报警信息中英文对照

- 格式:docx

- 大小:16.60 KB

- 文档页数:5

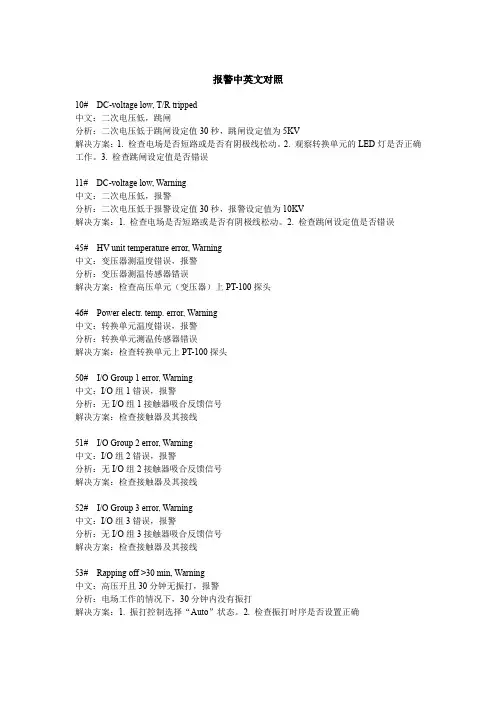

报警中英文对照10# DC-voltage low, T/R tripped中文:二次电压低,跳闸分析:二次电压低于跳闸设定值30秒,跳闸设定值为5KV解决方案:1. 检查电场是否短路或是否有阴极线松动。

2. 观察转换单元的LED灯是否正确工作。

3. 检查跳闸设定值是否错误11# DC-voltage low, Warning中文:二次电压低,报警分析:二次电压低于报警设定值30秒,报警设定值为10KV解决方案:1. 检查电场是否短路或是否有阴极线松动。

2. 检查跳闸设定值是否错误45# HV unit temperature error, Warning中文:变压器测温度错误,报警分析:变压器测温传感器错误解决方案:检查高压单元(变压器)上PT-100探头46# Power electr. temp. error, Warning中文:转换单元温度错误,报警分析:转换单元测温传感器错误解决方案:检查转换单元上PT-100探头50# I/O Group 1 error, Warning中文:I/O组1错误,报警分析:无I/O组1接触器吸合反馈信号解决方案:检查接触器及其接线51# I/O Group 2 error, Warning中文:I/O组2错误,报警分析:无I/O组2接触器吸合反馈信号解决方案:检查接触器及其接线52# I/O Group 3 error, Warning中文:I/O组3错误,报警分析:无I/O组3接触器吸合反馈信号解决方案:检查接触器及其接线53# Rapping off >30 min, Warning中文:高压开且30分钟无振打,报警分析:电场工作的情况下,30分钟内没有振打解决方案:1. 振打控制选择“Auto”状态。

2. 检查振打时序是否设置正确54# Rapping continuously >30 min, Warning中文:持续振打30分钟,报警分析:持续振打30分钟解决方案:1. 振打控制选择“Auto”状态。

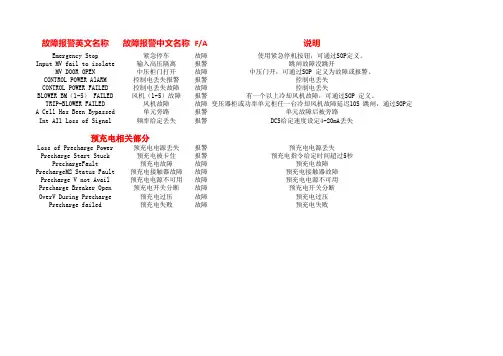

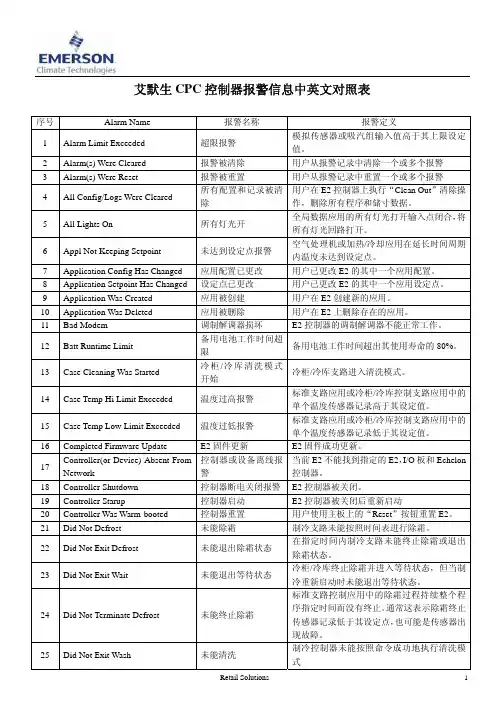

故障报警英文名称故障报警中文名称F/A说明

Emergency Stop紧急停车故障使用紧急停机按钮,可通过SOP定义。

Input MV fail to isolate输入高压隔离报警跳闸故障没跳开

MV DOOR OPEN中压柜门打开故障中压门开,可通过SOP 定义为故障或报警。

CONTROL POWER AlARM控制电丢失报警报警控制电丢失

CONTROL POWER FAILED控制电丢失故障故障控制电丢失

BLOWER BM(1-5) FAILED风机(1-5)故障报警有一个以上冷却风机故障,可通过SOP 定义。

TRIP-BLOWER FAILED风机故障故障变压器柜或功率单元柜任一台冷却风机故障延迟10S 跳闸,通过SOP定A Cell Has Been Bypassed单元旁路报警单元故障后被旁路

