omron micro_switch_tech_guide

- 格式:pdf

- 大小:466.03 KB

- 文档页数:14

Industrial AutomationSysmac NJ5 CPU, 20 mB memory, built-in EtherCAT (16 servo axes, in total 192 EtherCAT nodes) and EtherNet/IPController functionality Motion control, OPC-UA, Sequence control Max. number of synchronous axes16Max. number of axes (incl. virtual)16Max. number of robots0Primary task cycle time0.5 msProgram memory20 MBVariables memory 6 MBCommunication port(s)EtherCAT Master, EtherNet/IP, USBCommunication option(s)CAN, CompoNet Master, DeviceNet Master, DeviceNet Slave, EtherCAT Slave, MODBUS Master, MODBUS Slave, PROFIBUS DP Master, PROFIBUS DP Slave, PROFINET Master, Serial RS-232C, Serial RS-422, Serial RS-485Max. number of remote I/O nodes192I/O system CJ I/O Bus Max. number of expansion units40 Height90 mm Width90 mm Depth90 mm Weight550 gGX-JC033-port EtherCAT Junction module, 24 VDC power supplyGX-JC066-port EtherCAT Junction module, 24 VDC power supplyGX-JC06-H6-port EtherCAT Junction module, 24 VDC power supply, with node switchesHMC-SD492 4 GB SD memory cardNJ-PA3001Sysmac NJ power supply unit, 100-240 VAC, 30 W, "RUN" output relayNJ-PD3001Sysmac NJ power supply unit, 24 VDC, 30 W, "RUN" output relayW4S1-05D 5-port enhanced Ethernet switchCJ1W-BAT01Battery for CJ1M PLCsCJ1W-TER01End plate for CJ1 CPU rack or expansion rack. Only required as spare part.FDK CR14250SE Battery Safety DatasheetEN PDF 147 KBNJ-Series DatasheetEN PDF 3.05 MBNJ-Series CPU Unit Hardware Users ManualENPDF 6.95 MBNJ-series -[DeviceNet]-3G3MX2-series Inverter Connection GuideENZIP 2.98 MBNJ-series -[DeviceNet]-3G3RX-V1-series InverterConnection GuideENZIP 3.75 MBNJ-series -[DeviceNet]-ABB IRC5 Robot Controller Connection GuideEN ZIP 5.81 MBNJ-series -[DeviceNet]-NE1A-series Safety Network Controller Connection GuideENPDF 3.47 MBNJ-series -[EtherCAT]-3G3MX2-series Inverter Connection GuideENPDF 1.72 MBNJ-series -[EtherCAT]-3G3MX2-series Type V1Connection GuideENPDF 2.18 MBNJ-series -[EtherCAT]-3G3RX-V1-series InverterConnection GuideENPDF 2.28 MBNJ-series -[EtherCAT]-Balluff BNI ECT-508Connection GuideENPDF 1.85 MBNJ-series -[EtherCAT]-Balluff RFID (BIS V Series)Connection GuideENPDF 1.76 MBNJ-series -[EtherCAT]-CKD MW4G-seriesNW4Gx-T7ECxxx (W4G-OPP8-xEC-xx)Connection GuideEN PDF 1.2 MBNJ-series -[EtherCAT]-Copley Accelnet Connection GuideENZIP 5.75 MBNJ-series -[EtherCAT]-Copley Xenus Plus XEL Connection GuideENZIP 3.81 MBNJ-series -[EtherCAT]-DELTA ELECTRONICS ASDA-A2-series Connection GuideEN ZIP 3.72 MBNJ-series -[EtherCAT]-DELTA R1-EC-series Slave Remote Module Connection GuideENPDF 2.22 MBNJ-series -[EtherCAT]-DENSO WAVE RC8Robot Controller Connection GuideENPDF 3.54 MBNJ-series -[EtherCAT]-E3NW-ECT DigitalSensor Communication UnitConnection GuideEN PDF 2.01 MBNJ-series -[EtherCAT]-E3X-ECTConnection GuideENPDF 2.41 MBNJ-series -[EtherCAT]-Elmo Gold Solo Whistle Digital Servo Drive Connection GuideEN ZIP 3.49 MBNJ-series -[EtherCAT]-FANUC R-30iB Robot Controller Connection GuideENPDF 3.82 MBNJ-series -[EtherCAT]-FESTO CPX-FB38 Valve Terminals MPA Connection GuideENPDF 2.47 MBNJ-series -[EtherCAT]-FESTO CTEU-EC Valve Terminals VTUB-12Connection GuideENPDF 2.52 MBNJ-series -[EtherCAT]-FESTO Valve Terminals MPA CPX-FB37Connection GuideENPDF 2.01 MBNJ-series -[EtherCAT]-FH-series Vision System Connection GuideENPDF 2.38 MBNJ-series -[EtherCAT]-FQ-MS12x(-M)-ECT Vision Sensor Connection GuideENPDF 2.63 MBNJ-series -[EtherCAT]-GRT1-ECT SmartSlice Connection GuideENPDF 2.9 MBNJ-series -[EtherCAT]-GX-ILM08C -[IO-Link]-Balluff Cylinder Sensor (BMF 203K)Connection GuideEN PDF 2.24 MBNJ-series -[EtherCAT]-GX-ILMxxx -[IO-Link]-E2E-series Proximity SensorConnection GuideEN PDF 2.31 MBNJ-series -[EtherCAT]-GX-ILMxxx -[IO-Link]-E3Z-series Photoelectric SensorConnection GuideEN PDF 2.24 MBNJ-series -[EtherCAT]-GX-series Analog I/O TerminalConnection GuideENPDF 1.74 MBNJ-series -[EtherCAT]-GX-series Digital I/O TerminalConnection GuideENPDF 1.74 MBNJ-series -[EtherCAT]-GX-series Encoder Input TerminalConnection GuideENPDF 1.75 MBNJ-series -[EtherCAT]-HENGSTLER ACURO(R)AC58-series Absolute EncoderConnection GuideENPDF 1.47 MBNJ-series -[EtherCAT]-HIWIN D1-N-series Connection GuideENZIP 3.85 MBNJ-series -[EtherCAT]-HMS Anybus Communicator Connection GuideENPDF 1.93 MBNJ-series -[EtherCAT]-HMS Anybus X-gateway Connection GuideENPDF 3.16 MBNJ-series -[EtherCAT]-HORIBA STEC SEC-Z500X-series Mass Flow ControllerConnection GuideEN PDF 1.5 MBNJ-series -[EtherCAT]-Hivertec HES-C400/NJ Connection GuideENPDF 2.14 MBNJ-series -[EtherCAT]-Hivertec HES-M4xx/NJ Connection GuideENPDF 1.89 MBNJ-series -[EtherCAT]-IAI ACON/ACON-CA/PCON/PCON-CA/DCON-CA ControllerConnection GuideEN PDF 1.38 MBNJ-series -[EtherCAT]-IAI Corporation MSCON Controller Connection GuideENPDF 2.88 MBNJ-series -[EtherCAT]-IAI Corporation MSEP Controller Connection GuideENPDF 1.48 MBNJ-series -[EtherCAT]-IAI SCON-CA/SCON-CAL Controller Connection GuideENPDF 2.12 MBNJ-series -[EtherCAT]-IAI X-SEL Controller XSEL-R/S/RX/SX/RXD/SXDConnection GuideEN PDF 2.67 MB NJ-series -[EtherCAT]-KYOWA SENERGYController (MotionLinxSeries)Connection GuideEN PDF 1.72 MBNJ-series -[EtherCAT]-M-System R30-seriesRemote I/OConnection GuideENPDF 1.74 MBNJ-series -[EtherCAT]-M-System R8-seriesRemote I/OConnection GuideENPDF 2.19 MBNJ-series -[EtherCAT]-MTS KG R-series LinearPosition SensorsConnection GuideENPDF 2.46 MBNJ-series -[EtherCAT]-NX-ECC + NX-ILM400 -[IO-Link]- E2E-seriesProximity SensorConnection GuideEN PDF 2.44 MBNJ-series -[EtherCAT]-NX-ECC + NX-ILM400 -[IO-Link]- E3Z-seriesPhotoelectric SensorConnection GuideEN PDF 2.5 MBNJ-series -[EtherCAT]-NX-ECC + NX-ILM400 -[IO-Link]- FESTO SFAW-series W Flow SensorConnection GuideEN PDF 2.62 MBNJ-series -[EtherCAT]-NX-ECC + NX-ILM400 -[IO-Link]- FESTO SPAE-Pressure SensorConnection