press fit design guide line压接设计指南

- 格式:ppt

- 大小:3.36 MB

- 文档页数:23

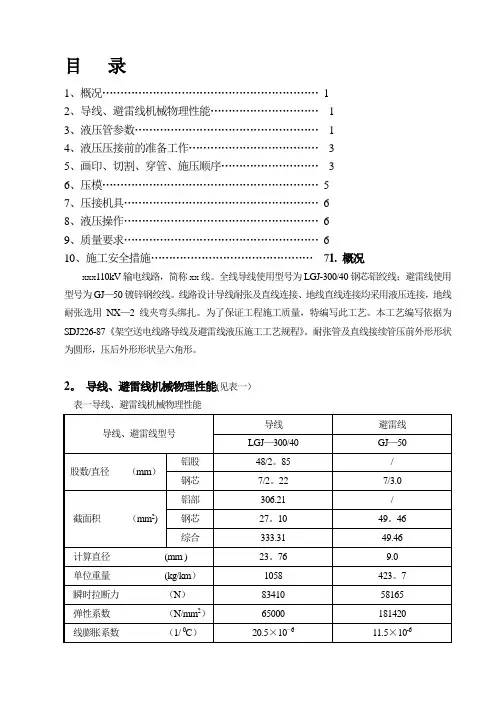

目录1、概况 (1)2、导线、避雷线机械物理性能 (1)3、液压管参数 (1)4、液压压接前的准备工作 (3)5、画印、切割、穿管、施压顺序 (3)6、压模 (5)7、压接机具 (6)8、液压操作 (6)9、质量要求 (6)10、施工安全措施………………………………………71. 概况xxx110kV输电线路,简称xx线。

全线导线使用型号为LGJ-300/40钢芯铝绞线;避雷线使用型号为GJ—50镀锌钢绞线。

线路设计导线耐张及直线连接、地线直线连接均采用液压连接,地线耐张选用NX—2线夹弯头绑扎。

为了保证工程施工质量,特编写此工艺。

本工艺编写依据为SDJ226-87《架空送电线路导线及避雷线液压施工工艺规程》。

耐张管及直线接续管压前外形形状为圆形,压后外形形状呈六角形。

2。

导线、避雷线机械物理性能(见表一)表一导线、避雷线机械物理性能直流电阻(20℃) (Ω/km)0。

09433 /3. 液压管参数3.1液压管外形(如图一、图二,图中尺寸均为实测值)JY-300/25型导线耐张管图二 JY-300/25型导线直线接续管3.2 液压管尺寸(见表二)表二液压管尺寸表(单位:mm)3.3液压管内外径测量和计算方法外径在管上均选三点检测,每点互成90°测量二个数据,以三个检测点共六个数据的平均值作为压前的外径;内径在管两端检测,每端互成90°测两个数据,以两端共四个数据的平均值作为压前内径(耐张管外径只检测二点,内径只检测管口一点)。

