道达尔多特士 EP 2多用途极压锂基润滑脂

- 格式:pdf

- 大小:83.60 KB

- 文档页数:1

2号极压锂基脂参数

2号极压锂基脂是一种新型的润滑脂,其参数优秀,使用广泛。

本文将从多个角度介绍2号极压锂基脂的特点和应用,以便读者更好地了解和使用该产品。

2号极压锂基脂的化学成分具有良好的稳定性和耐高温性能。

这种脂肪酸锂盐基底油可以在高温下保持稳定,不会发生分解或氧化,从而确保了设备的可靠运行。

此外,2号极压锂基脂还具有良好的抗腐蚀性能,可以有效防止设备在潮湿环境下受到腐蚀。

2号极压锂基脂具有优异的极压性能和抗磨损性能。

在高负荷和高速运行条件下,该脂润滑剂能够有效减少摩擦和磨损,延长设备的使用寿命。

此外,2号极压锂基脂还能够形成均匀的润滑膜,减少设备的噪音和振动,提高设备的工作效率。

除了以上特点,2号极压锂基脂还具有良好的抗氧化性能和防腐蚀性能。

在长时间使用过程中,该脂润滑剂能够有效抵抗氧化和腐蚀,延长设备的使用寿命,并减少维护和更换的频率。

基于以上特点,2号极压锂基脂在工业设备的润滑中得到广泛应用。

它可以用于各种高速轴承、齿轮、链条和滑动部件的润滑,如电机、风机、泵和重型机械等。

同时,由于其优异的性能,2号极压锂基脂也可以用于汽车、船舶和航空器等交通工具的润滑。

2号极压锂基脂是一种性能优越的润滑脂,具有优异的化学稳定性、

极压性能和抗磨损性能。

它广泛应用于各种工业设备和交通工具的润滑中,能够有效延长设备的使用寿命,提高设备的工作效率。

希望通过本文的介绍,读者能够更好地了解和应用2号极压锂基脂,为设备的正常运行和维护保养提供帮助。

道达尔EP2润滑脂是一款极压锂基润滑脂,其具有以下重要指标和特性:首先,从润滑性来看,EP2润滑脂具有出色的抗磨性和抗压性,能够为设备提供良好的润滑保护。

它适用于各种设备,如轴承、齿轮、链条和压缩机等,能够有效减少摩擦和磨损,延长设备寿命,并降低运行维护成本。

其次,从耐温性能来看,EP2润滑脂在高温环境下也能保持良好的稳定性和润滑效果。

道达尔EP2润滑脂在40℃时的运动需大于700BAR,这个数据在同类润滑脂中表现优秀。

在高温下,它的粘度适中,抗氧化性能好,不会轻易变稀,能确保稳定的润滑效果。

再来看粘度特性,EP2润滑脂对低温度的适应性较强,即使在低温环境下,其粘度也不会大幅度上升,从而保证了润滑性能。

在噪音抑制方面,EP2润滑脂能够有效降低设备的噪音,为操作人员提供更加舒适的工作环境。

至于其他特性,EP2润滑脂具有良好的抗水性,即使在潮湿环境下也不会影响其性能。

即使在有水的情况下使用,也不会乳化产生油泥。

而良好的防腐蚀性则意味着EP2润滑脂能够为设备提供良好的防腐保护,防止腐蚀性物质对设备的损害。

而关于保存难度,由于EP2润滑脂的抗氧化性能优异,因此保存不易产生油泥,能够有效延长产品的使用寿命。

同时,它的包装规格齐全,用户可以根据实际需要选择合适的包装规格。

综上,道达尔EP2润滑脂具有优良的润滑性、耐高温性能、粘度特性、噪音抑制能力、防腐防锈能力以及易于保存等特性,是一款适用于各种设备的高品质润滑产品。

其卓越的性能和适用性使其在工业领域具有广泛的应用前景。

无论是机械设备、汽车工业还是精密仪器,道达尔EP2润滑脂都能够为设备提供持久、稳定的润滑保护,降低运行维护成本,提高设备效率。

需要注意的是,虽然EP2润滑脂具有优良的性能和广泛的适用性,但在使用前,仍需根据设备的具体需求和工作环境选择合适的润滑脂类型和粘度。

在使用过程中,也需遵循正确的使用方法和注意事项,以确保最佳的润滑效果和使用寿命。

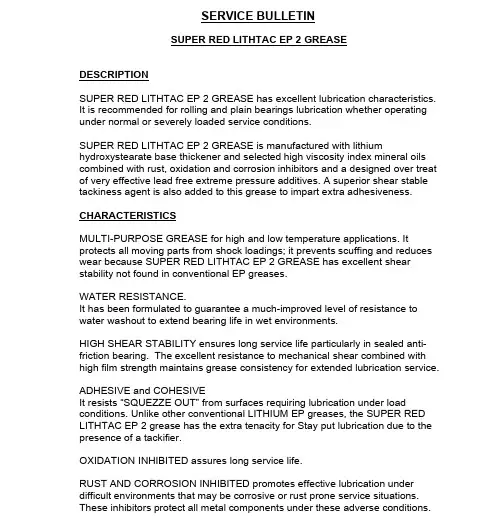

SERVICE BULLETINSUPER RED LITHTAC EP 2 GREASEDESCRIPTIONSUPER RED LITHTAC EP 2 GREASE has excellent lubrication characteristics. It is recommended for rolling and plain bearings lubrication whether operating under normal or severely loaded service conditions.SUPER RED LITHTAC EP 2 GREASE is manufactured with lithium hydroxystearate base thickener and selected high viscosity index mineral oils combined with rust, oxidation and corrosion inhibitors and a designed over treat of very effective lead free extreme pressure additives. A superior shear stable tackiness agent is also added to this grease to impart extra adhesiveness.CHARACTERISTICSMULTI-PURPOSE GREASE for high and low temperature applications. It protects all moving parts from shock loadings; it prevents scuffing and reduces wear because SUPER RED LITHTAC EP 2 GREASE has excellent shear stability not found in conventional EP greases.WATER RESISTANCE.It has been formulated to guarantee a much-improved level of resistance to water washout to extend bearing life in wet environments.HIGH SHEAR STABILITY ensures long service life particularly in sealed anti-friction bearing. The excellent resistance to