GuideEN PDF 2.42 MBNJ-series -[EtherCAT]-NX-ECC + NX-ILM400 -[IO-Link]- FESTO VPPM-seriesConnection GuideENPDF 2.35 MBNJ-series -[EtherCAT]-NX-ECC + NX-ILM400 -[IO-Link]- Piab ABVac.EjectorpiCOMPACT23Connection GuideEN PDF 2.68 MBNJ-series -[EtherCAT]-NX-ECC + NX-ILM400 -[IO-Link]- Turck I/O Hub(TBIL)Connection GuideEN PDF 2.76 MBNJ-series -[EtherCAT]-NX-PG0122 -[Pulse]-ORIENTAL MOTOR RK IIStepping MotorConnection GuideEN ZIP 6.11 MBNJ-series -[EtherCAT]-NX-PG0122 -[Pulse]-ORIENTAL MOTORStepping Motor αSTEPConnection GuideEN ZIP 8.5 MBNJ-series -[EtherCAT]-ORIENTAL MOTORNETC01-ECT NetworkConverterConnection GuideEN PDF 2.96 MBNJ-series -[EtherCAT]-ORIENTAL MOTORaSTEP DC Multi-AxisDrive (AZDxA-KED)Connection GuideEN PDF 3.99 MBNJ-series -[EtherCAT]-PHOENIX CONTACTAXL E ECx Axioline EConnection GuideEN PDF 2.71 MBNJ-series -[EtherCAT]-PHOENIX CONTACTAxioline F-series I/OsystemConnection GuideEN PDF 2.07 MBNJ-series -[EtherCAT]-SANYO DENKISANMOTION R TYPE SConnection GuideEN ZIP 4.28 MBNJ-series -[EtherCAT]-SMC EX180-SEC5-X23xSI UnitConnection GuideEN PDF 2.04 MBNJ-series -[EtherCAT]-SMC EX260-SECx SIUnitConnection GuideEN PDF 2.14 MBNJ-series -[EtherCAT]-SMC EX600-SECx SIUnitConnection GuideENPDF 2.62 MBNJ-series -[EtherCAT]-SMC IN587 SI unitConnection GuideENPDF 2.27 MBNJ-series -[EtherCAT]-SMC JXCE1 Direct inputtype Step MotorControllerConnection GuideEN PDF 1.59 MBNJ-series -[EtherCAT]-THK Network Unit TNU-EC Electrical Actuator Controller Connection GuideEN PDF 2.28 MBNJ-series -[EtherCAT]-Turck BL20-E-GW-EC GatewayConnection GuideENPDF 2.13 MBNJ-series -[EtherCAT]-VAT612/615/642/650/652/951/952/62/67Control ValveConnection GuideEN PDF 2.91 MBNJ-series -[EtherCAT]-WAGO I/O-SYSTEM 750-series Fieldbus Coupler Connection GuideENPDF 2.55 MBNJ-series -[EtherCAT]-YASKAWA Σ-V-series SGDV-xxxxE1Connection GuideEN ZIP 6.95 MBNJ-series -[EtherCAT]-ZW-7000-seriesDisplacement Sensor Connection GuideENPDF 2.11 MBNJ-series -[EtherCAT]-ZW-CE1 Displacement SensorConnection GuideENPDF 1.98 MBNJ-series -[EtherNet/IP]-ABB IRC5 Robot Controller Connection GuideEN ZIP 6.44 MBNJ-series -[EtherNet/IP]-CJ2-series Controller Connection GuideENZIP 6.41 MBNJ-series -[EtherNet/IP]-CK3M-CPU1x1Connection GuideENPDF 3.93 MBNJ-series -[EtherNet/IP]-DENSO WAVE RC7M Robot Controller Connection GuideEN ZIP 3.83 MBNJ-series -[EtherNet/IP]-DENSO WAVE RC8Robot Controller Connection GuideEN ZIP 5.39 MBNJ-series -[EtherNet/IP]-FH-series Vision System Connection GuideENZIP 1.96 MBNJ-series -[EtherNet/IP]-FQ2-series Smart CameraConnection GuideEN ZIP 3.55 MBNJ-series -[EtherNet/IP]-FZ4-series Vision SensorConnection GuideENZIP 1.74 MBNJ-series -[EtherNet/IP]-FZ5-series Vision SystemConnection GuideEN ZIP 1.93 MBNJ-series -[EtherNet/IP]-IAI CorporationACON/PCON/DCON/SCON Controller Connection GuideEN ZIP 2.73 MBNJ-series -[EtherNet/IP]-IAI Corporation XSEL-Rx/Sx ControllerConnection GuideEN ZIP 4.93 MBNJ-series -[EtherNet/IP]-Nidec Sankyo SC5000-seriesConnection GuideENZIP 7.36 MBNJ-series -[EtherNet/IP]-Omron Adept Robot ePLCConnection GuideENZIP 2.47 MBNJ-series -[EtherNet/IP]-Omron Adept Robot ePLCIOConnection GuideEN ZIP 2.6 MBNJ-series -[EtherNet/IP]-PHOENIX CONTACT AXL E-series I/O DeviceConnection GuideEN ZIP 2.22 MBNJ-series -[EtherNet/IP]-SMC EX600-SENx SI UnitConnection GuideEN ZIP 2.59 MBNJ-series -[EtherNet/IP]-SMC JXC91 Step Motor ControllerConnection GuideEN PDF 2.1 MBNJ-series -[EtherNet/IP]-Seiko Epson RC180 Robot Controller Connection GuideENZIP 2.6 MB NJ-series -[EtherNet/IP]-Turck BL20-E-GW-ENMultiprotocol GatewayConnection GuideEN ZIP 2.21 MBNJ-series -[EtherNet/IP]-Turck TBEN-seriesCompact Block I/O-moduleConnection GuideENZIP 1.57 MBNJ-series -[EtherNet/IP]-V680S-series RFIDConnection GuideEN ZIP 2.28 MBNJ-series -[EtherNet/IP]-WAGO I/O-SYSTEM 750-series Ethernet FieldbusCouplerConnection GuideEN ZIP 2.44 MBNJ-series -[EtherNet/IP]-Yamaha Motor RCX-series Robot ControllerConnection GuideEN ZIP 3.98 MBNJ-series -[EtherNet/IP]-Yamaha Motor TS-seriesSingle-axis RobotControllerConnection GuideEN ZIP 5.84 MBNJ-series -[EtherNet/IP]-Yamaha RCX340 RobotControllerConnection GuideEN ZIP 4.75 MBNJ-series -[EtherNet/IP]-ZW-7000-seriesDisplacement SensorConnection GuideEN ZIP 2.52 MBNJ-series -[EtherNet/IP]-ZW-CE1 DisplacementSensorConnection GuideEN ZIP 4.26 MBNJ-series -[EthernetTCP/IP]- FQ-CR-seriesConnection GuideEN ZIP 3.11 MBNJ-series -[EthernetTCP/IP]- Janome SewingMachine JR3000-seriesRobotConnection GuideEN ZIP 1.85 MBNJ-series -[EthernetTCP/IP]- MARS TOHKEN2D Image Reader (MVF-300/500 Series)Connection GuideEN PDF 2.05 MBNJ-series -[EthernetTCP/IP]- SCHOTTMORITEX MLEF-seriesDigital ControllerConnection GuideEN ZIP 2.75 MBNJ-series -[EthernetTCP/IP]- V750-seriesRFID SystemConnection GuideEN ZIP 4.7 MBNJ-series -[EthernetTCP/IP]- ZW-seriesDisplacement SensorConnection GuideEN ZIP 4.35 MBNJ-series -[RS-232C]-G9SP Safety ControllerConnection GuideEN ZIP 4.5 MBNJ-series -[RS-232C]-V400-R2-series UltraSmall Multi-code ReaderConnection GuideEN ZIP 4.64 MBNJ-series -[RS-232C]-V500-R2-series FixedLaser-Type BarcodeReaderConnection GuideEN ZIP 4.71 MBNJ-series -[RS-232C]-V750-series RFIDSystemConnection GuideEN ZIP 5.11 MBNJ-series -[RS-232C]-ZW-series DisplacementSensorConnection GuideEN ZIP 4.68 MBNJ-series -[RS-485CompoWay/F]-E5CC/E5EC/E5ACDigital ControllerConnection GuideEN ZIP 4.71 MBNJ-series -[RS-485CompoWay/F]-KM1/KE1-seriesConnection GuideEN ZIP 5.4 MBNJ-series -[RS-485Modbus]- ORIENTALMOTOR BLE-seriesBrushless MotorConnection GuideEN ZIP 2.67 MBNJ-series -[RS-485 Modbus]- ORIENTAL MOTOR RK II-series Stepping MotorConnection GuideEN ZIP 5.5 MB NJ-series -[RS-485Modbus]- ORIENTALMOTOR αSTEP AR-seriesConnection GuideEN ZIP 2.83 MBNJ-series -[RS-485Modbus]- ORIENTALMOTOR αSTEP AZ-seriesConnection GuideEN ZIP 3.01 MBNJ/NX