Int AI1 Loss of Signal频率给定丢失报警DCS给定速度设定4-20mA丢失

预充电相关部分

Loss of Precharge Power预充电电源丢失报警预充电电源丢失

Precharge Start Stuck预充电被卡住报警预充电指令给定时间超过5秒PrechargeFault预充电故障故障预充电故障

PrechargeM2 Status Fault预充电接触器故障故障预充电接触器故障

Precharge V not Avail预充电电源不可用故障预充电电源不可用

Precharge Breaker Open预充电开关分断故障预充电开关分断

OverV During Precharge预充电过压故障预充电过压

Precharge failed预充电失败故障预充电失败。

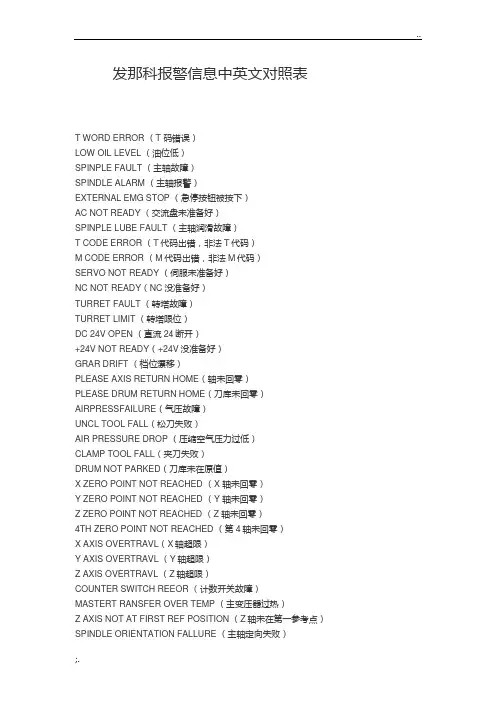

发那科报警信息中英文对照表T WORD ERROR (T 码错误)LOW OIL LEVEL (油位低)SPINPLE FAULT (主轴故障)SPINDLE ALARM (主轴报警)EXTERNAL EMG STOP (急停按钮被按下)AC NOT READY (交流盘未准备好)SPINPLE LUBE FAULT (主轴润滑故障)T CODE ERROR (T代码出错,非法T代码)M CODE ERROR (M代码出错,非法M代码)SERVO NOT READY (伺服未准备好)NC NOT READY(NC没准备好)TURRET FAULT (转塔故障)TURRET LIMIT (转塔限位)DC 24V OPEN (直流24断开)+24V NOT READY(+24V没准备好)GRAR DRIFT (档位漂移)PLEASE AXIS RETURN HOME(轴未回零)PLEASE DRUM RETURN HOME(刀库未回零)AIRPRESSFAILURE(气压故障)UNCL TOOL FALL(松刀失败)AIR PRESSURE DROP (压缩空气压力过低)CLAMP TOOL FALL(夹刀失败)DRUM NOT PARKED(刀库未在原值)X ZERO POINT NOT REACHED (X 轴未回零)Y ZERO POINT NOT REACHED (Y 轴未回零)Z ZERO POINT NOT REACHED (Z 轴未回零)4TH ZERO POINT NOT REACHED (第4轴未回零)X AXIS OVERTRAVL(X轴超限)Y AXIS OVERTRAVL (Y轴超限)Z AXIS OVERTRAVL (Z轴超限)COUNTER SWITCH REEOR (计数开关故障)MASTERT RANSFER OVER TEMP (主变压器过热)Z AXIS NOT AT FIRST REF POSITION (Z轴未在第一参考点)SPINDLE ORIENTATION FALLURE (主轴定向失败)TOOL DESENT OR TOOL DATA REEOR (刀具数据错误)PLEASE UNLOAD THE TOOL ON SPRINELK (请卸下主轴上的刀)PLEASE LOAD TOOL ON APINDLE (请装上主轴上的刀)A AXIS UNCLAMP FAIL (A 轴松开失败)A AXIS CLAMP FAIL (A 轴夹紧失败)DRUM OUT TO APRONDLEIS FALL (刀库摆向换刀位失败)MG SWING OVERLOAD(刀库摆动过载)DRUM BACK PARK IS FALL (刀库摆回原始位失败)TURRENT MOTOR1 OVERLOAD (刀库移动电机过载)COOLANT MOTOR OVERLOAD (冷却泵过载)DRUM ATC FAULT (自动换刀失败)TOOLS UNLOCKED (刀具未锁紧)BATTERY ALARM (电池报警)DRUM POSITION SWITCH ERROR (刀库位置检测开关故障)DRUM NOW NOT AT PARK (刀库未在原始位置)IT DANGOU TO MOVE DRUM (刀库禁动)POT UO FAILOR POT NOT AT UP POSITION (刀套未在水平位)POT DOWN FAIL (刀套翻下动作失败)IT IS DANGOUR TO MOVE ARM (机械手禁动)THE SPINDLE STATU IS ERROR (主轴状态错误)ARM MOTOR OR ARM SWITCH FALL (机械手或机械手开关故障)CENTRE LUBRICATION FALL (中心润滑故障)THE WORK NOT CLAMPED (工件未夹紧)AUTO TOOL CHANGE FAULT (自动换刀失败)TOOL DATA OUT OF RANGE (指令刀具号超出范围)THE ORDER TOOL NOW IN SPINDLE (目标刀具在主轴上)THE THREE SPINDLE SWITCH FAULT (主轴上的接近开关)THE CENTRE COOLANT IS LOWER (刀具内冷泵液位过低)DRUM RETURN 1# POSITION FAULT (刀库自动回零失败)SPINDLE OVERLOAD (主轴过载)TURRENT MOTOR OVERLOAD (刀盘转动电机过载)CHIP CONVEYER OVERLOAD (拉屑器过载)HARD LIMIT OR SERVO ALARM (硬限位或伺服报警)NO LUB OIL (无润滑油)INDEX HEAD UNLOCKED (分度头未锁紧)MT NOT READY(机床没准备好)MG OVERLOAD (刀库过载)LUB EMPTY(润滑无油)AIR PRESSURE(气压不足)COOLANT NOT READY(冷却没准备好)LUBE EMPTY(油雾油位低,润滑油位低)LUB PRESSURE LOW(润滑压力低)CONVEY VERLOAD(排屑过载)LUB OVERLOAD(润滑过载)LUBE PRESSURE LOW(油雾压力低)SERIAL SPINDLE ALARM (串行主轴报警)NC BATTERY LOW ALARM(NC电池低报警)MAGAZINE MOVE LIMIT SWITCH ERROR(刀库移动限位开关故障)SPINDLE TOOL UNLAMP POSITION LIMIT SWITCH ERROR(主轴刀具UNLAMP位置限位开关故障)MAGAZINE NOT IN POSITION OR SENSOR ERROR(刀库不在位或传感器错误)AIR PRESSURE LOW ALARM(气压低报警)MOTOR OVERLOAD(电机过载)T CODE > MAGAZINE TOOLST CODE < 1 ERROR5TH AXIS HARDWARE OVERTRAVER LIMIT ERRORDOOR IS OPENED(开门)LUB PRESSURE SWITCH ERROR(油压开关错误)SPINDLE OIL COOLANT UNIT ERRORSPINDLE LOAD ABNORMAL(主轴负荷异常)TRANSDUCER ALARM(传感器报警)BED-HEAD LUBRICATE OFF(床头润滑关闭)EMG OFFHYDRAULIC CHUCK PRESS LOW(液压夹头压力低)HYDRAULIC TAIL PRESS LOW(液压尾座压力低)LUB 0IL LOW(油压低)TURRET CODE ERROR(转塔码错误)TURRET RUN OVERTIME(转塔运行超时)MANUAL HANDLE INTERRUPTTRY TO RUN SPINDLE WHILE CHUCK NOT LOCKTRY TO RUN SPINDLE WHILE TAIL NOT LOCKSPINDLE NEUTRAL GEARMAGAZINE ADJUSTHYDRAULIC NOT RUNSAFETY DOOR BE OPENEDSAFETY DOOR NOT CLOSENOT ALL AXIS HAVE GONE BACK REFIN ADJUST,IGNORE GOING BACK REFAFTER EXCHANGE TOOL,CYCLE STARTATC MOTOR QF16 OFFX AXIS IS LOCKED(X 轴被锁定)Y AXIS IS LOCKED(Y 轴被锁定)Z AXIS IS LOCKED(Z 轴被锁定)A AXIS IS LOCKED(A 轴被锁定)SPINDLE MOTOR FAN QF26 OFF(主轴电机风扇QF26关闭) SPINDLE ORIENTATION INCOMPLETE(主轴定位不完全)M FUNCTION NOT COMPLETE(M 功能无法完成)SPINDLE NOT IN GEAR POSITION(齿轮不在主轴位置)SPINDLE NOT CHANGED TO LOW GEAR(主轴没有变为低档)SPINDLE NOT CHANGED TO HIGH GRAR(主轴没有变为高档)MAG NOT BACKWARDSPINDLE TOOL NOT CLAMPSPINDLE TOOL NOT UNCLAMPMAG NOT IN POSITIONMAG DOES NOT ROTATEMAG DOES NOT STOP RUNNINGA AXIS HAVE NOT CLAMPEDA AXIS HAVE NOT UNCLAMPEDSET D499=1,"MAG.JOG" SWITCH ONHYDRAULIC MOTOR QF7 OFF(液压马达QF7关闭)HYDRAULIC TEMPRETURE HIGH(液压使用温度高)HYDRAULIC FILTER BLOCKED(液压过滤器阻止)HYDRAULIC OIL LEVEL LOW(液压油位低)HYDRAULIC FAN QF8 OFF(液压风扇QF8关闭)HELIX CONYER QF9 OR QF10 OFFCHAIN CONYER QF11 OFFCOOLANT MOTOR QF12 OFF(冷却液电机QF12关闭)COOLNT LEVEL LOW,CYCLE STOP AFTER 20 MINUTESINNER COOLANT BLOCK(内冷却堵塞)SPINDLE COOLANT MOTOR QF14 OFF(主轴冷却液电机QF14关闭)INNER COOLANT QF13 OFF(内冷却液QF13关闭)MAG MOTOR QF15 OFFCABINET COOLANT EQUIP QF20 OFFOIL GATHER QF24 OFFAIR PRESSURE LOW(低气压)SPINDLE COOLANT MOTOR FAULT(主轴冷却液电机故障)LUB.OIL IS LOW(润滑油低)DOOR OPEN(门打开)FRONT DOOR(R) OPEN(前门打开)LEFT DOOR OPEN(左门打开)LUBRICATION OIL QF23 OFF(润滑油QF23关闭)LUBRICATION PRESS LOW(润滑油位低)IN ADJUST,MAG CAN'T EXCHANGE T(在调整,刀库不能交换T)NOT ALL DOOR CLOSED(门没有全部关闭)IN M06,MAG NOT READY(在M06,刀库未准备好)MAGAZINE NOT READY(刀库未准备好)POCKET NOT HORIZANTALIN M06,Z NOT BACK TO 2ND REFIN M06,Z AXIS NOT IN PSW1ATC NOT IN ZERO POSITIONSPINDLE ORIENTATION UNCOMPLETEPOCKET NOT HOR./MAG NOT BCKWRDPOCKET NOT VER./MAG NOT FORWRDUNCLAMP TOOL HAS NOT COMPLETEDCLAMP TOOL HAS NOT COMPLETEDAIM TOOL NO. IS WRONGMAG NOT BACKWARDAFTER RETRACT,SET R.T.BACK OFFZ NOT IN PSW2,FORBID ATC RUNNINGD499 EQUAL 1MAG.JOG SOFT SWITCH IS ONZ NOT IN PSW2,FORBID MAG FORWARDCHEKE SPINDLE MODULE ALARMOIL WATER SEPARATOR QF24 OFFSET THE SOFT SWITCH MAG.JOG OFFSET D499 TO 0 设定D499为0K PARAM ABOUT MAG SET IS WRONG 关于MAG的K参数设定错误MECHANICAL BRAKE NOT RELEASED机床抱闸没有松开MECHANICAL BRAKE IS WRONG 机床抱闸错误PLEASE ADD LUB.OIL 请加润滑油PROBE BATTERY VOLTAGE IS LOW 探头电池电压低PROBE IS ERR 探头错误PARAMETER WRITE ENABLE(参数写使能)PMC EDIT ENABLE(PMC编辑使能)CHECK LUB ROUTINSPINDLE GEAR SIGNAL MISS 主轴档位信号消失T_CLAMPED_SIGNAL MISS T夹紧信号消失SP OVERRIDE SWITCH DISCONNECTION 主轴倍率开关断路FEED OVERRIDE SWITCH DISCONNECTION 进给倍率开关断路THE TOTAL NUMBER OF POCKETS SET ERRCHANGE T STOPED BECAUSE NO AIR 因为缺少压空交换停止THE COOLANT WATER TOO LOW,ADD COOLANT WATER AT ONCE 冷却水少立即加水COOLANT LEVEL LOW,ADD COOLANT WATER 冷却水液位低PLEASE REPLACE CNC BATTERY QUICKLY 请立即更换CNC电池。

