模具专业英语Unit 5 What Is a Machine Control Unit.ppt.

- 格式:ppt

- 大小:1010.50 KB

- 文档页数:16

班级:姓名:学号:一、选择填空(选择合适的词,将句子含义补充完整,每小题1分,共30分)1. The problem of injecting a melted plastic into a mold cavity from a reservoir of melted material has been ________ difficult to solve.A extractB extrudeC extremelyD extinct2. The process ________ of feeding a plastic compound in powdered or granular form from a hopper through metering and melting stages and then injecting it into a mold.A consentsB constantC consumesD consists3. After a brief cooling period, the mold is opened and the _________ part ejected.A frozenB meltedC solidifiedD sold4. It must therefore be removed _________.A annuallyB manuallyC normallyD mainly5. Furthermore, all thermoplastic materials contract as they solidify, which means that the molding will ________ on the core which forms it.A shrinkB shareC shiftD shut6. A compromised between the two extremes must therefore be accepted to obtain the ________ molding cycle.A operateB optimumC optimisticD optical7. The layout of a circuit is often complicated by the fact that flow ways must not be _______ too close to any other hole in the same mould plate.A drilledB drawnC chilledD thrilled8. The internal thread comes within the broad definition of an ________ undercut in that the thread forms a restriction which prevents the straight draw removal of the molding from the core.A internetB internalC installD inventor9. Finally, continued movement of the stripper plate ________ the molding from the mould.A exertsB excludesC extendsD extracts10. In this the threaded portion is machined in the split halves which are opened _________ molding being extracted.A prior toB previous thanC in order toD so that11. The _________ should be strong enough to give an initial impetus to the floating cavity plate.A. core B springs C thread D pillar12. The major part of the feed system (runners and sprue) is __________ in the feed plate.A accomplishedB accommodatedC comprisedD accompany13. This flow-way is ________ the feed system.A turnedB classifiedC utilizedD termed14. The sprue, the runner and the gate will be _________ after a part is complete.A discardedB dismissedC dispersedD disputed15. For reference, are the included tapers _________ by various standard parts suppliers.A adaptedB adoptedC mountedD addicted16. The first is a sprue bush with a spherical recess which is used in ________ with a spherical front ended nozzle as illustrated.A confrontB consistC conjunctionD comprise班级:姓名:学号:17. This drawback will not present if slight misalignment _________ at the seating of the flat-faced sprue bush and nozzle.A occursB persistsC obscuresD perceives18. The register ring is a circular member ________ on to the front face.A floatedB fittedC filledD sat19. The ________ of efficient runner design is that the runner should provide a maximum cross-section area from the standpoint of pressure transfer and a minimum contact on the periphery from the standpoint of heat transfer.A criterionB crimeC criticD cream20. It is not always practicable, however, to have a ________ runner system and this particularly applies to moulds which incorporate a large number of differently shaped impressions.A beltB bendingC balancedD base21. The gate freezes ___________ the impression is filled so that the injection plunger can be withdrawn without the probability of void being created in the molding by suck-back.A hours laterB beforeC meanwhileD soon after22. Packing the impression with material in excess of that required to ________ for shrinkage is minimized.A conductB compensateC controlD consult23. The guide applies, except where __________ stared, to the general case of a molding with a wall section between 0.75mm and 4mm.A howeverB otherwiseC unlessD but24. The parting surfaces of a mould are those portion of both mould plates ________ the impressions.A adjacent toB adjust toC accommodate toD addict to25. For appearance this is the ideal _________ as the parting line is not noticeable unless flash develops.A arrayB assetC arrangementD alignment26. The suitable choice for the parting line is on the centre of the double-bevel which ________ for half of the required form to be die-sunk into each of the two mould halves.A premisesB permitsC toleratesD allows27. The plastic material when under pressure within the impression, will _______ a force which will tend to open the mould in the lateral direction.A extractB examineC extinctD exert28. The cavity and core give the molding its external and internal shapes ___________.A respectivelyB prospectivelyC preciselyD differently29. In this design, the splits are mounted in guides on a flat mould plate and they are __________ in one plane by mechanical or hydraulic means.A activeB analyzedC actuatedD action30. The primary purpose of the __________ is to machine cylindrical forms.A latheB planerC milling machineD grinding machine班级:姓名:学号:二、阅读(根据阅读材料,回答问题,每小题10分,共20分)The cross-sectional shape of the runner used in a mould is usually one of four forms: fully round (a), trapezoidal (b), modified trapezoidal(c) and hexagonal (d).The criterion of efficient runner design is that the runner should provide a maximum cross-section area from the standpoint of pressure transfer and a minimum contact on the periphery from the standpoint of heat transfer. The ratio of cross-sectional area to periphery will, therefore, give a direct indication of the efficiency of the runner design; the higher the value, the greater the efficiency. Ratios for various types of runner section are given in Figure 1. As can be seen, the round and square types of runner are the two most satisfactory designs from this standpoint; whereas the ratios exhibited by the semicircular and rectangular types make their use generally undesirable.Figure 1Question: 1.Which type of runner is the most efficient runner from the standpoint of pressure transfer and heat transfer?2. Please give the value of efficiency of the equilateral triangle (等边三角形) type of runner according to the criterion mentioned above.Equilateral triangle三、英译汉(将下列英文句子翻译成中文,每小题10分,共50分)1. The work on the cavity and core can further be classified depending upon whether the form is of a simple or a complex nature.2. The terms “cold forging”and “cold extrusion”are often used interchangeably and refer to well-known forming operations.3. As can be seen, no leakage can occur if the two apertures are slightly out of the line and no restriction to flow will occur either, providing that the sprue bush has an aperture slightly larger than that of the nozzle.4. The ratio of cross-sectional area to periphery will, therefore, give a direct indication of the efficiency of the runner design; the higher the value, the greater the efficiency.班级:姓名:学号:5. The movement between the two mould halves will be resisted by the guide pillars, but even so, because of the large forces involved, it is desirable to balance the mould by reversing the step so that the parting surface continues across the mould as a mirror image of the section which includes the impression.。

1) Designer - 设计师。

2) Assembly drawing - 模具组装图。

3) Mold layout - 模具结构图。

4) 2D product drawing - 2D产品图。

5) 3D product data - 3D产品数据。

6) Part drawing - 散件图。

7) Insert molding - 镶件模。

8) 2 color mold / Double injection tool - 双色模。

9) Hydraulic system - 油/水压系统。

10) Parting line - 分模线。

11) Air venting - 排气槽。

12) Cooling system - 冷却系统。

13) Screw - 镙丝。

14) Hot runner system - 热流道。

15) Valve gate - 伐针入水口。

16) Fan gate - 扇型入水口。

17) Pin point gate - 针点进胶。

18) Moon gate / Banana gate - 香蕉,象牙入水口。

19) Submarine gate - 潜水口。

20) Injection machine tonnage - 注塑机吨数。

21) Number of cavity - 穴数。

22) Steel - 钢材。

23) Copper - 铜。

24) Tungsten copper - 钨铜。

25) Beryllium copper - 铍铜。

26) Hardening - 加硬/淬火。

27) Tempering - 回火。

28) Chroming - 电镀。

29) Painting - 喷漆。

30) Resin - 胶材。

31) Printing - 丝印。

32) Texturing - 嗮纹/咬花。

33) Socket screw - 带肩镙丝。

34) Inter lock / Straight lock - 模锁。

![[电子教案]模具专业职场英语 (5)](https://uimg.taocdn.com/d18810c352d380eb63946db6.webp)

机械设计制造模具专业英语Introduction机械设计制造模具专业英语,也称作Mechanical Design and Manufacturing Mold English,是指在机械设计与制造模具领域使用的英语专业术语和表达方式。

机械设计制造模具专业英语在国际工程领域具有重要的地位,掌握这些专业英语词汇和表达方式是从事机械工程设计及制造模具工作的专业人员的基本要求。

Importance of Mechanical Design and Manufacturing Mold English随着经济全球化的发展,跨国企业之间的合作也越发频繁。

跨国机械设计制造模具领域的沟通与合作需要一种共同的语言,因此,机械设计制造模具专业英语的重要性愈发凸显。

1. 提高沟通效率机械设计制造模具专业英语的掌握可以有效提高与国外同行之间的沟通效率,减少误解和不必要的麻烦。

当进行跨国合作时,准确的理解对方的需求以及清晰地传达自己的设计意图非常重要,而机械设计制造模具专业英语的运用可以帮助实现这一目标。

2. 深入了解最新技术和工程领域进展机械设计制造模具专业英语是关于机械设计制造和模具领域的专业术语和表达方式的总结和归纳。

通过学习这些专业英语,可以更深入地了解最新的技术和工程领域进展。

同时,它也是获取国外设计制造模具资讯和技术文献的重要途径。

3. 提升竞争力掌握机械设计制造模具专业英语的人员在求职市场上具有更大的竞争优势。

在跨国企业或国际组织中,能够流利地运用机械设计制造模具专业英语的工程人员受到更高的重视,往往能获得更好的职业机会和发展前景。

4. 加强行业合作与交流机械设计制造模具专业英语的学习和应用也促进了国际间机械设计制造模具领域的合作与交流。

通过共同的语言,技术与经验可以更容易地共享和传递,从而促进行业的发展与进步。

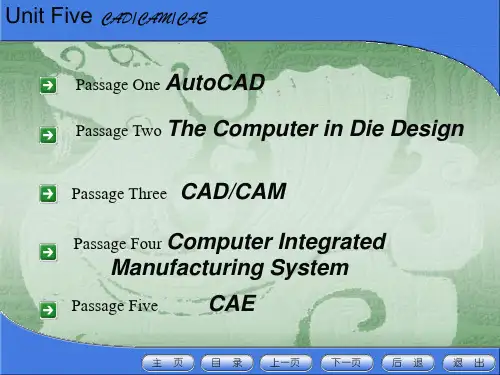

Essential Vocabulary in Mechanical Design and Manufacturing Mold English下面是一些在机械设计制造模具专业英语中经常使用的关键词汇:1.Mechanical Design and Manufacturing Mold: 机械设计制造模具2.Tooling and Mold Making: 工装模具制造3.CAD/CAM: 计算机辅助设计/计算机辅助制造4.Tolerance: 公差5.Injection Molding: 注塑成型6.Die Casting: 压铸C Machining: 数控加工8.Rapid Prototyping: 快速原型制作9.Finite Element Analysis: 有限元分析10.Assembly: 装配这只是机械设计制造模具专业英语中的一小部分关键词汇。