所得的内外径必须符合压前管内外径允许的公差范围.4。

液压压接前的准备工作4。

1对使用的导线、避雷线,其结构及规格应认真进行检查,其规格应与工程设计相符,并符合同家标准的各项规定。

4。

2所使用的各种接续管及耐张管,应用精度为0.02 mm的游标卡尺测量受压部分的内外直径;外观检查应符合规定;用钢尺测量各部长度,其尺寸、公差应符合标准要求。

4。

3在使用液压设备之前,应检查其完好程度,以保证正常操作。

压接工艺设计范文一、引言压接工艺是一种常用的金属连接方法,在许多行业中都有广泛的应用。

本文将设计一种适用于金属材料连接的压接工艺,并探讨其可行性和效果。

二、压接工艺的选择在选择适合的压接工艺之前,首先需要确定连接材料的种类和要求。

本文以两种金属材料A和B为例,其连接要求为坚固、密封性好并且能够承受一定的载荷。

三、压接工艺设计1.选择适当的压接方法根据金属材料的特性和要求,选择适合的压接方法是关键的。

本文选择了点焊作为压接方法,因为点焊可以提供坚固的连接和良好的密封性。

2.设计压接机构压接机构是实现压接的关键组成部分。

本文设计了一种压接机构,其主要由压接头、压接臂和压接座组成。

其中,压接头是与金属材料接触的部分,压接臂是连接压接头和压接座的部件,压接座用于固定金属材料。

3.确定压接参数压接参数的确定对于良好的工艺效果至关重要。

本文首先通过试验确定了压接力和压接时间的范围,然后通过设计试验确定了最佳的压接力和压接时间。

最后,通过工艺实施确定了具体的压接参数。

四、实施及效果分析1.实施过程本文按照设计的压接工艺进行了实施。

首先,将金属材料A和B放置在压接座上;然后,调整压接机构,使得压接头与金属材料接触;最后,施加压接力并保持一定的时间。

完成压接后,进行了检测和评估。

2.效果分析通过对压接接头进行断裂强度测试,验证了压接工艺的可行性和连接强度。

测试结果表明,压接接头的断裂强度远高于要求的工作载荷,证明了压接工艺的有效性。

此外,通过观察压接接头的断面形貌,验证了压接工艺的密封性。

五、总结本文设计了一种适用于金属材料连接的压接工艺,并对其进行了实施和效果分析。

结果表明,所设计的压接工艺具有良好的可行性和效果。

尽管本文以金属材料A和B为例进行了设计,但该压接工艺可以应用于其他金属材料的连接,具有一定的普适性。

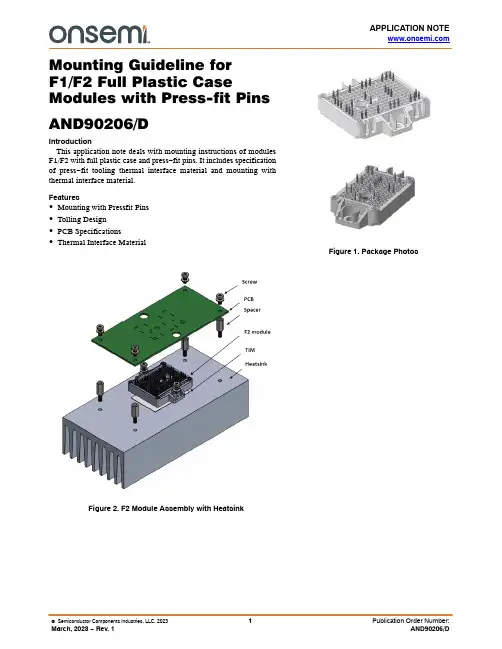

APPLICATION NOTE Mounting Guideline forF1/F2 Full Plastic Case Modules with Press-fit Pins AND90206/DIntroductionThis application note deals with mounting instructions of modules F1/F2 with full plastic case and press−fit pins. It includes specification of press−fit tooling thermal interface material and mounting with thermal interface material.Features∙Mounting with Pressfit Pins∙Tolling Design∙PCB Specifications∙Thermal Interface MaterialFigure 2. F2 Module Assembly with HeatsinkFigure 1. Package PhotosSpecification of PCBMinimum PCB thickness is 1.6 mm. Solder mask is recommended on both sides of the PCB. Recommended PCB hole plating options include immersion tin, immersion silver, electroless nickel immersion gold ENIG), and organic solderable preservative (OSP). HAL plating is not recommended. For PCB specifications please see Table 1.Figure 3. PCB Hole DimensionsTable 1. PCB SPECIFICATIONS FOR F1 AND F2MODULES WITH 1.2 MM PRESS −FIT PINSMin.Typ.Max.Initial Drilled Hole Diameter Ø[mm]1.12 1.15Cu Thickness in the Hole [m m]2550Sn Thickness [m m] (Chemical Tin)15Final Hole Ø [mm]1 1.09Annular ring [m m]200Thickness of Conductive Layer [m m]3570−105400Board Thickness [mm]1.6Design Restrictions within Mounting AreaPCB bending during the press −in process causes mechanical stress to other PCB components, such as capacitors and resistors. Experiments to verify a safe minimum distance between passive components and the plated through hole were conducted with FR4 PCB. V arious sizes (0603, 0805, 1206, 1210, 1812, and 2220) of mechanically sensitive components were evaluated. Based on experimental results, the recommended minimum space between center of the plated through hole and the edge of the component is 4 mm, as shown in Figure 4.Figure 4. PCB Layout RestrictionsPCB Fixing and DimensionsSpacers should be used to fix the PCB to the heatsink.Number of space posts is not given. Space posts positions should be designed symmetrically, weight of the PCB components should be considered. PCB bending or flexing should be avoided. Distance from the space post to the module (dimension x) is recommended to be at least 10 mm from module outer edges.Figure 5. Module Fixed on a HeatsinkLength of the space posts should match the length of press −in tool distance keeper – see section Press −in tool for F2 package.Recommended length of the space post is 12.4 mm + 0 mm −0.05 mm. An air gap may be present between the module and PCB (as on Figure 5), this airgap allows tolerance of the module case.Press −in ProcessThe press −fit connection generates a good electrical, and strong mechanical connection between the module and the PCB. This section deals with the mounting process to achieve suitable press −fit connections here are several types of presses available: from simple toggle presses to the automated pneumatic presses shown in Figure 6.Figure 6. Press −in Machine ExampleIf possible, monitor the press −in/press −out distance,speed, and force to achieve mechanical stability and high reliability of the press −fit connection. The travel distance during the press −in process should be controlled to ensure that the press −fit zone of the pins sits properly in the plated through hole. The speed also influences the quality