135 lb (61 kg)165 lb (75 kg) Built Better To last LongerWasher-Extractors Variable Speed DriveAutomatic Supply InjectionThe benefits ofour AutomaticSupply InjectionSystem willshow up inreduced waste ofdetergents andmore consistentlaundry results.A self-cleaning,multi-compart-ment dispenserautomaticallydispenses deter-gents for prewashand main wash and fabric softener for final rinse. In addition, tubing and electrical connections are provided on the rear of the machine for easy on-site hookup to a central liquid supply system.Durable 304stainless steelconstructionon the washer-extractorswon't corrode,chip, crack orpit with normal use, and is extremely corrosive-resistant. In fact, the stainless exterior, top and front panels will maintain their lustrous appearance for years. Stainless Steel ConstructionSince all fabrics have different extract speed requirements, our line of softmount washer-extractors have variable extraction speeds. A low extraction speed is ideal for synthetics, permanent press and blends. A mid-range extraction speed is ideal for mattress pads, blankets and spreads. A high extraction speed is ideal for terry and cotton items.A higher G-force during extrac-tion lowers the water retention of the fabrics being processed.A lower water retention also reduces the gas or electricity used during the drying process saving both time and money. Shorter dryer tumbling time also reduces linting and extends linen life. High speed extraction elimi-nates preconditioning of items to be ironed, saving energy while increasing production. High speed extraction removes a large per-centage of moisture from laundry loads and may allow flatwork to be fed through flatwork finisher without prior drying.Superior Performance SuspensionExtensiveengineeringefforts havedeveloped aheavy-dutysuspensionsystemdesigned forsuperiorwashing performance and to absorb out-of-balance load vibrations without the need for special foundations.Speed Queen’s 18- lb through 55-lb. extra large capacity softmountwasher-extractors fit through 36”door openings. Softmount washer-extractors require no additionalcement base, making installationeasier and less costly.Easy InstallationWith theuse of themicro-processorcontrol, ourwasher-extractorscan be customized for specializedapplications or operated using anyof the 39 preset programs. Thereare a total of 99 cycles available.A screen with step-by-step digitaltext and numeric instructions pro-vides feedback to the operators ofwhat cycle the washer is in andprovides more detailed informationfor technical service during diag-nostic checks.Flexible, User-FriendlyControlSX18 - 75lb modelsSX100-165lb modelsFully Programmable Electronic Control。

烘干机使用说明书摘要:1.烘干机的概述2.烘干机的安装与使用3.烘干机的维护与保养4.安全注意事项5.烘干机的故障处理正文:【烘干机的概述】烘干机是一种家用电器,主要用于将洗涤后的衣物快速干燥。

烘干机在工作时,通过加热空气并循环流动,使衣物中的水分蒸发,从而达到快速干燥的目的。

烘干机具有操作简便、效率高、占地面积小等优点,是现代家庭生活中不可或缺的家电之一。

【烘干机的安装与使用】在安装烘干机时,应选择一个通风良好、电源方便接通的地方。

按照产品说明书的要求,将烘干机摆放在平稳的地面上,并确保烘干机底部的空气进出口畅通无阻。

接下来,将电源插头插入电源插座,打开烘干机上的开关,即可开始使用。

在使用烘干机时,应确保衣物已经过洗涤,并将衣物挂在烘干机的晾衣架上。

关闭烘干机门,选择合适的烘干程序,即可开始烘干。

烘干过程中,请勿打开烘干机门,以免影响烘干效果。

待烘干程序完成后,打开烘干机门,将干燥的衣物取出即可。

【烘干机的维护与保养】为了确保烘干机的正常运行和延长使用寿命,应定期进行维护与保养。

首先,每次使用烘干机后,应清理衣物残留的线头、毛发等杂物,防止堵塞烘干机的通风口。

其次,定期清洁烘干机内部,可采用湿布擦拭或专用清洁剂进行清洁。

最后,定期检查烘干机的电源线、插头等部件,发现损坏及时更换。

【安全注意事项】在使用烘干机时,请务必遵守以下安全注意事项:1.请勿在烘干机上放置未洗涤的衣物,以免污染。

2.请勿将烘干机用于洗涤衣物,以免损坏设备。

3.请勿在烘干机上晾晒非衣物物品,以免损坏设备。

4.请勿让儿童单独操作烘干机,以免发生意外。

5.请勿将烘干机放置在易燃、易爆物品附近,以免发生火灾。

【烘干机的故障处理】在使用烘干机过程中,可能会遇到一些故障。

遇到故障时,请不要自行拆卸维修,以免造成人身伤害。

应立即切断电源,并联系售后服务人员进行处理。

常见的故障及处理方法如下:1.烘干机无法启动:请检查电源线、插头是否正常,或者联系售后服务人员进行检查。

扫描二维码,即刻体验产品 精致工艺和领先科技热泵式干衣机使用说明书使用前请仔细阅读说明书请妥善保存,以备参阅本产品只适合在中国大陆销售和使用CB N9G2U1卡萨帝为了精确实现您的格调生活,对其家族每一类产品都赋予了专属的境界理念。