mechanical shear combined with high film strength maintains grease consistency for extended lubrication service. ADHESIVE and COHESIVEIt resists “SQUEZZE OUT” from surfaces requiring lubrication under load conditions. Unlike other conventional LITHIUM EP greases, the SUPER RED LITHTAC EP 2 grease has the extra tenacity for Stay put lubrication due to the These inhibitors protect all metal components under these adverse conditions.- 2 -OPERATING TEMPERATURE RANGEThe recommended temperature range is from -20 o C to 130 o C, however they may be used at higher temperatures with the lubrication frequency increased accordingly.APPLICATIONSSUPER RED LITHTAC EP 2 GREASE is suitable for application in heavy-duty plain and rolling element bearings operating under the most severe conditions, bushings and pins in severe duty industrial applications such as mining, logging etc. It is also a general-purpose grease suitable for truck chassis, fifth wheel and wheel bearings. It is not recommended for CV joints.TYPICAL TESTS ASTM METHODAppearance Red & TackyNLGI - 2 Penetration at 25o C -Worked 60 Strokes D.217 275Worked10,000 Strokes D.217 292Dropping Point, o C D.2265 192Water Washout at 80o C, % D.1264 5Wheel Bearing Leakage, g D.1263 3Oxidation Resistance Pressure -Drop, 100 hours, kpa D.942 25Timken, OK Load, Kg D.2509 284-Ball Weld, Kg/f D.2596 3304-Balll Wear Scar, mm D.2266 0.48Rust Prevention Characteristics D.1743 No rust Mineral Oil Viscosity cSt at 40o C D.445 300"The facts stated and the recommendations made herein are believed to be accurate. No guarantee of their accuracy is made however, and unless otherwise expressly provided in written contract, the products are sold without conditions or warranties, expressed or implied. Purchasers should determine the suitability of such products for their particular purposes.Effective: September 2004Cancels: January 2002。

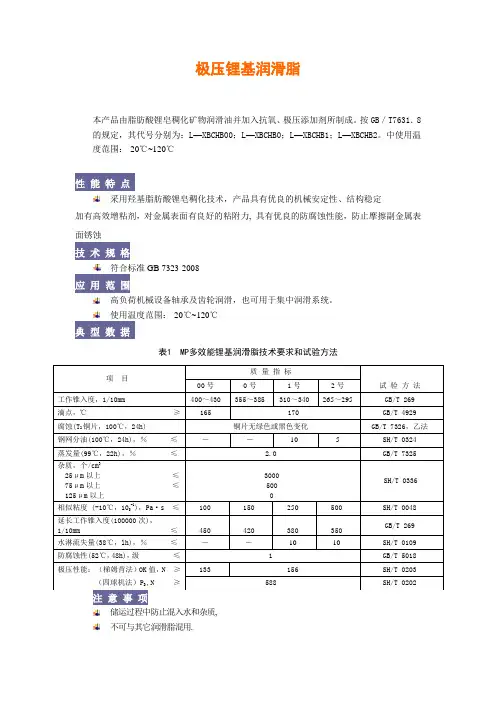

极压锂基润滑脂本产品由脂肪酸锂皂稠化矿物润滑油并加入抗氧、极压添加剂所制成。

按GB /T7631.8的规定,其代号分别为:L —XBCHB00;L —XBCHB0;L —XBCHB1;L —XBCHB2。

中使用温度范围:-20℃~120℃性 能 特 点采用羟基脂肪酸锂皂稠化技术,产品具有优良的机械安定性、结构稳定加有高效增粘剂,对金属表面有良好的粘附力, 具有优良的防腐蚀性能,防止摩擦副金属表面锈蚀技 术 规 格符合标准GB 7323-2008 应 用 范 围高负荷机械设备轴承及齿轮润滑,也可用于集中润滑系统。

使用温度范围:-20℃~120℃典 型 数 据表1 MP 多效能锂基润滑脂技术要求和试验方法注 意 事 项储运过程中防止混入水和杂质, 不可与其它润滑脂混用.项 目质 量 指 标试 验 方 法 00号 0号 1号 2号 工作锥入度,1/10mm400~430 355~385310~340 265~295GB/T 269 滴点,℃ ≥ 165170GB/T 4929 腐蚀(T 2铜片,100℃,24h)铜片无绿色或黑色变化GB/T 7326,乙法 钢网分油(100℃,24h),% ≤ --105 SH/T 0324 蒸发量(99℃,22h),% ≤ 2.0 GB/T 7325杂质,个/cm 325μm 以上 ≤ 75μm 以上 ≤ 125μm 以上3000 500 0SH/T 0336相似粘度 (-10℃,10S -1),Pa ·s ≤ 100 150 250 500 SH/T 0048 延长工作锥入度(100000次),1/10mm ≤ 450 420 380 350 GB/T 269 水淋流失量(38℃,lh),% ≤ --1010SH/T 0109 防腐蚀性(52℃,48h),级 ≤ 1GB/T 5018 极压性能: (梯姆肯法)OK 值,N ≥(四球机法)P B ,N ≥133156 SH/T 0203 588SH/T 0202。

