热风机操作说明书

- 格式:rtf

- 大小:6.73 MB

- 文档页数:11

TH2000-40暖风机使用说明书一、用途TH2000-40暖风机是一种燃烧轻柴油或者煤油,加热空气送热风取暖的野外取暖设备,主要供石油、地质、工路建设、矿山、军队野外集训等施工单位在野外住帐蓬或其它临时性住房时取暖使用,亦可在固定房屋使用。

除用于供热取暖外,还可用于通风换气。

二、主要性能1.额定供热量:2.最大耗油量:3.送风量:4.送风温度:5.热效率:6.运行噪声:7.适用环境:8.外形尺寸:9.质量:2.暖风机供热量与耗油量、油的热值和暖风机热效率有关。

而耗油量取决于油嘴型号和油泵压力。

当油嘴型号、油的热值和暖风机效率确定后(1.0gal/45°H、油的热值10200kcal/kg、热效率85%)主要取决于油泵压力。

表1给出了供热量与油泵压力的关系,供使用时选取。

三、构造作用暖风机由壳体、供油系统、燃烧器、燃烧换热器、控制系统、送风机、送回风管、烟筒、轮子、支腿等部分组成,见图1。

1.壳体壳体由上下两部分组成,上下壳体由橡胶拉手联接。

在壳体上设有热风出口、循环空气入口、工具箱、前盖、支腿等。

卸开上壳体可对燃烧换热器、送风机进行装卸维修。

打开前盖可对控制盒、燃烧器、供油系统进行装卸维修。

打开工具箱可存取电缆、室温控制器、备件工具和使用说明书等。

2.供油系统供油系统由油桶、吸油管、过滤器、流量控制器及油管等组成,见图2:(1)吸油管前部装有过滤网,吸油时可防止杂物进入堵塞供油系统。

(2)过滤器将油进行过滤并可分离水分。

(3)流量控制器可自动排除供油系统中的空气,调节吸油量。

3.燃烧器燃烧器由电机、风机、油泵、电磁阀、程控器及复位按钮、火焰调节螺杆、光电管、点火电极、油嘴、风门调节旋钮、点火变压器等组成,见图3,详细结构见ST120使用说明书。