! " #$ "% & '( ') *+ , " '( - '. /01 '( '2/0 & '( '3&- 42+5/01 & " '( )'( '*+6/1 ' " '(7 /0 ' ( 84( )& 4 '( ' /09:;< - 4 % " " /0=>1'( ' ?2+ & " '(2/0@ & - 4A2B ' ' & 'CD1 & '- ( "EF ' (EG ' " HIJ)JK "L M % 'NO (NB (?PQB " (?RSTF U 44 V( H ' ( )" H 'W XY - - " L@ Z -.@ [ -\])^\ ' ) ( \_)^` ?("& ) ( ?("& ab_ "& ( ' ( ?("& ab\c (dD@ U ' ' ' b@ "( 'ef " ' %B] %g h ? ' "i B ' ) j ' H dD U '_k U ' " j_kD U 'l@ " ' 'mn - j ? ' 3' (' '' ( 'opqrstuv &Hwd 4 'xqyv - ? "zi j " '{i ' " '| q}~v "Y " ' G)w %@) @ % % 'F1 "( ' '*+ " '( ?("&@ "'o &o ' H "l ("& ? 'efd@ ' (' (j ' '-;/ " (' " ' '_1?("&] "?(44" ' '1 " 'ab_ U ' ( ?("&ab\ U ' (D%? &NO1 (~ Hwd 4' -wd U ' 'rstu ' H"j ' '-¡ ¢£¤ ' ' ('? '¥¦ j j "w^\§ '-"¨ =©=> ' "('4"( ' ?ª¥ ' j¤D«K ' ('j '4 '¬®¯°p±² - ? ""&( & &dD«M % ''4 ' " % & U 'K ¯z){ ' 4' - j &8 ' ³ "x´µ¯K j '( ¶ 3 ' ' (·¸¹ Y º ("8 ' ) j ³ " '¹»¼½ Y (" ? ' (-' " '¾¿qÀ v ÁÂà ' '84 ³ - "Än ' j '" 'mÅ " ' - ' ""&Æ ÇÈ " ? 3" ?ÉÊ·Ë "(44 'ÌÍ5Î jo " H2ÏÐ & ' Ñ "ÒÓ '¼Ò89Ôv ' 'ÕÖ a× Ø ÙÚÛÜZ Ý [ - j ? - (- j & 4Z [ Ý G@ 4 Ñ -3 -Z [ [ G@ - j- ? - -? -Z [ Z z G@ ( '-Z [ Þ { G@ % '-Z [ ß à á @ j' 'Z [ â ãäá @ '' 'Z [ å æ á @ ( &' 'Z [ ç ` & " ? " '4' -Z [ è é¨@ ? H"( ''Z [ Ýê ë~ " ''Z [ ÝÝ éy U '& (" - ( ? "¶"" -? ìíîc ( ïðÁñ j '/ îòK@ó j ? t]pó j ( t]ô' % ' j 'õö ' " ' % ' j '9 õ÷ (- " ' % ' j '¥ õ% 'H ? øùúûû ¶güýþ4 & 'ìíÿ õ4 " 8ef³4 Ñ (' 8 ³@? '? ' " '4(" & '4(" - & 2 p' '' 'ùñ B"&' H )"&' H m- Ñ '·º" ' &4o' ' "" ·l' - ' R Y·l4 4 H ? Y»¼½ - H ( ¾8" ' ¿º% ' " " À"& )"('4 ' "" )©ÁÑ " - )? ' - ³´Âà H 4 78·t" 4 ÄÅV( ¸j ' ÆÇÈ" 9É' ø' '' ' " M ' ' "Ñ " ' U "34ñ B% 'H ' ø' ( 3 ' ( 1V( - Â;" ' ' ""gp" )"% & 44 ' ""Êp"" 4 <' ( <Ë""Ì" 'j ÌÍ( (' vÎV( 4 ' ( "3 ( ' ' ( "l4 j ' ( "3 (' ' ( "·l% " h K? ' Ï@4 's Kp" ' H}Ky4 j ' ( ? Ñ·l ü& Ð4 Ñ íH ' Ñ' 'H - ' YÒ? "H ÓÔÕ" ? "H QÖ" ? 44 D? '' @' ? Ñ,ü( " ' &t×( - ' 3 ( - ' 3 ( ØK- " " î- ' ""3 - ' "" m& ' ' Ù4 3 4 s K ' " ' MÚ8? ³V( 4 3 ( ' ²( ' 3 V( 4 ·²- ' & 3 " H & ÒK²Û4 (' & TDzÛj ( ÜÝ' ' 4 '3 - H ' ' "4 ' ¸;' - '"Þß' " 3 ' j ( $S- (4 (' - - B? '- & à:Á' ( ( 1" 4 ' ( 1áÅ" â@' - ' ãK- (4 (' ' ('' ' (' ù /' j " 3 - 4 ä"% & j ' 3 "% &&' % j ' "% & j 'HÐ' 3 ' U 44 (ø åæ" ø( - ç n" H 3 " H 3 ' j N(?' è}"&( y"&( & & 4 y Ê- j é4 'ê' % ëL( &(F" ' ~8ì Y³?('' ( & \\(' j ( & î(" - ( &Ù (' ( ( &7(" "& ( &à (? ? H¼í' 'îï? 44 ~? H ~"( ' ? H 4 'é¨~' ("& ¥ë@' ("& U ' ¥ëd' -- ( &H\(" 44 ' ? ( & M " 'Éð(' ?? ( & ð(' " ' & ( &ã7 =(( @" ? H}~" % ? H}~á ~j @% ' " {}~@( ' & ' ? H z ~( ' - za*@" ' ? Ñ ñü" ' ? Ñ U ' ñüd" ' ? Ñ U ñüd@?("& ? Hò`j ' ó@( ^K~PY B ôÊ ×- ' " - m9ã4 "& - õ/" j - ö" - ;Ij ã÷ ø' ù Ò' ú& ' Hûüý"& j 'þÿ4 % - 'H/p% - 'H p" " ' % " ' eÿ`k" 4 " ' %ç ef" ' ' K@" O' `& ò& - ?$9ã¹"( - Jí9ã% Ô q v% K"( '( ' 0& '( '2 0'( ' 0 ~j j ¦2? & ' » ¥92" ¦D" ' & E F" % 5K" 5K' j ª¥0&Mê ê[ ê êß--%M Z [--c M Z ß--% pU d¯DH H d¯' (' ¤ ÄdD" j `k" ' ' K@" ' ' ð'( ' " ' ' 0 K@( ^U ' 8? '³q9ãpvd"(?# ' ×5Á&' LÔ'( ' " " - 0" ' "" ' H /9'" '( K 6## +" '( H KF! 8tK ³ " % 5K" ""? #T4 - $4 "& %2" &µ4 '"& ()M*MÝ)[ Ý)ßM[ ß Z ß--&' - $'"(? ' +( ,0D¯8" '( ""³ KB## - .+" '( D" - 3 ' ""(( & ' ""3 ( ' ""( =( ' B " ' & '<=p 4 's Kp' H3 "& 43 " H Ky'' ? p>?H '/Kpj ' ? Ús»' "- "" ' HÚs y" z0¯? - " {0¯" ' H |&( 3 1' 8- ' ³ K(- 3 3 ? H " ~' ""- & 23p" ' &io4 '- ²4 "4j' % & "q5V( ' 3 " ' & 4 'þ6" H3 " ' 3 " H X7 ' j 8/' j Ñ - j ' 4 9:' "" 3 ' "" øj ' 3 j ' ÆÇ' (' j '" ' ? H' ' 4 "fÇ' " ' ;<' " ' ' ;<=' B( 4 '% ' & ¢g" 4 " HÄÅX7M ' j >?@A4 '- 4 ' (' & " BC"(- 3 "(- DE4 FG?' " H' j '" M & -4 'IJ& ' ' Ù3 & '?K4 (' 3 ' (? LM" " " Ã- "( NO' ' ' PQ=H ' e{íz& ? R e" ' ? RS e- j % T @" - ' "UH Y" ' ' " ¸Y?' H 8? ³?' H 38? ³ ' HV(?' è}-- j ?( ' 4 ''4 (' 4 3 & ' 4 ÁW( 3 ? H (X' ' "" j 3 4 % 8 ³1Y- (( & & (5? ' ~( "M" ( M" " 'H\? ¼Z( 3 " ' &t[c " ' & 3 ( ît[' j 3 ' j \]( " % "_\" H N" 3 " ÂÃ" - 4 Âòn? H ~4 ? H¼Z~" ? H}~4 dK3 4' ? ' @? Hë~" ? 'ë( ' ? " z G% ' ? " { G( ' "( ' ? H z¨@( ' ? H zë@" ' " ;" ' ñ? e。

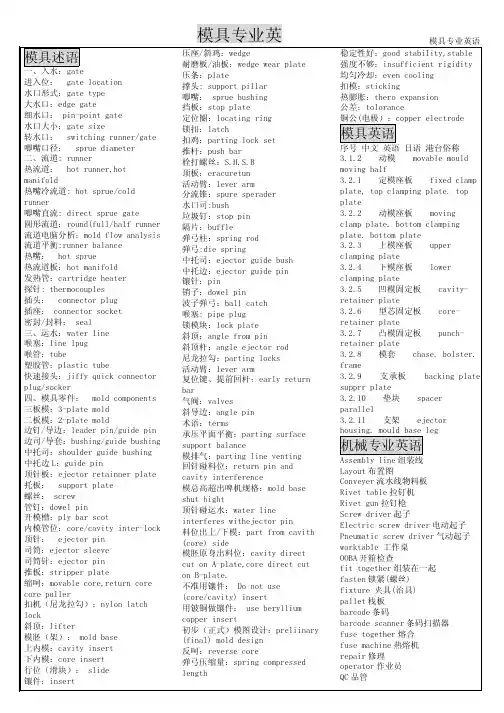

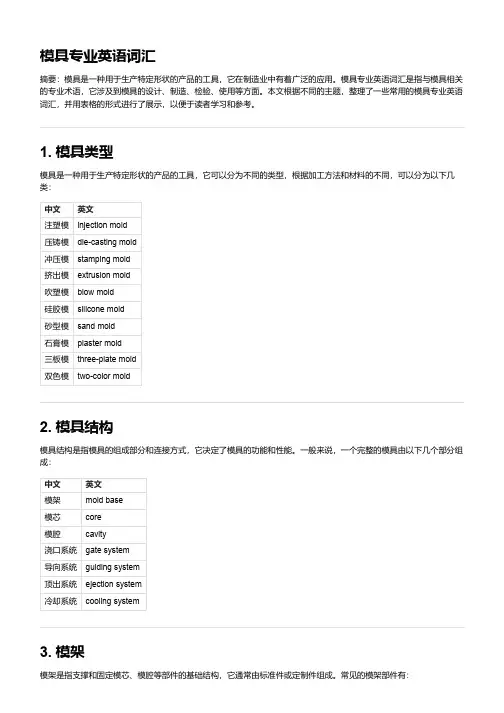

模具专业英语词汇摘要:模具是一种用于生产特定形状的产品的工具,它在制造业中有着广泛的应用。

模具专业英语词汇是指与模具相关的专业术语,它涉及到模具的设计、制造、检验、使用等方面。

本文根据不同的主题,整理了一些常用的模具专业英语词汇,并用表格的形式进行了展示,以便于读者学习和参考。

1. 模具类型模具是一种用于生产特定形状的产品的工具,它可以分为不同的类型,根据加工方法和材料的不同,可以分为以下几类:中文英文注塑模injection mold压铸模die-casting mold冲压模stamping mold挤出模extrusion mold吹塑模blow mold硅胶模silicone mold砂型模sand mold石膏模plaster mold三板模three-plate mold双色模two-color mold2. 模具结构模具结构是指模具的组成部分和连接方式,它决定了模具的功能和性能。

一般来说,一个完整的模具由以下几个部分组成:中文英文模架mold base模芯core模腔cavity浇口系统gate system导向系统guiding system顶出系统ejection system冷却系统cooling system3. 模架模架是指支撑和固定模芯、模腔等部件的基础结构,它通常由标准件或定制件组成。

常见的模架部件有:中文英文定模座板fixed clamping plate动模座板moving clamping plate定模套板fixed bolster plate动模套板moving bolster plate支承板backing plate垫块spacer block4. 模芯和模腔模芯和模腔是指与被加工材料直接接触并形成产品形状的部件,它们通常由钢材或其他硬质材料制成。

常见的与模芯和模腔相关的术语有:中文英文凹面(内型面)concave surface (inner surface)凸面(外型面)convex surface (outer surface)分型面(合型面)parting surface (matching surface)型芯固定板(凸模固定板)core-retainer plate (punch-retainer plate)凹模固定板(凸模固定板)cavity-retainer plate (die-retainer plate)5. 浇口系统浇口系统是指将熔融或液态材料从注塑机或压铸机输送到型腔中的通道,它包括浇口、流道、冷料井等部件。

