三合一产品使用说明书

- 格式:doc

- 大小:34.78 KB

- 文档页数:8

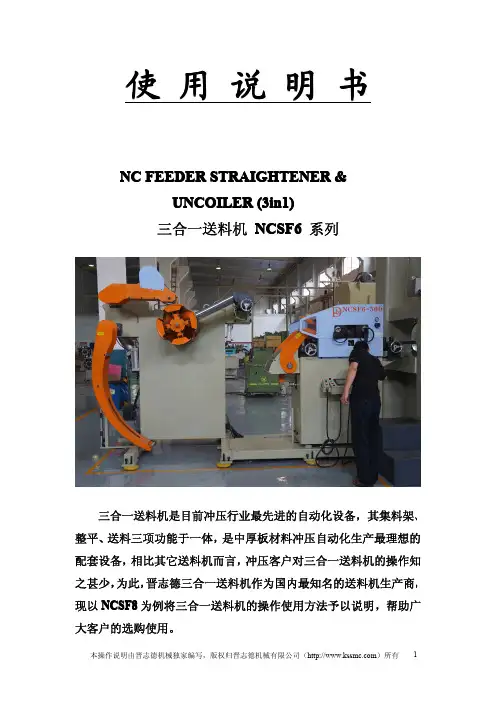

凯利车载三合一控制系统用户手册系统包含:电机控制器、充电器、BMS(铅酸电池均衡)版本:1.12019年2月目录第一章概述 (3)第二章系统特性 (3)第三章命名规则 (4)第四章主要功能与规格参数 (5)4.1充电器 (5)4.1.1参数 (5)4.1.2保护功能 (6)4.1.3特点 (6)4.2电机控制器 (7)4.2.1特点 (7)4.2.2安装 (7)4.2.3配置 (8)4.3 BMS(铅酸电池均衡) (9)第五章安装方式 (10)5.1安装尺寸图 (10)5.2接线方式 (11)第六章充电曲线 (12)第七章维护 (12)联系我们 (13)第一章概述车载三合一控制系统是凯利公司自主研发,集充电器、电机控制器、BMS(铅酸电池均衡)于一体,整合整车主要电子零部件,实现高度集成的电器系统。

单项性能均优异于同类别单款产品。

第二章系统特性1、全新方案设计,安全、智能、可靠、功率密度大、效率高。

2、功能强大:内部集成电池电压、电流、温度采集功能,可估算各电池电量,支持通讯、参数标定,指示各种状态错误类型,功能集成度高。

3、体积小巧,采用高可靠性的控制芯片,同时优化电路、三维空间,集成电机控制器、充电器、电池均衡于一体,提高产品应用环境,适用各种车型。

4、内置微处理器,全过程实时监测各电池工况,智能均衡各电池电量,使其工作于最佳状态,能有效延长电池使用寿命。

5、底部铝制外壳,选配散热风扇,工作效率高。

第三章命名规则以下是凯利车载三合一控制系统的命名规则:控制器类型:功率范围:3KW,4KW,5KW例如:KTA7230B:凯利三合一控制系统,交流电机72V3KW,带均衡。

第四章主要功能与规格参数4.1充电器凯利三合一控制系统拥有自主研发的蓄电池充电电压均衡管理功能,具有优化的充放电曲线。

充电时、接好蓄电池和充电器插件,本机可自动检测待充蓄电池现存电量和环境温度,根据待充蓄电池不同的放电量和实时的环境温度进行充电,蓄电池充足后自动关闭充电系统。

GTR 350 MF (beam/spot/wash) 图案光束染色三合一产品说明书广州德利亚光电科技有限公司感谢您使用本公司的产品,为了您的使用安全,请在使用前仔细阅读本说明书(本说明书包含如何安全安装以及正确使用的重要信息,请仔细阅读后按要求进行安装和操作,并妥善保管此说明书,以备不时之需。

)一、开箱检查:由于灯具在购买过程中必须经过搬运、长途运输等过程。

为确保您所收到的灯具的完整性,请在接收灯具时,检查灯具各个配件是否正常。

二、灯具包装配件(特殊要求时例外)电源线*1条信号线*1条说明书*1份吊桥*2件三、技术参数:电压: AC100V~240V/50~60Hz灯泡: YODN350W 17R色温: 7500K灯泡寿命: 1500小时颜色盘: 14种颜色+白光图案盘: 1个旋转图案盘 + 1个金属图案盘棱镜:16棱镜和6面棱镜,两个可以双向旋转的棱镜盘,光束角度可以自由缩放光束: 多级光束角度变化效果调焦: 线性调焦调光: 0-100%线性调节投光范围: X向540度,Y向270度,可自动校正定位扫描速度: X向3.0秒/540度,Y向2.0秒/250度光束角度: 平行光束角0°-2.3°放大角度:2.5°-36°雾化光角度8°频闪: 双频闪结构,0.5-14次/秒可调控制方式: 20/24国际标准DMX512 通道其它功能: 远程控制灯泡开关。

外观: 耐高温塑料外壳,高强度合金冷压成型内核材料防护等级: IP20净重: 23KG流明值参数: 20m/186700Lux 40m/48175Lux 60m/20855Lux四、显示屏说明A.软件特点:1.液晶65万色触摸TFT界面,操作方便,界面美观.2.物理按键和触摸两种操作方式既完全独立又可结合使用3.可独立用物理按键完成所有操作4.可独立用触摸方式完成所有操作5.可混用物理按键和触摸方式完成所有操作B.智能度高比如:复位中检测霍尔、光耦是否错误并进行提示。

