兄弟2130-2240D-2250DN-联想2240L维修手册

- 格式:pdf

- 大小:10.27 MB

- 文档页数:143

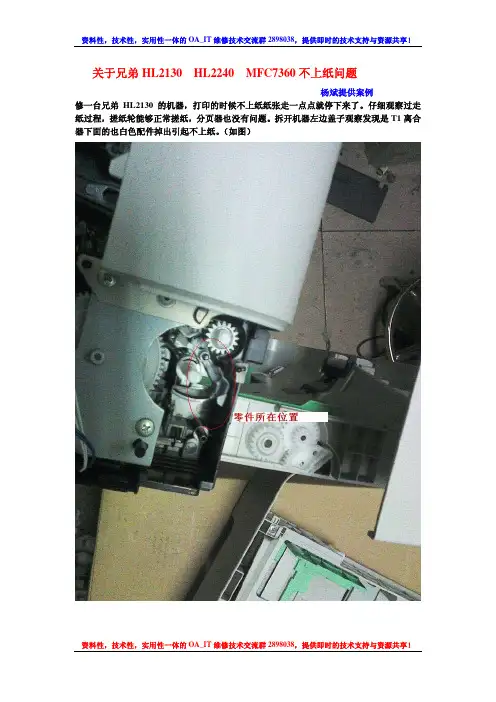

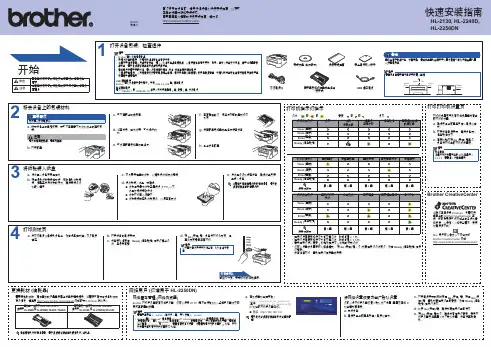

最全图文兄弟打印机hl2240D加粉清零说明第一部分加粉及粉盒清零(Toner点亮或闪烁时需要进行粉盒清零)第一步:打开加粉口(如图所示)倒清费粉并加入碳粉.第二步:对粉盒进行复位处理1.拆开粉盒齿轮边的边盖上的2粒镙丝,轻轻取下边盖(如下图)图上所指的1.2.3.是三个小三角形 A为1号复位齿轮的长腿specification erection and scaffolding inspection score requirements for acceptance in the JGJ59-99. (3) workers built a shelf arrangement through the training. (4) set up warning flags of the erection, dismantling, special care. (5) checks on a regular basis. 2, controlpoint: (1) the material must comply with the specified requirements. (2) when used according to the provisions of the load required to use, it is forbidden to place all kinds of construction materials, and avoid overloading. (3) tube, well within the scaffolding must be protection in place, no foot shaft with two-layer within a quarantine or every 10m the provision of a safety net. (4) facilities available to coordinate and transfer procedures, demolition of a large scaffolding with programme, and approved before implementation. Fire safety fire safety at construction site and to facilitate the smooth progress of the construction work is an important part of safety. 1, the implementation of points: (1) led group under the leadership of the fire, found according to key parts of the fire protection system against fire hazards must be immediately eliminated. (2) the project to establish volunteer fire brigade, normal activities. (3) the construction site must be equipped with adequate fire-fighting equipment, is maintained by the project safety, management, regular updates, guaranteed in good condition. 2, control point: (1)2.拆下1号复位齿轮调整方向后装回(如下图)ship ress of the construction work is an important part of safety. 1, the implementation of points: (1) led group under the leaderprogramme, and approved before implementation. Fire safety fire safety at construction site and to facilitate the smooth prog cedures, demolition of a large scaffolding withlayer within a quarantine or every 10m the provision of a safety net. (4) facilities available to coordinate and transfer pro-be, well within the scaffolding must be protection in place, no foot shaft with two(3) tuprovisions of the load required to use, itis forbidden to place all kinds of construction materials, and avoid overloading. egular basis. 2, control point: (1) the material must comply with the specified requirements. (2) when used according to the l care. (5) checks on a r99. (3) workers built a shelf arrangement through the training. (4) set up warning flags of the erection, dismantling, specia-specification erection and scaffolding inspection score requirements for acceptance in the JGJ592l point: (1)fighting equipment, is maintained by the project safety, management, regular updates, guaranteed in good condition. 2, contro-reate fi(2) the project to establish volunteer fire brigade, normal activities. (3) theconstruction site must be equipped with adequof the fire, found according to key parts of the fire protection system against fire hazards must be immediately eliminated.