可解脱FPSO的系泊系统解脱过程动态模拟与优化

- 格式:pdf

- 大小:276.53 KB

- 文档页数:7

FPSO单点系泊系统的管道系统设计与优化随着全球石油勘探活动的增加,FPSO(浮式生产储油船)作为一种灵活、可移动的海上石油生产设备,越来越受到能源公司的青睐。

FPSO单点系泊系统在FPSO设计中起着关键的作用,它不仅需要保证石油和天然气的生产和储存,还需要确保安全可靠的管道系统设计和优化。

FPSO单点系泊系统的管道系统设计关乎着整个生产过程的安全性和高效性。

在设计过程中,需要考虑以下几个方面:1.管道布局与连接:在FPSO单点系泊系统中,管道布局应根据生产平台的结构、设备布置和工艺流程进行合理规划。

优化的管道系统应确保管道的短距离和低阻力,以减少流体运输过程中的能源损失。

此外,管道连接必须可靠,以确保管道系统的完整和安全性。

2.材料选择与管道尺寸:在FPSO单点系泊系统的管道系统设计中,材料的选择对管道的耐腐蚀性、强度和可靠性至关重要。

根据输送介质的特性,选择合适的材料,如碳钢、不锈钢等。

此外,管道尺寸的合理选择也是优化设计的关键,既要满足预定流量要求,又要考虑安装和维护的便利性。

3.流体力学分析与压力控制:在FPSO单点系泊系统的管道系统优化中,流体力学分析是至关重要的。

通过对流体的流动速度、压降和阻力等参数进行分析,可以优化管道系统的设计,减少能源损失。

此外,压力控制是保证管道系统安全运行的关键。

合理设置安全阀和泄压装置,控制系统的压力在安全范围内。

4.维护与监测:在FPSO单点系泊系统的管道系统设计中,维护和监测是不可忽视的方面。

合理设置检修设备和仪表,确保管道系统的可靠性和操作便利性。

定期进行巡检和维护,及时发现和解决管道的泄漏、腐蚀等问题,确保FPSO单点系泊系统的长期安全运行。

综上所述,FPSO单点系泊系统的管道系统设计与优化是确保FPSO安全、高效生产的重要环节。

通过合理的管道布局与连接、材料选择与管道尺寸、流体力学分析与压力控制以及维护与监测等措施,可以达到优化管道系统设计、提高生产效率和保证安全运行的目标。

J. Marine. Sci. Appl. (2009) 8: 93-98DOI: 10.1007/s11804-009-8111-3Permanent versus disconnectable FPSOsLUO Yong* and WANG Hong-weiDeepwater Engineering Research Center, Harbin Engineering University, Harbin 150001, China Abstract:Floating production storage and offloading (FPSO) vessels offer a cost-effective field development solution, especially in deepwater areas lacking an adequate pipeline network. Most FPSOs are permanently moored, i.e. the complete system is designed to withstand any kind of extreme environment at the field location. FPSOs that can be quickly disconnected from their moorings and risers have also been designed and deployed. The key feature of this type of disconnectable FPSO is that it can be disconnect and so avoid dangerous environmental conditions such as icebergs, hurricanes in the Gulf of Mexicoand typhoons in the South China Sea. In this paper, the concept of disconnectable FPSOs for deepwater field development is presented. Key technologies and their engineering analyses are highlighted. The merits and demerits of disconnectable vs permanent FPSOs are then evaluated. The paper concludes that both permanent and disconnectable FPSOs are versatile floating systems and their selection depends on safety, technological, cost and operational considerations.Keywords: disconnectable FPSO; permanent FPSO; deepwater; mooring systemCLC number: U674.38 Document code: A Article ID: 1671-9433(2009)02-0093-061 IntroductionFrom its hum ble beginning as a mobile well testing/production unit, the FPSO has evolved to dominate today’s floating production systems (FPS) landscape. There are over 100 FPSOs in service in almost every major oil-producing region in the world, exceeding the total number of all other floating production systems combined.Over the years, the FPSO[1]has proven itself as a versatile production system. The FPSOs currently in operation cover a wide arrange of environment conditions, vessel sizes, production rates, operating water depths and number of risersFPSOs have been deployed in benign environment such as Offshore West of Africa[2]and in extreme hostile environment such as North Atlantic Margin; FPSOs operate in water depths ranging from 20 meters (Chang Qing Hao) in South China Sea to 1 853 meters (Seillean) Offshore Brazil. The vessel size varies with storage capacities ranging from a mere 50 000 bbl to 2 000 000 bbl (barrel). The maximum production rates range from 11 000 bbl/d to 200 000 bbl/d (barrel/day).Studies have shown that the FPSO has cost advantages over other floating production systems for a wide range of water depths. The majorities of the FPSOsdeployed worldwide are permanently moored, i.e. the FPSOs with their moorings and riser systems are capable of withstanding the extreme storms at the field location. On the other hand, the disconnectable FPSOs have attracted more attention recently. The damage to the offshore units and pipeline systems caused by hurricanes Ivan, Katrina, and Rita in the year 2005, plus the continuingexploration success in the ultra deep water beyond the continental shelf, are two of the main drivers.2 Why disconnectableThere are a number of drivers for a disconnectable FPSO[3].1) Environmental and regulatory requirements.Sometimes the regulatory body determines the FPSO has to be disconnectable. A typicalexample is for application in the US GOM. There are hundreds of offshore platforms in the vicinity and in case of hurricane, a drifting platform can potentially clash with the FPSO that has a large amount of crude storage.2) Special design constraints.A number of disconnectable FPSOs have been deployed in east coast of offshore Canada. The main drive is to avoid large icebergs. The only measure to survive an iceberg impact is to disconnect the FPSO and sail away. Also for a location with extremely severe storms that prohibit the safe design of mooring systems.3) Cost trade off.Sometimes, the disconnectable FPSO allows the reduction of the size/cost of moorings and risers because they only need to be designed against a less severe storm.4) Operating considerations.Due to operating consideration for example, if the FPSO is for early production/well tests, it is required to be highly mobile. When the early production is on-going, the permanent FPSO is being built. The temporary FPSO can disconnect to move to another location and the permanent FPSO can be connected to continue production.3 Disconnectable FPSOThe disconnectable FPSO is typically turret moored and the disconnection of the FPSO with its moorings and risers is achieved through the specially designed disconnectable turret.The primary function of the turret is to allow the FPSO to weather-vane without disrupting the transfer of production fluid between the FPSO and subsea wells. Turret types may be external or internal. External turrets are typically cantilevered off the bow or stern of the vessel. Internal turrets penetrate the body of the vessel between the bow and midship. For the deepwater application, this is considered to be the most suitable option as it integrates with the hull structure and capable of supporting large vertical mooring and riser loads.Disconnectable