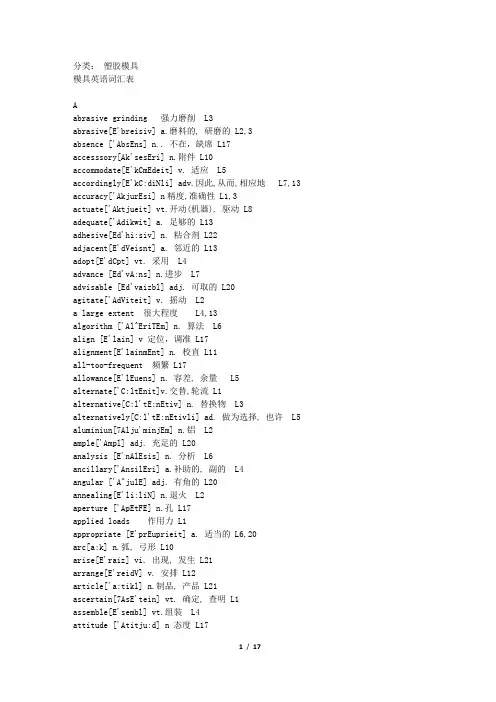

分类:塑胶模具模具英语词汇表Aabrasive grinding 强力磨削 L3 abrasive[E'breisiv] a.磨料的, 研磨的 L2,3 absence ['AbsEns] n.. 不在,缺席 L17accesssory[Ak'sesEri] n.附件 L10accommodate[E'kCmEdeit] v. 适应 L5accordingly[E'kC:diNli] adv.因此,从而,相应地 L7,13 accuracy['AkjurEsi] n精度,准确性 L1,3actuate['Aktjueit] vt.开动(机器), 驱动 L8adequate['Adikwit] a. 足够的 L13adhesive[Ed'hi:siv] n. 粘合剂 L22adjacent[E'dVeisnt] a. 邻近的 L13adopt[E'dCpt] vt. 采用 L4advance [Ed'vA:ns] n.进步 L7advisable [Ed'vaizbl] adj. 可取的 L20agitate['AdViteit] v. 摇动 L2a large extent 很大程度 L4,13algorithm ['Al^EriTEm] n. 算法 L6align [E'lain] v 定位,调准 L17alignment[E'lainmEnt] n. 校直 L11all-too-frequent 频繁 L17allowance[E'lEuens] n. 容差, 余量 L5alternate['C:ltEnit]v.交替,轮流 L1alternative[C:l'tE:nEtiv] n. 替换物 L3alternatively[C:l'tE:nEtivli] ad. 做为选择, 也许 L5 aluminiun[7Alju'minjEm] n.铝 L2ample['Ampl] adj. 充足的 L20analysis [E'nAlEsis] n. 分析 L6ancillary['AnsilEri] a.补助的, 副的 L4angular ['A^julE] adj. 有角的 L20annealing[E'li:liN] n.退火 L2aperture ['ApEtFE] n.孔 L17applied loads 作用力 L1appropriate [E'prEuprieit] a. 适当的 L6,20arc[a:k] n.弧, 弓形 L10arise[E'raiz] vi. 出现, 发生 L21arrange[E'reidV] v. 安排 L12article['a:tikl] n.制品, 产品 L21ascertain[7AsE'tein] vt. 确定, 查明 L1assemble[E'sembl] vt.组装 L4attitude ['Atitju:d] n 态度 L17auxiliary [C:^'ziljEri]adj. 辅助的 L8avoid[E'vCid] v.避免 L7axis['Aksis] n.轴 L5axle['Aksl] n.轮轴, 车轴 L1Bbackup['bAk7Qp] n. 备份 L9batch [bAtF] n 一批 L17bearing['bZEriN] n.轴承,支座 L21bed[bed] n. 床身 L5behavior[bi'heivjE] n. 性能 L1bench-work 钳工工作 L4bend[bend] v.弯曲 L1beneath[bi'ni:W] prep在···下 L4bin [bin] n. 仓,料架 L19blank [blANk] n. 坯料 L20blank [blANk] v. 冲裁,落料 L17blanking tool 落料模 L17blast [blQst] n.一阵(风) L18blemish['blemiF] n. 缺点, 污点 L13bolster['bEulstE] n. 模座,垫板 L4,5boost[bu:st] n. 推进 L9boring['bC:riN] n.镗削, 镗孔 L4,5bracket ['brAkit] n. 支架 L19brass [brAs] n.黄铜 L2break down 破坏 L1breakage ['breikidV] n.破坏 L17bridge piece L16brine[brain] n. 盐水 L2brittle['britl] adv.易碎的 L1buffer [bQfE] n.缓冲器 L8built-in 内装的 L9bulging [bQldViN] n. 凸肚 L22burr [bE:] n. 毛刺 L17bush [buF] n. 衬套 L17bush[buF]n. 衬套 L5by far (修饰比较级, 最高级)···得多, 最 L3 by means of 借助于 L5Ccabinet ['kAbinit] n.橱柜 L7call upon 要求 L17carbide['ka:baid] n.碳化物 L10carburzing['ka:bjuretiN] n. 渗碳 L2 carriage['kAridV] n.拖板, 大拖板 L5carry along 一起带走 L18carry down over 从···上取下 L21carry out 完成 L17case hardening 表面硬化 L2case[keis] n. 壳, 套 L2cast steel 铸钢 L17casting['ka:stiN] n. 铸造,铸件 L3category['kAtE^Euri] n. 种类 L6,15caution ['kC:FEn] n. 警告,警示 L17cavity and core plates 凹模和凸模板 L11cavity['kAviti] n.型腔, 腔, 洞 L4,10centre-drilling 中心孔 L5ceramic[si'rAmik] n.陶瓷制品 L3chain doted line 点划线 L11channel['tFAnl] n.通道, 信道 L8characteristic[kArEktE'ristik] n.特性 L1 check[tFek] v.核算 L21chip[tFip] n.切屑, 铁屑 L3chuck [tFQk] n.卡盘 L5,8chute [Fu:t] n. 斜道 L19circa ['sEkE:] adv. 大约 L7circlip['sE:klip] n.(开口)簧环 L22circuit['sE:kit] n. 回路, 环路 L13circular supoport block L5circulate['sE:kjuleid] v.(使)循环 L13clamp [klAmp] vt 夹紧 L17clamp[klAmp] n.压板 L12clay[klei] n. 泥土 L2,7clearance ['kliErEns] n. 间隙 L17clip [klip] vt. 切断,夹住 L19cold hobbing 冷挤压 L4cold slug well 冷料井 L12collapse[kE'lAps] vi.崩塌, 瓦解 L22collapsible[kE'lApsEbl] adj.可分解的 L22 combination [kCmbi'neiFEn] n. 组合 L18 commence[kE'mens] v. 开始, 着手 L16 commence[kE'mens]v. 开始 L21commercial [kE'mE:FEl] adj. 商业的 L7 competitive[kEm'petitiv] a. 竞争的 L9 complementary[7kCmpli'mentEri] a. 互补的 L5 complexity [kem'pleksiti] n.复杂性 L8 complicated['kCmplEkeitid] adj.复杂的 L2 complication [kCmpli'keiFEn] n. 复杂化 L5,20 compression [kEm'preFEn] n.压缩 L1comprise[kEm'prais] vt.包含 L16compromise['kCmprEmaiz] n. 妥协, 折衷 L13 concern with 关于 L6concise[kEn'sais] a. 简明的, 简练的 L9confront[kEn'frQnt] vt. 使面临 L14connector[kE'nektE] n. 连接口, 接头 L14 consequent['kCnsikwEnt] a. 随之发生的, 必然的 L3 console ['kCnsoul] n.控制台 L8consume [kEn'sjum] vt. 消耗, 占用 L7 consummate [kEn'sQmeit] vt. 使完善 L6container[kEn'teinE] n. 容器 L11contingent[ken'tindVEnt] a.可能发生的 L9contour['kEntuE] n.轮廓 L5,21conventional[kEn'venFEnl] a. 常规的 L4converge[kEn'vE:dV] v.集中于一点 L21conversant[kCn'vE:sEnt] a. 熟悉的 L15conversion[kEn'vE:FEn] n 换算, 转换 L7conveyer[ken'veiE] n. 运送装置 L12coolant['ku:lEnt] n. 冷却液 L13coordinate [kEu'C:dnit] vt. (使)协调 L8copy machine 仿形(加工)机床 L4core[kC:] n. 型芯, 核心 L2,4corresponding [ka:ri'spCdiN] n.相应的 L7 counteract [kauntE'rAkt] vt. 反作用,抵抗 L20 couple with 伴随 L20CPU (central processing unit) 中央处理器 L9 crack[krAk ] v.(使)破裂,裂纹 L1,17critical['kritikl] adj.临界的 L2cross-hatching 剖面线 L16cross-section drawn 剖面图 L11cross-slide 横向滑板 L5CRT (cathoder-ray tube) 阴极射线管 L9crush[krQF]vt.压碎 L1cryogenic[7kraiE'dVenik ]a.低温学的 L1crystal['kristl] adj.结晶状的 L1cubic['kju:bik] a. 立方的, 立方体的 L3cup [kQp] vt (使)成杯状, 引伸 L18curable ['kjurEbl] adj. 可矫正的 L20curvature['kE:vEtFE] n.弧线 L21curve [kE:v] vt. 使弯曲 L20cutter bit 刀头, 刀片 L3cyanide['saiEnaid] n.氰化物 L2Ddash [dAF] n. 破折号 L6daylight ['deilait] n. 板距 L12decline[di'klain] v.下落,下降,减少, L3,9deform[di'fC:m] v. (使)变形 L1,3demonstrate['demEstreit ] v证明 L21depict[di'pikt ] vt 描述 L18deposite [di'pCzit] vt. 放置 L20depression[di'preFEn] n. 凹穴 L12descend [di'sent] v. 下降 L20desirable[di'zairEbl] a. 合适的 L2detail ['diteil] n.细节,详情 L17deterioration[ditiEri:E'reiFEn] n. 退化, 恶化 L12 determine[di'tE:min] v.决定 L16diagrammmatic[7daiEgrE'mAtik].a.图解的,图表的 L10 dictate['dikteit] v. 支配 L12die[dai] n.模具, 冲模, 凹模 L2dielectric[daii'lektrik] n. 电介质 L10die-set 模架 L19digital ['didVitl ] n.数字式数字, a.数字的 L3,6 dimensional[dddi'menFEnl] a. 尺寸的, 空间的 L3 discharge[dis'tFa:dV] n.v. 放电, 卸下, 排出 L3 discharge[dis'tFa:dV] v.卸下 L8discrete [dis'cri:t] adj. 离散的,分立的 L7 dislodge[dis'lCdV] v. 拉出, 取出 L12dissolution[disE'lu:FEn] n.结束 L9distinct [dis'tiNkt] a.不同的,显著的 L6distort [dis'dC:t] vt. 扭曲 L20distort[dis'tC:t] vt. (使)变形, 扭曲 L1distributed system 分布式系统 L9dowel ['dauEl] n. 销子 L19dramaticlly [drE'mAtikli] adv. 显著地 L7drastic ['drAstik] a.激烈的 L17draughting[dra:ftiN] n. 绘图 L16draughtsman['drAftsmEn] n. 起草人 L16drawing['drC:iN] n. 制图 L11drill press 钻床 L8drum [drQm] n.鼓轮 L8dual ['dju:El] adv. 双的,双重的 L18ductility [dQk'tiliti ] n.延展性 L1,21dynamic [dai'nAmik ] adj 动力的 L6Eedge [edV] n .边缘 L20e.g.(exempli gratia) [拉] 例如 L12ejector [i'dVektE] n.排出器, L18ejector plate 顶出板 L16ejector rob 顶杆 L5elasticity[ilA'stisiti] n.弹性 L1electric dicharge machining 电火花加工L3 electrical discharge machining电火花加工 L10electrochemical machining 电化学加工L3 electrode[i'lektrEud] n. 电极 L10electro-deposition 电铸 L4elementary [elE'mentEri] adj.基本的 L2 eliminate[i'limineit] vt. 消除, 除去 L10 elongate[i'lCN^et] vt. (使)伸长, 延长 L1 emerge [i'mE:dV] vi. 形成, 显现 L20 emphasise['emfEsaiz] vt. 强调 L4endeavour[en'devE] n. 尽力 L17engagement[in'^eidVment] n. 约束, 接合 L22 enhance[in'hAns] vt. 提高, 增强 L9ensure [in'FuE] vt. 确保,保证 L17envisage[in'vizidV] vt.设想 L15erase[i'reis] vt. 抹去, 擦掉 L16evaluation[i'vAlju7eiFEn] n. 评价, 估价L1 eventually[i'vEntFuEli ] adv.终于 L21 evolution[evE'lu:FEn] n.进展 L16excecution[eksi'kju:FEn] n. 执行, 完成 L9 execute ['ekskju:t] v. 执行 L8exerte [i^'zE:t] vt. 施加 L20experience[iks'piriEns] n. 经验 L16 explosive[iks'plEusiv]adj.爆炸(性)的 L22 extend[eks'tend] v. 伸展 L2external[eks'tE:nl] a. 外部的 L5,11 extract[eks'trAkt] v. 拔出 L14extreme[iks'tri:m] n. 极端 L13extremely[iks'tri:mli] adv. 非常地 L12 extremity[iks'tmiti] n. 极端 L13extrusion[eks'tru:VEn] n. 挤压, 挤出 L3FF (Fahrenheit)['fArEnhait]n.华氏温度 L2fabricate ['fAbrikeit] vt.制作,制造 L7 facilitate [fE'siliteit] vt. 帮助 L6facility[fE'siliti] n. 设备 L4facing[feisiN] n. 端面车削 L5fall within 属于, 适合于 L15fan[fAn] n.风扇 L7far from 毫不, 一点不, 远非 L9fatigue[fE'ti^] n.疲劳 L1feasible ['fi:zEbl] a 可行的 L18feature ['fi:tFE] n.特色, 特征 L7,17feed[fi:d] n.. 进给 L5feedback ['fi:dbAk] n. 反馈 L8female['fi:meil] a. 阴的, 凹形的 L11ferrule['ferEl] n. 套管 L14file system 文件系统 L9fitter['fitE] n.装配工, 钳工 L4fix[fiks] vt. 使固定, 安装, vi. 固定 L11fixed half and moving half 定模和动模 L11flat-panel technology 平面(显示)技术 L9 flexibility[fleksi'biliti] n. 适应性, 柔性 L9 flexible['fleksEbl] a. 柔韧的 L13flow mark 流动斑点 L13follow-on tool 连续模 L18foregoing ['fC:'^EuiN]adj. 在前的,前面的L8foretell[fC:'tell] vt. 预测, 预示, 预言 L9 forge[fC:dV] n. v. 锻造 L3forming[fC:miN] n. 成型 L3four screen quadrants 四屏幕象限 L9fracture['frAktFE] n.破裂 L21free from 免于 L21Ggap[^Ap] n. 裂口, 间隙 L10gearbox['^iEbCks] n.齿轮箱 L5general arrangement L16govern['^QvEn] v.统治, 支配, 管理 L13grain [^rein] n. 纹理 L20graphic ['^rAfik] adj. 图解的 L6grasp [^rAsp] vt. 抓住 L8grid[^rid] n. 格子, 网格 L16grind[^raind] v. 磨, 磨削, 研磨 L3grinding ['^raindiN] n. 磨光,磨削 L3,20 grinding machine 磨床 L5gripper[^ripE] n. 抓爪, 夹具 L9groove[^ru:v] n. 凹槽 L12guide bush 导套 L5guide pillar 导柱 L5guide pillars and bushes 导柱和导套 L11Hhandset['hAndset] n. 电话听筒 L4hardness['ha:dnis] n.硬度 L1,2hardware ['ha:dwZE] n. 硬件 L6headstock['hedstCk] n.床头箱, 主轴箱 L5hexagonal[hek'sA^Enl] a. 六角形的, 六角的 L11 hindrance['hindrEns] n.障碍, 障碍物 L11hob[hCb] n. 滚刀, 冲头 L4hollow-ware 空心件 L21horizontal[hCri'zCntl] a. 水平的 L16hose[hEuz] n. 软管, 水管 L13hyperbolic [haipE'bClik] adj.双曲线的 L7Ii.e. (id est) [拉] 也就是 L12identical[ai'dentikl] a同样的 L16identify [ai'dentifai] v. 确定, 识别 L7idle ['aidl] adj.空闲的 L8immediately[i'mi:djEtli] adv. 正好, 恰好 L12impact['impAkt] n.冲击 L1impart [im'pa:t] v.给予 L11,17implement ['implimEnt] vt 实现 L6impossibility[impCsE'biliti] n.不可能 L21impression[im'preFEn] n. 型腔 L11in contact with 接触 L1in terms of 依据 L1inasmuch (as)[inEz'mQtF] conj.因为, 由于L3inch-to-metric conversions 英公制转换 L7 inclinable [in'klainEbl] adj. 可倾斜的 L20inclusion [in'kluFEn] n. 内含物 L19inconspicuous[inkEn'spikjuEs] a. 不显眼的 L14 incorporate [in'kC:pEreit] v 合并,混合L17 indentation[7inden'teiFEn ] n.压痕 L1indenter[in'dentE] n. 压头 L1independently[indi'peinEntli] a. 独自地, 独立地 L16 inevitably[in'evitEbli] ad. 不可避免地 L14 inexpensive[inik'spensiv]adj. 便宜的 L2inherently [in'hiErEntli] adv.固有的 L7injection mould 注塑模 L11injection[in'dVekFEn] n. 注射 L11in-line-of-draw 直接脱模 L14insert[in'sE:t] n. 嵌件 L16inserted die 嵌入式凹模 L19inspection[in'spekFEn] n.检查,监督 L9installation[instE'leiFEn] n. 安装 L10integration [inti'^reiFEn] n.集成 L6intelligent[in'telidVEnt]a. 智能的 L9intentinonally [in'tenFEnEli] adv 加强地,集中地 L17interface ['intEfeis] n.. 界面 L6internal[in'tE:nl] a. 内部的 L1,5interpolation [intEpE'leiFEn] n.插值法 L7 investment casting 熔模铸造 L4irregular [i'regjulE] adj. 不规则的,无规律 L17 irrespective of 不论, 不管 L11irrespective[iri'spektiv] a. 不顾的, 不考虑的 L11 issue ['isju] vt. 发布,发出 L6Jjoint line 结合线 L14Kkerosene['kerEsi:n] n.煤油 L10keyboard ['ki:bC:d ] n. 健盘 L6knock [nRk] v 敲,敲打 L17Llance [la:ns] v. 切缝 L19lathe[leiT] n. 车床 L4latitude ['lAtitju:d] n. 自由 L17lay out 布置 L13limitation[limi'teiFEn] n.