欧普-条形码技术应用介绍

- 格式:ppt

- 大小:2.81 MB

- 文档页数:27

条码的基础知识目录一、条码的基础知识 (2)1.1 条码的基本概念 (3)1.1.1 条码的定义 (4)1.1.2 条码的起源和发展 (5)1.2 条码的分类 (6)1.2.1 按照使用范围分类 (8)1.2.2 按照编码方式分类 (9)1.3 条码的结构 (9)1.3.1 条码的组成元素 (10)1.3.2 条码的排列方式 (11)1.4 条码的编码规则 (13)1.4.1 EAN/UPC条码编码规则 (14)1.4.2 ITF14条码编码规则 (15)1.4.3 39条码编码规则 (16)二、条码的应用 (16)2.1 物流跟踪与管理系统 (18)2.2 零售商品管理 (19)2.3 仓储管理 (20)2.4 工业自动化生产线 (21)三、条码的技术与发展 (22)3.1 条码识别技术的发展 (23)3.2 条码打印技术的发展 (24)3.3 条码扫描设备的发展 (26)3.4 条码应用系统的集成与发展 (27)四、条码的标准与规范 (29)4.1 国际条码标准 (30)4.2 国家或地区条码标准 (31)4.3 条码应用中的规范与要求 (32)一、条码的基础知识定义与构成:条码是一种由特定规则排列的黑白条棒状图形,通过光电扫描设备读取并转换为计算机可识别的数据。

条码由一系列规则排列的条和空组成,其中条代表不同的信息,空则用于区分不同的条码符号。

条码通常由条形码数字、起始符、中间分隔符和终止符等构成。

条码类型:根据不同的应用需求和特性,条码分为多种类型,如UPC码、EAN码、Code 39码、Code 128码等。

每种类型的条码具有不同的编码规则和使用场景。

UPC码主要用于美国零售业的商品标识,EAN码则广泛应用于全球商品标识。

编码原理:条码的编码原理是将数字信息按照一定的规则进行编码,形成特定的图形符号。

不同的条和空代表不同的数字信息,通过光电扫描设备将这些图形符号转换为电信号,再进一步转换为计算机可识别的数据。

PEX1000系列工业型条形码打印机使用者手册系列型号:PEX1120/ PEX1130/ PEX1160 PEX1220/ PEX1230/ PEX1260⏹ 热转式 ⏹ 热敏式版权声明©©2021 TSC Auto ID Technology Co., Ltd,本手册和手册中所述之条形码打印机软件和固件版权均归TSC Auto ID Technology Co., Ltd所有。

本手册提供购买设备的操作者参考和使用,未经明确的书面许可,不得为了其他目的使用、复制。

所有其他品牌名称、产品名称或商标,隶属于其他个别拥有者。

因持续产品的改进,故手册中所述的机种规格、配件、零件、设计及程序内容应以实机为主,如有变更,恕不另行通知。

TSC尽力确保手册内容正确无误,但错误在所难免。

TSC保留更正任何这类错误的权利,并声明不对因此所造成的后果负责。

I目录1. 打印机简介 (1)1.1 产品规格 (2)1.1.1 标准配备 (2)1.1.2 选购配备 (4)1.2 一般规格 (4)1.3 打印规格 (5)1.4 碳带规格 (6)1.5 纸张规格 (6)2. 产品介绍 (7)2.1 拆封与检查 (7)2.2 打印机方向 (8)2.3 检查安装空间 (9)2.4 打印机组件 (13)2.4.1 外观 (13)2.4.2 内部 (14)2.2.3 后部 (15)2.5.1 LED辅助警示灯和操作按键 (17)3. 安装 (19)3.1 安装打印机 (19)3.2 安装碳带 (20)3.3 安装标签纸 (24)3.4 剥纸模式装纸 (28)4. 调整钮 (32)4.1 碳带张力调整旋钮 (33)4.2 皱折解说及排除 (34)4.3 碳带张力调整建议 (37)5. TSC Console (39)5.1 启动TSC Console (39)5.2 新增以太网络接口 (41)5.3 设置Wi-Fi并新增至TSC Console接口 (43)5.4 初始化打印机的Wi-Fi模块(选配) (46)5.6 设置打印后动作 (48)6. 打印机内键功能(Menu) (49)6.1进入选单 (49)6.2 选单简介 (50)6.3 Setting (51)6.3.1 TSPL (52)6.3.2 ZPL (55)6.4 Sensor(传感器设置) (58)6.5 Interface(通讯接口) (59)6.5.1 Serial Comm(串行端口设置) (60)6.5.2 Ethernet(以太网络设置) (61)6.5.3 Wi-Fi (62)6.5.4 Bluetooth(蓝牙) (63)6.5.5 GPIO (64)6.6 Advanced(高级设置) (69)6.7 File Manager(档案管理) (71)6.8 Diagnostic(打印机诊断) (72)7. 故障排除 (78)8. 保养办法 (81)9. 安规认证 (83)10. 历史纪录 (89)1. 打印机简介感谢您对本公司所出品的条形码打印机的支持。

