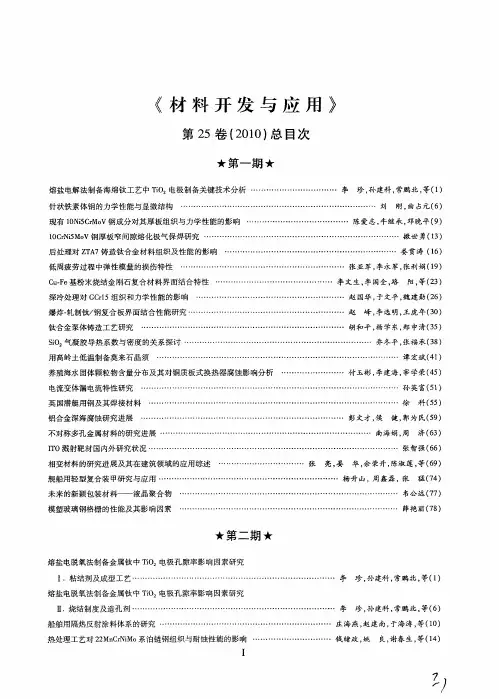

《工业金刚石》2010年总目次

- 格式:pdf

- 大小:117.22 KB

- 文档页数:2

2021年12月 第6期第41卷 总第246期金刚石与磨料磨具工程D i a m o n d &A b r a s i v e s E n g i n e e r i n g D e c .2021N o .6 V o l .41 S e r i a l 246‘金刚石与磨料磨具工程“2021年总目次2021年第1期(总第241期)M P C V D 金刚石的制备与应用研究进展马志斌(1) 基于孕镶金刚石颗粒的硬质合金基底的预固晶预处理新方法简小刚,马千里,唐金垚,等(5) 沉积气压对金刚石膜微米纳米结构转变的影响范冰庆,王传新,徐远钊,等(12) 钨表面激光处理对金刚石膜附着力的影响黄逸豪,马志斌(17) 用于六面顶压机的2种叶蜡石成分及传压性能对比江明全,王义鹏,杨功章,等(21) 新型组装方式烧结纯P c B N 材料邓福铭,王 浩,宋美娇,等(27) N i –C r 合金钎焊镀W 金刚石的微观结构分析苏仕超,肖 冰,王树义,等(32) S L S 和F D M S 制造超薄金刚石锯片对比研究张绍和,苏 舟,刘磊磊,等(38) C V D 金刚石刀具微铣削A A 356铝合金的磨损分析张亚博,白清顺,何 欣,等(44)单颗磨粒划擦S i C f /S i C 陶瓷基复合材料的试验研究周雯雯,王建青,赵 晶,等(51)超声振动螺线磨削砂轮表面的功率谱密度分析王秋燕,梁志强,白硕玮,等(58)18C r N i M o 7–6钢高速外圆磨削残余应力和硬度的试验分析张银霞,原少帅,王子乐,等(65) 基于动态惯性权重粒子群算法的磨削低能耗加工方法张 昆,田业冰,丛建臣,等(71) 基于机器视觉的滚抛磨块缺陷检测方法贾 坡,田建艳,杨英波,等(76) 1,2,4三氮唑和苯并三氮唑对316L 不锈钢化学机械抛光的影响王 浩,陈国美,倪自丰,等(83) 磨粒半径对金刚石研磨加工影响机制的仿真研究张桐齐,岳晓斌,雷大江,等(89) 基于热性能分析的P D C 切削齿选型试验研究王传留(95) 中国超硬材料行业2019年运行情况孙兆达,李志宏,赵兴昊,等(101)2021年第2期(总第242期)超硬磨具发展情况栗正新(1) 微波诱发热爆法制备钛铝碳结合剂金刚石复合材料代 振,张旺玺,梁宝岩,等(4) 热力耦合下轴向旋转热管砂轮的强度分析姜华飞,陈佳佳,傅玉灿,等(9) 单层C B N 砂轮感应钎焊温度的优选方法研究李奇林,丁 凯,雷卫宁,等(17) 金刚石工具用适配型C u S n Z n N i 预合金粉末的研制于 奇,马 佳,龙伟民,等(23) 静态高压国内外最新进展王义鹏,寇自力,江明全(28) 金刚石合成过程中放炮现象的分析及预警刘乾坤,何文江,杜欢龙,等(35) 低功率M P C V D 制备金刚石薄膜朱海丰,王艳坤,丁文明,等(39) 高导热金刚石/铝复合材料的真空热压制备徐 洋,沈维霞,范静哲,等(46) 