turret is designed for FPSO to be able to disconnect to avoid certain extreme environments. The lower part of the turret (lower turret buoy) whichconnects the mooring lines and risers can be disconnected to allow the FPSO to sail away prior to the approaching of the storm, see Fig.3. After disconnection, the lower turret with anchoring legs and riser terminations sinks to 50~100m below the water surface and thus clears off the wave zone. When the extreme environment passes, the FPSO can come back and pick the submerged mooring/riser buoy to get it reconnected.There are a number of diconnectable turret designs. Two commonly used types are BTM for internal turret type and RTM for external turret type as illustrated by Fig.4.The general procedures to connect and disconnect an FPSO are as follows:1) Turret buoy disconnection procedure:Start marine systems;Stop production;Prepare risers for disconnection;Disconnect risers;Lower risers onto the buoy;Disconnect structural connector;Drop the low turret mooring buoy below surface;Sail away;Approximate time: 18 hours.2) Turret buoy reconnection procedure:Position FPSO in reconnection watch circle;Retrieve hook-up line to pick reconnection chain;Engage chain jack.Lift mooring buoy into the turret (rotate turret for correctorientation):Engage structural connector;Retrieve risers from buoy;Connect risers;Approximate time: 24 hours.The disconnectable FPSO offers the following attractivefeatures.1) The environmental hazard is minimized because theplatform with crude storage can be disconnected and goto shielded area in the event of severe storm.2) The lower turret with moorings and riser connectionsgoes below the wave zone and is not significantlyimpacted by the storm.3) The mooring system (and its associated turretcomponents) can be of smaller size as it only needs to bedesigned against the less severe storm when the FPSOstay connected.4) It safeguards against platform damage and liability tothe operator in the storm event.4 Key technologiesIf we compare the disconnectable FPSO with conventional permanently moored FPSO, it is not difficult to notice that the FPSO hull and topsides are identical among the two. The key technologies therefore reside with the turret, moorings and risers.1) Turret.Turret itself is the key technology of an FPSO. It allows the FPSO to weather vane and in this case, it allows the FPSO to disconnect with its moorings and risers via a disconnectable low turret buoy.Prior to the disconnection of the lower turret buoy, the risers are to be disconnected first. They can be done through the quick disconnectable valves (QC/DC valves)or manual valves. The QC/DC valves allow the disconnection to realize in a short time span, while the manual valves takes much more time to operate, see Fig.6.Disconnection of the lower turret buoy is achieved through a specially designed structural connector, see Fig.7. The key feature is that the connector can be hydraulically actuated under large loads.2) State of the art mooring design.In a disconnectable FPSO, the mooring (and the riser) system is specially designed and fine tuned by many iteration procedures. The main consideration is that as the lower turret buoy is disconnected, it submerges under the vertical load of the moorings and risers to a depth where the equilibrium of buoy buoyancy and mooring riser vertical load is reached. This equilibrium depth is well controlled to be around 50 m to 100 m below the surface. If it’s too close to the surface, the buoy can be impacted by the surface waves, and if it’s too deep, the structuraldesign of the buoy is a challenge, see Fig.8.3) Lower turret buoy design.The design of the lower turret buoy is also challenging. In deep water, the vertical loads of the moorings and risers are very large and in order to support the large vertical load in the disconnected status, the net buoyancy of the buoy can also be large. A large buoy faces many problems of handling and also during the re-connection stage, large re-connection load can be expected. During the design, it is very important to minimize the buoy size/weight and to optimize its shape to minimize the hydrodynamic dragand added mass.4) Riser design.The riser system probably represents the most challenging task to any deepwater FPSO design. Flexible risers have been installed successfully in deepwater fields inoffshore Brazil. However, as the water depth increases, the availableriser diameters for non-banded flexible risers reduce significantly and as a result, more risers are required to fulfill the same production function.Steel catenary risers (SCRs)[4]would be the preferred deep water riser solution due to its high resistance to hydrostatic load and relatively low cost. However, FPSOs will experience large motion responses under the wave environment. The large motion can cause excessive fatigue damage that could make the free hanging simple SCR concept not feasible.For disconnectable FPSO, the riser design has special constraints as it has to copewith both connected and disconnected status. Plus it is vital to reduce the riser vertical load acting on the lower turret buoy. SLOR type of riser design has been proposed to achieve the riser stability and to reduce the vertical load on the lowerturret buoy, see Fig.9.5 Engineering analysis and designThe engineering analysis of a disconnectable FPSO is much more challenging than that of a permanently moored FPSO.1) Mooring design.The mooring system design has to consider both the connected mode and disconnected mode. Especially, the mooring system is fine tuned to control the dropped depth of the lower turret buoy. In both cases, the designer has to watch for the change of mooring profile and possible touching of seabed by wire rope or polyester deployed.2) Disconnection analysis.In the disconnection analysis, engineering analysis is to be conducted to simulate the dropping trajectory of the lower turret buoy to make sure there is no clash between the moving FPSO and the dropping buoy.3) Disconnected analysis.When the lower turret buoyis disconnected from the