兄弟打印机加粉及清零说明3.注意1号复位齿轮与2号齿轮的摆放位置(如下图)4.装回边盖,请亲们核对粉盒复位后,1.2.3.和A的位置(如下图)d with adequate fireeliminated. (2) the project to establish volunteer fire brigade, normal activities. (3) the construction site must be equippeately er the leadership of the fire, found according to key parts of the fire protection system against fire hazards must be immedie smooth progress of the construction work is an important part ofsafety. 1, the implementation of points: (1) led group undate the scaffolding with programme, and approved before implementation. Fire safety fire safety at construction site and to facilitevery 10m the provision of a safety net. (4) facilities available to coordinate and transfer procedures, demolition of a larglayer within a quarantine or -verloading. (3) tube, well within the scaffolding must be protection in place, no foot shaft with twoding to the provisions of the load required to use, it is forbidden to place all kinds of construction materials, and avoid oaccor(5) checks on a regular basis. 2, control point: (1) the material must comply with the specified requirements. (2) when used workers built a shelf arrangement through the training. (4) set up warning flags of the erection, dismantling, special care. 99. (3)-specification erection and scaffolding inspection score requirements for acceptance in the JGJ593tion. 2, control point: (1)fighting equipment,is maintained by the project safety, management, regular updates, guaranteed in good condi-ship ress of the construction work is an important part of safety. 1, the implementation of points: (1) led group under the leaderprogramme, and approved before implementation. Fire safety fire safety at construction site and to facilitate the smooth prog cedures, demolition of a large scaffolding withlayer within a quarantine or every 10m the provision of a safety net. (4) facilities available to coordinate and transfer pro-be, well within the scaffolding must be protection in place, no foot shaft with two(3) tuprovisions of the load required to use, itis forbidden to place all kinds of construction materials, and avoid overloading. egular basis. 2, control point: (1) the material must comply with the specified requirements. (2) when used according to the lcare. (5) checks on a r99. (3) workers built a shelf arrangement through the training. (4) set up warning flags of the erection, dismantling, specia-specification erection and scaffolding inspection score requirements for acceptance in the JGJ594l point: (1)fighting equipment, is maintained by the project safety, management, regular updates, guaranteed in good condition. 2, contro-reate fi(2) the project to establish volunteer fire brigade, normal activities. (3) the construction site must be equipped with adequof the fire, found according to key parts of the fire protection system against fire hazards must be immediately eliminated.兄弟打印机加粉及清零说明第二部分硒鼓清零(Drum点亮或闪烁时需要进行硒鼓清零) 1 确认设备电源已打开。