SeriesBrochureEN PDF 6.96 MBNJ/NX-Series CPU UnitBuilt-in EtherCAT PortUsers ManualENPDF 16.3 MBNJ/NX-Series CPU UnitBuilt-in EtherNet/IP PortUsers ManualEN PDF 13.4 MBNJ/NX-Series CPU UnitMotion ControlUsers ManualEN PDF 20 MBNJ/NX-Series CPU UnitSoftwareUsers ManualENPDF 22.3 MBNJ/NX-SeriesInstructionsReference ManualENPDF 16 MBNJ/NX-Series MotionControl InstructionsReference ManualENPDF 4.93 MBNJ/NX-Series OPC UACPU UnitsUsers ManualENPDF 3.73 MBNJ/NX-SeriesTroubleshooting ManualUsers ManualENPDF 16.4 MBNJ/NX-Series for MotionControlGetting Started GuideENPDF 18.1 MBNJ/NX-series -[EtherCAT]- CKDABSODEX driver(AX9000TS/TH-U5)Connection GuideEN PDF 1.73 MBNJ/NX-series -[EtherCAT]- HitachiADV-Series AC ServoDrivesConnection GuideEN ZIP 4.29 MBNJ/NX-series -[EtherCAT]- Inficongauge (BPG402-SE)Connection GuideEN PDF 1.22 MBNJ/NX-series -[EtherCAT]- KashiyamaDry Vacuum Pump (E-CAT01 1ch)Connection GuideENPDF 1.59 MBNJ/NX-series -[EtherCAT]- NX-ECC +NX-ILM400 -[IO-Link]-CKD Sensor (PPXseries)Connection GuideEN PDF 2.43 MBNJ/NX-series -[EtherCAT]- NX-ECC +NX-ILM400 -[IO-Link]-CKD Sensor (WFCseries)Connection GuideEN PDF 2.75 MBNJ/NX-series -[EtherCAT]- NX-ECC +NX-ILM400 -[IO-Link]-CKD WFK2 Flow sensorConnection GuideEN PDF 2.09 MBNJ/NX-series -[EtherCAT]- NX-ECC +NX-ILM400 -[IO-Link]-MTS Sensors (E-Series)Connection GuideEN PDF 2.4 MBNJ/NX-series -[EtherCAT]- NX-ECC +NX-ILM400 -[IO-Link]-PATLITE Beacon (NE-IL)Connection GuideEN PDF 2.02 MBNJ/NX-series -[EtherCAT]- NX-ECC +NX-ILM400 -[IO-Link]-PATLITE Tower (LR6-IL)Connection GuideEN PDF 2.08 MBNJ/NX-series -[EtherCAT]- NX-ECC +NX-ILM400 -[IO-Link]-SMC (ISA3-xxx)Connection GuideEN PDF 2.61 MBNJ/NX-series -[EtherCAT]- NX-ECC +NX-ILM400 -[IO-Link]-SMC (xSE20Bx-L(-M/-P)-x)Connection GuideEN PDF 2.13 MBNJ/NX-series -[EtherCAT]- NX-ECC +NX-ILM400 -[IO-Link]-SMC ITVx000/-IO*Connection GuideEN PDF 1.89 MBNJ/NX-series -[EtherCAT]- NX-ECC +NX-ILM400 -[IO-Link]-SMC Servo 24VDC(JXCL1)Connection GuideEN PDF 2.23 MBNJ/NX-series -[EtherCAT]- NX-ECC +NX-ILM400 -[IO-Link]-Schmalz Ejector (SCPSi)Connection GuideEN PDF 2.4 MBNJ/NX-series -[EtherCAT]- NX-ECC +NX-ILM400 -[IO-Link]-ifm (O5D10x/O5D15x)Connection GuideEN PDF 2.42 MBNJ/NX-series -[EtherCAT]- NX-ECC +NX-ILM400 -[IO-Link]-ifm (PN7x94)Connection GuideEN PDF 2.72 MBNJ/NX-series -[EtherCAT]- NX-ECC +NX-ILM400 -[IO-Link]-ifm (TN24xx)Connection GuideEN PDF 2.74 MBNJ/NX-series -[EtherCAT]- NX-ECC +NX-ILM400 -[IO-Link]-ifm TR7439 Pt100/1000Connection GuideEN PDF 2.43 MBNJ/NX-series -[EtherCAT]- NidecSankyo S-FLAG II SeriesAC Servo (DB6xx41)Connection GuideEN PDF 2.65 MBNJ/NX-series -[EtherCAT]- ORIENTAL MOTOR Stepper Motor(AZ-series)Connection GuideEN PDF 2.89 MBNJ/NX-series -[EtherCAT]- SANYO DENKI AC ServoSANMOTION R 3E MODEL TYPE SConnection GuideEN PDF 3.08 MBNJ/NX-series -[EtherCAT]- SANYODENKI AC ServoSANMOTION RADVANCED MODEL TYPE FConnection GuideEN PDF 3.61 MBNJ/NX-series -[EtherCAT]- SHIMADZU Power Unit for TurboMolecular Pump (TMP)Connection GuideEN PDF 1.29 MBNJ/NX-series -[EtherCAT]- SICK Absolute Encoder (AFS60/AFM60)Connection GuideEN PDF 1.52 MBNJ/NX-series -[EtherCAT]- Schmalz Compact Terminal(SCTSi-ECT)Connection GuideEN PDF 1.33 MB NJ/NX-series -[EtherCAT]- WeidmüllerRemote I/O System (u-remote IP20)Connection GuideEN PDF 1.8 MBNJ/NX-series -[EtherCAT]- YASKAWA Σ-7-seriesConnection GuideEN ZIP 3.77 MBNJ/NX-series -[EtherNet/IP]- Balluff BNI EIP-50x-105-Z015Connection GuideEN PDF 3.35 MBNJ/NX-series -[EtherNet/IP]- CKD ABSODEX Driver (AX9000TS/TH-U6)Connection GuideEN PDF 1.71 MBNJ/NX-series -[EtherNet/IP]- HMSAnybus Communicator Connection GuideEN PDF 1.51 MBNJ/NX-series -[EtherNet/IP]- Hilscher netTAP NT100 Gateway (NT 100-RE-DN)Connection GuideEN PDF 3.5 MBNJ/NX-series -[EtherNet/IP]- IAI RCON system & MCON /MSCON / MSEP ControllerConnection GuideEN PDF 1.9 MBNJ/NX-series -[EtherNet/IP]- KOGANEI Manifold Solenoid Valve (F Series)Connection GuideEN PDF 2.43 MBNJ/NX-series -[EtherNet/IP]- Nordson ProBlue Adhesive MeltersConnection GuideEN PDF 2.61 MBNJ/NX-series -[EtherNet/IP]- ORIENTAL MOTOR αSTEP Compatible Driver (AZD-xEP)Connection GuideEN PDF 1.82 MB NJ/NX-series -[EtherNet/IP]- SMCSolenoid Valve (SI UnitEX260-SEN#)Connection GuideEN PDF 1.65 MBNJ/NX-series -[EtherNet/IP]- SchmalzK.K. Compact Terminal(SCTSi-EIP)Connection GuideEN PDF 1.69 MBNJ/NX-series -[EtherNet/IP]- ifm IO-Link master (AL1322)Connection GuideEN PDF 3.18 MBNJ/NX-series -[EtherNet/IP]- ifm IO-Link master (AL1920)Connection GuideENPDF 3.07 MBNJ/NX-seriesInstructions ReferenceReference ManualENPDF 67.9 MBNJ/NX-series MachineAutomation ControllerBrochureENPDF 1.95 MBNJ/NX-series MachineAutomation ControllerDatabase ConnectionCPU UnitBrochureEN PDF 1.24 MBNJ/NX/NY-seriesSysmac Library User’sManual for SafetySystem Monitor LibraryUsers ManualEN PDF 922 KBOmron GX-JC0x-xEtherCAT Junction BoxEtherCAT ESI fileENZIP 3.36 KBRedundancy and MotionSafetyFlyerENPDF 960 KBSysmacCatalogueEN PDF 43.5 MBSysmac CNCBrochureEN PDF 1.07 MBSysmac StudioOperation ManualEN PDF 65.9 MBSysmac: A FullyIntegrated PlatformBrochureENPDF 9.22 MB。