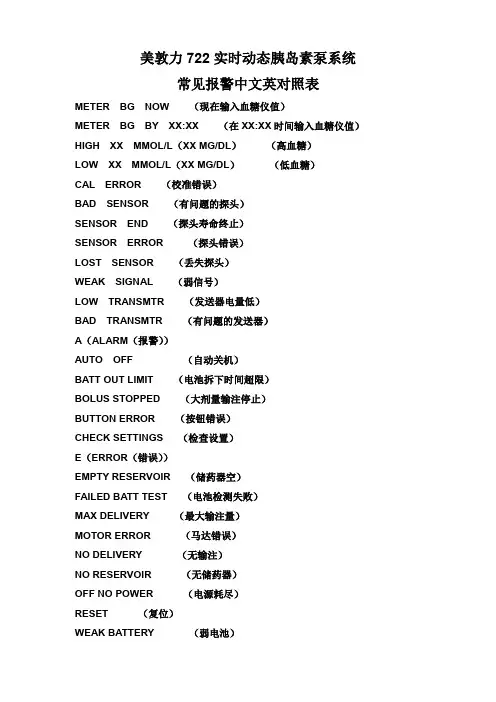

美敦力722实时动态胰岛素泵系统

常见报警中文英对照表

METER BG NOW (现在输入血糖仪值)

METER BG BY XX:XX (在XX:XX时间输入血糖仪值)HIGH XX MMOL/L(XX MG/DL)(高血糖)

LOW XX MMOL/L(XX MG/DL)(低血糖)

CAL ERROR (校准错误)

BAD SENSOR (有问题的探头)

SENSOR END (探头寿命终止)

SENSOR ERROR (探头错误)

LOST SENSOR (丢失探头)

WEAK SIGNAL (弱信号)

LOW TRANSMTR (发送器电量低)

BAD TRANSMTR (有问题的发送器)

A(ALARM(报警))

AUTO OFF (自动关机)

BATT OUT LIMIT (电池拆下时间超限)

BOLUS STOPPED (大剂量输注停止)

BUTTON ERROR (按钮错误)

CHECK SETTINGS (检查设置)

E(ERROR(错误))

EMPTY RESERVOIR (储药器空)

FAILED BATT TEST (电池检测失败)

MAX DELIVERY (最大输注量)

MOTOR ERROR (马达错误)

NO DELIVERY (无输注)

NO RESERVOIR (无储药器)

OFF NO POWER (电源耗尽)

RESET (复位)

WEAK BATTERY (弱电池)。

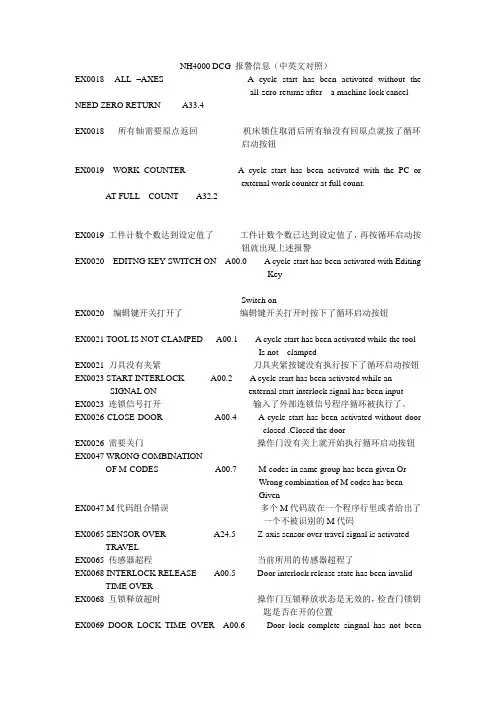

NH4000 DCG 报警信息(中英文对照)EX0018 ALL –AXES A cycle start has been activated without theall-zero-returns after a machine lock cancel NEED ZERO RETURN A33.4EX0018 所有轴需要原点返回机床锁住取消后所有轴没有回原点就按了循环启动按钮EX0019 WORK COUNTER A cycle start has been activated with the PC orexternal work counter at full count.AT FULL COUNT A32.2EX0019 工件计数个数达到设定值了工件计数个数已达到设定值了,再按循环启动按钮就出现上述报警EX0020 EDITNG KEY SWITCH ON A00.0 A cycle start has been activated with EditingKeySwitch onEX0020 编辑键开关打开了编辑键开关打开时按下了循环启动按钮EX0021 TOOL IS NOT CLAMPED A00.1 A cycle start has been activated while the toolIs not clampedEX0021 刀具没有夹紧刀具夹紧按键没有执行按下了循环启动按钮EX0023 START INTERLOCK A00.2 A cycle start has been activated while an SIGNAL ON external start interlock signal has been inputEX0023 连锁信号打开输入了外部连锁信号程序循环被执行了。