通用锂基润滑脂通用锂基润滑脂概述1、概述通用锂基脂是由1,2-羟基硬脂肪酸锂皂稠化中等粘度矿物油,井加人抗氧防锈添加剂制成,按其锥人度分为l、2、3三个牌号。

2、用途通用锂基脂属于长寿命、多用途的润滑脂,可取代钙基、钠基及钙钠基脂,系这些润滑脂的换代产品。

其具有良好的抗水性、机械安定性、防锈性与氧化安定性,广泛适用于-20℃~120℃温度范围内各种机械设备的滚动轴承和滑动轴承及其它摩擦部位的润滑。

l号适用于集中给脂系统。

2号适用于中转速、中负荷的机械设备。

如汽车,拖拉机轮毂轴承,中小型电动机、水泵和鼓风机等。

3号适用于矿山机械、汽车、拖拉机轮毂轴承,大中型电动机等设备。

3、产品性能(l)其有良好的抗水、防锈性能。

可以在潮湿和与水接触的机械部件上使用。

(2)良好的帆械安定性和胶体安定性。

在高速运转的机械剪切作用下,润滑脂不会变稀或流失。

(3)耐热性好,滴点高。

可在较高温度条件下使用。

4、注意事项(l)通用锂基脂不宜用大容器盛装,以免引起析油。

如有少量析油,可在常温下搅拌或研磨均匀后使用。

(2)不要与其它脂类混合使用。

(3)其它同钙基脂注意事项。

二、汽车通用锂基润滑脂1、概述汽车通用锂基脂是由1,2-轻基硬脂肪酸锤皂稠化低凝点矿物油,并加入防锈剂和抗氧剂而制成。

2、用途汽车通用锂基脂适用于-30℃~120℃范围内汽车轮毂轴承、底盘、水泵等摩擦部位的润滑,也可用于坦克的负重轮和引导轮轴承。

比钙基脂和复合钙基脂延长换油期二倍,减少磨损,简化品种。

满足从哈尔滨到海南岛广大地区汽车的使用要求,可以使润滑和维护费降低40%以上。

进口汽车和国产新车普遍推荐使用这种润滑脂。

3、产品性能(l)具有良好的高低温性,可在-30℃~120℃的宽温度范围内使用。

(2)良好的抗水性和防锈性能,可在潮湿和与水接触的机械部件上使用。

(3)具有良好的机械安定性、胶体安定性、氧化安定性、抗水性和润滑性 在高速运转的机械剪切作用下,脂不会变质、流失,保证良好的润滑。

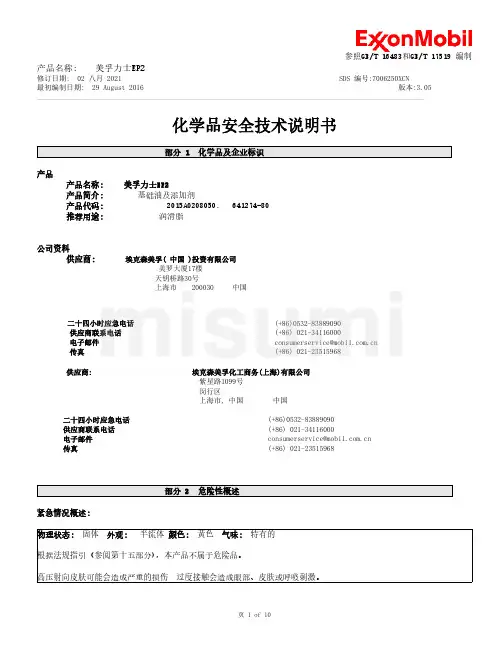

修订日期: 02 八月 2021 SDS 编号:7006250XCN最初编制日期: 29 August 2016 版本:3.05 ______________________________________________________________________________________________________________________化学品安全技术说明书产品产品名称: 美孚力士EP2产品简介: 基础油及添加剂产品代码: 2015A0208050, 641274-80推荐用途: 润滑脂公司资料供应商: 埃克森美孚( 中国 )投资有限公司美罗大厦17楼天钥桥路30号上海市 200030 中国二十四小时应急电话(+86**************供应商联系电话(+86*************电子邮件*************************.cn传真(+86*************供应商: 埃克森美孚化工商务(上海)有限公司紫星路1099号闵行区上海市, 中国中国二十四小时应急电话供应商联系电话电子邮件传真(+86**************(+86**************************************.cn (+86*************紧急情况概述:物理状态: 固体外观: 半流体颜色: 黄色气味: 特有的根据法规指引(参阅第十五部分),本产品不属于危险品。

高压射向皮肤可能会造成严重的损伤过度接触会造成眼部、皮肤或呼吸刺激。

修订日期: 02 八月 2021 SDS 编号:7006250XCN最初编制日期: 29 August 2016 版本:3.05______________________________________________________________________________________________________________________根据法规指引(参阅第十五部分),本产品不属于危险品。