三合一清洗剂安全技术说明书一、产品介绍三合一清洗剂是一种多功能清洁产品,具有清洁、除菌和去除异味的功能。

它可以用于家庭、办公室、学校、医院等各种场所,适用于清洁各种硬表面,如地板、墙壁、家具、玻璃等。

二、安全注意事项1. 本产品仅供外部使用,切勿内服或接触眼睛。

如不慎接触眼睛,请立即用清水冲洗,并及时就医。

2. 儿童应在成人监护下使用本产品。

请确保儿童不会将产品误食或误用。

3. 本产品含有清洁成分,请避免长时间接触皮肤以免引起过敏或刺激。

如不慎接触皮肤,请立即用清水冲洗。

4. 请勿将本产品与其他清洁剂混合使用,以免产生有害气体或化学反应。

5. 使用本产品时请保持通风良好,避免长时间吸入高浓度气味。

6. 请将本产品存放在阴凉、干燥的地方,避免阳光直射。

7. 如不慎误食本产品,请立即向医生求助,并出示产品包装盒以获取正确的处理建议。

三、使用方法1. 清洁:将适量的本产品倒入清水中,按比例稀释,然后用拖把或抹布蘸取稀释后的清洁剂,进行地板、墙壁、家具等硬表面的清洁。

清洁过程中,可根据需要调整清洁剂的浓度。

2. 除菌:将本产品直接喷洒在需要除菌的表面上,待几分钟后用清水擦拭即可。

如需除菌效果更好,可使用刷子轻轻刷洗。

3. 去除异味:将本产品直接喷洒在需要去除异味的空间中,待几分钟后,室内空气中的异味会得到明显改善。

四、产品成分本产品主要成分为表面活性剂、消毒剂、香料等。

其中的表面活性剂可以有效去除污渍和油脂,消毒剂可以杀灭细菌和病毒,香料可以增添清香。

五、产品优势1. 多功能:本产品具有清洁、除菌和去除异味的多种功能,能够满足用户对清洁的不同需求。

2. 高效:本产品采用优质成分,能够快速有效地清洁各种硬表面,并杀灭细菌和病毒。

3. 安全环保:本产品采用环保配方,不含有害物质,对人体和环境无害。

4. 方便使用:本产品使用方便,无需额外稀释,直接喷洒或倒入水中即可使用。

六、常见问题解答1. 本产品能否用于清洗衣物?不可以,本产品适用于清洁硬表面,不适用于衣物清洗。

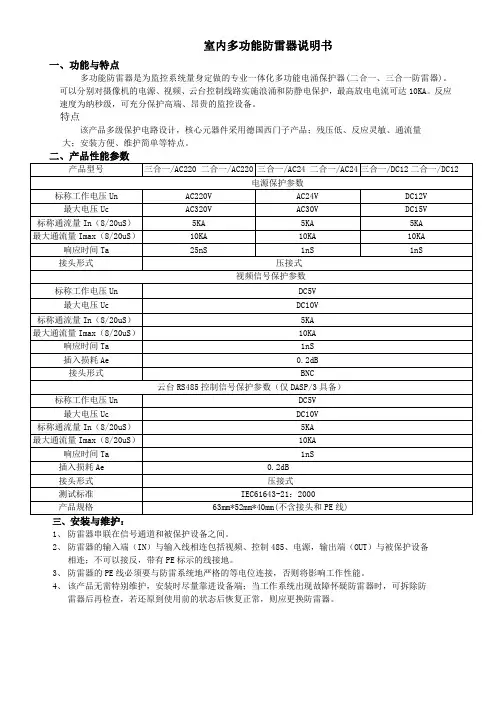

室内多功能防雷器说明书

一、功能与特点

多功能防雷器是为监控系统量身定做的专业一体化多功能电涌保护器(二合一、三合一防雷器)。

可以分别对摄像机的电源、视频、云台控制线路实施浪涌和防静电保护,最高放电电流可达10KA。

反应速度为纳秒级,可充分保护高端、昂贵的监控设备。

特点

该产品多级保护电路设计,核心元器件采用德国西门子产品;残压低、反应灵敏、通流量大;安装方便、维护简单等特点。

三、

1、防雷器串联在信号通道和被保护设备之间。

2、防雷器的输入端(IN)与输入线相连包括视频、控制485、电源,输出端(OUT)与被保护设备

相连;不可以接反,带有PE标示的线接地。

3、防雷器的PE线必须要与防雷系统地严格的等电位连接,否则将影响工作性能。

4、该产品无需特别维护,安装时尽量靠进设备端;当工作系统出现故障怀疑防雷器时,可拆除防

雷器后再检查,若还原到使用前的状态后恢复正常,则应更换防雷器。

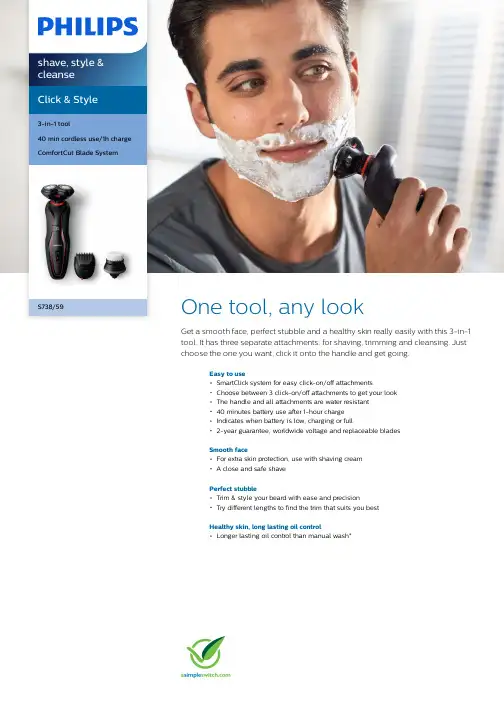

Click & Style3-in-1 tool40 min cordless use/1h chargeComfortCut Blade SystemS738/59One tool, any lookGet a smooth face, perfect stubble and a healthy skin really easily with this 3-in-1tool. It has three separate attachments: for shaving, trimming and cleansing. Justchoose the one you want, click it onto the handle and get going.Easy to useSmartClick system for easy click-on/off attachmentsChoose between 3 click-on/off attachments to get your lookThe handle and all attachments are water resistant40 minutes battery use after 1-hour chargeIndicates when battery is low, charging or full2-year guarantee, worldwide voltage and replaceable bladesSmooth faceFor extra skin protection, use with shaving creamA close and safe shavePerfect stubbleTrim & style your beard with ease and precisionTry different lengths to find the trim that suits you bestHealthy skin, long lasting oil controlLonger lasting oil control than manual wash*HighlightsSmartClick SystemThe SmartClick attachment system makes it easy to turn your Click&Style into a shaver,beard trimmer or cleansing brush. Just click the attachment you need onto the handle to complete your style.Click-on/click-off attachmentsJust click the attachment you need onto the handle to turn it into a shaver, beard trimmer or facial cleansing brush. Click it off again when you’ve finished. For a smooth face, choose the shaver, For perfect stubble, reach for the trimmer. Want a clean face? Time for the cleaning brush. One tool, any look.Smooth shaveShave wet with shaving cream for extra skin protection, or dry for convenience.Smooth faceThe dual rotary shaving attachment isdesigned for a close and clean shave with no nicks and cuts. The shaving heads move in 3directions to easily follow your face's curves.Perfect stubbleCreate anything from perfect stubble to aneatly trimmed beard or mustache. Get creative and then just rinse under the tap to clean.5 different length settingsChoose from 5 length settings: 1mm for perfect 3-day stubble to 5mm for a short beard.Long lasting oil controlSimply click-on the brush and use it with your daily cleansing product. The rotating brush is as gentle as your hands but gives longer lasting oil control effectiveness than manual wash*.Water resistantUse wet or dry. Comfortably shave in theshower if you prefer.Philips Green LogoPhilips Green Products can reduce costs,energy consumption and CO2 emissions. How?They offer a significant environmentalimprovement in one or more of the Philips Green Focal Areas – Energy efficiency,Packaging, Hazardous substances, Weight,Recycling and disposal and Lifetime reliability.SpecificationsShaving PerformanceShaving system: ComfortCut Blade System AccessoriesSmartClick: Beard styler, Oil-control cleansing brushMaintenance: Protective capPouch: Travel pouchEase of useDisplay: Battery lightCleaning: Fully washableOperation: Cordless use DesignHandle: Anti-slip grip, Easy gripPowerAutomatic voltage: 100-240 VBattery Type: NiMHRun time: Up to 40 minutesCharging: 1 hour full charge, Quick charge for 1shaveService2-year guaranteeReplacement head: Replace every 2 yrs withSH30Styling trimmer: Replace every 2 yrs withYS511Cleansing brush RQ560 or RQ563: Replaceevery 3-6 months* SmartClick cleansing brush - compared to manualcleansing in same condition, according to the resultsfrom the external clinical test on 30 candidates and in 3hours after cleansing© 2019 Koninklijke Philips N.V.All Rights reserved.Specifications are subject to change without notice. Trademarks are the property of Koninklijke Philips N.V. or their respective owners.Issue date 2019‑08‑01 Version: 4.5.1。

过滤、洗涤、干燥机(罐式三合一)产品使用说明书温州亚光机械制造有限公司一、设备用途LXG型过滤、洗涤、干燥机(又称罐式三合一),广泛用于制药、化工、农药、食品等行业的固液分离、固体洗涤、固体干燥和固体卸料可实现全过程为封闭的连续操作,是上述行业过滤洗涤干燥首选设备。

二、设备结构简介该设备为不锈钢制立式容器,由罐体装置、搅拌装置、轴端密封装置、升降机构、液压装置、罐底座(固定或可拆式)、加热装置、传动机构、过滤装置、卸料装置、取样装置、洗涤(清洗)灭菌装置、行程指示装置、触摸屏与手动操作控制装置、液压泵站、主电控柜(包括变频器、CPU等),及其它电器附件等部件组成。

实现机、电、仪一体化。

三、设备工艺特点在同一容器内完成过滤、洗涤、干燥全过程连续操作。

1.过滤:在加压或真空状态下操作,实现固液分离。

过滤时滤饼平整,固液分离效果好。

2.洗涤:在容易内侧装有特制360°旋转喷淋装置,使清洗(洗涤)液均匀分布于容器内,可实现容器内部清洗和物料桨化洗涤。

通过升降桨叶搅拌将滤饼和洗涤液混合,使浆状结晶及滤饼得到充分洗涤。

3.干燥:滤饼被搅拌桨叶逐层刮松,设备加热装置均匀对滤饼加热,在真空状态下用热气体对湿物料加热,加速蒸发,达到干燥目的。

4.取样:滤饼干燥适当时间后,进行在线取样分析滤饼湿份,达到产品内控质量要求,即可冷却,为卸料作准备。

5.卸料:刮松物料,通过搅拌叶推动从罐壁侧面出料口自动卸料。

四、设备技术参数及规格1.技术参数:.40μm(由用户工艺选用)2、设备规格2.1LXG××─×W型过滤洗涤干燥机(无菌型)规格:2.2LXG××─×型过滤洗涤干燥机(工业原料型)规格:注:其它设备规格可根据用户工艺要求设计非标准型号2.3管口设置清洗口、洗涤(sip)口、气体进口、捕集器真空口、反吹口、平衡口、温度计口、取样口、出料口、零压口、压力表口、放空口、手孔(人孔)、视镜口、灯镜口、滤液口、加热(冷却)口等。