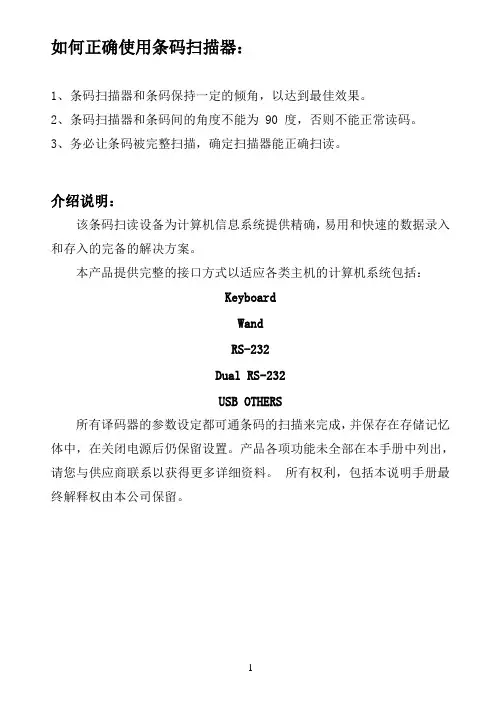

如何正确使用条码扫描器:1、条码扫描器和条码保持一定的倾角,以达到最佳效果。

2、条码扫描器和条码间的角度不能为 90 度,否则不能正常读码。

3、务必让条码被完整扫描,确定扫描器能正确扫读。

介绍说明:该条码扫读设备为计算机信息系统提供精确,易用和快速的数据录入和存入的完备的解决方案。

本产品提供完整的接口方式以适应各类主机的计算机系统包括:KeyboardWandRS-232Dual RS-232USB OTHERS所有译码器的参数设定都可通条码的扫描来完成,并保存在存储记忆体中,在关闭电源后仍保留设置。

产品各项功能未全部在本手册中列出,请您与供应商联系以获得更多详细资料。

所有权利,包括本说明手册最终解释权由本公司保留。

目录自动感应条码扫描器使用说明 (4)扫描功能 (5)输出模式 (5)蜂鸣器 (5)条码正反图像设定 (6)添加条码ID(条码辨别号) (6)条码读取触发模式 (6)键盘接口 (7)PC传输模式 (7)键盘传送速度 (7)世界各国键盘语言 (7)RS-232接口 (8)波特率 (8)握手协议 (8)数据位 (9)停止位 (9)校验位 (9)光笔接口 (10)传送速度 (10)条码正反图像设定 (10)条形码开启与关闭 (10)Code11 (10)Code39 (10)Code93 (11)Code128 (11)Code bar (11)交叉25码 (11)工业25码 (11)MSI/Plessey (12)UPC/EAN (12)条形码符号设定 (13)Code11 (13)Code39 (13)Code93 (14)Code128 (14)Code bar (14)交叉25码 (15)工业25码 (15)MSI/Plessey (16)UPC/EAN (16)编辑设定条形码 (19)条码字符一般/特别设定 (20)条形码末端字符设定 (21)使用高级设定模式设置条码阅读器 (22)设置种类 (23)编辑键值 (24)选项编号和描述 (25)F1-接口选项 (25)F2-Code39选项 (25)F2-UPC/EAN选项 (26)F2-UPC/EAN补充选项 (26)F2-Code93选项 (27)F2-Code128选项 (27)F2-CodeBar选项 (27)F2-交叉25码选项 (28)F2-工业25码选项 (28)F2-MSI选项 (28)F2-Code11选项 (29)F2-激光器/CCD选项 (29)F2-其它译码选项 (29)F2-定义蜂鸣器和LED选项 (29)F4-定义一般按键区表选项 (30)F3-条码编辑设定 (31)F4-格式组合设定码 (32)F5-字符串设定码 (33)附录-A 特殊字符和ALT组合键表格 (34)附录-B ALT组合键的表格 (35)附录-C 故障问题及解决方案 (36)自动感应条码扫描器使用说明:1、自动感应条码扫描器通电时默认为自动感应模式。