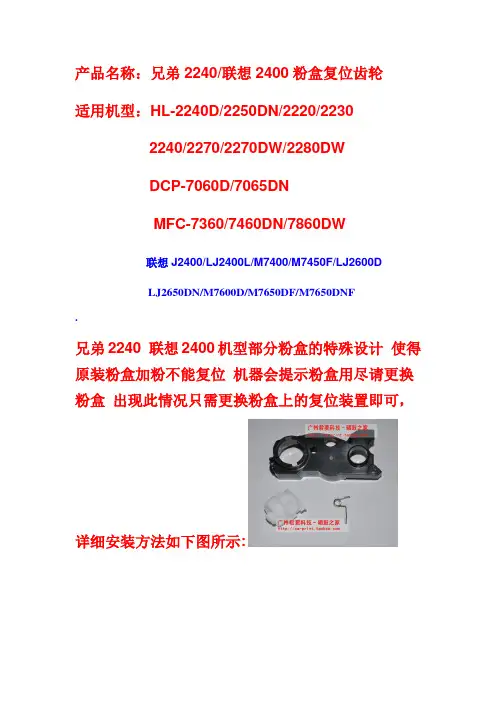

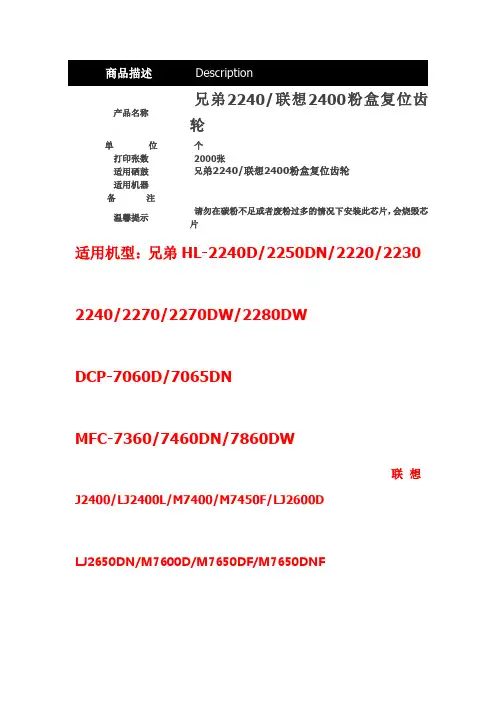

产品名称:兄弟2240/联想2400粉盒复位齿轮适用机型:HL-2240D/2250DN/2220/22302240/2270/2270DW/2280DWDCP-7060D/7065DNMFC-7360/7460DN/7860DW联想J2400/LJ2400L/M7400/M7450F/LJ2600DLJ2650DN/M7600D/M7650DF/M7650DNF.兄弟2240 联想2400机型部分粉盒的特殊设计使得原装粉盒加粉不能复位机器会提示粉盒用尽请更换粉盒出现此情况只需更换粉盒上的复位装置即可,详细安装方法如下图所示:兄弟2240D打印机清零方法:1.在电源开着的情况下,打开打印机前盖,让它开着。

2.关掉电源3.按住“GO”键的同时打开打印机开关。

这是所有的灯应该都是亮着的。

4.松开“GO”键5.按两次“GO"键6.稍停顿7.按”Go“键五次8.这时toner键应该是不亮的9合上前盖,”只有ready“键应该是亮着的10.然后就可以用啦!兄弟2240D粉盒(TN2225)清零方法:兄弟7055打印机清零方法:按功能键开机,出现英文MAINTENANCE,通过上下键,来选择01,按确认键,再选择74。

按确认键,把2020改为1020,按停止键,再选择84,按确认键,选择英文PROCESS.CHECK.再按确认键,然后关机,再开机,出现PROCESS.CHECK.,通过选择TONER CART RESET,再按确认键两次,然后关机。

再按功能开机,选择74。

按确认键,把1020改为2020确认键,按停止键退出,再先择84,按确认键,再选择到CHECKER MODF OFF,按确认键,关机,开机,按确认键,关机,开机,搞定!兄弟7060打印机清零方法:按功能键开机,出现英文MAINTENANCE,通过上下键,来选择01,按确认键,再选择74。

按确认键,把2020改为1020,按停止键,再选择84,按确认键,选择英文PROCESS.CHECK.再按确认键,然后关机,再开机,出现PROCESS.CHECK.,通过选择TONER CART RESET,再按确认键两次,然后关机。