(1)电机与风机及油泵同轴安装,通电后,电机、油泵、风机同时工作。

(2)风机为燃烧提供空气,同时为烟气的顺利排放提供动力。

燃烧空气量的大小(风门的大小)可根据耗油量的大小进行调节。

User Manual Ceramic TowerHeaterMODEL: WHT05711. READ these instructions carefully before installing and operating theappliance. Keep them for further reference.2. R ecord in the space below the “SERIAL/MODEL NUMBER” found on the backor bottom of your appliance and retain this information for future reference. SERIAL NUMBER:MODEL NUMBER:DATE OF PURCHASE:Save and staple your sales receipt to your manual for warranty coverage.SAFETY INFORMATIONImportant Safety Instructions ..........................................................................................................................................3-4 Electrical Requirements. (4)SET UP & USEParts & Features (6)Control Panel (7)Operation Guide (8)TROUBLESHOOTING & WARRANTYLimited Warranty (11)IMPORTANT SAFETY INSTRUCTIONSWhen using electrical appliances, basic precautions should always be followed to reduce the risk of fire, electric shock, and injury to persons, including the following:1. Read all instructions before using this heater.2. T his heater is hot when in use. To avoid burns, do not let bare skin touch hot surfaces. If provided, use handles when moving this heater. Keep combustible materials, such as furniture, pillows, bedding, papers, clothes, and curtains at least 3 feet (0.9m) from the front of the heater and keep them away from the sides and rear.3. E xtreme caution is necessary when any heater is used by or near children or invalids and whenever the heater is left operating and unattended.4. A lways unplug heater when not in use.5. D o not operate any heater with a damaged cord or plug or after the heater malfunctions, has been dropped or damaged in any manner. Discard heater or return heater to authorized service facility for examination, electrical or mechanical adjustment, or repair.6. Do not use outdoors.7. T his heater is not intended for use in bathrooms, laundry areas and similar indoor locations. Never locate heater where it may fall into bathtub or other water container.8. D o not run cord under carpeting. Do not cover cord with throw rugs, runners, or similar coverings. Do not route cord under furniture or appliances. Arrange cord away from traffic area and where it will not be tripped over.9. T o disconnect heater, first turn controls to off, then remove plug from outlet.10. D o not insert or allow foreign objects to enter any ventilation orexhaust opening as this may cause an electric shock or fire, or damage the heater.11. T o prevent a possible fire, do not block air intakes or exhaustin any manner. Do not use on soft surfaces, like a bed, whereopenings may become blocked.12. A heater has hot and arcing or sparking parts inside. Do not useit in the areas where gasoline, paint, or flammable liquids areused or stored.13. U se this heater only as described in this manual. Any other usenot recommended by the manufacturer may cause fire, electric shock, or injury to persons.14. CAUTION: Always plug heaters directly into a wall outlet/receptacle. Never use with an extension cord or relocatablepower tap (outlet/power strip).15. T his heater draws 12.5 amps during operation. To preventoverloading a circuit, do not plug the heater into a circuit that already has other appliances working.16. T he output of this heater may vary and its temperature maybecome intense enough to burn exposed skin. Use of this heater is not recommended for persons with reduced sensitivity to heat or an inability to react to avoid burns.17. Don’t leave the heater on unattended.SAVE THESE INSTRUCTIONSHOUSEHOLD USE ONLYELECTRICAL REQUIREMENTSThis appliance has a polarized plug (one blade is wider than the other). To reduce the risk of electric shock, this plug is intended to fit into a polarized outlet only one way. If the plug does not fit into the outlet, reverse the plug. If it still does not fit, contact a qualified electrician. Do not attempt to modify the plug in any way.NOTE:N either Westinghouse nor the dealer can accept any liability for damage to the product or personal injury resulting from failure to observe the electrical connection procedures.WARNING:T o reduce the risk of electric shock, do not use with an extension cord.SAFETY FEATURESTip-Over Safety FeatureThis heater is equipped with a tip-over safety feature. Once the heater is tipped over, an internal switch will automatically shut the heater off. Once the heater is restored an upright position, the heater will resume operation.Overheat Safety FeatureThis heater is equipped with an overheat safety feature. When the heaters internal components reach a certain temperature that could cause overheating and possible fire, the heater will automatically shut off.PARTS & FEATURESIN THE BOX•CERAMIC TOWER HEATER•USER MANUALAir IntakeBack HousingCONTROL PANEL Power Indicator LightOPERATION INSTRUCTIONS1. Plug in the heater into standard household electrical outlet.2. A djust the TEMPERATURE control dial clockwise past the “LO” until the power indicator light illuminates. Continue moving clockwise until you reach your desired temperature.3. A djust FUNCTION control to desired setting. If you want to use the heater withthe oscillation function, use the settings for “MIN ” – fan only, “LO” heat, “HI” heatlocated on the right side of the control. If you want to use the heater withoutthe oscillation function, use the settings for “MIN ” – fan only, “LO” heat, “HI” heat located on the left side of the control.4. T o turn off the heater, adjust the FUNCTION control to “0”position and the TEMPERATURE control dial to “MIN” position. Then, unplug the unit.NOTE: I n low heat position, unit is operating at 1000w. In high heat position, unitis operating at 1500w. Keep that in mind as you try and get the desiredheat output from your unit.For “Fan Only” function, TEMPERATURE control still needs to be rotated clockwise past the “LO” position until power indicator light illuminates.MAINTENANCE1. Turn off the power switch on the top of the unit.2. Unplug the unit and let it cool completely.3. T o keep the heater clean, the outer shell may be cleaned with a soft, dampcloth. You may use a mild detergent if necessary. After cleaning, dry the unit with a soft cloth. CAUTION: DO NOT let liquid enter the heater.4. D O NOT use alcohol, gasoline, abrasive powders, furniture polish, or roughbrushes to clean the heater. This may cause damage or deterioration to the surface of the heater.5. DO NOT immerse the heater in water.6. Wait until the unit is completely dry before use.7. If you do not use the heater for a long time, store in a safe, dry place. STORAGEStore the heater in a cool, dry location when not in use. To prevent dust and dirt build-up, use the original packaging to repack the unit.BEFORE YOU CALL FOR SERVICEIF THE APPLIANCE FAILS TO OPERATE:A) Check to make sure that the appliance is plugged in securely. If it is not, removethe plug from the outlet, wait 10 seconds and plug it in again securely.B) C heck for a blown circuit fuse or a tripped main circuit breaker. If these seem tobe operating properly, test the outlet with another appliance.IF NONE OF THE ABOVE SOLVES THE PROBLEM, CONTACT CUSTOMER SERVICE. DO NOT TRY TO ADJUST OR REPAIR THE APPLIANCE YOURSELF. CUSTOMER SERVICEIMPORTANTDO NOT RETURN THIS PRODUCT TO THE STOREIf you have a problem with this product, please contact the W Appliance Co. Customer Satisfaction Center at 1-855-855-0294. DATED PROOF OF PURCHASE, MODEL # AND SERIAL # REQUIRED FOR WARRANTY SERVICESPECIFICATIONS• Voltage Rating: 120 V (60Hz)• Power Consumption: 1500W• Unit Dimensions (WxDxH): 6.85” x 6.2” x 18.74”• Unit Weight: 3.75 lbs.LIMITED WARRANTYWestinghouse brand is used under license. Any repair, replacement, or warranty service, and all questions about this product should be directed to W Appliance Co. at 1 (855) 855-0294 from the USA or Puerto Rico.W Appliance Co. warrants to the original purchaser that the product will be free from defects in material, parts and workmanship for the period designated for this product. The warranty commences the day the product is purchased and covers up to a period of1 year (12 months) for labor/1 year (12 months) for parts (manufacturing defects only)/carry in service.W Appliance Co. agrees that it will, at its option, replace the defective product with either a new or remanufactured heater equivalent to your original purchase during the warranty period.Exclusions: This warranty does not apply to thebelow:1. I f the appearance or exterior ofthe product has been damaged ordefaced, altered or modified in design orconstruction.2. I f the product’s original serial numberhas been altered or removed or cannotbe readily determined.3. I f there is damage due to power linesurge, user damage to the AC powercord or connection to improper voltagesource.4. I f damage is due to general misuse,accidents or acts of God.5. I f repair attempts are done byunauthorized service agents, use ofparts other than genuine parts or partsobtained from persons other thanauthorized service companies.6. O n units that have been transferredfrom the original owner.7. O n products that have been purchasedas refurbished, like new, second-hand, ina “As-Is” or “Final Sale” terms.8. T o products used in a commercial orrental setting.9. T o products used in settings other thanordinary household use or used otherthan in accordance with the providedinstructions.10. T o damages for service calls forimproper installations.11. T o glass parts and other accessoryitems that are included with the unit.12. T ransportation and shipping costsassociated with the replacement ofthe unit.13. S ervice calls to instruct you how to useyour heater.14. S ervice calls to repair or replace thehouse fuse, reset the circuit breaker orcorrect the wiring in the house. REPAIR OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE EXCLUSIVE REMEDY OF THE CUSTOMER; W Appliance Co. SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR BREACH OF ANY EXPRESS OR IMPLIED WARRANTY ON THIS PRODUCT, EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW. ANY IMPLIED WARRANTY OF MERCHANTABILITY OF FITNESS FOR A PARTICULAR PURPOSE ON THIS PRODUCT IS LIMITED TO THE DURATION OF THE WARRANTY.Some states do not allow the exclusion or limitations of incidental or consequential damages, or limitations on how long the warranty lasts. In these cases the above exclusions or limitations may not apply to you. This warranty gives you specific legal rights and you may also have other rights which vary from state to state.Obtaining Service: To obtain service, product literature, supplies or accessories please call1 (855) 855-0294 to create a ticket for exchange/ repair. Please make sure to provide the date of purchase, model number and a brief description of the problem. Our customer service representativewill contact you or send detailed return instructions.W Appliance Co. does not warrant that the appliance will work properly in all environmental conditions, and makes no warranty and representation, either implied or expressed, with respectto the quality, performance, merchantability, or fitness for a particular purpose other than the purpose identified within this user manual. W Appliance Co. has made every effort to ensure that this user manual is accurate and disclaims liability for any inaccuracies or omissions that may have occurred. Informationin this user manual is subject to change without notice and does not represent a commitment on the part of W Appliance Co. W Appliance Co. reserves the right to make improvements to this user manual and/or to the products described in this user manual at any time without notice. If you find information in this manual that is incorrect, misleading, or incomplete, please contact us at1- 855-855-0294.W Appliance Co.,1356 BroadwayNew York, NY 10018Page 11, WESTINGHOUSE, and INNOVATION YOU CAN BE SURE OFare trademarks of Westinghouse Electric Corporation. Used underlicense by W Appliance Company. All Rights Reserved.090617 Page 12。

