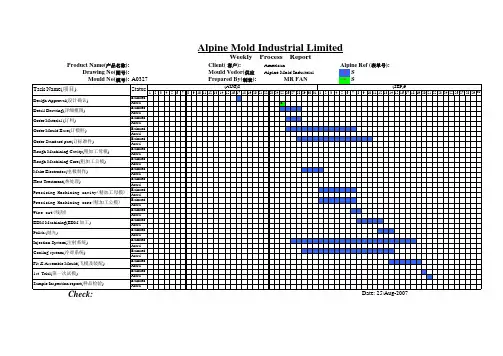

Fabrication Schedule 制造计划

- 格式:pdf

- 大小:62.37 KB

- 文档页数:2

下载温馨提示:该文档是我店铺精心编制而成,希望大家下载以后,能够帮助大家解决实际的问题。

文档下载后可定制随意修改,请根据实际需要进行相应的调整和使用,谢谢!并且,本店铺为大家提供各种各样类型的实用资料,如教育随笔、日记赏析、句子摘抄、古诗大全、经典美文、话题作文、工作总结、词语解析、文案摘录、其他资料等等,如想了解不同资料格式和写法,敬请关注!Download tips: This document is carefully compiled by theeditor. I hope that after you download them,they can help yousolve practical problems. The document can be customized andmodified after downloading,please adjust and use it according toactual needs, thank you!In addition, our shop provides you with various types ofpractical materials,such as educational essays, diaryappreciation,sentence excerpts,ancient poems,classic articles,topic composition,work summary,word parsing,copy excerpts,other materials and so on,want to know different data formats andwriting methods,please pay attention!Title: Optimizing Production Processes for Enhanced Efficiency: A Practical ApproachIn today's competitive industrial landscape, optimizing production processes is crucial for businesses to stay ahead.Efficient production not only ensures timely delivery but also enhances overall quality, customer satisfaction, andcost-effectiveness. In this article, we'll explore a practical approach to optimizing production processes, focusing on key strategies and best practices.1. Process Analysis and Mapping:The first step in optimizing production processes is to conduct a comprehensive analysis of existing workflows. This involves identifying each step involved in the production process, from raw material acquisition to final product delivery. Utilizing tools such as process mapping techniques helps visualize the workflow and identify potential bottlenecks or inefficiencies.2. Identifying Key Performance Indicators (KPIs):Setting measurable KPIs is essential for monitoring and evaluating the effectiveness of production processes. KPIs may include metrics such as production cycle time, defect rates, equipment utilization, and inventory turnover. By regularly tracking these indicators, businesses can pinpoint areas that require improvement and measure the impact of optimization efforts.3. Implementing Lean Principles:Adopting lean manufacturing principles can significantly streamline production processes and eliminate wastage. Techniques such as 5S (Sort, Set in order, Shine, Standardize, Sustain), Kanban, and Just-in-Time (JIT) inventory management help minimize inventory holding costs, reduce lead times, and enhance overall efficiency.4. Automation and Technology Integration:Embracing automation technologies and integrating advanced systems can revolutionize production processes. Automated machinery and robotics can perform repetitive tasks with precision and speed, reducing manual labor requirements and minimizing the risk of human error. Additionally, implementing software solutions such as Enterprise Resource Planning (ERP) systems facilitates seamless coordination across departments and enhances decision-making capabilities.5. Continuous Improvement Culture:Cultivating a culture of continuous improvement is essential for sustaining optimized production processes over the long term. Encouraging employee involvement in identifying inefficiencies, brainstorming solutions, and implementing changes fosters a sense of ownership and commitment to excellence. Regular performance reviews and feedback loops ensure thatproduction processes remain agile and responsive to evolving market demands.Optimizing production processes is not a one-time endeavor but an ongoing journey towards operational excellence. By employing a systematic approach that combines analysis, innovation, and continuous improvement, businesses can achieve significant enhancements in productivity, quality, and competitiveness.现代竞争激烈的工业领域中,优化生产工艺对企业保持领先地位至关重要。

生产制造工作计划(7篇)生产制造工作计划1制造部是公司生产系统的综合管理部门,在生产副总的直接领导下,组建生产制造部,主持本部门的全面工作,拟定本部门岗位职责和工作标准。

配合各部门协调各车间按时完成生产计划。

制造部负责从原材料投入到产品制造全过程中的生产管理工作。

20_年,我部门紧密围绕公司"销售目标"和"质量方针"为核心展开工作。

现将本部门20_年度的工作思路整理如下:1、拟定本部门的工作目标和工作计划,并督促本部门人员及时完成拟定目标和计划。

2、熟悉各车间的产品和生产流程。

3、规范各车间生产报表,统一格式,按规定的要求填写。

检查并落实各车间数据的准确性、可靠性。

4、编制月度生产计划、周生产计划、日计划。

做好各车间生产协调工作,督促各车间按生产计划实施,并与每周五召开一次生产例会,总结本周计划完成情况同时下达下周工作计划。

5、配合技术部做好新产品试制工作,及时安排生产,提高公司产品的市场竞争力。

6、外协管理。

及时沟通,做到先进先出,确保产品按期交付。

要求账、卡、物一致。

7、与设备科沟通,每周合理安排设备检修和维护时间,做好生产准备工作。

8、与生产车间共同商议,查找质量隐患,排查过程,确保生产过程的稳定性。

与质量部、技术部共同牵手,进行产品质量改进工作,确保产品质量的稳定性,提高产品的质量水平,提升有效生产率。

9、每月月底组织盘点,将生产数与入库数及废品数进行分析,找出产品差额数,降低成本,减少损失。

10、找出生产中存在的瓶颈,协助车间解决。

理清生产流程,使各工序衔接紧密,提高生产效率。

12、每周进行一次大型安全隐患排查并对隐患点限期进行整改。

检查各车间劳保用品配戴情况,正确配戴劳保。

推行5s工作,合理规划各车间定置点。

每周对各车间进行检查并评定结果,使车间物流畅通,流程顺畅。

13、对本部门人员进行培训,提升业务技能。

14、配合体系办,做好iso/tsl6949体系审核工作。

面料采购工作规划和目标Fabric procurement is an essential part of the fashion production process. It involves sourcing and purchasing the materials needed to create garments and other textile products. As a fashion brand or manufacturer, having a well-organized and strategic fabric procurement plan is crucial to ensuring a smooth production process and meeting your targets.面料采购是时尚生产过程中不可或缺的一部分。