限度,限制,局限(性) L3 local intelligence局部智能 L9locate [lEu'keit] vt. 定位 L18logic ['lCdVik] n. 逻辑 L7longitudinal['lCndVE'tju:dinl] a. 纵向的 L5 longitudinally['lCndVE'tju:dinl] a. 纵向的 L13 look upon 视作, 看待 L17lubrication[lju:bri'keiFEn ] n.润滑 L21Mmachine shop 车间 L2machine table 工作台 L8machining[mE'Fi:niN] n. 加工 L3made-to-measure 定做 L15maintenance['meintinEns] n.维护,维修 L7majority[mE'dVa:riti] n.多数 L21make use of 利用 L2male[meil] a. 阳的, 凸形的 L11malfunction['mAl'fQNFEn] n. 故障 L9mandrel['mAdtil] n.心轴 L22manifestation[mAnifEs'teiFEn] n. 表现, 显示 L9 massiveness ['mAsivnis ] 厚实,大块 L19measure['meVE] n. 大小, 度量 L1microcomputer 微型计算机 L9microns['maikrCn] n.微米 L10microprocessor 微处理器 L9mild steel 低碳钢 L17milling machine 铣床 L4mineral['minErEl] n.矿物, 矿产 L2minimise['minimaiz] v.把···减到最少, 最小化 L13minute['minit] a.微小的 L10mirror image 镜像 L16mirror['mirE] n. 镜子 L16MIT (Massachusetts Institute of Technology) 麻省理工学院 L7 moderate['mCdErit]adj. 适度的 L1,2modification [mRdifi'keiFEn ] n. 修改, 修正 L6modulus['mCdjulEs] n.系数 L1mold[mEuld] n. 模, 铸模, v. 制模, 造型 L3monitor ['mCnitE ] v. 监控 L6monograph['mCnE^ra:f] n. 专著 L4more often than not 常常 L20motivation[mEuti'veiFEn] n. 动机 L9mould split line 模具分型线 L12moulding['mEudiN] n. 注塑件 L5,11move away from 抛弃 L17multi-imprssion mould 多型腔模 L12Nnarrow['nArEu] a. 狭窄的 L12NC (numerical control ) 数控 L7nevertheless[7nevETE'les] conj.,adv.然而,不过 L11nonferrous['nCn'ferEs] adj.不含铁的, 非铁的 L2normally['nC:mli]adv.通常地 L22novice['nCvis] n. 新手, 初学者 L16nozzle['nCzl] n. 喷嘴, 注口 L12numerical [nju'merikl] n. 数字的 L6Oobjectionable [Eb'dVekFEbl] adj. 有异议的,讨厌的 L17observe[Eb'zE:v] vt. 观察 L2obviously ['CbviEsli] adv 明显地 L17off-line 脱机的 L6on-line 联机 L9operational [CpE'reiFEnl] adj.操作的, 运作的 L8opportunity[CpE'tju:niti] n. 时机, 机会 L13opposing[E'pEuziN] a.对立的, 对面的L12opposite['CpEzit] n. 反面 L1 a.对立的,对面的 L12 optimization [Rptimai'zeiFEn] n.最优化 L6orient ['C:riEnt] vt. 确定方向 L8orthodox ['C:WEdCks] adj. 正统的,正规的 L19overall['EuvErC:l] a.全面的,全部的 L8,13overbend v.过度弯曲 L20overcome[EuvE'kQm] vt.克服, 战胜 L10overlaping['EuvE'lApiN] n. 重叠 L4overriding[EuvE'raidiN] a. 主要的, 占优势的 L11 Ppack[pAk] v. 包装 L2package ['pAkidV] vt.包装 L7pallet ['pAlit] n.货盘 L8panel ['pAnl] n.面板 L7paraffin['pArEfin] n. 石蜡 L10parallel[pArElel] a.平行的 L5penetration[peni'treiFEn ] n.穿透 L1peripheral [pE'rifErEl] adj 外围的 L6periphery [pE'rifEri] n. 外围 L18permit[pE'mit] v. 许可, 允许 L16pessure casting 压力铸造 L4pillar['pilE] n. 柱子, 导柱 L5,17pin[pin] n. 销, 栓, 钉 L5,17pin-point gate 针点式浇口 L12piston ['pistEn] n.活塞 L1plan view 主视图 L16plasma['plAzmE] n. 等离子 L9plastic['plAstik] n. 塑料 L3platen['plAtEn] n. 压板 L12plotter[plCtE] n. 绘图机 L9plunge [plQndV] v翻孔 L18plunge[plQndV] v.投入 L2plunger ['plQndVE ] n. 柱塞 L19pocket-size 袖珍 L9portray[pC:'trei] v.描绘 L21pot[pCt] n.壶 L21pour[pC:] vt. 灌, 注 L22practicable['prAktikEb] a. 行得通的 L14 preferable['prefErEbl] a.更好的, 更可取的 L3 preliminary [pri'liminEri] adj 初步的,预备的 L19 press setter 装模工 L17press[pres] n.压,压床,冲床,压力机 L2,8prevent [pri'vent] v. 妨碍 L20primarily['praimErili] adv.主要地 L4procedure[prE'si:dVE] n.步骤, 方法, 程序 L2,16 productivity.[prEudQk'tiviti] n. 生产力 L9profile ['prEufail] n.轮廓 L10progressively[prE'^resiv] ad.渐进地 L15project[prE'dVekt] n.项目 L2project[prE'dVekt] v. 凸出 L11projection[prE'dVekFEn] n.突出部分 L21proper['prCpE] a. 本身的 L10property['prCpEti] n.特性 L1prototype ['prEutEtaip] n. 原形 L7proximity[prCk'simiti] n.接近 L9prudent['pru:dEnt] a. 谨慎的 L16punch [pQntF] v. 冲孔 L3punch shapper tool 刨模机 L17punch-cum-blanking die 凹凸模 L18punched tape 穿孔带 L3purchase ['pE:tFEs] vt. 买,购买 L6push back pin 回程杆 L5pyrometer[pai'nCmitE] n. 高温计 L2Qquality['kwaliti] n. 质量 L1,3quandrant['kwCdrEnt] n. 象限 L9quantity ['kwCntiti] n. 量,数量 L17quench[kwentF] vt. 淬火 L2Rradial['reidiEl] adv.放射状的 L22ram [rAm] n 撞锤. L17rapid['rApid]adj. 迅速的 L2rapidly['rApidli]adv. 迅速地 L1raster['rAstE] n. 光栅 L9raw [rC:] adj. 未加工的 L6raw material 原材料 L3ream [ri:m] v 铰大 L17reaming[ri:miN] n. 扩孔, 铰孔 L8recall[ri'kC:l] vt. 记起, 想起 L13recede [ri'si:d] v. 收回, 后退 L20recess [ri'ses] n. 凹槽,凹座,凹进处 L4,18redundancy[ri'dQndEnsi] n. 过多 L9re-entrant 凹入的 L12refer[ri'fE:] v. 指, 涉及, 谈及 L1,12reference['refErEns] n.参照,参考 L21refresh display 刷新显示 L9register ring 定位环 L11register['redVstE] v. 记录, 显示, 记数 L2regrind[ri:'^aind](reground[ri:'gru:nd]) vt. 再磨研 L12 relative['relEtiv] a. 相当的, 比较的 L12relay ['ri:lei] n. 继电器 L7release[ri'li:s] vt. 释放 L1relegate['relE7geit] vt. 把··降低到 L9reliability [rilaiE'biliti] n. 可靠性 L7relief valves 安全阀 L22relief[ri'li:f] n.解除 L22relieve[ri'li:v ]vt.减轻, 解除 L2remainder[ri'meindE] n. 剩余物, 其余部分 L4 removal[ri'mu:vl] n. 取出 L14remove[ri'mu:v] v. 切除, 切削 L4reposition [ripE'ziFEn] n.重新安排 L17 represent[7repri'zentE] v 代表,象征 L11 reputable['repjutEbl] a. 有名的, 受尊敬的 L15 reservoir['rezEvwa: ] n.容器, 储存器 L22 resident['rezidEnt] a. 驻存的 L9resist[ri'zist] vt.抵抗 L1resistance[ri'zistEns] n.阻力, 抵抗 L1 resolution[7rezE'lu:FEn] n. 分辨率 L9 respective[ri'spektiv] a.分别的,各自的 L11 respond[ris'pCnd] v.响应, 作出反应 L9 responsibility[rispCnsE'biliti] n.责任 L13 restrain[ris'trein]v.抑制 L21restrict [ris'trikt] vt 限制,限定 L18 restriction[ris'trikFEn] n. 限制 L12retain[ri'tein] vt.保持, 保留 L2,12 retaining plate 顶出固定板 L16reveal [ri'vil] vt.显示,展现 L17reversal [ri'vEsl] n. 反向 L1,20right-angled 成直角的 L20rigidity[ri'dViditi] n. 刚度 L1rod[rCd] n. 杆, 棒 L1,5rotate['rEuteit] vt.(使)旋转 L5rough machining 粗加工 L5rough[rQf] a. 粗略的 L5,21routine [ru:'ti:n] n. 程序 L7rubber['rQbE] n.橡胶 L3,22runner and gate systems 流道和浇口系统 L11Ssand casting 砂型铸造 L3satisfactorily[7sAtis'fAktrili] adv. 满意地 L1 saw[aC:] n. 锯子 L4scale[skeil]n. 硬壳 L2score[skC:] v. 刻划 L14scrap[skrAp] n.废料, 边角料, 切屑 L2,3 screwcutting 切螺纹 L4seal[si:l] vt.密封 L22secondary storage L9section cutting plane 剖切面 L16secure[si'kjuE] v.固定 L22secure[si'kjuE] vt.紧固,夹紧,固定 L5,22segment['se^mEnt] v. 分割 L10sensitive['sensitiv]a.敏感的 L1,7sequence ['si:kwEns] n. 次序 L6sequential[si'kwenFEl] a.相继的 L16seriously['siEriEsli] adv.严重地 L1servomechanism ['sE:vE'mekEnizm] n.伺服机构 L7 Servomechanism Laboratoies 伺服机构实验室 L7 servomotor ['sE:vEmEutE] n.伺服马达 L8setter ['setE] n 安装者 L17set-up 机构 L20sever ['sevE] v 切断 L17severity [si'veriti] n. 严重 L20shaded[FAdid] adj.阴影的 L21shank [FANk] n. 柄. L17shear[FiE]n.剪,切 L1shot[FCt] n. 注射 L12shrink[FriNk] vi. 收缩 L11side sectional view 侧视图 L16signal ['si^nl] n.信号 L8similarity[simi'lAriti] n.类似 L15simplicity[sim'plisiti] n. 简单 L12single-point cutting tool 单刃刀具 L5situate['sitjueit] vt. 使位于, 使处于 L11slide [slaid] vi. 滑动, 滑落 L20slideway['slaidwei] n. 导轨 L5slot[slCt] n. 槽 L4slug[slQ^] n. 嵌条 L12soak[sEuk] v. 浸, 泡, 均热 L2software ['sCftwZE] n. 软件 L6solid['sClid] n.立体, 固体 L9solidify[sE'lidifai] vt.vi. (使)凝固, (使)固化 L13 solution[sE'lu:FEn] n.溶液 L2sophisiticated [sE'fistikeitid] adj.尖端的,完善的 L8 sound[saund] a. 结实的, 坚固的) L1spark erosion 火花蚀刻 L10spindle['spindl] n. 主轴 L5,8spline[splain] n.花键 L4split[split] n. 侧向分型, 分型 L12,14spool[spu:l] n. 线轴 L14springback n.反弹 L20spring-loaded 装弹簧的 L18sprue bush 主流道衬套 L11sprue puller 浇道拉杆 L12square[skwZE] v. 使成方形 L4stage [steidV] n. 阶段 L16,19standardisation[7stAndEdai'zeiFEn] n. 标准化 L15 startling['sta:tliN] a. 令人吃惊的 L10steadily['stedEli ] adv. 稳定地 L21step-by-step 逐步 L8stickiness['stikinis] n.粘性 L22stiffness['stifnis] n. 刚度 L1stock[stCk] n.毛坯, 坯料 L3storage tube display 储存管显示 L9storage['stC:ridV] n. 储存器 L9straightforward[streit'fC:wEd]a.直接的 L10strain[strein] n.应变 L1strength[streNW] n.强度 L1stress[stres] n.压力,应力 L1stress-strain应力--应变 L6stretch[stretF] v.伸展 L1,21strike [straik] vt. 冲击 L20stringent['strindVEnt ] a.严厉的 L22stripper[stripE] n. 推板 L15stroke[strouk] n. 冲程, 行程 L12structrural build-up 结构上形成的 L11sub-base 垫板 L19subject['sQbdVikt] vt.使受到 L21submerge[sEb'mE:dV] v.淹没 L22subsequent ['sQbsikwent] adj. 后来的 L20 subsequently ['sQbsikwentli] adv. 后来, 随后 L5 substantial[sEb'stAnFEl] a. 实质的 L10substitute ['sQbstitju:t] vt. 代替,.替换 L7 subtract[sEb'trAkt] v.减, 减去 L15suitable['su:tEbl] a. 合适的, 适当的 L5suitably['su:tEbli] ad.合适地 L15sunk[sQNk](sink的过去分词) v. 下沉, 下陷 L11 superior[sE'piEriE] adj.上好的 L22susceptible[sE'septEbl] adj.易受影响的 L7sweep away 扫过 L17symmetrical[si'metrikl] a. 对称的 L14 synchronize ['siNkrEnaiz] v.同步,同时发生L8Ttactile['tAktail] a. 触觉的, 有触觉的 L9 tailstock['teilstCk] n.尾架 L5tapered['teipEd] a. 锥形的 L12tapping['tApiN] n. 攻丝 L8technique[tek'ni:k] n. 技术 L16tempering['tempErN] n.回火 L2tendency['tendEnsi] n. 趋向, 倾向 L13tensile['tensail] a.拉力的, 可拉伸的 L2 拉紧的, 张紧的 L1 tension ['tenFEn] n.拉紧,张紧 L1terminal ['tE:mEnl ] n. 终端机 L6terminology[tE:mi'nClEdVi ] n. 术语, 用辞 L11theoretically [Wi:E'retikli ] adv.理论地 L21thereby['TZEbai] ad. 因此, 从而 L15thermoplastic['WE:mEu'plAstik] a. 热塑性的, n. 热塑性塑料 L3thermoset['WE:mEset] n.热固性 L12thoroughly['WQrEuli] adv.十分地, 彻底地 L2thread pitch 螺距 L5thread[Wred] n. 螺纹 L5thrown up 推上 L17tilt [tilt] n. 倾斜, 翘起 L20tolerance ['tClErEns] n..公差 L17tong[tCN] n. 火钳 L2tonnage['tQnidV] n.吨位, 总吨数 L3tool point 刀锋 L3tool room 工具车间 L10toolholder['tu:lhEuldE] n.刀夹,工具柄 L5toolmaker ['tu:l'meikE] n 模具制造者 L17toolpost grinder 工具磨床 L4toolpost['tu:l'pEust] n. 刀架 L4torsional ['tC:FEnl] a扭转的 . L1toughness['tCfnis] n. 韧性 L2trace [treis] vt.追踪 L7tracer-controlled milling machine 仿形铣床 L4transverse[trAns'vE:s] a. 横向的 L5tray [trei] n. 盘,盘子,蝶 L19treatment['tri:tmEnt] n.处理 L2tremendous[tri'mendEs] a. 惊人的, 巨大的 L9trend [trend] n.趋势 L7trigger stop 始用挡料销 L17tungsten['tQNstEn] n.钨 L10turning['tE:niN] n.车削 L4,5twist[twist ] v.扭曲,扭转 L1two-plate mould 双板式注射模 L12Uultimately['Qltimitli] adv终于. L6undercut moulding 侧向分型模 L14undercut['QndEkQt] n. 侧向分型 L14undercut['QndEkQt] n.底切 L12underfeed['QndE'fi:d] a, 底部进料的 L15undergo[QndE'^Eu] vt.经受 L1underside['QndEsaid] n 下面,下侧 L11undue[Qn'dju:] a.不适当的, 过度的 L4,10uniform['ju:nifC:m] a.统一的, 一致的 L12utilize ['ju:tilaiz] v 利用 L17Utopian[ju'tEupiEn] adj.乌托邦的, 理想化的 L21Vvalve[vAlv] n.阀 L22vaporize['veipEraiz] vt.vi. 汽化, (使)蒸发 L10 variation [vZEri'eiFEn] n. 变化 L20various ['vZEriEs] a.不同的,各种的 L1,20vector feedrate computation 向量进刀速率计算 L7 vee [vi:] n. v字形 L20velocity[vi'lCsiti] n.速度 L1versatile['vEsEtail] a.多才多艺的,万用的 L5,8 vertical['vE:tikl] a. 垂直的 L16via [vaiE] prep.经,通过 L8vicinity[vE'siniti] n.附近 L13viewpoint['vju:pCint] n. 观点 L4Wwander['wCndE] v. 偏离方向 L13warp[wC:p] v. 翘曲 L2washer ['wCFE] n. 垫圈 L18wear [wZE] v.磨损 L7well line 结合线 L13whereupon [hwZErE'pCn] adv. 于是 L19winding ['waindiN] n. 绕, 卷 L8with respect to 相对于 L1,5withstand[wiT'stAnd] vt.经受,经得起 L1work[wE:k] n. 工件 L4workstage 工序 L19wrinkle['riNkl] n.皱纹vt.使皱 L21Yyield[ji:ld] v. 生产 L9Zzoom[zu:] n. 图象电子放大 L9GLOSSARY。