EX0026 CLOSE DOOR A00.4 A cycle start has been activated without doorclosed .Closed the doorEX0026 需要关门操作门没有关上就开始执行循环启动按钮EX0047 WRONG COMBINATIONOF M-CODES A00.7 M codes in same group has been given OrWrong combination of M codes has beenGivenEX0047 M代码组合错误多个M代码放在一个程序行里或者给出了一个不被识别的M代码EX0065 SENSOR OVER A24.5 Z-axis sensor over travel signal is activated TRA VELEX0065 传感器超程当前所用的传感器超程了EX0068 INTERLOCK RELEASE A00.5 Door interlock release state has been invalid TIME OVEREX0068 互锁释放超时操作门互锁释放状态是无效的,检查门锁钥匙是否在开的位置EX0069 DOOR LOCK TIME OVER A00.6 Door lock complete singnal has not beenturned on within specified timeEX0069 门关闭时间超时门关闭时间没有在规定时间完成,重新关门EX0089 SPEED DETECTION CIRCUITABNORMAL A018.1 Speed detection signal of monitor circuit isabnormalThough spindle or rotary tool spindle hasnot been rotated, speed detection signal ison.Though spindle or rotary tool spindle hasbeen rotating over fixed speed, speeddetection signal is off.EX0089 速度侦测电路异常速度侦测的主电路异常虽然侦测速度的信号已经发出了但是主轴或动力头还是没有转动主轴或动力头的速度超出了规定的速度,速度侦测信号关闭EX0097 Panel I/O ALARM A01.2 An I/O alarm has been occurred in the flattype operation panelEX0097 操作盘输入输出报警输入输出报警信息是由操作盘发生的EX0099 PANEL ALARM A06.5 An alarm has been occurred in the flat typeoperation panelEX0099 操作盘报警这个报警信息是由操作盘发生的EX0104 OUT OF POSITION FOR ATC A01.1 Tool change command has been givenwithout returning axes to the ATCPOSITIONEX0104 不在换刀点位的位置刀具换刀时轴没有返回到换刀点EX0108 APC NOT IN HOME POSITION A22.7 Tool change command has been givenwithout an APC cw or ccw completionsignalEX0108 APC不在原点位置APC正转或者反转没有到达原点位置执行了换刀动作EX0109 U-AXIS OUT OF ZERO POINT A34.3 When spindle tool is not for U-axis .U-axis is not at zero pointEX0109 U轴不在原点位置当工具轴不在原点位置时不能设为轴EX0111 Z-AXIS NOT IN REFERENCEPOINT A03.6 Tool change command has been givenwithout returning Z-axis to the 2ndzero pointEX0111 Z轴不在参考点Z 轴不在第二参考点就执行了换刀EX0116 REFERENCE POINT PARAMETERERROR A01.4 The parameter for zero return is notcorrect. NC or PC parameter is notproperly set.EX0116 错误的参考点参数原点返回参数不正确,NC 或PC 参数设置不当EX0119 SUB ARM IS NOT MAGAZINE The sub-arm is not at magazine side though SIDE A23.6 Both spindle tool data and next tool data is . set to ―0‖EX0119 待要交换的刀杯不在刀库一侧虽然主轴刀具和等待刀具都设为“0但是待要交换的刀杯不在刀库侧EX0120 SUB ARM IS NOT SPINDLE A01.3SIDE The sub –arm is not at spindle side thougheither spindle tool data or next tool data isset .EX0120 待要交换的刀杯不在主轴一侧虽然主轴刀具和等待刀具都设了数据,但是待要交换的刀杯不在主轴侧EX0121 TOOL DATA SETTING ERROR A01.5 Tool change command has been givenwhile the data for waiting pot or spindletool is not stored in magazineEX0121 刀具数据设置错误换刀时的刀号不能在主轴或刀库里发现EX0123 NO EMPTY POT A3.0 No empty pot exists during ATC cyclecheck the tool data.EX0123 没有空刀杯刀库里的刀杯已经全被占用了EX0124 SPECIFIED POT NOTINDEXED A03.2 The pot specified by T code has not beenindexed at change –position during ATCcycleEX0124 没有找到指定的刀杯ATC 循环期间被T代码指定的刀杯没有被找到EX0146 SPINDLE TOOL DA TA ERROR A24.2 During A TC cycle ,spindle tool checksignal is not activated while a spindletool data exists ,or ,spindle tool checksignal is activated while there is no tooldataEX0146 主轴刀号错误主轴刀号不存在EX0155 ATC HOME POSITION SIGNALOFF A01.6 ATC has deviated from home positionduring spindle rotationEX0155ATC 原点位置信号关掉在主轴旋转时ATC脱离了原点位置EX0156 ATC MOTOR OVERLOAD A01.7 The ATC motor thermal relay hastripped.reset contact. ATC motor maybe overloaded.EX0156 ATC 马达过载A TC 马达热保护器跳掉了,ATC 马达超载了EX0158 ATC CYCLE TIME OVER A02.0 ATC cycle has not been completedwithin specified time. Check forpossible error in stop positionEX0158 换刀超时换刀在规定的时间内没有完成,检查是否在换刀点EX0159 ATC ARM H.P. SIGNALKEEPING OFF A02.1 A TC arm home position check signalhas not been turned on during ATCcycleEX0159 机械手臂不在原点位置换刀过程中检测机械手臂原点信号没有打开EX0160 ATC NOT IN HOMEPOSITION A02.2 Spindle rotation or rigid tap commandhas been given when ATC is not athome positionEX0160 ATC 不在原点位置主轴旋转或攻丝命令在运行中时执行了ATC换刀EX0161 ATC ARM NOT IN HOME A02.3 Tool change or T-code command hasbeen given when ATC arm is not athome positionPOSITIONEX0161 ATC 手臂不在原点位置A TC 手臂不在原点位置时执行了换刀EX0165 TOOL CLAMP SIGNAL OFF A02.4 Tool clamp check signal has beenturned off during spindle rotationEX0165 刀具夹紧信号关主轴旋转时刀具夹紧检测信号关了EX0166 TOOL IS NOT CLAMPED A02.5 Spindle rotation spindle orientation orrigid tap command has been givenwhile tool is not clampedEX0166 刀具没有夹紧刀具没有夹紧执行了主轴旋转主轴定位或攻丝EX0167 TOOL IS NOT CLAMPED A02.6 Tool change command has been givenwhile tool is not clampedEX0167 刀具没有夹紧刀具没有夹紧时执行了换刀动作EX0168 ATC ARM NOT IN HOME POSITION A02.7 A cycle start has been activated whileATC arm is not at home positionEX0168 ATC 手臂不在原点位置当ATC手臂不在原点位置时按下了循环启动按钮EX0169 ATC SHUTTER IS NOT CLOSED A06.0 A cycle start has been activatedwithout ATC shutter closedEX0169 刀库门没有关刀库门没关按下了循环启动按钮EX0198 ATC ARM H.P. SIGNAL KEEPING ON A03.1 ATC arm home position checksignal has not been turned off duringATC cycleEX0198 检测ATC手臂原点的检测信号始终检测ATC手臂原点的检测信号始终处于打开状态在ATC运行过程中处于打开状态EX0201 IMPROPER T-CODE SPECIFIED A0.4 The tool called with T-code commandhas not been registered to themagazineEX0201 指定的T代码是错误呼叫的T代码在刀库里没有注册EX0202 SPINDLE TOOL DATA SPECIFIED A04.1 The spindle tool has been given witha T-code commandEX0202 刀号被主轴指定了所呼叫的刀号已经在主轴上了EX0204 NO EMPTY POT FOR T0 A05.7 No empty pot exists when specifyingT0 commandEX0204 没有为T0准备空刀杯当执行T0命令时没有空刀杯存在EX0205 M33&T-CODE IN SAME BLOCK A04.2 Both anM33 and a T-code commandhave been given in the same blockgive an M33 command in a signalblockEX0205 M33 与T 代码在同一个程序段上M33不能与T代码写在一行EX0207 T-CODE NOT COMMANDED A05.6 An M06 command has been specifiedwithout specifying T-code command EX0207 没有T代码指令没有给出T代码执行了M06命令EX0210 SBC CYCLE TIME OVER A04.3 SBC cycle has not been completedwithin specified time check forpossible error of stop positionEX0210 机械手交换时间超时机械手交换在指定时间没有完成,检查停止位置可能错误EX0212 SUB ARM NOT IN HOME A04.5 A cycle start has been activated whilesub arm is not at home position POSITIONEX0212 机械手臂不在原点位置机械手臂不在原点位置时按下了循环启动按钮EX0218 TOOL DA TA SETTING ERROR A04.6 T-code command has been given whilespindle tool data or waiting pot tooldata is not registered to the magazinetool data is not properly setEX0218 刀号设置错误A04.6 主轴刀号和等待刀号在刀库里没有注册,刀号设置不当EX0219 TOOL LIFE EDNING A04.7 The life of all tools in its group isexhaustedEX0219 刀具寿命结束组里所有刀具寿命都用完了EX0220 TOOL GROUP DATA ERROR A05.0 M66 or M67 command has been givenwhile tool group or tool life data(#1133) is improperly setEX0220 刀具组数据错误M66或M67不能执行,刀具组或刀具寿命数据设置不当EX0230 SELET MAGAZINE AUTO MODE A05.1 The manual operation mode has beenselected on the magazine operationpanel when T-code command hasbeen given. Select the automaticoperation modeEX0230 刀库自动模式被选择当执行T代码呼叫时,刀库操作盘上的手动模式被选择了,请选择自动模式EX0231 CLOSE MAGAZINE DOOR A05.2 The magazine door has been openedclose the magazine doorEX0231 关闭刀库门刀库门开着,请关闭刀库门EX0233 PRESS CYCLE START BUTTON A05.4 Press the cycle start button .T-cycleis startedEX0233 按下循环启动按钮按下循环启动按钮,T循环开始执行EX0234 CARRYING POT DA TA IS EXISTING A29.2 Carrying pot data exists not duringSBC cycle operation .Clear the dataafter returning the tool to properposition by manual operationEX0234 搬送刀杯数据是存在的搬送刀杯数据存在机械手臂循环操作不能执行手动操作使该刀具返回到合适的位置后清除该数据EX0240 T-DATA IS SET FOR EMP. POT A06.4 Tool data is set for the empty potduring ATC cycle。