金刚石–W C –C o 复合材料的高温高压合成杨亚楠,王海阔,侯志强,等(53) 金属/金刚石复合磨料在树脂磨具中的应用刘恒源,徐三魁,韩志静,等(59) 电镀金刚石线锯表面磨粒分布密度的多相机视觉检测赵玉康,毕文波,葛培琪(64)P C B N 刀具高速切削淬硬钢材料的研究叶智彪,江文清,罗 涛(69)金刚石与磨料磨具工程总第246期胎体组分对热压孕镶金刚石钻头胎体腐蚀磨损性能的影响刘志江,姚远基,王文正,等(75) 钇铝石榴石晶体化学机械抛光液成分优化研究张自力,金洙吉,慕 卿,等(82) 基于响应曲面法的304不锈钢化学机械抛光工艺参数优化刘海旭,武庆东,曹潇俊,等(89) 铸件浇冒口砂轮自适应切割王维信,孟广耀,王 哲,等(96)2021年第3期(总第243期)砂轮修整技术的发展崔仲鸣(1) 基于磨削法的金刚石磨料工具精密修磨技术崔仲鸣,冯常财,庄召鹏,等(5) 金刚石砂轮的E C D 修锐和整形研磨及其对硬脆材料的加工康喜军,田牧纯一,久保明彦,等(12) 六方氮化硼直接转化合成多晶立方氮化硼的研究王永凯,位 星,王大鹏,等(19) 聚晶金刚石的研究进展与展望邹 芹,向刚强,王 瑶,等(23) 绕丝结构砂轮磨削沟槽结构化表面唐成志,吕玉山,李兴山,等(33) 3D 打印金刚石工具的研究进展张云鹤,黄景銮,宋运运,等(40) 陶瓷结合剂研磨盘制备及研磨蓝宝石性能研究路家斌,聂小威,阎秋生,等(48) 单晶硅裂纹萌生的刻划深度研究陈自彬,葛梦然,毕文波,等(55) 金刚石线锯切割碳化硅陶瓷的机理与工艺研究陈勇彪,张松辉,张晓红,等(60) 增强纤维对超薄超硬树脂砂轮切割偏摆问题的影响杜晓旭,李大水,李彩虹,等(68) 基于金刚石固结磨具的圆柱滚子高效研磨工艺研究雷 阳,杨晓光,冯凯萍,等(74) 5G 覆铜板叠层复合材料高效切磨工艺试验研究高 航,杨 勇,许启灏,等(82) 静电雾化微量润滑粒径分布特性与磨削表面质量评价贾东洲,张乃庆,刘 波,等(89)2021年第4期(总第244期)再制造加工技术的研究进展刘文浩,陈 燕,周 睿,等(1) 航空发动机叶片再制造技术的应用及其发展趋势李文辉,温学杰,李秀红,等(8) 面向再制造的高能束射流清洗技术综述李 博,郑文光,黄 军,等(19) 垂直排列石墨烯纳米金刚石复合材料的制备及其导热性能研究杨晨光,成晓哲,穆云超,等(25) 石墨烯/纳米金刚石复合电极性能研究张金辉,李 敬,郁建元(31) 六面顶压机合成过程中线性卸压机构的设计与应用王本亮,熊莎莎,冯晓鹏,等(36) F e 基胎体中添加Z n 粉后的金刚石磨边轮组织及性能孙为云,孙长红,康 杰,等(45) 结合剂强度和不同镀层对金刚石工具出刃高度的影响朱振东,张作栋,栗晓龙,等(53) 磨粒有序排布曲面砂轮设计及磨削性能实验研究李瑞昊,石广慧,黄 辉(58) 钎焊C B N 砂轮与陶瓷C B N 砂轮磨削粉末冶金高温合金的加工性能对比研究张 曦,李本凯,丁文锋(64) 刚玉砂轮缓进深切磨削K 444镍基高温合金研究刘 爽,李 敏,丁文锋,等(72) 氮化硅陶瓷轴承外圈磨削的双目标工艺优化谢天舒(82) 