它涉及获取和购买制作服装和其他纺织品所需的材料。

作为一个时尚品牌或制造商,拥有一个有条不紊且具有战略性的面料采购计划对于确保生产过程顺利进行并实现目标至关重要。

One key aspect of fabric procurement is setting clear goals and targets for sourcing materials. This involves determining the types of fabrics needed, the quantities required, as well as the quality standards that must be met. By setting specific goals, fashion brands can better allocate their resources, negotiate prices with suppliers, and ensure that they are purchasing the right materials for their production needs.面料采购的一个关键方面是为采购材料设定清晰的目标和指标。

制造工作计划范文英语版IntroductionThe manufacturing industry plays a crucial role in the global economy, contributing to various sectors such as automotive, electronics, consumer goods, and more. To ensure the success of manufacturing operations, it is essential to develop a comprehensive work plan that outlines the goals, strategies, resources, and timelines for achieving production targets. This manufacturing work plan aims to provide a detailed framework for managing manufacturing operations, addressing key aspects such as production schedules, inventory management, quality control, and workforce optimization.Goals and ObjectivesThe primary goal of the manufacturing work plan is to optimize production processes, reduce costs, and improve overall efficiency. To achieve this, the following objectives will be pursued:1. Increase production output by 20% within the next 12 months2. Reduce manufacturing defects by 15% through improved quality control measures3. Minimize production downtime by 10% through proactive maintenance and equipment optimization4. Implement lean manufacturing principles to streamline operations and eliminate waste5. Enhance workforce productivity through training and skills development programs Production SchedulesThe manufacturing work plan will incorporate detailed production schedules to ensure that manufacturing operations are organized and efficient. The schedules will be developed based on demand forecasts, production capacity, and resource availability. Key aspects of the production schedules include:1. Daily production targets for each manufacturing line2. Weekly production plans aligned with customer orders and sales projections3. Monthly production schedules based on inventory levels and market demand4. Quarterly production forecasts to facilitate long-term planning and resource allocation Inventory ManagementEffective inventory management is essential for maintaining smooth manufacturing operations and meeting customer demand. The work plan will outline strategies foroptimizing inventory levels, minimizing stockouts, and reducing excess inventory. The key components of the inventory management plan include:1. Just-in-time inventory system to minimize storage costs and improve efficiency2. Implementing advanced supply chain management tools to track inventory levels and demand patterns3. Establishing safety stock levels to mitigate the risk of stockouts4. Regular inventory audits and cycle counts to ensure accuracy and prevent losses Quality ControlQuality control is a critical aspect of manufacturing, as it directly impacts customer satisfaction and brand reputation. The manufacturing work plan will focus on implementing robust quality control measures to identify and rectify production defects. The quality control plan will include the following elements:1. Implementing statistical process control (SPC) techniques to monitor production processes and identify variations2. Conducting regular quality inspections at key stages of the production process3. Implementing corrective and preventive action (CAPA) processes to address quality issues4. Training employees on quality control standards and best practicesMaintenance and Equipment OptimizationTo ensure uninterrupted production operations, the manufacturing work plan will prioritize proactive maintenance and equipment optimization. The maintenance schedule will be developed based on equipment usage, maintenance intervals, and historical failure rates. Additionally, the plan will address equipment optimization through the following initiatives:1. Implementing predictive maintenance techniques to identify potential equipment failures before they occur2. Regular equipment calibration and performance testing to ensure accuracy and reliability3. Upgrading obsolete equipment to improve efficiency and reduce downtime4. Training maintenance staff on best practices and equipment troubleshooting Workforce OptimizationThe manufacturing work plan will also focus on optimizing the workforce to improve productivity and efficiency. This will involve identifying skill gaps, providing training programs, and implementing performance improvement initiatives. Key elements of the workforce optimization plan include:1. Conducting skills assessments to identify training needs and skill gaps2. Implementing training programs to enhance technical skills and improve productivity3. Establishing performance metrics and KPIs to monitor workforce productivity4. Implementing employee engagement initiatives to improve morale and motivation ConclusionIn conclusion, the manufacturing work plan outlined above provides a comprehensive framework for managing manufacturing operations effectively. By focusing on production schedules, inventory management, quality control, maintenance, equipment optimization, and workforce optimization, manufacturing companies can improve efficiency, reduce costs, and achieve production targets. This work plan will be continuously evaluated and updated to adapt to changing market conditions and business requirements. With a clear focus on continuous improvement, manufacturing organizations can thrive in a competitive global marketplace.。

制造业月度生产计划编制英文回答:Manufacturing Monthly Production Planning.In the manufacturing industry, monthly production planning is a crucial process that involves determining the production targets and schedules for each month. This planning is essential to ensure that the production process runs smoothly and efficiently, meeting the demands of customers while optimizing the use of resources.The first step in the monthly production planning process is to analyze the demand forecast. This involves examining historical sales data, market trends, and customer orders to estimate the expected demand for the upcoming month. By understanding the demand patterns, manufacturers can better plan their production schedules and allocate resources accordingly.Once the demand forecast is determined, the next stepis to assess the production capacity. This involves evaluating the available resources such as labor, raw materials, and machinery. Manufacturers need to consider factors such as machine downtime, employee availability, and material availability to determine the maximum production capacity for the month.After analyzing the demand forecast and production capacity, the next step is to develop a production plan. This plan outlines the production targets for each product or product line, along with the schedule for each production run. It also considers factors such as lead times, setup times, and batch sizes to optimize the production process.The production plan should also take into account any constraints or limitations. For example, if there is a shortage of raw materials or a bottleneck in the production process, adjustments need to be made to ensure that the plan is feasible. This may involve sourcing alternative suppliers or reorganizing the production flow.Monitoring and control are crucial aspects of the monthly production planning process. Regular reviews and updates are necessary to ensure that the plan is on track and any deviations are addressed promptly. This may involve adjusting production schedules, reallocating resources, or implementing contingency plans to mitigate any potential disruptions.In conclusion, monthly production planning in the manufacturing industry is a complex process that requires careful analysis of demand forecasts, assessment of production capacity, and the development of a comprehensive production plan. By effectively planning and managing production, manufacturers can optimize resource utilization, meet customer demands, and ensure the smooth operation of their manufacturing processes.中文回答:制造业月度生产计划编制。