极压锂基脂和通用锂基脂1.引言1.1 概述概述部分的内容:锂基脂是一种常见的润滑脂,其具有优异的性能和广泛的应用领域。

本文主要介绍了两种锂基脂:极压锂基脂和通用锂基脂。

极压锂基脂是一种添加了极压剂的润滑脂,它具有较高的载荷承受能力和极限压力性能。

它通常用于在高温高压的条件下工作的设备,如重型机械、工业设备和汽车传动系统。

极压锂基脂能够有效地减少金属间的磨损和摩擦,延长设备的寿命和维护周期。

它在极端工况下表现出色,具有良好的稳定性和抗氧化性能。

通用锂基脂是一种多功能润滑脂,广泛适用于各种工业和机械设备。

它具有良好的温度稳定性、氧化安定性和防腐性能。

通用锂基脂适用于一般工作条件下的润滑,如轴承、齿轮和链条等。

它能够提供良好的润滑效果,并减少设备的磨损和摩擦。

通过比较这两种锂基脂,可以看出它们在性能和应用方面存在一些区别。

极压锂基脂具有更高的极限压力性能,适用于高温高压的工况,而通用锂基脂则适用于一般工作条件。

选择合适的锂基脂对于设备的正常运行和维护至关重要。

接下来的章节将详细介绍极压锂基脂和通用锂基脂的组成、性能特点以及在不同工况下的应用。

通过深入了解这两种润滑脂,我们可以更好地选择和使用适合的产品,从而提高设备的可靠性和延长使用寿命。

1.2 文章结构文章结构部分内容如下:本文主要分为引言、正文和结论三个部分。

引言部分包括概述、文章结构和目的。

首先,我们将对极压锂基脂和通用锂基脂进行深入研究和探讨。

接着,我们将介绍文章的结构,明确各个部分的内容和目的。

最后,我们分析本文的目的,即为读者提供全面的极压锂基脂和通用锂基脂的知识。

正文部分将分为两个小节,分别介绍极压锂基脂和通用锂基脂。

在极压锂基脂部分,我们将详细介绍其特点、应用领域以及相关研究成果。

同时,我们还会对极压锂基脂的优势和劣势进行分析和评价。

在通用锂基脂部分,我们将对其特性、用途和市场需求进行详细描述,并探讨其与极压锂基脂的不同之处和应用范围。

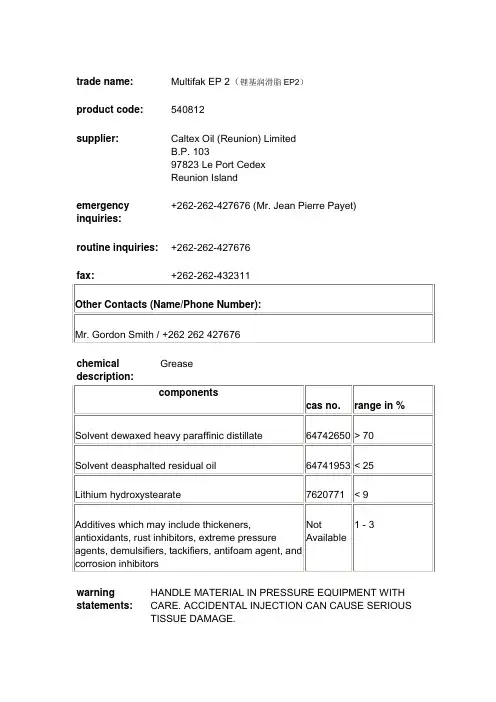

trade name: Multifak EP 2(锂基润滑脂EP2)product code: 540812supplier: Caltex Oil (Reunion) LimitedB.P. 10397823 Le Port CedexReunion Islandemergencyinquiries:+262-262-427676 (Mr. Jean Pierre Payet) routine inquiries: +262-262-427676chemicaldescription:Greasewarning statements: HANDLE MATERIAL IN PRESSURE EQUIPMENT WITH CARE. ACCIDENTAL INJECTION CAN CAUSE SERIOUS TISSUE DAMAGE.eyes:Expected to cause no more than minor eye irritation characterized by tearing or a burning sensation.oral:If more than several mouthfuls are swallowed, abdominal discomfort, nausea, and diarrhea may occur.inhalation: Product not volatile at ambient temperatures. Vapours, mist,or fumes in high concentrations, as generated from sprayingor heating in an enclosed space, may cause irritation.skin:Believed to be slightly irritating with possible redness, edema,or drying of the skin.May cause skin discolouration following prolonged or repeatedcontact. long term toxic effects:The base oil component(s) are not expected to becarcinogenic based on IARC criteria. This product has notbeen tested as a whole for chronic health effects.See Section 11 for additional information.eyes:Flush eyes immediately with fresh water for at least 15 minutes while holding the eyelids open.If irritation persists, see a doctor.skin:Wash skin thoroughly with soap and water.If skin irritation persists or a rash develops as a result ofexcessive contact, see a doctor.Launder contaminated clothing.ingestion:If swallowed and person is conscious, give water ormilk. DO NOT make person vomit except on advice ofmedical personnel. If advice cannot be obtained, takeperson with container and label to nearest emergencytreatment center. Never give anything by mouth to anunconscious person.inhalation: This material is not expected to be an acute inhalationproblem under typical applications. However, if exposedto excessive levels of fumes, mists, or dusts, remove tofresh air and get medical attention.advice to doctor: High-pressure equipment can cause small, oftenbloodless, puncture wounds where material may havebeen injected deep into the extremity. Within 24 hours,there is usually extensive swelling, discoloration andintense pain in the affected part. Requires immediatetreatment at a surgical emergency centre; elsedisfigurement or amputation of the affected part mayoccur.Treatment of high pressure wounds may include: 1)surgical decompression, debridement, and drainage. 2)broad-spectrum antibiotic and 3) anti-inflammatorymedication. See Shoo, M.J., et al. High pressureinjection injuries of the hand. J. Trauma, 20:229-238,1980.ignition temp. (degrees c): Not DeterminedNot Determinedflammable limits (% byvolume):flash point (degrees c): Not Determinedfire extinguishing agents: According to the U.S. National FireProtection Association Guide, use water fog,dry chemical, foam, or carbondioxide. Water or foam may causefrothing. Use water to cool fire-exposedcontainers. If a leak or spill has not ignited,use water spray to disperse the vapours andto provide protection for persons attemptingto stop the leak.explosion hazards: For fires involving this material, do not enterany enclosed or confined space withoutself-contained breathing apparatus to protectagainst the hazardous effects of combustionproducts or oxygen deficiency.in case of spill: Shovel up material and place in disposable container, observing precautions outlined in this MSDS. Scrub contaminated area with detergent