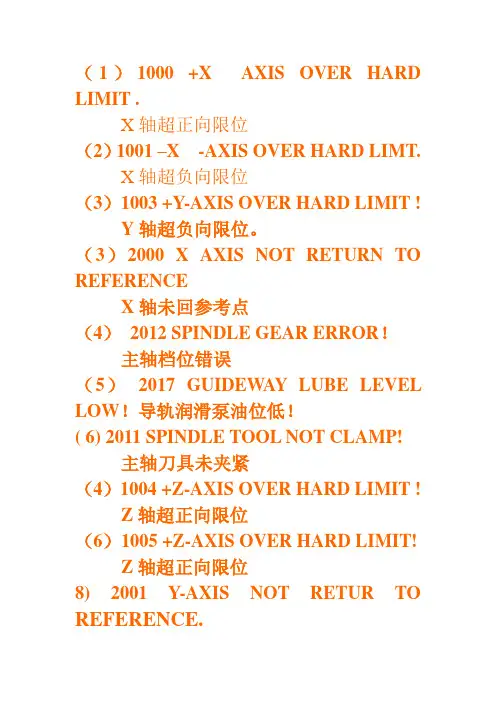

(1)1000 +X AXIS OVER HARD LIMIT .X轴超正向限位(2)1001 –X -AXIS OVER HARD LIMT.X轴超负向限位(3)1003 +Y-AXIS OVER HARD LIMIT !Y轴超负向限位。

(3)2000 X AXIS NOT RETURN TO REFERENCEX轴未回参考点(4)2012 SPINDLE GEAR ERROR!主轴档位错误(5)2017 GUIDEWAY LUBE LEVEL LOW!导轨润滑泵油位低!( 6) 2011 SPINDLE TOOL NOT CLAMP!主轴刀具未夹紧(4)1004 +Z-AXIS OVER HARD LIMIT !Z轴超正向限位(6)1005 +Z-AXIS OVER HARD LIMIT!Z轴超正向限位8) 2001 Y-AXIS NOT RETUR TO REFERENCE.Y轴未进行回参考点操作。

(9)2002 Z-AXIS NOT RETUR TO RETERENCE.Z轴未进行回参考点操作(10)2003 4-AXIS NOT RETURN TO RETERENCE.第四轴未进行回参考点操作。

(13)2013 SPINDLE GEAR NEITHER AT HIGH NOR AT LOW!主轴高低档未到位,或高低档位异常(14)SPINDLE GEAR CHANGE FAILURE!主轴换档失败原因:主轴在指令了换档后一定时间内未正确换至合适档位。

处理:检查换档机构或相关电路。

(16)2016 MACHINE DOOR LINCLOSED!机床安全门没有关好!原因:安全门开关没有闭合。

处理:重新关闭机床安全门。

并确认安全门开关信号是否正确。

(18)2019 SPINDLE GOOLINGPOWER OFF CHECK QM5!主轴冷却单元电源断开!原因:恒温油箱电源断开!,QM5跳闸!(19)2020 SPINDLE COOLING LWIT TROUBLE. (OIL THERMOSTAT, ALARM)恒温油箱故障!(20)2021 SERV0 POWER OFF CHECK QM3!伺服驱动电源断开!(21)2022 CHIP CONVYOR CHECK QM8!排削器电源断开,检查QM8! (22) 2023 HYDRAULIC PUMP POWER OFF CHECK QM9!液压泵电源断开!检查QM9.(23) 2024 HYDRAULIC PUMP PRESSURE ABNORMAL!液压泵压力异常!(24)2026 WOR KPIECE COOLING PUMP POWER OFF CHECK QM7冷却泵电源空气开关QM7断开(25)2027 GUIDEWAY LUBE PUMP POWER OFF CHECK FA14!润滑泵电源断开!检查保护开关FA14.(26) 2029 4TH –AXIS LIN CLAMPED! 第四轴未加紧!原因:检查第四轴未加紧或系统未检测到加紧开关信号。

一、红色警示灯警示:

HIGH ENGINE TEMPERATURE:发动机水温高(停车、息火、检查)LOW BREAK FLUID LEVEL:刹车油太少(到4S添加制动油)ENGINE SYSTEMS FAULT:发动机控制系统故障(停车、息火、4S)ACCELERATION REDUCED:加速减少(请4S检查)

SPEED LIMITED MODE:限速行驶模式(请4S检查)

DRIVER DOOR OPEN:左前门没关好

DRIVER'S REAR DOOR OPEN:左后门没关好

PASSENGER DOOR OPEN:右前门没关好

PASSENGER REAR DOOR OPEN:右后门没关好

BONNET OPEN:引擎盖没关好

BOOT OPEN:后背箱没关好

LOW OUTSIDE TEAMPERAYURE:车外温度太低(摄氏1度以下)

二、橘色警示灯警示:

LOW WASHER FLUID LEVEL:玻璃水快没了

POWER STEERING FAILURE:转向辅助故障(请4S检查)

LOW OUTSIDE TEAMPERAYURE:车外温度太低(摄氏4度一1度)

三、警示灯不警示的信息:

ODOMETER DATA ERROR:里程表数据不准(请4S检查)

FUEL COMPUTER DATA ERROR:燃油计算机数据错误(请4S检查)

四、警示声和低燃油灯警示:

LOW FUEL LEVEL:该加油了(80、40、20、0公里时)。

Alarm triggered 警告器已启动车辆警报触发,检查非法进入Alarm system service reqd 请检查报警系统联系长安福特授权经销商检查Overvoltag e Stop safely 电压过高,请安全停车供电系统故障,联系长安福特授权经销商检查Power system malfunction 供电系统故障Low battery 蓄电池电压低蓄电池电压低,联系长安福特授权经销商检查Driver door open 左前门未关驾驶侧车门开Driver side rear door open 左后门未关左后门开Passenger door open 右前门未关前乘客侧车门开Passenger side rear door open 右后门未关后乘客侧车门开Luggage comp. open 后备箱未关后备箱盖开Bonnet open 引擎盖未关引擎盖开启Immobilize r active 被动防盗系统启动发动机防盗锁定系统启动,检查钥匙Steering malfunction 转向系统故障联系长安福特授权经销商检查Key not detected 钥匙未检测到未识别有效被动钥匙Car operative Press STOP汽车运转中,请按停止键发动机仍在运转,关闭点火开关Key outside car 钥匙在车外车内未检测到有效被动钥匙Key battery low 钥匙电池电量低立即更换钥匙电池Steering locked -Retry 转向系统锁定,请重试按启动键Front lights malfunctio n 前大灯故障联系长安福特授权经销商检查Low beam:Bulb fault 近光灯故障检查近光灯灯泡Rear fog light :Bulb fault 后雾灯故障检查雾灯灯泡Stop lamps :Bulb fault 刹车灯故障检查刹车灯灯泡Engine malfunction 发动机故障联系长安福特授权经销商检查Check engine oil level 请检查机油油位发动机机油液位过低Water detected in fuel 燃油中有水燃油中有水Low washer fluid level 洗涤液液位低洗涤液液位过低Service oil 请保养机油需要更换发动机油Park brake malfunctio n 驻车制动故障联系长安福特授权经销商检Release park brake 请松开驻车制动释放驻车制动Re-Apply park brake 请重新启用驻车制动再次拉起驻车制动Park brake applied 驻车制动启动已经拉起驻车制动Park brake released 驻车制动释放驻车制动器已释放Park brake service reqd. 请保养驻车制动EPB 故障,联系长安福特授权经销商检查Power steering malfunctio n 动力转向系统故障联系长安福特授权经销商检查ESP off 电子稳定系统关稳定性控制关闭ESP malfunction 电子稳定系统故障。

