芝麻油工艺图

- 格式:xls

- 大小:18.13 KB

- 文档页数:1

小磨芝麻油制作工艺流程The process of making small-grain sesame oil, also known as toasted sesame oil, is a traditional method that involves roasting and pressing sesame seeds to extract the flavorful oil. This process has been passed down through generations and is still widely practiced today. In this article, we will explore the various steps involved in making small-grain sesame oil, from sourcing the sesame seeds to the final bottling of the oil.The first step in making small-grain sesame oil is sourcing high-quality sesame seeds. These seeds are typically harvested from sesame plants that have reached maturity. Farmers carefully select the sesame pods and collect the seeds, which are then cleaned to remove any impurities. The quality of the sesame seeds plays a crucial role in the flavor and aroma of the final oil, so it is important to choose seeds that are fresh and free from any contaminants.Once the sesame seeds have been cleaned, they are ready to be roasted. Roasting is a critical step in the process as it brings out the rich, nutty flavor of the seeds. Traditionally, sesame seeds were roasted in a large wok over an open flame. The seeds are constantly stirred to ensure even roasting and prevent them from burning. The roasting process can take anywhere from 15 to 30 minutes, depending on the desired flavor intensity.After roasting, the sesame seeds are allowed to cool before being crushed or ground. This step is essential for releasing the oil from the seeds. In traditional methods, the cooled seeds are placed in a stone mortar and ground using a stone pestle. This labor-intensive process requires strength and precision to ensure the seeds are properly crushed. The ground seeds are then transferred to a cloth bag or basket and pressed to extract the oil. The pressure applied during pressing helps separate the oil from the solid residue.The extracted oil is then filtered to remove any impurities or remaining solid particles. This step iscrucial for achieving a clear and pure oil. Traditionally,a cloth filter is used to strain the oil, removing any unwanted particles. The filtered oil is then transferred to clean containers for storage. It is important to store the oil in a cool and dark place to maintain its freshness and extend its shelf life.In modern production methods, mechanical presses are often used to extract the oil from the roasted sesame seeds. These machines provide a more efficient and consistent process, ensuring a higher yield of oil. However, somesmall-scale producers still prefer to use traditional methods, as they believe it results in a superior qualityoil with a more authentic flavor.In conclusion, the process of making small-grain sesame oil involves several steps, including sourcing high-quality sesame seeds, roasting, crushing, pressing, filtering, and bottling. Each step requires careful attention to detailand a deep understanding of the traditional techniques. The result is a flavorful and aromatic oil that is widely usedin various cuisines around the world. Whether made usingtraditional or modern methods, small-grain sesame oil continues to be a cherished ingredient in many dishes, adding a distinct nutty flavor and aroma.。

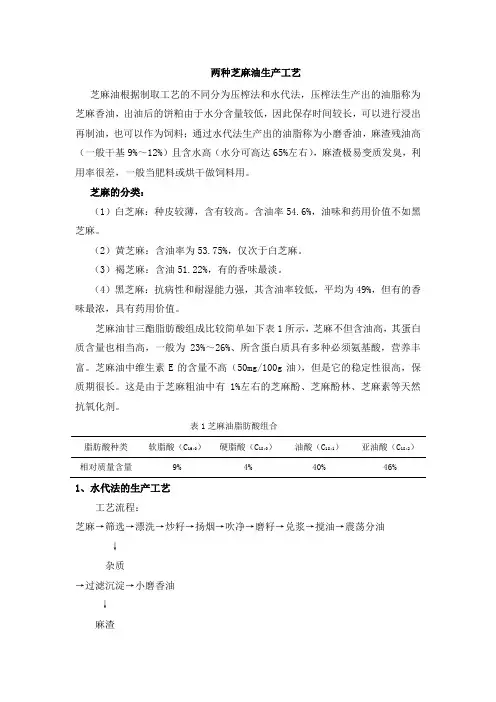

两种芝麻油生产工艺芝麻油根据制取工艺的不同分为压榨法和水代法,压榨法生产出的油脂称为芝麻香油,出油后的饼粕由于水分含量较低,因此保存时间较长,可以进行浸出再制油,也可以作为饲料;通过水代法生产出的油脂称为小磨香油,麻渣残油高(一般干基9%~12%)且含水高(水分可高达65%左右),麻渣极易变质发臭,利用率很差,一般当肥料或烘干做饲料用。

芝麻的分类:(1)白芝麻:种皮较薄,含有较高。

含油率54.6%,油味和药用价值不如黑芝麻。

(2)黄芝麻:含油率为53.75%,仅次于白芝麻。

(3)褐芝麻:含油51.22%,有的香味最淡。

(4)黑芝麻:抗病性和耐湿能力强,其含油率较低,平均为49%,但有的香味最浓,具有药用价值。

芝麻油甘三酯脂肪酸组成比较简单如下表1所示,芝麻不但含油高,其蛋白质含量也相当高,一般为23%~26%、所含蛋白质具有多种必须氨基酸,营养丰富。

芝麻油中维生素E的含量不高(50mg/100g油),但是它的稳定性很高,保质期很长。

这是由于芝麻粗油中有1%左右的芝麻酚、芝麻酚林、芝麻素等天然抗氧化剂。

表1芝麻油脂肪酸组合脂肪酸种类软脂酸(C16:0)硬脂酸(C18:0)油酸(C18:1)亚油酸(C18:2)相对质量含量9% 4% 40% 46%1、水代法的生产工艺工艺流程:芝麻→筛选→漂洗→炒籽→扬烟→吹净→磨籽→兑浆→搅油→震荡分油↓杂质→过滤沉淀→小磨香油↓麻渣清理:清理的目的是去除杂质及不成熟的种子。