制造计划、制造排程英文回答:Production Planning and Scheduling.Production planning and scheduling are two essential processes in manufacturing that ensure the timely and efficient production of goods. Production planning determines what products will be produced, in what quantities, and when, while production scheduling determines the specific sequence in which operations will be performed.Production Planning.Production planning involves a series of steps to determine the production requirements of a company. These steps include:1. Forecasting demand: Estimating future demand forproducts based on historical data, market research, and other relevant factors.2. Determining production capacity: Assessing the available resources, including equipment, labor, and materials, to determine the production capacity of the company.3. Developing a master production schedule (MPS): Outlining the production targets for each product, taking into account demand forecasts and production capacity.4. Creating a material requirements plan (MRP): Determining the materials needed for production and the timing of their purchase or production.5. Developing a capacity plan: Ensuring that the production capacity is aligned with the production plan, considering factors such as equipment availability, labor capacity, and supplier lead times.Production Scheduling.Production scheduling involves sequencing the operations required to produce goods. The goal of scheduling is to minimize production time, reduce bottlenecks, and optimize resource utilization. Common scheduling techniques include:1. First-come, first-served (FCFS): Processing tasks in the order they arrive.2. Shortest job first (SJF): Prioritizing tasks with the shortest processing time.3. Critical ratio scheduling (CRS): Scheduling tasks based on their critical ratio, which is the ratio of remaining processing time to remaining slack time.4. Earliest due date (EDD): Scheduling tasks based on their due dates, giving priority to tasks with earlier due dates.5. Theory of constraints (TOC): Identifying andaddressing constraints in the production process to improve overall efficiency.Integration of Production Planning and Scheduling.Production planning and scheduling are closely integrated processes. The production plan provides the basis for scheduling, while scheduling provides feedback to the planning process. This integration helps ensure that production is aligned with demand, resources are utilized efficiently, and production goals are met.中文回答:生产计划和调度。

制造工作计划范文大全英文1. IntroductionThe manufacturing work plan is a strategic document that outlines the goals, objectives, and timelines for the production of a particular product. It provides a roadmap for the manufacturing process, including the allocation of resources, the identification of potential risks, and the establishment of quality control measures. This plan is essential for ensuring that the manufacturing process runs smoothly and efficiently, and that the final product meets the required standards and specifications.2. Goals and ObjectivesThe primary goal of the manufacturing work plan is to produce a high-quality product that meets the needs and expectations of our customers. This will require a commitment to excellence in every aspect of the manufacturing process, from the selection of raw materials to the final inspection of the finished product. In order to achieve this goal, the following objectives have been identified:- To develop a detailed production schedule that outlines the sequence of tasks and the allocation of resources required to meet production targets.- To establish quality control measures that will be implemented at every stage of the manufacturing process, including incoming raw materials inspection, in-process quality checks, and final product testing.- To identify potential risks and develop contingency plans to mitigate these risks and ensure that production targets are met.- To monitor and evaluate the progress of the manufacturing process on an ongoing basis, and make adjustments as necessary to ensure that production targets are met.3. Production ScheduleThe production schedule is a critical component of the manufacturing work plan, as it provides a detailed roadmap for the manufacturing process. It outlines the sequence of tasks that need to be completed, as well as the allocation of resources required to complete these tasks. The production schedule will be developed in consultation with key stakeholders, including production managers, engineers, and procurement staff, to ensure that it reflects the capabilities and constraints of the production facility.The production schedule will be broken down into a series of milestones, with each milestone representing a key stage of the manufacturing process. These milestones will be linked to specific production targets, and will be used to measure progress and identify potential bottlenecks or delays. The production schedule will also include contingency plans for dealing with unexpected events or disruptions that may impact production.4. Resource AllocationAn important aspect of the manufacturing work plan is the allocation of resources, including both human and material resources. This will involve determining the number of production staff required, as well as the skill sets and qualifications needed to carry out specific tasks. It will also involve identifying the raw materials and components required for production, and developing a procurement plan to ensure that these materials are available when needed.The resource allocation plan will also include a budget for the manufacturing process, which will outline the costs associated with production, including labor, materials, equipment, and overheads. This budget will be used to monitor and control costs, and to ensure that the manufacturing process remains within budget.5. Quality ControlQuality control is a critical component of the manufacturing work plan, as it is essential for ensuring that the final product meets the required standards and specifications. Quality control measures will be implemented at every stage of the manufacturing process, including:- Incoming raw materials inspection: All raw materials and components will be inspected upon arrival at the production facility to ensure that they meet the required specifications and quality standards.- In-process quality checks: Throughout the manufacturing process, in-process quality checks will be carried out to identify any defects or non-conformities, and to take corrective action as necessary.- Final product testing: Once the final product has been manufactured, it will undergo rigorous testing to ensure that it meets the required standards for quality and performance.Any products that do not meet the required standards will be rejected and either reworked or disposed of, to ensure that only high-quality products are released to the market.6. Risk ManagementThe manufacturing work plan will also include a risk management strategy, which will identify potential risks that may impact the manufacturing process, and develop contingency plans to mitigate these risks. This will involve conducting a thorough risk assessment, which will be used to identify potential hazards and develop strategies to manage or eliminate these risks.Potential risks that may be identified include:- Supply chain disruptions: Any disruptions to the supply chain, such as delays in the delivery of raw materials, could impact the manufacturing process. Contingency plans willbe developed to ensure that production targets are still met, even in the event of supply chain disruptions.- Equipment failures: Any failures in manufacturing equipment could lead to delays or disruptions in production. Preventive maintenance programs will be implemented to minimize the risk of equipment failures, and contingency plans will be developed to address any equipment failures that do occur.- Quality control failures: Any failures in the quality control process could lead to the release of defective products. Contingency plans will be developed to address any quality control failures and ensure that only high-quality products are released to the market.7. Monitoring and EvaluationThe manufacturing work plan will include a monitoring and evaluation strategy, which will be used to track the progress of the manufacturing process and identify any potential issues or bottlenecks. This will involve the use of key performance indicators (KPIs) to measure progress against production targets, as well as regular reviews and inspections to identify any potential areas for improvement.The monitoring and evaluation process will also involve regular consultations with key stakeholders, including production managers, engineers, and quality control staff, to ensure that the manufacturing process is running smoothly and efficiently.8. ConclusionThe manufacturing work plan is a critical document that provides a roadmap for the manufacturing process, including the allocation of resources, the identification of potential risks, and the establishment of quality control measures. By developing a detailed production schedule, allocating resources effectively, implementing rigorous quality control measures, and developing a risk management strategy, we can ensure that the manufacturing process runs smoothly and efficiently, and that the final product meets the required standards and specifications.。