三合一服务器操作说明书JF-v8.0 4——成都佳发安泰科技有限公司——目录三合一服务器操作说明书JF-v8.0 (1)目录 (2)一、系统升级说明 (3)1.1 主程序的升级说明 (3)1.2 远程管理中心的升级说明 (3)二、软件程序主界面的介绍 (3)2.1 程序主界面截图 (3)2.2 操作区域介绍 (4)2.3 服务器型号区域介绍 (4)2.4 公司的Logo区域 (4)三、软件主程序操作介绍 (4)3.1 设置 (4)3.2 状态 (12)3.3 重启 (13)3.4 关机 (13)四、管理中心远程设置的介绍 (13)4.1 说明 (13)4.2 管理中心的进入 (14)4.3 管理中心的设置 (15)五、液晶面板操作说明 (31)5.1面板功能 (31)5.2按键说明 (31)一、系统升级说明1.1主程序的升级说明程序升级到JF-V8.0,增加系统本身的错误自检功能,可对当前系统工作状态以及下属设备注册正常与否进行统计,并对相关的系统连接、运行错误给出调试方法,方便用户自己维护系统运行。

同时软件的操作界面呈现给用户视觉效果非常直观,简单容易操作,进一步贴近了用户的切需求。

1.2远程管理中心的升级说明对远程管理中心服务器进行。

主要升级的功能是增加对视频指挥,应急指挥两个子系统的管理,为视频指挥系统做好预留口,为将来实现网上巡查系统和视频指挥系统,两个系统的完美结合做好准备。

增加用户权限的分级管理,解码设备的接入验证等方面的管理。

二、软件程序主界面的介绍2.1程序主界面截图2.2操作区域介绍从程序主界面的截图上我们可以看出,程序主要分为三个区域,第一个也是最主要的区域就是操作区域,它包含四个选项:设置、状态、重启、关机。

每个功能模块都起到不同的作用。

关于每个模块的作用和操作我们在下面的软件操作章节进行详细的介绍。

在此我们这是让用户对升级后的系统主程序有一个概念性的了解。

2.3服务器型号区域介绍在程序的主界面的中央处,我们看到的是当前的服务器的名称及其型号。

485型二氧化碳三合一传感器使用说明书第1章产品简介1.1产品概述该变送器广泛适用于农业大棚、花卉培养等需要CO2、光照度及温湿度监测的场合。

传感器内输入电源,感应探头,信号输出三部分完全隔离。

安全可靠,外观美观,安装方便。

1.2功能特点本产品采用高灵敏度的气体检测探头,信号稳定,精度高。

具有测量范围宽、线形度好、使用方便、便于安装、传输距离远等特点。

A、CO2温湿度三合一(普通版):只适用于室内、平缓环境。

B、CO2温湿度三合一(带外置探头版):适用于室内、室外均可,外壳IPV65全防水,可应用于各种恶劣环境。

1.3主要参数1.3.1CO2参数CO2精度±(50ppm+3%读数)(25℃)非线性<1%F·S预热时间2min(可用)10min(最大精度) 1.3.2温湿度参数1.3.3温度参数表一不同温度下温度测量精度如上表所示,在5-60摄氏度范围内最大偏差在±0.5内,小于0℃和大于60摄氏度情况下偏差递增。

1.3.4湿度参数内容最小值典型值最大值单位分辨率(12bit)-0.04-%RH 线性偏差-±3.0见后表2%RH 重复度-±0.1-%RH 工作范围0-100%RH 响应时间(63%)-8-秒长期漂移-<0.5-%RH/年滞后性-±1-%RH 非线性度-<0.1-%RH表二不同湿度下湿度测量精度如上表所示,在20-80%RH范围内典型偏差±3%,小于20%和大于80%的湿度情况下情况下偏差递增。

1.3.5温度对湿度测量的影响上文表二描述了不同湿度情况对湿度测量的影响,下表描述了不同的温度对湿度测量精度的影响。

表三不同温度下的相对湿度如上表所示,在15摄氏度到55摄氏度,30到80的湿度范围内,湿度的精度最高,是±4.5%,其余情况湿度递增。

1.4探头参数与选型CO2探头选型如下:型号量程精度是否抗高预热时间响应时间5KN5000ppm±(50ppm+5%)×<120S<30S 5KW5000ppm±(50ppm+5%)√<60S<15S 1BW1%±(50ppm+5%)√<60S<15S 3BW3%±(50ppm+5%)√<60S<15S 65B65%±(50ppm+5%)×<30S<15S 100B100%±(50ppm+5%)×<30S<15S1.5系统框架图第2章硬件连接2.1设备安装前检查安装设备前请检查设备清单:12V 防水电源1台(选配)USB 转485设备1台(选配)保修卡/合格证1份2.2接口说明宽电压电源输入12-24V 均可。

用户手册Air Performer8000i 系列三合一智能凉暖风空气净化器AMF870目录1 重要事项 (1)安全 (1)电磁场 (EMF) (3)回收 (3)2 您的三合一智能凉暖风空气净化器 (4)产品概述 (4)显示概述 (5)遥控器概述 (6)3 使用入门 (7)安装滤网 (7)首次使用遥控器 (7)了解 Wi-Fi 指示灯 (7)Wi-Fi 连接 (8)4 使用三合一智能凉暖风空气净化器 (9)了解空气质量指示灯 (9)打开和关闭 (10)摇摆送风 (11)功能切换 (11)设置风速/温度 (12)劲速模式 (12)模式切换 (13)设置童锁 (14)设置定时 (14)光传感器 (14)5 清洁和保养 (14)清洁计划 (15)清洁机身 (15)清洁微粒传感器 (15)清洁滤网表面 (16)更换滤网 (16)滤网重置 (18)更换电池 (18)6 存放 (19)7 故障排除 (20)8 保修和支持 (21)1 重要事项安全使用本产品之前,请仔细阅读本用户手册,并妥善保管以备日后参考。

为了确保实现出色的性能,请务必将三合一智能凉暖风空气净化器升级到最新版本。

您可以通过智慧家App进行此升级。

危险• 切勿让任何液体或易燃性清洁剂进入产品,以免发生触电和/或火灾。

• 为了避免过热和火灾,请勿盖住设备。

警告• 本产品的某些部件可能会变得很热且造成烫伤。

对于有儿童和脆弱人群的场合,必须提供持续监督。

• 本产品不适合由肢体不健全、感觉或精神上有障碍或缺乏相关经验和知识的人(包括儿童)使用,除非有负责其安全的人对他们使用本产品进行监督或指导。

• 3 岁到 8 岁之间的儿童只有在产品已放置或安装在其预期的正常工作位置,并已得到有关安全使用产品的监督或指示且了解可能产生的危险时,才可开启/关闭该产品。

• 3 岁到 8 岁之间的儿童不得插入、调节和清洁产品或进行用户维护。

• 3 岁以下儿童应远离,除非持续监督。

松井三机一体除湿机说明书产品简介松井三机一体除湿机是一款高效除湿设备,采用先进的除湿技术,能够快速有效地去除空气中的湿气,保持室内空气清新干燥。

本产品集除湿、空气净化、风扇三种功能于一体,能够满足您在不同场合对空气质量的需求。

产品特点1.三合一功能:除湿、空气净化、风扇功能集于一身,满足不同需求。

2.高效除湿:采用先进的除湿技术,可快速降低室内湿度。

3.静音设计:运行时噪音低,不影响您的生活和工作。

4.智能控制:设有智能湿度控制功能,可根据环境湿度自动开启或关闭除湿功能。

5.便捷移动:轻巧便捷,可根据需求随时移动至不同区域使用。

使用说明1.插电使用:将除湿机插入电源,按下电源开关,选择相应功能模式。

2.智能湿度控制:按照环境湿度情况,可选择自动模式或手动模式。

3.定时功能:可设置定时开关机,方便节能使用。

4.清洁维护:定期清洁除湿机的滤网,保持良好运行状态。

5.移动使用:根据实际需要移动除湿机至不同房间使用,但避免长时间暴露在阳光下。

安全注意事项1.请勿将手或金属物品插入除湿机内部,以免发生触电或损坏设备。

2.使用过程中如有异常请及时停止使用,并联系专业维修人员进行检修。

3.请放置在平稳的地面上使用,避免摇晃或翻倒导致损坏。

4.长时间不使用时,请拔掉电源插头,以免引起火灾危险。

售后服务1.如对产品有任何问题或疑问,请及时联系我们的售后服务热线。

2.售后服务时间:周一至周五,上午9:00-下午5:00。

3.我们承诺为您提供优质、高效的售后服务。

感谢您购买我们的松井三机一体除湿机,希。

WT-32系列综合分析仪是一款集农药残毒、重金属、亚硝酸盐、二氧化硫、甲醛等检测项目为一体的综合分析仪器,其整机设计人性化,操作过程全部有语音提示。

测定农药残留采用的是国家标准《蔬菜中有机磷和氨基甲酸酯类农药残毒量的快速检测》(GB/T 5009.199-2003)规定的酶抑制率法。

本方法能快速检测有机磷和氨基甲酸酯类农药在蔬菜中的残留,以便能及时发现问题,采取措施,控制高残留农药蔬菜的上市,降低农药中毒机率,保障人民食品安全。

测定亚硝酸盐操作程序按国家标准《食品中亚硝酸盐与硝酸盐的测定方法》(GB/T5009.33-1996)的要求设计而成。

测定二氧化硫操作程序按国家标准《食品中亚硫酸盐的测定》(GB/T5009.34-2003)的要求设计而成。

该仪器以其自动化程度高、检测项目多、检测成本低廉,灵敏度高,操作简便快捷,结果准确可靠等诸多特点得以在市场上迅速得以普及,被广泛用于蔬菜批发市场、蔬菜生产基地、农药残留监测监控系统、卫生防疫、环境保护、工商管理、科研院所等部门对含有农药残毒、重金属、亚硝酸盐、二氧化硫、甲醛的果品、蔬菜、水产品等食物进行粗筛。