热风机安全操作规程范本一、安全意识1. 了解热风机的基本原理、结构、工作方式和安全操作规程。

2. 充分认识热风机工作时的风险,始终保持高度的警惕性。

3. 严格遵守公司的安全管理制度和操作规程,维护个人与他人的安全。

二、热风机的使用和维护1. 在使用热风机之前,必须对热风机进行外观检查,确认没有损坏或松动的零部件。

2. 在使用热风机之前,必须确认电源插头与插座相匹配,插头接触良好。

3. 在使用热风机之前,必须确认热风机的电源开关处于关闭状态。

4. 在插入电源之前,必须确保热风机放置在稳定的水平表面上,以防止意外倾倒。

5. 在使用热风机的过程中,严禁擅自拆卸、修理或改变热风机的结构。

6. 在使用热风机之前,必须保持热风机周围的通风通畅,避免遮挡风口或阻塞风道。

三、热风机的操作要点1. 在启动热风机之前,请确保周围没有可燃材料,确保工作场所整洁。

2. 在使用热风机的过程中,必须保持一定的安全距离,避免接触高温表面。

3. 在使用热风机的过程中,必须保持热风机稳定,避免热风机意外移动。

4. 在使用热风机的过程中,必须保持热风机风口、风道和排风口干净,避免积尘或堵塞。

5. 在使用热风机的过程中,应始终保持观察,监测热风机的工作状态,如异常现象及时报告。

四、热风机的停机操作1. 在停止使用热风机之前,必须先关闭电源开关,然后再拔下电源插头。

2. 在拔下电源插头之前,必须确认热风机已完全停止运行,避免发生意外触电。

3. 在停止使用热风机之后,请将热风机放置在安全地方,避免儿童或未经培训的人员接触。

五、热风机的维护保养1. 定期查看热风机的电源线,如有损坏或老化应及时更换。

2. 定期清洁热风机的外表面和内部,避免积尘或污垢影响热风机的工作效果。

3. 定期检查热风机的运转情况,如发现异常应及时报告,避免故障发生。

4. 定期对热风机进行维修保养,如更换零部件或维修电路,应由专业人员进行。

六、紧急情况处理1. 在热风机发生故障或出现异常情况时,应立即关闭电源,并及时汇报给相关负责人。

风机使用说明书1、特别注意事项2、收货检验及风机安装前准备3、风机安装4、风机接线方法5、风机的起动及调试6、风机维护和贮存1、特别注意事项1.1风机外壳或电机外壳必须可靠接地1。

2禁止反方向旋转,禁止超额定电流运行,禁止缺相运行;1。

3风机轴承加油次数不少于1000小时/次1.4禁止在运转中维护风机2、收货检验及风机安装前准备2.1收货后立即检查风机包装是否完整无损,风机的铭牌参数是否符合要求,各随带附件是否齐全。

2。

2仔细检查风机在运输过程中有无变形或损坏,坚固件是否松动或胶落,叶轮是否有擦碰现象,并对风机各部分零件进行检查。

如发现异常现象,应待修复后使用。

2.3用500W兆欧表测量风机外壳与电机绕组是的绝缘电阻,其值大于0。

5兆欧,否则应对电机绕组进行烘干处理,烘干时温度不允许超过120℃,用手旋转风机叶轮,短时通电测试风机空转情况。

2.4准备好风机安装所需的各种材料、工具及场地。

3、风机安装3.1仔细阅读风机使用说明书及产品样本,熟悉和了解风机的规格、形式、叶轮旋转方向和气流进出方向等;再次检查风机各零部件是否完好,否则应待修复后方可安装使用。

3。

2风机安装时必须有安全装置以防止事故发生,并由熟悉相关安全要求的专业人士安装和接线。

3.3联接风机进出口的风管有单独支撑,不允许将管道重叠重量加在风机的部件上;风机安装时应注意风机的水平位置,对风机与地基的结合面与出风管道的联接应调整,使之自然吻合,不得强行联接.3。

4风机安装后,用手或杠杆拨动叶轮,检查是否有过紧或擦碰现象,有无妨碍转动的物品,无异常现象下,方可进行试运转,风机传动装置的外露部份应有防护罩(用户自备)如风机进风口不接管道时,也需添置防护网或其他安装装置(用户自备)。

3.5风机所配电控箱必须与对应风机相匹配(指功率、电压、气动方式、控制形式等)。

3.6风机接线应由专业电工接线,接线必须正确可靠,尤其是电控箱处的接线编号与风机接线柱上的编号一致对应,风机外壳应可靠接地,接地必须可靠,不能用接零代替接地。

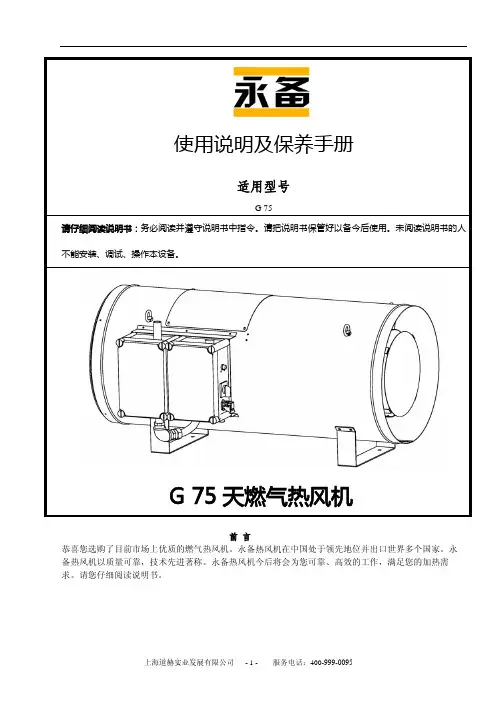

使用说明及保养手册适用型号G 75请仔细阅读说明书:务必阅读并遵守说明书中指令。

请把说明书保管好以备今后使用。

未阅读说明书的人不能安装、调试、操作本设备。

G 75天燃气热风机前 言恭喜您选购了目前市场上优质的燃气热风机。

永备热风机在中国处于领先地位并出口世界多个国家。

永备热风机以质量可靠,技术先进著称。

永备热风机今后将会为您可靠、高效的工作,满足您的加热需求。

请您仔细阅读说明书。

警告:如果不能准确遵守该手册中的指令,错误使用本设备可能会引起火灾、爆炸并由此产生财产损失、人身伤害等!﹣请勿在设备附近储存或者使用汽油及其它挥发性易燃物 ﹣仅由专业人员进行维修警告:本加热器不能用于家庭房间加热或者车辆内部加热!警告:安全对于你和其他人都至关重要,所以在操作本设备之前务必请仔细阅读说明书!警告:火灾、窒息、爆炸危险!固体可燃物,如建筑材料,纸及纸板等与加热器应该按照本说明书的规定保持安全距离!切勿在有挥发性易燃气体,以及存在有汽油、溶剂、稀释剂、粉尘、未知化学物等空间使用本加热器! 一般危险性警告:!不能按照该加热器的说明进行操作可能引起身体伤害和财产损失,危险包括火灾、爆炸、窒息、一氧化碳中毒及漏电。

!仅由阅读并理解操作规程的人员使用加热器。

!如果需要任何协助,请联系生产厂家。

警告:在帐篷、棚屋、车辆内部及其他封闭空间使用燃气加热器会有一氧化碳中毒危险,甚至危及生命!适用于中国地区的警告:仅使用三爪插头,连接带地线电源!警告:在有挥发性气体或者燃料出现时不能开机!维修或者移动加热器前要拔掉插头!▲该加热器为直燃热风机。