of the press −fit connection; therefore, speed recommended by IEC standard should be applied.Figure 7. Pressfit Tool for F2 ModuleGeneral Press −in ProcessUse of tooling with distance keeper is recommended.Figure 8. Shows the general sequence of press in procedure.Press −in procedure. The press −in tool is comprised of two parts: the upper press −in tool is flat (or with special design for modules with TIM. Please see Press −in tool for module with PCM section) to contact with the module backside evenly and the lower press −in tool has engraved spaces to accommodate the press −fit pins and PCB components. The two parts of the tool need to be aligned to each other. In the first step of the assembly, the printed circuit board is placed on the alignment pins of the lower part of the press −in tool (a). Then, the module is placed on top of the printed circuit board using the alignment pins (b).Figure 8. Press −in ProcessIt is necessary to check if the module and the printed circuit board are in alignment. In the next step, the press−in force is applied via the upper part of the press−in tool to the backside of the module evenly. The module should be pressed−in with a speed of 25~50 mm/min until the distance keepers of the upper tool touch the PCB while press−in distance and force are monitored at the same time (c). It is required to adjust the traveling distance of the press to avoid damages to the module case due to pressure being applied.A simple manual press does not use a distance sensing system, so a distance keeper should be designed on the press−in tool to terminate press−in process appropriately. When the distance keeper contacts the surface, press−inforce rises sharply, and the press−in process can be terminated by reaching the limit of the press−in force. The distance keeper should be designed to avoid the collision with other PCB components.Figure 9. Distance Keeper of the Upper Tool Design The total press−in force is the result of the number of pins in a module, multiplied with the force required for a single pin. Press−in forces lower than 40 N/pin mean that press−fit pin may have a less secure connection in the plated through hole. The primary reason for the low press−fit force is that the diameter of plated through hole is too large for the press−fit pins. Press−in forces higher than 80 N/pin can cause mechanical damage to the press−fit terminal, the PTH, or to the tracks on the PCB. The recommended press−in speed ranges from 25 mm/min to 50 mm/min in accordance with the recommendations in IEC 60352−5.Figure 10. PCB Thickness SpecificationThe press−fit pins must be pressed into the holes of the PCB to the correct depth. The center of the press−fit zone has to be at least 0.5 mm below the top surface and at least 0.5mm above the bottom surface of the PCB (Figure 10).Figure 11. Force vs. Distance during PressfitProcessForce measured in a module is a sum of all pins being pressed at once (Figure 11).Force measurement per one pin was conducted, the press−fit pin was mounted in 1.6 mm thick PCB with chemical Sn surface finish. Test conditions and PCB specification are compliant with IEC 60352−5.Table 2. SINGLE PRESS−FIT PIN TESTPress−in Force Press−out ForcePCB hole f0.98 –1.02 mmf1.11 –1.12 mmf0.98 –1.02 mmf1.11 –1.12 mm(min)(max)(min)(max) Minimum49.8 N40.9 N29.4 N38.3 N Mean55.9 N47.4 N40.5 N48.2 N Maximum62.1 N57.1 N48.0 N65.9 N Samplesize20201920Press−in Tool for Module with PCMTo prevent damages on PCM peripheral spacers and point spacers are required. This spacers should not touch PCM on the DBC. 0.4 mm is recommended for the height of spacers. Distance keeper of the press−in tool needs to be 0.4 mm taller than no PCM cases.Figure 12. Press−fit Tool for F2 Module with PCMFigure 13. Point Spacer Alignment with PCMPeripheral spacer and point spacer prevent pre −applied PCM from being deformed or damaged during press −in process. Peripheral spacer distributes mechanical stress by press −in process over the edge of DBCPress −out ProcessIn some situations, it is necessary to remove power modules from the PCB. It is possible to disconnect the contact between module pins and PTH. The press −out process can be performed with the same equipment used in the press −in process. Careful handling in the press −out process is essential to