关于制造工作计划4篇关于制造工作计划4篇日子在弹指一挥间就毫无声息的流逝,相信大家对即将到来的工作生活满心期待吧!一起对今后的学习做个计划吧。

计划怎么写才能发挥它最大的作用呢?以下是小编整理的制造工作计划4篇,欢迎大家分享。

制造工作计划篇1陈总在制造公司xx年的工作规划中,首先对xx年的工作进行了简单的总结,一方面肯定了xx年取得的成绩,同时也指出了工作中存在的不足。

同时,围绕吴总“提高质量、降低成本”的目标,明确xx年制造公司要重点做好的两项工作,一是从细处着手,采取综合措施,进一步提升产品质量。

二是全方位开展降耗活动,降低产品制造成本,特别是要作好板材、铜管、铝箔、制冷剂、气体、电线等物资的控制。

质量是企业生存之本,为使xx年产品质量再上新高,陈总要求作好如下工作:一是紧密跟踪售后和检验,确保产品质量问题得到有效、持续的改进,重点是老问题的跟踪和新问题的改进落实;二是进一步完善和细化工艺,更好的保证产品质量;三是车间严格首件检验和“三检”制度,严把制造过程质量关;四是持续进行员工培训,不断提高其技能,以技能保证产品质量。

对出问题和易出问题的环节进行重点培训;新员工和老员工培训要有区别;出问题点与不出问题点培训有区别;特殊工种、关键工种与一般工种培训有区别;五是细化质量责任制,加大考核力度,根除因责任心不强导致的质量问题;六是严格按体系文件要求执行,确保体系有效运行;七是学习国内外同行业名牌企业先进产品质量管理方法,提升出口产品质量。

按照自找问题,自我否定的方法,提升水平。

xx年是管理提升年,为提升管理水平,陈总要求制造公司要建立和完善以下八项工作制度:1、车间调度会制度;2、车间质量分析会制度;3、车间技术准备会制度;4、车间成本费用分析会制度;5、管路现场评审会制度;6、车间考评制度;7、车间专检制度;8、车间合理化建议奖励制度。

优秀的干部员工队伍是企业发展的重要保证。

在人员培训和梯队建设方面,陈总也作了具体的安排和布署,要求各部门要发现人、培养人,用好人,做好员工的职业生涯规划。

设备的详细制造进度计划英文回答:Detailed Manufacturing Schedule for Equipment.Project Scope.The project scope includes the development and manufacture of a new type of medical equipment. The equipment is designed to be used in hospitals and clinics for the diagnosis and treatment of various diseases. The equipment must meet all applicable regulatory requirements and be manufactured in accordance with Good Manufacturing Practices (GMP).Manufacturing Schedule.The following is a detailed manufacturing schedule for the equipment:Phase 1: Design and Development (6 months)。

Conceptual design.Detailed design.Prototyping.Testing and validation.Phase 2: Manufacturing Planning (3 months)。

Process planning.Material sourcing.Equipment procurement.Facility layout.Phase 3: Production (12 months)。

Raw material inspection.Component fabrication.Assembly.Testing and inspection.Packaging and labeling.Phase 4: Installation and Commissioning (2 months)。

制造业策划书模板3篇篇一制造业策划书一、项目概述1. 项目名称:[具体名称]2. 项目背景:简要介绍制造业项目的背景和动机。

3. 项目目标:明确项目的长期和短期目标。

4. 项目范围:界定项目的范围和边界。

二、市场分析1. 目标市场:确定目标市场和客户群体。

2. 市场规模:评估市场规模和潜力。

3. 竞争情况:分析竞争对手的优势和劣势。

4. 市场趋势:研究市场的发展趋势和变化。

三、产品或服务1. 产品或服务描述:详细描述制造业产品或服务的特点和优势。

2. 产品或服务定位:确定产品或服务在市场中的定位。

3. 产品或服务创新:提出产品或服务的创新点和差异化竞争策略。

四、生产流程1. 生产设施:描述生产所需的设施和设备。

2. 生产流程:绘制生产流程的流程图,并说明各个环节的操作和控制。

3. 质量控制:制定质量控制计划,确保产品或服务符合质量标准。

4. 供应链管理:优化供应链,确保原材料的及时供应和成本控制。

五、营销策略1. 产品定价:确定产品或服务的定价策略。

2. 销售渠道:选择合适的销售渠道,如直销、分销或电子商务。

3. 促销活动:制定促销活动计划,提高产品或服务的知名度和销售额。

4. 客户关系管理:建立客户关系管理系统,提高客户满意度和忠诚度。

六、组织与管理1. 组织结构:设计合理的组织结构,明确各个部门和岗位的职责和权限。

2. 人力资源管理:制定人力资源计划,招聘、培训和绩效管理。

3. 生产管理:建立生产管理制度,确保生产计划的顺利执行。

4. 财务管理:制定财务预算和成本控制计划,确保项目的盈利能力。

七、项目实施计划1. 项目阶段:划分项目的各个阶段,并明确每个阶段的任务和目标。

2. 项目时间表:制定项目的时间表,包括各个阶段的开始和结束时间。

3. 项目里程碑:确定项目的里程碑,以便及时评估项目的进展情况。

4. 项目风险评估:识别项目可能面临的风险,并制定相应的风险管理计划。

八、财务预测1. 收入预测:预测项目的收入情况,包括销售额和市场份额。

造纸厂生产计划表模板英文回答:A paper mill production schedule template is a useful tool for planning and organizing the production process in a paper mill. It helps in scheduling the different tasks and activities involved in the production of paper, ensuring efficient use of resources and timely delivery of products.The template typically includes the following information:1. Date: The date on which the production is scheduled to begin.2. Shift: The specific shift during which the production is planned.3. Machine/Equipment: The machine or equipment to beused for the production.4. Product: The type of paper product to be manufactured.5. Quantity: The planned quantity of paper to be produced.6. Raw Materials: The type and quantity of raw materials required for the production.7. Production Time: The estimated time required to complete the production process.8. Personnel: The number and type of personnel required for the production.9. Quality Control: The quality control measures to be implemented during the production process.10. Remarks: Any additional notes or comments related to the production.By using a production schedule template, the paper mill can effectively plan and manage its production activities. It helps in optimizing the use of resources, minimizing downtime, and meeting customer demands in a timely manner.中文回答:造纸厂生产计划表模板是一个有用的工具,用于规划和组织造纸厂的生产过程。