简述条形码技术的应用方式条形码技术是一种将数字、字母和符号等信息以条形的形式进行编码并用于识别的技术。

它被广泛应用于商品管理、物流追踪、库存管理、销售统计等领域。

本文将从不同的应用方式来介绍条形码技术的应用。

一、商品管理在商品管理中,条形码技术可以用于商品的售价和库存管理。

每个商品都被分配一个独一无二的条形码,通过扫描条形码,可以快速准确地获取商品的信息,包括名称、规格、生产日期、供应商等。

在收银台,只需扫描商品的条形码,系统就能自动识别商品并计算出总价,大大提高了工作效率。

二、物流追踪条形码技术在物流追踪中起到了至关重要的作用。

每个包裹都被贴上一个唯一的条形码,物流公司可以通过扫描条形码来追踪包裹的运输情况。

在整个物流过程中,通过扫描条形码可以实时记录包裹的位置、状态和运输信息,确保包裹能够按时送达目的地。

同时,物流公司还可以通过条形码技术对整个物流过程进行管理和优化,提高物流效率。

三、库存管理条形码技术在库存管理中也发挥着重要的作用。

每个库存商品都被贴上一个条形码,通过扫描条形码可以快速准确地记录商品的进货和出货情况,实时更新库存信息。

通过条形码技术,企业可以实现库存的自动化管理,减少人为错误和盗窃现象,提高库存的准确性和安全性。

四、销售统计条形码技术在销售统计中也起到了重要的作用。

每个销售的商品都被贴上一个条形码,通过扫描条形码可以快速准确地记录销售的商品信息。

通过条形码技术,企业可以实时获取销售数据,包括销售量、销售额、销售渠道等,为企业提供决策参考。

同时,条形码技术还可以与企业的销售管理系统进行对接,实现销售数据的自动化处理和分析,提高销售效率和准确性。

五、移动支付随着移动支付的普及,条形码技术也被应用于移动支付领域。

通过扫描商家的条形码,消费者可以快速完成支付,无需使用现金或刷卡。

条形码技术使得移动支付更加便捷和安全,提升了消费者的支付体验。

六、车辆管理条形码技术在车辆管理中也有广泛的应用。

未经用友软件股份有限公司事先书面许可,本手册的任何部分不得以任何形式进行增删、改编、节选、翻译、翻印或仿制。

本手册的全部内容用友软件股份有限公司可能随时加以更改,此类更改将不另行通知。

具体应用以软件实际功能为准本手册的著作权属于用友软件股份有限公司版权所有·翻制必究2014年6月第一次印刷用友、UFERP、U8、NC、iCRM为用友软件股份有限公司的注册商标。

Windows, Windows NT, SQL Server是Microsoft Corporation的注册商标。

本书中涉及的其他产品商标为相应公司所有。

在中华人民共和国印制。

目录目录 (I)第1章系统概述 (1)1.1产品介绍 (1)1.2主要功能 (1)1.3产品接口 (2)1.4操作流程 (3)第2章应用准备 (4)2.1选项 (4)2.2条码规则 (7)2.3标签类别 (11)2.4标签设计 (11)2.5条码规则分配 (13)2.6拣货策略 (14)2.7无线菜单 (16)2.8流程配置 (16)2.9界面设计 (18)2.10无线端服务器及账套配置 (19)2.9无线端基础设置 (20)2.10无线端的查询功能 (22)第3章条码生成 (25)3.1条码生成 (25)3.2条码档案 (29)第4章条码扫描 (31)4.1条码扫描 (31)4.2收货 (35)4.2.1采购收货流程1:收货入库 (35)4.2.2采购收货流程2:收货-检验-入库 (36)4.2.3生产入库流程1:下线入库 (38)4.2.4生产入库流程2:下线上托-入库-上架 (39)4.3发货 (40)II 目录4.3.1材料出库流程1:逐单领料 (41)4.3.2材料出库流程2:多单合并发料 (41)4.3.3销售出库流程1:库管员直接发货 (46)4.3.4销售出库流程2:业务通知发货,库管出库 (46)4.3.5销售出库流程3:发货-拣货-移位-拼箱-出库 (47)4.4库内移动 (52)4.4.1调拨流程1:直接调拨 (52)4.4.2调拨流程2:按申请调拨 (53)4.4.3货位调整流程 (54)4.5盘点 (54)4.6仓储作业 (56)4.6.1上架 (56)4.6.2拣货-PC端应用 (56)4.6.3拣货-无线端应用 (60)4.6.4条码关联-PC端应用 (61)4.6.5条码关联-无线端应用 (63)4.6.6装箱-PC端应用 (63)4.6.7装箱-无线端应用 (66)4.6.8拆箱 (70)第5章应用方案 (75)5.1主题一:如何防止发错货 (75)5.2主题二:如何严格保证近效期先出或批号先进先出 (81)5.3主题三:如何快速准确的采集序列号 (85)5.4主题四:如何利用条码监控窜货 (93)5.5主题五:货位管理-入库上架,拣货下架 (95)第1章系统概述1.1产品介绍随着条码技术的普及,越来越多的用户认识到只有条码技术与ERP软件相结合才能做到及时、准确的数据采集。