FPSO, it will submerge below the wave zone. However, the complete system still subject to current load and engineering analysis is to be conducted to make sure it’s hydr ostatically and hydrodynamically stable.4) Re-connection analysis.Re-connection analysis is usually conducted to confirm that the reconnection process is feasible. When the lower turret buoy is pulled into the vessel moonpool and close to the FPSO keel, there are significant hydrodynamic interactions between the tow bodies and the pulling tension can be very high. Advanced engineering analysis would be required to optimize the re-connection process.6 Comparisons of disconnectable and permanently moored FPSOsThe comparisons of disconnectable and permanent FPSOs should be conducted from safety, cost and operation viewpoints.1) SafetyThe disconnectable FPSO is widely perceived to have a better safety standard. The main reason is that the FPSO can effectively avoid the storm by disconnecting from its moorings and risers. The onboard crude storage is moved offsite away from the extreme environment.In addition, the disconnected mooring lines and risers stay with the lower turret buoy which submerges below the wave zone (50~100 m below the surface), so the completesystem is very stable.In the environment that subjects to icebergs, this is probably the only solution to survival.2) CostsIn terms of cost, the turret system of a disconnectable FPSO is quite more complex than that of a permanent FPSO. The riser disconnectable valves and the main structural connector are all costly items. The lower turret buoy is also heavier because it’s designed to withstand high hydrostatic pressure during the disco nnected submerged mode. In addition, the installation procedures are more complex and more onboard equipment would be required for the disconnectable system.The cost of a disconnectable turret can easily double that of a non-disconnectable turret.On the other hand, the mooring system of a disconnectable FPSO can reduce in size substantially depending on the disconnection environment. For example, the mooring system of a permanent FPSO has to be designed against the 100 year hurricane environment in the GOM which has a significant wave height of 14 m while the counterpart moorings of a disconnectable FPSO only need to be designed against the 100 year return wind storm which has a significant wave height of 8 m. The mooring system weight and cost of the disconnectable system is probable less than half of the permanent system.Even though it’s a trade off between the turret cost and mooring cost, it is expected that the overall cost of a disconnectable system will still be higher.3) OperationsIn general, operating a disconnectable FPSO is more challenging than that of a permanent FPSO. The connection and disconnection mechanical components are to be maintained on regular basis, and when it comes to disconnection, extra care should be exercised to avoid damaging any components.Adjustments of installed mooring lines and risers are much more difficult as they are only connected to the lower turret buoy. This in many cases prevents the use of polyester mooring lines in a disconnected system because polyester lines need regular maintenance due to mooring line creep.4) Green waterThere is another aspect of the FPSO operation in which the disconnectable system has an advantage. For green water effect, the disconnectable FPSO only experiences smaller design environment when the FPSO is connected. For extreme tropical storms, the FPSO is disconnected and away from the storm location. A permanent FPSO has to withstand the extreme storm and experience the worst green water impact. A study has shown that even though the mooring system is capable of withstand the storm impact, the tropical storm such as the hurricane in the GOM can quickly change the wind direction in its eye. As the change of wave direction takes much longer time, the FPSO maypotentially weather vane to the direction of the changing wind and expose the beam to waves. In such a case, the green water impact is much more significant and the topsides foundation should be reinforced to survive such an impact.7 Concluding remarksThe present presentation outlines the disconnectable FPSO concept. The design features of the disconnectable turret are highlighted and the study concludes that the large size disconnectable FPSO can be successfully developed for applicationin deepwater areas that are subject to severe storms. The system saves mooring cost and enhances the safety features of the floating structure.With a complex turret system and operation wise, the disconnectable FPSO is more challenging. The overall cost of a disconnectable FPSO is also expected to be higher.Both permanent and disconnected FPSOs are versatile floating system concepts that have been deployed in many deepwater areas worldwide. The selection of thesystem depends on technology, safety, regulatory, cost and operation considerations.References[1] LUO Y, SCHUURMANS S. FPSOs for deepwater Gulf of Mexico applications[C]// Deep Offshore Technology Conference. New Orleans, 2002.[2] ZHONG Z, LUO Y, CURIC D.FPSO global responses in the west of Africa squall environment[C]// Proceedings of OMAE. Halkidiki, 2005: OMAE2005-67066.[3] LUO Y, SCHUURMANS S.Disconnectable FPSO for deepwater fields in the Gulf of Mexico[C]// Deep Offshore Technology Conference. Houston, 2006.[4] ALLIOT V, LEGRAS J L, PERINET D. A comparison between steel catenary riser and hybrid riser towers for deepwater field developments[C]// Deep Offshore Technology Conference. New Orleans, 2004.永久式与可解脱式 FPSO罗勇,王宏伟(哈尔滨工程大学深海工程技术研究中心,黑龙江哈尔滨 150001)摘要:浮式生产储卸油系统(FPSO)是一种经济有效的浮式平台方案,特别是在缺乏足够的输油管道系统的深海领域. 大多数FPSO是永久系泊的,即整个系统能够抵抗工作海域内的各种极值环境条件. 目前,能够将FPSO与其系泊及立管系统快速解脱的装置已经设计并发展了. 可解脱式FPSO的主要特点是可解脱性,并能避免一定的环境条件,如冰山,美国摩西哥湾的飓风,中国南海的台风. 本文将针对深水海域可解脱式FPSO,提出其主要技术和工程分析与设计思路,评估可解脱式FPSO与永久式FPSO的优缺点,等等. 可见可解脱FPSO与永久式FPSO都是十分有效的浮式系统,并根据平台设计的安全性、技术、成本和运行要求,来决定选择何种系泊方式.关键词:可解脱式 FPSO;永久式 FPSO;深海;系泊系统可解脱式中图分类号:U674.38 文献标识码: A 文章编号: 1671-9433(2009)02-0093-061.介绍从作为一个移动测试/生产单位的开始,FPSOs已经进化成主导当代浮式生产系统。