Microchip Technology Inc.User GuideSensor less Field Oriented Control with SAM E54Contents1. Introduction (2)1.1. SAME54 Microcontroller Card for ATBLDC24V Motor Control Starter Kit (2)1.2. ATBLDC24V-STK Features (3)1.3. Microchip ATSAME54 MOTOR MCU Board (4)1.3.1. MCU Card (4)1.3.2. Power Supply (4)1.3.3. Embedded Debugger (4)1.3.4. 67-pin MCU-DRIVER Board Interface (5)1.4. Motor Specification (6)2. Software Requirement (7)3. Getting Started with ATBLDC24V-STK (7)4. Firmware User Configuration (11)5. Software Implementation (12)6. References (14)7. Revision History (14)1.Introduction1.1.S AME54 Microcontroller Card for ATBLDC24V Motor Control Starter KitThe ATSAME54MOTOR is a MCU card for Atmel® Motor control low voltage starter kits. The hardware has the ARM® M4 core -based SAME54 MCU, with integrated on-board debug support. The MCU card can be directly used with the currently available ATSAMD21BLDC24V-STK®, a low voltage BLDC, PMSM motor control starter kit. The kit contains a driver board hardware with half-bridge power MOSFET drivers, current and voltage sensing circuit, Hall, and Encoder interface, fault protection circuits, etc. Supported by the Atmel studio integrated development platform, the kit provides easy access to the features of SAME54 MCU and explains how to integrate the device in a custom motor control application.Figure 1 Atmel low voltage motor control kit1.2.A TBLDC24V-STK FeaturesATBLDC24V-STK has the following features:• Pluggable MCU card interface• Debug support using on-board Atmel EDBG device• Three half-bridge MOSFET driver• Motor BEMF sensing• Motor individual phase current sensing• DC-bus voltage sensing• Hall sensor interface• Encoder s ensor interface• Over-current protection support• Over-voltage protection at 30VDC• 5V and 3.3V MCU card support• Selectable MCU supply voltage• Reverse power supply voltage protection• Atmel Xplained Pro compatible header interface• On board Temperature sensor• On board serial flash• LED fault indications• Atmel studio plug-and-use support using unique ID device1.3.M icrochip ATSAME54 MOTOR MCU Board1.3.1.MCU CardSAM E54 is a high-performance Flash microcontroller (MCU) based on the 32-bit ARM® Cortex®-M4 RISC (403 CoreMark at 120MHz) processor with floating point unit (FPU). The device operates at a maximum speed of 120 MHz, features up to 1024 Kbytes of Flash, up to 4 Kbytes of TCM (Tightly Coupled Memory)and up to 256 Kbytes of SRAM.The device is intended to work with external 12MHz oscillator. An external reset switch is connected to the MCU RESET pin.Figure 2 ATSAME54 MCU Card1.3.2.Power SupplyThe ATSAME54 MOTOR MCU card takes 3.3VDC supply from the 67-pin edge connector. Both the EDBG device and the Main MCU operate from 3.3VDC. The power supply selection jumper on the Driver board should be connected to 3V3 selection..1.3.3.Embedded DebuggerThe ATSAME54 MCU is interfaced to the EDBG debug device. The EDBG uses SWD interface for programming and debugging the main MCU. A debug header is also provided on the MCU board with ARM Cortex® debug pin out. An external debugger can be connected to this debug port.The DGI is a proprietary communication interface used by the Atmel Data Visualizer software to communicate with the development kits through the EDBG. ATSAME54 connected to the EDBG device, with DGI SPI interface and uses the Atmel ADP protocol.High Speed USB port of the EDBG is accessible at the driver board. EDBG USB enumerates as a composite device supporting debug, DGI SPI, and CDC interfaces.The USB port of the EDBG is connected to the Micro-USB connecter on the driver board.1.3.4.67-pin MCU-DRIVER Board InterfaceATSAME54 MCU card is connected to driver board through 67-pin interface as shown below.Figure 3 67 Pin MCU-Driver Board Interface1.4.M otor Specification2.Software RequirementTo run this demo below mentioned software should be installed on the PC.3.Getting Started with ATBLDC24V-STKThis chapter is a step-by-step guide to get started with the ATSAME54 for ATBLDC24V-STK.1.ATBLDC24V-STK kit contains a fully assembled chassis and 24VDC power adaptor.2.Make sure switch SW1 on driver board (ATBLDC24V) is set to USB/X5V.3.Make sure jumper (J26) on driver board (ATBLDC24V) is set to 3.3V.4.Connect the power adaptor to the “SUPPLY-IN connector”. Connect white color cable to + PIN.Figure 4 Kit with Power and USB Ports Connected5.Connect the Micro-USB cable to the “EDBG-USB connector” and PC USB port.6.Switch ON the power adaptor.7.The power LED indications on the MCU card are now ON.8. If MCU is pre-programmed then directly open "Data Visualizer". If it’s not, then program itthrough Atmel studio and run the program first and then open the data visualizer9.In the "Data Visualizer Connect Window" select the kit from the DGI control panel's drop downlist.Figure 5 Data Visualizer Connect Window10.Click "Connect".11.The Data Visualizer default window will pop up once the connection is made. All the fields shallshow default values as shown below.Figure 6 Data Visualizer Start Window12.Click on "START/STOP" button to turn the motor ON with default values.Figure 7 Data Visualizer Motor Start Window13.One can adjust the graph by selecting checkbox "Automatically fit Y" for better visualization.14.To change the parameter, enter the value in a input field and press "Enter". For example, tochange the motor speed, type in the desired speed within the Reference Speed (RPM) input box and press "Enter".Figure 8 Data Visualizer Change Parameter Online15.To stop the motor, click on the “Stop" button. It will ramp down and stop the motor.Figure 9 Data visualizer Stop motor window4.Firmware User ConfigurationAlgorithm can be fine-tuned for any motor by updating motor parameters in “userparams.h” file. Following are the configurations available for the user to modify the motor and algorithm parameters.5.Software ImplementationPWM event generation unit is configured to trigger AFEC module to start adc conversion. Once the trigger is received by AFEC module, two configured phase current measurements are simultaneously sampled and conversion takes place. Phase current result ready event will generate interrupt. Then DC bus voltage is measured inside interrupt. In addition, speed POT is measured if it is enabled.The FOC algorithm is executed inside ADC end of conversion interrupt handler. This interrupt is dedicated for fast controlling and it’s in sync with PWM. If any fast controlling tasks need to be added then this is the place. Apart from this, slow control loop is also available and its