EUP20T-1HMC-0(104100000101)SummaryProduct FeatureDimension(mm)EUP20T-1HMC-0 is a constant current output mode LED driver. The output current can be easily set via DIP switch.The driver supports leading edge (Triac) and trailing edge (ELV)dimmer, and can be compatible with the systems of various brands (Philips, Panasonic, Lutron, Simon, ABB,Siemens,Dalitek etc.) to achieve a smooth dimming effect.220VAC-240VAC 50/60Hz81%@230VAC, Full load ≥0.95@230VAC,full load Cold start, 15A(twidth=30us measured at 50% Ipeak@230VAC 0.12Amax@230VAC,150*43*29mm(L*W*H)IP20-20℃~50℃-40℃~85℃, 20-90%RH 75℃PC 30,000h@tc:75℃48V Max ±5%<3%Triac/ELV>15,000 times1350mA/9-40VDC/14W 400mA/9-40VDC/16W 450mA/9-40VDC/18W 500mA/9-40VDC/20W550mA/9-36VDC/19.8W 600mA/9-33VDC/19.8W650mA/9-30VDC/19.5W 700mA/9-28VDC/19.6WEUP20T-1HMC-0TcLifetimeMaterialDimensionPacking Size IP Rating Working Temp.Storage Temp.; Humidity Dimming Mode Switch Cycle 3 years Warranty Condition No Load Output Voltage Turn On Delay Time<1s, at 230Vac Efficiency Current <20%@230VAC,full loadTHD Inrush Current Current/Voltage/Power Ripple CurrentChannel Current Tolerance Voltage FrequencyPower Factor Over temperature Short Circuit Over Load Shut down the output, recovers automatically when temp. back to normal.When the output voltage is exceeded, decreases and, recovers automatically when the load is reduced.Shut down the output automatically recovers after faulty condition is removed.OthersFunction ModelOutputInputProtectionTechnical Parameters·Single channel output, output current level selectable by DIP S.W.·Support Leading edge (Triac) and Trailing edge (ELV) dimmer ·Dimming range from 40VAC to 240VAC ·Built-in active PFC function·Class 2 power supply. Full protective plastic housing ·Dimming effect smooth, no flicker·Protections: Short circuit, over load, over temperature·Suitable for indoor LED lighting application, such as down light, spotlights, panel light, and so onNet weight: 130g±5%/PCS; 50PCS/Carton; 7kg±5%/Carton; Carton Size: 374*314*166mm(L*W*H) ApplicationDownlightPanel LightFlood LightSpotlightCeiling Light Track LightFloor LightDecorative LightWiring DiagramAmbient Temperature(℃)L o a d (%)20406080100120-20-10102030405060Dimming CurveDerating CurvePF VS Load ※ The contents of this manual are updated without prior notice. If the function of the product you are using is inconsistent with the instructions, the function of the product shall prevail.Please contact us if you have anyquestions .Cautions1.The product shall be installed and serviced by a qualified person.2.This product is non-waterproof. Please avoid the sun and rain. When installed outdoors please ensure it is mounted in a water proof enclosure.3.Good heat dissipation will prolong the working life of the controller. Please ensure good ventilation.4.Please check if the output voltage and current of any LED power supplies used comply with the requirement of the product.5.Please ensure that adequate sized cable is used from the controller to the LED lights to carry the current. Please also ensure that the cable is secured tightly in the connector.6.For safety consideration, PVC or rubber cord of 0.75-1.5mm2 is recommended for input and output terminal(s) . Flat power cord is not suitable. Ensure all wire connections and polarities are correct before applying power to avoid any damages to the LED lights.7.If a fault occurs please return the product to your supplier. Do not attempt to fix this product by yourself.20406080100120Input(%)O u t p u t (%)Current Selection TableRemark: Function default setting is: 350mA (@switch are all OFF state)0.860.880.900.920.940.960.981.00Load(%)P F。

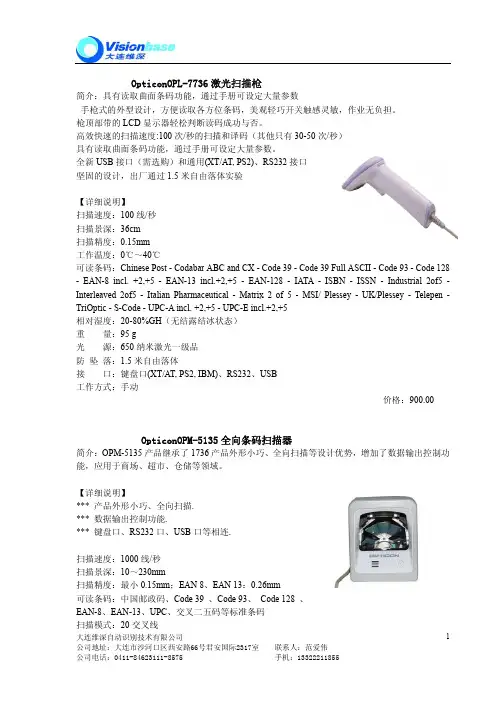

大连维深自动识别技术有限公司公司地址:大连市沙河口区西安路66号君安国际2317室 联系人:范爱伟1OpticonOPL-7736激光扫描枪简介:具有读取曲面条码功能,通过手册可设定大量参数手枪式的外型设计,方便读取各方位条码,美观轻巧开关触感灵敏,作业无负担。

枪顶部带的LCD 显示器轻松判断读码成功与否。

高效快速的扫描速度:100次/秒的扫描和译码(其他只有30-50次/秒)具有读取曲面条码功能,通过手册可设定大量参数。

全新USB 接口(需选购)和通用(XT/AT, PS2)、RS232接口坚固的设计,出厂通过1.5米自由落体实验【详细说明】扫描速度:100线/秒扫描景深:36cm扫描精度:0.15mm工作温度:0℃~40℃可读条码:Chinese Post - Codabar ABC and CX - Code 39 - Code 39 Full ASCII - Code 93 - Code 128 - EAN-8 incl. +2,+5 - EAN-13 incl.+2,+5 - EAN-128 - IATA - ISBN - ISSN - Industrial 2of5 - Interleaved 2of5 - Italian Pharmaceutical - Matrix 2 of 5 - MSI/ Plessey - UK/Plessey - Telepen - TriOptic - S-Code - UPC-A incl. +2,+5 - UPC-E incl.+2,+5相对湿度:20-80%GH (无结露结冰状态)重 量:95 g光 源:650纳米激光一级品防 坠 落:1.5米自由落体接 口:键盘口(XT/AT, PS2, IBM)、RS232、USB工作方式:手动价格:900.00OpticonOPM-5135全向条码扫描器简介:OPM-5135产品继承了1736产品外形小巧、全向扫描等设计优势,增加了数据输出控制功能,应用于商场、超市、仓储等领域。