该设备使用房屋内部的氧气助燃。

应确保设备正常工作并且被加热房屋适当通风。

目录:前言-----------------------------------------------------------------1 警告-----------------------------------------------------------------2 技术参数-------------------------------------------------------------3 功能介绍-------------------------------------------------------------3 安装说明-------------------------------------------------------------4 操作说明-------------------------------------------------------------5 维护与保养-----------------------------------------------------------6 常见问题解决---------------------------------------------------------7 电路图---------------------------------------------------------------8 质保-----------------------------------------------------------------8技术参数:型号G 75输出热量(Kcal)64500送风量 (m³/h)6500天燃气耗气量(m³/h)7.6液化气耗气量(Kg/h) 5.7电压 (V)220风机功率 (W)380整机重量 (Kg)38外形尺寸 (mm)1130x625x555 功能介绍安装说明安装参数(单台G系列热风机)型号G 75进气管路的接口尺寸 G 3/4天然气供气量(m³/h)≥8天然气进气压力(KPa) 3液化气供气量(Kg/h)≥6液化气进气压力(KPa) 3电源线是否必须接地 是重要提示:燃气热风机电源线必须接地才能点着火,进气压力必须在上表中的压力范围内,供气量达到上表中的数值才能达到热风机的额定输出热量。

暖风机控制台说明书摘要:一、暖风机控制台说明书简介1.产品名称与型号2.产品用途与适用范围3.产品性能与特点二、暖风机控制台使用说明1.操作面板概述2.开关机操作3.温度调节4.风速调节5.定时功能6.安全保护功能三、暖风机控制台维护与保养1.清洁与保养2.故障排查与处理3.正确使用与注意事项四、暖风机控制台附录1.技术参数2.安装与拆卸图解3.保修政策与联系方式正文:一、暖风机控制台说明书简介本说明书详细介绍了暖风机控制台的各项功能、使用方法、维护保养以及注意事项等内容。