我们提供给客户朋友的不仅仅是一批高质量的实验室检测仪器、设备,更是一套相应的检测技术,提供优质的服务、保证良好的使用效果是我们义不容辞的责任。

“急客户之所急,想客户之所想”是我们的服务准则!如果您在使用过程中有什么好的建议或意见请直接与我们联系。

目录仪器操作说明--------------------------------------------------------------------------3农药残留检测--------------------------------------------------------------------------6亚硝酸盐(硝酸盐)检测------------------------------------------------------------10重金属检测---------------------------------------------------------------------------12仪器使用注意事项----------------------------------------------------------------14 附:仪器附件及试剂清单仪器操作说明*尊敬的客户,欢迎您选择我公司的产品,请在使用仪器之前,对照仪器仔细阅读仪器使用说明书,以便您能更快捷的了解该款仪器,并可正确的应用,同时也可避免因操作不当对仪器造成不必要的损坏。

Series WE35 3-Way NPT Brass Ball ValveSpecifications - Installation and Operating InstructionsBulletin V-WE35The SERIES WE35 incorporates a full port 3-way brass ball valve for great flow rates with minimal pressure drop. The valve features a blowout proof stem for added safety, reinforced PTFE seats and seals for longer life, and a brass ball for better performance. Actuators are direct mounted creating a compact assembly for tight spaces.The Series WE35 can be configured with either an electric or pneumatic actuator. Electric actuators are available in weatherproof or explosion-proof, a variety of supply voltages, and two-position or modulating control. Two-position actuators use the supply voltage to drive the valve open or closed, while the modulating actuator accepts a 4 to 20 mA input for valve positioning. Actuators feature thermal overload protection and permanently lubricated gear train.The pneumatic double acting actuator uses an air supply to drive the valve open and closed. The actuator has two supply ports, with one driving the valve open and the other driving the valve closed. Spring return pneumatic actuators use the air supply to open the valve and internally loaded springs return the valve to the closed position. Also available is the SN solenoid valve to electrically switch the air supply pressure between the air supply ports for opening and closing the valve. Actuators are constructed of anodized and epoxy coated aluminum for years of corrosion freeservice.WE35-DHD00-T1WE35-DDA02-L1WE35-DDA02-T3-NN05WE35-DDA02-T1-AA01WE35-DTD01-T3-ABy DwyerVALVE BILL OF MATERIALSVALVE DIMENSIONAL DRAWINGAUTOMATED VALVE DRAWINGSW/ PNEUMATIC ACTUATORW/ ELECTRIC ACTUATORW/ EXPLOSION-PROOF ELECTRIC ACTUATORPNEUMATIC ACTUATORNote: For optimal operation, pneumatic actuators should be run with a supply of clean, lubricated air.Spring Return Actuator OperationAir to PORT 2 (the left hand port) causes the actuator to turn counterclockwise (CCW). Loss of air to PORT 2 causes air to exhaust and the actuator turns clockwise (CW). This is the FAIL CLOSE operation.Double Acting Actuators OperationAir to PORT 2 (the left hand port) causes the actuator to turn counterclockwise (CCW). Air to PORT 1 (the right hand port) causes the actuator to turn clockwise (CW).Pneumatic Actuator MaintenanceRoutine maintenance of pneumatic actuator:• Keep the air supply dry and clean• Keep the actuator surface clean and free from dust• Periodic checks should be done to make sure all fittings are tight• Pneumatic actuators are supplied with lubrication to last the entire life span of the actuator under normal operating conditions.The outer surface of the pneumatic actuator should be clean to avoid friction or corrosion. All fittings and connections should be tight to prevent leaks during operation. Check the bolts mounting the valve to the actuator to make sure they have not come loose during shipping or installation. Make sure the valve and actuator are not rubbing or jamming against other components during operation. The actuator should be inspected annually to make sure all fittings and bolts are tight and nothing has come loose during operation.Disassembling Pneumatic ActuatorsBefore beginning disassembly, ensure that the air supply to the actuator has been disconnected, all accessories have beenremoved, and that the actuator has been disassembled from the valve.1. Loosen the end cap fasteners (23) with a wrench (size varies depending on actuator model). On the spring return actuator, alternate 3 to 5 turns on each fastener until the springs are completely decompressed. Use caution when removing the cap since the springs are under load until the fasteners are fully extended.2. Remove the pinion snap ring (13) with a lock ring tool. The indicator (12) may now be removed.3. Turn the pinion shaft (2) counter clockwise until the pistons are at the full end of travel. Disengage the pistons (15) from the pinion. (Note: Low pressure air- -3 to 5 psi MAXIMUM--might be required to force the pistons completely from the body.) Note the position of the pistons before removing them from the actuator body.4. Remove the pinion through the bottom of the actuator. The actuator is now completely disassembled.Be sure the actuator surfaces are free of debris and scratches before reassembling.1. Apply a light film of grease to all O-rings and the pinion before replacing.2. Put the pinion (2) back through the actuator with the flats of the pinion shaft running parallel with the body.3. When reassembling the actuator, make sure that the piston racks are square to the actuator body and returned to their original orientation.(Note: The normal operation of all spring return pneumatic actuators is FAIL CLOSED. To change the orientation to FAIL OPEN, rotate the racks 180º to create a reverse operation.4. When replacing springs in a spring return actuator, ensure that the springs are replaced in their identical position in the end cap from which they were removed. (Note: In some circumstances, you might want to change the standard 80 pound spring set to fit your application and available air pressure.)5. Seal the end caps with a petroleum lubricant and bolt to actuator body.6. Check the seal of the actuator by covering seal areas (pinion, end caps) with soapy water and using low pressure air to the actuator to ensure that no bubbles are produced.Reassembling Pneumatic ActuatorsELECTRIC ACTUATORSElectric Installation1. Operate valve manually and place in the open position.2. Remove any mechanical stops the valve might have. (DO NOT REMOVE ANYPARTS NECESSARY FOR THE PROPER OPERATION OF THE VALVE,SUCH AS THE PACKING GLAND, PACKING NUT, ETC.)3. Ensure that the actuator output shaft and valve stem are aligned properly. Ifthey are not, operate the valve manually until they are correct.4. Remove actuator cover.5. Bring power to the actuator. CAUTION: Make sure power is OFF at the mainbox.6. Wire the actuator per the diagram attached to the inside of the cover. Specialactuators (those with positioner boards, etc.) will have diagrams enclosedinside the cover.7. Securely tighten bolts used to mount the actuator to a mounting bracket ordirectly to the valve mounting pad if it is ISO5211 compliant.8. Cycle the unit several times and check the open and closed positions of thevalve. Cams are pre-adjusted at the factory; due to the variety of valve designs and types however, slight adjustments might be required.9. Replace cover and tighten screws.To Set The Open Position1. Cycle the valve to the open position by applying power to terminals. The top camand switch control this position. In the open position, the set screw in the top cam will be accessible.2. If the valve is not open completely:a. Slightly loosen the set screw on the top cam.b. Rotate the cam clockwise (CW) by hand until the switch makes contact.Contact is made when a slight click can be heard. By making incrementalCW movements of the top cam, the valve can be positioned precisely in the desired position.c. When the top cam is set, tighten the set screw securely.3. If the valve opens too far:a. Apply power to terminals. This will begin to rotate valve CW. When valve isfully open and in the exact position desired, remove power from actuator.b. Loosen the set screw in the top cam.c. Rotate the top cam counterclockwise (CCW) until the switch arm drops offthe round portion of the cam onto the flat section. A slight click can be heard as the switch changes state.d. Continue applying power to terminals until valve is in the desired position.To Set The Closed Position1. Apply power to terminals to move the valve toward the closed position. Thebottom cam and switch control the closed position. In the closed position, the set screw in the bottom cam will be accessible.2. If the valve is not closed completely:a. Slightly loosen the set screw on the bottom cam.b. Rotate the cam counterclockwise (CCW) by hand until the switch makescontact. Contact is made when a slight click can be heard. By makingincremental CCW movements of the bottom cam, the valve can be positioned precisely in the desired position.c. When the top cam is set, tighten the set screw securely.3. If the valve closes too far:a. Apply power to terminals. This will begin to rotate valve CCW. When valve isfully closed and in the exact position desired, remove power from actuator.b. Loosen the set screw in the top cam.c. Rotate the top cam clockwise (CW) until the switch arm drops off the roundportion of the cam onto the flat section. A slight click can be heard as theswitch is no longer making contact with the round part of the cam.d. Continue applying power to terminals until valve is in the desired position.Electric Actuators Wiring Diagram: ACT-TI & ACT-MIWiring Diagrams forTI01-A to TI06-A1: 110 VAC, TI01-B to TI06-B: 220 VAC, TI01-C to TI06-C: 24 VACNHOTONLYOPTIONAL BRAKEWiring Diagrams forTI01-D to TI06-D: 24 VDCREVERSING RELAY SUPPLIED BY CUSTOMEROPERATION:POWER TO 1 & 2 FOR CCW ROTATION POWER TO 3 & 4 FOR CW ROTATION TERMINALS 5 & 6 FOR FIELD LIGHT INDICATION CONNECTIONSW.#1 SW.#2SWITCH #1 OPEN SWITCH SWITCH #2 CLOSE SWITCHWiring Diagrams forMI01-A to MI06-A1: 110 VAC, MI01-B to MI06-B: 220 VAC, MI01-C to MI06-C: 24 VACSW. 1, CLOSESW. 2, OPEN BRAKE OPTIONALSW. 3, CLOSE SW. 4, OPEN Wiring Diagrams forMI01-D to MI06-D: 24 VDCSW. 1, CLOSESW. 2, OPEN BRAKE OPTIONALSW. 3, CLOSE SW. 4, OPENElectric Actuators Wiring Diagram: ACT-TD & ACT-MDWiring Diagrams forTD01-A to TD06-A: 110 VAC, TD01-B to TD06-B: 220 VAC,Wiring Diagrams forWiring Diagrams for TD01-D to TD06-D: 24 VDCNote: To speed up installation of the control wires to the ACT-MDXX modulating actuator, it is recommended to remove the control module from the actuator. The control module can be removed by removing the two mounting screws on the left and right of the control module. Install the control wires to the correct terminal points and then reinstall the control module.Electric Actuator MaintenanceOnce the actuator has been properly installed, it requires no maintenance. The gear train has been lubricated and in most cases will never be opened. Duty Cycle Definition“Duty Cycle” means the starting frequency.Formula: Running Time ÷ (Running Time + Rest Time) x 100% = duty cycle –> Rest Time = Running Time x (1 - duty cycle) ÷ duty cycleFor example: The running time is 15 seconds30% duty cycle 15 x [(1 - 30%) / 30%] = 35 –> The rest time will be 35 seconds 75% duty cycle 15 x [(1 - 75%) / 75%] = 5–> The rest time will be 5 seconds If the duty cycle is higher, the rest time will be shortened, which means the starting frequency will be higher.Thermal OverloadAll actuators are equipped with thermal overload protection to guard the motor against damage due to overheating.Mechanical OverloadAll actuators are designed to withstand stall conditions. It is not recommended to subject the unit to repeated stall conditions.Explosion-Proof Electric Actuators1. DO NOT under any circumstances remove the cover of theactuator while in a hazardous location. Removal of the cover while in a hazardous location could cause ignition of hazardous atmospheres.2. DO NOT under any circumstances use an explosion-proof electric actuator in a hazardous location that does not meet the specifications for which the actuator was designed.3. Always verify that all electrical circuits are de-energized before opening the actuator.4. Always mount and cycle test the actuator on the valve in a non-hazardous location.5. When removing the cover, care must be taken not to scratch, scar of deform the flame path of the cover and base of the actuator, since this will negate the NEMA rating of the enclosure.6. When replacing the cover, take care that the gasket is in place to assure proper clearance after the cover is secured.7. All electrical connections must be in accordance with the specifications for which the unit is being used.8. Should the unit ever require maintenance, remove from the hazardous location before attempting to work on the unit.If the actuator is in a critical application, it is advisable to have a standby unit in stock.Electric Actuators Performance RatingMAINTENANCE/REPAIRUpon final installation of the Series WE, only routine maintenance is required. The Series WE is not field serviceable and should be returned if repair is needed. Field repair should not be attempted and may void warranty.WARRANTY/RETURNRefer to “Terms and Conditions of Sale” in our catalog and on our website. Contact customer service to receive a Return Goods Authorization number before shipping the product back for repair. Be sure to include a brief description of the problem plus any additional application notes.NOTES__________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ ____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________11__________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________________________________________©Copyright 2017 Dwyer Instruments, Inc.Printed in U.S.A. 11/17FR# 444339-00 Rev. 112。