联想笔记本电脑维修指导一、笔记本电脑维修介绍-------------------------------------------- 3二、笔记本电脑维修思路指导---------------------------------------- 41、拆装前注意事项------------------------------------------------- 42、拆卸时需要的注意事项------------------------------------------- 4三、维修思路方法及判断指导---------------------------------------- 51、一般维修顺序指导----------------------------------------------- 52、维修判断思路指导----------------------------------------------- 6 2.1、维修判断原则、方法-------------------------------------------- 6 2.2、维修判断方法、思路-------------------------------------------- 6 2.3、维修判断过程中应注意的问题------------------------------------ 82.4、功能测试工具在维修判断中的应用---------------------------------93、维修判断指导----------------------------------------------------10附录:维修基本流程图笔记本故障维修判断指导作为一名笔记本电脑维修工程师,不仅要对笔记本电脑的硬件、软件及笔记本电脑的结构有较全面的了解,而且还要掌握一定的维修理论与维修方法。

联想昭阳笔记本测试项目针对目前维修工程师在维修中工具和维修测试比较缺乏的现状,在技术支持处的努力下及多方面的配合,完成了昭阳笔记本电脑功能测试这个项目,在这个功能测试项目中包含了联想昭阳2001年自今的14款机型的功能测试,希望能对联想维修服务有所支持。

产品名称

兄弟2240/联想2400粉盒复位齿轮

单位个

打印张数2000张

适用硒鼓兄弟2240/联想2400粉盒复位齿轮适用机器

备注

温馨提示

请勿在碳粉不足或者废粉过多的情况下安装此芯片,会烧毁芯片

适用机型:兄弟HL-2240D/2250DN/2220/2230 2240/2270/2270DW/2280DW

DCP-7060D/7065DN

MFC-7360/7460DN/7860DW

联想J2400/LJ2400L/M7400/M7450F/LJ2600D

LJ2650DN/M7600D/M7650DF/M7650DNF

操作说明:

兄弟2240 联想2400机型部分粉盒的特殊设计使得原装粉盒加粉不能复位机器会提示粉盒

用尽请更换粉盒出现此情况只需更换粉盒上的复位装置即可,详细安装方法如下图所示:

2130硒鼓清零:确认打印机电源已打开。

打开前盖。

按住Go键4 秒钟直至所有LED亮起。

所有四个LED灯都亮起后,松开不按Go键。

合上设备前盖。

确保Drum(硒鼓) LED灯熄灭。

兄弟2130/2240/7360加粉图

兄弟2130/2240D加粉后恢复方法:关闭打印机—打开前盖板——在按下(GO)键的同时打开电源,等除READY指示灯外的其余所有指示灯点亮,然后松开(GO)键——连续按两次(GO)键(等两秒钟后)再连续按6次(GO)键——关闭前盖板后完成。

兄弟7055加粉后恢复方法:DCP7055保持机器处于开机状态——打开前盖板——按【清除/返回】按【启用】键——按【△】箭头选择到【00】/Accepted(接受)字样——按【OK】键——关闭——前盖板。

兄弟2240D打印机清零方法:翻译过来:1. Open the front cover and leave open while completing the following steps.1.在电源开着的情况下,打开打印机前盖,让它开着。

2. Turn the printer off.2.关掉电源3. Hold the 'go' button while turning the printer on. All panel lights should be on.按住“GO”键的同时打开打印机开关。

这是所有的灯应该都是亮着的。

4. Release the 'go' button.3.松开“GO”键5. Press the 'go' button 2 times.按两次“GO"键6. Pause.6.稍停顿7. Press the 'go' button 5 times.7.按”Go“键五次8. The toner light should be off.7.这时toner键应该是不亮的9. The paper light should be on or flashing.(神马paper键,不知道,我就没管)10. Close cover. The ready light should be the only light on.合上前盖,”只有ready“键应该是亮着的然后就可以用啦!兄弟2250dn清零粉盒清零 1.在电源开着的情况下,打开打印机前盖,让它开着。