SYS HOST COLD ST冷启动系统报警信息WARM ST热启动BATT FAIL电池电压低,应更换电池了RAM FAIL随机存储器数据读取故障ROM FAIL随机存储器数据读取故障RESET--------TOT RES累计总量重置规零TOT PART累计总量寄存器差异修正TOT CORR累计总量寄存器错误CONF CSUM校验和错误TOT ROLL OVR总量寄存器溢出(正向)TOT ROLL UDR总量寄存器溢出(反向)PRINTING ER打印错误COMMS TASK 01TX FAIL发送数据失败通讯RX FAIL接收数据失败CRC FAIL CRC 校验错误MONITOR软件看门狗时间溢出EXCEPTION从其他计算机收到错误信号LINK 1从机地址1错误LINK 2从机地址2错误LINK 3从机地址3错误LINK 4从机地址4错误LINK 5从机地址5错误LINK 6从机地址6错误LINK 7从机地址7错误LINK 8从机地址8错误LINK 9从机地址9错误LINK 10从机地址10错误CHROMAT LINK TX FAIL发送数据失败色谱通讯RX FAIL接收数据失败CRC FAIL CRC 校验错误MONITOR软件看门狗时间溢出EXCEPTION从其他计算机收到错误信号LINK 1从机地址1错误LINK 2从机地址2错误LINK 3从机地址3错误LINK 4从机地址4错误LINK 5从机地址5错误LINK 6从机地址6错误LINK 7从机地址7错误LINK 8从机地址8错误LINK 9从机地址9错误LINK 10从机地址10错误SLAVE LINK TX FAIL发送数据失败作从机通讯RX FAIL接收数据失败CRC FAIL CRC 校验错误MONITOR软件看门狗时间溢出EXCEPTION从其他计算机收到错误信号LINK 1从机地址1错误LINK 2从机地址2错误LINK 3从机地址3错误LINK 4从机地址4错误LINK 5从机地址5错误LINK 6从机地址6错误LINK 7从机地址7错误LINK 8从机地址8错误LINK 9从机地址9错误LINK 10从机地址10错误PRINTER CONF ERR配置错误或I/O板故障打印机ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误BKGND TASK CONF ERR配置错误或I/O板故障后台任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误DIO SCAN TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误DISPLAY TASK CONF ERR配置错误或I/O板故障显示任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误IO CONNS TASK CONF ERR组态错误IO通讯ZERO DIV零点误差TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误FAIL IO1IO 板1 通讯故障FAIL IO2IO 板2 通讯故障FAIL IO3IO 板3 通讯故障FAIL IO4IO 板4 通讯故障FAIL IO5IO 板5 通讯故障FAIL IO6IO 板6 通讯故障FAIL IO7IO 板7 通讯故障TSK ERR任务出错IO CONNS TASK CONF ERR配置错误或I/O板故障IO通讯ZERO DIV零除错误TSK OFLOW写保护NONITOR软件看门狗时间溢出CALC FAIL计算错误REPORTS TASK CONF ERR配置错误或I/O板故障报告AERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误TOTALS TASK CONF ERR配置错误或I/O板故障总量ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS CONPRESS TASK CONF ERR配置错误或I/O板故障气体压缩ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS CV TASK CONF ERR配置错误或I/O板故障气体热值ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS CORRECT TASK CONF ERR配置错误或I/O板故障气体修正ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS DP COND TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS DP INC TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS DP FLOW TASK CONF ERR配置错误或I/O板故障气体差压流量任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS PTZ TASK CONF ERR配置错误或I/O板故障气体PTZ计算ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS CHROMAT TASK CONF ERR配置错误或I/O板故障气相色谱仪ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS TURB INCTASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS DENS COPY TASK CONF ERR配置错误或I/O板故障气体密度拷贝ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ KF/MF TASK CONF ERR配置错误或I/O板故障液体 KF/MF 系数ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ M CORR TASK CONF ERR配置错误或I/O板故障液体M系数修正ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ LIQ CON TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ TURB TASK CONF ERR配置错误或I/O板故障液体涡轮ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ VOL CORR TASK CONF ERR配置错误或I/O板故障液体体积修正ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误PRV SEQ TASK CONF ERR配置错误或I/O板故障标定顺序ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误PRV BIDI TASK CONF ERR配置错误或I/O板故障双向标定ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误ULT CONTROL TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误ULT FLOWRATE TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误STN SUM FLOW TASK CONF ERR配置错误或I/O板故障总计流量ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误DENSITY TASK CONF ERR配置错误或I/O板故障密度ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误STR STATUS TASK CONF ERR配置错误或I/O板故障管线状态ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误FWA CALC TASK CONF ERR配置错误或I/O板故障正向计算ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误BVM TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误STN AVE TASK CONF ERR配置错误或I/O板故障平均值ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误DISCREP TASK CONF ERR配置错误或I/O板故障差异ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误CALC TASK CONF ERR配置错误或I/O板故障计算ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误PID CTL TASK CONF ERR配置错误或I/O板故障比例微分调节计算ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误ALM SUPPRESS TASK CONF ERR配置错误或I/O板故障警报抑制ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误BATCH/FSW TASK CONF ERR配置错误或I/O板故障批控ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误AGA8FULL TASK CONF ERR配置错误或I/O板故障AGA8全组分ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误CALIB TASK CONF ERR配置错误或I/O板故障标定任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误US LIQ TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误SAMPLER TASK CONF ERR配置错误或I/O板故障取样任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LOGICALC TASK CONF ERR配置错误或I/O板故障逻辑任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ COR IO TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ COR IF TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ COR FLOW TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误PRV CPRV TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误FAULT TASK CONF ERR配置错误或I/O板故障故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误FLOWTIME TASK CONF