道路运输车辆管理信息系统需求规格说明书编号:CLGL_REQ_001版本:V1.0发布时间:2009-12-30成都兆益科技发展有限责任公司文件变更记录*A - 增加 M - 修订 D - 删除目录1产品介绍 (1)2产品面向的用户群体 (1)3产品应当遵循的标准或规范 (2)4产品范围 (2)5产品中的角色 (2)6产品的功能性需求 (2)6.1需求分类 (2)6.2我要申请 (4)6.2.1固定资产申请 (4)6.2.2设备购置入库申请 (5)6.3设备维护 (6)6.3.1设备管理查看 (6)6.3.2设备管理浏览 (7)6.3.3设备管理 (7)6.3.4设备库浏览 (9)6.3.5设备出入库记录 (9)6.3.6设备库存 (10)6.3.7设备库存分类统计 (11)6.3.8我的设备 (11)6.3.9设备库存出库 (12)6.4工作任务 (13)6.4.1我的工作 (13)6.4.2我参与未完成 (13)6.4.3我与已完成 (14)6.4.4所有未完成 (15)6.4.5所有已完成 (15)6.5条码维护 (16)6.5.1条码生成 (16)6.5.2条码生成历史 (17)6.6参数设置 (18)6.6.1管理类别 (18)6.6.2签名管理 (19)6.6.3报废期限管理 (20)6.6.4设备来源管理 (21)6.6.5供应商管理 (22)6.6.6规格管理 (23)7产品非功能性需求 (24)8接口需求 (31)9其它需求 (31)《需求规格说明书》客户确认本《需求规格说明书》完整地体现“中银保险浙江分公司”项目的需求,同意项目按此说明书进行实施。

签字(签章):日期:1产品介绍云南省公路运输管理局负责云南省道路运输车辆的行业管理工作。

随着社会主义市场经济体制的不断建立和完善,信息技术的飞速发展,政府职能正在逐步由管理型向服务型转变,推行电子政务是对传统行政管理方式的深刻变革,其实质是对现有的政府形态进行改造,利用信息技术来构造更适合信息时代要求的政府治理结构和运行方式,因此,大力推进信息化建设,实现信息资源共享,在建设省、州市、县三级网络和数据交换平台的基础上,以数据为核心,整合道路运输信息资源,逐步建立信息交换共享和集中发布协调机制,建设一个规范、统一、信息资源共享的全省数据中心,统一管理道路运输公共数据资源,通过对各类数据资源进行集成加工,为政府和社会提供服务。