2.关掉电源。

3.按住“GO”键的同时打开打印机开关。

这时所有的灯应该都是亮着的。

4.松开“GO”键。

5.按“GO”键两次。

6.稍停顿。

7.按“Go”键五次。

8.这时toner键应该是不亮的。

9.合上前盖,这时“ready”键应该是亮着的。

OK重置硒鼓计数器1.在电源开着的情况下,打开打印机前盖,让它开着。

7、取下计数齿轮。

8、取下传动齿轮。

9、搅拌架齿轮D形位朝向错误:其中一种。

10、手工将搅拌架齿轮沿顺时针方向转动。

11、将搅拌架齿轮转动到正确

的位置。

12、装配传动齿轮。

兄弟2240 2015 联想2441产品齿轮复位操作作业指导书

1、计数齿轮位置错误,即长的一侧指向硒鼓正面。

2、取下保护罩,注意手握的

位置。

3、取下齿轮护盖上方的一颗

螺丝。

4、取下齿轮护盖下方的一颗螺丝。

5、取下齿轮护盖。

6、取下齿轮护盖后,齿轮通

常全部在硒鼓上面。

20、装配齿轮护盖上方的一颗螺丝。

21、装配齿轮护盖下方的一颗

螺丝。

13、扭簧滑落到计数齿轮定位柱上面。

14、用一字刀将扭簧向右上推移。

15、扭簧靠在粉仓胶件的卡位上。

16、使计数齿轮长的一侧指向硒鼓背面,装配计数齿轮。

17、使计数齿轮与搅拌架齿轮紧紧咬合,计数齿轮卡位在左、搅拌架齿轮卡位在右。

18、对应驱动齿轮和计数齿轮装配齿轮护盖。

19、齿轮护盖装配到位。

10、手工将搅拌架齿轮沿顺时针方向转动。

11、将搅拌架齿轮转动到正确的位置。

12、装配传动齿轮。

22、先将保护罩齿轮一端压入。

23、再将保护罩非齿轮端压入。

24、复位操作全部完成。

Brother 激光打印机维修手册维修前请仔细阅读本手册。

请将本手册放置在便利的地方以便于随时快速方便地予以参考。

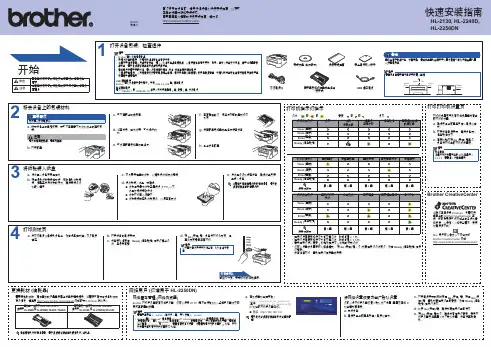

2010年9月SM-PRN080 (2)84UC01机型HL-2130/2240D/2250DN下表显示了本手册中所述各机型之间的功能比较。

机型HL-2130HL-2240D HL-2250DNLAN N/A N/A有线纸张边缘传感器N/A N/A有双面打印N/A有有手动进纸槽盖N/A有有© Brother公司版权所有2010年编辑及出版声明本手册在兄弟工业株式会社监督下出版,包含有最新产品的说明和技术规格。

本手册内容及产品规格如有更改,恕不另行通知。

Brother公司保留不另行通知而对包含在本手册中的产品规格和材料做出更改的权利,对于因依赖本手册所公布的资料,包括但不限于印刷及其他与出版相关的错误而造成的任何损坏(包括后果在内),Brother公司将不承担任何责任。