适用于广大用户了解产品相关信息,正确使用和维护产品。

二、暖风机控制台使用说明1.操作面板概述暖风机控制台采用一体化设计,操作面板简洁明了,包括开关机键、温度调节键、风速调节键、定时键以及安全保护功能键等。

2.开关机操作用户只需按下开关机键,即可实现暖风机的开启与关闭。

开机状态下,按住开关机键3 秒,可实现关机操作。

3.温度调节通过旋转温度调节键,用户可实现对暖风机出风温度的调节,范围为18℃-35℃。

4.风速调节通过旋转风速调节键,用户可实现对暖风机出风风速的调节,范围为1-3 档。

5.定时功能用户可通过定时键设置暖风机的运行时间,最长可达8 小时。

设置完成后,暖风机将在设定的时间内自动关机。

6.安全保护功能暖风机控制台具有多重安全保护功能,如过热保护、倾倒保护等,确保用户安全使用。

三、暖风机控制台维护与保养1.清洁与保养使用过程中,请定期清理暖风机进风口、出风口的灰尘,保持清洁。

长时间不使用时,请将产品放在干燥通风处。

2.故障排查与处理如遇故障,请先检查电源线、插座是否正常,再检查产品内部元件是否损坏。

如有问题,请联系售后服务。

3.正确使用与注意事项使用时,请确保暖风机放置平稳,避免在潮湿环境中使用,避免让儿童单独操作。

四、暖风机控制台附录1.技术参数暖风机控制台的技术参数包括额定电压、额定频率、额定功率等,具体数值请参见产品标签。

工业暖风机使用说明书全文共四篇示例,供读者参考第一篇示例:工业暖风机使用说明书一、前言:感谢您选择我们的工业暖风机。

本说明书将为您提供关于工业暖风机的操作、维护和安全注意事项。

请您在操作之前仔细阅读本说明书,并按照指引进行正确操作,以确保设备能够正常运行,提供最佳的暖风效果。

二、产品介绍:工业暖风机是专门用于室内暖房的设备,适用于工厂、仓库、车间等大空间。

采用高效电热元件,能够快速提供暖风,将空间内的温度快速升高,提供舒适的工作环境。

工业暖风机外形美观,操作简单,便于移动和安装。

三、操作说明:1. 请将工业暖风机设置在稳固的平面上,确保设备稳定。

2. 将电源插头插入插座,并打开电源开关。

3. 调节温度设定,设置合适的暖风温度。

4. 根据需要选择不同的风速档位,控制风速。

5. 当不使用时,请关闭电源开关,并拔掉电源插头。

四、安全注意事项:1. 请确保工业暖风机处于通风良好的位置,不要遮挡暖风机进风口和出风口。

2. 使用过程中请勿将易燃物品放置在暖风机附近,以免引发火灾。

3. 使用过程中请勿将水或其他液体溅到暖风机上,以免触电或损坏设备。

4. 如果发现设备存在异响、烟雾等异常现象,请及时停止使用,并联系售后服务人员进行检修。

五、维护保养:1. 定期清洁暖风机的表面和进风口,避免灰尘积聚影响设备散热。

2. 定期检查电源线是否完好,避免损坏或短路。

3. 定期检查暖风机的工作状态,确保设备正常运行。

4. 如果发现设备故障或异常,请及时联系专业维修人员进行维修处理,切勿私自拆卸或修理。

1.请勿将工业暖风机用于其它用途。

2.请勿在设备运行时触碰暖风机表面,避免烫伤。

3.请勿在高温、潮湿或易燃环境下使用工业暖风机。

4.请儿童和宠物远离工业暖风机,避免意外伤害发生。

七、结语:工业暖风机是提供温暖的理想设备,正确的使用和维护将延长设备的使用寿命,为您提供更好的使用体验。

我们将以优质的产品和周到的售后服务,为您提供满意的服务体验。

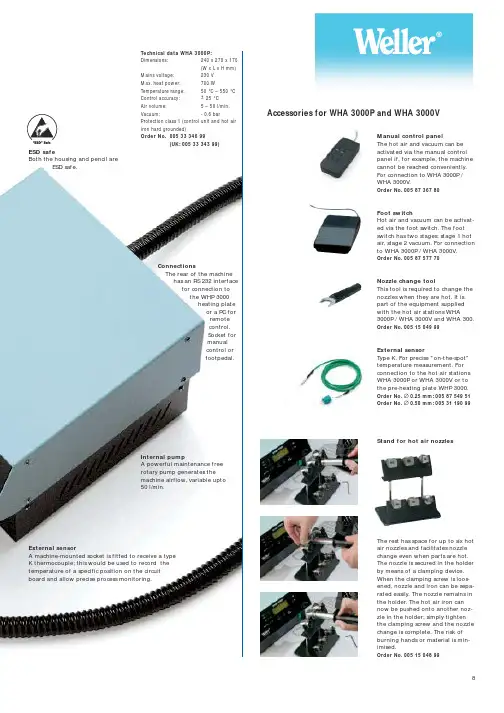

ESD safeBoth the housing and pencil areESD safe.Internal pumpA powerful maintenance free rotary pump generates themachine airflow, variable upto 50 l/min.External sensorA machine-mounted socket is fitted to receive a type K thermocouple; this would be used to record the temperature of a specific position on the circuitboard and allow precise process monitoring.Technical data WHA 3000P:Dimensions:240 x 270 x 170(W x L x H mm)Mains voltage:230 V Max.heat power:700 W Temperature range:50 °C – 550 °CControl accuracy:±25 °C Air volume: 5 – 50 l/min.Vacuum:- 0.6 barProtection class 1 (control unit and hot air iron hard grounded)Order No.005 33 346 99(UK:005 33 343 99)8ConnectionsThe rear of the machine has an RS 232 interface for connection to the WHP 3000heating plate or a PC for remote control.Socket for manual control orfootpedal.Manual control panelThe hot air and vacuum can be activated via the manual control panel if, for example, the machine cannot be reached conveniently.For connection to WHA 3000P /WHA 3000V.Order No.005 87 367 80Foot switchHot air and vacuum can be activat-ed via the foot switch. The foot switch has two stages: stage 1 hot air, stage 2 vacuum. For connection to WHA 3000P / WHA 3000V.Order No.005 87 577 70Nozzle change toolThis tool is required to change the nozzles when they are hot. It is part of the equipment supplied with the hot air stations WHA3000P / WHA 3000V and WHA 300.Order No.005 15 049 99External sensorType K. For precise "on-the-spot"temperature measurement. For connection to the hot air stations WHA 3000P or WHA 3000V or to the pre-heating plate WHP 3000.Order No.∅0.25 mm:005 87 549 51Order No.∅0.50 mm:005 31 190 99The rest has space for up to six hot air nozzles and facilitates nozzle change even when parts are hot.The nozzle is secured in the holder by means of a clamping device.When the clamping screw is loos-ened, nozzle and iron can be sepa-rated easily. The nozzle remains in the holder. The hot air iron can now be pushed onto another noz-zle in the holder; simply tighten the clamping screw and the nozzle change is complete. The risk of burning hands or material is min-imised.Order No.005 15 048 99Stand for hot air nozzlesAccessories for WHA 3000P and WHA 3000V700WThe control technology used in Weller hot air equipment guarantees precise and repeatable processeswhen soldering/desoldering SMD components. This process control is further enhanced by the application of Weller patented nozzle technology.700-W Hot Air Stations These stations use temperature and volume controlled hot air with Weller patented technology nozzles and the HAP 3000 hot air pencil to solder and desolder the larger dual in line and quad pack components.There are three stations in the range giving users the option of digital control with an integral air supply,digital control with an external air or inert gas supply or analogue control with an integral air supply.A wide range of hot air nozzles type ND and NQ with integral hot plates to heat the component body and types NR and DR without hot plates complete the range.WMD 3KThree channel digitally controlled repair station with an integral pump to provide variable volume airflow and fixed value vacuum.The station is supplied with an 80 watt miniature soldering iron,80 watt through hole desoldering tool and 100 watt hot air pencil.WMD 1AA single channel digitally control-led repair station with an integral pump to provide variable volume air flow and fixed value vacuum.The station is supplied with a 100 watt hot air pencil but all other Temtronic tools of compati-ble rating could be driven.WAD 101A single channel digitally control-led hot air station for use with compressed air or inert gas. The station is supplied with a 100 watt hot air pencil but all other Tem-tonic tools apart from the through hole desoldering pencil can be driven.WMA 3VA single channel, analogue con-trolled repair station for use with compressed air or inert gas. The station is supplied with a 100 watt hot air pencil, vacuum pick up and solder paste/adhesive dispenser all able to be operated simultaneously.Hot Air TechnologyEquipment overviewWHA 3000PDigitally controlled hot air station with an integral air supply and vacuum pick up at the nozzle.To cater for demanding repair operations.WHA 3000VDigitally controlled hot air sta-tion for use with a compressed air or inert gas supply and vac-uum pick up at the nozzle.WHA 300Analogue controlled hot air sta-tion with an integral air supply without vacuum pick up.This station is suited to less complex repair operations and other heating processes such as heat shrinking.2WHA 3000 SetThe versatile system for demanding workWHA 3000P700 watt hot air station with patentedWeller nozzle technology for maximumprocess control and user friendly opera-tion. The powerful variable speed con-trolled turbine generates an air volumeof upto 50 litres/min.An ion trap so that charge free hot air isdirected at the component.Memory space to store upto 10 thermalprofiles to ensure process repeatabilityAlternatively:WHA 3000V700 watt hot air station similar in allrespects to the WHA 3000P but operat-ing from an external compressed air orinert gas supply.Hot air nozzle stand (option)Provides storage for upto 6 hot air noz-zles and allows quick and easy nozzlechanges even when hot.WBH 3000SCircuit board holder with a pivoting stand for the HAP 3000 hot air pencil.Circuit boards upto 310 mm x 320 mm.can be accommodated.The circuit board holder ensures that the hot air pencil is vertical to the printed cir-cuit board under repair and the pivoting stand allows the HAP 3000 hot air pencil to be raised and lowered precisely onto the component being reworked.WHP 3000IR Heating plate total heated area 120 mm x 190 mm with 3 ceramic elements. The plate is used to preheat the circuit board under repair, to reduce the possibility of thermal damageSet temperatures and actual tempera-tures are digitally displayed.An external sensor can be connected to display actual temperatures at specific areas of the circuit under repair.The hot plate can be controlled from its own internal control system or inte-grated into the control system of the WHA 3000P/V.When used with the WHA 3000P/V the hot plate sits beneath the WBH 3000S board holder.WHA 3000PS Set consists of:•WHA 3000P 700 Watt hot air station with built in pump•WBH 3000S circuit board holder with pivoting stand•WHP 3000 Heating plate Order No.005 33 556 99(UK:005 33 553 99)WHA 3000VS Set consists of:•WHA 3000V 700 Watt hot air station driven by a compressed air or inert gas supply •WBH 3000S circuit board holder with a pivoting stand•WHP 3000 Heating plate Order No.005 33 596 99(UK:005 33 593 99)The components of the WHA 3000P SetCircuit board holder WBH 3000SRetains and secures the circuit board under repair and allows positioning of the board in X and Y directions.A wide range of accessories avail-able separately permits boardsupto a max size of 310 mm x 320 mm both single and double sided to be accommodated in a perfectly flat condi-tion.Heating plate WHP 3000The WHP 3000increases the flexi-bility of the WHA systems. It provides underside heating to the board under repair, reducing the heat requirement from the hot air pencil and therefore minimising the risk of thermal damage to the board as well as speed-ing up the repair process.The heated surface comprises 3high temperature ceramic ele-ments that ensure fast and effi-cient heating.The WBH 3000S incorporates a piv-oting stand to mount the HAP 3000hot air pencil. This stand allows the HAP 3000 to be raised and lowered onto the component under repair.An added safety feature is the Stop + Go function, which will automatically switch the hot air pencil into a standby mode if the stand is pivoted to the side of the board holder without first switching off the hot air.The pre-heating plate WHP 3000(supplied separately) can be fitted under the board holder to provide background heating.Technical data WBH 3000S:Dimensions:440 x 320 x 446(H x W x L mm)Order No.005 33 163 99Circuit board holder WBH 3000As the WBH 3000S but without pivoting stand.Technical data WBH 3000.Dimensions:100 x 320 x 446(H x W x L mm)Order No.005 33 162 995Accessories for circuit board holder WBH 3000 / WBH 3000S:Adjustable circuit board stop. Order No.005 87 548 73Support for large-dimensioned circuit boards.Order No.005 87 557 45Downholder for circuit boards. Order No.005 87 557 41Clamping set for irregular shaped circuit boards (mobile phones,video/digital camera boards etc.). Order No.005 87 549 24A digital electronic control system guarantees precise temperature control and provides otherfunctions, such as Auto off and stand by temperature. Set and actual temperatures are displayed digitally.Two heated zones can be selected The temperature of a specific point on the board under repair can be monitored and controlled by means of an optional external sensor. If used the temperature display will show the actual value of the temperature of the board at the point of contact, not the temperature of the hot plate ele-ments.An RS 232 interface connection from either of the WHA stations can be used to enable the hot plate to be used as an underside heater in a multilevel processsequence. If this option is required then we recommend that the WBH 3000 board holder is used.The pre-heating plate is designed to sit between the side supports of the board holder.Technical data WHP 3000:Dimensions:254 x 395 x 70(B x L x H)Heatable surface:120 x 190 mm Mains voltage:230 V Power:small heating zone 200 Wlarge heating zone 600 WTemperature range:50°C – 400°C Protection class:1Order No.005 33 386 99(UK:005 33 383 99)Heating plate WHP 3000As the WHP 3000 but with a heatable surface of 190 x 245 mm.Technical data:Dimensions:254 x 395 x 70(B x L x H)Heatable surface:190 x 245 mm Mains voltage:230 V Power:1200 WTemperature range:50°C – 400°C Protection class:1Order No.005 33 646 99(UK:005 33 643 99)WHA 3000VDigital 700 W hot air station forFunction and equipment corresponds to WHA 3000PTechnical data WHA 3000V:Dimensions:240 x 270 x 100(W x L x H mm)Mains voltage:230 V Max.heat power:700 W Temperature range:50 °C – 550 °CControl accuracy:±25 °C Air volume: 5 – 50 l/min.Max.vacuum:-0.6 bar Compressed air supply / Inert gas (N 2): 4 – 6 barProtection class 1 (control unit and hot air iron hard grounded)Order No.005 33 366 99(UK:005 33 363 99)ConnectionsFollowing connections are on the rear side:•RS 232 for connecting the pre-heating plate or a PC.•Connection for manual control panel or foot switch.ConnectionsCompressed air / inert gas 4 – 6 bar.Temperature checkConnection of the temperature sensor (available as an accessory)for highly accurate process monitoring.Air generationThe airflow rate is controlled digitally by means of a pro-portional valveAlternatively,an inert gas, such as nitro-gen could be used in place of compressed air for more demanding tasks.ESD safeHousing and iron are ESD safe.6700WWHA 3000PDigital 700 W hot air station with built in turbineThe WHA 3000P will perform demanding repair tasks oncircuit boards with complex fine pitch surface mountedcomponents.The advanced control technology coupled with user-friendly operation, guarantees precision of repairprocesses. While the sophisticated automatic operationmode guarantees repeatability of the process andincreases productivity and quality.Extensive range accessories compliment the machine topromote flexibility.Stop and GoThe tool holder AKT 30 is a stable support for the hot air pencil. When the pencil is replaced in the support after soldering or desoldering the airflow rate is automati-cally switched to the standby mode, at a minimal flow rate, sufficient to maintain the nozzle at its operating temperature. Removal of the pencil will switch the air-flow back to its selected flow rate.Order No.005 15 043 99ESD safeThe hot air is deliv-ered through an ion trap toremove any charge and the toolhandle and tubing are manufac-tured from static dissipativematerials.SettingUp down pushbuttons set theoperating parame-ters of the air tempera-ture, air volume andprocess time.LED indicators highlight theoperating mode, start/ stop andvacuum functions.LCD DisplayHigh contrast LCD characters clearlydisplay the operating parameters.Manual operationOperating parameters are selectedby the operator to cope with repairtasks.Automatic modeA three-stage temperature/timeprofile controlling air temperature,air volume and process time can bestored in the machine memory tocarry out repeatable repair opera-tions. The WHP 3000 hot plate canalso be controlled in this mode.Upto 10 individual programmes canbe stored in the machines memory.Hot air pencilThe ergonomic and power-ful hot air pencil (700 W)together with the exten-sive range of patentedtechnology nozzles (seepages 11-13) make this tool veryversatile. Hot air nozzles aresecured to the tool by a clampingscrew. A vacuum plate will lift thecomponent from the board afterreflow.A nozzle removal tool suppliedwith the machine enables rapidremoval and replacement of noz-zles, even when hot.7PC SoftwareTo provide control from a PC.。