生产制造项目计划书项目背景:我们计划开展一个生产制造项目,以满足市场对特定产品的需求。

该计划旨在提供详细的项目计划,确保项目的成功实施并达到预期目标。

项目目标:1. 完成产品设计和开发阶段,包括原型制作和样品测试。

2. 建立生产线,确保设备和资源的顺利采购并投入使用。

3. 实施生产计划,包括材料采购、加工生产和质量控制。

4. 完成产品的包装和配送,确保按时交付客户。

项目计划:1. 项目启动阶段1.1 项目背景调研在这个阶段,我们将调研市场需求和竞争情况,明确项目的可行性和优势。

1.2 项目可行性分析我们将分析项目投资回报率和实施风险,以确定项目的可行性。

1.3 项目目标设定在这个阶段,我们将明确项目的目标和预期成果。

2. 产品设计和开发阶段2.1 需求分析我们将与客户或市场调研团队合作,明确产品的需求和规格。

2.2 原型制作基于需求分析,我们将制作产品的原型,并进行测试和改进。

2.3 样品生产在原型制作完成后,我们将进一步开展样品生产,以确保产品符合要求。

3. 生产线建设阶段3.1 设备采购我们将根据生产线的需求,选择合适的设备,并进行采购。

3.2 生产线布局和安装我们将设计并安装生产线,确保设备能够高效运作,并满足产品的生产要求。

3.3 人员培训在生产线建设完成后,我们将进行员工培训,确保他们能够熟练操作设备和执行生产工艺。

4. 生产计划和控制阶段4.1 原材料采购我们将根据生产计划,制定原材料采购计划,并与供应商建立合作关系。

4.2 加工生产在原材料准备就绪后,我们将开始产品的加工生产,并进行质量控制。

4.3 质量控制我们将建立质量控制措施,确保产品符合规定的质量标准。

4.4 生产进度跟踪我们将跟踪生产进度,并及时调整生产计划,以应对可能出现的问题。

5. 产品包装和配送阶段5.1 产品包装我们将制定适当的产品包装方案,确保产品在运输和存储过程中不受损。

5.2 产品配送我们将根据客户要求,制定产品配送计划,并确保按时交付客户。

制造工作计划范文英语Introduction:The manufacturing industry plays a crucial role in the economic growth and development of nations. Its efficiency and competitiveness greatly impact the overall productivity of a country. To ensure success in the manufacturing sector, having a well-organized and strategic work plan is essential. This article presents a comprehensive manufacturing work plan that covers various aspects of the manufacturing process, including production planning, quality control, supply chain management, and resource allocation.Section 1: Production Planning1.1 Define production goals and objectives:Identify the specific targets and objectives for the production process. This includes determining the desired output quantity, quality standards, and timelines for each product.1.2 Product design and development:Work with the engineering and design teams to develop innovative and cost-effective products that meet customer requirements and market trends.1.3 Production capacity analysis:Analyze the existing production capacity to identify any bottlenecks or constraints that may hinder production. Assess the need for expanding production facilities or acquiring new machinery to meet the production goals.1.4 Production scheduling:Develop a detailed production schedule that outlines the order and timeline of each production task. Consider factors such as production lead time, machine availability, and resource allocation to optimize the production process.1.5 Material requirement planning:Estimate the quantity and types of raw materials required for each production cycle. Maintain an efficient inventory management system to ensure adequate supply of materials while minimizing storage costs.Section 2: Quality Control2.1 Quality standards and criteria:Establish clear quality standards and criteria to be met by each product. This includes setting specific performance, safety, and durability benchmarks.2.2 Quality testing and inspection:Implement a robust quality testing and inspection process at various stages of production to identify any defects or deviations from the quality standards. This includes using testing equipment, statistical analysis, and visual inspections.2.3 Corrective action and continuous improvement:Develop a system for addressing and resolving any quality issues that arise during the production process. Implement continuous improvement initiatives to enhance product quality and reduce defects.Section 3: Supply Chain Management3.1 Supplier selection and evaluation:Identify and evaluate potential suppliers based on their quality standards, pricing, delivery capabilities, and reliability. Establish strong partnerships with reliable and quality-focused suppliers.3.2 Material sourcing and procurement:Develop a streamlined process for sourcing and procuring raw materials from suppliers. Implement effective procurement strategies, such as bulk purchasing, to optimize cost and minimize lead time.3.3 Inventory management:Implement an efficient inventory management system to ensure adequate stock of raw materials while avoiding overstocking or stockouts. Use inventory forecasting techniques to maintain an optimal inventory level.3.4 Logistics and distribution:Establish an effective logistics network to ensure timely and efficient delivery of products to customers. This includes selecting reliable transportation partners, optimizing shipping routes, and implementing tracking systems.Section 4: Resource Allocation4.1 Manpower planning:Assess the manpower requirements for each production cycle and allocate resources accordingly. This includes identifying workers' skills and competencies, training programs, and shift scheduling.4.2 Machinery and equipment allocation:Ensure optimal utilization of machinery and equipment by allocating them efficiently to production tasks. Regularly assess the need for upgrades or replacements to improve productivity and efficiency.4.3 Budgeting and cost control:Develop a detailed budget for manufacturing operations, including costs for labor, machinery, raw materials, and overhead expenses. Implement cost control measures to minimize wastage and optimize resource utilization.Conclusion:The success of a manufacturing business largely depends on the efficiency and effectiveness of its work plan. The manufacturing work plan outlined in this article provides a comprehensive guide for managing various aspects of the manufacturing process. By properly planning and implementing strategies for production planning, quality control, supply chain management, and resource allocation, organizations can achieve optimal productivity, cost-effectiveness, and customer satisfaction in the manufacturing sector.。

生产制造工作计划5篇(经典版)编制人:__________________审核人:__________________审批人:__________________编制单位:__________________编制时间:____年____月____日序言下载提示:该文档是本店铺精心编制而成的,希望大家下载后,能够帮助大家解决实际问题。

文档下载后可定制修改,请根据实际需要进行调整和使用,谢谢!并且,本店铺为大家提供各种类型的经典范文,如总结报告、演讲致辞、条据文书、策划方案、合同协议、应急预案、规章制度、教学资料、作文大全、其他范文等等,想了解不同范文格式和写法,敬请关注!Download tips: This document is carefully compiled by this editor. I hope that after you download it, it can help you solve practical problems. The document can be customized and modified after downloading, please adjust and use it according to actual needs, thank you!And, our store provides various types of classic sample essays for everyone, such as summary reports, speeches, policy documents, planning plans, contract agreements, emergency plans, rules and regulations, teaching materials, essay summaries, other sample essays, and so on. If you want to learn about different sample essay formats and writing methods, please stay tuned!生产制造工作计划5篇通过制定工作计划我们可以更好地提前预测和解决工作中的问题,新的工作即将开始,大家需要花时间制定一份详细的工作计划,本店铺今天就为您带来了生产制造工作计划5篇,相信一定会对你有所帮助。