漂洗:可以除去筛选后残留的细微杂质,使芝麻更为洁净;另外,漂洗时,在水池中浸泡1小时,使芝麻均匀吃透水分,在炒籽时可使蛋白质变性更为彻底完善,同时还可以延长炒籽时间避免发生炒焦、炒糊或里生外焦的现象。

一般油厂均采用清洗机进行漂洗,洗后芝麻含水量以35%左右为宜。

炒籽:炒芝麻时,掌握火候,时间和温度很重要。

开始时由于芝麻含水量大,宜急火炒料;当炒熟程度达70%时,要降低火力,并随时检查芝麻的老嫩程度,一般是使温度达到200℃左右为宜。

芝麻油制作工艺

芝麻油是一种中国传统的食用油,具有独特的香气和口感。

芝麻油的制作工艺历史悠久,可以追溯到数千年前的中国古代。

在中国传统的生产过程中,芝麻油的制作分为多个步骤,采用传统的手工制作和机械制作相结合的方式,让芝麻油保持了原始的口感和香气。

芝麻油制作的原材料是芝麻籽,以下是芝麻油制作的主要流程:

1. 选料:选择成熟的芝麻,去掉杂质,保证原料的品质。

2. 烘晒:将生芝麻放在烤炉中进行烘烤,达到一定程度的干燥,烘干后的芝麻有更好的质量和更高的油脂含量。

3. 研磨:将烘烤后的芝麻放入石磨或机械压榨器中进行压榨和研磨。

石磨研磨的芝麻油口感更好,但效率较低,机械压榨器更快但口感不如石磨。

4. 过滤:将磨出的芝麻油进行过滤,去除芝麻渣和杂物。

5. 沸馏:将过滤后的芝麻油进行沸馏,提取其中的杂质和水分。

6. 澄清:经过沸馏后,芝麻油会出现悬浮物,需要进行澄清处理,以保证芝麻油的品质和口感。

7. 储存:芝麻油经过以上工序后,即可储存或出售。

总体而言,传统的手工制作方式可以保证芝麻油的原始口感和香气,但效率比较低;机械化生产方式虽然效率高,但可能会导致芝麻油品质下降。

在今天,芝麻油的生产已经实现了机械化和工业化生产,但一些传统制作的方法和手艺仍然保留,以保证提供消费者更高品质的芝麻油。

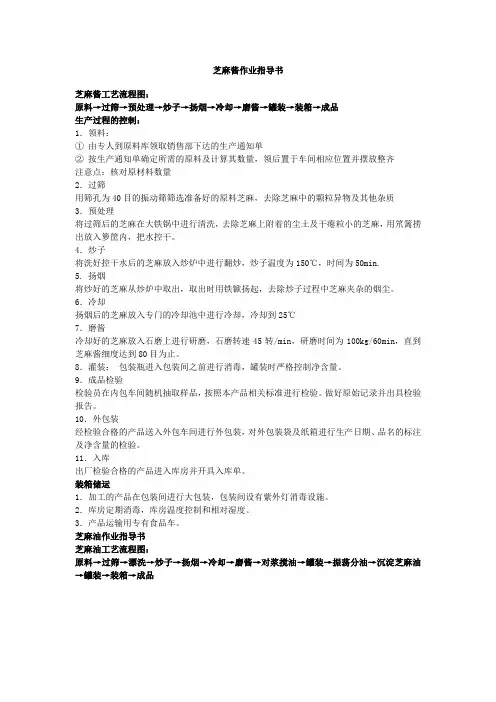

芝麻酱作业指导书芝麻酱工艺流程图:原料→过筛→预处理→炒子→扬烟→冷却→磨酱→罐装→装箱→成品生产过程的控制:1.领料:① 由专人到原料库领取销售部下达的生产通知单② 按生产通知单确定所需的原料及计算其数量,领后置于车间相应位置并摆放整齐注意点:核对原材料数量2.过筛用筛孔为40目的振动筛筛选准备好的原料芝麻,去除芝麻中的颗粒异物及其他杂质3.预处理将过筛后的芝麻在大铁锅中进行清洗,去除芝麻上附着的尘土及干瘪粒小的芝麻,用笊篱捞出放入箩筐内,把水控干。

4.炒子将洗好控干水后的芝麻放入炒炉中进行翻炒,炒子温度为150℃,时间为50min.5. 扬烟将炒好的芝麻从炒炉中取出,取出时用铁锨扬起,去除炒子过程中芝麻夹杂的烟尘。

