3M高压电缆附件原理及产品方案

- 格式:pdf

- 大小:2.13 MB

- 文档页数:33

电机电有限公司自2004年成立以来经销批发的电缆终端附件畅销消费者市场,在消费者当中享有较高的地位,公司与多家电气工程公司,零售商,和代理商本着薄利多销互惠互利的原则,建立了长期稳定的合作关系。

经销的电缆终端附件品种齐全、价格合理,公司实力雄厚,重信用、守合同、保证产品质量,承诺价一赔十,赢得了广大客户的信任。

深圳久电机电有限公司作为3M华南最大的3M代理商,主要经销3M(1-110KV)电缆附件,3M绝缘,防水胶带,电缆修复套装,70#,23#,2228,13#胶带,兼营德国KP,耐克森,等进口电缆附件及各种国标配件。

联系方式:183******** QQ:2644648206。

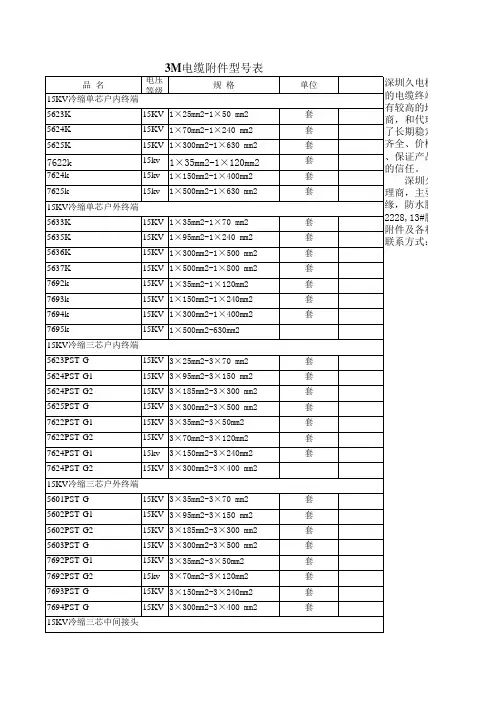

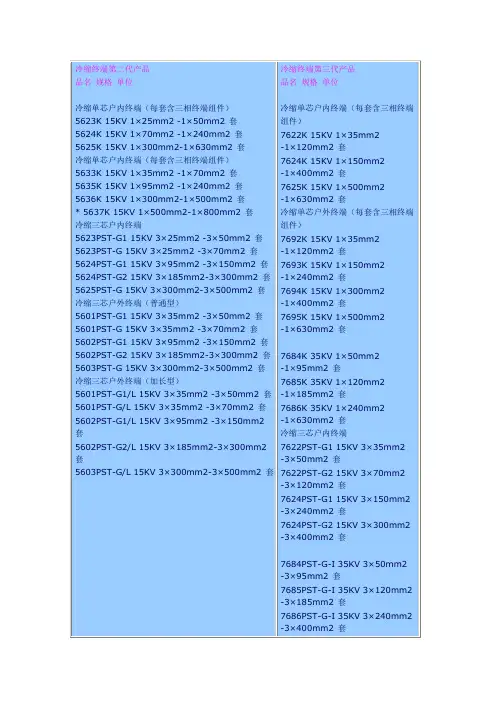

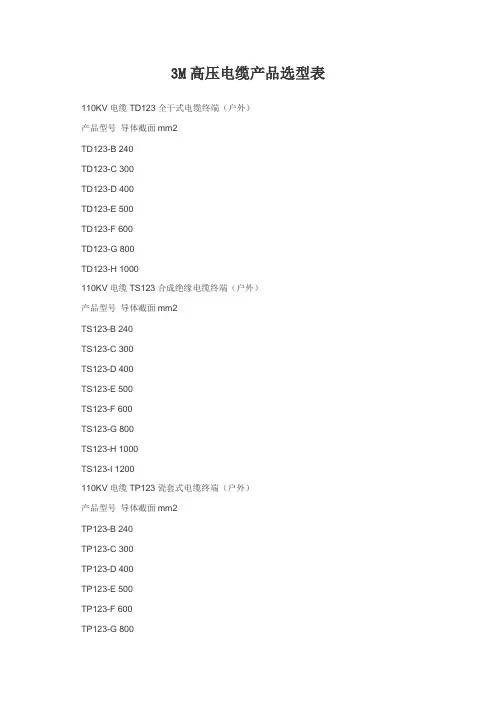

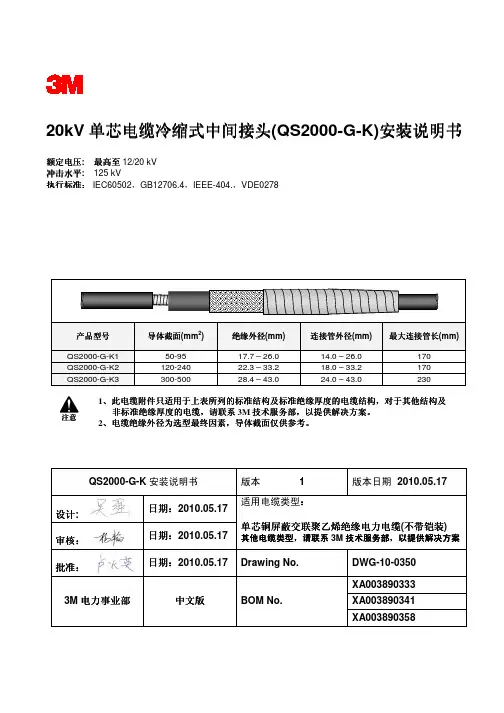

3M高压电缆产品选型表110KV电缆TD123全干式电缆终端(户外)产品型号导体截面mm2TD123-B 240TD123-C 300TD123-D 400TD123-E 500TD123-F 600TD123-G 800TD123-H 1000110KV电缆TS123合成绝缘电缆终端(户外)产品型号导体截面mm2TS123-B 240TS123-C 300TS123-D 400TS123-E 500TS123-F 600TS123-G 800TS123-H 1000TS123-I 1200110KV电缆TP123瓷套式电缆终端(户外)产品型号导体截面mm2TP123-B 240TP123-C 300TP123-D 400TP123-E 500TP123-F 600TP123-G 800TP123-I 1200110KV电缆TG123 D/L全干式六氟化硫开关终端(长型)产品型号导体截面mm2TG123D/L-B 240TG123D/L-C 300TG123D/L-D 400TG123D/L-E 500TG123D/L-F 600TG123D/L-G 800TG123D/L-H 1000TG123D/L-I 1200110KV电缆TG123 D/S全干式六氟化硫开关终端(短型)产品型号导体截面mm2TG123D/S-B 240TG123D/S-C 300TG123D/S-D 400TG123D/S-E 500TG123D/S-F 600TG123D/S-G 800TG123D/S-H 1000TG123D/S-I 1200110KV电缆TG123W充油式六氟化硫开关终端产品型号导体截面mm2TG123W-B 240TG123W-C 300TG123W-D 400TG123W-E 500TG123W-F 600TG123W-H 1000TG123W-I 1200110KV电缆TT123 D/L全干式变压器终端(长型)产品型号导体截面mm2TT123D/L-B 240TT123D/L-C 300TT123D/L-D 400TT123D/L-E 500TT123D/L-F 600TT123D/L-G 800TT123D/L-H 1000TT123D/L-I 1200110KV电缆TT123 D/L全干式变压器终端(短型)产品型号导体截面mm2TT123D/S-B 240TT123D/S-C 300TT123D/S-D 400TT123D/S-E 500TT123D/S-F 600TT123D/S-G 800TT123D/S-H 1000TT123D/S-I 1200110KV电缆预制绝缘中间接头(豪华型)产品型号导体截面mm2SC123P-B 240SC123P -C 300SC123P -D 400SC123P -E 500SC123P -G 800SC123P -H 1000SC123P -I 1200110KV电缆预制绝缘中间接头(增强型)产品型号导体截面mm2SC123Q-B 240SC123Q-C 300SC123Q -D 400SC123Q -E 500SC123Q -F 600SC123Q -G 800SC123Q -H 1000SC123Q -I 1200110KV电缆预制推入式直通接头(豪华型)产品型号导体截面mm2SS123P-B 240SS123P-C 300SS123P -D 400SS123P-E 500SS123P-F 600SS123P -G 800SS123P -H 1000SS123P -I 1200110KV电缆预制推入式直通接头(增强型)产品型号导体截面mm2SS123Q-B 240SS123Q-C 300SS123Q -D 400SS123Q -F 600SS123Q -G 800SS123Q -H 1000SS123Q -I 12003M选型:15KV第二代单芯橡塑绝缘电力电缆冷缩终端(户内)型号:5623K 导体面积(mm2):25-505624k 导体面积(mm2):70-2405625k 导体面积(mm2):300-63015KV第二代单芯橡塑绝缘电力电缆冷缩终端(户外)型号:5633K 导体面积(mm2):35-705635k 导体面积(mm2):95-2405636k 导体面积(mm2):300-5005637k 导体面积(mm2):500-800注:电缆绝缘外径为选型的最终决定因素,导体截面仅作参考。