ERR配置错误或I/O板故障流量时间ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误SGERG TASK CONF ERR配置错误或I/O板故障SGERG计算ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误PRV MMPRV TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS GCFWA TASK CONF ERR配置错误或I/O板故障色谱正向任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误I/O01 ADC 01 (E.G. PRESSURE)LL低低位报警模拟输入通道1(如压力)L高位报警H低位报警HH高高位报警ROC变化率超限DSCRP当前值与前一数值差异过大DEV OPEN设配开U-RANGE欠量程O-RANGE超量程INTEG-FAIL铂电阻输入电流超限SCALING数值范围DEV ERR设备故障I/O01 ADC 02LL低低位报警模拟输入通道1L高位报警H低位报警HH高高位报警ROC变化率超限DSCRP当前值与前一数值差异过大DEV OPEN IO板通讯故障U-RANGE欠量程O-RANGE超量程INTEG-FAIL铂电阻输入电流超限SCALING数值范围DEV ERR设备故障I/O01 DAC 01U-RANGE欠量程数字量输入通道1O-RANGE超量程SCALING数值范围DEV ERR设备故障I/O01 DAC 02U-RANGE欠量程数字量输入通道2O-RANGE超量程SCALING数值范围DEV ERR设备故障I/O01 FREQ 01LOW PRD测量周期小于低限频率输入通道1HIGH PRD测量周期超过高限DEV-OPEN IO板通讯故障DEV-ERR设备故障I/O01 PID 01CONF ERR配置错误或I/O板故障比例积分微分控制输入通道1DEV ERR设备故障I/O01 PRT 01LL低低位报警铂电阻温度计输入通道1L高位报警H低位报警HH高高位报警ROC变化率超限DSCRP当前值与前一数值差异过大DEV OPEN IO板通讯故障U-RANGE欠量程O-RANGE超量程INTEG-FAIL铂电阻电流输入超限SCALING数值范围DEV ERR设备故障I/O01 PIP 01A-FAIL A脉冲故障脉冲输入通道1B-FAIL B脉冲故障O-FLOW过流量BAD PULSE失效的脉冲DEV ERR设备故障I/O01 POP 01OVERFLOW过流量脉冲输出通道1DEV ERR设备故障I/O01 STATUS RAM FAIL随机存储器故障IO板通道状态ROM FAIL只读存储器故障PIC FAIL IO板硬件故障TPU FAIL IO板硬件故障EEPROM FIAL可擦写存储器故障TASK ERR任务出错CONF ERR组态错误TASK FAIL IO板故障WARM ST冷启动DEV ERR设备故障STR01 DP STACK CALC CONF ERR配置错误或I/O板故障管线1差压计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 DOWN/UP CALC CONF ERR配置错误或I/O板故障管线1下/上计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01GAS INC CALC CONF ERR配置错误或I/O板故障I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 PIPE COR CALC CONF ERR配置错误或I/O板故障管线1管路修正系数计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 STATUS CALC CONF ERR配置错误或I/O板故障管线1状态计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 LFC CALC CONF ERR配置错误或I/O板故障I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 MAINT CALC CONF ERR配置错误或I/O板故障管线1主计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 CHROM.P CALC CONF ERR配置错误或I/O板故障I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 CHROM.S CALC CONF ERR配置错误或I/O板故障I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 CHROM.T CALC CONF ERR配置错误或I/O板故障I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 I/L VLV CALC CONF ERR配置错误或I/O板故障管线1入口阀门计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 O/L VLV CALC CONF ERR配置错误或I/O板故障管线1出口阀门计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 AGA8 CALC CONF ERR配置错误或I/O板故障管线1AGA8计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 ISO5167 CALC CONF ERR配置错误或I/O板故障管线1ISO5167计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 ISO6976 CALC CONF ERR配置错误或I/O板故障管线1ISO6976计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 TFWA FWD CALC CONF ERR配置错误或I/O板故障管线1TFWA正向计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 TFWA REV CALA CONF ERR配置错误或I/O板故障管线1TFWA反向计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 MASS FR LL低低位报警管线1瞬时质量流量L低位报警H高位报警HH高高位报警STR01 UVOL FR LL低低位报警管线1瞬时工况体积流量L低位报警H高位报警HH高高位报警STR01 CVOL FR LL低低位报警管线1瞬时标况体积流量L低位报警H高位报警HH高高位报警STR01 ENGY FR LL低低位报警管线1瞬时能量流量L低位报警H高位报警HH高高位报警STR01 UPSTR DENS LL低低位报警管线1上游管线密度L低位报警H高位报警HH高高位报警STR01 DWNSTR PRESS LL低低位报警管线1下游管线压力L低位报警H高位报警HH高高位报警STR01 RECOVD PRESS LL低低位报警管线1恢复压力L低位报警H高位报警HH高高位报警STR01 UPSTR TEMP LL低低位报警管线1上游管线温度L低位报警H高位报警HH高高位报警STR01 STD DENS LL低低位报警管线1标准密度L低位报警H高位报警HH高高位报警STR01 DWNSTR DENS LL低低位报警管线1下游管线密度L低位报警H高位报警HH高高位报警STR01 UPSTR PRESS LL低低位报警管线1上游管线压力L低位报警H高位报警HH高高位报警STR01 DWNSTR TEMP LL低低位报警管线1下游管线温度L低位报警H高位报警HH高高位报警STR01 REAL RDENS LL低低位报警管线1真实密度L低位报警H高位报警HH高高位报警ROC变化率超限DSCRP与前一数值差异过大FAIL A A通道开路或短路FAIL B B通道开路或短路STR01 PRESS LOSS LL低低位报警管线1压损L低位报警H高位报警HH高高位报警STR01 CORR PIPE DIAM LL低低位报警管线1管径修正L低位报警H高位报警HH高高位报警STR01 CORR ORIF DIAM LL低低位报警管线1孔板直径修正L低位报警H高位报警HH高高位报警STR01 UPSTR COMPRESS LL低低位报警管线1上游管线压缩系数L低位报警H高位报警HH高高位报警STR01 STD COMPRESS LL低低位报警管线1标准压缩系数L低位报警H高位报警HH高高位报警STR01 MOL WEIGHT LL低低位报警管线1摩尔权重系数L低位报警H高位报警HH高高位报警STR01 COMPONENT TOT LL低低位报警管线1组分摩尔总量L低位报警HH高高位报警STR01 NORMAL LL低低位报警L低位报警H高位报警HH高高位报警STR01 BETA LL低低位报警管线1BETA系数L低位报警H高位报警HH高高位报警STR01 REYNOLDS NO LL低低位报警管线1雷诺数L低位报警H高位报警HH高高位报警STR01 EXP FACTOR LL低低位报警管线1指数因子L低位报警H高位报警HH高高位报警STR01 DISCH COEFF LL低低位报警L低位报警H高位报警HH高高位报警STR01 FLOW COEFF LL低低位报警管线1流量系数L低位报警H高位报警HH高高位报警STR01 VEL OF APP FAC LL低低位报警L低位报警H高位报警HH高高位报警STR01 IDEAL RDENS LL低低位报警L低位报警H高位报警HH高高位报警STR01 IDEAL DENS LL低低位报警管线1理想密度L低位报警H高位报警HH高高位报警STR01 IDEAL CV LL低低位报警管线1理想热值L低位报警H高位报警HH高高位报警STR01 REAL CV LL低低位报警管线1真实热值L低位报警H高位报警HH高高位报警STR01 PID PV COEFF LL低低位报警管线1比例微分调解系数L低位报警H高位报警HH高高位报警STR01 BASE COMPRESS LL低低位报警管线1基本压缩系数L低位报警H高位报警HH高高位报警STR01 THERMAL EXP FAC LL低低位报警管线1L低位报警HH高高位报警STR01 INLET VLV ILLEGAL不合理的操作位置或指令管线1入口阀门SEAL FAIL密封失效MOVE FAIL阀门动作没有到位MOVE UNCM无指令动作UNAVAIL无效的操作STR01 OUTLET VLV ILLEGAL不合理的操作位置或指令管线1出口阀门SEAL FAIL密封失效MOVE FAIL阀门动作没有到位MOVE UNCM无指令动作UNAVAIL无效的操作STR01 MOLE SELECT K_COMP键盘模式管线1气体摩尔量方式选择ADDNLS色谱模式SPLITS分离模式DL COMP下载气体组分模式USER COMP用户模式STR01 CHROM TELEM RX FAIL接收数据失败管线 1色谱通信CONFIG配置错误CRITICAL临界NCRITICAL非临界MOLE LO摩尔量低MOLE HI摩尔量高MOLE DV摩尔量有误差REP TOUT通讯失败STR01 DP CELL LL低低位报警管线1压差单元L低位报警H高位报警HH高高位报警WARNING警告SELECT选择错误DISCREP有差异的DENIED否定的COMMON普通报警。