6.冷却扬烟后的芝麻放入专门的冷却池中进行冷却,冷却到25℃7.磨酱冷却好的芝麻放入石磨上进行研磨,石磨转速45转/min,研磨时间为100kg/60min,直到芝麻酱细度达到80目为止。

8.灌装:包装瓶进入包装间之前进行消毒,罐装时严格控制净含量。

9.成品检验检验员在内包车间随机抽取样品,按照本产品相关标准进行检验。

做好原始记录并出具检验报告。

10.外包装经检验合格的产品送入外包车间进行外包装,对外包装袋及纸箱进行生产日期、品名的标注及净含量的检验。

11.入库出厂检验合格的产品进入库房并开具入库单。

装箱储运1.加工的产品在包装间进行大包装,包装间设有紫外灯消毒设施。

2.库房定期消毒,库房温度控制和相对湿度。

3.产品运输用专有食品车。

芝麻油作业指导书芝麻油工艺流程图:原料→过筛→漂洗→炒子→扬烟→冷却→磨酱→对浆搅油→罐装→振荡分油→沉淀芝麻油→罐装→装箱→成品。

成都市XXXXX食品有限公司芝麻油作业指导书编制:审核:日期:目录目录.......................................................................................1芝麻油工艺流程及关键控制点.......................................................2关键控制点(原料筛选)作业指导书 (3)关键控制点(炒子)作业指导书 (4)扬烟冷却作业指导书 (5)压榨作业指导书........................................................................6过滤沉淀作业指导书 (7)洗瓶作业指导书 (8)灌装作业指导书............。

. (9)包装作业指导书………………………………………………………………10 成品(入库)作业指导书………………………………………………………11生产车间清洁、消毒作业指南。

………………………………………。

………1 2成都市XXXXXXXX食品有限公司(生产工艺流程图及关键控制点)1芝麻油生产工艺流程图1.1生产工艺关键控制点生产工艺流程图中带※号部分,都是本公司的生产工艺关键控制点.其中:a) 原料筛选:将原料进行筛选,筛选出霉烂、变质等原材料杂质,必须保证每批投入使用的原料都合格,不合格原料不投入生产.b)炒子:将筛选好的芝麻在预热后的旋转炒锅中翻炒,先大火、后小火,大约炒30左右使其不焦不糊,生熟均匀至芝麻肉色变暗红为止。

关键控制点(原料筛选)作业指导书一、操作步骤:1、将每批投入使用的原料,进行筛选。

2、将筛选好的半成品运到炒料间,进行炒料。

二、具体操作:1、将每批投入使用的原料,运到筛选间后进行筛选,筛选出霉烂、变质原料及杂质等,必须保证每批投入使用的原料均合格,不合格原料不投入使用.并做好记录.2、将筛选好的半成品,运到炒料间,进行炒料。

小磨芝麻油制作工艺流程Making small batch sesame oil is a traditional craft that has been passed down for generations in many parts of Asia. 小磨芝麻油的制作工艺是一项源远流长的传统工艺,已经在亚洲许多地区代代相传。

The process of making small batch sesame oil involves several key steps, starting with selecting high-quality sesame seeds. 制作小磨芝麻油的过程涉及到几个关键步骤,首先是选择优质的芝麻种子。

Once the sesame seeds are selected, they are cleaned and roasted to enhance their flavor. 一旦选好了芝麻种子,就会对其进行清洗和烘烤,以增强其香味。

After roasting, the sesame seeds are then crushed using a traditional stone mill to extract the oil. 烘烤后,芝麻种子会被传统的石磨碾磨,以提取油脂。

The oil is then filtered to remove any impurities, resulting in a pure and fragrant sesame oil. 接着会对油进行过滤,去除任何杂质,最终产出纯净芳香的芝麻油。

Small batch sesame oil is prized for its rich nutty flavor and high nutritional value. 小磨芝麻油因其丰富的坚果味和高营养价值而备受推崇。

In addition to its culinary uses, sesame oil is also valued for its medicinal properties in traditional Chinese medicine. 除了用于烹饪外,芝麻油在传统中医学中也因其药用价值而受到重视。

古法压榨芝麻油的工艺流程下载温馨提示:该文档是我店铺精心编制而成,希望大家下载以后,能够帮助大家解决实际的问题。

文档下载后可定制随意修改,请根据实际需要进行相应的调整和使用,谢谢!并且,本店铺为大家提供各种各样类型的实用资料,如教育随笔、日记赏析、句子摘抄、古诗大全、经典美文、话题作文、工作总结、词语解析、文案摘录、其他资料等等,如想了解不同资料格式和写法,敬请关注!Download tips: This document is carefully compiled by theeditor. I hope that after you download them,they can help yousolve practical problems. The document can be customized andmodified after downloading,please adjust and use it according toactual needs, thank you!In addition, our shop provides you with various types ofpractical materials,such as educational essays, diaryappreciation,sentence excerpts,ancient poems,classic articles,topic composition,work summary,word parsing,copy excerpts,other materials and so on,want to know different data formats andwriting methods,please pay attention!陶瓷地砖楼面的施工工艺流程在进行陶瓷地砖楼面的施工之前,需要进行一系列准备工作。