avoid mechanical damage to both the module and the PCB. PCB can be re −used once with a new module. Please note: in case a module which was pressed out of a PCB should be used again, it is necessary to solder the module to the PCB; this is because the press −fit zone will remain deformed after the press −out process. An additional press −in cycle will result in low holding forces between the press −fit pin and PCB hole.Figure 14. Press −out ToolFigure 15. Press −out Process of Power Module Heatsink SpecificationThe following surface qualities are required for the heatsink to achieve a good thermal conductivity, according to DIN 4768−1. Roughness (Rz) should be 10 m m or less and flatness, based on a length of 100 mm, should be 50 m m or less. The heatsink should have no contamination,unevenness, and burrs on the surface contacting the module.The interface surface of the heatsink must be free of particles and contamination. Avoid handling the heatsink surface with bare hands or contacting any foreign materials.If it is necessary to remove contamination from heatsink,cleaning can be accomplished using dry cloth soaked with solvent, such as isopropyl or ethylene alcohol.Figure 16. Heatsink Surface SpecificationThermal GreaseThermal grease can be applied to the heatsink or the module substrate using a rubber roller or spatula or by screen printing. Alternatively, apply thermal paste by screen printing, for example using a honeycomb pattern. The recommended thermal paste thickness is 80−180 m m.Thickness of the TIM layer more than this recommendation will unnecessarily increase thermal resistance. When applying thermal grease, the material must be applied uniformly on the whole surface which is in contact to the module substrate surface. If the module is re −mounted,surfaces should be cleaned, and TIM needs be applied again.Pre−applied Phase–Change MaterialModules can be pre−applied with phase−change material. Typical thickness of the TIM layer is 160m m and its thermal conductivity is 3.4 W/mK.Figure 17. Tim Pattern Example on F2 ModuleIt comes pre−applied on the DBC surface ready to be mounted on the heatsink. The honeycomb pattern allows the press tool to touch copper DBC and allows PCM to spread on a whole surface. For proper TIM spreading in application, TIM spreading temperature must be achieved on the TIM material, this temperature is specified as minimum 45︒C. For best spreading results it is recommended to apply 80︒C for 20 minutes.Screw SpecificationWhen using screws with flat washers:∙Metric screw: M4 (recommended screw type DIN7984)∙Flat washer: D = 8 mm ISO 7092 (DIN 433)∙Spring washer: D = 8 mm DIN 127 or DIN 128∙Mounting torque: 1.6−2.0 Nm∙Screw holes on heatsink need to be countersunk. A torque wrench shall be used to tighten the mounting screws at the specified torque. Excessive torque may result in damage or degradation of the device. The inaccuracy of torque wrench tightening method can range up to ±12%. This must be considered to prevent over−tightening the fastener. Due to excessive temperature fluctuations washers should be used to prevent the loosening of the screws. After accurate tightening of the screws the spring washer exerts a constant force on the joint. The flat washer distributes this force on the plastic surface. When using screws with pre−assembled washers: Screws with pre−assembled washers (SEMS or kombi screws) combine the screw and the washers into a single component. These screws eliminate the need to slip the washers into place by hand, boosting the speed and efficiency of the assembly process. The specifications of these screws are provided below:∙Screw size: M4 according to DIN 6900 (ISO 10644; JIS B1188)∙Flat washer: According to DIN 6902 Type C (ISO 10673 Type S; JIS B1256) Washer outer diameter: 8mm diameter can be fitted onto the module ∙Split lock spring washer: According to DIN6905 (JIS B1251)∙Mounting torque range: 1.6−2.0 Nm∙Recommended insertion of screw thread in the heatsink is 6mm.Methods of Screw ClampingThere are two recommended screw clamping methods which apply to all modules. The F1 module is used as an example. Figure 18 describes one method for fastening the module to the heatsink. Fasten two screws simultaneously to prevent tilting or rising of one side of module during fastening. Electric