本产品为您带来的是即时干燥。

CB N9G2U1为家用热泵式干衣机。

请仔细阅读本说明书来帮助您安全、舒适地使用产品。

为了能安全地使用产品,请在使用产品之前务必仔细阅读安全注意事项等内容。

12关于本产品的安全注意事项 .........................................................3本产品的外观及部件介绍 . (6)干衣机各部分构件名称(正面) ............................................6干衣机各部分构件名称(背面) ............................................7附件 .....................................................................................7本产品使用前的安装设置 . (8)注意事项 ..............................................................................8连接电源 ..............................................................................9连接进水管(使用空气洗功能时).......................................8调整底脚 ..............................................................................9连接排水管(如有需要) .. (10)安装香薰模块(如有需要)...)...............................................10安装烘干支架 .....................................................................11干衣前准备 .................................................................................12使用本产品的基本操作步骤 ........................................................13本产品的干衣方式及功能介绍 . (15)显示屏 ..............................................................151. 开机操作............................................152. 干衣程序选择..............................................................16干衣程序指南 .....................................................................24负载参考 ............................................................................24本产品的日常保养与维护 ...........................................................25有疑问?先看这儿! (28)(若对干衣机有疑问,请先按本章内容检查处理。

衬衫缝后复司机Automatic back york pleat sewing machine(MB3008A)使用说明书Instruction Manual常州智谷机电科技有限公司CHANGZHOU WISDOM &VALLEY ELECTRICAL TECHNOLOGY CO.,LTD在使用本设备之前请先阅读本使用说明书Please read the operation manual of the touch screen interface before using the device 请将本使用说明书放在便于查阅的地方保管Please keep this operation manual of touch screen interface in convenient placeforreference2022.04.03版本信息/Version感谢购买IMB工业用缝纫机。

在使用此机器之前,请仔细阅读以下的说明,这样可以更好地帮到您了解此机器的相关操作。

这些说明是根据现行的条例明确阐述了正确的工作方法。

Thank you for purchasing this industrial sewing machine from IMBBefore using this automatic unit,please read the following instructions,which will help you tounderstand how the machine operates.These instructions illustrate the correct working methods to comply with current regulations.在没有得到IMB授权许可的前提下,此说明书的任何部分是不可以被复制或者转录的。