上海道赫实业发展有限公司服务热线:400-999-0095使用说明及保养手册适用型号D H系列:D H30D H40D H50D H60请仔细阅读说明书:务必阅读并遵守说明书中指令。

请把说明书保管好以备今后使用。

未阅读说明书的人不能安装、调试、操作本设备。

DH系列燃油热风机警告:如果不能准确遵守该手册中的指令,错误使用本设备可能会引起火灾、爆炸并由此产生财产损失、人身伤害等!﹣请勿在设备附近储存或者使用汽油及其它挥发性易燃物﹣仅由专业人员进行维修警告:安全对于你和其他人都至关重要,所以在操作本设备之前务必请仔细阅读说明书!警告:本加热器不能用于家庭房间加热或者车辆内部加热!警告:火灾、窒息、爆炸危险!固体可燃物,如建筑材料,纸及纸板等与加热器应该按照本说明书的规定保持安全距离!切勿在有挥发性易燃气体,以及存在有汽油、溶剂、稀释剂、粉尘、未知化学物等空间使用本加热器!一般危险性警告:!不能按照该加热器的说明进行操作可能引起身体伤害和财产损失,危险包括火灾、爆炸、窒息、一氧化碳中毒及漏电。

!仅由阅读并理解操作规程的人员使用加热器。

!如果需要任何协助,请联系生产厂家。

警告:不能使用汽油、酒精或者其他挥发性燃料!不能使用加热器油箱以外的燃油!加油前应当先停机!在有挥发性气体或者燃料出现时不能开机!燃烧室内存有燃油时不能开机!维修或者移动加热器前要拔掉插头!不能使用铜丝或者其他金属丝替代保险丝!警告:在帐篷、棚屋、车辆内部及其他封闭空间使用燃油加热器会有一氧化碳中毒危险,甚至危及生命!适用于中国地区的警告:仅使用三爪插头,连接带地线电源!▲该加热器为直燃热风机。