screwdrivers can tighten the screws with the specified torque. Screw holes on heatsink need to be countersunk. If method 1 cannot be applied, the method as described in Figure 19 is also acceptable. Fasten the first screw loosely to prevent tilting or rising of the module (step1). Then insert the second screw with final torque to be fully tightened with the heatsink (step 2). Finally, apply full torque to the first screw for solid tightening with the heatsink. For F1/F2 packages using metal clips, the torque is between 1.6−2.0 Nm using M4 screws.Figure 18. Fixing Screws on the HeatsinkFigure 19. Fixing One after One for Power ModuleAssembly of Multiple Modules on the PCB and HeatsinkThe overall structure of the mounted module should be considered. If the PCB is large and heavy with other components assembled to it, there is some risk the PCB can bend, creating mechanical stress to the module and the PCB. When multiple modules are applied to the same PCB, height tolerance between modules can result in the mechanical stresses on the board and modules. To reduce stress, space posts should be added on the heatsink, as illustrated on figure 19 to prevent movement of the PCB. The recommended height of the space posts is 12.4 (+0/−0.1) mm. The effective distance between center of stand−off and the space post (=X) is 50 mm minimum. If distance keepers are used during the press−in process, resulting in tighter height tolerances; distances between the stand−off of the case and the space post (= X) smaller than 50 mm can be used. Figure 19 shows the assembly procedure when space posts are used and the overall assembly structure: Modules are first pressed into the PCB following the recommendations introduced in Section “Heatsink Surface” before heatsink mounting. Maintaining tight height tolerances between module and PCB is important. Next, the thermal interface material is applied. Then the modules and the PCB are placed on the heatsink (a). Then the module is mounted onto the heatsink via the module plastic clamp. Finally, the PCB needs to be fixed on the space posts (c).Figure 20. Assembling Multiple Modules on a PCB Handling of PCM Pre−applied ModuleDuring a transport and storage of the modules extreme thermal and mechanical shock should be avoided. The tray is designed to prevent direct contact to the PCM layer of the module substrate as shown in the Figure 21. PCM_ pre applied modules should be stored in this tray box before its use. Table 3 shows recommended storage conditions. Table 3. RECOMMENDED STORAGE CONDITIONS FOR MODULES WITH PCMStorage temperatures10 – 40 ︒CHumidity condition10 < RH < 55%Time Max 12 monthsPCM printing layer should be treated as a functional area of the module and be protected from damage or removing when handling or mounting. PCM pre−applied module is delivered in a tray box with a tight cover.Figure 21. Modules in a Transport Tray BoxIt is recommended to open the cover carefully side−by side to prevent mechanical damage to the PCM layer. Also during the assembly process attention is needed not to touch the PCM layer directly. If the PCM layer is contaminated or more thant 10% of the entire printed area is damaged, then it is recommended to remove the PCM layer according to instructions stated below. In case of rework prior to operation of modules, standard PCB / heat sink disassembly process can be applied. If the module was operated and the PCM melted and distributed already, then bond strength between heat sink and the module may be strong, and the module cannot be easily removed from the heatsink. In such cases it is recommended to use a knife to detach the module or apply some heat (45−60︒C) to re−melt PCM to detach the module easily. Use a soft plastic scraper to remove the PCM layer from the module back side and heat sink. For the removal of remaining PCM residues it is recommended to use microfiber cloth and isoprophyle alcohol.PUBLICATION ORDERING INFORMATIONTECHNICAL SUPPORTNorth American Technical Support:Voice Mail: 1 800−282−9855 Toll Free USA/Canada Phone: 011 421 33 790 2910LITERATURE FULFILLMENT :Email Requests to:*******************onsemi Website: Europe, Middle East and Africa Technical Support:Phone: 00421 33 790 2910For additional information, please contact your local Sales Representative。