frequency can be configured by “SLOW_LOOP_TIME_SEC” in user configurations. Slow loop execution frequency should be in multiple of PWM frequency. Speed ramp and speed PI control loop is executed from slow control loop. If any additional tasks one has to execute at slower rate, then “SlowControlLoop()” function is a place holder.ADCEOCInterruptHandlerRead 2 phase currents Software trigger for DC bus and POTmeasurementClarke Transform Convert balanced three-phase quantities to balanced two-phase quadrature quantitiesPark TransformTwo-phase orthogonal stationary system to orthogonal rotating reference framePLL EstimatorBEMF based PLL observer to Estimate Motor Position and SpeedPI ControllersId(Flux), Iq (Torque) PI controllersInverse Park Transform Rotating reference frame to Orthogonal stationary reference frame Inverse Clarke Transform2 axis orthogonal frame to3 phase stationary frameSVPWMSpace vector modulation to update PWM duty cycleSTOP SlowControlLoopSpeedRamp()PI ControlSpeed PI controlSTOPFigure 10 Control loop flow chart6.ReferencesApp Note - /downloads/en/AppNotes/00002520B.pdfAtmel Studio 7 - /microsite/atmel-studio/Data Visualizer - https:///Products/Details/0b2891f4-167a-49fc-b3f0-b882c7a11f98 7.Revision History。

MICRO SWITCH Rocker SwitchesTP SeriesDESCRIPTIONHoneywell MICRO SWITCH TP rocker switches are designed for flush mount to the panel for a low profile button or above panel for a distinctive button appearance. The buttons are removable and interchangeable and are available in either a transparent plastic (to accept legend inserts), or translucent plastic. Colored opaque buttons are also available for color coding of switch functions, for example, a green button for a “start” or “run” function and a black button for general purpose. The 1-, 2-, or 4-pole rocker switches are furnished with two 6-32 internal locking threads in the rocker cover which will accept 6-32 machine screws for panel mounting. To maximize applications and minimize inventory, the TP rocker switches are readily available without buttons. Ordering the buttons separately permits them to be paired with switches containing the desired circuitry and number of poles.VALUE TO CUSTOMERS• 2- and 3-position maintained and momentary rocker switch actions• Up to four poles per switch to provide control, signaling, and redundant circuits as requiredFEATURES• 1, 2, or 4 poles• 2- or 3-actuator positions with maintained or momentary action• Standard silver alloy contacts for power-duty switching; gold-plated contacts for low energy/processor-based circuits (milliamps)• Above panel or flush panel mounting• Mounts to panels with two machine screws to maintain panel integrity• Step-base design and barriers between poles minimizes possibility of electrical bridging• Combination head terminal screws facilitate leadwire connections • Rugged design• Variety of opaque button colors or a transparent button that accepts legend inserts• Wide temperature range: -54 °C to 71 °C [-65 °F to 160 °F]• UL, CSA, and CE certified for global applicationsPOTENTIAL APPLICATIONS• Flight decks for commercial and business jets• Control panels for industrial machinery and equipment • Operator interface controls for marine vehicles•Main and auxiliary control panels for road construction equipment• Agriculture equipmentPORTFOLIOHoneywell offers two Series of MICRO SWITCH rocker switches: TP Series and AML Series .Sensing and Internet of Things005438Issue 1* Reference order guides on pages 3 and 4.¹ Any rocker switch with momentary button action.² Rocker switch with maintained button action only.CE Electrical Ratings10 (2) 250 Vac; 10 A resistive, 2 A inductive2 Sensing and Internet of Things 3TP SERIES TWO-POSITION ORDER GUIDE* These positions are momentary. All others are maintained.1Order buttons from page 5, Table 8.2Refer to page 2 for electrical ratings.3Includes 12PA3 button.TERMINAL CIRCUIT IDENTIFICATIONTerminal identifications are referred to in the order guides to indicate which circuits are made in each rocker position (i.e., 1-2 refers to circuit closure through terminals 1 and 2).One PoleTwo PoleFour PoleCONSTRUCTIONAbove panel mounting gives a distinct button appearance. Flush panel mounting presents a low button profile.ROCKER INTERNAL COMPONENTSRemovable plastic button Identi cation lug/ribOne-piece bushing and cover Enclosed switching chamberMolded-in terminal insertHigh strength temperature-resistant non-tracking plastic caseLocking featureCover seal Mounting holewith internal thread Premolded elastomer sealCombinationhead-terminal screwsABOVE VS. FLUSH PANEL MOUNT COMPARISONAbove panel mountingFlush panel mountingTP SERIES THREE-POSITION ORDER GUIDE(without button)(without button)* These positions are momentary. All others are maintained.1 Order buttons from page 5, Table 8.2 Refer to page 2 for electrical ratings.3 Includes 12PA3 button.4 Sensing and Internet of Things 5TP SERIES BUTTON ORDER GUIDEBUTTON OPTIONSButtons are removable and interchangeable. They measure 22,1 mm x 37,1 mm [0.87 in x 1.46 in]. Transparent (colorless plastic) buttons accept under-the-surface legend inserts for station and function identification. Legend inserts are not furnished. Legend inserts can be furnished by a local supplier. Translucent (white plastic) buttons have a clear appearance with a white internal coating. Colored (opaque plastic) buttons are suitable for color coding switch functions.TP SERIES FOUR-POLE, THREE-POSITION SPECIAL CIRCUITRYCatalog listings with -10, -12, and -70 suffixes shown in the order guide (page 4) have special “On-On-On” circuitry as presented in the “three-position order guide”. The catalog listings with the suffix type circuits identified can be installed to provide a different circuit “on” in each of the three different rocker positions.Reference the following example for the 4TP8-10 three-position rocker switch.1 = Circuit closed; 0 = Circuit open* Requires user to install a jumper between terminal #2 and terminal #5. Input and output terminals are #3 and #4.ORDERING SWITCHES WITH TRANSPARENT OR TRANSLUCENT BUTTONSTo order switches with a translucent or transparent button, convert the catalog listings per the following examples. 