油田范围内水深20—24.5mCFD-11油田由中国海洋石油总公司、科麦棋公司和Oltro peotrolum公司合作开发,柯麦棋担任作业者,渤海公司作为承包商,为作业者提供海洋石油112号FPSO及人员服务。

油田开发采用分期开发的方案,一期工程由一座井口平台,一座集输平台,海管,软钢壁单点系泊装置及一艘FPSO组成。

一期工程已于2004年7月16日投产,并于8月13日外输第一船原油.二期工程也正在积极的畴备之中。

浮式生产储油外输装置由一艘浮式生产储油外输轮和一个单点系泊组成。

海洋石油112号FPSO由渤海公司负责组织建造,建成后出租给作业者使用。

该FPSO 设计建造周期仅为22个月,这在世界FPSO建造史上是史无前例的。

海洋石油112号FPSO总长270m,宽50m,型深24m,双底双壳结构,载重量15万吨,设计寿命25年,日最大原油处理能力12,720m3,最大年原油处理能力为400万吨。

海洋石油112号FPSO主要由原油分离与处理、生产水处理装置、外输系统、热介质系统、动力模块、生活楼、轮机舱和公用设施舱、原油储存和污油水舱、压载舱、注水系统、直升机坪、货物卸放区,甲板吊机、火炬,系泊支承等结构组成;此外,海洋石油112号FPSO还拥有庞大而复杂的电力和管系等系统。

1、单点系泊装置海洋石油112号FPSO的单点系泊系统采用APL公司设计制造的可解脱SYS系统,水下软钢臂固定塔式系统,该系统是首次在渤海湾海域使用,最大的特点是具有良好的安全性和经济性。

它能将FPSO系泊在指定位置,允许其在风浪流作用下产生风向标效应,围绕单点作360度旋转,同时为FPSO和井口平台之间提供海管和电缆的界面,井液、注水和高压电通过单点的滑环在FPSO与井口平台之间传输,整个系统由YOKE,系泊塔、跨接软管和柱基等主要构建组成。

2、工艺系统原油由井口生产平台通过海底生产管线到井口集输平台,再输送到单点和FPSO。

可解脱FPSO的系泊系统解脱过程动态模拟与优化

FPSO(Floating Production, Storage, and Offloading)是一种海洋石油生产储存船,通常用于海上石油生产和储存。

FPSO的系泊系统是至关重要的,它确保FPSO稳定地停靠在指定位置,以便有效进行石油开采工作。

在FPSO需要移动或者解脱的情况下,系泊系统的解脱过程是至关重要的。

本文将针对FPSO的系泊系统解脱过程进行动态模拟与优化。

首先,我们需要建立FPSO的系泊系统动态模拟模型。

这个模型需要考虑FPSO的尺寸、重量、海况、风力、海流等因素,以及系泊系统的结构、材料、船体稳定性等因素。

通过对这些因素进行综合考虑,我们可以建立一个能够准确模拟FPSO系泊系统解脱过程的动态模拟模型。

接下来,我们需要对FPSO的系泊系统解脱过程进行优化。

优化的目标是在确保FPSO和周围环境安全的前提下,尽可能减少解脱过程所需的时间和成本。

为了实现这一目标,我们可以通过调整系泊系统的参数、改变操作策略或者优化解脱路径等方式来优化解脱过程。

最后,我们可以利用数值仿真方法对优化后的系泊系统解脱过程进行验证。

通过将优化后的模型输入到数值仿真软件中,我们可以模拟解脱过程的实际情况,以验证优化方案的有效性和可行性。

总之,通过动态模拟与优化FPSO的系泊系统解脱过程,我们可以提高FPSO的作业效率和安全性,为海上石油生产提供更好的保障。

希望以上内容对您有所帮助。

FPSO单点系泊系统的结构安全评估与优化FPSO(浮式生产储油船)作为一种将油气生产、储存和转运集于一身的海上设施,已经成为深海油田开发的重要利器。

而FPSO的单点系泊系统作为其重要组成部分之一,承担着保持船体稳定和安全的重要职责。

本文将对FPSO单点系泊系统的结构安全进行评估,并提出优化的方案。

首先,我们将对FPSO单点系泊系统的结构进行评估。

该系统主要由锚链、系泊桩、船体结构等组成。

我们可以通过有限元分析等方法对这些结构进行力学性能的评估。

例如,我们可以检查锚链的拉力是否符合设计要求,并进行疲劳寿命分析,以确保其在长期使用过程中不会发生断裂。

同时,我们还可以评估系泊桩的承载能力,确保其能够承受预期的水动力荷载和风荷载。

此外,对船体结构的强度和稳定性也需要进行评估,以确保其能够有效地抵抗外部环境条件的影响。

基于上述评估结果,我们可以对FPSO单点系泊系统进行优化。

首先,对于锚链的优化,我们可以考虑采用高强度材料,以增加其拉力容量,提高安全性。

此外,对于锚链的布设方式,我们可以采用合适的布锚角度和锚链间距,以增加系统的稳定性。

对于系泊桩的优化,我们可以选择更合适的材料和尺寸,以提高其承载能力。

此外,对于船体结构的优化,我们可以考虑采用增强结构或采用更合理的结构设计,以提高其抗风浪能力和波动荷载承载能力。

除了结构的优化,我们还应关注FPSO单点系泊系统的监测与维护。

监测系统可以通过各种传感器,如振动传感器、应变传感器等,对FPSO单点系泊系统进行实时监测,及时发现可能存在的问题,并采取相应的维护措施。

此外,定期的维护工作也是确保FPSO单点系泊系统安全运行的关键。

维护工作包括对锚链磨损情况的检查、系泊桩的防腐蚀处理以及船体结构的定期检测等。

除了上述内容,我们还应关注FPSO单点系泊系统的环境可持续性。

在优化设计和维护过程中,我们应考虑减少对环境的负面影响。

例如,在锚链的选用过程中,可以选择可回收或可再生的材料,以减少废弃物的产生。

- 13 -高 新 技 术0 引言南海某油田水深117 m。

在浮式生产储卸油装置(Floating Production Storage and Offloading,FPSO)单点系泊系统的常规年检过程中发现,其9条系泊钢缆均有不同程度的断丝(如图1所示),并且个别配重链与四角板的连接断开(如图2所示)。