MEP-12T 手動電子控制壓合機 - 12 噸操作手冊Part Number: 1398725-3, Rev B介紹 (5)關於這個手冊 (5)安全 (5)停機標簽 / 警示標簽 (5)安全蓋 / 防護罩 (6)雷射感應器 (6)緊急關閉機器(EMO) / ESTOP (7)光柵 (7)光柵手控鍵開關 (7)氣動系統 (7)萬向滑輪 (8)防震措施 (8)骨架結構及重量分佈 (8)安裝 (8)拆箱 (8)開始組裝 (9)設備標示牌 (10)電氣供應回路 (10)壓縮空氣的供應 (10)壓合機概觀 (11)目的 (11)能力 (11)選擇性配件 (13)觸控式SVGA 顯示器 (13)板厚測量 (13)SPC (Statistical Process Control)統計過程控制 (13)電腦條碼機 (13)雷射定位器 (13)光柵 - CE 認證 (13)數位彩色相機 (13)彩色印表機 (13)機器特性與結構 (14)配置 (14)操作 (15)開始起動 (15)起動電源 (15)操作者介面 (16)開機 (16)使用者存取 (17)選擇PC板 (18)PC板的運作 (18)運轉畫面按鈕 (19)畫面上PC板的配置 (22)開始壓合 (22)第一件物品確認信號(First Article Signoff) (23)中斷壓合循環(Interrupting the Pressing Cycle) (23)變更壓合順序(Changing the Pressing Sequence) (23)有關電路板、連接器、治具及程式的錯過狀況 (23)壓合治具PRESSING TOOLS (25)支撐固定裝置 (平臺 / 支撐座) (25)編程和數據輸入 (25)治具編輯器 (26)目的 (26)進入 (26)連接器編輯器 (28)目地 (28)進入 (28)模態編輯器 (30)目地 (30)說明 (30)壓合數據編輯器 (36)PRESS SEQUENCE 壓合順序 (38)SPC 選擇 (39)Process Data程序數據 (40)CPK (Process Capability)加工能力 (40)X-Bar (Process Average)加工的平均數 (40)Std Dev. (Standard Deviation)標準偏差 (40)UCL (Upper Control Limit)控制上限 (40)LCL (Lower Control Limit) 控制下限 (40)VCL (Variability Control Limit)變化性控制限度 (40)Point Data 點數據 (40)Options選擇 (41)Range Bars (41)Control Limits控制限度 (41)Spec. Limits規格限度 (41)Grid 網 (41)Shaded 色差 (41)Thick Lines 粗線 (41)Print 列印 (41)維修功能(公用的) (42)機器記錄 (42)Error Log 錯誤記錄 (42)User Log 使用者記錄 (42)Joystick 控制桿 (44)Analog Inputs 類比輸入 full force range (44)Points 點 (45)Control 控制 (45)Calibration校正 (46)Tools工具 (46)Machine Zero機器歸零 (46)輸入/輸出螢幕 (47)Servo Terminal伺服終端 (48)伺服參數 (49)Setup Parameters (51)Machine Operation (51)Load Cells (52)Save (52)Cancel (52)使用 (53)預防保養 (54)Accessing the Press Head (54)Cleaning (54)Inspection (54)Lubricating (54)Z Axis Rods (54)Z Axis Screw (54)Torquing Critical Bolts (54)Clean Water Trap In Air System (54)PM Schedule (55)Load Cell Calibration (56)Calibration Procedure for Initial Setup of MEP-12T: (56)Load Cell Calibration (58)Balance Load Cells (59)Calibrate the load cells (60)APPENDIX A - SPARE PARTS LIST (62)APPENDIX B – FEATURES & SPECIFICATIONS (63)APPENDIX C: ELECTRICAL & MECHANICAL SCHEMATICS: (64)介紹關於這個手冊這個手冊包含對於12 公噸手操作電動壓合機(MEP-12T)的安裝, 安全, 操作, 和保養程序。