and water using stiff broom or mop. Pick up liquid with an absorbent and place in a disposable container. Avoid eye and skin contact. Prevent contamination of groundwater or surface water.Minimum feasible handling temperatures should be maintained. Periods of exposure to high temperatures should be minimised. Water contamination should be avoided.eyes: Avoid eye contact. The wearing of chemical safety goggles or face shield is recommended.skin: Exposed employees should exercise reasonable personalcleanliness; this includes cleansing exposed skin several timesdaily with soap and water, and laundering or dry cleaning soiledwork clothing at least weekly.inhalation: None required when handling at minimum feasible temperatures.ventilation: Under normal applications of this product, general dilutionventilation is adequate.exposurelimits:None established for product.The ACGIH TLV for mineral oil mists is 5 mg/m3 for a daily 8-hourexposure. A short term exposure limit (STEL) of 10 mg/m3 isrecommended.note: The following data may represent a range of approximate or typicalvalues for products in the same family. Precise technical information is provided in Product Bulletins and can be obtained from your Marketing Representative.appearance & odor: Brown, buttery semi-solidboiling point (deg. c): Not Determinedvaporpr.(************):Lowdensity (kg/l at 15 deg. c): Not Determinedvapor density (air = 1): Not Determinedph of undiluted product: Not Applicablesolubility (water): Negligiblepercent volatile by volume: Not Determinedevaporation: Not Determinedviscosity (all product grades): 17-18mm2/**********hazardous polymerizations: DO NOT OCCURproducts of combustion: Carbon monoxide, carbon dioxide, andaldehydes and ketones, combustionproducts of nitrogen or sulfur.conditions to avoid: Heat, Strong Oxidizersgeneral: High-Pressure Equipment Information: Accidentalhigh-velocity injection under the skin of materials of this typemay result in serious injury. Seek medical attention at onceshould an accident like this occur. The initial wound at theinjection site may not appear to be serious at first; but, if leftuntreated, could result in disfigurement or amputation of theaffected part. Take this information with you if you seekmedical treatment.This product contains petroleum base oils which may berefined by various processes including severe solventextraction, hydrocracking and hydrotreating. These oils havenot been listed in the U.S. National Toxicology Program(NTP) Annual Report nor have they been classified by theInternational Agency for Research on Cancer (IARC) ascarcinogenic or probably carcinogenic to humans. environmental No specific ecotoxicity data on this product are available.effects:waste disposal: Place contaminated materials in disposable containers anddispose of in a manner consistent with applicableregulations. Contact local environmental or health authoritiesfor approved disposal of this material.remarks: None Determined.transport of dangerous goods:UN Number: Not ApplicableDangerous Goods Class: Not ApplicableProper Shipping Name: Not ApplicableHazchem Code (Australia/NZ): Not ApplicableAdditional Information: None Determined.respirator information: None determined.No specific notes on this product.To the best of our knowledge, the information provided in this MSDS documentis correct. Access to this information is being provided via the Internet so thatit can be made available to as many potential users as possible. We do not assume any liability for consequences of the use of this information since it may be applied under conditions beyond our control or knowledge. Also, it is possible that additional data could be made available after this MSDS was issued. Certain hazards are described herein, however these may not be the only hazards that exist. All materials may present unknown hazards and should be used with caution. Customers are encouraged to review this information, follow precautions, and comply with all applicable laws and regulations regarding the use and disposal of this product. For specific technical data or advice concerning this product as supplied in your country please contact your local sales representative. The final determination of the suitability of any material is the sole responsibility of the user.Approved HES Services Revision Date: Oct-23-1999。