基于不同纳米划痕顺序的6H –S i C 单晶片材料去除机理研究郜 伟,张银霞,黄鹏举(92) 不锈钢打磨砂带用酚醛树脂关键参数测试与分析邢 波,赵金坠,宋运运,等(98)29第6期‘金刚石与磨料磨具工程“2021年总目次2021年第5期(总第245期)特种加工技术在再制造领域中的应用与发展牛梓源,陈 燕,张泽群,等(1) 钎涂金刚石在盾构刀具再制造中的应用吴奇隆,张 雷,孙华为,等(9) 纳米金刚石粒径对N i –P 化学复合镀层耐磨性和耐腐蚀性的影响向春彦,张凤林,王 健,等(14) F e -B -C 体系金刚石单晶的高温高压制备与表征徐 洋,张壮飞,黄国峰(21) N 掺杂石墨化纳米金刚石超级电容器电极材料性能张金辉,李 敬,郁建元,等(26) 铜化学机械抛光的弱缓蚀剂研究徐 浩,宋恩敏,卞 达,等(32) 铝粉改性低温陶瓷结合剂的性能研究王延铭,侯永改,夏学锋,等(40) G H 4169超声辅助磨削表面完整性研究韩 璐,康仁科,张 园,等(46) C F R P 砂轮与钢基体砂轮高速磨削过程中的动力学特性杨淮文,冯 伟,朱建辉,等(52) 微粉金刚石钎焊砂轮磨削氧化铝陶瓷的磨削力和表面粗糙度特征李全城,沈剑云,黄国钦(59) 砂带磨削接触压强模型分析与实验王亚杰,黄 云(65) 金刚石涂层刀具加工石墨的切削性能陈守峰,王成勇,郑李娟,等(70) 镍–硼/金刚石超薄切割片的制备与性能张 兰,宋文韬,李 纳,等(77) 金刚石薄圆锯片基体的磨削工艺参数优化邱陆一,王秋燕,白硕玮,等(84) 基于剪切增稠液的高速钢铣刀刃口修整王明海,张静波,龙志凯,等(89) 基于机器人平台的固结磨料工具抛光叶片路径规划刘纪东,徐成宇,朱永伟(95)2021年第6期(总第246期)金刚石表面石墨烯的制备及应用研究进展余 威,栗正新(1) 机匣零件气道面及支板面的机器人磨抛加工曾庆双,郭皓邦,李鼎威(7) 基于环境模型优化的机器人磨抛阻抗控制王竞航,彭云峰(12) 钛合金材料页轮磨抛材料去除深度模型胡智杰,曹诗宇,黄文健,等(18) 孔隙密度对化学气相沉积泡沫金刚石导热性能的影响李崧博,于杨磊,焦增凯,等(24)M P C V D 法制备金刚石膜的工艺李思佳,冯曙光,郭胜惠,等(31) 保温时间对P r 6O 11刻蚀金刚石单晶的影响朱振东,马金明,陈冰威,等(38) 采用旋转电极的金刚石表面镀镍方法及工艺张 杨,崔仲鸣,冯常财,等(44) T i H 2对C u 60Z n 40合金结合剂结构和性能的影响韩 平,刘恒源,徐三魁,等(51) 基于灰色关联理论的R B –S i C 陶瓷电火花机械复合磨削工艺参数优化黄书强,魏宗泽,饶小双,等(56) 基于逐步回归分析法的表面粗糙度预测张家有,宋万万,白玉珍,等(63) 径向振动匹配层换能器的设计参数及模态优化郭帅宏,李 军,王欢涛(68) 电镀金刚石线锯使用性能的试验研究张晨政,葛培琪,陈自彬,等(74) 磨料质量分数对磨硅片用金刚石砂轮磨削性能的影响骆苗地,赵金伟,丁玉龙,等(80) 不同斧型钻齿切削刃角下的破岩方式李尚劼,赵 星,黄继庆,等(85)39。