三合一止回阀说明书一、简介、三合一止回阀安装在一般建筑,公寓及工厂的供排水,冷暖水处理,及锅炉的冷凝水,二次供水管道的泵出口上,用来防止泵停止运转而引起的管道内的介质倒流。

多功能三合一止回阀,是水泵出口上推荐使用的阀门,当水泵停止工作时,可以快速止回,这样就可以防止水锤产生.当泵初始运行时,阀瓣在凭借水底推力打开,阀门开启,同时弹簧在弹簧力的凭借下快速的关闭了,随着水流越来越小,几乎停止时,阀瓣完全闭合三合一多功能止回阀.没有水回流倒流现象,这样因为水不回流不倒流,不产生能动,防止水锤现象.二、结构特点1、用一个阀门,可以圆满地完成三种功能:止回阀、截止阀、平衡阀。

2、泵停止运转时,弹簧力先合上阀瓣,因而防止倒流。

3、通过调节开度,可以调节泵的输出量。

4、密封垫用丁腈橡胶制作,因而根本不会泄漏,可以吸收冲力。

5、弹簧是用不锈钢制作,因而具有很强的耐蚀性。

6、可节约水量的设备材料和费用,缩小安装空间。

7、由于形状和结构高等成流线型,因而压降很小。

8、水平管道,垂直管道上均可安装。

三工作原理当水泵启动后,液体从进口进入,顶开阀瓣,流向出口.当水泵停止时,由于阀瓣上安装了快闭弹簧,在介质出现倒流之前,流速接近于零时迅速关闭,防止了水锤的产生,消除了噪音.调节阀杆开度,可改变流量的大小.关闭阀杆,可起到截止阀的作用.主要用于水泵出口或其它防止液体倒流的地方,可有效的防止普通止回阀液体倒流时产生的水锤冲击和噪音,是止回阀的更新换代产品.安装了加速关闭弹簧,利用快关原理防止水锤的产生,防止介质倒流,达到静音关闭.四、适用范围三合一止回阀安装在一般建筑,公寓及工厂的供排水,冷暖水处理,及锅炉的冷凝水,二次供水管道的泵出口上,用来防止泵停止运转而引起的管道内的介质倒流。

五、管道比较图六,外形尺寸三合一止回阀主要外形尺寸七,安装及维护1、安装时要注意阀体外水流标示(箭头)如果箭头模糊不清,可观察阀门通经两侧以低进高出的原则安装,遵循方向安装,垂直、水平均可.2、止回功能:本产品出厂前调节杆为关闭状态安装管道后应逆时针旋转手轮使阀杆上升到最大刻度位置.3、截止功能:顺时针旋紧手轮即可截断流量达到截止功能.4、节流平衡功能:调节阀杆在开度最大的情况下顺时针旋转手轮可使流量变小;反之变大.在变频泵的领域中此功能可以起到降低能耗之功效.。

远距离实时中文机使用说明书目录产品概述 (2)注意事项 (2)首次使用 (3)1.SIM卡安装 (3)2.按键说明 (3)3.连接充电座然后充电 (4)4.开机和休眠 (4)基本功能 (4)1.读卡功能 (4)1)手动读卡 (4)2)自动读卡 (9)2.GPRS通讯 (11)1)手动GPRS通讯 (11)2)自动GPRS通讯 (13)3.查询功能 (15)1)查询记录 (15)2)查询地点 (16)3)查询本机信息 (17)B通讯 (18)错误处理 (19)1.GPRS通讯错误提示说明 (19)2.2.4G读卡失败 (19)3.巡检点安装说明 (10)产品概述☆CPU:16位低功耗,高性能的微处理器,内带2KRAM。