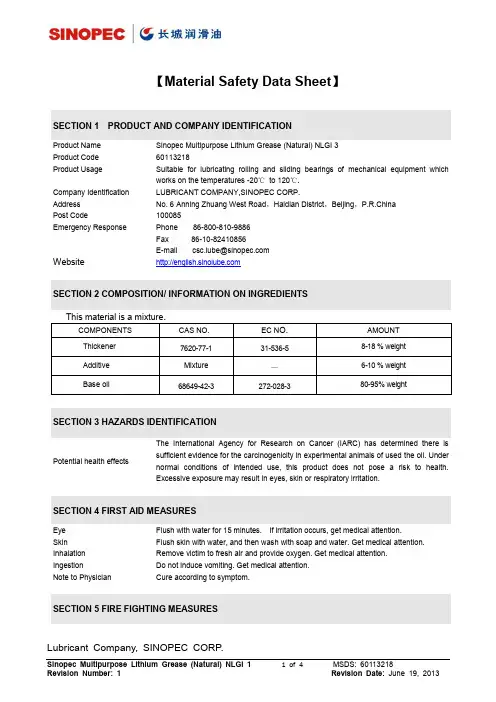

【Material Safety Data Sheet】SECTION 1 PRODUCT AND COMPANY IDENTIFICATIONProduct Name Sinopec Multipurpose Lithium Grease (Natural) NLGI 3Product Code 60113218Product Usage Suitable for lubricating rolling and sliding bearings of mechanical equipment whichworks on the temperatures -20℃to 120℃.Company Identification LUBRICANT COMPANY,SINOPEC CORP.Address No. 6 Anning Zhuang West Road,Haidian District,Beijing,P.R.ChinaPost Code 100085Emergency Response Phone 86-800-810-9886Fax 86-10-82410856E-mailWebsite SECTION 2 COMPOSITION/ INFORMATION ON INGREDIENTSSECTION 3 HAZARDS IDENTIFICATIONPotential health effects The International Agency for Research on Cancer (IARC) has determined there is sufficient evidence for the carcinogenicity in experimental animals of used the oil. Under normal conditions of intended use, this product does not pose a risk to health. Excessive exposure may result in eyes, skin or respiratory irritation.SECTION 4 FIRST AID MEASURESEye Flush with water for 15 minutes. If irritation occurs, get medical attention.Skin Flush skin with water, and then wash with soap and water. Get medical attention. Inhalation Remove victim to fresh air and provide oxygen. Get medical attention.Ingestion Do not induce vomiting. Get medical attention.Note to Physician Cure according to symptom.SECTION 5 FIRE FIGHTING MEASURESExtinguishing media Carbon dioxide, foam, dry chemical and water fog. Extinguishing Method SprayCombustion products Fumes, smoke, carbon monoxide, sulfur oxides, aldehydes and other decomposition products, in the case of incomplete combustion.Forbidden media WaterSECTION 6 ACCIDENTAL RELEASE MEASURESProtective Measures Wear appropriate personal protective equipment when cleaning up spills.Spill Management FOR LARGE SPILLS: Remove with vacuum truck or pump to storage/salvage vessels. FOR SMALL SPILLS: Soak up residue with an absorbent such as clay, sand or other suitable material. Place in non-leaking container and seal tightly for proper disposal.SECTION 7 HANDLING AND STORAGEStorage Do not store in open or unlabeled containers. Store in a cool, dry place with adequate ventilation. Keep away from open flames and high temperatures.Empty container warning Empty containers retain residue (liquid and/or vapor) and can be dangerous. DO NOT PRESSURIZE, CUT, WELD, BRAZE, SOLDER, DRILL, GRIND OR EXPOSE SUCH CONTAINERS TO HEAT, FLAME.SECTION 8 EXPOSURE CONTROLS/PERSONAL PROTECTIONExposure controls Provide adequate ventilation to control airborne concentrations below the exposure guidelines/limits.Respiratory Protection If engineering controls do not maintain airborne concentrations to a level which is adequate to protect worker health, an approved respirator must be worn.Eye Protection Chemical Goggles, or Safety glasses with side shields.Hand Protection Use protective gloves which is chemically resistant to this material.Personal protection Use protective clothing and shoes which are chemically resistant to this material. Note to sanitation Wash hands with water an use cosmetic to protect.SECTION 9 PHYSICAL AND CHEMICAL PROPERTIESAppearance: Pale yellow to dark brown smooth ointmentOdor No peculiar smellWorkedCone Penetention,0.1mmNO.1 310~340Dropping Point, ℃>170SECTION 10 STABILITY AND REACTIVITYStability Stable (at room temperature)Conditions and materials toavoidExtreme heat and high energy sources of ignition and strong oxidizers.Hazardous decompositionproductProduct does not decompose at ambient temperatures. Hazardous polymerization Will not occur.SECTION 11 TOXICOLOGICAL INFORMATIONAcute Toxicity ORAL TOXICITY (RATS): Practically low toxic (LD50: greater than 5000mg/kgBW). —-Based on testing of similar products and/or the components.INHALATION TOXICITY (RATS): Practically low toxic (LC50: greater than 10000mg/m3). —-Based on testing of similar products and/or the components.SECTION 12 ECOLOGICAL INFORMATIONEcological toxicity Though long time infiltration, it may produce ecological toxicity.Mobility When released into the environment, adsorption to sediment and soil will Be the predominant behavior.Persistence and degradability This product is expected to be inherently biodegradable.Bioaccumulative potential Bioaccumulation is unlikely due to the very low water solubility of this product; therefore bioavailability to aquatic organisms is minimal.SECTION 13 DISPOSAL CONSIDERATIONSWaste disposal Product is suitable for burning in an enclosed, controlled burner for fuel value. In addition, the product is suitable for processing by an approved recycling facility or can be disposed of at an appropriate government waste disposal facility.Note to release Use protection things ,including protection gloves, glasses and respirator, because explosion may happen heating in the container.SECTION 14 TRANSPORT INFORMATIONTransport The transport department work abiding by all the law ,rule and regulations.SECTION 15 REGULATORY INFORMATIONNational regulation Solid waste pollution prevention and cure law of The People’s Republic of China.State Regulation Water pollution standard of local government.SECTION 16 OTHER INFORMATIONOther data Get information and manual from the market department or technology department.The above information is based on the data of which we are aware and is believed to be correct as of the date hereof. Since this information may be applied under conditions beyond our control and with which we may be unfamiliar and since data made available subsequent to the date hereof may suggest modifications of theinformation, we do not assume any responsibility for the results of its use. This information is furnished upon condition that the person receiving it shall make his own determination of the suitability of the material for his particular purpose.。