1. To order a switch with a translucent button (without the black trim) for above panel mounting, substitute TP216 for TP16. For example, a 1TP16-1 catalog listing would be converted to a 1TP216-1 catalog listing which includes a translucent button with above panel mounting.2. To order a switch with a translucent button (without the black trim) for flush panel mounting, substitute TP201 for TP1. For example, a 1TP1-1 catalog listing would be converted to a 1TP201-1 catalog listing which includes a translucent button with flush panel mounting.3. To order a switch with a transparent button for above panel mounting, substitute TP4 for TP16. For example, a 1TP16-1 catalog listing would be converted to a 1TP4-1 catalog listing which includes a transparent button with above panel mounting.4. To order a switch with a transparent button for flush panel mounting, substitute TP12 for TP1. For example, a 1TP1-1 catalog listing would be converted to a 1TP12-1 catalog listing which includes a transparent button with flush panel mounting.6 Figure 1. TP Series: Single pole, flush panel mountingNote: Various button styles shownFigure 2. TP Series: Single pole, above panel mountingFigure 3. TP Series: Double pole, flush panel mountingFigure 4. TP Series: Double pole, above panel mountingSensing and Internet of Things 7Figure 5. TP Series: Four pole, flush panel mountingFigure 7. TP Series: Panel cutoutFigure 6. TP Series: Four pole, above panel mountingNote: Various button styles shownADDITIONAL MATERIALSThe following associated literature is available on the Honeywell web site at :• Product line guide • Product range guideWarranty/RemedyHoneywell warrants goods of its manufacture as being free of defective materials and faulty workmanship during the appli-cable warranty period. Honeywell’s standard product warranty applies unless agreed to otherwise by Honeywell in writing; please refer to your order acknowledgment or consult your local sales office for specific warranty details. If warrantedgoods are returned to Honeywell during the period of coverage, Honeywell will repair or replace, at its option, without charge those items that Honeywell, in its sole discretion, finds defec-tive. The foregoing is buyer’s sole remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and fitness for a particular purpose. In no event shall Honeywell be liable for consequential, special, or indirect damages.While Honeywell may provide application assistance personally, through our literature and the Honeywell web site, it is buyer’s sole responsibility to determine the suitability of the product in the application.Specifications may change without notice. The information we supply is believed to be accurate and reliable as of this writing. However, Honeywell assumes no responsibility for its use.005438-1-EN | 1 | 05/18© 2018 Honeywell International Inc. All rights reserved.m WARNINGPERSONAL INJURYDO NOT USE these products as safety or emergency stop devices or in any other application where failure of the product could result in personal injury.Failure to comply with these instructions could result in death or serious injury.m WARNINGMISUSE OF DOCUMENTATION• The information presented in this product sheet is for reference only. Do not use this document as a product installation guide.•Complete installation, operation, and maintenanceinformation is provided in the instructions supplied with each product.Failure to comply with these instructions could result in death or serious injury.For more informationHoneywell Sensing and Internet of Things services its customers through a worldwide network of sales offices and distributors. For application assistance, current specifications, pricing or the nearest Authorized Distributor, visit or call:Asia Pacific +65 6355-2828Europe +44 (0) 1698 481481USA/Canada+1-800-537-6945Honeywell Sensing and Internet of Things 9680 Old Bailes Road Fort Mill, SC 29707 www. 。

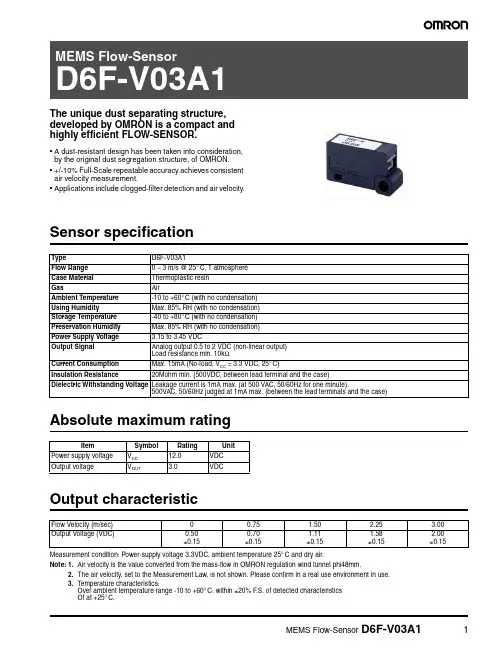

The unique dust separating structure, developed by OMRON is a compact and highly efficient FLOW-SENSOR.•A dust-resistant design has been taken into consideration, by the original dust segregation structure, of OMRON.•+/-10% Full-Scale repeatable accuracy achieves consistent air velocity measurement.•Applications include clogged-filter detection and air velocity.Sensor specificationAbsolute maximum ratingOutput characteristicMeasurement condition: Power-supply voltage 3.3VDC, ambient temperature 25°C and dry air.Note:1.Air velocity is the value converted from the mass-flow in OMRON regulation wind tunnel phi48mm.2.The air velocity, set to the Measurement Law, is not shown. Please confirm in a real use environment in use.3.T emperature characteristics:Over ambient temperature range -10 to +60°C: within ±20% F .S. of detected characteristics Of at +25°C.Type D6F-V03A1Flow Range 0 – 3 m/s @ 25°C, 1 atmosphere Case Material Thermoplastic resin GasAirAmbient Temperature -10 to +60°C (with no condensation)Using Humidity Max. 85% RH (with no condensation)Storage Temperature -40 to +80°C (with no condensation)Preservation Humidity Max. 85% RH (with no condensation)Power Supply Voltage 3.15 to 3.45 VDCOutput Signal Analog output 0.5 to 2 VDC (non-linear output)Load resistance min. 10k ΩCurrent Consumption Max. 15mA (No-load, V CC = 3.3 VDC, 25°C)Insulation Resistance20Mohm min. (500VDC, between lead terminal and the case)Dielectric Withstanding Voltage Leakage current is 1mA max. (at 500 VAC, 50/60Hz for one minute).500VAC, 50/60Hz judged at 1mA max. (between the lead terminals and the case)ItemSymbol Rating Unit Power supply voltage V CC 12.0VDC Output voltageV OUT3.0VDCFlow Velocity (m/sec)00.75 1.50 2.25 3.00Output Voltage (VDC)0.50±0.150.70±0.151.11±0.151.58±0.152.00±0.15DimensionsOmron Electronic Components, LLCTerms and Conditions of Sales1.Definitions: The words used herein are defined as follows.