生产类专有名词组织机构及职位XX电子有限公司XX Electronics CO., Ltd总经理办公室General manager’s office企管部Enterprise management department (EM)行政部Administration department (AD)销售部Sales department (SD)财务部Financial department (FD)技术部Technology department (TD)物控部Production material control department (PMC)生产部Production department(PD)模具部Mold manufacturing department, Tooling manufacturing department (TM) 品管部Quality Assurance department (QA)冲压车间Stamp workshop, press workshop注塑车间injection workshop装配车间Assembly workshop模具装配车间Mold and die Assembly workshop金属加工车间Metal machine workshop电脉冲车间Electric discharge process workshop线切割车间wire cutting process workshop工磨车间Grinding workshop总经理General manager (GM)副总经理Vice-general manager经理manager董事长president副董事长Vice-presidentXX部门经理Manager of XX department主任、主管supervisor拉长Line leader组长Foreman, forelady秘书secretary文员clerk操作员operator助理assistant职员staff连接器connector端子terminal条型连接器bar connector阴连接器Housing阳连接器wafer线束wire harness间距space额定电压rated voltage额定电流rated current接触电阻contact resistance绝缘电阻insulation resistance超声波焊接ultrasonic welding耐压withstand voltage针pin物料编号part number导线wire基体金属Base metal电缆夹cable clamp倒角chamfer接触面积contact area接触件安装孔contact cavity接触长度contact length接触件电镀层contact plating接触压力contact pressure接触件中心距contact space接触簧片contact spring插孔socket contact法兰、凸缘Flange界面间隙interfacial gap键Key键槽keyway过渡段ramp屏蔽套shielding定位基准Datum reference扁平电缆flat cable ,Ribbon cable柔性印刷电线Flexible printed wiring 多层印制电路Multilayer printed circuit 焊盘pad图形pattern间距pitch负极Negative pole正极positive pole原理图Schematic diagram单面板single sided board双面板Two-sided board,Double-sided board表面安装surface Mounting翘曲warp,bow波峰焊wave soldering编织层braid同轴电缆coaxial cable电介质dielectric电缆中导线的头数ends外部干扰external interference填充物filler护套jacket比重specific gravity电阻的温度系数Temperature coefficient of resistance 三、模具塑料模具mould of plastics注塑模具injection mould冲压模具die模架mould base定模座板Top clamping plateTop plateFixed clamp plate水口推板stripper plateA板A plateB板B plate支承板support plate方铁spacer plate底针板ejector plate面针板ejector retainer plate回针Return pin导柱Guide pin有托导套Shoulder Guide bush直导套Straight Guide bush动模座板Bottom clamp plateMoving clamp plate基准线datum line基准面datum plan型芯固定板core-retainer plate凸模固定板punch-retainer plate顶针ejector pin单腔模具single cavity mould多腔模具multi-cavity mould多浇口multi-gating浇口gate缺料starving排气breathing光泽gloss合模力mould clamping force锁模力mould locking force挤出extrusion开裂crack循环时间cycle time老化aging螺杆screw麻点pit嵌件insert活动镶件movable insert起垩chalking浇注系统feed system主流道sprue分流道runner浇口gate直浇口direct gate , sprue gate轮辐浇口spoke gate , spider gate点浇口pin-point gate测浇口edge gate潜伏浇口submarine gate , tunnel gate 料穴cold-slug well浇口套sprue bush流道板runner plate排飞槽vent分型线(面)parting line定模stationary mould,Fixed mould动模movable mould, movable half上模upper mould,upper half下模lower mould,lower half型腔cavity凹模cavity plate,cavity block拼块split定位销dowel定位销孔dowel hole型芯core斜销angle pin, finger cam滑块slide滑块导板slide guide strip楔紧块heel block, wedge lock拉料杆sprue puller定位环locating ring冷却通cooling channel脱模斜度draft滑动型芯slide core螺纹型芯threaded core热流道模具hot-runner mould绝热流道模insulated runner mould熔合纹weld line (flow line)三板式模具three plate mould脱模ejection换模腔模具interchangeable cavity mould脱模剂release agent注射能力shot capacity注射速率injection rate注射压力injection pressure差色剂colorant保压时间holdup time闭模时间closing time定型装置sizing system阴模female mould,cavity block阳模male mould电加工设备Electron Discharge Machining数控加工中心CNC machine center万能铁床Universal milling machine卧式刨床Horizontal planer车床Engine lathe平面磨床Surface grinding machine去磁机Demagnetization machine万能摇臂钻床Universal radial movable driller 立式钻床Vertical driller超声波清洗机Ultrasonic clearing machine 四、品管SPC statistic process control品管保证Quality Assurance品管控制Quality control来料检验IQC Incoming quality control巡检IPQC In-process quality control校对calibration动态试验dynamic test环境试验Environmental test非破坏性试验non-destructive test光泽gloss击穿电压(dielectric) breakdown voltage拉伸强度tensile strength冷热骤变试验thermal shock test环境试验炉Environmental chamber盐雾实验salt spray test绝缘电阻测试验仪Insulating resistance meter 内应力internal stress疲劳fatigue蠕变creep试样specimen撕裂强度tear strength缩痕shrink mark, sink mark耐久性durability抽样sampling样品数量sample sizeAQL Acceptable Quality level批量lot size抽样计划sampling planOC曲线operation curve试验顺序sequence of tests环境温度ambient temperature可焊性solderability阻燃性flame resistance五、生产注塑机injection machine冲床Punch machine混料机blender mixer尼龙nylon黄铜brass青铜bronze紫(纯)铜copper料斗hopper麻点pit配料compounding涂层coating飞边flash预热preheating再生料reworked material再生塑料reworked plastics工艺设计process design紧急停止emergency stop延时time delay六.物控保质期shelf lifeABC分类法ABC Classification反常需求Abnormal Demand措施信息Action Message活动报告标志Action-report-flag基于活动的成本核算Activity-based Costing (ABC) 实际能力Actual Capacity实际成本Actual Costs调整现有库存量Adjust-on-hand已分配量Allocation替代工序Alternative Routine装配订单Assembly Order装配零件表Assembly Parts List装配Assembly计划自动重排Automatic Rescheduling可达到库存Available Inventory可用材料Available Material达到库存Available Stock可利用工时Available Work可签约量Available-to-promise平均库存Average Inventory欠交订单Back Order倒序计划Back Scheduling倒冲法Back flush未完成订单Backlog现有库存余额Balance-on-hand Inventory批号Batch Number批量生产Batch Production标杆瞄准Benchmarking工时清单Bill of Labor提货单Bill of Lading物料清单Bill of Material分库Branch Warehouse经营规划Business Plan采购员Buyer能力管理Capacity Management能力需求计划Capacity Requirements Planning (CRP) 保管费率Carrying Cost Rate保管费Carrying Cost单元式制造Cellular Manufacturing修改批量日期Change Lot Date修改工序Change Route修改产品结构Change Structure检查点Check Point闭环物料需求计划Closed Loop MRP通用工序标识Common Route ID计算机集成制造Computer-integrated Manufacturing (CIM)配置代码Configuration Code约束管理/约束理论Constraints Management/Theory of Constraints (TOC) 依成本的材料清单Costed Bill of Material急需零件Critical Part累计提前期Cumulative Lead Time现有运转时间Current Run Hour现有运转数量Current Run Quantity周期盘点Cycle Counting调整日期Date Adjust有效日期Date Available修改日期Date Changed结束日期Date Closed截止日期Date Due生产日期Date in Produced库存调整日期Date Inventory Adjust作废日期D ate Obsolete收到日期Date Received交付日期Date Released需求日期Date Required发货日期Date to Pull空负荷Dead Load需求管理Demand Management需求Demand实际能力Demonstrated Capacity非独立需求Dependent Demand直接增减库存处理法Direct-deduct Inventory Transaction Processing发料单Disbursement List派工单Dispatch List分销资源计划Distribution Resource Planning (DRP)鼓-缓冲-绳子Drum-buffer-rope经济订货批量Economic Order Quantity (EOQ)工程变更生效日期Engineering Change Effect Date工程变更生效单Engineering Change Effect Work Order工程停止日期Engineering Stop Date例外控制Exception Control呆滞材料分析Excess Material Analysis急送代码Expedite Code加工订单Fabrication Order补足欠交Fill Backorder总装提前期Final Assembly Lead Time确认的计划订单Firm Planned Order固定订货批量F ixed Order Quantity集中预测Focus Forecasting完全跟踪Full Pegging通用生产管理原则Generally Accepted Manufacturing Practices 毛需求Gross Requirements在制品库存In Process Inventory独立需求Independent Demand投入/产出控制Input/ Output Control检验标识Inspection ID厂际需求Interplant Demand库存周转率Inventory Carry Rate仓库库位类型Inventory Location Type库存周转次数Inventory Turnover发送订单Issue Order项目记录Item Record物料项目Item加工车间Job Shop准时制生产Just-in-time (JIT)看板Kanban人工工时Labor Hour最后运输日期Last Shipment Date提前期Lead Time层Level负荷量Load Leveling负荷报告Load Report负荷Load仓位代码Location Code仓位备注Location Remarks仓位状况Location Status按需订货Lot for Lot批量标识Lot ID批量编号Lot Number批量Lot Size低位码Low Level Code机器能力Machine Capacity机器加载Machine Loading外购或自制决策Make or Buy Decision面向订单生产的产品Make-to-order Product面向库存生产的产品Make-to-stock Product制造周期时间Manufacturing Cycle Time制造资源计划Manufacturing Resource Planning (MRP II)主生产计划Master Production Schedule (MPS)物料成本Material Cost物料发送和接收Material Issues and Receipts物料需求计划Material Requirements Planning (MRP)登陆标志MPS Book Flag MPS多重仓位Multiple Location净改变式MRP N et Change MRP净需求Net Requirements新仓位New Location新组件New Parent新仓库New Warehouse不活动报告No Action Report现有库存量On-hand Balance未结订单Open Order订单输入Order Entry订货点Order Point订货方针Order Policy订货承诺Order Promising订货备注Order Remarks双亲Parent零件清单Part Bills零件批次Part Lot零件编号Part Number零件Part反查Pegging领料单Picking List领料/提货Picking计划订单Planned Order后减库存处理法Post-deduct Inventory Transaction Processing 前减库存处理法Pre-deduct Inventory Transaction Processing 发票价格Price Invoice采购订单价格Price Purchase Order优先计划Priority Planning产品控制Product Control产品线Production Line生产规划编制Production Planning产品率Production Rate产品结构树Production Tree预计可用库存Projected Available Balance采购订单跟踪Purchase Order Tracking已分配量Quantity Allocation仓位数量Quantity At Location欠交数量Quantity Backorder完成数量Quantity Completion需求量Quantity Demand毛需求量Quantity Gross进货数量Quantity In排队时间Queue Time队列Queue重生成式MRP Regenerated MRP重排假设Rescheduling Assumption资源需求计划Resource Requirements Planning粗能力计划Rough-cut Capacity Planning工艺路线Routing安全库存量Safety Stock保险期Safety Time预计入库量Scheduled Receipt残料率Scrap Factor发送零件Send Part维修件Service Parts发货地址Ship Address发货单联系人Ship Contact发货零件Ship Date发货单Ship Order工厂日历Shop Calendar车间作业管理Shop Floor Control损耗系数Shrinkage Factor标准产品成本Standard Product Cost标准机器设置工时Standard Set Up Hour标准单位运转工时Standard Unit Run Hour标准工资率Standard Wage Rate状况代码Status Code库存控制Stores Control建议工作单Suggested Work Order约束理论Theory of Constraints (TOC)时间段Time Bucket时界Time Fence单位成本Unit Cost采购计划员Vendor Scheduler采购计划法Vendor Scheduling工作中心能力Work Center Capacity工作中心Work Center在制品Work in Process工作令跟踪Work Order Tracking工作令Work Order工作进度安排Work Scheduling零库存Zero Inventories经济订货批量=Squat(2*年订货量*平均一次订货准备所发生成本/每件存货的年储存成本) 美国生产和库存控制协会APICS,American Production & Inventory Control Society 七.QS-9000中的术语APQP Advanced Product Quality Planning and Control Plan,产品质量先期策划和控制计划PPAP Production Part Approval Process,生产件批准程序FMEA Potential Failure Mode and Effects Analysis,潜在失效模式及后果分析MSA Measure System Analysis,测量系统分析SPC Statistical Process Control,统计过程控制审核Audit能力Capability能力指数Capability Indices控制计划Control Plans纠正措施Corrective Action文件Documentation作业指导书Job Instruction, work instruction不合格品Nonconformance不合格Nonconformity每百万零件不合格数Defective Parts Per Million, DPPM 预防措施Preventive Action程序Procedures过程流程图Process Flow Diagram, Process Flow Chart 质量手册Quality Manual质量计划Quality Plan质量策划Quality Planning质量记录Quality Records原始数据Raw Data反应计划Reaction Plan返修Repair。