人造金刚石的生产、市场、趋势及新生产工艺扈楠021131021由于有些矿物在自然界产出较少,不能满足工业生产的需要,从19世纪四十年代开始了人造矿物的研究。

许多人造矿物的性能已接近或超过相应的天然矿物,有些人造矿物可以代替某些天然矿物,成本比开采天然矿物的成本还低,并且可以控制矿物的质量和大小。

所以人造矿物的研究和生产发展很快。

金刚石以其最大的硬度、半导体性质以及光彩夺目的光泽,分别应用于钻头切割、电子工业和宝石工业上。

故人造金刚石的意义显得尤为重大。

人造金刚石是用超高压高温或其他人工方法,使非金刚石结构的碳发生相变转化而成的金刚石。

与天然金刚石相比,它具有生产成本低,应用效果好的优点。

由于非金属材料和其他硬脆材料,如大理石、花岗石、耐火材料、玻璃、陶瓷、混凝土等加工工业的发展,对锯片、钻头用金刚石质量的要求越来越高,需求量越来越大,目前世界上工业用金刚石的85%以上已由人造金刚石代替。

1生产状况目前世界上生产人造金刚石的国家主要有:美国、南非、爱尔兰、瑞典、英国、德国、俄罗斯、乌克兰、亚美尼亚、日本、中国、罗马尼亚、波兰、捷克、朝鲜、希腊、印度等近20个国家。

世界人造金刚石的产量为7~10亿克拉,其中年产量在1亿克拉以上的国家有美国、英国、俄罗斯等。

我国人造金刚石年产量2亿克拉以上,居世界第一位。

世界人造金刚石产量年增长率为8%~15%。

美国的GE公司、英国的DeBeers公司和德国的Winter公司是目前世界上生产人造金刚石的三大集团,垄断着世界人造金刚石的生产技术和消费市场,代表着世界人造金刚石的发展方向。

GE公司1955年首先宣布人工合成金刚石的工业方法,且曾一度在单晶工艺方面处于领先地位,目前与其他两家公司相比,该公司的聚晶技术更为先进,年产量达1.65亿克拉,所采用的压机吨位一般在38~100MN之间。

DeBeers公司1987年合成出世界上最大的宝石级单晶体(11.14克拉)和工业级单晶体(重14.20克拉),1992年又创造了合成重量39.40克拉的工业级单晶金刚石的世界纪录。