(a) Terms:These terms and conditions(b) Seller:Omron Electronic Components LLC and its subsidiaries(c) Buyer:The buyer of Products, including any end user in section III through VI(d) Products:Products and/or services of Seller(e) Including:Including without limitation2.Offer; Acceptance: These Terms are deemed part of all quotations, acknowledgments,invoices, purchase orders and other documents, whether electronic or in writing, relating to the sale of Products by Seller. Seller hereby objects to any Terms proposed in Buyer's purchase order or other documents which are inconsistent with, or in addition to, these Terms.3.Distributor: Any distributor shall inform its customer of the contents after and includingsection III of these Terms.1.Prices; Payment: All prices stated are current, subject to change without notice by Seller.Buyer agrees to pay the price in effect at time of shipment. Payments for Products received are due net 30 days unless otherwise stated in the invoice. Buyer shall have no right to set off any amounts against the amount owing in respect of this invoice.2.Discounts: Cash discounts, if any, will apply only on the net amount of invoices sent toBuyer after deducting transportation charges, taxes and duties, and will be allowed only if (a) the invoice is paid according to Seller's payment terms and (b) Buyer has no past due amounts owing to Seller.3.Interest: Seller, at its option, may charge Buyer 1.5% interest per month or the maximumlegal rate, whichever is less, on any balance not paid within the stated terms.4.Orders: Seller will accept no order less than 200 U.S. dollars net billing.5.Currencies: If the prices quoted herein are in a currency other than U.S. dollars, Buyershall make remittance to Seller at the then current exchange rate most favorable to Seller; provided that if remittance is not made when due, Buyer will convert the amount to U.S. dollars at the then current exchange rate most favorable to Seller availableduring the period between the due date and the date remittance is actually made.ernmental Approvals: Buyer shall be responsible for all costs involved in obtainingany government approvals regarding the importation or sale of the Products.7.Taxes: All taxes, duties and other governmental charges (other than general real propertyand income taxes), including any interest or penalties thereon, imposed directly orindirectly on Seller or required to be collected directly or indirectly by Seller for themanufacture, production, sale, delivery, importation, consumption or use of the Products sold hereunder (including customs duties and sales, excise, use, turnover and license taxes) shall be charged to and remitted by Buyer to Seller.8.Financial: If the financial position of Buyer at any time becomes unsatisfactory to Seller,Seller reserves the right to stop shipments or require satisfactory security or payment in advance. If Buyer fails to make payment or otherwise comply with these Terms or any related agreement, Seller may (without liability and in addition to other remedies) cancel any unshipped portion of Products sold hereunder and stop any Products in transit until Buyer pays all amounts, including amounts payable hereunder, whether or not then due, which are owing to it by Buyer. Buyer shall in any event remain liable for all unpaid accounts.9.Cancellation; Etc: Orders are not subject to rescheduling or cancellation unless Buyerindemnifies Seller fully against all costs or expenses arising in connection therewith. 10.Force Majeure: Seller shall not be liable for any delay or failure in delivery resulting fromcauses beyond its control, including earthquakes, fires, floods, strikes or other labor disputes, shortage of labor or materials, accidents to machinery, acts of sabotage, riots, delay in or lack of transportation or the requirements of any government authority.11.Shipping; Delivery: Unless otherwise expressly agreed in writing by Seller:(a) All sales and shipments of Products shall be FOB shipping point (unless otherwisestated in writing by Seller), at which point title to and all risk of loss of the Products shall pass from Seller to Buyer, provided that Seller shall retain a security interest in theProducts until the full purchase price is paid by Buyer;(b) Delivery and shipping dates are estimates only; and(c) Seller will package Products as it deems proper for protection against normalhandling and extra charges apply to special conditions.12.Claims: Any claim by Buyer against Seller for shortage or damage to the Productsoccurring before delivery to the carrier must be presented in detail in writing to Seller within 30 days of receipt of shipment.1.Suitability: IT IS THE BUYER’S SOLE RESPOINSIBILITY TO ENSURE THAT ANYOMRON PRODUCT IS FIT AND SUFFICIENT FOR USE IN A MOTORIZED VEHICLE APPLICATION. BUYER SHALL BE SOLELY RESPONSIBLE FOR DETERMINING APPROPRIATENESS OF THE PARTICULAR PRODUCT WITH RESPECT TO THE BUYER’S APPLICATION INCLUDING (A) ELECTRICAL OR ELECTRONICCOMPONENTS, (B) CIRCUITS, (C) SYSTEM ASSEMBLIES, (D) END PRODUCT, (E) SYSTEM, (F) MATERIALS OR SUBSTANCES OR (G) OPERATING ENVIRONMENT.Buyer acknowledges that it alone has determined that the Products will meet theirrequirements of the intended use in all cases. Buyer must know and observe allprohibitions of use applicable to the Product/s.e with Attention: The followings are some examples of applications for whichparticular attention must be given. This is not intended to be an exhaustive list of all possible use of any Product, nor to imply that any use listed may be suitable for any Product:(a) Outdoor use, use involving potential chemical contamination or electricalinterference.