3M™ Electrical Products Medium voltage joints, terminations and cable accessories.344677810 234Ever since the installation of the first 3M ™ Cold Shrink termination in 1972, we have developed products that deliver market leading efficiencies and reliability to our customers.3M ™ Cold Shrink technology ensures that a constant radial pressure is applied to the cable. This combined with acomprehensive factory testing programme and a simple installation process makes Cold Shrink the preferred termination solution for public and private networks operators across the world.34Prepare the cable as normal and clean with 3M ™ Cable Wipes.Place the 3M ™ Cold Shrink termination body over the cable and position at the correct point on the cable.Begin to remove the inner core, allowing the termination to shrink down onto the cable.Once the inner core has been fully removed, the termination installation is complete.123M ™ Plug-In EPDM Separable ConnectorsOur easy to install range of plug-in separable connectors are moulded using high quality EPDM and meet the requirements of EN 50180 and EN 50181.FeaturesŔStraight, elbow and symmetrical and assymetrical T-plug ŔAvailable for outer cone bushings type A, B, C andC1 (250 A, 400 A, 630 A and 1250 A) ŔSimple and safe installation on a wide range of cable sizes ŔMaintenance-freeŔOne piece design, with built in capacitive test point ŔFully screened, moisture-proof connectionŔFully type tested to Cenelec HD 629.1 and IEC60502-4ŔAvailable for voltage classes 6.6/11(12)kV, 20/22(24)kV, and 19/33(36)kV53M ™ Cold Shrink Fully Integrated Quick Termination III (QTIII)This fully integrated premium cable termination offers the greatest simplicity and flexibility in our range. Our premium termination covers a wide range of cable sizes and types. This termination has a shorter adjustable tail to enable it to fit into a wide range of boxes and with fewer installation steps it means there is less room for jointer error.3M ™ Cold ShrinkPart Integrated Quick Terminations (QTII)Although this part integrated Cold Shrink termination requires additional installation steps to our Premium QTIII range it still offers additional benefits over heat shrink cable terminations, which have many more parts to install, QTIIIQTIIMoisture Blocking Mastic Integrated into termination Applied separately using Scotch ® 70 Silicone Tape Outer Insulator Very good track resistance Good track resistance Stress Control Tube Integrated into termination Integrated into termination Silicone Grease providing Stress ReliefNo – integrated mastic is enough Yes – applied separately Stress Control MasticIntegrated into terminationNo – requires silicone greaseAll 3M™ Cold Shrink cable joints include built in componentsto ensure sound insulation, stress control and adequateearth potential over the screens. The 3M™ Cold Shrinktechnology ensures constant radial pressure is exertedover the cable for the duration of the cable joint’s life.34Place the 3M™ Cold Shrink splice body onto the prepared cable, connect the cores and clean thoroughly.Thoroughly grease theconnector cable in preparationfor the splice body.Once in position, beginto remove the inner coilfrom the splice body.For extra peace of mind,the splice body positionis easily checked usingthe marked centre point.1278Place the earth copper screen stocking over the splice body. Secure with3M™ Constant Force Springs.Insulate the constant forcesprings with Scotch® 23Rubber Splicing Tape andthen overlay with Scotch®Rubber Mastic Tape 2228.Position the pre-parked3M™ Cold Shrink OuterProtection Tube over thestocking and begin to removethe inner supporting core.Continue to removethe inner core until theouter tube is fully shrunk,completing the cable joint.56 FeaturesŔPrefabricated one-piece Cold Shrink splice body with integrated semi-conductive electrode forms a faraday cage over the connector and eliminates the use oftapes or additional moulded or metallic electrodesŔFast and easy installation at temperaturesranging from -20°C to +50°C ŔSuitable for a broad range of c able type and sizes ŔPermanent radial contact pressureŔSimple assembly by pulling out the spiral coreŔMeets and exceeds the requirements of European Standard CENELEC HD 629.1 and IEC 60502-4.QS1000QS2000QSIII QS200Splice Body Type Moulded Moulded Moulded ExtrudedRange Coverage 50mm² to 400mm²50mm² to 400mm²300mm² to 630mm²50mm² to 1000mm²Voltage Class 6.6/11(12)kV20/22(24)kV to19/33(36)kV 19/33(36)kV 6.6/11(12) kV to19/33(36)kV100% Factory TestedSplice BodyYes Yes Yes No67Our EPDM elastomer caps environmentally seal and protect exposed cables ends against dirt, moisture and mechanical deterioration.FeaturesŔEasy and quick to install ŔNo tools required for installation ŔCovers a wide range of cross sections ŔHigh mechanical strengthŔWaterproof, meets the requirements of ANSI C119.1 ŔResistant to various chemicals and ozone ŔApplication temperature up to 90°COur 3M ™ Cold Shrink Abandonment Kit CSCAK Series is a temporary or permanent solution for cable abandonment. The kits consist of 3M ™ Cold Shrink End Caps, 3M ™ Cold ShrinkPre-Stretched Tube, Scotch ® 23 Self Amalgamating Insulation Tape and earth connection components.FeaturesŔQuick, simple and reliable installationŔ A temporary or permanent solution for cable abandonment ŔEnvironmental sealing and mechanical protection ŔEnsures a permanent, waterproof seal and insulation ŔAvailable for single core, copper wire screened,medium voltage cables up to 33kV ŔWaterproof, meets the requirements of ANSI C119.1 ŔResistant to various chemicals and ozone ŔApplication temperature up to 90°C8Scotch ® Super 33+ Vinyl Electrical TapeA premium grade, 0.178mm thickness, highly conformable, PVC insulating tape with aggressive adhesive and elastic backing ensures easy, moisture tight electrical and mechanical protection. Excellent electrical insulating properties to provide primary electrical insulation for joints up to 600V.FeaturesŔExcellent cold weather handlingŔResistant to UV rays, abrasion, moisture, acids, and alkalis ŔFlame retardant, to UL510 ŔTemperature range -18ºC to 105ºCScotch ® Super 88 Electrical TapePremium grade, 0.2mm thick, all weather PVC insulating tape, designed to perform continuously in very low temperatures, and is conformable for installation at -18ºC. Aggressive