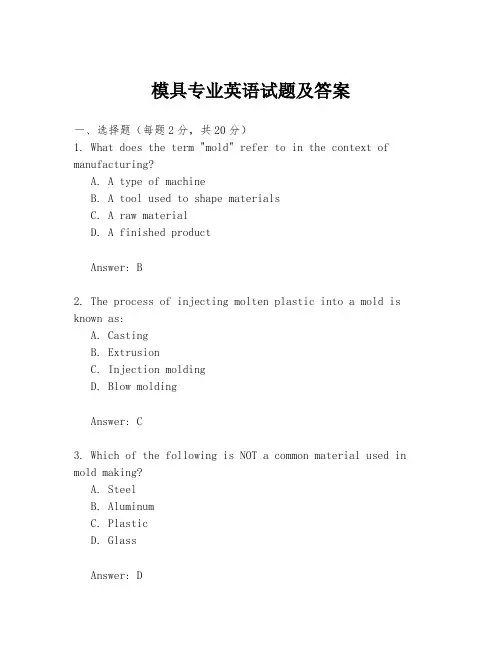

模具专业英语试题及答案一、选择题(每题2分,共20分)1. What does the term "mold" refer to in the context of manufacturing?A. A type of machineB. A tool used to shape materialsC. A raw materialD. A finished productAnswer: B2. The process of injecting molten plastic into a mold is known as:A. CastingB. ExtrusionC. Injection moldingD. Blow moldingAnswer: C3. Which of the following is NOT a common material used in mold making?A. SteelB. AluminumC. PlasticD. GlassAnswer: D4. The term "ejection system" in molds refers to:A. The system that heats the moldB. The system that cools the moldC. The system that removes the finished part from the moldD. The system that guides the mold into placeAnswer: C5. What is the purpose of the "runner system" in an injection mold?A. To cool the moldB. To eject the partC. To guide the material into the mold cavityD. To support the moldAnswer: C6. The "draft angle" in mold design is used to:A. Increase the strength of the moldB. Facilitate the removal of the part from the moldC. Improve the aesthetics of the partD. Control the flow of material into the moldAnswer: B7. What is the role of "shrinkage" in mold design?A. To increase the size of the partB. To decrease the size of the partC. To prevent warpingD. To improve the surface finishAnswer: B8. The "cavity" in a mold is the space that:A. Houses the moldB. Contains the cooling channelsC. Shapes the partD. Stores the raw materialAnswer: C9. "Flash" in molding is:A. A desirable feature for part aestheticsB. The thin layer of material that forms between the mold partsC. A type of mold release agentD. The process of cutting the part from the runner system Answer: B10. The term "gating system" refers to the part of the mold that:A. Controls the flow of material into the moldB. Supports the mold during productionC. Provides access for maintenanceD. Ejects the finished partAnswer: A二、填空题(每题1分,共10分)11. The _______ is the process of cutting away excessmaterial to form a part.Answer: machining12. In mold making, the term "plastic" refers to a material that can be _______.Answer: molded13. The _______ is the part of the mold that opens and closes to release the part.Answer: ejector14. A _______ mold is one that is used to produce multiple parts in a single cycle.Answer: multi-cavity15. The _______ is the process of creating a three-dimensional model from a two-dimensional drawing.Answer: prototyping16. The _______ is the process of making a mold from a solid block of material.Answer: machining17. A _______ is a tool used to cut threads into a hole.Answer: tap18. The _______ is the process of applying heat and pressure to shape a material.Answer: thermoforming19. The _______ is the process of removing material from aworkpiece to achieve the desired shape.Answer: milling20. The _______ is the process of joining two or more pieces of material together.Answer: welding三、简答题(每题5分,共30分)21. Explain the difference between a "hot runner" and a "cold runner" mold system.Answer: A hot runner mold system maintains the temperature of the plastic melt throughout the entire runner system, allowing for continuous flow and reducing waste. A cold runner mold system, on the other hand, cools the plastic in the runner system, resulting in a solidified runner thatis typically considered waste.22. What are the main factors to consider when designing a mold for injection molding?Answer: The main factors include material selection, part geometry, shrinkage, draft angles, gating and runner system design, cooling and heating requirements, ejection system design, and cycle time.23. Describe the role of a "core pin" in a mold.Answer: A core pin is a component。