说明书的内容可能被修改,而不需预先通知。

SPEEDQUEEN美国速比坤商用烘干机

型号:LES17

操作手册

烘干前准备工作

节能贴示

✧确认绒毛过滤器始终保持清洁。

✧不要过度装载。

✧不要过度烘干衣物。

✧衣物仍旧潮湿情况下拿出来熨烫。

✧相似面料大量放在一起烘干能到到最佳节能效果。

免烫织物在烘干时,装载

量不宜过大以防止褶皱。

✧不同面料选择相应的烘干程序。

✧放置烘干机时,尽可能保持排风管道短而直。

✧在烘干进程中,不要打开滚筒门。

✧尽量安排在湿度低的天气里烘干,这样可以提高烘干效率。

✧不同面料的衣物依次烘干,减少烘干机预热。

帮助与提示

警告:为减少火灾隐患,如果织物上留有食用油、机油、可燃化学品或稀释剂等等,则严禁放入烘干机。

详细的安装说明书在烘干机里面,包括了必要的安装提示和排风设置。

静电容易使衣物吸附在一起(类似女士内衣等),尤其是在过度烘干的情况下。

在水洗程序的漂洗阶段添加液体柔顺剂或者在烘干程序中添加柔顺纸,都能有效柔顺衣物并且解除静电。

不用把容易落毛的衣物和免烫或者针织品放在一起洗涤或烘干。

烘干免烫衣物时,程序一停止,立即将衣物取出。

根据衣物标签(防火,防油防水等),选择合适的洗涤和烘干程序。

如果需要熨烫,把计时器调节到ENERGY SA VER 节能状态。

烘干机操作

装载

不用过度加载衣物。

过度加载会造成变色或者永久性损伤。

在加载时,滚筒要留有足够的空间可以使衣物自由滚动以减少褶皱。

大件织物和小件衣服同时烘干可以达到最佳效果。

免烫衣物在烘干时,加载量要小,要留出足够的空间让衣物滚动。

适合的滚动可以减少褶皱。

图1标明了理想的加载量。

平均加载量为滚筒的1/3到1/2(潮湿衣物)。

如果加载量过小的话,会引起不均匀滚动。

造成烘干时间长和褶皱多。

如果需要烘干小件衣物,可以在滚筒中添加毛巾或者不易脱毛的物件来增加滚动效果。

烘干程序

警告:为减少火灾隐患,在操作前仔细阅读安全说明。

用于烘干小容量的厚衣物,比如兰色牛仔裤。

同样也用于过度烘干薄衣物,比如床单和衬衫。

过度烘干会引起褶皱、脱毛并且耗能。

比较节能,用于烘干大容量的薄衣物,比如床单和衬衫,或者粗斜纹棉布、厚浴巾、比较湿的衣物。

选择LESS DRY 可以节能并且不容易造成过度烘干。

如果衣物在程序结束后仍然潮湿,那就把定时器的旋钮转到MORE DRY。

如果衣物在程序结束时处于过度烘干状态,那就把旋钮调到COOL DOWN(冷却)。

让衣物能够慢慢冷却到室温状态。

这样可以减少褶皱。

标识为黑点(·),此程序最节能,并让衣物保持最佳湿度以便熨烫。

烘干程序及操作

此程序主要用于烘干运动服或者工作服,还有精细织物。

通过织物选择器来决定用烘干温度。

AUTOMATIC REGULAR/DELICATE CYCLE自动常规/精细程序可以选择:MORE DRY强行烘干和LESS DRY普通烘干。

此程序的烘干时间可达到75分钟。

一般,棉布厚织物烘干时间需要50到75分钟。

薄织物的烘干时间需要20到40分钟。

此程序适用于免烫和人造织物。

通过织物选择器来决定用烘干温度。

AUTOMATIC PERMANENT PRESS/KNITS CYCLE自动免烫/针织品程序可以选择:MORE DRY强行烘干和LESS DRY普通烘干。

操作——烘干衣物

重要提示:在使用前仔细阅读安装手册。

重要提示:第一次使用前,用清洁剂和湿布来擦洗烘干机滚筒。

重要提示:衣物烘干前,仔细检查是否混入尖锐物品,以免损伤机器。

1、衣物分类放置。

2、打开绒毛过滤器的盖子,清洗过滤器,然后盖上盖子。

3、将衣物松散的放入滚筒内(最大9.0KG)。

如需要,加入织物柔顺纸。

重要提示:为防止损伤烘干机,烘干过程中不要过量使用柔顺纸(每次一张就可以了)。

烘干程序及操作

4、关上滚筒门,门在打开状态时,机器不能启动。

5、设定织物选择器。

根据衣物上的厂商标签来选择合适的烘干温度。

6、选择合适的烘干程序,这些程序设有固定的烘干时间。

标识为黑点(·),此程序最节能,并让衣物保持最佳湿度以便熨烫。

7、推进定时旋钮,启动烘干机。

注意:要随意停止烘干程序,可以打开滚筒门或者将定时器旋钮调到OFF位置。

要重新启动烘干机,如有必要,重新设定定时器,并且推进旋钮。

程序结束报警

(不适用于所有型号)

该报警的音量有三种选择:OFF关闭,LOUD响亮,或者在这两者之间。

如果没有选择关闭,程序结束后,报警声自动响起并持续到门打开,或者把定时器调到OFF位置也可以关闭报警。

选择配件

烘干架,配件编号510239,属于选择配件,要另外购买。

烘干架用于烘干不能滚动的物件,比如网球鞋,毛线衫,填充玩具或者一些精细织物。

马达超负荷保护装置

该保护装置在马达超负荷情况下,自动启动。

等到机器冷却后,该装置会自己复原。

按下定时器,可以重新启动烘干机。

如果该保护装置再次启动,关闭烘干机,请服务人员来解决问题。

绒毛过滤器

绒毛过滤器位于烘干机门打开的下方位置。

每次使用前,都要清理绒毛过滤器。

打开盖子,清理过滤器,然后盖好盖子。

每年都要取出过滤器,并用真空吸尘器清理下面的管道。