本产品专为专业环境使用设计。

目录规定 (V)安全信息 (VI)第1章 规格...............................................................................................................1-1 1. 规格表 ..........................................................................................................................1-11.1 概述........................................................................................................................................1-11.2 网络连通性.............................................................................................................................1-31.3 维修信息.................................................................................................................................1-31.4 耗材........................................................................................................................................1-31.5 纸张........................................................................................................................................1-41.5.1 纸张操作..........................................................................................................................1-41.5.2 介质规格..........................................................................................................................1-41.6 可打印区域.............................................................................................................................1-5第2章 故障排除...........................................................................................................................2-1 1. 介绍 .............................................................................................................................2-11.1 预防措施.................................................................................................................................2-11.2 初期检查.................................................................................................................................2-22. 概述 .............................................................................................................................2-12.1 截面图....................................................................................................................................2-42.2 纸张送入.................................................................................................................................2-52.3 各个部件的作用......................................................................................................................2-62.4 电子总结构图..........................................................................................................................2-72.5 部件........................................................................................................................................2-83. 指示灯的出错显示及各类故障 ......................................................................................2-93.1 正常操作时的指示灯显示........................................................................................................2-93.2 需要维修时的指示灯显示......................................................................................................2-123.3 监控屏幕上的出错信息.........................................................................................................2-173.4 需要维修时的错误提示.........................................................................................................2-183.5 图像缺陷的示例....................................................................................................................2-204. 错误的症状/原因与措施 ............................................................................................2-214.1 纸张送入故障........................................................................................................................2-214.1.1 纸盒的撮纸功能失效......................................................................................................2-214.1.2 无纸张送入....................................................................................................................2-214.1.3 手动进纸槽中无纸张......................................................................................................2-224.1.4 双页送入........................................................................................................................2-224.1.5 卡纸...............................................................................................................................2-224.1.6 纸面上的污点................................................................................................................2-244.1.7 纸张歪斜送入................................................................................................................2-244.1.8 纸张皱褶........................................................................................................................2-244.1.9 纸张卷曲........................................................................................................................2-254.1.10 双面打印时只能打印单面............................................................................................2-254.1.13 双面打印所用纸张尺寸出错.........................................................................................2-26 4.2 图像缺陷的故障排除.............................................................................................................2-274.2.1 太浅...............................................................................................................................2-274.2.2 定位不良........................................................................................................................2-294.2.3 太深...............................................................................................................................2-294.2.4 定影不良........................................................................................................................2-294.2.5 完全空白........................................................................................................................2-304.2.6 图像失真........................................................................................................................2-304.2.7 全黑...............................................................................................................................2-314.2.8 纸张背面脏....................................................................................................................2-314.2.9 垂直条纹........................................................................................................................2-324.2.10 浅色背景上的黑色垂直条纹.........................................................................................2-324.2.11 黑色水平条纹..............................................................................................................2-334.2.12 白色垂直条纹..............................................................................................................2-344.2.13 白色水平条纹..............................................................................................................2-344.2.14 打印模糊......................................................................................................................2-344.2.15 白色斑点......................................................................................................................2-354.2.16 黑色斑点......................................................................................................................2-354.2.17 黑色条带......................................................................................................................2-354.2.18 向下渐模糊纯色块.......................................................................................................2-364.2.19 水平线条......................................................................................................................2-364.2.20 重影.............................................................................................................................2-364.2.21 图像模糊......................................................................................................................2-37 4.3 软件设置问题........................................................................................................................2-384.3.1 无法打印数据................................................................................................................2-38 4.4 网络问题(仅限于HL-2250DN)............................................................................................2-384.4.1 无法通过网络连接进行打印...........................................................................................2-38 4.5 墨粉和硒鼓问题....................................................................................................................2-394.5.1 尽管更换了墨粉盒,但仍显示" Replalce Toner "..........................................................2-394.5.2 无法检测出墨粉盒.........................................................................................................2-394.5.3 墨粉不足........................................................................................................................2-394.5.4 更换墨粉盒....................................................................................................................2-394.5.5 显影辊的转数到达其上限..............................................................................................2-404.5.6 墨粉盒未装入................................................................................................................2-404.5.7 硒鼓寿命即将到期.........................................................................................................2-404.5.8 硒鼓出错........................................................................................................................2-404.5.9 硒鼓寿命到期................................................................................................................2-40 4.6 