组装、冲压、喷漆等专业词汇Assembly line组装线Layout布置图Conveyer流水线物料板Rivet table拉钉机Rivet gun拉钉枪Screw driver起子Electric screw driver电动起子Pneumatic screw driver气动起子worktable 工作桌OOBA开箱检查fit together组装在一起fasten锁紧(螺丝)fixture 夹具(治具)pallet栈板barcode条码barcode scanner条码扫描器fuse together熔合fuse machine热熔机repair修理operator作业员QC品管supervisor 课长ME制造工程师MT制造生技cosmetic inspect外观检查inner parts inspect部检查thumb screw大头螺丝lbs. inch镑、英寸EMI gasket导电条front plate前板rear plate后板chassis 基座bezel panel面板power button电源按键reset button重置键Hi-pot test of SPS高源高压测试Voltage switch of SPS电源电压接拉键sheet metal parts 冲件plastic parts塑胶件SOP制造作业程序material check list物料检查表work cell工作间trolley台车carton纸箱sub-line支线left fork叉车personnel resource department 人力资源部production department生产部门planning department企划部QC Section品管科stamping factory冲压厂painting factory烤漆厂molding factory成型厂common equipment常用设备uncoiler and straightener整平机punching machine 冲床robot机械手hydraulic machine油压机lathe车床planer |'plein|刨床miller铣床grinder磨床driller??床linear cutting线切割electrical sparkle电火花welder电焊机staker=reviting machine铆合机position职务president董事长general manager总经理special assistant manager特助factory director厂长department director部长deputy manager | =vice manager副理section supervisor课长deputy section supervisor =vice section superisor副课长group leader/supervisor组长line supervisor线长assistant manager助理to move, to carry, to handle搬运be put in storage入库pack packing包装to apply oil擦油to file burr 锉毛刺final inspection终检to connect material接料to reverse material 翻料wet station沾湿台Tiana天那水cleaning cloth抹布to load material上料to unload material卸料to return material/stock to退料scraped |'skræpid|报废scrape ..v.刮;削deficient purchase来料不良manufacture procedure制程deficient manufacturing procedure制程不良oxidation |' ksi'dei n|氧化scratch刮伤dents压痕defective upsiding down抽芽不良defective to staking铆合不良embedded lump镶块feeding is not in place送料不到位stamping-missing漏冲production capacity生产力education and training教育与训练proposal improvement提案改善spare parts=buffer备件forklift叉车trailer=long vehicle拖板车compound die合模die locker锁模器pressure plate=plate pinch压板bolt螺栓name of a department部门名称administration/general affairs dept总务部automatic screwdriver电动启子thickness gauge厚薄规gauge(or jig)治具power wire电源线buzzle蜂鸣器defective product label不良标签identifying sheet list标示单screwdriver holder起子插座pedal踩踏板stopper阻挡器flow board流水板hydraulic handjack油压板车forklift叉车pallet栈板glove(s)手套glove(s) with exposed fingers割手套thumb大拇指forefinger食指midfinger中指ring finger无名指little finger小指band-aid创可贴iudustrial alcohol工业酒精alcohol container沾湿台head of screwdriver起子头sweeper扫把mop拖把vaccum cleaner吸尘器rag 抹布garbage container灰箕garbage can垃圾箱garbage bag垃圾袋chain链条jack升降机production line流水线chain链条槽magnetizer加磁器lamp holder灯架to mop the floor拖地to clean the floor扫地to clean a table擦桌子air pipe 气管packaging tool打包机packaging打包missing part漏件wrong part错件excessive defects过多的缺陷critical defect极严重缺陷major defect主要缺陷minor defect次要缺陷not up to standard不合规格dimension/size is a little bigger尺寸偏大(小) cosmetic defect外观不良slipped screwhead/slippery screw head螺丝滑头slipped screwhead/shippery screw thread滑手speckle斑点mildewed=moldy=mouldy发霉rust生锈deformation变形burr(金属)flash(塑件)毛边poor staking铆合不良excesssive gap间隙过大grease/oil stains油污inclusion杂质painting peel off脏污shrinking/shrinkage缩水mixed color杂色scratch划伤poor processing 制程不良poor incoming part事件不良fold of pakaging belt打包带折皱painting make-up补漆discoloration羿色water spots水渍polishing/surface processing表面处理exposed metal/bare metal金属裸露lack of painting烤漆不到位safety安全quality品质delivery deadline交货期cost成本engineering工程die repair模修enterprise plan = enterprise expansion projects企划QC品管die worker模工production, to produce生产equipment设备to start a press开机stop/switch off a press关机classification整理regulation整顿cleanness清扫conservation清洁culture教养qualified products, up-to-grade products良品defective products, not up-to-grade products不良品waste废料board看板feeder送料机sliding rack滑料架defective product box不良品箱die change 换模to fix a die装模to take apart a die拆模to repair a die修模packing material包材basket蝴蝶竺plastic basket胶筐isolating plate baffle plate; barricade隔板carton box纸箱to pull and stretch拉深to put material in place, to cut material, to input落料to impose lines压线to compress, compressing压缩character die字模to feed, feeding送料transportation运输(be)qualfied, up to grade合格not up to grade, not qualified不合格material change, stock change材料变更feature change 特性变更evaluation评估prepare for, make preparations for 准备parameters参数rotating speed, revolution转速manufacture management制造管理abnormal handling异常处理production unit生产单位lots of production生产批量steel plate钢板roll material卷料manufacture procedure制程operation procedure作业流程to revise, modify修订to switch over to, switch---to throw--over switching over切换engineering, project difficulty工程瓶颈stage die工程模automation自动化to stake, staking, reviting铆合add lubricating oil加润滑油shut die架模shut height of a die架模高度analog-mode device类模器die lifter举模器argon welding氩焊vocabulary for stamping冲压常词汇stamping, press冲压punch press, dieing out press冲床uncoiler & strainghtener整平机feeder送料机rack, shelf, stack料架cylinder油缸robot机械手taker取料机conveyer belt输送带transmission rack输送架top stop上死点bottom stop下死点one stroke一行程inch寸动to continue, cont.连动to grip(material)吸料location lump, locating piece, block stop 定位块reset复位smoothly顺利dent压痕scratch刮伤deformation变形filings铁削to draw holes抽孔inquiry, search for查寻to stock, storage, in stock库存receive领取approval examine and verify审核processing, to process加工delivery, to deliver 交货to return delivenry to.to send delinery backto retrn of goods退货registration登记registration card登记卡to control管制to put forward and hand in提报safe stock安全库存acceptance = receive验收to notice通知application form for purchase请购单consume, consumption消耗to fill in填写abrasion磨损reverse angle = chamfer倒角character die字模to collect, to gather收集failure, trouble故障statistics统计demand and supply需求career card履历卡to take apart a die卸下模具to load a die装上模具to tight a bolt拧紧螺栓to looser a bolt拧松螺栓to move away a die plate移走模板easily damaged parts易损件standard parts标准件breaking.(be)broken,(be)cracked 断裂to lubricate润滑common vocabulary for die engineering 模具工程常用词汇die 模具figure file, chart file图档cutting die, blanking die冲裁模progressive die, follow (-on)die连续模compound die复合模punched hole冲孔panel board镶块to cutedges=side cut=side scrap切边to bending折弯to pull, to stretch拉伸Line streching, line pulling线拉伸engraving, to engrave刻印upsiding down edges翻边to stake铆合designing, to design设计design modification设计变化die block模块folded block折弯块sliding block滑块location pin定位销lifting pin顶料销die plate, front board模板padding block垫块stepping bar垫条upper die base上模座lower die base下模座upper supporting blank上承板upper padding plate blank上垫板spare dies模具备品spring 弹簧bolt螺栓document folder文件夹file folder资料夹to put file in order整理资料spare tools location手工备品仓first count初盘人first check初盘复棹人second count 复盘人second check复盘复核人equipment设备waste materials废料work in progress product在制品casing = containerazation装箱quantity of physical invetory second count 复盘点数量quantity of customs count会计师盘,点数量the first page第一联filed by accounting department for reference会计部存查end-user/using unit(department)使用单位summary of year-end physical inventory bills年终盘点截止单据汇总表bill name单据名称This sheet and physical inventory list will be sent to accounting department together (Those of NHK will be sent to financial department)本表请与盘点清册一起送会计部-(NHK厂区送财会部)Application status records of year-end physical inventory List and physical inventory card 年终盘点卡与清册使用-状况明细表blank and waste sheet NO.空白与作废单号plate电镀mold成型material for engineering mold testing工程试模材料not included in physical inventory不列入盘点sample样品incoming material to be inspected进货待验description品名steel/rolled steel钢材material statistics sheet物料统计明细表meeting minutes会议记录meeting type 会别distribution department分发单位location地点chairman主席present members出席人员subject主题conclusion结论decision items决议事项responsible department负责单位pre-fixed finishing date预定完成日approved by / checked by / prepared by核准/审核/承办PCE assembly production schedule sheetPCE组装厂生产排配表model机锺work order工令revision版次remark备注production control confirmation生产确认checked by初审approved by核准department部门stock age analysis sheet库存货龄分析表on-hand inventory现有库存available material良品可使用obsolete material良品已呆滞to be inspected or reworked待验或重工total合计cause description原因说明part number/ P/N 料号type形态item/group/class类别quality品质prepared by制表notes说明year-end physical inventory difference analysis sheet 年终盘点差异分析表physical inventory盘点数量physical count quantity帐面数量difference quantity差异量cause analysis原因分析raw materials原料materials物料finished product成品semi-finished product半成品packing materials包材good product/accepted goods/ accepted parts/good parts良品defective product/non-good parts不良品disposed goods处理品warehouse/hub仓库on way location在途仓oversea location海外仓spare parts physical inventory list备品盘点清单spare molds location模具备品仓skid/pallet栈板tox machine自铆机wire EDM线割EDM放电机coil stock卷料sheet stock片料tolerance工差score=groove压线cam block滑块pilot导正筒trim剪外边pierce剪边drag form压锻差pocket for the punch head挂钩槽slug hole废料孔feature die公母模expansion dwg展开图radius半径shim(wedge)楔子torch-flame cut火焰切割set screw止付螺丝form block折刀stop pin定位销round pierce punch=die button圆冲子shape punch=die insert异形子stock locater block定位块under cut=scrap chopper清角active plate活动板baffle plate挡块cover plate盖板male die公模female die母模groove punch压线冲子air-cushion eject-rod气垫顶杆spring-box eject-plate弹簧箱顶板bushing block衬套insert 入块club car高尔夫球车capability能力parameter参数factor系数phosphate皮膜化成viscosity涂料粘度alkalidipping脱脂main manifold主集流脉bezel斜视规blanking穿落模dejecting顶固模demagnetization去磁;消磁high-speed transmission高速传递heat dissipation热传rack上料degrease脱脂rinse水洗alkaline etch龄咬desmut剥黑膜D.I. rinse纯水次Chromate铬酸处理Anodize阳性处理seal封孔revision版次part number/P/N料号good products良品scraped products报放心品defective products不良品finished products成品disposed products处理品barcode条码flow chart流程表单assembly组装stamping冲压molding成型spare parts=buffer备品coordinate座标dismantle the die折模auxiliary fuction辅助功能poly-line多义线heater band 加热片thermocouple热电偶sand blasting喷沙grit 砂砾derusting machine除锈机degate打浇口dryer烘干机induction感应induction light感应光response=reaction=interaction感应ram连杆edge finder巡边器concave凸convex凹short射料不足nick缺口speck瑕??shine亮班splay 银纹gas mark焦痕delamination起鳞cold slug冷块blush 导色gouge沟槽;凿槽satin texture段面咬花witness line证示线patent专利grit沙砾granule=peuet=grain细粒grit maker抽粒机cushion缓冲magnalium镁铝合金magnesium镁金metal plate钣金lathe车mill锉plane刨grind磨drill铝boring镗blinster气泡fillet镶;嵌边through-hole form通孔形式voller pin formality滚针形式cam driver铡楔shank摸柄crank shaft曲柄轴augular offset角度偏差velocity速度production tempo生产进度现状torque扭矩spline=the multiple keys花键quenching淬火tempering回火annealing退火carbonization碳化alloy合金tungsten high speed steel钨高速的moly high speed steel钼高速的organic solvent有机溶剂bracket小磁导liaison联络单volatile挥发性resistance电阻ion离子titrator滴定仪beacon警示灯coolant冷却液crusher破碎机模具工程类plain die简易模pierce die冲孔模forming die成型模progressive die连续模gang dies复合模shearing die剪边模riveting die铆合模pierce冲孔forming成型(抽凸,冲凸)draw hole抽孔bending折弯trim切边emboss凸点dome凸圆semi-shearing半剪stamp mark冲记号deburr or coin压毛边punch riveting冲压铆合side stretch侧冲压平reel stretch卷圆压平groove压线blanking下料stamp letter冲字(料号) shearing剪断tick-mark nearside正面压印tick-mark farside反面压印冲压名称类extension dwg展开图procedure dwg工程图die structure dwg模具结构图material材质material thickness料片厚度factor系数upward向上downward向下press specification冲床规格die height range适用模高die height闭模高度burr毛边gap间隙weight重量total wt.总重量punch wt.上模重量五金零件类inner guiding post导柱inner hexagon screw六角螺钉dowel pin固定销coil spring弹簧lifter pin顶料销eq-height sleeves=spool等高套筒pin销lifter guide pin浮升导料销guide pin导正销wire spring圆线弹簧outer guiding post外导柱stop screw止付螺丝located pin定位销outer bush外导套模板类top plate上托板(顶板)top block上垫脚punch set上模座punch pad上垫板punch holder上夹板stripper pad脱料背板up stripper上脱料板male die公模(凸模)feature die公母模female die母模(凹模)upper plate上模板lower plate下模板die pad下垫板die holder下夹板die set下模座bottom block下垫脚bottom plate下托板(底板) stripping plate外打(脱料板) outer stripper外脱料板inner stripper脱料板lower stripper下脱料板零件类punch冲头insert入块(嵌入件)deburring punch压毛边冲子groove punch压线冲子stamped punch字模冲子round punch圆冲子special shape punch异形冲子bending block折刀roller滚轴baffle plate挡块located block定位块supporting block for location 定位支承块air cushion plate气垫板air-cushion eject-rod气垫顶杆trimming punch切边冲子stiffening rib punch = stinger 加强筋冲子ribbon punch压筋冲子reel-stretch punch卷圆压平冲子guide plate定位板sliding block滑块sliding dowel block滑块固定块active plate活动板lower sliding plate下滑块板upper holder block上压块upper mid plate上中间板spring box弹簧箱spring-box eject-rod弹簧箱顶杆spring-box eject-plate弹簧箱顶板bushing bolck衬套cover plate盖板guide pad导料块塑件&模具相关英文compre sion molding压缩成型flash mold溢流式模具plsitive mold挤压式模具split mold分割式模具cavity型控母模core模心公模taper锥拔leather cloak仿皮革shiver饰纹flow mark流痕welding mark溶合痕post screw insert螺纹套筒埋值self tapping screw自攻螺丝striper plate脱料板piston活塞cylinder汽缸套chip细碎物handle mold手持式模具移转成型用模具encapsulation molding低压封装成型射出成型用模具two plate两极式(模具)well type蓄料井insulated runner绝缘浇道方式hot runner热浇道runner plat浇道模块valve gate阀门浇口band heater环带状的电热器spindle阀针spear head刨尖头slag well冷料井cold slag冷料渣air vent排气道h=0.02~0.05mmw=3.2mmL=3~5mmwelding line熔合痕eject pin顶出针knock pin顶出销return pin回位销反顶针sleave套筒stripper plate脱料板insert core放置入子runner stripper plate浇道脱料板guide pin导销eject rod (bar)(成型机)顶业捧subzero深冷处理three plate三极式模具runner system浇道系统stress crack应力电裂orientation定向sprue gate射料浇口,直浇口nozzle射嘴sprue lock pin料头钩销(拉料杆) slag well冷料井side gate侧浇口edge gate侧缘浇口tab gate搭接浇口film gate薄膜浇口flash gate闸门浇口slit gate缝隙浇口fan gate扇形浇口dish gate因盘形浇口H=F=1/2t~1/5tT=2.5~3.5mmdiaphragm gate隔膜浇口ring gate环形浇口subarine gate潜入式浇口tunnel gate隧道式浇口pin gate针点浇口Φ0.8~1.0mmRunner less无浇道(sprue less)无射料管方式long nozzle延长喷嘴方式sprue浇口;溶渣品质人员名称类QC quality control 品质管理人员FQC final quality control 终点品质管制人员IPQC in process quality control 制程中的品质管制人员OQC output quality control 最终出货品质管制人员IQC incoming quality control 进料品质管制人员TQC total quality control 全面质量管理POC passage quality control 段检人员QA quality assurance 质量保证人员OQA output quality assurance 出货质量保证人员QE quality engineering 品质工程人员品质保证类FAI first article inspection 新品首件检查FAA first article assurance 首件确认TVR tool verification report 模具确认报告3B 3B 模具正式投产前确认CP capability index 能力指数CPK capability index of process 模具制程能力参数SSQA standardized supplier quality合格供应商品质评估OOBA out of box audit 开箱检查QFD quality function deployment 品质机能展开FMEA failure model effectiveness analysis 失效模式分析 8 disciplines 8项回复容FA final audit 最後一次稽核CAR corrective action request 改正行动要求corrective action report 改正行动报告FQC运作类AQL Acceptable Quality Level 运作类允收品质水准S/S Sample size 抽样检验样本大小ACC Accept 允收REE Reject 拒收CR Critical 极严重的MAJ Major 主要的MIN Minor 轻微的AOQ Average Output Quality 平均出厂品质AOQL Average Output Quality Level 平均出厂品质Q/R/S Quality/Reliability/Service 品质/可靠度服务MIL-STD Military-Standard 军用标准S I-S IV Special I-Special IV 特殊抽样水准等级P/N Part Number 料号L/N Lot Number 特采AOD Accept On Deviation 特采UAI Use As It 首件检查报告FPIR First Piece Inspection Report 百万分之一PPM Percent Per Million 批号制程统计品管专类SPC Statistical Process Control 统计制程管制SQC Statistical Quality Control 统计品质管制R Range 全距AR Averary Range 全距平均值UCL Upper Central Limit 管制上限LCL Lower Central Limit 管制下限MAX Maximum 最大值MIN Minimum 最小值GRR Gauge Reproducibility&Repeatability 量具之再制性与重测性判断量可靠与否DIM Dimension 尺寸DIA Diameter 直径FREQ Frequency 频率N Number 样品数其它品质术语类QCC Quality Control Circle 品质圈QIT Quality Improvement Team 品质改善小组PDCA Plan Do Check Action 计划执行检查总结ZD Zero Defect 零缺点QI Quality Improvement 品质改善QP Quality Policy 目标方针TQM Total Quality Management 全面品质管理MRB Material Reject Bill 退货单LQL Limiting Quality Level 最低品质水准RMA Return Material Audit 退料认可QAN Quality Amelionrate Notice 品质改善活动ADM Absolute Dimension Measuremat 全尺寸测量QT Quality Target 品质目标7QCTools 7 Quality Controll Tools 品管七大手法通用之件类ECN Engineering Change Notes 工程变更通知(供应商) ECO Engineering Change Order 工程改动要求(客户) PCN Process Change Notice 工序改动通知PMP Product Management Plan 生产管制计划SIP Specification In Process 制程检验规格SOP Standard Operation Procedure 制造作业规IS Inspection Specification 成品检验规BOM Bill Of Material 物料清单PS Package Specification 包装规SPEC Specification 规格DWG Drawing 图面系统文件类QC Quality System 品质系统ES Engineering Standarization 工程标准CGOO China General PCE厂文件H Huston (美国)休斯敦C Compaq (美国)康伯公司C China 中国大陆A Assembly 组装(厂)S Stamping 冲压(厂)P Painting 烤漆(厂)I Intel 英特尔公司T TAIWANIWS International Workman Standard 工艺标准ISO International Standard Organization 国际标准化组织GS General Specification 一般规格CMCS C-China M-Manufact C-Compaq S-Stamping Compaq产品在冲压厂制造作业规CQCA Q-Quality A-Assembly Compaq产品在组装厂品管作业规CQCP P-Painting Compaq产品在烤漆厂品管作业规部类PMC Production & Material Control 生产和物料控制PPC Production Plan Control 生产计划控制MC Material Control 物料控制ME Manafacture Engineering 制造工程部PE Project Engineering 产品工程部A/C Accountant Dept 会计部P/A Personal & Administration 人事行政部DC Document Center 资料中心QE Quality Engineering 品质工程(部)QA Quality Assurance 品质保证(处)QC Quality Control 品质管制(课)PD Product Department 生产部LAB Labratry 实验室IE Industrial Engineering 工业工程R&D Research & Design 设计开发部P Painting 烤漆(厂)A Asssembly 组装(厂)S Stamping 冲压(厂)生产类PCS Pieces 个(根,块等)PRS Pairs 双(对等)CTN Carton 卡通箱PAL Pallet/skid 栈板PO Purchasing Order 采购订单MO Manufacture Order 生产单D/C Date Code 生产日期码ID/C Identification Code (供应商)识别码SWR Special Work Request 特殊工作需求L/N Lot Number 批号P/N Part Number 料号其它OEM Original Equipment Manufacture 原设备制造PCE Personal Computer Enclosure 个人电脑外设PC Personal Computer 个人电脑CPU Central Processing Unit 中央处理器SECC SECC` 电解片SGCC SGCC 热浸镀锌材料NHK North of Hongkong 中国大陆PRC People's Republic of China 中国大陆U.S.A the United States of America 美国A.S.A.P As Soon As Possible 尽可能快的E-MAIL Electrical-Mail 电子N/A Not Applicable 不适用QTY Quantity 数量VS 以与REV Revision 版本JIT Just In Time 零库存I/O Input/Output 输入/输出OK Ok 好NG Not Good 不行,不合格C=0 Critical=0 极严重不允许ESD Electry-static Discharge 静电排放5S 希腊语整理,整顿,清扫,清洁,教养ATIN Attention 知会CC Carbon Copy 副本复印相关人员APP Approve 核准,认可,承认CHK Check 确认AM Ante Meridian 上午PM Post Meridian 下午CD Compact Disk 光碟CD-ROM Compact Disk Read-Only Memory 只读光碟FDD Floppy Disk Drive 软碟机HDD Hard Disk Drive 碟碟机REF Reference 仅供参考CONN Connector 连接器CAV Cavity 模穴CAD Computer Aid Design 计算机辅助设计ASS'Y Assembly 装配,组装MAT'S Material 材料IC Integrated Circuit 集成电路T/P True Position 真位度TYP Type 类型WDR Weekly Delivery Requitement 周出货需求C?T Cycle Time 制程周期L/T Lead Time 前置时间(生产前准备时间)S/T Standard Time 标准时间P/M Product Market 产品市场3C Computer,Commumcation,Consumer electronic's 消费性电子5WIH When,Where,Who,What,Why,How to5M Man,Machine,Material,Method,Measurement4MIH Man,Materia,Money,Method,Time 人力,物力,财务,技术,时间(资源) SQA Strategy Quality Assurance 策略品质保证DQA Desigh Quality Assurance 设计品质保证MQA Manufacture Quality Assurance 制造品质保证SSQA Sales and service Quality Assurance 销售与服务品质保证LRR Lot Rejeet Rate 批退率BS Brain storming 脑力激荡EMI Electronic Magnetion Inspect高磁测试FMI Frequency Modulatim Inspect 高频测试B/M Boar/Molding(flat cable)C/P Connector of PCA/P AssemblySPS Switching power supply 电源箱DT Desk Top 卧式(机箱)MT Mini-Tower 立式(机箱)DVD Digital Vedio DiskVCD Vdeio Compact DiskLCD Liquid Crystal DisplayCAD Computer AID DesignCAM Computer AID ManufacturingCAE Computer AID EngineeringABIOS Achanced Basic in put/output system 先进的基本输入/输出系统CMOS Complemeruary Metoll Oxide Semiconductor 互补金属氧化物半导体PDA Personal Digital Assistant 个人数字助理IC Integrated Circuit 集成电路ISA Industry Standard Architecture 工业标准体制结构MCA Micro Channel Architecture 微通道结构EISA Extended Industry Standard Architecture 扩充的工业标准结构SIMM Single in-line memorymodule 单项导通汇流组件DIMM Dual in-line Memory Module 双项导通汇流组件LED Light-Emitting Diode 发光二级管FMEA Failure Mode Effectivenes 失效模式分析W/H Wire Harness 金属线绪束集组件F/C Flat Calle 排线PCB Printed Circuit Board 印刷电路板CAR Correction Action Report 改善报告NG Not Good 不良WPR Weekly Delivery Requirement 周出货要求PPM Parts Per Million 百万分之一TPM Total Production Maintenance 全面生产保养MRP Material Requiremcnt Planning 物料需计划OC Operation System 作业系统TBA To Be Design 待定,定缺D/C Drawing ChangeP/P Plans & ProceduneEMI Electrical-Music Industry 电子音乐工业RFI Read Frequency Input 读频输入MMC Maximum Material ConditionMMS Maximum Material SizeLMC Least Material ConditionLMS Least Material Size模具技术用语各种模具常用成形方式accurate die casting 精密压铸 powder forming 粉末成形calendaring molding 压延成形 powder metal forging 粉末锻造cold chamber die casting 冷式压铸 precision forging 精密锻造cold forging 冷锻 press forging 冲锻compacting molding 粉末压出成形 rocking die forging 摇动锻造compound molding 复合成形 rotary forging 回转锻造compression molding 压缩成形 rotational molding 离心成形dip mold 浸渍成形 rubber molding 橡胶成形encapsulation molding 注入成形 sand mold casting 砂模铸造extrusion molding 挤出成形 shell casting 壳模铸造foam forming ?泡成形 sinter forging 烧结锻造forging roll 轧锻 six sides forging 六面锻造gravity casting 重力铸造 slush molding 凝塑成形hollow(blow) molding 中空(吹出)成形 squeeze casting 高压铸造hot chamber die casting 热室压铸 swaging 挤锻hot forging 热锻 transfer molding 转送成形injection molding 射出成形 warm forging 温锻investment casting 精密铸造 matched die method 对模成形法laminating method 被覆淋膜成形 low pressure casting 低压铸造lost wax casting 脱蜡铸造 matched mould thermal forming 对模热成形模各式模具分类用语bismuth mold 铋铸模 landed plunger mold 有肩柱塞式模具burnishing die 挤光模 landed positive mold 有肩全压式模具button die 镶入式圆形凹模 loading shoe mold 料套式模具center-gated mold 中心浇口式模具 loose detail mold 活零件模具chill mold 冷硬用铸模 loose mold 活动式模具clod hobbing 冷挤压制模 louvering die 百叶窗冲切模composite dies 复合模具 manifold die 分歧管模具counter punch 反凸模 modular mold 组合式模具double stack mold 双层模具multi-cavity mold 多模穴模具electroformed mold 电铸成形模 multi-gate mold 复式浇口模具expander die 扩径模 offswt bending die 双折冷弯模具extrusion die 挤出模 palletizing die 叠层模family mold 反套制品模具 plaster mold 石膏模blank through dies 漏件式落料模 porous mold 通气性模具duplicated cavity plate 复板模 positive mold 全压式模具fantail die 扇尾形模具 pressure die 压紧模fishtail die 鱼尾形模具 profile die 轮廓模flash mold 溢料式模具 progressive die 顺序模gypsum mold 石膏铸模 protable mold 手提式模具hot-runner mold 热流道模具 prototype mold 雏形试验模具ingot mold 钢锭模 punching die 落料模lancing die 切口模 raising(embossing) 压花起伏成形re-entrant mold 倒角式模具 sectional die 拼合模runless injection mold 无流道冷料模具 sectional die 对合模具segment mold 组合模 semi-positivemold 半全压式模具shaper 定型模套 single cavity mold 单腔模具solid forging die 整体锻模 split forging die 拼合锻模split mold 双并式模具 sprueless mold 无注道残料模具squeezing die 挤压模 stretch form die 拉伸成形模sweeping mold 平刮铸模 swing die 振动模具three plates mold 三片式模具 trimming die 切边模unit mold 单元式模具 universal mold 通用模具unscrewing mold 退扣式模具 yoke type die 轭型模模具厂常用之标准零配件air vent vale 通气阀 anchor pin 锚梢angular pin 角梢 baffle 调节阻板angular pin 倾斜梢 baffle plate 折流档板ball button 球塞套 ball plunger 定位球塞ball slider 球塞滑块 binder plate 压板blank holder 防皱压板 blanking die 落料冲头bolster 上下模板 bottom board 浇注底板bolster 垫板 bottom plate 下固定板bracket 托架 bumper block 缓冲块buster 堵口 casting ladle 浇注包casting lug 铸耳 cavity 模穴(模仁)cavity retainer plate 模穴托板 center pin 中心梢clamping block 锁定块 coil spring 螺旋弹簧cold punched nut 冷冲螺母 cooling spiral 螺旋冷却栓core 心型 core pin 心型梢cotter 开口梢 cross 十字接头cushion pin 缓冲梢 diaphragm gate 盘形浇口die approach 模头料道 die bed 型底die block 块形模体 die body 铸模座die bush 合模衬套 die button 冲模母模die clamper 夹模器 die fastener 模具固定用零件die holder 母模固定板 die lip 模唇die plate 冲模板 die set 冲压模座direct gate 直接浇口 dog chuck 爪牙夹头dowel 定位梢 dowel hole 导套孔dowel pin 合模梢 dozzle 辅助浇口dowel pin 定位梢 draft 拔模锥度draw bead 力调整杆 drive bearing 传动轴承ejection pad 顶出衬垫 ejector 脱模器ejector guide pin 顶出导梢 ejector leader busher 顶出导梢衬套ejector pad 顶出垫 ejector pin 顶出梢ejector plate 顶出板 ejector rod 顶出杆ejector sleeve 顶出衬套 ejector valve 顶出阀eye bolt 环首螺栓 filling core 椿入蕊film gate 薄膜形浇口 finger pin 指形梢finish machined plate 角形模板 finish machined round plate 圆形模板fixed bolster plate 固定侧模板 flanged pin 带凸缘?flash gate 毛边形浇口 flask 上箱floating punch 浮动冲头 gate 浇口gate land 浇口面 gib 凹形拉紧?goose neck 鹅颈管 guide bushing 引导衬套guide pin 导梢 guide post 引导柱guide plate 导板 guide rail 导轨head punch 顶?冲头 headless punch 直柄冲头heavily tapered solid 整体模蕊盒 hose nippler 管接头impact damper 缓冲器 injection ram 压射柱塞inlay busher 嵌入衬套 inner plunger 柱塞inner punch 冲头 insert 嵌件insert pin 嵌件梢 king pin 转向梢king pin bush 主梢衬套 knockout bar脱模杵land 合模平坦面 land area 合模面leader busher 导梢衬套 lifting pin 起模顶?lining 衬 locating center punch 定位中心冲头locating pilot pin 定位导梢 locating ring 定位环lock block 压块 locking block 定位块locking plate 定位板 loose bush 活动衬套making die 打印冲子 manifold block 歧管档块master plate 靠模样板 match plate 分型板mold base 塑胶模座 mold clamp 铸模紧固夹mold platen 模用板 moving bolster 换模保持装置moving bolster plate 可动侧模板 one piece casting 整体铸件parallel block 平行垫块 paring line 分模线parting lock set 合模定位器 pass guide 穴型导板peened head punch 镶入式冲头 pilot pin 导?pin gate 针尖浇口 plate 衬板pre extrusion punch 顶挤冲头 punch 冲头puncher 推杆 pusher pin 衬套梢rack 机架 rapping rod 起模杆re-entrant mold 凹入模 retainer pin 嵌件梢retainer plate 托料板 return pin 回位梢riding stripper 浮动脱模器 ring gate 环型浇口roller 滚筒 runner 流道runner ejector set 流道顶出器 runner lock pin 流道拉梢screw plug 头塞 set screw 固定螺丝。