该设备使用房屋内部的氧气助燃。

应确保设备正常工作并且被加热房屋适当通风。

目录警告---------------------------------------------------------------2技术参数-----------------------------------------------------------3工作原理-----------------------------------------------------------3注意事项-----------------------------------------------------------4运行热风机---------------------------------------------------------4储存热风机---------------------------------------------------------6热风机保养维护-----------------------------------------------------6零件目录-----------------------------------------------------------15售后服务-----------------------------------------------------------16◆技术参数:◆工作原理:(参考图1)1.本加热器是使用煤油或者柴油为燃料,直接燃烧式,吹出热风的加热设备。

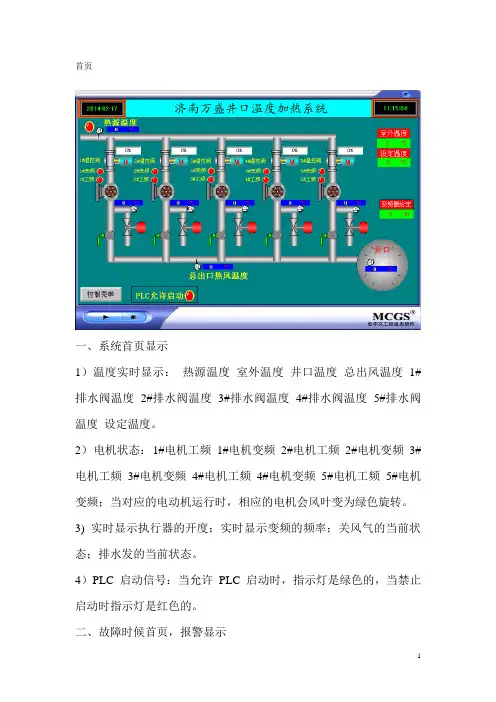

首页一、系统首页显示1)温度实时显示:热源温度室外温度井口温度总出风温度1#排水阀温度2#排水阀温度3#排水阀温度4#排水阀温度5#排水阀温度设定温度。

2)电机状态:1#电机工频1#电机变频2#电机工频2#电机变频3#电机工频3#电机变频4#电机工频4#电机变频5#电机工频5#电机变频;当对应的电动机运行时,相应的电机会风叶变为绿色旋转。

3) 实时显示执行器的开度;实时显示变频的频率;关风气的当前状态;排水发的当前状态。

4)PLC启动信号:当允许PLC 启动时,指示灯是绿色的,当禁止启动时指示灯是红色的。

二、故障时候首页,报警显示1)传感器报警:当传感器报警时,相对应的传感器温度,就不显示温度,直接显示温度报警。

2)电机故障报警:当鼓风机相应的电机故障是,电机停止报警报警。

3)显示变频器报警:显示变频器报警,显示变频器短时间多此报警。

变频器多次故障报警后需按复位按钮复位。

三.用户管理通过用户管理界面来切换到相应的画面。

其中有:(温度控制参数设置)、(系统运行参数设置)、(温度记录)、(报警记录)、(热源温度参数设置)、(温度参数设置)、(风机运行温度设置)、(用户登录)、(重新启动系统)。

进入想不同的界面,需要不同的权限,在未取得权限的情况下,有的界面无法进入,需登录获取相应的权限后方能进入。

登录方式,点击登录按钮弹出用户登录界面。

选择操作员或工程师输入对应的密码后登录。

登录成功后,就可以点击相应的界面进入。

四、重新启动按钮,按下此按钮后弹出重新启动确认界面。

点击确认后系统重启。

五、温度补偿功能系统有温度补偿模式和固定温度模式。

当温度固定模式时,稳定温度设定值有效,控制总出风温度。

当温度补偿模式时:根据室外温度的变化,控制总出风温度。

PID调节器:根据现场情况的调节PID值。

1. PID常用口诀:参数整定找最佳,从小到大顺序查,先是比例后积分,最后再把微分加,曲线振荡很频繁,比例度盘要放大,曲线漂浮绕大湾,比例度盘往小扳,曲线偏离回复慢,积分时间往下降,曲线波动周期长,积分时间再加长,曲线振荡频率快,先把微分降下来,动差大来波动慢,微分时间应加长,理想曲线两个波,前高后低4比1。

使用说明及保养手册适用型号DHC —40请仔细阅读说明书:务必阅读并遵守说明书中指令。

请把说明书保管好以备今后使用。

未阅读说明书的人不能安装、调试、操作本设备。

DHC 系列燃油热风机上海道赫实业发展有限公司服务热线:400-999-0095前 言恭喜您选购了目前市场上最好的燃油热风机。

永备热风机以质量可靠,技术先进著称。

永备热风机今后将会为您可靠、高效的工作,满足您的加热需求。

请您仔细阅读说明书。

警告:如果不能准确遵守该手册中的指令,错误使用本设备可能会引起火灾、爆炸并由此产生财产损失、人身伤害等!﹣请勿在设备附近储存或者使用汽油及其它挥发性易燃物 ﹣仅由专业人员进行维修警告:本加热器不能用于家庭房间加热或者车辆内部加热!警告:安全对于你和其他人都至关重要,所以在操作本设备之前务必请仔细阅读说明书!警告:火灾、窒息、爆炸危险!固体可燃物,如建筑材料,纸及纸板等与加热器应该按照本说明书的规定保持安全距离!切勿在有挥发性易燃气体,以及存在有汽油、溶剂、稀释剂、粉尘、未知化学物等空间使用本加热器! 一般危险性警告:!不能按照该加热器的说明进行操作可能引起身体伤害和财产损失,危险包括火灾、爆炸、窒息、一氧化碳中毒及漏电。

!仅由阅读并理解操作规程的人员使用加热器。

!如果需要任何协助,请联系生产厂家。

警告:在帐篷、棚屋、车辆内部及其他封闭空间使用燃油加热器会有一氧化碳中毒危险,甚至危及生命!适用于中国地区的警告:仅使用三爪插头,连接带地线电源!警告:不能使用汽油、酒精或者其他挥发性燃料!加油前应当先停机!在有挥发性气体或者燃料出现时不能开机!燃烧室内存有燃油时不能开机!维修或者移动加热器前要拔掉插头!▲该加热器为直燃热风机。

该设备使用房屋内部的氧气助燃。

应确保设备正常工作并且被加热房屋适当通风。

目录:前言---------------------------------------------------------------- 2 警告---------------------------------------------------------------- 2 技术参数------------------------------------------------------------ 3 功能介绍-------------------------------------------------------------3 操作说明-------------------------------------------------------------4 维护与保养-----------------------------------------------------------4 常见问题解决---------------------------------------------------------6 零件目录------------------------------------------------------------ 6电路图---------------------------------------------------------------7技术参数:型号DHC-40输出热量Kcal30100送风量 (立方米/小时)1000耗油量 (升/小时) 3.5油箱容积 (升)40电压 (伏)220主送风机功率 (瓦)80燃烧器电机功率 (瓦)30电磁泵(瓦) 35整机重量 (公斤)40外形尺寸 (米) 0.86×0.52×0.82 功能介绍:操作面板1、上电后显示当前环境温度,当设备出现故障时显示E12、温控旋钮,可以设定需要的环境温度3、开关4、电源线(220V,50Hz)5、外接温控器插座。