Barcode Data CollectorOPL 9728The OPL 9728 data collector uses barcode laserscanning technology and RS-232C forcommunication. Specifications ManualAll information subject to change without notice.Document HistoryModel Number: OPL 9728 Specification Number: SS07019Edition: 2A Original Spec Number: SS03043Date: 2006-12-01Copyright 2007 Opticon. All rights reserved.This manual may not, in whole or in part, be copied, photocopied, reproduced, translated or converted to any electronic or machine readable form without prior written consent of Opticon.Limited Warranty and DisclaimersPLEASE READ THIS MANUAL CAREFULLY BEFORE INSTALLING OR USING THE PRODUCT.Serial NumberA serial number appears on all Opticon products. This official registration number is directly related to the device purchased. Do not remove the serial number from your Opticon device. Removing the serial number voids the warranty.WarrantyUnless otherwise agreed in a written contract, all Opticon products are warranted against defects in materials and workmanship for two years after purchase. Opticon will repair or, at its option, replace products that are defective in materials or workmanship with proper use during the warranty period. Opticon is not liable for damages caused by modifications made by a customer. In such cases, standard repair charges will apply. If a product is returned under warranty and no defect is found, standard repair charges will apply. Opticon assumes no liability for any direct, indirect, consequential or incidental damages arising out of use or inability to use both the hardware and software, even if Opticon has been informed about the possibility of such damages.PackagingThe packing materials are recyclable. We recommend that you save all packing material to use should you need to transport your data collector or send it for service. Damage caused by improper packaging during shipment is not covered by the warranty.TrademarksTrademarks used are the property of their respective owners.Opticon Inc. and Opticon Sensors Europe B.V. are wholly owned subsidiaries of OPTOELECTRONICS Co., Ltd., 12-17, Tsukagoshi 4-chome, Warabi-shi, Saitama, Japan 335-0002. TEL +81-(0) 48-446-1183; FAX +81-(0) 48-446-1184SUPPORTUSA Europe Phone: 800-636-0090Email:**********************Email:*******************Web: Web: Contents1.Abstract (5)2.Overview (5)3.Physical Features (6)3.1.Dimensions (6)3.2.Weight (6)3.3.Color (6)4.Environmental Specifications (7)4.1.Operating Temperature and Humidity (7)4.2.Storage Temperature and Humidity (7)4.3.Ambient Light Immunity (7)5.Controls (8)6.Electrical Specifications (8)6.1.Main Battery (8)6.2.Battery Operating Time and Charging Time (8)7.Optical Specifications (9)ser Scan Specifications (9)ser Scan Standards (9)ser Scan Tilt (9)7.2.2.Scan Curvature (10)8.Technical Specifications (10)8.1.Print Contrast Signal (PCS) (10)8.2.Minimum Resolution (10)8.3.Scan Area and Resolution (11)8.3.1.Depth of Field (11)8.4.Pitch, Skew, and Tilt (12)8.4.1.Pitch Angle (12)8.4.2.Skew Angle and Dead Zone (13)8.4.3.Tilt Angle (14)8.5.Curvature (15)9.Interface Specifications (16)9.1.Infrared Transmission (IrDA) (16)9.1.1.Specifications (16)9.1.2.Transmission Speed (16)10.Serial Number (16)11.Packaging Specifications (17)11.1.Individual Packaging Specification (17)11.2.Accessory Specification (17)12.Durability (18)12.1.Shock (18)12.1.1.Drop Test (without packaging) (18)12.2.Vibration Strength (18)12.3.Dust and Drip Proof (19)13.Reliability (19)14.Regulatory Compliance (20)ser Safety (20)14.2.EMC (20)14.3.RoHS (20)14.4.State of California: Perchlorate Best Management Practices (20)15.Safety (21)15.1.Shock (21)15.2.Temperature Conditions (21)15.3.Foreign Materials (21)15.4.Other (21)16.Mechanical Drawing (22)Table of FiguresFigure 1: Reading a barcode (6)Figure 2: Scan tilt and curvature (10)Figure 3: Depth of field (11)Figure 4: Pitch (12)Figure 5: Skew and dead zone (13)Figure 6: Tilt angle (14)Figure 7: Curvature (15)Figure 8: Serial number diagram (16)Figure 9: Individual packaging (17)Figure 10: Shock test (18)Figure 11: Mechanical drawing (22)1. AbstractThis manual provides specifications for the OPL 9728 barcode data collector (hereafter referred to as “data collector”).2. OverviewThis data collector uses laser technology. To start a scan, press the trigger switch. Do not allow the data collector to directly touch the surface of a barcode when scanning.Operating the data collector via a trigger switch enables low-power operation and longerbattery life.Supported symbologies:Linear (1D) Postal 2DJAN/UPC/EAN, incl. add-on Chinese Post Composite Codes*Codabar/NW-7 Korean Postal Authority Code MicroPDF417*Code 11 PDF417*Code 39Code 93Code 128GS1-128 (EAN-128)GS1 Databar (RSS)IATAIndustrial 2of5Interleaved 2of5ISBN-ISSNMatrix 2of5MSI/PlesseyS-CodeTelepenTri-OpticUK/Plessey* Requires use of an external library.Using the built-in clock function, you can add a time stamp to the scanned data.The OPL 9728 can use a variety of cradles:•CRD 9723 single-bay cradle (1 x charging, 1 x communication)•CRD 9723 multi-bay cradle (5 x charging, 1 x communication)•CRD 9723 multi-bay cradle (5 x charging, 5 x communication)•CRD 9722 single-bay cradle (1 x charging, no communication)Applications can be developed for this product using the Software Development Kit (SDK).Software can be developed in the C programming language. These development tools are available as accessories.Figure 1: Reading a barcode.3. Physical Features3.1. DimensionsW 129 mm x D 44 mm x H 22.3 mm3.2. Weight105g (lithium-ion battery weight is included)3.3. ColorGray4. Environmental Specifications4.1. Operating Temperature and HumidityTemperature: 0 to 40° CHumidity: 20 to 85%4.2. Storage Temperature and HumidityTemperature: -20 to +60° CHumidity: 20 to 90%4.3. Ambient Light ImmunityDecoding performance is guaranteed when the range of illumination on a barcodesurface is between zero and the following values:Incandescent light 3,000 lxFluorescent light 3,000 lxlxSunlight 