模具专业英语试题及答案一、选择题(每题1分,共10分)1. What is the term for the process of shaping plastic materials using pressure?A. CastingB. ExtrusionC. Injection moldingD. Blow molding2. The part of the mold that forms the external shape of the product is called:A. CoreB. CavityC. EjectorD. Runner3. Which of the following is not a common type of mold?A. Plastic moldB. Die-cast moldC. Ceramic moldD. All of the above are common types of molds4. The term "draft" in mold design refers to:A. The angle of the parting lineB. The slope of the side wallsC. The thickness of the moldD. The length of the mold5. The function of a mold base is to:A. Provide cooling for the moldB. Support the mold componentsC. Control the temperature of the plasticD. Inject the plastic material6. What is the purpose of using a gate in a mold?A. To provide a path for the material to enter the moldB. To support the plastic part during ejectionC. To control the flow rate of the materialD. To cool the material as it enters the mold7. The cooling system in a mold is designed to:A. Speed up the cooling of the plastic partB. Slow down the cooling of the plastic partC. Prevent the mold from overheatingD. Both A and C8. Which of the following is a common material for mold making?A. WoodB. SteelC. PlasticD. Glass9. The "shrinkage" in mold design refers to the:A. Reduction in size of the plastic part as it coolsB. Increase in size of the plastic part as it coolsC. Change in shape of the plastic part during moldingD. Thickness of the plastic part10. What is the term for the process of removing the excess material from the mold?A. TrimmingB. DeburringC. AnnealingD. Hardening二、填空题(每空1分,共10分)1. The ________ is the part of the mold that comes intodirect contact with the plastic material.2. The ________ system in a mold is used to control the temperature of the mold during the molding process.3. A ________ is a type of mold defect that occurs when the plastic material does not fill the mold completely.4. The ________ is the process of removing the plastic part from the mold after molding.5. The ________ is the distance between the parting line and the edge of the mold.6. The ________ is the process of cutting the plastic part to the desired shape after molding.7. The ________ is the process of removing any excess material or flash from the plastic part.8. The ________ is the process of creating a cavity in the mold to shape the plastic material.9. The ________ is the process of applying heat and pressure to the plastic material to shape it in the mold.10. The ________ is the process of cooling the plastic part after it has been shaped in the mold.三、简答题(每题5分,共20分)1. Explain the importance of draft in mold design.2. Describe the function of a mold base in the molding process.3. What are the considerations when choosing materials for mold making?4. Discuss the role of the cooling system in a mold.四、论述题(每题15分,共30分)1. Discuss the various types of gates used in injection molding and their respective advantages and disadvantages.2. Elaborate on the steps involved in the process of injection molding, from material preparation to the final product.五、翻译题(每题5分,共10分)1. 将以下句子从中文翻译成英文:“模具设计中的分型线是模具打开时塑料件的分离线。