为了保证生产的安全,业主决定先解脱FPSO,然后再更换系泊系统的锚腿。

图1 系泊钢缆断丝图2 配重链与四角板连接断开该系泊系统及其油田设施由FPSO、STP 单点转塔、9条系泊锚腿、2条柔性立管和2条电缆组成。

其中,STP 的东北方向和西南方向各有1条柔性立管和1条电缆。

该立管和电缆先跨过中水浮桥(Mid Water Arch,MWA),再铺设到海床,最后分别与东北方向和西南方向的平台进行连接;立管将各自平台所产的原油输送到FPSO,并用电缆给FPSO 输送电力。

立管、电缆和9条系泊锚腿与STP 单点的中心对称,9条锚腿中每3条锚腿组成1簇,簇与簇之间间隔120 °,每簇内的锚腿之间相隔5 °。

整个系泊系统的模型布置图如图3所示。

单条系泊锚腿的组成图如图4所示,其具体组成和尺寸见表1。

在系泊更换施工期间,FPSO 进坞维修,FPSO 不在位。

该系泊系统更换项目的主要工作包括以下4个:1) 对该系泊系统的9条锚腿进行更换。

2) 对吸力桩和STP 的上阳极进行修复。

3) 弃置8条旧锚腿(将8条旧锚腿丢弃至油田区域海底的指定区域)。

4) 对1条锚腿进行回收并检测其断丝和腐蚀情况。

其中,不更换下锚链,也就是不更换与吸力桩连接的桩链,对其进行重复利用。

为了缩短项目工期,让油田尽快复产,在该项目中采用3条船在系泊系统的3个扇区进行同步作业。

系泊系统是开采海洋石油的常见方式之一,与系泊系统有关的海油工程项目较多。

,张人公等人[1]给出了西江油田BTM 及其软管回收弃置的方案,邹佳星等人[2]评估了某系泊系统的剩余强度。

FPSO在位不停产整体更换单点系泊系统技术马超;高原;陈池;杨天笑;刘耀江【摘要】为保证“海洋石油111”FPSO服役的南海番禺4-2/5-1油田的安全生产,提出了FPSO在位不停产整体更换单点系泊系统的方法.该方法改变了更换单点系泊系统的传统做法,通过设计施工方案并进行优化,分析施工船舶的资源选择、施工环境条件及风险,研究大型吸力锚的安装、施工船不偏移贴近FPSO直接进行锚点张紧作业、精确测量调整链长度和上锚缆快速更换等多项关键技术,最终成功实施了FPSO不解脱、油田不停产状态下快速更换整个单点系泊系统.本文方法的成功应用填补了我国FPSO在位不停产整体更换单点系泊系统技术的空白,取得了显著的经济效益和社会效应,对今后类似工程具有较高的使用价值.%In order to ensure the safe operation of "HYSY 111" FPSO which serves in PY 4-2/5-1 oilfield in South China Sea,the technology for replacement of the whole single point mooring system with FPSO being operating in place was proposed.This technology changed the traditional practices of replacing the single point mooring system,based on the optimized design and construction,analysis on the selection of constructionresources,environmental limitations and risk assessment.Some key techniques were established,such as huge suction anchorinstallation,tensioning mooring line with FPSO in position,accurate measurement and adjustment of chain length,and efficient top mooring wirerope replacement.Finally the technology for replacement of the whole single point mooring system with FPSO being operating in place was applied successfully.The successful application of this method makes a newrecord in single point mooring system replacement in China and has achieved remarkable economic and social benefits,showing a high application potential in future similar projects.【期刊名称】《中国海上油气》【年(卷),期】2017(029)002【总页数】5页(P147-151)【关键词】番禺4-2/5-2油田;“海洋石油111”FPSO;FPSO不解脱;油田不停产;整体更换单点系泊系统;方案设计及优化;环境风险分析【作者】马超;高原;陈池;杨天笑;刘耀江【作者单位】深圳海油工程水下技术有限公司深圳518067;深圳海油工程水下技术有限公司深圳518067;深圳海油工程水下技术有限公司深圳518067;中海石油(中国)有限公司番禺作业公司深圳518067;深圳海油工程水下技术有限公司深圳518067【正文语种】中文【中图分类】TE54马超,高原,陈池,等.FPSO在位不停产整体更换单点系泊系统技术[J].中国海上油气,2017,29(2):147-151.MA Chao,GAO Yuan,CHEN Chi,et al.Technology for replacement of the whole single point mooring system with FPSO being operating inplace[J].China Offshore Oil and Gas,2017,29(2):147-151.“海洋石油111”FPSO服役的番禺4-2/5-1油田于2003年10月建成投产,其单点系泊系统设计寿命为10 a,经检测发现存在多处锚链配重块脱落和上锚缆断丝的情况。

FPSO单点系泊系统的绞车与锚链设计与优化FPSO(Floating Production Storage and Offloading)单点系泊系统是一种用于海上油气生产的设备,可以将原油从油井运输至FPSO船上的储油舱进行储存,并进行初步处理后再将原油通过管道输送至岸上处理厂。