adhesive ensures moisture tight electrical and mechanical protection.FeaturesŔTemperature range -40ºC to 105ºC ŔExcellent abrasion and puncture resistance ŔHigh tensile and mechanical strength ŔFlame retardant, to UL510Scotch ® 23 Rubber Splicing TapeA highly conformable, self-amalgamating EPR (Ethylene Propylene Rubber) tape, ideal for insulation and moisture sealing in many applications such as bus bar connections, re-jacketing, and primary insulation up to 69kV.FeaturesŔSpecial polyester liner that willnot stick when unwinding ŔStretch up to 100% for void-free,moisture-resistant insulation ŔNon-vulcanising and shelf-stable ŔOperating temperature up to 90ºCScotch ® ElectricalSemi-Conducting Tape 13A highly conformable, semi-conducting, EPR (Ethylene Propylene Rubber) tape. Conforms easily to irregular shapes and retains itsconductivity when stretched. This tape is used for high voltage connections and provides cable shield continuation and is compatible with all solid dielectric cable insulations.FeaturesŔSemi Conducting (low resistivity) ŔWithstands temperatures up to 90°C ŔPrevents partial discharge ŔExcellent resistance to solvents,UV and moisture9Scotch ® 70 Silicone Rubber Electrical TapeHigh temperature arc and track resistant tape composed of self-fusing, inorganic silicone rubber, 0.3mm thickness. This tape provides moisture sealing on outdoor systems, transformers and terminations up to 69kV. Extremely conformable, even at very low temperatures.FeaturesŔExcellent track and arc resistance ŔHigh dielectric strength 34kV/mmŔExcellent instantaneous fusion; does not needto be held down ŔClass H material (180ºC continuous operation)Scotch ®2228 Rubber Mastic TapeA conformable self-amalgamating rubber electrical insulating and sealing tape with an EPR (Ethylene Propylene Rubber) backing coated with a strong, temperature-stable mastic adhesive. This tape is 1.65mm thick and used to insulate, pad, and seal bus bar and connections up to 1000V.FeaturesŔGood adaptability to uneven surfaces ŔHigh material thickness for quickassembly of insulations and seals ŔTemperature resistance up to 90°CŔOutstanding weather and moisture resistanceScotch ® Cable Jacket Repair Tape 2234Professional grade mastic tape designed for cablejacket repair. This tape is flexible and self-amalgamating with good moisture resistance. It has a tough,abrasion-resistant backing and is quick and easy to apply. FeaturesŔFlexible and resistant to ageingŔResistance to weathering, oil, ozone and UV ŔMoisture-resistant, flame–retardant adhesive ŔTemperature range of -30 to 90°C3M ™ Scotchfil ™Electrical Insulation PuttyA soft, pliable putty which can be wrapped, stretched or moulded around irregular shapes for quick smooth insulation build-up. Use for joint insulation for electrical conductors at temperatures up to 80°C and over-wrap with Super 33+™ or Super 88 Vinyl Electrical Tape. Also suitable for some cable repair applications.FeaturesŔSoft and pliable – simply mould with your fingers ŔPermanently elastic and age-resistant ŔSelf-amalgamatingŔTemperature range of 0ºC to 80°C10Product family Joint type Application91-AH Heat Shrink Un-armoured power cables, standard buried application 91-AHA Heat Shrink Armoured power cables, standard buried application 92-NBA ResinUn-armoured power cables, standard buried application 92-NBA-GS Resin (CMR Free)Un-armoured power cables, standard buried application 92-NA-U Resin Un-armoured power cables, hazardous area application LVI-2Resin Armoured power cables, standard buried applicationLVI-2-PTU Resin Armoured Pilot and Telecom cables, standard buried application LVI-3Resin Armoured power cables, hazardous area applicationLVI-3-IC Resin Armoured Pilot and Telecom cables, hazardous area buried application 91-AC Cold Shrink Un-armoured power cables, indoor applicationLC Cold Shrink Armoured power or pilot and telecom cables, indoor application LC-STFFCold ShrinkArmoured power or pilot and telecom cables, indoor application,fire resistant3M supply a range of locating and marking, cable cleaners, wire pulling lubricants andcable marking products to complete your work.Contact us for more details.Low voltage jointingWe have a full portfolio of low voltage inline joints, including heat shrink, cold shrink and resin joints, for a wide range of applications.Sustainability at 3M –expanding our positiveglobal impact.3M will be investing approximately $1billion over the next20 years to accelerate three new environmental goals.ŔWe have committed to being carbon neutral across ourglobal operations by 2050, achieving a 50% reductionby 2030 and 80% by 2040 (from a 2019 baseline)ŔReduce water use by 25% at our facilities by 2030,including 10% by 2022 and 20% by 2025ŔReturn higher quality water to the environmentafter use in manufacturing operationsŔCombined these two goals will reduce 3M’s wateruse by 2.5 billion gallons (approx. 9.5 billion litres)each year1112© 3M 2021. All rights reserved. 3M is a trademark of 3M Company. OMG237173.3M™ EPDM Separable Connectors 11kV EPDM Indoor Plug In - for Single Core Copper Wire Screened Cables20kV EPDM Indoor Plug In - for Single Core Copper Wire Screened Cables33kV EPDM Indoor Plug In - for Single Core Copper Wire Screened Cables3M™ Cold Shrink Termination Products 11kV Indoor Terminations – Single Core11kV Indoor Terminations - Three Core11kV Outdoor Terminations - Three Core20kV Indoor Terminations - Single Core20kV Outdoor Terminations - Single Core20kV Outdoor Terminations -Three Core33kV Indoor Terminations - Single Core33kV Outdoor Terminations - Single Core33kV Indoor / Outdoor Terminations -Three Core3M Termination Accessories Barrier Boot KitsGland Kits & Seals3M™ Cold Shrink Jointing Products 11kV Straight Joints – Single Core11kV Straight Joints – Three Core**Add your choice of outer protection module, cold shrink or resin11kV Polymeric Trifurcating Joints11kV Stop End Joints11kV Branch Joints - Single Core11kV Branch Joints - Three Core20kV Straight Joints - Single Core20kV Branch Joints - Single Core33kV Straight Joints – Single Core33kV Straight Joints - Three Core33kV Transition Trifurcating JointsUK Selection – contact your local region for variationsUnit 7 Lumley CourtDrum Industrial EstateChester-le-StreetDH2 1ANT: 0191 410 4292E:***************************.ukW: 。