常用润滑脂的使用场合钙基润滑脂(分为1号、2号、3号、4号):适用于汽车、拖拉机、冶金、纺织等机械设备的润滑。

使用温度范围为-10~60℃。

石墨钙基润滑脂:适用于压延机的人字齿轮,汽车弹簧,起重机齿轮转盘,矿山机械,绞车和钢丝绳等高负荷、低转速的粗糙机械的润滑。

复合钙基润滑脂:适用于较高温及潮湿条件下摩擦部位的润滑。

合成钙基润滑脂:适用于工业、农业、交通运输等机械设备的润滑,使用温度小于60℃。

合成复合钙基润滑脂:适用于较高温度条件下摩擦部位的润滑。

钠基润滑脂(常见的有2号、3号、4号):2号、3号均适用于工作温度不超过120℃的机械摩擦部位的润滑。

4号适用于工作温度不超过130℃的重负荷机械设备的润滑。

不能用于与潮湿空气或水接触的润滑部位。

钙钠基润滑脂:适用于铁路机车和列车的滚动轴承、小电动机和发电机的滚动轴承以及其他高温轴承等的润滑。

通用锂基润滑脂(分为1号、2号、3号):适用于工作温度在-20~120℃范围内各种机械设备的滚动轴承和滑动轴承及其他摩擦部位的润滑。

极压锂基润滑脂(分为00号、0号、1号、2号):适用于工作温度在-20~120℃范围内高负荷机械设备的轴承及齿轮的润滑,也可用于集中润滑系统。

汽车通用锂基润滑脂:适用于工作温度在-30~120℃范围内的汽车轮毂轴承、底盘、水泵和发电机等摩擦部位的润滑。

合成锂基润滑脂:适用于工作温度在-20~120℃范围内各种机械设备的滚动和滑动摩擦部位的润滑。

极压复合锂基润滑脂(分为1号、2号、3号):适用于工作温度在-20~160℃范围的高负荷机械设备润滑。

铝基润滑脂:用于航运机器摩擦部分润滑及金属表面的防蚀。

复合铝基润滑脂(分为0号、1号、2号):1号用于高温并有集中供脂系统的润滑设备,2号用于没有集中供脂系统的润滑设备,其适用温度范围为-20~150℃。

合成复合铝基润滑脂:适用于较高温度和潮湿条件下摩擦部位的润滑。

使用温度不高于120℃。

极压复合铝基润滑脂(分为0号、1号、2号):适用于工作温度在-20~160℃范围的高负荷机械设备及集中润滑系统。

通用锂基润滑脂概述1、概述通用锂基脂是由1,2-羟基硬脂肪酸锂皂稠化中等粘度矿物油,井加人抗氧防锈添加剂制成,按其锥人度分为l、2、3三个牌号。

2、用途通用锂基脂属于长寿命、多用途的润滑脂,可取代钙基、钠基及钙钠基脂,系这些润滑脂的换代产品。

其具有良好的抗水性、机械安定性、防锈性与氧化安定性,广泛适用于-20℃~120℃温度范围内各种机械设备的滚动轴承和滑动轴承及其它摩擦部位的润滑。

l号适用于集中给脂系统。

2号适用于中转速、中负荷的机械设备。

如汽车,拖拉机轮毂轴承,中小型电动机、水泵和鼓风机等。

3号适用于矿山机械、汽车、拖拉机轮毂轴承,大中型电动机等设备。

3、产品性能(l)其有良好的抗水、防锈性能。

可以在潮湿和与水接触的机械部件上使用。

(2)良好的帆械安定性和胶体安定性。

在高速运转的机械剪切作用下,润滑脂不会变稀或流失。

(3)耐热性好,滴点高。

可在较高温度条件下使用。

4、注意事项(l)通用锂基脂不宜用大容器盛装,以免引起析油。

如有少量析油,可在常温下搅拌或研磨均匀后使用。

(2)不要与其它脂类混合使用。

(3)其它同钙基脂注意事项。

二、汽车通用锂基润滑脂1、概述汽车通用锂基脂是由1,2-轻基硬脂肪酸锤皂稠化低凝点矿物油,并加入防锈剂和抗氧剂而制成。

2、用途汽车通用锂基脂适用于-30℃~120℃范围内汽车轮毂轴承、底盘、水泵等摩擦部位的润滑,也可用于坦克的负重轮和引导轮轴承。

比钙基脂和复合钙基脂延长换油期二倍,减少磨损,简化品种。

满足从哈尔滨到海南岛广大地区汽车的使用要求,可以使润滑和维护费降低40%以上。

进口汽车和国产新车普遍推荐使用这种润滑脂。

3、产品性能(l)具有良好的高低温性,可在-30℃~120℃的宽温度范围内使用。

(2)良好的抗水性和防锈性能,可在潮湿和与水接触的机械部件上使用。

(3)具有良好的机械安定性、胶体安定性、氧化安定性、抗水性和润滑性在高速运转的机械剪切作用下,脂不会变质、流失,保证良好的润滑。

2号极压锂基润滑脂与黄油2号极压锂基润滑脂与黄油: 一场摩擦与润滑的旋风摩擦和润滑是工业界和生活中经常遇到的问题,无论是机械设备的运转,还是日常生活中的摩擦物体,都需要润滑剂来减少因摩擦而产生的能量损失和磨损。

而在众多润滑剂中,2号极压锂基润滑脂和黄油被广泛使用,并在特定领域各具优势。

本文将探讨这两种润滑剂的特点、应用领域和优劣势,并分享我对它们的个人观点和理解。

1. 2号极压锂基润滑脂的特点与应用领域1.1 特点2号极压锂基润滑脂以锂基油为基础,添加了极压抗磨剂、抗氧化剂等一系列的添加剂。

这使得它具有很好的稳定性、抗氧化性和抗磨性能。

它还具有防锈、防腐蚀和良好的密封性能。

1.2 应用领域2号极压锂基润滑脂广泛应用于重型机械设备、轴承、齿轮和轴颈等高负荷和高温环境下的润滑。

它的稳定性和抗磨性能使得它成为很多工业设备的首选润滑剂。

2. 黄油的特点与应用领域2.1 特点黄油是以动物脂肪或牛奶脂肪为原料制成的一种润滑剂。

它具有高黏稠度和润滑性,能够长时间保持在摩擦表面。

黄油还具有良好的食用性质和一定的营养价值。

2.2 应用领域黄油的主要应用领域是食品工业,例如酥皮、蛋糕和面包制作中,黄油常用于增加食品的口感和香味。

黄油在化妆品和药品制造中也有一定的应用。

3. 2号极压锂基润滑脂与黄油的优劣势对比3.1 优势2号极压锂基润滑脂具有稳定性和抗磨能力强的优点,在高温、高负荷工况下表现出色。

相比之下,黄油在润滑性能上相对而言略逊一筹。

3.2 劣势黄油在食品工业和化妆品领域有广泛的应用,而2号极压锂基润滑脂的应用主要集中在工业领域。

在特定领域的应用范围上,2号极压锂基润滑脂存在一定的劣势。

4. 个人观点与理解通过对2号极压锂基润滑脂和黄油的比较,我认为这两种润滑剂在特定领域都有各自的优劣势。

2号极压锂基润滑脂在工业领域具有优异的性能,可以提供持续的润滑和保护;而黄油在食品和化妆品领域则发挥其独特的作用,为产品提供更好的口感和品质。

201号复合锂基润滑脂2009-06-06 点击数:162一、概述本产品由复合锂稠化剂稠化精制高粘度矿油,并加有抗氧、防锈,抗极压等多种添加剂精制而成。

本产品与美国宜美史克公司IMSCO2021锂基复合润滑脂性能相当。

三、产品特点本产品具有优良的耐高温性能,极压润滑性、抗水性、防锈性和机械安定性能,具有较长的润滑寿命。

四、用途本产品适用于石油化工、纺织、印染、钢铁和浮法玻璃等各行业生产中的高温中、低速轴承,各种中、重负荷滚珠、滚柱、滑动轴承以及烘烤设备的齿轮、链条、托轮等传动部位和联轴节等部位的润滑。

适用温度:-20℃~+230℃五、包装形式1㎏、18kg塑料桶包装。

六、用注意事项使1、使用前,将润滑部位用煤油或其它溶剂清洗干净,吹干后再涂抹本产品。

2、启用后,应及时将盖封严,以防混入杂质及污染。

3、请勿与其它油脂混用,以免影响使用效果。

4、本产品应贮存于清洁、干燥及避光处。

长春西格玛润滑技术实业有限责任公司地址:吉林省长春市南关区新城大街1495号邮编:130118电话:86-431-84511649传真:86-431-84530952网址:孚力士滑脂EP (Mobilux EP) 系列典型性质Mobilux EP 0 Mobilux EP 1 Mobilux EP 2 Mobilux EP 3NLGI 等级0 1 2 3稠化剂类型锂基锂基锂基锂基颜色,目视棕色棕色棕色棕色工作锥入度,25ºC, ASTM D 217,mm/10 370 325 280 235 基础油粘度,ASTM D 445cSt @ 40ºC 160 160 160 160蒂姆肯OK 承载能力,ASTM D 2509,lb 40 40 40 40四球磨损测试,ASTM D 2266,磨痕,mm 0.4 0.4 0.4 0.4 四球焊接承载能力,ASTM D 2509,Kg 250 250 250 250滴点,D 2265,ºC 190 190 190 190锈蚀保护,ASTM D 6138,蒸馏水0-0 0-0 0-0 0-0Mobilith SHC Series (美孚力富SHC系列)润滑脂产品简介Mobilith SHC 系列润滑脂是超优性能的产品,可用于在极端温度下作业的各种装置。