50,000ConditionsBarcode Sample: OPTOELECTRONICS Test SamplePCS: 0.9mmResolution: 0.25Symbology: 8-digit Code 39Quiet Zone: 10 mmN/W Ratio: 1:2.5Direct light or specular reflection light from a source should be prevented from enteringthe acceptance area.Note: α, β and γ respectively represent pitch, skew and tilt. Please see section 8 for howthese values are defined.5. ControlsItem Specifications Remarks MPU 16-bitCPUBuilt-in ROM 128 KB DownloadControlsBuilt-in RAM 4 KBFlash ROM 512 KB–2 MB 512 KB standardExternal memorySRAM 512 KB–1 MB 512 KB standardLCD Semi-transparent dot matrix LCD For all OPL 97xxDPI 112 x 64 dpiBacklight InstalledDisplayFunctions Clock time, battery power, failure notificationRTC (Clock) Real time clock YY/MM/DD/HH/MM/SS(Leap year supported)Accurate within 90 seconds per month6. Electrical Specifications6.1. Main BatteryThe main battery is a lithium-ion secondary battery.Nominal capacity: 600 mAhBattery life: rechargeable 300 times6.2. Battery Operating Time and Charging TimeParameter Specifications Notes Backup battery 3 mAh manganese dioxide lithium-ion battery1 mA or less At standbyCurrent consumption70 mA or less Backlight offUsable time 50 hours or more 1 scan/5sWithout backlight, nocommunicationData hold time 72 hours or more After main battery dischargedNote: Battery life may be shorter than specified above when the quality of the batterypack is degraded.7. Optical Specifications7.1. Laser Scan SpecificationsUnit Parameter SpecificationLight-emitting element Red laser diode —Emission wavelength 650 ±10 (25° C) nmLight output 1.0 or less mWScanning method Bi-directional scanning —Scanning speed 100 ±20 scans/sScan angleScan angle: 54 ±5 °Read angle: 44 (Min) °Note: Refer to chapter 8, “Technical Specifications,” to read about scanningperformance.7.2. Laser Scan Standards7.2.1. Laser Scan TiltMaximum tilt between both ends of laser scan line.Less than 1.2° upward tilt from the scan origin.Maximum of 3.1 mm when measured at a point 150 mm away from the scanorigin. (The skew angle of this measurement was 0°.)Measurement was done from the center of the scan line.7.2.2. Scan CurvatureMaximum gap between the straight line connecting both ends of laser scan lineand the actual laser scan line.Less than 1.27° curvature from the scan origin.Maximum of 3.3 mm curvature when measured at a point 150 mm away from thescan origin. Measurement was done from the center of the scan line.Figure 2: Scan tilt and curvature8. Technical SpecificationsThe conditions for technical specifications are as follows, unless otherwise specified in each section.ConditionsAmbient temperature and humidity: Room temperature (5 to 35º C)Room humidity (45% to 85% RH)Ambient light: 500 to 900 lxBackground: Barcode = blackSpace = whiteMargin = whiteBackground of label = black8.1. Print Contrast Signal (PCS)0.45 or higher (over 70% of reflectivity of space and quiet zone).PCS=Scanning performance may decline if dirt or scratches mar the optical window. Keep the optical window clean.8.2. Minimum Resolution0.15 mm8.3. Scan Area and Resolution8.3.1. Depth of FieldThe depth of field is measured from the edge of the data collector. The scanning range is within the circular arc centered on the scan origin.0M i n i mu m re a d i n g d is t a nc eR es o l u t i o n 1.0R es o l u t i o n 0.5R es o l u t i o n 0.15R eso l u t i o n 0.2544゚35406075145240365Figure 3: Depth of fieldSymbology Resolution (mm)Decode Depth (mm)PCSCode 39 1.0 60–300 0.9 Code 39 0.5 35–210 0.9 Code 39 0.25 35–120 0.9 Code 390.1535–700.9ConditionsBarcode Sample: OPTOELECTRONICS Test SampleN/W ratio: 1:2.5Angle:α = 0°, β = 15°, γ = 0°Curvature: R = ∞Resolution Symbology PCS Quiet Zone Digit1.0 mm Code 39 0.9 25 mm 10.5 mm Code 39 0.9 18 mm 30.25 mm Code 39 0.9 10 mm 80.15 mm Code 39 0.9 7 mm 10Note: dirt or scratches on the mask will degrade scanning performance. Always handle the data collector carefully.8.4. Pitch, Skew, and Tilt8.4.1. Pitch Angleα = ±25°Figure 4: PitchConditionsBarcode Sample: OPTOELECTRONICS Test SampleDistance: 90 mm from the edge of the data collectorLabel: Pitch, Skew AnglePCS = 0.9, Resolution = 0.25 mm, Symbology = 9-digit Code 39,Quiet Zone = 10 mm, N/W Ratio = 1:2.5Dead Zone, Tilt AnglePCS = 0.9, Resolution = 0.26 mm, Symbology = 13-digit JAN, Quiet Zone = 10 mm Angle: Curvature: R = ∞, Skew Angle = β +15° (for measuring Pitch Angle and Tilt Angle)8.4.2. Skew Angle and Dead ZoneSkew angle: β = ±50° (Excluding dead zone)Dead zone: β = ±8° (There are some areas in which decoding fails due to specular reflection)(Depth of field: Within 90 mm from the minimum scannable distance).D e a d ar e a8゚8゚β=50゚β=50゚Figure 5: Skew and dead zoneConditionsBarcode Sample: OPTOELECTRONICS Test SampleDistance: 90 mm from the edge of the data collectorLabel:Pitch, Skew AnglePCS = 0.9, Resolution = 0.25 mm, Symbology = 9-digit Code 39, Quiet Zone = 10 mm, N/W Ratio = 1:2.5 Dead Zone, Tilt AnglePCS = 0.9, Resolution = 0.26 mm, Symbology = 13-digit JAN, Quiet Zone = 10 mm Angle:Curvature: R = ∞, Skew Angle = β +15° (for measuring Pitch Angle and Tilt Angle)8.4.3. Tilt Angleγ = ±20°γ=20°γ=20°Figure 6: Tilt angleConditionsBarcode Sample: OPTOELECTRONICS Test SampleDistance: 90 mm from the edge of the data collectorLabel:Pitch, Skew AnglePCS = 0.9, Resolution = 0.25 mm, Symbology = 9-digit Code 39, Quiet Zone = 10 mm, N/W Ratio = 1:2.5 Dead Zone, Tilt AnglePCS = 0.9, Resolution = 0.26 mm, Symbology = 13-digit JAN, Quiet Zone = 10 mm Angle:Curvature: R = ∞, Skew Angle = β +15° (for measuring Pitch Angle and Tilt Angle)8.5. CurvatureWith 8-digit JAN/UPC/EAN barcodes, decoding performance is guaranteed when R≥15 mm.With 13-digit JAN/UPC/EAN barcodes, decoding performance is guaranteed when R≥20 mm.Figure 7: CurvatureConditionsBarcode Sample: OPTOELECTRONICS Test SamplePCS = 0.9, Resolution = 0.26 mm, Quiet Zone = 10 mmDistance: 90 mm from the edge of the data collectorβ = +15°Angle: SkewAngleThe scanning range will vary according to the