110kV高压电缆附件产品解决方案¾3Innovation3Innovation3 高压电缆附件产品系列中间接头中间接头敞开式(户外)敞开式(户外)封闭式封闭式电缆终端电缆终端 3 高压电缆附件3 高压电缆附件瓷套式(TP123)瓷套式(TP123)合成绝缘式(TS123)合成绝缘式(TS123)GIS 开关终端GIS 开关终端变压器终端变压器终端直通接头(SS123)直通接头(SS123)绝缘接头(SC123)绝缘接头(SC123)全干式(TD123)全干式(TD123)充油式(TG123W)充油式(TG123W)全干式(TG123D)全干式(TG123D)充油式(TT123W)充油式(TT123W)全干式(TT123D)全干式(TT123D)高压电缆中间接头的类型按照安装方式可分为:¾绕包型¾组装式¾预制型3Innovation3Innovation 1.绕包型接头3 I 胶带绕包电缆接头9应用最早9绝缘带层间不可避免存在气隙和杂质9绕包机对环境和工艺要求较高9可能出现应力锥厚度不同及变形的情况——现在已经较少采用高压电缆中间接头的类型高压电缆中间接头的类型2.组装型接头9分为三部分:环氧绝缘筒,应Array力锥和压紧弹簧9主体绝缘部分在工厂预制9由于环氧材料和电缆绝缘材料的膨胀系数相差很大,可能因为温度变化而出现位移,所以需加装压紧弹簧——是向整体预制型过渡的产品,逐渐将被淘汰3Innovation3Innovation3.整体预制型接头,如3SC123型9导体屏蔽、主绝缘及应力锥由富含弹性的硅橡胶整体预制而成9硅橡胶的过盈配合可保证充足的界面压力9在负荷及温度变化的情况下可自动平衡,无需弹簧——有利于施工安装和质量控制,是高压中间接头附件的发展方向!高压电缆中间接头的类型3InnovationSC123 硅橡胶预制推入式电缆中间接头绝缘接头在此断开屏蔽层接交叉互联箱基本设计:9外屏蔽, 内屏蔽和绝缘一体式设计,在工厂预制而成9金属保护管/PVC 管/热缩管/绝缘密封胶综合外护套恢复方式9特殊工具推入式安装,保证过盈量产品特点:9多层外护套恢复方式保证可靠的电气绝缘和密封防水9硅橡胶主体可根据电缆冷热变化自动平衡,无需弹簧9预制式内电极形成法拉第笼屏蔽,防止放电预制式内电极SC123 硅橡胶预制推入式电缆中间接头安装过程1.推入硅橡胶接头主体到电缆一端2.连接接管,将接头主体推回到预定位置(用钢架)3. 树脂+铜胆+PVC套筒,恢复绝缘及护套3InnovationSC123 硅橡胶预制推入式电缆中间接头安装过程3Innovation3Innovation 瓷套充油式Development 合成绝缘式GIS 充油式户外全干式3M 可提供全系列产品GIS/变压器全干可插拔式高压电缆终端附件的分类和发展3InnovationTS123 合成绝缘式电缆户外终端硅橡胶堵油密封圈基本设计:-合成绝缘子(内填充聚异丁烯油)-硅橡胶伞裙, 玻璃纤维加强聚酯管,-优良的防潮,抗污和憎水性能的硅橡胶外绝缘-防污等级可达IV级,可提供防污大小伞裙-预制式硅橡胶应力锥-尾端硅橡胶堵油密封圈TS123 合成绝缘式电缆户外终端产品特点:9结合传统充油和硅橡胶外绝缘的两方面优点9重量较轻,便于安装9运输中不易被损坏9抗闪烙性好9抗紫外线性好3Innovation3InnovationTD123 全干式硅橡胶绝缘电缆户外终端尾部灌胶及热缩密封基本设计:-全干式设计硅橡胶伞裙及应力锥-尾部灌胶加热缩套管可靠密封-优良的防潮,抗污和憎水性能的硅橡胶外绝缘-防污等级为IV级-预制式硅推入设计,安装方便TD123 全干式硅橡胶绝缘电缆户外终端产品特点:9重量最轻,仅20KG,便于上塔9全干式无任何漏油风险9预制伞裙及应力锥推入式便于安装9不充油,全免维护9抗闪烙性好9抗紫外线性好3InnovationTD123 全干式硅橡胶绝缘电缆户外终端安装过程3Innovation硅橡胶作为外绝缘材料的优点特有的疏水性优异的抗紫外线老化性优良的抗爬电性能3Innovation中压等级常用绝缘材料陶瓷硅橡胶三元乙丙橡胶EVA(热缩材料)硅橡胶作为外绝缘材料的优点什么是外绝缘的疏水性?疏水性------外界水落在外绝缘表面上形成水珠状或水饼状的性能,与外绝缘材料的表面张力大小有关,一般用接触角的大小来衡量。