2023 年12 月第 6 期金刚石与磨料磨具工程Dec. 2023第43卷总第 258 期Diamond & Abrasives Engineering No. 6 Vol. 43 Serial 258《金刚石与磨料磨具工程》2023 年总目次2023 年第 1 期(总第 253 期)固态纳米孔高能束制造方法·····································································································陈 威,郑李娟,艾思棋,等(1)超硬材料行业绿色低碳发展调研报告······························································································李利娟,张贝贝,孙兆达(10)3D打印金刚石复合片及其钻头的研究进展················································································吴晶晶,张绍和,曲飞龙,等(14)孕镶金刚石钻头钻进花岗岩岩屑特性室内试验研究······································································康 鑫,段隆臣,刘卫卫,等(23)FeCoCu预合金粉末含量和烧结温度对碳化钨基钻头性能的影响·······································································李俊萍,胡 立(29)磨损齿PDC钻头的切削性能试验····························································································张春亮,王锦成,柯晓华,等(35)砾岩层PDC切削齿优选试验··································································································程书婷,王红波,纪 慧,等(43)陶瓷材料的DIW工艺在陶瓷基金刚石工具中应用的关键技术问题··················································王娅妮,张绍和,张 谦,等(49)润滑剂对金属磨具湿法成形组织和性能的影响············································································邵俊永,黎克楠,冯圆茹,等(59)超硬磨料砂轮自动化复合修整机床CAM系统开发······································································陈根余,蓝圣增,王彦懿,等(66)金刚石工具加工SiO2f/SiO2复合材料的可行性研究······································································高 航,李睿祺,许启灏,等(75)GFRP低频轴向振动制孔的钻削力特性和套料钻磨损分析·····························································董香龙,郑 雷,韦文东,等(82)C/SiC复合材料微孔的电镀金刚石钻头钻削加工··········································································庞继伟,李 升,郭明波,等(90)基于YOLOv5和DeepSORT的金刚石锯丝磨损监测····································································袁俊涛,赵礼刚,秦 齐,等(96)安装角度对交叉孔试件振动抛磨效果的影响分析·······································································贾 建,李秀红,李文辉,等(102)涡轮叶片内冷通道的磨料流光整加工特性················································································郑志鑫,董志国,李孟楠,等(110)基于控制研磨深度的金刚石研磨质量分析······················································································庞 飞,雷大江,王 伟(118)2023 年第 2 期(总第 254 期)面向航空航天难加工材料磨削过程的模拟与智能控制·································································赵 彪,雷小飞,陈 涛,等(127)可溶性晶体性质对生物骨材料切削质量影响因素探究·································································郭 鹏,赵 韡,郝宇聪,等(144)烧结压力对低液相Fe基预合金钻头胎体性能的影响···································································王志明,方小红,孙武成,等(151)基于SPH方法的钢筋混凝土切削模拟研究···············································································谭松成,石恒超,王伟雄,等(161)固体润滑剂表面金属化及其对Fe基钻头胎体力学性能的影响························································管成凯,郑朝文,余思琴,等(170)超纳米金刚石薄膜的快速生长及结构分析······················································································位少博,王 兵,熊 鹰(176)多孔磁性钢渣磨料的制备与性能表征······················································································裴晶晶,张玉柱,邢宏伟,等(182)基于K-Means聚类与凸包检测的金刚石磨粒分割与评价················································································李弘扬,方从富(188)熔盐法合成Ti和TiC镀覆层对金刚石热稳定性的影响·····························································武玺旺,皇甫战彪,刘雪坤,等(196)镍基钎料真空钎焊镀钨金刚石的研究······················································································王树义,肖 冰,肖皓中,等(202)金刚石微粉含量对硅酸钠基导热胶粘接和导热性能的影响···························································黄雷波,夏学锋,杨雪峰,等(210)磁流变弹性体制备及其在精密加工应用研究进展·······································································龙浩天,路家斌,胡 达,等(218)FDMS工艺制备金刚石工具技术浅析······················································································张 谦,张绍和,王娅妮,等(233) 2金刚石与磨料磨具工程总第 258 期 局部感应钎焊锯片基体的热变形分析······················································································侯超鹏,李奇林,丁 凯,等(241)天线反射面表面富树脂层的精密抛光参数对表面粗糙度的影响规律···············································刘建奇,康仁科,田俊超,等(250)弹性磁极磨头磁力研磨TC4钛合金的工艺优化·········································································任 泽,朱永伟,董彦辉,等(257)喷油嘴喷孔流道磨料流光整特性仿真与试验·············································································李孟楠,董志国,郑志鑫,等(265)2023 年第 3 期(总第 255 期)单层金刚石工具螺旋钻削复合材料的性能比较······················································SULTAN AIreen,史忠德,ATTIA Helmi,等(273)基于工业三维检测的点云配准技术研究进展·············································································王水仙,邓朝晖,葛吉民,等(285)四柱压机的精密压制技术·····································································································冯克明,王庆伟,杜晓旭,等(298)水气联合雾化制备超细铁粉及其在激光焊锯片上的应用······························································李 鑫,李世进,乐 晨,等(305)金刚石刀具微纳米切削单晶镍亚表面损伤··································································································孙思光,李 翔(313)切削SiCp/6005Al复合材料的PCD刀具磨损·············································································林洁琼,贾 茹,周 岩,等(322)小模数齿轮的缓进深切成形磨削实验····························································································易 军,李治宏,周 炜(332)SiCp/Al复合材料端磨磨削力模型构建与试验研究······································································曹桂新,董志国,张泽华,等(340)基于响应曲面法和NSGA2的凸轮轴磨削参数优化·····································································项雄标,张新娜,周康康,等(348)DD9镍基单晶高温合金的缓进给磨削烧伤实验··········································································康恺煜,余广渊,杨万鹏,等(355)金字塔型砂带磨粒排布对表面磨抛形貌的影响··········································································李孝辉,田凤杰,韩 晓,等(364)双平面研磨Si3N4圆柱滚子的表面质量····················································································黄贺利,李颂华,吴玉厚,等(371)金刚石磁性磨料与SiC磁性磨料的研磨加工性能分析·································································董彦辉,牛风丽,任 泽,等(379)光学球罩抛光运动轨迹均匀性模拟分析·························································································王伟明,李 震,李庆忠(386)旋转磁场磁流体研磨锗片的多物理场耦合数值模拟······················································································刘建河,周洺玉(392)2023 年第 4 期(总第 256 期)超声加工制备表面微织构及使役性能研究进展··········································································别文博,赵 波,陈 凡,等(401)中国超硬材料行业2022年运行报告························································································李利娟,张贝贝,赵兴昊,等(417)cBN-Fe磁性磨粒的制备工艺及性能························································································马雨寒,张宝瑞,周长乐,等(422)基于Bi2O3-B2O3体系的陶瓷结合剂金刚石砂轮制备及其对单晶硅的磨削性能··································白福厚,廖燕玲,轩 闯,等(432)合成聚晶金刚石过程的颗粒冷压破碎······················································································崔喜伟,秦 越,毛荣琪,等(440)主轴外圆超光滑研磨工艺·····································································································李 彬,宋晓宇,吴媛媛,等(447)陶瓷CBN砂轮的研究进展····································································································吴恒恒,许 桥,周宏根,等(455)硫酸钙晶须增强的树脂磨片磨削性能····················································································································林江程(474)钻探用聚晶金刚石复合片的显微组织及性能·············································································朱 培,卢灿华,张 涛,等(482)钴粉形貌对聚晶金刚石复合片性能的影响················································································宋晨杰,魏文亮,汪锦杰,等(489)三氯化铁-草酸体系不锈钢化学机械抛光液设计与优化································································王泽宇,彭亚男,苏建修,等(497)基于永磁体的磁流变抛光励磁装置设计与仿真················································································曹顺涛,陈观慈,李明春(504)激光熔覆金刚石−金属耐磨涂层的组织和性能···········································································庞爱红,孙贵乾,董俊言,等(514)。