MobilizationSchedule海外项目施工投标动员计划第一篇:Mobilization Schedule海外项目施工投标动员计划MOBILIZATION SCHEDULE1.Site Installation Plan1.1.Contractor’s Site Office & AccommodationThe site office and accommodation will be constructed in accordance with the requirement of construction management and considering the actual area provided by the Employer.The site office will be designed to be 1800m2 and includes site office, storage area, parking area, water tower for portable water, wash room and temporary sewerage system.There are 38 site office rooms designed which will accommodates 68 people as office.And there are 48 site accommodation rooms designed which will accommodate 250 people.1.2.Plants and Workshops Concrete plant, asphalt-concrete plant, tower cranes, workshops for carpenters, rebar fabrication, steel structure assembling etc., are arranged according to the construction requirement.Attached Layout DrawingsStandard physical mapping for site planStandard Concrete PlantMaterial Equipment Office, Lab, Concrete Plant, Precast Area LayoutAsphalt Plant Layout 1.3.Utility Plan 1.3.1.Utility at Site Office Water: The portable water will be sourced outside of airport and transported by water tank truck.The water tanks will be provided on site to ensure the water supply.Water Tank Electricity: According to the site visit, the employer can provide electricity power supply based on which the power supply will be connected to access point provided by the Employer.A backupgenerator at capacity of 400kw will be provided on site.Generators to be provided on site1.3.2.Utility at Construction Site Water: The water supplied for construction works, such as earth works, concrete mixing, site cleaning etc.will be provided by transporting from outside rivers and by the wells constructed at site.Water tanks to contain water will be constructed to the requirements of the construction.Temporary Reservoir Electricity According to the site visit, the employer can provide electricity power supply based on which the power supply will be connected to access point provided by the Employer.One 400kw generator, one 200kw generators and two 75kw generators will be provided on site as backup.The 400kw back generator will be used backup the power system for concrete mixing station, rock crush station and Asphalt mixing station.The two 75kw back generators will be used backup the other equipments and site lighting.2.Mobilization & Demobilization Schedule 2.1.Personnel Mobilization & Demobilization Personnel mobilization and demobilization are arranged as shown in the attached “Personnel Mobilization & Demobilization Plan”.2.2.Equipment Mobilization & Demobilization Equipment mobilization and demobilization are arranged as shown in the attached “Equipment Mobilization & Demobilization”.2.3.Temporary Roads 2.3.1.Temporary roads for Site OfficeA Temporary road for site office with 6 meter width will be constructed to connect the ring road for water treatmen and site yard.2.3.2.Temporary Roads at Construction site Main temporary roads will be constructed as shown in the attached drawing.Other temporary roads will be constructed during the constructionperiod according to the requirement.2.4.Temporary Drainage 2.4.1.Temporary Drainage at Site Office The temporary drainage will be constructed with concrete block on site which shall be 300mm*400mm and 500mm away from the fencing work.The drainage shall be covered and rain water shall be connected by PVC pipe to the drainage.Drainage system2.4.2.Temporary Drainage at Construction Site 1.The drainage plan at way extension part: the temporary drainage system will be constructed parallel to the permanent drainage system.It was designed 25meter away from the permanent drainage and 1500mm in width and 500mm in deep.To avoid disturbing the backfilling work, the additional drainage may be added to divert the water into the main drainage system.The rain water will be diverted to the river through the temporary drainage system.2.The drainage plan at apron area: with considering of the permanent drainage system, there are two-drainage with 1500mm in wide and 500mm in deep will be constructed near apron and taxi lane.The two-drainage will divert the water into the river.The drainage system will beimproved during the construction to satisfy the requirement of construction.2.5.Fencing 2.5.1.Fencing at Site Office and Accommodation The Site Office and Accommodation areas will be fenced with 2100mm masonry-steel structure.The steel structure will be supported with block wall and column at 5m at interval.Fencing system at Site Office and Accommodation Areas2.5.2.Fencing at Construction Site The construction area also will be fenced with 2100mm-high steel fencing system and barbwire.To ensure the safety of construction and the airport, the regular patrol will be arranged.Fencing system at construction area3.Construction histogram:第二篇:施工项目投标申请书(范文模版)施工项目投标申请书2009年4月8日投标单位部门(公章)江西有色工程有限公司拟投项目渝武高速公路收费站内环外移改建工程项目交通安全设施工程(共分标段),拟投标段及标的额:3500万元。