伽帝芙热风机使用说明书伽帝芙热风机是一种高效、便捷的加热设备,适用于电器、机械、五金、塑料、化工等行业的加热、干燥和固化工作。

本说明书将为您详细介绍伽帝芙热风机的使用方法和注意事项,以保障您的安全和效果。

一、产品组成和特点伽帝芙热风机由高温电热器、风机、控制器、外壳等部分组成。

它的特点有以下几点:1、高温电热器具有优异的加热效果和长寿命的特点,可快速加热并保持恒温。

2、风机具有强大的风量和风压,可将热风均匀地吹送到加热区域,提高了加热的速度和效率。

3、控制器采用数字显示和集成灯,可实时监测温度和工作状态,并可通过PID自动控制系统进行温度调节。

4、外壳采用优质镀锌板材料制成,具有优良的耐腐蚀性和美观性。

二、使用方法1、安全使用伽帝芙热风机使用前应先检查电源线是否正常,电压是否符合要求。

同时,应避免机器放置在潮湿、易燃、易爆、腐蚀等场所。

2、操作步骤将机器通电后,按下控制器上的开机按钮,设定加热温度和时间等参数,待预热指示灯点亮后即可开始加热作业。

在操作过程中,应根据需要调节风量和温度,确保物料在加热过程中均匀受热。

作业完成后,应先将温度降至安全温度后再关闭机器。

三、注意事项1、使用过程中应注意安全,不要将手部或其他物体伸入加热区域。

2、机器加热后表面温度较高,应避免接触,以免烫伤。

3、机器应定期清洗和保养,以延长使用寿命和保障加热效果。

4、若出现故障或异常情况,应及时停机并联系专业人员进行检修。

综上所述,伽帝芙热风机是一种高性能、高效率的加热设备,应用广泛。

在使用过程中,要严格按照操作规程进行,注意事项和安全要求,从而保障我们的安全和加热效果。

荣芝暖风机制冷说明书

1、开/关按键:按此键可开关空调,开/关时清除原来设定的定时以及睡眠等功能。

2、风速按键:按此键,风速循环变化,风速从小变大,一共是五个档位,除湿模时下按此键不能调节风速,此时为低档风速。

3、上下按键:每按一次下或上键,设定温度就会下降或者上升1摄氏度,连续2秒以上按住上或者下,温度值快速变化,直到手指松开才会发射信息,温度设定范围在16-30摄氏度之间,自动模式下不可调节温度,为了节能能源,建议用户设定温度制热式比期望值要低2摄氏度,制冷时高2摄氏度。

4、上下扫风按键:简单扫风时,用于选择扫风和停止扫风,定格扫风时,用于选择上下扫风状态,在关机状态下,同时按△键和上下扫风键,可在简单扫风模式和定格扫风模式之间切换,切换时遥控器上的扫风键闪烁2秒。

5、左右扫风键:简单扫风时,用于选择扫风和停止扫风,定格扫风时,用于选择左右选择扫风状态,在关机状态下,同时按△键和上下扫风键,可在简单扫风模式和定格扫风模式之间切换,切换时遥控器上的左左右扫风图标闪烁2秒。

6、制冷按键:按此键空调运行制冷模式,开机制冷模式下,长按“制冷”键5秒,可开启或者关闭凉感功能,凉感功能开启时遥控器显示制冷或者凉。

高科热风机操作流程

1.开机前准备:

1.1检查皮带的松紧程度

1.2检查软连接是否有漏点

1.3检查地角螺丝是否松动

1.4打开现场主电机隔离开关,轴流风机隔离开关

2.开机、停机

系统启动后,当程序运行中塔顶进风风道温度D09TT.D02TT上升至大约90℃.流化床热风机DM1072VC开启。

DM1102FA开启。

3.停机:关闭现场开关

4.注意事项:

4.1热风机的温度,风机温度是否过高

4.2风机震动的振幅是否过大

4.3听风机运行时的声音是否正常。

有无异声响

4.4正常运行时轴承的温度应该小于80℃

4.5生产时过滤网压差小于0.5

5.故障分析及解决方法:

5.1润滑脂加入过多。

应及时去除多余的润滑脂。

5.2轴承损坏,应及时更换轴承。

5.3如果皮带松会丢转应及时更换皮带或紧皮带。

5.4进风量小时,应更换滤布或中效过滤器。

5.5当增加风量时而固定床的粉却没沸腾。

这是可能是固定床筛板堵了,应及时清理。

5.6风机温度高,由于轴承磨损相互摩擦产热,应更换轴承。

5.7风机温度高。

可能风扇损坏,更换风扇。

移动暖风机用户手册暖风机功率:10,20,29,44 kW型号:B 35,B 70,B 100,B 150CED注意:在安装,使用或维修暖风机前请认真阅读和理解本手册。

不正确的操作使用暖风机可能导致严重后果。

请保存这本手册以备将来参考。

安全说明 2 产品描述 3 开箱 3 燃料信息 3 安装 3 通风条件 4 运行原理 4 操作 4 储存,搬运或运输 4 产品保养 5 故障处理 5 维修程序 6 附件10 保修说明10安全说明警告注意:在安装,使用或维修暖风机前请认真并且完整地阅读此用户手册。

不正确的使用暖风机可能造成灼伤,火灾,爆炸,电极和一氧化碳中毒,进而导致严重伤害,甚至死亡。

危险:一氧化碳中毒可能导致死亡。

一氧化碳中毒:一氧化碳中毒的早期症状和流感相似,有头痛,眩晕或恶心等症状。

如果你有这些症状,暖风机可能运行不正常。

应立刻获得新鲜空气!需要维修暖风机。

一些人相对其他人更容易受一氧化碳影响,这些人包括孕妇,患有心脏病或肺病,贫血者。

另外,饮酒后或处于高海拔地区的人也更易受CO影响。

在确保你已经阅读并且了解所有的警告后,请保存好这本参考手册。

它将是你安全和正确使用暖风机的指南。

z为了防止火灾或爆炸,使用柴油或煤油。

不要使用汽油,石脑油,涂料稀释剂,酒精或其他高度易燃燃料。

z加燃料a)加燃料的相关人员必须是得到许可并且对厂商的说明书和暖风机安全加燃料的相关规定很熟悉。

b)只能使用暖风机指定的柴油或煤油。

c)所有的火焰指示灯都熄灭了,并且暖风机冷却以后,才能加燃料。

d)在加燃料的时候,要检查油管和油管连接处是否有泄漏。

在暖风机运行前,任何一个泄漏处都必须修理好。

e)暖风机附近的建筑物的燃料储备量绝对不能超过暖风机一天的燃料使用量,大量的燃料储备必须安置在建筑物外面。

f)所有燃料存藏的地方与暖风机,喷火器,焊接设备和类似的点火源至少距离1米(除了与暖风机的燃料存储器)g)燃料储存应尽量限制在不让燃料渗透或在地势低的区域不被点燃的区域。