☆规格尺寸:125mm * 60mm * 25mm☆重量:☆显示屏:128x64点的液晶显示屏,白色背光,可显示繁体和简体中文。

☆电源:3.6V锂离子充电电池,750mAH。

☆读卡:EM、2.4G、电子标签。

☆容量:能够存储记录1万条,地点1000个,警报信息1000个。

☆通讯:USB,通讯速率57600bps。

注意事项★请勿自行修理或改装本机。

★请勿使本机受潮或进水。

如果本机浸水,请不要开机以免您受到电击。

★为了避免火灾或者电击,请勿将本机放在潮湿、灰尘多、或者受污染严重的环境中。

★请勿使用已破裂或坏掉屏幕的产品。

坏掉的玻璃或丙烯酸可能会伤害您的手或脸。

请到兰德华服务中心更换屏幕。

★请勿将本机长期处于过热状态,例如太阳,火等类似物体。

★请务必备份重要的资料。

请注意,兰德华公司对数据丢失不承担任何责任。

★请使用由兰德华公司提供的附件。

★切勿弄湿本机,切勿使用苯或稀释剂等化学物清洗本机。

否则有可能导致火灾,电击或使本机受损。

★如果不按此说明操作,可能会对本机造成物理损伤或损坏。

首次使用1.SIM卡安装说明:卸下塑料帽子的两颗螺丝,将其拆下,在中间位置有一SIM卡插槽,把SIM卡正面(没有金属IC的一面)与彩屏一致,SIM卡缺口朝下,插到底就可以了。

Designed to meet tomorrow's intensive storage requirements, Synology RackStation RS4017xs+ provides reliable, high-performance network attached storage for enterprises seeking rock-solid stability along with business collaboration applications and virtualization acceleration. With up to 40 drive scalability, RS4017xs+ simplifies data management with minimal time investment required for setup and maintenance. Synology RS4017xs+ is backed by Synology's 5-year limited warranty. RackStationRS4017xs+Highlights• 3U chassis and 16 drive trays design toprovide high storage capacity• Ultra-high performance of over4,900 MB/s sequential read throughputand 690,000 sequential read IOPS1• Intel Xeon D-1541 8-core CPU and 8GB(up to 64GB) DDR4 ECC UDIMM• Dual 10GBase-T ports and optional10GbE NICs support, providing upto 6 x 10GbE ports for maximumperformance throughput• Scale up to 40 drives with 2 x SynologyRX1217/RX1217RP2• Complete virtualization solution forVMware, Citrix, Microsoft Hyper-V, andOpenStack• Advanced Btrfs file system offering65,000 system-wide snapshots and1,024 snapshots per shared folder• Backed with 5 year, next business dayreplacement service Powerful Storage Solution with Ample UpgradabilityEquipped with an Intel Xeon D-1541 8-core CPU, 8GB DDR4 ECC UDIMM,and 16 x 3.5" drive bays in a 3U form factor , Synology RS4017xs+ is the idealcompanion for intensive data processing, video post-productions, and virtualizationapplications that increasingly require more storage space.RS4017xs+ comes natively with dual 10GBase-T ports and four Gigabit ports,along with two 8-lane PCIe 3.0 slots for additional high performance networkinterface cards (NICs). When configured with 6 x 10GbE ports with Link Aggregationenabled, RS4017xs+ provides ultra-high sequential throughput at over4,900 MB/s and 690,000 sequential IOPS1.System memory and storage capacity of RS4017xs+ can be further extended. Upto 64GB of DDR4 ECC UDIMM can be installed to support multiple virtualizationinstances, and with two Synology RX1217/RX1217RP2 expansion units connected,a combined total of 40 drive bays can be freely arranged for storage management.Rock-Solid Data ProtectionThe Snapshot Replication application provides schedulable, near-instantaneousdata protection. It replicates 65,000 system-wide backup copies to offsite serversand local volumes, bringing near-instantaneous data protection and ensuring datain shared folder or virtual machines in iSCSI LUNs remain available in the event ofdisaster.With block-level incremental backup and cross-version deduplication, SynologyHyper Backup provides multi-version backup with optimized storage spaceutilization and allows multiple backup destinations to local shared folders, externalhard drives, network shared folders, rsync server, and public cloud services.Btrfs: Next Generation Storage EfficiencyRS4017xs+ integrates the Btrfs file system, bringing the most advanced storage technologies to meet the management needs of modern large-scale businesses:• Flexible Shared Folder / User Quota System provides comprehensive quota control on all user accounts and shared folders.• Advanced snapshot technology with customizable backup schedule allowsup to 1,024 copies of shared folder backups and 65,000 copies of system-wide snapshots without occupying huge storage capacity and system resources.• File or folder level data restoration brings huge convenience and saves time for users who wish to restore only a specific file or folder.• File self-healing: Btrfs file system is able to auto-detect corrupted files with mirrored metadata, and recover broken data using the supported RAIDvolumes, which include RAID 1, 5, 6, and 10.Virtualization ReadyRS4017xs+ provides seamless storage solutions for virtualization environments, including VMware, Citrix, Hyper-V, and OpenStack. With VMware vSphere 6 and VAAI integration certified, RS4017xs+ helps offload specific storage operations and optimizes computation power for unparalleled performance and efficiency in VMware environments. Windows Offloaded Data Transfer (ODX) and Synology Advanced LUN support greatly improves the efficiency on massive data transfer and migration. With OpenStack support, RS4017xs+ can be used as a block-based storage component for servers complying with the Cinder API. Comprehensive Business ApplicationsPowered by the innovative Synology DiskStation Manager (DSM), RS4017xs+ comes fully-equipped with applications and features designed specifically for large-scale business:• Windows® AD and LDAP support allows easy integration with existing business directory services without recreating user accounts.• Windows ACL support provides fine-grained access control and efficientprivilege settings, allowing RS4017xs+ to fit seamlessly into currentinfrastructure.• MailPlus allows your business to set up a secure, reliable, and private mailserver while giving your employees a modern mail client for receiving andsending messages.• Powerful collaboration suite with Synology Office, Calendar and Chatfor secure and high performance private communications and contentorganization that your organization can easily manage and control.Virtualization ReadySynology RS4017xs+ is an optimized and certified storage solution for avarious virtualization environments.Synology Collaboration Suite Powerful and secure private cloud solution for business collaboration and organization with simple buteffective management options.Reliability, Availability & Disaster RecoverySystem reliability is of paramount importance to businesses which depend upon their commercial servers every day. RS4017xs+ responds to these concerns with wide-ranging availability and redundancy features:• Synology High Availability ensures seamless transition between clustered servers in the event of server failure with minimal impact on applications.• Redundant power supplies, system fans and network ports with failover support ensure maximum continuous service uptime.• High reliability system design including fan-less CPU heat-sink and passive cooling technology, preventing single points of failure.• DDR4 ECC UDIMM reduces power consumption and has error detection and correction capabilities during data transmission.Future-proof NetworkingEquipped with two 10GbE and four 1GbE ports, RS4017xs+ can accommodate two additional PCIe network interface cards for flexiblenetwork bandwidth management.Hardware Overview1Power button and indicator 2Beep off button 3Drive tray4Drive status indicator 5PSU fan 6Power port7PSU indicator 8Console port 91GbE RJ-45 port 1010GbE RJ-45 (10GBase-T) port 11USB 3.0 port12Expansion port13PCIe expansion slot14RESET button679Technical SpecificationsHardwareCPU Intel Xeon D-1541 8-core 2.1GHz, burst up to 2.7GHz Hardware encryption engine Yes (AES-NI)Memory8 GB DDR4-2133 ECC UDIMM, expandable up to 64GB Compatible drive type16 x 3.5/2.5" SATA HDD/SSDExternal ports• 2 x USB 3.0 port• 2 x Expansion portSize (HxWxD)• 132.3 x 430.5 x 624.5 mm• 132.3 x 482 x 656.5 mm (with server ears)• 3RUWeight17.4 kgLAN• 2 x 10GbE RJ45 (10GBase-T)• 4 x 1GbE RJ45PCIe 3.0 slot• 2 x 8-lane x8 slot• High-performance network interface card supportScheduled power on / off YesSystem fan 3 (80 x 80 x 32 mm)AC input power voltage100V to 240V ACPower frequency50 to 60Hz, single phaseOperating temperature5°C to 35°C (40°F - 95°F)Storage temperature-20°C to 60°C (-5°F to 140°F)Relative humidity5% to 95% RHMaximum operating altitude5,000 m (16,400 ft)GeneralNetworking protocol CIFS, AFP, NFS, FTP, WebDAV, CalDAV, iSCSI, Telnet, SSH, SNMP, VPN (PPTP, OpenVPN™, L2TP)File system• Internal: Btrfs, ext4• External: Btrfs, ext4, ext3, FAT, NTFS, HFS+, exFAT3Storage management • Maximum single volume size: 108TB / 200TB (at least 32GB RAM required, for RAID 5 or RAID 6 groups only)• Maximum internal volumes: 1,024• Maximum iSCSI Targets: 128• Maximum iSCSI LUNs: 512• iSCSI LUN clone / snapshot supportSupported RAID type Basic, JBOD, RAID 0, RAID 1, RAID 5, RAID 6, RAID 10File sharing capability • Maximum user account: 16,000• Maximum user group: 512• Maximum shared folder: 512• Maximum concurrent CIFS / AFP / FTP connections: 2,048Privilege Windows Access Control List (ACL)Virtualization VMware vSphere® 6, Microsoft Hyper-V®, Citrix®, OpenStack®Directory service Windows® AD integration: Domain users login via Samba (CIFS) / AFP / FTP / File Station, LDAP integrationSecurity FTP over SSL / TLS, IP auto-block, firewall, encrypted network backup over Rsync, HTTPS connectionUtilities Synology Web Assistant, Cloud Station Drive, Cloud Station Backup, Cloud Sync Decryption Tool, Evidence Integrity Authenticator,Photo Station Uploader, Snapshot Manager for VMware, Snapshot Manager for Windows, NFS Plug-in for VMware VAAI Supported clients Windows 7 onward, Mac OS X® 10.10 onwardSupported browsers Chrome®, Firefox®, Internet Explorer® 9 onwards, Safari® 8 onwards; Safari (iOS 7 onwards), Chrome (Android™ 4.0 onwards) on tabletsLanguage English, Deutsch, Français, Italiano, Español, Dansk, Norsk, Svensk, Nederlands, Русский, Polski, Magyar,Português do Brasil, Português Europeu, Türkçe, Český,ApplicationsFile Station Virtual drive, remote folder, Windows ACL editor, compress / extract archived files, bandwidth control for specific users or groups,creating sharing links, transfer logsBackup solutions Network backup; local backup; desktop backup; configuration backup; OS X Time Machine; backup data to public cloud;shared folder sync - maximum task number: 32FTP Server Bandwidth control for TCP connections, custom FTP passive port range, anonymous FTP, FTP SSL / TLS and SFTP protocol, boot over the network with TFTP and PXE support, transfer logsHigh Availability Manager Combines two RS4017xs+ into one high-availability clusterSecurity Advisor Malware detection / removal, user account / password, network, system-related security scaniOS / Android™ applications DS cloud, DS file, DS finder, DS cam, DS note, MailPlus, ChatWindows Phone® applications DS file, DS finderAdd-on PackagesAntivirus Essential Full system scan, scheduled scan, white list customization, virus definition auto updateChat Messaging service that runs locally, ensuring sensitive corporate information remains safely stored on company premises while providing users usability equivalent of public cloud services. Built to work with Office and Calendar seamlessly.Cloud Station Suite Default concurrent file transfers: 2,000, retain historical and deleted file versionsCloud Sync One or two-way synchronization with public cloud storage providers including Amazon Cloud Drive, Amazon S3-compatible storage, Baiduyun, Box, Dropbox, Google Cloud Storage, Google Drive, hubiC, Megafon Disk, Microsoft OneDrive, OpenStack Swift-compatible storage, WebDAV servers, Yandex DiskLog Center SSL connection, log rotation: 6 months, 1 year, 2 years, 3 years, email notificationMailPlus Intuitive webmail interface for MailPlus Server; customizable mail labels, filters and user interfaceMailPlus Server Secure, reliable, and private mail solution with high-availability, load balancing, security and filtering design (Includes 5 free email account licenses, additional accounts require the purchasing of additional licenses)Note Station Rich-text note organization and versioning, encryption, sharing, media embedding and attachmentsOffice Real-time collaboration on your private cloud. Work seamlessly together on documents and spreadsheets on your secured company network while combining the convenience and usability of a public cloud service.Storage Analyzer Volume and quota usage, total size of files, volume usage and trends based on past usage, size of shared folders, largest / most / leastfrequently modified filesSurveillance Station Maximum IP camera: 90 (total of 2,700 FPS at 720p, H.264)(Includes two free camera licenses, additional cameras require the purchasing of additional licenses)VPN Server Maximum connections: 30; supported VPN protocol: PPTP, OpenVPN™, L2TPWeb Station Virtual host (up to 30 websites), PHP / MariaDB®, 3rd-party applications supportOther packages Additional 3rd-party packages are available on Package CenterEnvironment and PackagingEnvironment safety RoHS compliantPackage content • RS4017xs+ main unit • Quick Installation Guide • Accessory pack• 2 x AC power cordOptional accessories • 8GB / 16GB DDR4-2133 ECC UDIMM (RAMEC2133DDR4-8G / RAMEC2133DDR4-16G)• Synology E10G17-F2 / E10G15-F1 10Gbps Ethernet adapters• Synology Expansion Unit RX1217/RX1217RP• Synology RKS1317-Rail Kit Sliding• Synology Surveillance Video Decoder VS360HD• Surveillance Device License Pack• MailPlus License Pack• Docker DSM License PackWarranty 5 years*Model specifications are subject to change without notice. Please refer to for the latest information.1. Performance figures may vary depending on environment, usage and configuration.2. RS4017xs+ supports up to 2 Synology Expansion Unit RX1217/RX1217RP, sold separately.3. exFAT Access is purchased separately in Package Center.SYNOLOGY INC.Synology is dedicated to taking full advantage of the latest technologies to bring businesses and home users reliable and affordable ways to centralize data storage, simplify data backup, share and sync files across different platforms, and access data on-the-go. Synology aims to deliver products with forward-thinking features and the best in class customer services.Copyright © 2017, Synology Inc. All rights reserved. Synology, the Synology logo are trademarks or registered trademarks of Synology Inc. Other product and company names mentioned herein may be trademarks of their respective companies. Synology may make changes to specification and product descriptions at anytime, without notice.RS4017xs+-2017-ENU-REV001HeadquartersSynology Inc. 3F-3, No. 106, Chang An W. Rd., Taipei, Taiwan Tel: +886 2 2552 1814 Fax: +886 2 2552 1824ChinaSynology Shanghai 20070, Room 516, No. 638, Hengfeng Rd., Zhabei Dist., Shanghai, ChinaUnited KingdomSynology UK Ltd.Unit C, Denbigh WestBusiness Park, Third Avenue,Bletchley, Milton Keynes,MK1 1DH, UKTel: +44 1908 366380GermanySynology GmbHGrafenberger Allee125 40237 DüsseldorfDeutschlandTel: +49 211 9666 9666North & South AmericaSynology America Corp.3535 Factoria Blvd SE #200,Bellevue, WA 98006, USATel: +1 425 818 1587FranceSynology France SARL39 rue Louis Blanc, 92400Courbevoie, FranceTel: +33 147 176288。