depth of field.9. Interface Specifications9.1. Infrared Transmission (IrDA)9.1.1. SpecificationsThe dedicated cradle enables the OPL 9728 to perform infrared transmission ofdata with IrDA Ver1.2 low power specification.9.1.2. Transmission SpeedDefault transmission speed is set at 115.2 kbps. However, you can easily changethe transmission rate to 57.6 kbps, 38.4 kbps, 19.2 kbps, 9600 bps, 4800 bps, or2400 bps.10. Serial NumberThe serial number shown below is affixed to the back of the OPL 9728.Figure 8: Serial number diagramUppercase: Management Barcode(Symbology: Code 39, Resolution: 0.12 to 0.2, N/W Ratio: 1:2.5 to 1:3)Lowercase: Model Names, Serial Numbers (The height of letters is 1.2 ± 0.3)Serial numbers are seven-digit numbers and start from number 0000001 regardless of batch.11. Packaging Specifications11.1. Individual Packaging SpecificationPut the data collector in a protective foam bag and place it in an individual packing box,then place the accessories into the box. Close the box and affix a label to the side of thebox.Figure 9: Individual packaging11.2. Accessory SpecificationThese accessories are enclosed in an individual package:• 1 lithium-ion battery• 1 hand strap12. Durability12.1. Shock12.1.1. Drop Test (without packaging)No malfunction occurred after the following drop test.Drop Test: Drop the data collector from a height of 1.5 m onto a concrete floor.Each side of the data collector impacted the floor three times.Figure 10: Shock test12.2. Vibration StrengthNo malfunction occurred after the following vibration test.Vibration test: Increase the frequency of the vibration from 12 Hz to 100 Hz withaccelerated velocity 19.6 m/s2 (2 G) for 6 minutes in non-operating state. Repeat thisroutine 10 times for 60 minutes in each of X, Y, Z direction once for a total of 180minutes.12.3. Dust and Drip ProofIEC IP54Dust PreventionLevel Details5 Ingress of dust is not entirely prevented, but it must not enter in sufficient quantity to interfere with the satisfactory operation of the equipment; complete protection against contact.Water PreventionLevel Details4 Water splashing against the enclosure from any direction shall have no harmful effect.13. ReliabilityMTBF (Mean Time Between Failures) of this product except for the laser diode and the mirror motor scan unit is 8 years.Life cycle of the laser scan engine (including the life cycle of the laser diode and the mirrormotor) is 10,000 hours.Keypad operating life: The keypad expected usability is 1,000,000 uses (cycles) when the key is pressed with 1 kgf force.The estimate of MTBF and product life cycle is based on standard operation of the productwithin the recommended temperature range and without extreme electronic or mechanicalshock.The MTTR (Mean Time To Repair) of this product is one hour.14. Regulatory Compliance14.1. Laser SafetyThe data collector emits laser beams.JIS C6802: 2005: Laser class 1IEC 825-1/EN 60825-1: Laser class 1FDA CDRH Laser class I. Complies with 21 CFR 1040.10 and 1040.11 except fordeviations pursuant to laser notice No. 50 dated June 24, 2007.Class I laser devices are not considered to be hazardous when used for their intendedpurpose. Avoid staring into the laser beam.14.2. EMCEN55022EN55024VCCI Class B: This is a Class B product, to be used in a domestic environment based onthe Technical Requirement of the Voluntary Control Council for Interference fromInformation Technology Equipment (VCCI). If this is used near a radio or televisionreceiver in a domestic environment, it may cause radio interference. Please install anduse the equipment according to the instruction manual.FCC Part 15 Subpart B Class B: This device complies with part 15 of the FCC Rules.Operation is subject to the following two conditions: (1) this device may not cause harmfulinterference, and (2) this device must accept any interference received, includinginterference that may cause undesired operation.14.3. RoHSRoHS: The restriction of the use of certain hazardous substances in electrical andelectronic equipment, 2002/95 EC.14.4. State of California: Perchlorate Best Management PracticesThe batteries on some Opticon products may contain Perchlorate. To comply withCalifornia Perchlorate Best Practice Regulations and the Law for the Promotion ofUtilization of Recyclable Resources (Japan), products that may contain Perchloratematerials should be properly labeled on the exterior of all outer shipping packages and/orin locations that otherwise satisfy the California Perchlorate Best Management Practices.15. SafetyHandle this product carefully. Do not deliberately subject it to any of the following.15.1. ShockDo not throw or drop the data collector.Do not drop or put heavy items on this product or its cable.15.2. Temperature ConditionsDo not use the data collector at temperatures outside the specified range.Do not use near heat sources such as radiators, heat registers, stoves, or other types ofdevices that produce heat.Do not use in areas exposed to direct sunlight for long periods of time.Do not pinch or forcibly bend the cable, especially at very low temperature.15.3. Foreign MaterialsDo not use the data collector near water or other liquids, as well as in extremely highhumidity.Do not immerse the data collector in liquids.Do not use in dusty environments.Do not subject the data collector to chemicals.Do not insert foreign substances into the device.15.4. OtherDo not plug/unplug the connectors before disconnecting the power.Do not attempt to disassemble, modify or update this device.Do not use near microwaves, medical devices, or RF-emitting devices.The data collector may not perform properly in environments when placed near aflickering light, such as a computer monitor, television, etc. Do not use in the reach ofblinking lights such as CRT.The data collector may be damaged by voltage drops.16. Mechanical Drawing12358A B CD E FJ K LT U V 6M N O9W X Y Z74G H IPQ R S C L RB S S h i f t0.*...-E N TOPTIC ON1294420.422.320Figure 11: Mechanical drawing。