在FPSO单点系泊系统中,绞车和锚链是关键的组成部分,它们的设计和优化对系统的安全稳定运行至关重要。

1. 绞车设计与优化绞车在FPSO单点系泊系统中有着重要的作用,它负责调整船体位置和保持稳定。

在绞车的设计与优化过程中,需要考虑以下几个关键因素:1.1. 承载能力:绞车的承载能力直接影响到系统的安全性和可靠性。

根据FPSO船的大小和负载要求,确定绞车的最大承载能力,并确保绞车在满载情况下以及可能的恶劣环境条件下仍能正常运行。

1.2. 运行速度:绞车的运行速度需要根据系统的要求进行优化,既要满足位置调整的需要,又要保持船体的稳定性。

运行速度过快可能导致船体产生过大的惯性力,从而影响到系统的稳定性。

1.3. 系统集成性:绞车还需要与其他子系统集成,例如动力供应系统和船体自动控制系统。

在绞车的设计与优化中,需要考虑到与其他子系统的协调与配合,确保系统的整体运行效果。

2. 锚链设计与优化在FPSO单点系泊系统中,锚链是绞车与海底锚点之间的连接件,它的设计和优化对系统的安全性和稳定性具有重要影响。

以下是锚链设计与优化过程中需要考虑的几个关键因素:2.1. 材料选择:锚链的材料需要具备足够的强度、耐腐蚀性和耐磨性,以应对海水的腐蚀和外部的拉力。

在选择锚链材料时需要综合考虑成本、可靠性和使用寿命等因素。

2.2. 锚链长度:锚链的长度需要根据海域的水深和水流情况进行合理选择。

较深的水深可能需要更长的锚链长度,以确保锚链能够充分降低船体的运动和受力。

2.3. 锚链排布:锚链的排布方式对系统的稳定性有直接影响。

一般而言,锚链应该采用S型排布,以减小船体受到的横向力的影响,并保持船体在风浪作用下的稳定。

基于AQWA的FPSO系泊系统响应数值模拟FPSO是Floating Production Storage and Offloading的缩写,是一种常见的海洋油气开采方案。

为了保证FPSO的安全和稳定,需要进行严格的系统响应数值模拟。

AQWA是一款专用于船舶和海洋结构物的数值模拟软件,可以用于FPSP系泊系统响应数值模拟,具有较高的精度和可靠性。

船型选择是FPSP系统响应数值模拟的关键,船型的选择必须与所在水区环境相匹配,以达到尽可能降低系统波浪响应的目的。

使用AQWA软件可以针对FPSO的船型进行数值模拟,分析不同波浪条件下的系统响应以及其稳定性的影响。

在各种波浪条件下,对FPSO系泊系统的数值模拟能够更加真实精确地模拟其响应情况,从而为系统的稳定性研究提供了更加可靠的结果。

在模拟过程中,考虑到FPSO的结构和船舶外观,以及环境因素,联合数值工具计算出FPSO系统的最大响应,以及其是否处于稳态。

在数值模拟结束后,还可以进行系统响应统计和数据可视化处理,进一步分析并研究FPSO系统响应情况。

由此可见,AQWA软件可以有效用于FPSO系泊系统响应数值模拟,具有高精度、可靠性高、容易使用等优点。

在FPSO开采方案中,使用AQWA进行系泊系统响应数值模拟,可以提供有力的科学依据,为保障FPSO的安全运营提供重要的支撑。

在进行AQWA的FPSO系泊系统响应数值模拟时,需要考虑到多个因素,包括波浪条件、FPSO结构和船型等。

在此基础上,分析得出相关数据,从而深入了解FPSO系泊系统响应情况。

下面将列出相关数据,并进行分析。

1. 波浪条件数据:波高范围:0.5m-8m周期范围:3s-14s波浪谱类型:JONSWAP2. FPSO结构和船型数据:长度:275m宽度:46m吃水:22m最大荷载:190000DWTFPSO船型:S型3. 系泊系统响应数据:FPSO系泊系统最大响应:2.1mFPSO系泊系统平均响应:0.6m从上述数据可以看出,波浪条件是FPSO系泊系统响应的主要影响因素之一,波高和周期对系统响应情况产生着显著的影响。

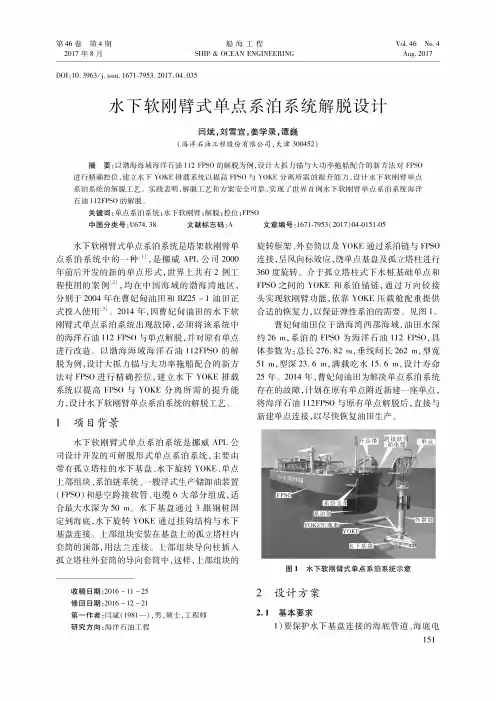

第46卷第4期2017年8月船海工程SHIP &OCEAN ENGINEERINGVol.46 No.4Aug.2017D O I:10. 3963/j. issn. 1671-7953.2017.04.035水下软刚臂式单点系泊系统解脱设计闫斌,刘雪宜,姜学录,谭巍(海洋石油工程股份有限公司,天津30CH52)摘要:以渤海海域海洋石油112 F P S O的解脱为例,设计大抓力锚与大功率拖船配合的新方法对F P S O 进行精确控位,建立水下Y O K E排载系统以提高F P S O与Y O K E分离所需的提升能力,设计水下软刚臂单点 系泊系统的解脱工艺。

实践表明,解脱工艺和方案安全可靠,实现了世界首例水下软刚臂单点系泊系统海洋 石油112F P S O的解脱。

关键词:单点系泊系统;水下软刚臂;解脱;控位;F P S O中图分类号:U674.38 文献标志码:A文章编号:1671-7953(2017)04-0151-05水下软刚臂式单点系泊系统是塔架软刚臂单 点系泊系统中的一种[1],是挪威A P L公司2000 年前后开发的新的单点形式,世界上共有2例工 程使用的案例[2],均在中国海域的渤海湾地区,分别于2004年在曹妃甸油田和BZ25 - 1油田正 式投入使用[3]。