VOLITION TM综合布线产品及方案优势目录第一章3M布线系统的优势 (1)1.1、公司背景 (1)1.2、产品系列 (1)1.3、产品总体优势 (2)1.4、3M Volition TM布线系统有别于其它产品的布线系统 (2)第二章光纤产品 (4)2.1、光纤布线是网络发展的必然趋势 (4)2.2、3M Volition TM全光纤布线系统的优势 (5)2.3、3M公司的专利技术-VF-45光纤接口的主要特点 (5)2.4、与VF-45相配套的其它光产品 (10)2.4.1、光纤 (10)2.4.2、光缆跳线 (11)2.3.3、光配线架 (12)2.4.4、光纤出线盒 (13)2.5、典型工程案例及产品质量保证 (14)第三章铜缆产品 (15)3.1、RJ-45 端接模块 (15)3.2、RJ-45 配线架 (17)3.3、用于语音或数据的STG,RCP 端子排(均支持屏蔽) (18)第四章方案组合优势 (23)4.1、集中化布线 (23)4.2、开放空间布线 (24)4.3、光铜合一 (25)4.4、全程屏蔽双点接地 (25)第一章3M布线系统的优势1.1、公司背景1.2、产品系列1、从缆材看有屏蔽、非屏蔽和光纤之分;2、从网络解决方案分有5类、增强5类、6类和光纤到桌面3、从缆材护套分有PVC和低烟阻燃无卤材质两种;4、从端接产品看,有从RJ45低速度产品到支持多媒体高速数据传输的端接产品。

1.3、产品总体优势3M公司,有着几十年的电信设计及施工经验,3M公司的综合布线产品,超出EIA/TIA 568及ISO/IEC 11801等多项国际和国内标准,以其优质的产品性能和精良的产品制作工艺为智能化建筑综合布线领域提供了完整而具有前瞻性的解决方案。

3M布线系统以其系统完善性和制造工艺的精确性而著称于世。

它有以下几个特点:A、系统的完善性:3M开放式布线系统可以为用户提供的系统有3M结构化铜缆(屏蔽、非屏蔽)布线系统、3M全光纤布线系统。

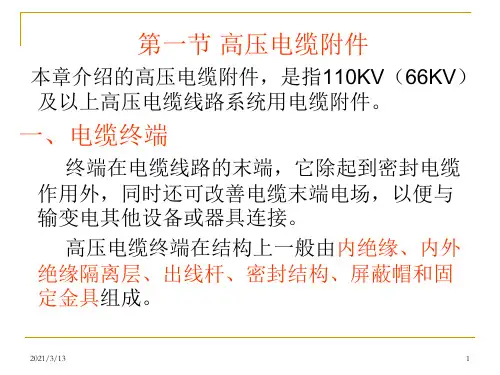

高压电力电缆附件的分类和作用

高压电力电缆附件的分类和作用如下:

一、分类

高压电力电缆附件通常分为以下几种类型:

1.预制附件:这些附件在制造时已经与电缆的一部分连接,通常用于室内或室外配电装置。

预制附件具有快速安装和抗干扰能力强等特点。

2.热缩附件:这些附件使用热缩材料制成,可以紧密地包裹在电缆上。

热缩附件具有防水、防潮和耐腐蚀等特点,适用于各种环境条件。

3.冷缩附件:这些附件使用弹性材料制成,可以收缩并紧贴在电缆上。

冷缩附件具有安装简单、运行稳定等特点,适用于室内和室外配电装置。

4.浇注附件:这些附件由浇注材料制成,通常用于地下配电装置。

浇注附件具有防水、防潮和耐腐蚀等特点,能够长期在地下环境中运行。

二、作用

高压电力电缆附件的作用主要包括以下几个方面:

1.确保高压电缆在传输电力时保持稳定和安全。

2.保护电缆免受环境因素的影响。

3.连接高压电缆与电气设备,实现电力的传输和控制。

以上信息仅供参考。

3m冷缩电缆头概述3m冷缩电缆头是一种用于电缆终端连接的重要电工材料。

它能在电缆终端形成一个坚固、耐用的保护层,有效防止电缆头受到外界环境的损坏。

本文将介绍3m冷缩电缆头的原理、特性及安装步骤。

读者可通过本文了解该产品的优势和适用范围,以便在工程或维护项目中正确选择和使用3m冷缩电缆头。

一、原理3m冷缩电缆头利用热收缩材料的独特性质实现电缆头的保护。

在安装过程中,首先将冷缩电缆头套在电缆终端上,然后加热,使其收缩并与电缆紧密贴合。

冷缩材料收缩后具有出色的防水、耐酸碱、耐老化性能,能有效防止电缆头遭受水、化学腐蚀和日晒雨淋等外界因素的损坏。

二、特性1. 耐用性:3m冷缩电缆头采用高质量的材料制造,具有出色的耐磨、耐压和抗剪切性能。

它可以在恶劣环境下长时间保护电缆终端不受损。

2. 防水性能:3m冷缩电缆头经过精密设计,能够有效防水。

它可以在水下或湿润环境中工作,保证电缆终端的安全稳定。

3. 热稳定性:3m冷缩电缆头具有优异的耐高温性能,可在高温条件下工作而不会变形或失效。

这使得它非常适用于需要承受高温环境的应用场景。

4. 宽范围适用:3m冷缩电缆头适用于不同类型和规格的电缆终端连接。

无论是低压电缆还是高压电缆,无论是单芯电缆还是多芯电缆,都可以使用3m冷缩电缆头进行保护。

5. 易安装:3m冷缩电缆头安装简便,只需将它套在电缆终端上,然后使用热源进行加热即可。

安装过程简单快捷,无需专门培训,节省了时间和人力成本。

三、安装步骤1. 清洁:在安装3m冷缩电缆头之前,先将电缆终端进行彻底清洁,确保表面没有任何杂质和油污。

2. 套入:将3m冷缩电缆头套在电缆终端上,确保它完全覆盖了电缆绝缘层和绞线。

3. 热收缩:使用热风枪或其他合适的加热工具对冷缩电缆头进行加热,使其收缩并与电缆紧密结合。

加热时要保持适当的距离和温度,避免将冷缩电缆头烧坏。

4. 整理:在冷缩电缆头完全收缩后,将其表面整理平整,确保没有起皱或其他不良现象。

QTLV 系列0.6/1kV 冷缩式电缆终端技术资料1. 产品介绍组件主要配置硅橡胶冷缩终端主体 硅橡胶冷缩分叉指套 绝缘胶带 PVC 胶带 铜编织接地线* 恒力弹簧** 在针对带铠装电缆的接地包中提供产品特点冷缩结构设计冷缩结构设计:采用冷缩技术,安装快速简单,无需特殊培训,不必费力推,不必动火和专用工具;优良的耐候性能及电气性能优良的耐候性能及电气性能: 优质硅橡胶终端主体,抗电痕、抗紫外线老化且表面疏水,使用寿命长;适用范围广泛适用范围广泛:能提供单芯至五芯等芯及不等芯全系列产品; 接地连接接地连接:采用恒力弹簧固定接地线,不用焊接或铜绑线,接地快速、可靠、方便。

3M QTLV 系列0.6/1kV 电缆终端采用冷缩技术,无需动火及特殊工具,也无逐渐套入的麻烦,只需轻轻抽取芯绳就能快速完成安装。

接地采用恒力弹簧,无需焊接或铜线绑扎,施工省时省力省空间。

产品采用优质硅橡胶原料,具有优良的耐候性能及电气性能,产品撕裂强度高且永久变形率小,可用于电缆的绝缘防护及密封作用。

2. 产品产品硅橡胶原材料主要性能参数硅橡胶原材料主要性能参数项目测试方法单位标准值硬度GB/T531.1-2008 邵氏A 38~42拉伸强度GB/T528-2009 MPa ≥7.5断裂伸长率GB/T528-2009 % ≥650撕裂强度GB/T529-2008 kN/m ≥25击穿强度GB/T1408.1-2006 kV/mm ≥16扯断永久变形率GB/T528-2009 % ≤83. 产品电气性能3M QTLV系列冷缩终端按照JB/T 7829-2006进行试验,试验结果均满足要求。