化学品安全技术说明书(MSDS)锂基润滑脂1,化学品名称及用途产品名称:锂基润滑脂(俗称黄油)用途:车用或普通设备用脂------------------------------------------------------------------------------- 2,组成/成分资料成分:精制矿物油、皂类增稠剂、适当的性能添加剂。

此产品不含任何等于或高于规定限值的有害成分(请参阅第八节职业接触限度)------------------------------------------------------------------------------- 3,危险性概述此产品不属于危险产品。

但必须按照良好的工业卫生条件和安全操作规程进行使用。

------------------------------------------------------------------------------- 4,急救措施眼睛:一旦误入眼睛,将眼睛张大,用大量清水冲洗。

若眼睛仍有任何红肿、疼痛或不适,应尽快就医。

皮肤:皮肤若接触到油品,应尽快用清水和肥皂彻底加以清洗,更换严重受污染的衣物,清洗下面弄脏的皮肤。

吸入气体:产品在规定温度下使用不会生烟。

如若吸入高温下产生的油烟造成鼻喉部刺激或咳嗽,应尽快移至空气新鲜处;如果仍有不适,应送医诊治。

吞服:若污染了口部,应用水彻底冲洗;如有不适,请立即就医。

------------------------------------------------------------------------------- 5,灭火措施适用灭火媒介:使用泡沫、干粉或水沫,不要用水流。

特殊接触危险:燃烧或遇热可能会发出有毒烟雾。

特别保护仪器:限定空间内的火灾,应该由受训过的人员穿戴好氧气面具进行处理。

可以用水冷却附近的遇热区域/物品/包装;由于有沸溢危险,要避免直接喷射到储存容器里。

2号极压锂基脂使用温度要求一、概述2号极压锂基脂是由锂基油和极压添加剂组成的润滑脂。

由于其独特的化学组成,它在高温和极低温度条件下都能保持良好的润滑性能,是机械设备的理想润滑材料。

本文将详细介绍2号极压锂基脂的使用温度要求。

二、使用温度范围2号极压锂基脂的使用温度范围一般在-20℃至120℃之间。

在这个温度范围内,它可以有效地润滑设备,防止设备磨损,提高设备的使用寿命。

三、注意事项1. 温度过高或过低都会影响2号极压锂基脂的性能。

长时间超过120℃使用可能会导致润滑脂变质,从而失去润滑效果。

而低于-20℃时,润滑脂可能会变得稠厚,流动性变差,难以涂抹。

2. 在使用过程中,应定期检查2号极压锂基脂的温度,确保其在规定的温度范围内。

如果温度过高或过低,应及时采取措施,如更换润滑脂或采取冷却措施。

3. 在高温条件下使用时,应选择具有耐高温性能的润滑脂,以保证设备的正常运转。

在低温条件下使用时,应注意保持润滑脂的流动性,防止因润滑脂稠厚而影响设备的润滑效果。

4. 在使用过程中,应避免将2号极压锂基脂暴露在灰尘、水分等污染物中,以免影响其性能。

同时,应定期清洁润滑脂存储容器,以确保润滑脂的质量。

5. 如果设备需要在极端的温度条件下工作,如高温或低温环境,建议选择专业的高温或低温润滑脂,以保证设备的正常运转和延长设备的使用寿命。

四、润滑脂的更换为了确保设备的正常运行和延长设备的使用寿命,应定期更换润滑脂。

一般来说,2号极压锂基脂的更换周期为3-6个月,具体时间视设备的工作环境和运行状况而定。

在更换润滑脂时,应先清洁设备表面,然后涂抹新的润滑脂。

五、总结2号极压锂基脂是一种性能优良的润滑脂,适用于各种机械设备。

在使用过程中,应遵循其使用温度要求,避免长时间超过或低于规定的温度范围。

同时,应定期检查和更换润滑脂,以保证设备的正常运行和延长设备的使用寿命。

在极端温度条件下工作的设备,应选择专业的高温或低温润滑脂。

深圳市美润华润滑油有限公司,是华南地区最大的工业润滑油代理商。

公司2000年3月成立于中国南方经济、金融、贸易中心——深圳。

是中国区域最大最专业经营国际品牌润滑油的批发销售服务商,公司遵循“以质量求生存,以技术求发展,以市场为导向,以服务为宗旨”的经营理念,始终坚持以“科技创新、合作共赢、诚信高效、服务一流”为服务理念。

为用户全方位、多元化、宽层次服务,为各界同仁精诚合作,共创辉煌。

TOTAL MULTIS EP2

道达尔多特士MULTIS EP2极压锂基润滑脂

多用途极压润滑脂

使用推荐

TOTAL MULTIS EP2多用途极压润滑脂,适用于交通、农业及各种工程机械中,工作在潮湿、多尘和/或干燥条件下的滑动轴承、滚动轴承和球轴承的润滑、轮轴轴承润滑、连接件、汽车底盘润滑以及载有各种冲击或振动载荷的润滑系统z 适用于各种要求NLGl2级别极压润滑脂的工业润滑场合避免灰尘及污物污染,建议使用集中泵送系统或滑脂枪供脂

国际规范

ISO6743-9:L-XBCEB2

DIN51502:KP2K-20

性能优点:

多用途特性——由于多用途特性,该润滑脂可以替换大多数润滑脂,使库存更合理化并使维修简单化

—可形成耐久润滑膜,减少维修及停工成本

持久润滑膜——可与其他大多数皂基润滑脂混和使用

相容性——优异的机械稳定性,可避免使用过程中被挤出或出现稠度损失

机械稳定性——与金属粘结性能良好

热稳定性——良好的热稳定性,显著的抗温度变化能力

不含有害物质——不含铅及其他重金属,或其他对人体健康和环境有害的物质

典型数据

道达尔MULTIS EP2测试方法MULTIS EP2

皂基/稠化剂锂基

NLGl等级ASTM D2172

颜色Visual褐色

外观Visual光滑

操作温度范围℃-20~120

针入度(25℃)0.1mm ASTM D217220~250

梯姆肯OK承载能力lbs ASTM D2509265~295

抗腐蚀性ASTM D17430-0

滴点℃IP396>185

运动粘度(40℃)mm2/s(cSt)ASTM D445150。