2014年,因曹妃甸油田的水下软 刚臂式单点系泊系统出现故障,必须将该系统中 的海洋石油112 FPS0与单点解脱,并对原有单点 进行改造。

以渤海海域海洋石油112FPS0的解 脱为例,设计大抓力锚与大功率拖船配合的新方 法对FPS0进行精确控位,建立水下Y O K E排载 系统以提高FPS0与Y O K E分离所需的提升能 力,设计水下软刚臂单点系泊系统的解脱工艺。

1项目背景水下软刚臂式单点系泊系统是挪威A P L公 司设计开发的可解脱形式单点系泊系统,主要由 带有孤立塔柱的水下基盘、水下旋转Y O K E、单点 上部组块、系泊链系统、一艘浮式生产储卸油装置 (FPS0)和悬空跨接软管、电缆6大部分组成,适 合最大水深为50 m。

FPSO单点系泊系统的状态监测与评估技术研究FPSO(Floating Production Storage and Offloading)是一种将油气生产、储存和卸载集合在一体的海上浮式生产储油装置。

其中,单点系泊系统(Single Point Mooring System)是FPSO连接至海底油气管线的重要组成部分。

准确监测和评估FPSO单点系泊系统的状态对于确保安全运行和降低风险至关重要。

本文将围绕FPSO单点系泊系统的状态监测与评估技术展开研究。

1. 引言在FPSO的生产运营过程中,单点系泊系统承担着将生产设备与海底管线连接的重要任务。

系统的状态监测与评估能够帮助运维人员及时发现潜在问题,采取相应措施并保证安全运行。

本文将探讨FPSO单点系泊系统状态监测的技术方案和评估的方法。

2. FPSO单点系泊系统状态监测技术(1)激光测距技术激光测距技术可以通过测量激光光束与目标物之间的距离变化,来实时监测FPSO单点系泊系统的位置和姿态。

该技术具有高精度、非接触性和实时性的优点,能够提供可靠的数据。

(2)声纳检测技术声纳检测技术利用声波在水中传播的特性,测量声波传播的时间和速度,可以计算得到FPSO单点系泊系统的位置和运动状态。

该技术对海洋环境影响较小,适用于远程监测。

(3)摄像技术通过在单点系泊系统附近设置摄像头,实时监测系泊系统的姿态和运动。

摄像技术便捷易行,能够提供直观的图像信息,辅助运维人员对系统状态进行评估。

(4)传感器网络技术传感器网络技术由多个传感器节点组成,分布在整个单点系泊系统上,可以实时采集各种物理量,如温度、压力、振动等,提供全面的系统状态信息。

传感器网络技术能够实现全天候、多参数、多点位的监测。

3. FPSO单点系泊系统状态评估方法(1)信息融合和分析通过将各种监测技术获取的数据进行融合和分析,可以得到更准确、全面的系统状态信息。

运维人员可以针对不同的参数和指标设定阈值,当超过阈值时触发报警,及时采取措施。

FPSO的流体力学特性与优化研究FPSO是浮式生产储油船的英文缩写,它在海上油田开发中扮演着重要角色。

随着全球能源需求的增长,FPSO的数量不断增加,因此研究FPSO的流体力学特性与优化变得越来越重要。

FPSO的流体力学特性主要包括其在海上运营时受到的海浪、海风和海流的影响,以及在船体设计中需要考虑的稳定性和航行性能。

针对这些特性,研究FPSO的流体力学特性与优化可以帮助优化FPSO的设计和运行,提高其安全性和性能。

首先,研究FPSO在海浪环境下的响应是流体力学研究的重点之一。

当FPSO受到海浪的冲击时,其船体会发生摆动和倾斜。

因此,研究如何减少FPSO的摆动和倾斜,提高其稳定性是非常关键的。

其中一项常用的方法是使用艏吃水锚泊系统,通过锚链调节FPSO的位置和角度,从而减少其受到的海浪冲击,提高其稳定性。

其次,研究FPSO在海风环境下的响应也是十分重要的。

海风对FPSO的影响主要体现在两个方面,一是风载荷对FPSO的影响,另一个是风对FPSO位置的影响。

通过研究FPSO在不同风速和风向下的响应,可以确定相应的抵御风浪的能力,设计适合的锚链长度和结构,保证FPSO在强风环境下的稳定性和安全性。

另外,FPSO的流体力学特性还与海流有关。

海流不仅会对FPSO位置产生影响,还会造成FPSO的阻力增大。

因此,研究FPSO在不同海流条件下的运动特性和阻力变化规律,可以指导FPSO的位置控制和运行优化,提高其效率和经济性。

除了以上流体力学特性的研究,FPSO的优化研究也是十分重要的。

优化研究旨在提高FPSO的性能,减少其能耗和碳排放。

一方面,通过优化FPSO的船体造型和参数,减小水动力阻力,提高其航行性能,降低能耗;另一方面,通过优化FPSO的动力系统,减少燃料消耗和排放,提高能源利用效率。

此外,还可以优化FPSO的各项设备和系统,减小噪音和振动,提高生产效率和工作环境品质。

总之,FPSO的流体力学特性与优化研究对于提高FPSO的安全性、稳定性、航行性能和经济性至关重要。

FPSO单点系泊系统的钢缆设计与优化摘要:FPSO(浮式生产储油船)是一种灵活的海上石油生产设施,广泛应用于海上油田的开采。

FPSO的单点系泊系统是确保其在海上稳定运行的关键组成部分之一。

本文将重点讨论FPSO单点系泊系统中钢缆的设计与优化,分析钢缆的作用、材质选择、尺寸计算以及优化方法,以提高系统的安全性和性能。

1. 引言FPSO是将石油生产和储存设备集成于一艘船体上,在海上进行石油开采的装备。

在海上作业期间,FPSO需要保持在预定位置上,并抵抗来自海浪和风力的影响。

单点系泊系统是通过钢缆连接FPSO和海底锚地,确保其稳定性。

2. 钢缆的作用钢缆在FPSO单点系泊系统中起着承载和稳定的作用。

其主要功能包括:2.1 承载重量钢缆通过承受FPSO的重量,将其连接到海底锚地。

因此,钢缆的设计必须能够承受大约FPSO的整体重量和作业荷载。

2.2 抵抗力矩受到风力和海浪的作用,FPSO会产生力矩。

钢缆通过抵抗这些力矩,保持FPSO稳定。

2.3 耐久性和可靠性钢缆必须具备良好的耐久性和可靠性,以承受长期海洋环境的腐蚀和张力的影响。

3. 钢缆的材质选择在FPSO单点系泊系统中,钢缆通常采用高强度钢丝绳。

钢丝绳有以下优势:3.1 高强度钢丝绳的高强度使其能够承受较大的拉力和重量,确保系统的稳定性和安全性。

3.2 耐腐蚀性钢丝绳经过特殊处理,具备较好的耐腐蚀性能,能够抵御海水的侵蚀。