发那科报警信息中英文对照表T WORD ERROR (T 码错误)LOW OIL LEVEL (油位低)SPINPLE FAULT (主轴故障)SPINDLE ALARM (主轴报警)EXTERNAL EMG STOP (急停按钮被按下)AC NOT READY (交流盘未准备好)SPINPLE LUBE FAULT (主轴润滑故障)T CODE ERROR (T代码出错,非法T代码)M CODE ERROR (M代码出错,非法M代码)SERVO NOT READY (伺服未准备好)NC NOT READY(NC没准备好)TURRET FAULT (转塔故障)TURRET LIMIT (转塔限位)DC 24V OPEN (直流24断开)+24V NOT READY(+24V没准备好)GRAR DRIFT (档位漂移)PLEASE AXIS RETURN HOME(轴未回零)PLEASE DRUM RETURN HOME(刀库未回零)AIRPRESSFAILURE(气压故障)UNCL TOOL FALL(松刀失败)AIR PRESSURE DROP (压缩空气压力过低)CLAMP TOOL FALL(夹刀失败)DRUM NOT PARKED(刀库未在原值)X ZERO POINT NOT REACHED (X 轴未回零)Y ZERO POINT NOT REACHED (Y 轴未回零)Z ZERO POINT NOT REACHED (Z 轴未回零)4TH ZERO POINT NOT REACHED (第4轴未回零)X AXIS OVERTRAVL(X轴超限)Y AXIS OVERTRAVL (Y轴超限)Z AXIS OVERTRAVL (Z轴超限)COUNTER SWITCH REEOR (计数开关故障)MASTERT RANSFER OVER TEMP (主变压器过热)Z AXIS NOT AT FIRST REF POSITION (Z轴未在第一参考点)SPINDLE ORIENTATION FALLURE (主轴定向失败)TOOL DESENT OR TOOL DATA REEOR (刀具数据错误)PLEASE UNLOAD THE TOOL ON SPRINELK (请卸下主轴上的刀)PLEASE LOAD TOOL ON APINDLE (请装上主轴上的刀)A AXIS UNCLAMP FAIL (A 轴松开失败)A AXIS CLAMP FAIL (A 轴夹紧失败)DRUM OUT TO APRONDLEIS FALL (刀库摆向换刀位失败)MG SWING OVERLOAD(刀库摆动过载)DRUM BACK PARK IS FALL (刀库摆回原始位失败)TURRENT MOTOR1 OVERLOAD (刀库移动电机过载)COOLANT MOTOR OVERLOAD (冷却泵过载)DRUM ATC FAULT (自动换刀失败)TOOLS UNLOCKED (刀具未锁紧)BATTERY ALARM (电池报警)DRUM POSITION SWITCH ERROR (刀库位置检测开关故障)DRUM NOW NOT AT PARK (刀库未在原始位置)IT DANGOU TO MOVE DRUM (刀库禁动)POT UO FAILOR POT NOT AT UP POSITION (刀套未在水平位)POT DOWN FAIL (刀套翻下动作失败)IT IS DANGOUR TO MOVE ARM (机械手禁动)THE SPINDLE STATU IS ERROR (主轴状态错误)ARM MOTOR OR ARM SWITCH FALL (机械手或机械手开关故障)CENTRE LUBRICATION FALL (中心润滑故障)THE WORK NOT CLAMPED (工件未夹紧)AUTO TOOL CHANGE FAULT (自动换刀失败)TOOL DATA OUT OF RANGE (指令刀具号超出范围)THE ORDER TOOL NOW IN SPINDLE (目标刀具在主轴上)THE THREE SPINDLE SWITCH FAULT (主轴上的接近开关)THE CENTRE COOLANT IS LOWER (刀具内冷泵液位过低)DRUM RETURN 1# POSITION FAULT (刀库自动回零失败)SPINDLE OVERLOAD (主轴过载)TURRENT MOTOR OVERLOAD (刀盘转动电机过载)CHIP CONVEYER OVERLOAD (拉屑器过载)HARD LIMIT OR SERVO ALARM (硬限位或伺服报警)NO LUB OIL (无润滑油)INDEX HEAD UNLOCKED (分度头未锁紧)MT NOT READY(机床没准备好)MG OVERLOAD (刀库过载)LUB EMPTY(润滑无油)AIR PRESSURE(气压不足)COOLANT NOT READY(冷却没准备好)LUBE EMPTY(油雾油位低,润滑油位低)LUB PRESSURE LOW(润滑压力低)CONVEY VERLOAD(排屑过载)LUB OVERLOAD(润滑过载)LUBE PRESSURE LOW(油雾压力低)SERIAL SPINDLE ALARM (串行主轴报警)NC BATTERY LOW ALARM(NC电池低报警)MAGAZINE MOVE LIMIT SWITCH ERROR(刀库移动限位开关故障)SPINDLE TOOL UNLAMP POSITION LIMIT SWITCH ERROR(主轴刀具UNLAMP位置限位开关故障)MAGAZINE NOT IN POSITION OR SENSOR ERROR(刀库不在位或传感器错误)AIR PRESSURE LOW ALARM(气压低报警)MOTOR OVERLOAD(电机过载)T CODE > MAGAZINE TOOLST CODE < 1 ERROR5TH AXIS HARDWARE OVERTRAVER LIMIT ERRORDOOR IS OPENED(开门)LUB PRESSURE SWITCH ERROR(油压开关错误)SPINDLE OIL COOLANT UNIT ERRORSPINDLE LOAD ABNORMAL(主轴负荷异常)TRANSDUCER ALARM(传感器报警)BED-HEAD LUBRICATE OFF(床头润滑关闭)EMG OFFHYDRAULIC CHUCK PRESS LOW(液压夹头压力低)HYDRAULIC TAIL PRESS LOW(液压尾座压力低)LUB 0IL LOW(油压低)TURRET CODE ERROR(转塔码错误)TURRET RUN OVERTIME(转塔运行超时)MANUAL HANDLE INTERRUPTTRY TO RUN SPINDLE WHILE CHUCK NOT LOCKTRY TO RUN SPINDLE WHILE TAIL NOT LOCKSPINDLE NEUTRAL GEARMAGAZINE ADJUSTHYDRAULIC NOT RUNSAFETY DOOR BE OPENEDSAFETY DOOR NOT CLOSENOT ALL AXIS HAVE GONE BACK REFIN ADJUST,IGNORE GOING BACK REFAFTER EXCHANGE TOOL,CYCLE STARTATC MOTOR QF16 OFFX AXIS IS LOCKED(X 轴被锁定)Y AXIS IS LOCKED(Y 轴被锁定)Z AXIS IS LOCKED(Z 轴被锁定)A AXIS IS LOCKED(A 轴被锁定)SPINDLE MOTOR FAN QF26 OFF(主轴电机风扇QF26关闭) SPINDLE ORIENTATION INCOMPLETE(主轴定位不完全)M FUNCTION NOT COMPLETE(M 功能无法完成)SPINDLE NOT IN GEAR POSITION(齿轮不在主轴位置)SPINDLE NOT CHANGED TO LOW GEAR(主轴没有变为低档)SPINDLE NOT CHANGED TO HIGH GRAR(主轴没有变为高档)MAG NOT BACKWARDSPINDLE TOOL NOT CLAMPSPINDLE TOOL NOT UNCLAMPMAG NOT IN POSITIONMAG DOES NOT ROTATEMAG DOES NOT STOP RUNNINGA AXIS HAVE NOT CLAMPEDA AXIS HAVE NOT UNCLAMPEDSET D499=1,"MAG.JOG" SWITCH ONHYDRAULIC MOTOR QF7 OFF(液压马达QF7关闭)HYDRAULIC TEMPRETURE HIGH(液压使用温度高)HYDRAULIC FILTER BLOCKED(液压过滤器阻止)HYDRAULIC OIL LEVEL LOW(液压油位低)HYDRAULIC FAN QF8 OFF(液压风扇QF8关闭)HELIX CONYER QF9 OR QF10 OFFCHAIN CONYER QF11 OFFCOOLANT MOTOR QF12 OFF(冷却液电机QF12关闭)COOLNT LEVEL LOW,CYCLE STOP AFTER 20 MINUTESINNER COOLANT BLOCK(内冷却堵塞)SPINDLE COOLANT MOTOR QF14 OFF(主轴冷却液电机QF14关闭)INNER COOLANT QF13 OFF(内冷却液QF13关闭)MAG MOTOR QF15 OFFCABINET COOLANT EQUIP QF20 OFFOIL GATHER QF24 OFFAIR PRESSURE LOW(低气压)SPINDLE COOLANT MOTOR FAULT(主轴冷却液电机故障)LUB.OIL IS LOW(润滑油低)DOOR OPEN(门打开)FRONT DOOR(R) OPEN(前门打开)LEFT DOOR OPEN(左门打开)LUBRICATION OIL QF23 OFF(润滑油QF23关闭)LUBRICATION PRESS LOW(润滑油位低)IN ADJUST,MAG CAN'T EXCHANGE T(在调整,刀库不能交换T)NOT ALL DOOR CLOSED(门没有全部关闭)IN M06,MAG NOT READY(在M06,刀库未准备好)MAGAZINE NOT READY(刀库未准备好)POCKET NOT HORIZANTALIN M06,Z NOT BACK TO 2ND REFIN M06,Z AXIS NOT IN PSW1ATC NOT IN ZERO POSITIONSPINDLE ORIENTATION UNCOMPLETEPOCKET NOT HOR./MAG NOT BCKWRDPOCKET NOT VER./MAG NOT FORWRDUNCLAMP TOOL HAS NOT COMPLETEDCLAMP TOOL HAS NOT COMPLETEDAIM TOOL NO. IS WRONGMAG NOT BACKWARDAFTER RETRACT,SET R.T.BACK OFFZ NOT IN PSW2,FORBID ATC RUNNINGD499 EQUAL 1MAG.JOG SOFT SWITCH IS ONZ NOT IN PSW2,FORBID MAG FORWARDCHEKE SPINDLE MODULE ALARMOIL WATER SEPARATOR QF24 OFFSET THE SOFT SWITCH MAG.JOG OFFSET D499 TO 0 设定D499为0K PARAM ABOUT MAG SET IS WRONG 关于MAG的K参数设定错误MECHANICAL BRAKE NOT RELEASED机床抱闸没有松开MECHANICAL BRAKE IS WRONG 机床抱闸错误PLEASE ADD LUB.OIL 请加润滑油PROBE BATTERY VOLTAGE IS LOW 探头电池电压低PROBE IS ERR 探头错误PARAMETER WRITE ENABLE(参数写使能)PMC EDIT ENABLE(PMC编辑使能)CHECK LUB ROUTINSPINDLE GEAR SIGNAL MISS 主轴档位信号消失T_CLAMPED_SIGNAL MISS T夹紧信号消失SP OVERRIDE SWITCH DISCONNECTION 主轴倍率开关断路FEED OVERRIDE SWITCH DISCONNECTION 进给倍率开关断路THE TOTAL NUMBER OF POCKETS SET ERRCHANGE T STOPED BECAUSE NO AIR 因为缺少压空交换停止THE COOLANT WATER TOO LOW,ADD COOLANT WATER AT ONCE 冷却水少立即加水COOLANT LEVEL LOW,ADD COOLANT WATER 冷却水液位低PLEASE REPLACE CNC BATTERY QUICKLY 请立即更换CNC电池。