过滤、洗涤、干燥机(罐式三合一)产品使用说明书温州亚光机械制造有限公司一、设备用途LXG型过滤、洗涤、干燥机(又称罐式三合一),广泛用于制药、化工、农药、食品等行业的固液分离、固体洗涤、固体干燥和固体卸料可实现全过程为封闭的连续操作,是上述行业过滤洗涤干燥首选设备。

设备结构简介二、该设备为不锈钢制立式容器,由罐体装置、搅拌装置、轴端密封装置、升降机构、液压装置、罐底座(固定或可拆式)、加热装置、传动机构、过滤装置、卸料装置、取样装置、洗涤(清洗)灭菌装置、行程指示装置、触摸屏与手动操作控制装置、液压泵站、主电控柜(包括变频器、CPU等),及其它电器附件等部件组成。

实现机、电、仪一体化。

设备工艺特点三、在同一容器内完成过滤、洗涤、干燥全过程连续操作。

1.过滤:在加压或真空状态下操作,实现固液分离。

过滤时滤饼平整,固液分离效果好。

2.洗涤:在容易内侧装有特制360°旋转喷淋装置,使清洗(洗涤)液均匀分布于容器内,可实现容器内部清洗和物料桨化洗涤。

通过升降桨叶搅拌将滤饼和洗涤液混合,使浆状结晶及滤饼得到充分洗涤。

3.干燥:滤饼被搅拌桨叶逐层刮松,设备加热装置均匀对滤饼加热,在真空状态下用热气体对湿物料加热,加速蒸发,达到干燥目的。

4.取样:滤饼干燥适当时间后,进行在线取样分析滤饼湿份,达到产品内控质量要求,即可冷却,为卸料作准备。

5.卸料:刮松物料,通过搅拌叶推动从罐壁侧面出料口自动卸料。

设备技术参数及规格四、技术参数:..15μm、(由用户工艺选用)μm40设备规格2、型过滤洗涤干燥机(无菌型)规格:××─×W2.1LXG注:其它设备规格可根据用户工艺要求设计非标准型号管口设置2.3)口、气体进口、捕集器真空口、反吹口、平衡口、温度计口、sip 清洗口、洗涤(、视镜口、灯镜口、滤取样口、出料口、零压口、压力表口、放空口、手孔(人孔)液口、加热(冷却)口等。