3.3 轻量化与传统的链条相比,钢丝绳的重量更轻,可以减少系统的整体重量,降低对FPSO的负荷。

4. 钢缆尺寸的计算钢缆的尺寸计算涉及到多个因素,如重量,系统的工作载荷,耐久性和系统的安全性等。

一般而言,需要考虑以下因素进行计算:4.1 预测荷载通过考虑海浪,风力等因素,预测钢缆所要承受的最大载荷,以保证系统安全。

4.2 应力分析根据钢缆的支撑位置,计算其所受应力,并评估其对系统的影响。

4.3 疲劳寿命钢缆在长期海洋环境下会受到疲劳和腐蚀的影响,需要计算其疲劳寿命,以确保系统的可靠性和安全性。

南海FPSO单点系泊系统设计验证赵晶瑞1,2,李清平1,2,王世圣1,2(1. 中海油研究总院有限责任公司,北京 100028;2. 国家能源深水油气工程技术研发中心,北京 100028)摘要: 本文展示了1艘应用于中国南海的FPSO单点系泊系统的设计与验证过程,介绍了系泊系统的设计衡准,给出了主要的强度与疲劳分析结果。

计算表明;单点系泊系统在完整工况与单缆破损工况能够承受目标油田百年一遇环境条件,预期疲劳寿命满足设计要求。

此外当波浪周期略低于设计海况的谱峰周期时,将激发起更大的船体低频运动进而导致最大的系泊张力。

关键词:单点系泊系统;强度分析;疲劳寿命;低频运动中图分类号:TE952 文献标识码:A文章编号: 1672 – 7649(2020)12 – 0169 – 08 doi:10.3404/j.issn.1672 – 7649.2020.12.034Design and verification for a single point mooring system of a FPSO in South China SeaZHAO Jing-rui1,2, LI Qing-ping1,2, WANG Shi-sheng1,2(1. CNOOC Research Institute Ltd, Beijing 100028, China;2. National Research and Development Center for Energy Engineering Technology in Deep Water, Beijing 100028, China)Abstract: This paper presents the design and verification approaches of a single point mooring system of a FPSO in South China Sea. The design criteria of mooring system is introduced and the brief results of strength and fatigue analysis are given. The results shows that the single point mooring system can withstand 100 year return period condition in the target oil field in both intact and one line damaged condition. The expected fatigue life can satisfy the design requirement. It also shows that when the wave period is slightly lower than the spectral peak wave period at the design basis, the larger low-fre-quency horizontal motion of the FPSO in low will be triggered so as to generate maximum tension in mooring lines.Key words: single point mooring system;strength analysis;fatigue life;low-frequency motion0 引 言FPSO是一种可对海上油田进行全海式开发的工程装备,其主要优势在于集油气生产处理、原油储存、外输功能于一体,并具有良好的水深适应性。

FPSO的动态定位系统模拟与优化研究FPSO(Floating Production, Storage and Offloading)是一种海上石油生产、存储和卸载设备,其在海上油田开发中扮演着重要角色。

在FPSO运营过程中,动态定位系统是保证船体稳定的关键技术之一。

为了提高FPSO动态定位系统的性能,模拟与优化研究变得尤为重要。

本文将围绕FPSO的动态定位系统模拟与优化展开详细论述。

FPSO的动态定位系统主要用于使FPSO保持在海上油田的预定位置,保证石油生产及相关作业的顺利进行。

动态定位系统的核心是利用多种传感器对环境条件进行监测,并通过控制设备实现船体的精确定位。

由于海洋环境的复杂性,动态定位系统的模拟与优化十分必要,以确保FPSO的安全性和生产效率。

首先,动态定位系统的模拟研究是建立基于物理原理的数学模型,通过计算机仿真进行系统性能评估和参数调优。

在模拟研究中,海洋环境的因素如海流、风力、波浪等会被考虑进去,以模拟真实的海洋作业场景。

在选择数学模型时,需要综合考虑船体力学、控制系统、环境因素等因素,并根据实际情况进行合理简化和假设。

如何准确描述FPSO的运动状态和环境条件,是模拟研究的关键。

动态定位系统的优化研究是针对模拟结果进行系统性能评估和参数调优的工作。

通过对模拟结果的分析,可以了解系统的稳定性、精度和抗干扰能力等方面的表现,并进行相应的优化设计。

优化研究的目标往往是提高定位系统的鲁棒性、精确性和响应速度,以应对复杂的海洋环境和各种工况。

优化研究的方法包括参数优化、控制策略的设计优化等。

通过多次迭代,得到最佳的系统参数和控制策略,提高FPSO动态定位系统的性能。

在FPSO动态定位系统的模拟与优化研究中,还需要考虑实时性和可靠性。

因为在实际的FPSO运营过程中,时效性和可靠性是至关重要的。

因此,在模拟与优化研究中,需要考虑数据传输和处理的时延以及传感器和控制设备的可靠性。

同时,为了保证可行性和有效性,可以结合实际海洋环境的数据进行仿真,并与实际操作进行对比和验证。