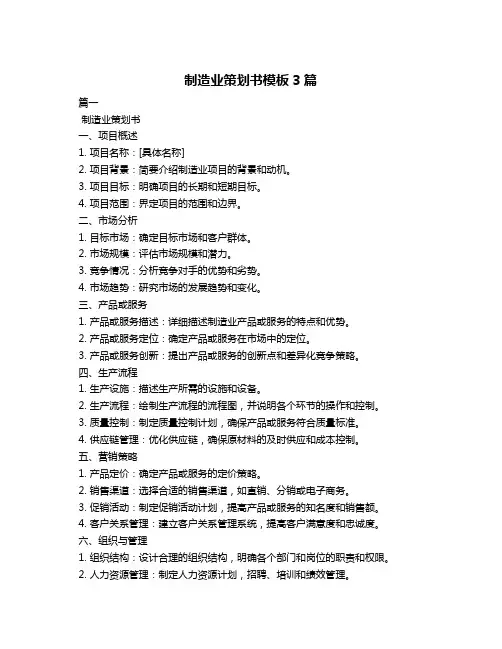

File No.:HNP20120206001pump

3

123412341234123412341

2

2.1

2.2

Total progress Contract decomposition Design List Drawing 2012-5-12012-6-1Schedule:

No

Discription 2012-2-12012-3-12012-4-1Contract :Item No.P101、P102、P103Qutity :项 目 生 产 进 度 表

User :CPECC

共1页 第1页Project :GCS

3

3.1

3.2

3.3

3.4

4

4.1

4.2

4.3

4.4

4.5

5

5.1

5.2

6

7Complie :Date :Performance test Painting / package Documentation delivery

Dalian Huaneng Corrosion-Resistant Pump Works Ltd.Co.

General parts casting Special parts machining General parts machining Hydraulic test Assembly/Test collectivity installation Motor Mechnical seal Bearing Coupling Casting and Machining special parts casting Purchase

离心泵

3

123412341234123412341

2

2.1

2.2

2012年2月2012年6月2012年5月项目总进度明细表位号:2012年3月2012年4月计划进度:

计划内容序号

P101、P102、P103数量合计:项 目 生 产 进 度 表

文件编号:HNP20120206001合同内容:项目名称:用户名称:中国石油工程建设公司GCS 项目共1页 第1页图纸合同分解设计3

3.1

3.2

3.3

3.4

4

4.1

4.2

4.3

4.4

4.5

5

5.1

5.2

6

7编制:审核:日期通用件加工专用件加工性能试验整机装配通用件铸造专用件铸造机械密封资料交付

电机铸件及加工采购联轴器轴承装配/试验水压试验大连华能耐酸泵厂有限责任公司涂漆、包装。