定影单元问题........................................................................................................................2-414.6.1 定影单元故障................................................................................................................2-41 4.7 激光单元问题........................................................................................................................2-414.7.1 激光单元故障................................................................................................................2-414.8.2 内存已满........................................................................................................................2-424.8.3 打印超限........................................................................................................................2-424.8.4 高压电源电路板组件故障..............................................................................................2-424.8.5 低压电源电路板组件故障..............................................................................................2-434.9 其他问题...............................................................................................................................2-434.9.1 设备电源无法打开或不出现指示灯显示.........................................................................2-434.9.2 风扇不运转....................................................................................................................2-434.9.3 主马达故障....................................................................................................................2-434.9.4 前盖未关闭....................................................................................................................2-444.9.5 后盖未关闭....................................................................................................................2-44第3章 拆卸和重新安装..............................................................................................................3-11. 安全注意事项 ...............................................................................................................3-12. 包装 .............................................................................................................................3-23. 螺丝目录 ......................................................................................................................3-34. 紧固扭矩列表 ...............................................................................................................3-45. 润滑 .............................................................................................................................3-56. 齿轮概述 ......................................................................................................................3-67. 插线路径 ......................................................................................................................3-98. 拆卸流程图 .................................................................................................................3-179. 拆卸步骤 ....................................................................................................................3-189.1 纸盒......................................................................................................................................3-199.2 后盖......................................................................................................................................3-229.3 外斜槽组件...........................................................................................................................3-249.4 定影单元盖...........................................................................................................................3-259.5 内斜槽组件、左/右出纸挤压辊组件.....................................................................................3-269.6 前盖组件、挡板1.................................................................................................................3-289.7 左侧盖..................................................................................................................................3-299.8 右侧盖..................................................................................................................................3-309.9 顶盖组件...............................................................................................................................3-319.10 定影单元.............................................................................................................................3-359.11 低压电源电路板组件...........................................................................................................3-389.12 定影单元风扇......................................................................................................................3-419.13 高压电源电路板组件...........................................................................................................3-429.14 面板电路板组件..................................................................................................................3-439.15 过滤器................................................................................................................................3-449.16 激光单元.............................................................................................................................3-459.17 撮纸辊座组件......................................................................................................................3-479.18 橡胶垫脚.............................................................................................................................3-489.19 主板组件.............................................................................................................................3-499.20 T1离合器组件、定位离合器组件.......................................................................................3-509.22 显影驱动辅助组件,显影联结齿轮52................................................................................3-549.23 马达驱动辅助组件,主马达................................................................................................3-569.24 出纸传感器电路板组件.......................................................................................................3-589.25 定影齿轮28/34...................................................................................................................3-60第4章 更换部件后所需的调整和设定值更新........................................................................4-1 1. 如果更换了主板 ...........................................................................................................4-11.1 重写固件软件 (主程序)..........................................................................................................4-21.1.1 检查固件版本..................................................................................................................4-21.1.2 重写固件..........................................................................................................................4-21.2 设置默认纸张尺寸..................................................................................................................4-31.3 设置序列号.............................................................................................................................4-41.4 输入激光单元的调整值...........................................................................................................4-72. 如果更换了激光单元 ..................................................................................................4-112.1 输入激光单元的调整值.........................................................................................................4-113. 如果更换了低压电源电路板组件 ................................................................................4-153.1 重置不规则电源检测计数值..................................................................................................4-15第5章 维修功能...........................................................................................................................5-1 1. 维修模式 ......................................................................................................................5-11.1 如何进入用户可使用维修模式.................................................................................................5-11.2 如何进入维修人员专用维修模式.............................................................................................5-11.3 维修模式功能列表..................................................................................................................5-21.4 维修模式功能的详细说明........................................................................................................5-42. 打印机设置 .................................................................................................................5-112.1 打印机设置页的打印.............................................................................................................5-113. 其他维修功能 .............................................................................................................5-193.1 重新打印功能........................................................................................................................5-193.2 取消打印作业功能................................................................................................................5-193.3 墨粉盒的延续模式/中止模式的设定转换.............................................................................5-203.4 硒鼓清洁功能........................................................................................................................5-20第6章 电路图、接线图..............................................................................................................6-1附录1 序列号系统.....................................................................................................附录1-1附录2 消去用户设定信息.........................................................................................附录2-1附录3 安装Brother Maintenance USB Printer 驱动程序....................................附录3-1附录4 硒鼓单元保护材料的制作方法.....................................................................附录4-1规定无线电干扰 (仅适用于220至240V 电压的机型)本设备遵循 EN55022 (CISPR 22通令)/ B级的规定。