模具行业常用英语口语与词汇中英文对照1. 这套模具资料都清楚了吗?1)是的,这套模具资料很清楚了;2)没有,我还有些地方需要和你再确认一下;3)现在,我们有基本的信息,例如:模穴数,产品材料,注塑机资料和模具材料等,但我们还没有标准件的标准,浇口要求和产品表面要求。

1. Is everything clear on this mould? ( Any question on this mould? )1)Yes, everything is clear.2)No, I need to confirm some questions with you.3)Now, we have the basic information, such as: cavity number, product material, moulding machine specifications and steel information etc. But we do not have the standard of spare parts, gate requirements and the surface requirement of the part.2. 这个产品有没有问题?1)没有问题,客户很专业;2)我检查到了以下问题:A. 除了骨位以外,大部分都加了拨模角。

它不会影响模具结构;B. 没加拨模角。

我没有办法确认产品的分型面和模具结构。

2. Any question on this product?1)No. Our customer is very professional.2)I found the following problems after checking it:A. The draft angle is almost added except for some ribs. It will not affect the mould structure.B. No draft angle on the part. We can not confirm the parting line and the mould construction.3. 模具有没有薄钢位?1)有,这里就有薄钢位, 模具强度会受影响;2)我仔细检查了产品的3D图,没有看到薄钢位,我如果以后发现了,我会立即告诉你。

Lesson 5 Jig and Fixture Design第五课课文讲授,主要以教师翻译讲解和学生的参与理解翻译为主,在文章的学习中,识记专业词汇。

授课时间为45’×2Jigs are workbolders which are designed to hold, locate, and support a workpiece while guiding the cutting tool throughout its cutting cycle. Jigs can be divided into two general classifications: drill jigs and boring jigs. Of these, drill jigs are, by far, the most common, Drill jigs are generally used for drilling, tapping, and reaming, but may, also be used for countersinking, counterboring, chamfering, and spotfacing. Boring jigs, on the other hand, are normally used exclusively for boring holes to a precise, predetermined size. The basic design of both classes of jigs is essentially the same, The only major difference is that boring jigs are normally fitted with a pilot bushing or bearing to support the outer end of the boring bar during the machining operation.译文夹具是工件夹紧装置,用于夹持、定位和支撑工件并在整个切削过程作为切削刀具的导向。

模具英语专业术语大全1. Introduction模具制造是制造业中的关键领域之一。

在模具制造过程中,使用了许多专业术语来描述不同的工艺和技术。

了解这些专业术语对于模具制造工程师和相关行业人员非常重要。

本文将介绍一些常用的模具英语专业术语,帮助读者更好地理解和应用这些术语。

2. Injection Molding Terminology(注塑成型术语)2.1 Injection Molding(注塑成型)Injection molding is a manufacturing process used to produce parts by injecting molten material into a mold cavity. This process is widely used in the production of plastic parts.A mold is a tool used in the injection molding process to shape the molten material into a desired form. It consists of a mold cavity and a mold core.2.3 Cavity(腔)The cavity is the part of the mold that forms the exterior of the molded part. It is the space where the molten material fills and solidifies.2.4 Core(芯)The core is the inner part of the mold that shapes the interior of the molded part. It is used in combination with the cavity to create the desired shape.2.5 Runner(导道)The runner is a channel that connects the injection machine to the mold cavity. It allows the molten material to flow into the mold cavity.The gate is the opening through which the molten material enters the mold cavity from the runner. There are different types of gates, such as edge gate, pin gate, and submarine gate.2.7 Cooling System(冷却系统)The cooling system is used to cool down the molten material inside the mold cavity and solidify it. It consists of cooling channels that circulate cooling water.2.8 Ejector System(射出系统)The ejector system is used to eject the molded part from the mold cavity after it has solidified. It consists of ejector pins or ejector plates.2.9 Mold Clamping(模具夹紧)Mold clamping is the process of securely holding the mold halves together during injection molding. It ensures that the mold cavity and the core mntn their proper alignment.2.10 Venting(排气)Venting is the process of allowing r to escape from the mold cavity during injection molding. It prevents r pockets and gas bubbles from forming inside the molded part.3. Die-Casting Terminology(压铸术语)3.1 Die-Casting(压铸)Die-casting is a manufacturing process used to produce metal parts by forcing molten metal into a mold cavity under high pressure. It is commonly used for the production of automotive and aerospace components.3.2 Die(压铸模具)A die is a tool used in the die-casting process to shape the molten metal into a desired form. It consists of two halves, the fixed half and the ejector half.3.3 Shot Sleeve(浇注套筒)The shot sleeve is a component of the die-casting machine that holds the molten metal before it is injected into the die cavity. It acts as a reservoir and provides a controlled flow of metal.3.4 Shot Chamber(浇注腔室)The shot chamber is the space in the die cavity where the molten metal is injected. It is formed by the fixed half of the die and the ejector half.3.5 Sprue(浇口)The sprue is the channel through which the molten metal flows from the shot sleeve to the shot chamber. It allows the metal to enter the die cavity.3.6 Runner System(导道系统)The runner system is a network of channels that distribute the molten metal from the sprue to multiple cavities in the die. It ensures even distribution of metal and helps mntn the desired temperature.3.7 Venting System(排气系统)The venting system is used to remove r and gases from the die cavity during the die-casting process. It prevents the formation of porosity and gas-related defects in the castings.3.8 Die Lubricant(模具润滑剂)Die lubricant is a substance applied to the die cavity surface to reduce friction between the molten metal and the die. It helps to prolong the life of the die and improve the quality of the castings.3.9 Casting Release Agent(浇注剂)A casting release agent is applied to the die cavity surface to facilitate the release of the solidified casting from the die. It helps prevent sticking and damage to the casting.3.10 Die-Casting Machine(压铸机)A die-casting machine is a specialized machine used to perform the die-casting process. It consists of a die-casting unit, a shot system, and a control system.4. Conclusion本文介绍了一些常用的模具英语专业术语,涵盖了注塑成型和压铸两个重要领域。

1.XXX!你现在有空吗,我可以问你一些问题吗?Could I ask you some questions if you are free?/ Are you free now? May I ask you some questions (a question)?2.请问此产品的面是否为外观面?表面做什么处理?是晒纹/抛光?Can you tell me whether the surface of this part is a visible/esthetic one? What will we do for its surface? Texture or Polishing?3.请问产品这个面可否加顶针或顶块?产品允许加扁顶针吗?Does this part need an ejector pin or an ejector bar? Can we add an ejector blade?4.这个产品的柱位我们打算做司筒。

(或镶针)可以吗?Can we add ejector sleeves or ejector pins in the boss of this part?5.产品的这个位置不能出模,我们打算做行位,在此面上会有分模线,你接受吗?There's an undercut at this position and it needs a slider. It will also have a parting line on this side, is that OK?6.产品里面的这个位置我们打算做斜顶或内行位,有问题吗?We will make the lifter and (inner) slider in this position, will that be a problem?7.你提供的2D产品图与3D产品图不一致,请问以哪一个图面为准?The 2D and 3D drawing you provided is not the same, can you tell me which one is correct?8.你提供的3D产品图有的地方没有出模角,有的地方胶位太厚,有的地方胶位太溥,这些产品问题我们可以自己修改吗?修改后会给交给你确认。