下表摘至电力工业电气设备质量检验测试中心(武高所)检测报告报告号:(2011)检字JDL486号试验顺序检测项目标准要求检测结果评注1 工频电压试验8kV,5min不击穿,不闪络8kV,5min组合试样未击穿和闪络符合要求2 工频电压试验7.2kV,4h不击穿,不闪络7.2kV,4h组合试样未击穿和闪络符合要求4. 产品选型(1)针对0.6/1kV单芯电缆产品型号适用电缆截面(mm2) 长度(mm)可按要求进行配置电缆QTLV-12 25~50 400 不带钢铠 QTLV-13 70~120 400 不带钢铠 QTLV-14 150~240 400 不带钢铠 QTLV-15 300~400 400 不带钢铠(2)针对0.6/1kV二芯电缆(等芯)产品型号适用电缆截面(mm2)长度(mm)可按要求进行配置电缆QTLV-22 25~50 400 不带钢铠 QTLV-23 70~120 400 不带钢铠 QTLV-24 150~240 400 不带钢铠 QTLV-25 300~400 400 不带钢铠(3)针对0.6/1kV三芯电缆(等芯)产品型号适用电缆截面(mm2)长度(mm)可按要求进行配置电缆QTLV-32 25~50 400 不带钢铠 QTLV-33 70~120 400 不带钢铠 QTLV-34 150~240 400 不带钢铠 QTLV-35 300~400 400 不带钢铠(4)针对0.6/1kV四芯电缆(等芯)产品型号适用电缆截面(mm2)长度(mm)可按要求进行配置电缆QTLV-42 25~50 400 不带钢铠 QTLV-43 70~120 400 不带钢铠 QTLV-44 150~240 400 不带钢铠 QTLV-45 300~400 400 不带钢铠(5)针对0.6/1kV五芯电缆(等芯)产品型号适用电缆截面(mm2)长度(mm)可按要求进行配置电缆QTLV-52 25~50 400 不带钢铠 QTLV-53 70~120 400 不带钢铠 QTLV-54 150~240 400 不带钢铠 QTLV-55 300~400 400 不带钢铠(6)针对0.6/1kV四芯电缆(不等芯,3+1)产品型号适用电缆截面(mm2)长度(mm)可按要求进行配置电缆QTLV-42(3+1) 25~50 400 不带钢铠 QTLV-43(3+1) 70~120 400 不带钢铠 QTLV-44(3+1) 150~240 400 不带钢铠 QTLV-45(3+1) 300~400 400 不带钢铠(7)针对0.6/1kV五芯电缆(不等芯,3+2)产品型号适用电缆截面(mm2)长度(mm)可按要求进行配置电缆QTLV-52(3+2) 25~50 400 不带钢铠 QTLV-53(3+2) 70~120 400 不带钢铠 QTLV-54(3+2) 150~240 400 不带钢铠 QTLV-55(3+2) 300~400 400 不带钢铠(8)针对0.6/1kV五芯电缆(不等芯,4+1)产品型号适用电缆截面(mm2)长度(mm)可按要求进行配置电缆QTLV-52(4+1) 25~50 400 不带钢铠 QTLV-53(4+1) 70~120 400 不带钢铠 QTLV-54(4+1) 150~240 400 不带钢铠 QTLV-55(4+1) 300~400 400 不带钢铠5. 储存3M QTLV系列产品从生产日期开始,有效储存期为1年,生产日期参见包装箱标签。

110kV高压电缆附件产品解决方案

¾

3Innovation

3Innovation

3 高压电缆附件产品系列

中间接头

中间接头敞开式(户外)敞开式(户外)封闭式

封闭式电缆终端电缆终端 3 高压电缆附件

3 高压电缆附件瓷套式(TP123)瓷套式(TP123)合成绝缘式(TS123)

合成绝缘式(TS123)GIS 开关终端GIS 开关终端变压器终端变压器终端直通接头(SS123)直通接头(SS123)绝缘接头(SC123)绝缘接头(SC123)全干式(TD123)全干式(TD123)充油式(TG123W)充油式(TG123W)全干式(TG123D)全干式(TG123D)充油式(TT123W)充油式(TT123W)全干式(TT123D)

全干式(TT123D)

高压电缆中间接头的类型

按照安装方式可分为:

¾绕包型

¾组装式

¾预制型

3Innovation

3Innovation 1.绕包型接头

3 I 胶带绕包电缆接头

9应用最早9绝缘带层间不可避免存在气隙和杂质9绕包机对环境和工艺要求较高9可能出现应力锥厚度不同及变形的情况

——现在已经较少采用

高压电缆中间接头的类型

高压电缆中间接头的类型

2.组装型接头

9分为三部分:环氧绝缘筒,应Array力锥和压紧弹簧

9主体绝缘部分在工厂预制

9由于环氧材料和电缆绝缘材料

的膨胀系数相差很大,可能因为

温度变化而出现位移,所以需

加装压紧弹簧

——是向整体预制型过渡的产

品,逐渐将被淘汰

3Innovation

3Innovation

3.整体预制型接头,如3SC123型

9导体屏蔽、主绝缘及应力锥由

富含弹性的硅橡胶整体预制而成9硅橡胶的过盈配合可保证充足

的界面压力9在负荷及温度变化的情况下可

自动平衡,无需弹簧

——有利于施工安装和质量控制,是高压中间接头附件的发展方向!高压电缆中间接头的类型

3Innovation

SC123 硅橡胶预制推入式电缆中间接头绝缘接头在此断开屏蔽层接交叉互联箱基本设计:

9外屏蔽, 内屏蔽和绝缘一体式设计,在工厂预制而成9金属保护管/PVC 管/热缩管/绝缘密封胶综合外护套恢复方式

9特殊工具推入式安装,保证过盈量

产品特点:9多层外护套恢复方式保证可靠的电气绝缘和密封防水

9硅橡胶主体可根据电缆冷热变化自动平衡,无需弹簧9预制式内电极形成法拉第笼屏蔽,防止放电预制式内电极

SC123 硅橡胶预制推入式电缆中间接头

安装过程

1.推入硅橡胶接头

主体到电缆一端

2.连接接管,将接

头主体推回到预

定位置(用钢架)