德国novopress详细说明◇ 由德国novopress经过多年研究的梦幻型压接机,在300-10平方的压接范围内可以自由设定压接的压缩比,特别适合于配合间隔出没隙大的有柔软性电缆导线与金具的压接,也非常适于扇形导线使用一般端子来进行压接,而不需要使用昂贵的扇形端子。

◇ 三连式的压接模片取代了传统的固定模具,可以更灵活的运用于配电系统以及信号系统的导线压接,本产品获得了IEC1238-1认证,拉力,温升,电阻热循环等式,均有优先表现。

◇ 压接后外形美观,呈正六角形,没有飞边,可提高生产者的品质形象。

压接范围:¢10-¢27mm的铜铝套管铜铝端子:10-300mm压接面宽度:7mm出力:16.5ton使用压力:700bar重量:7.5kg尺寸:395mm※ 具有手控有线遥控装置全球首创正六角形无极调整压接平方数由10~300mm2自由设定以上是HEX300-10六角型免换模压接机的详细信息,如果您对HEX300-10六角型免换模压接机的价格、厂家、型号、图片有什么疑问,请联系我们获取HEX300-10六角型免换模压接机的最新信息。

HEX300-10C六角形免换模压接机(Novopress)最大压接能力:300mm2套管全球唯一正六角型免换模具压接机油缸使用3/8”PT螺纹,配置PARKER液压快速接头工作压力700BAR 可连接相同工作压力的各式液压泵具特殊出力调节控制装置以及行程控制装置可以设定压接尺寸不需要更换任何模具适用于300mm2以下的套管或端子压接具行程控制设定显示装置压接头可以开启可用于接续套管压接推荐使用配套电动液压泵出力工作压力压接范围尺寸重量150KN700BAR铜铝端子套管10-300 mm2490*80*120mm9.82kg 电动泵UP-45SVG-4动力220V AC 450W输出压力100-700BAR可调储油量3.0L尺寸212*212*341mm重量17.2kgCTE/HEX 300-10C简介六角形免换模压接机:全球唯一正六角形免换模具压接机油缸使用3/8" PT 螺纹,配置PARKER液压快速接头工作压力700BAR可连接相同工作压力的各式液压泵具特殊出力调节控制装置以及行程控制装置可以设定压接尺寸不需要更换任何模具适用于300mm平方以下的套管或端子压接具行程控制设定显示装置压接头可以开启可用于接续套管压接推荐使用配套电动液压泵产地德国型号HEX 300-10C品名六角形免换模压接机出力150kN工作压力700BAR压接范围铜铝端子套管10-300mm平方尺寸490*80*120mmHPM 400免换模压接机—Novoprese最大压接能力:400m㎡套管C型头设计点压式免换模压接机(压坑)HPH 400油缸使用3/8”PT螺纹,配置parker液压快速接头工作压力700BAR 可连接相同工作压力的各式液压泵具特殊出力调节控制装置每次压缩40%,压接不产生飞边压接牢靠适用于R型端子及橡胶电缆,扇形导线压接等配合间隙较大的电缆电线压接HPM400为手摇式压接机压接完成自动退回2mm,具回油装置可控制活塞退回距离可更换模具进行分歧线C型套管压接一.【用途与性能】1.压接电力电缆导体铜、铝接线端子与接管。