五、设备安装及调试 21.设备安装1.1设备安装厂房按工程设计标准进行验收(包括水、电气、环境卫生等)符合GMP 要求。

1.2设备安装基础可靠,应用防震措施。

1.3设备安装说明1.3.1设备就位按部件组装次序进行(见产品竣工图)。

六、设备使用说明1.基本要求1.1设备安装应以上罐体上端面为基准面进行水平垂直调整。

1.2设备安装后检查1.2.1电压及电控系统联接(见电器原理图)。

1.2.2不同流体的进口、出口联接密封(氮气、水、溶剂、加热水、冷却水、滤出液、物料液等。

)1.2.3底部烧结滤网板罐底座与罐体的联接及密封。

1.2.4搅拌桨在传动轴上固定并调整与罐体间隙为6mm,烧结滤板间隙6mm。

1.2.5手动搅拌桨使其空转。

1.2.6液压泵站油箱及齿轮油箱油位和液控系统与电控系统联接(见说明书)1.2.7液压管、软管联接及排气。

1.2.8“O”形密封圈、平垫圈与罐体相关件密封口应吹除干净。

(罐底座斜面、出料口、视镜孔、人孔口等)1.2.9管路系统密封紧固螺栓松紧度适当,罐底座与上罐体用卡兰联接紧固。

1.2.1设备、液压泵站、电控系统得接地线。

1.2.11设备、电控、液控符合工厂防爆要求,0压开关、安全阀、温度计、压力表均需标定,以上检查合格后方可进行启动。

1.2.12罐底座与上罐体对中及对罐底提升罐上、下平衡同步。

1.2.13上升、下降液压缸、限位接进开关及形成脉冲器固定。

1.2.14液压缸润滑注油泵检查。

2.测试与控制2.1搅拌桨驱动2.1.1搅拌桨的转动方向与控制按钮标记一致2.1.2搅拌桨转速变频器调速,通过调速旋钮有小变大。

2.1.3搅拌桨的升降方向与按钮一致。

2.1.4搅拌桨升降速度设定及提升、下降行程开关固定。

2.2液压泵站驱动与控制2.2.1出料阀压缸(液压马达)进出口与控制阀进出口一致。

液压马达顺时针为出料阀开,逆时针为出料阀关。

2.2.2出料阀阀座与闷芯对中,调整电接头压力表上下限。

出料阀密封良好,固定开启、关闭接近开关位置。

、2.2.3升、降液压缸进出口与控制阀一致。

2.2.4电机旋转方向按箭头方向。

32.2.5适当调整液压泵站压力、流量,符合操作要求。

2.2.6必要时排尽油压管路中空气。

2.2.7接通油箱水冷器。

2.3电控柜测试2.3.1开启电源开关。

2.3.2显示电控触摸屏主页.2.3.3选择设定参数.2.3.4操作屏进行操作.2.3.5上部控制箱按钮与操作屏联动一致.(详见电控使用说明)2.4罐体及附件测试2.4.1罐内正压力和真空测试:正压气密性0.3MPa保压30分钟无渗漏。

真空-0.097MPa连续抽不下降。

2.4.2夹套压力测试,最高使用压力0.35MPa,保压30分钟无渗漏。

2.4.3清洗喷头测试。

2.4.4视镜灯开启关闭。

2.4.5罐底座、手孔、人孔、出料阀、取样阀开启、关闭测试。

2.5安全联锁装置测试2.5.1压力表、安全阀、O压开关测试。

2.5.2罐底座、手孔、出料阀、人孔、清洗门、行程指示器、阀门等接近开关动*注:指搅拌桨未旋转工况下禁止搅拌下降3启动准备3.1易爆有害物料的预防处理。

3.1.1向罐内填充易爆混合物之前,罐内为常压。

3.1.2罐内抽真空。

3.1.3充氮气消除真空为常压。

3.1.4在常压下试运行。

3.1.5重复该操作一定次数。

3.2投料前测试检查3.2.1液压泵站油箱和齿轮箱油位。

3.2.2烧结板和底座牢固程度及罐底座与罐体联接紧固程度。

3.2.3密封垫和液压装置的密封性能。

3.2.4安全开关系统性能。

4操作4.1启始状态44.1.1罐底座、手孔、出料阀、人孔、取样阀和接管阀门处于关闭状态,0压开关处于常压状态。

4.1.2搅拌桨在罐上位。

4.1.3粉尘过滤器在封头接口上。

4.2打开进料阀进料(按工厂工艺方法)4.2.1向罐内进料时,搅拌桨处于上位,,必要时可以下降搅拌桨低速搅拌,以便物料均匀分布。

4.2.2当物料到达工艺规定位置停止进料。

4.2.3关闭进料口阀门。

4.3加热/冷却(按工艺选用)4.3.1罐体夹套和过滤夹套过滤、清洗、干燥、出料时按不同工艺要求进行加热或冷却。

4.3.2机械密封压力及冷却控制。

4.3.3干燥通过低速搅拌物料,加速热传递。

4.4过滤4.4.1提升搅拌桨在适当位置停止。

4.4.2打开滤液出口阀的同时关闭平衡球阀,4.4.3逐步罐内加压、滤液抽真空,待滤液排放口玻璃管无液流时,在逐渐减压。

4.4.4在发现滤饼漏气(即裂缝)时,搅拌桨应进行低速表面平料。

4.5清洗4.5.1清洗液通过旋转喷球或取样口引入罐内。

4.5.2罐内清洗:清洗液在0.2~0.3MPa压力下旋转喷头进行清洗,直到滤液经滤饼流出,这时搅拌桨一直停在高位。

4.5.3桨化洗涤:罐内减压后洗涤液在0.2~0.3MPa压力下旋转喷头进行将化洗涤,逐渐缓慢下降搅拌桨并以适当转速进行浆化搅拌。

4.5.4清洗完毕后,停止搅拌,并提升搅拌桨到适当位置,再重复进行过滤操作。

4.5.5最终洗涤(清洗)罐体、搅拌桨、波纹管后,搅拌桨停在滤饼表面20~30mm 处为干燥作准备。

4.6干燥4.6.1在真空状态下干燥,这时打开平衡球阀,保证烧结板上下压力平衡。

4.6.2打开加热阀门进行加热。

4.6.3干燥适当时间后,缓慢下降搅拌桨进行低速搅拌,待物料呈粉状逐渐加速,使物料加速蒸发干燥。

(按工厂工艺进行)4.6.4打开取样阀,取样后关闭。

4.6.5取样分析合格后,罐内卸压为零,方可准备出料。

4.7出料4.7.1关闭夹套热水阀,打开夹套冷却水阀,对物料进行冷却降温至出料温度。

4.7.2缓慢下降搅拌桨,以足够搅拌转速搅碎滤饼。

4.7.3罐内为常压时方可打开出料阀,依靠处于低位的搅拌桨搅拌出料。

(根据流量及物料调整转速,通常为低速)4.8清洗残留物料(根据各厂工艺),但必须在允许范围内进行。

六、设备维护与保养1.电控柜、液位泵站维护与保养见使用说明书。

2.机械密封、减速机维护与保养见使用说明书。

3.主机接口密封圈每年更换一次,并定期清洗干净。

54.搅拌轴、机械密封接触面、升降缸活塞杆、立柱筒与导向筒接触面,每班应注入少量硅油润滑。

5.出料阀应防止阀座、阀芯擦伤阀口密封,出料门关闭应注意两法兰对中,防止表面擦伤并及时调整间隙。

否则影响密封。

6.烧结板表面注意保护,搅拌桨底面至烧结板面最小距离为6+2mm,定期进行检查,及时调整间隙。

7.拆装烧结板后重新装配应紧固,O型圈损坏应全部更换,拉杆、拉帽拉紧时受力均匀,防止密封圈泄露。

(0形圈应涂少量硅油)8.可拆接口管件应定期清洗消毒。

9.机械密封无菌腔定期用乙醇注入消毒,清洗后用纯净氮气吹除,确保无菌状态。

10.出料阀、取样阀无菌腔应定期清洗、消毒。

11.罐体内外表面应洁净,符合GMP要求。

12.管路密封圈应定期检查,更换O形圈,防止油泄漏。

13.减速机油箱及液压泵油箱及时检查油位。

14.定期检查接近开关间隙并紧固。

15.定期检查紧固螺栓,防止松动。

16.压力表、安全阀、温度计、行程装置、限位装置等仪表仪器应定期标定,确保计量准确。

17.用户制定适合生产工艺要求的SOP标准操作规程。

130 (增加灭菌SOP,防止烧结板变形)(严禁桨叶埋在湿滤静止起动,应提升至表面方可起动)(严禁在滤饼静止起动)(增加微正压氮气保护,防止粉尘飞扬,防止静电爆炸)6。