3. 树脂+铜胆+PVC套筒,恢复绝缘及护套

3Innovation

SC123 硅橡胶预制推入式电缆中间接头安装过程

3Innovation

3Innovation 瓷套充油式

Development 合成绝缘式

GIS 充油式

户外全干式

3M 可提供全系列产品

GIS/变压器

全干可插拔式

高压电缆终端附件的分类和发展

3Innovation

TS123 合成绝缘式电缆户外终端

硅橡胶堵油密封圈基本设计:

-合成绝缘子(内填充聚异丁烯油)

-硅橡胶伞裙, 玻璃纤维加强聚酯管,

-优良的防潮,抗污和憎水性能的硅橡胶外绝缘

-防污等级可达IV级,可提供防污大小伞裙

-预制式硅橡胶应力锥

-尾端硅橡胶堵油密封圈

TS123 合成绝缘式电缆户外终端

产品特点:

9结合传统充油和硅橡胶外绝缘的两方面优点

9重量较轻,便于安装

9运输中不易被损坏

9抗闪烙性好

9抗紫外线性好

3Innovation

3Innovation

TD123 全干式硅橡胶绝缘电缆户外终端

尾部灌胶及热缩密封基本设计:

-全干式设计硅橡胶伞裙及应力锥

-尾部灌胶加热缩套管可靠密封

-优良的防潮,抗污和憎水性能的硅橡胶外绝缘

-防污等级为IV级

-预制式硅推入设计,安装方便

TD123 全干式硅橡胶绝缘电缆户外终端

产品特点:

9重量最轻,仅20KG,便于上塔

9全干式无任何漏油风险

9预制伞裙及应力锥推入式便于安装

9不充油,全免维护

9抗闪烙性好

9抗紫外线性好

3Innovation

TD123 全干式硅橡胶绝缘电缆户外终端

安装过程

3Innovation

硅橡胶作为外绝缘材料的优点

特有的疏水性

优异的抗紫外线老化性

优良的抗爬电性能

3Innovation

中压等级常用绝缘材料

陶瓷

硅橡胶

三元乙丙橡胶

EVA(热缩材料)

硅橡胶作为外绝缘材料的优点

什么是外绝缘的疏水性?

疏水性------

外界水落在外绝缘表面上形

成水珠状或水饼状的性能,与外

绝缘材料的表面张力大小有关,

一般用接触角的大小来衡量。

3Innovation

疏水性与亲水性比较

硅橡胶瓷套

3Innovation

疏水性与亲水性接触角比较

硅橡胶瓷套

Contact Angle

接触角大接触角小

亲水性的外绝缘材料往往导致绝缘表面泄漏电流值较大,表面电阻降低

3Innovation

3Innovation

安装结束长时间后硅橡胶的疏水性

硅橡胶的疏水性不会随着时间的变化和外表面污物的沉积而降低——“疏水恢复性”

硅橡胶作为绝缘材料的优点

——优异的抗紫外线老化性

紫外线造成的龟裂

3Innovation

3Innovation

为什么硅橡胶抗紫外线?

H C Si

O

H C C C H

H

H H H

H

H H

H H Si

Si Si Si Si O

O

O O O O O 445 KJ/mole 键能:

Si-O = 445 kJ /mole C-C = 348 kJ /mole 紫外线光能UV = 398 kJ /mole

Si-O --硅橡胶

C-C --for EPDM, EVA,

聚氯乙烯

电痕现象

3 I

抗电痕能力

3 I

硅橡胶作为最接近无

机物的橡胶材料,其抗电痕和抗爬电能力比一般橡胶材料高30%以上

3Innovation

1)具有长期优异的耐污性能,清扫工作量极小2)外表面绝缘电阻较大,泄漏电流得到有效抑制3)长期户外运行不会老化

4)相同爬距的硅橡胶伞裙的污闪电压比瓷套式高100%-150%5)湿闪电压仍为干闪电压的90%以上,无明显降低

6)沿面泄漏距离(即绝缘子长度和大小)可以设计得较短小

硅橡胶外绝缘

9疏水性9抗紫外线性

硅橡胶作为绝缘材料的优点

GIS六氟化硫气体绝缘开关电缆终端

•充油式

TG 123W/L

TG 123W/S

•全干式

TG123D/L

TG123D/S IEC60859《额定电压72.5kV及以上气体

长型/短型绝缘金属封闭开关的电缆联接装置》

3Innovation

TG123D 全干式GIS开关电缆终端技术参数

顶推弹簧机构基本设计:

9IEC60859标准环氧树脂绝缘筒

9预制全干式硅橡胶应力锥

9表带式可插拔电缆终端结构

9应力锥压力环和顶推弹簧保证足够压力9支撑套筒和电缆夹提供可靠机械保护

3Innovation

TG123D 全干式GIS开关可插拔电缆终端

产品特点:

9可插拔式结构可以在先将绝缘筒预装在GIS

上,应力锥和电缆在现场插入,无需放气

9可插拔式结构便于检修和试验

9全干式无漏油风险和烦恼,全免维护

9顶推弹簧机构有效固定应力锥,防止移位

9IEC60859标准接口

3Innovation

TG123D 全干式GIS开关可插拔电缆终端

特殊工具推入

硅橡胶应力锥

应力锥及电缆插

入环氧套筒(预

先安装在GIS上)

表带式结构(可插拔)

3Innovation

全干式GIS开关可插拔电缆终端

3Innovation

3Innovation

TT123D 全干式变压器可插拔电缆终端

9基本结构及技术参数与GIS终端相同

9IEC60859标准---长型/端型

9可插拔式结构

9全干式无漏油风险和烦恼

9顶端带有均压罩

9可水平或垂直安装

9裕度较高,最高电压可达170kV

谢谢各位!。