MEP-12T手动电子控制压合机 - 12 吨操作手册Part Number: 1398725-3, Rev B 介绍 ..................................................................................................................................................................关於这个手册 ..............................................................................................................................................安全 (1)停机标签 / 警示标签 ..................................................................................................................................安全盖 / 防护罩 ...........................................................................................................................................雷射感应器 ..................................................................................................................................................紧急关闭机器(EMO) / ESTOP ....................................................................................................................光栅 ..............................................................................................................................................................光栅手控键开关 ......................................................................................................... 错误!未指定书签。

****有限公司工作指令文件修改记录表保存期限:新版发行后1个月第 1 页, 共 10 页 第 A 版第 0 次修改一、 范围本规范规定了连接器压接的基本工艺要求。

本规范适用于所有压接型连接器的压接。

二、 规范性引用文件下列文件中的条款通过本规范的引用而成为本规范的条款。

凡是注日期的引用文件,其随后所有的修改单(不包括勘误的内容)或修订版均不适用于本规范,然而,鼓励根据本规范达成协议的各方研究是否可使用这些文件的最新版本。

凡是不注日期的引用文件,其最新版本适用于本规范。

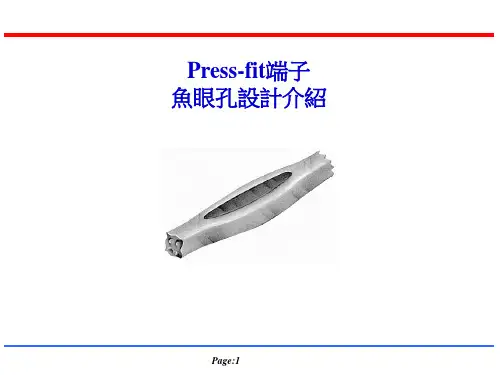

三、 术语和定义压接:压接是由弹性可变形插针或刚性插针与PCB 金属化孔配合而形成的一种连接。

在插针与金属化孔之间形成紧密的接触点,靠机械连接实现电气互连。

为了形成紧密的配合,针脚的横截面尺寸必须大于PCB 金属化孔孔径,在压接过程中,针脚横截面或金属化孔要产生变形。

刚性插针:在压接过程中不产生变形,而孔会变形。

因对孔径的公差要求严格,已经淘汰。

柔性插针:在压接过程中会受挤压而变形,而孔不变形。

压接垫板:fixture ,压接时用于支撑PCB ,防止连接器插针和PCB 损伤的工艺装置。

压接模具:tooling ,压接时适应不同连接器的需要而设计的,置于连接器的上面将连接器压接到PCB 的金制 作:洪 登 月 审 核: 生效日期 :2006.05.20 批 准: 批准日期:未 经 同 意 不 得 复 印***** 有 限 公 司 工 作 指 令 文 件 题 目:压接工艺规范***** 有限公司工作指令文件第 4 页,共10 页5.2 垫板和PCB厚度的处理能力IMPRESS 500E 垫板的厚度+PCB的厚度≤35mmTOX 垫板的厚度+PCB的厚度≤40mmHT604 垫板的厚度+PCB的厚度≤40mmHKP16 垫板的厚度+PCB的厚度≤50mm5.3 相关工艺参数压接模式:定行程(fixed stroke)、定压力(fixed force)、压力增量(delta force)压接行程:35~160mm压接力:根据不同的连接器进行设定压接速度:和压接模式对应,设备无此显示和调节功能六、品质水平压接后连接器和PCB的间隙在0~0.2mm,连接器无移位、扭曲、弯针、塑壳损坏、不出针等不良现象,PCB 无任何损坏,具体参见《PCBA验收标准》中第三部分“压接件”七、初始参数7.1 压接行程采用任何设备压接连接器,必须首先根据连接器、PCB、压接垫板、压接模具的尺寸调节好或设定好设备的行程,以保证压接时连接器不会过压。