剖析美国工业金刚石的发展轨迹(上)I. 引言- 工业金刚石在现代工业中的重要性- 美国工业金刚石的发展对全球工业的影响II. 历史背景- 工业金刚石的发现和应用- 美国工业金刚石产业的起源III. 美国工业金刚石的成长期(20世纪初 - 1950年代)- 工业金刚石的应用领域扩大- 工业金刚石生产技术的发展IV. 美国工业金刚石的巅峰期(1960年代 - 1980年代)- 工业金刚石的应用进一步扩展- 美国工业金刚石产业的垄断地位- 美国工业金刚石的技术领先地位V. 挑战和转型(1990年代 - 至今)- 全球工业金刚石产业格局的变化- 美国工业金刚石产业的面临的挑战- 美国工业金刚石产业的转型策略VI. 结论- 美国工业金刚石的发展和全球工业进步的关系- 美国工业金刚石产业的继续发展的挑战和前景I. 引言工业金刚石被誉为人造材料中的“硬质王者”,具有高硬度、高强度、高导热和高耐磨等特性,是现代制造业中不可或缺的材料。

它的应用范围广泛,涵盖了切削加工、磨削加工、化工、石油勘探等多个领域。

在美国,工业金刚石产业的发展历程可以追溯到20世纪初,随着技术的提升和市场的需求变化,这个产业迅速成长,并对全球工业进步产生了重要影响。

本文将从历史背景、成长期、巅峰期、挑战和转型等方面,剖析美国工业金刚石的发展轨迹,以期揭示这个产业在现代工业中的重要性和作用。

II. 历史背景工业金刚石的发现和应用可以追溯到19世纪末,当时法国科学家马蒂亚斯发现了人造金刚石的制备方法。

1903年,美国化学家霍华德发明了氧气-乙炔火焰,可以高温下制备金刚石。

此后,工业金刚石的生产和应用开始得到发展。

20世纪初,美国工业金刚石产业出现。

当时主要的应用领域是珠宝加工,如钻石切割、磨光等。

但是,由于生产工艺不成熟,金刚石的产量很低,价格也非常昂贵。

随着生产技术的提高,到20世纪40年代,工业金刚石的应用领域开始扩大,主要涉及到石油勘探、航空航天、化工以及切削加工等领域。

国内专利文摘

佚名

【期刊名称】《工业金刚石》

【年(卷),期】2010(000)003

【摘要】第一和第二人造金刚石区域是掺硼的。

第二人造金刚石区域比第一人造金刚石区域掺有更多的硼,并且与第一人造金刚石区域物理接触。

在另一示例性实施方案中,该第一和第二人造金刚石区域形成金刚石半导体,例如当连接到至少一个金属引线时的肖特基二极管。

在其它实施方案中该金刚石是CI2高增浓的金刚石,以增加该人造金刚石的导电性。

在示例性实施方案中的制造工艺包括沿着氢注入层分离该多个金刚石层中的一层。

【总页数】1页(P38-38)

【正文语种】中文

【中图分类】TN304.18

【相关文献】

1.国内专利文摘

2.国内专利文摘

3.国内专利文摘

4.国内专利文摘

5.家用及商用洗碗机专用洗涤剂国内专利文摘

因版权原因,仅展示原文概要,查看原文内容请购买。