(b) Use in consumer Products or any use in significant quantities.(c) Energy control systems, combustion systems, railroad systems, aviation systems,medical equipment, amusement machines, vehicles, safety equipment, andinstallations subject to separate industry or government regulations.(d) Systems, machines, and equipment that could present a risk to life or property.3.Prohibited Use: NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVINGSERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE PRODUCT IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USEWITHIN THE OVERALL EQUIPMENT OR SYSTEM.4.Motorized Vehicle Application: USE OF ANY PRODUCT/S FOR A MOTORIZEDVEHICLE APPLICATION MUST BE EXPRESSLY STATED IN THE SPECIFICATION BY SELLER.5.Programmable Products: Seller shall not be responsible for the Buyer's programming ofa programmable Product.1.Warranty: Seller's exclusive warranty is that the Products will be free from defects inmaterials and workmanship for a period of twelve months from the date of sale by Seller (or such other period expressed in writing by Seller). SELLER MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT ALL OTHER WARRANTIES, NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULARPURPOSE OF THE PRODUCTS.2.Buyer Remedy: Seller's sole obligation hereunder shall be to replace (in the formoriginally shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product or, at Seller's election, to repay or credit Buyer an amount equal to the purchase price of the Product; provided that there shall be noliability for Seller or its affiliates unless Seller's analysis confirms that the Products were handled, stored, installed and maintained and not subject to contamination, abuse,misuse or inappropriate modification. Return of any Products by Buyer must beapproved in writing by Seller before shipment.3.Limitation on Liability: SELLER AND ITS AFFILIATES SHALL NOT BE LIABLE FORSPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,WARRANTY, NEGLIGENCE OR STRICT LIABILITY. FURTHER, IN NO EVENT SHALL LIABILITY OF SELLER OR ITS AFFILITATES EXCEED THE INDIVIDUAL PRICE OF THE PRODUCT ON WHICH LIABILITY IS ASSERTED.4.Indemnities: Buyer shall indemnify and hold harmless Seller, its affiliates and itsemployees from and against all liabilities, losses, claims, costs and expenses (including attorney's fees and expenses) related to any claim, investigation, litigation or proceeding (whether or not Seller is a party) which arises or is alleged to arise from Buyer's acts or omissions under these Terms or in any way with respect to the Products.1.Intellectual Property: The intellectual property embodied in the Products is the exclusiveproperty of Seller and its affiliates and Buyer shall not attempt to duplicate it in any way without the written permission of Seller. Buyer (at its own expense) shall indemnify and hold harmless Seller and defend or settle any action brought against Seller to the extent that it is based on a claim that any Product made to Buyer specifications infringedintellectual property rights of another party.2.Property; Confidentiality: Notwithstanding any charges to Buyer for engineering ortooling, all engineering and tooling shall remain the exclusive property of Seller. All information and materials supplied by Seller to Buyer relating to the Products areconfidential and proprietary, and Buyer shall limit distribution thereof to its trustedemployees and strictly prevent disclosure to any third party.3.Performance Data: Performance data is provided as a guide in determining suitabilityand does not constitute a warranty. It may represent the result of Seller's test conditions, and the users must correlate it to actual application requirements.4.Change In Specifications: Product specifications and description may be changed at anytime based on improvements or other reasons. It is Seller’s practice to change part numbers when published ratings or features are changed, or when significantengineering changes are made. However, some specifications of the Product may be changed without any notice.5.Errors And Omissions: The information on Seller’s website or in other documentationhas been carefully checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.6.Export Controls: Buyer shall comply with all applicable laws, regulations and licensesregarding (a) export of the Products or information provided by Seller; (b) sale ofProducts to forbidden or other proscribed persons or organizations; (c)disclosure to non-citizens of regulated technology or information.1.Waiver: No failure or delay by Seller in exercising any right and no course of dealingbetween Buyer and Seller shall operate as a waiver of rights by Seller.2.Assignment: Buyer may not assign its rights hereunder without Seller's written consent.w: These Terms are governed by Illinois law (without regard to conflict of laws). Federaland state courts in Illinois have exclusive jurisdiction for any dispute hereunder.4.Amendment: These Terms constitute the entire agreement between Buyer and Sellerrelating to the Products, and no provision may be changed or waived unless in writing signed by the parties.5.Severability: If any provision hereof is rendered ineffective or invalid, such provision shallnot invalidate any other provision.Certain Precautions on Specifications and UseOMRON ON-LINEGlobal - USA - Cat. No. J01C-E-01Printed in USAOMRON ELECTRONIC COMPONENTS LLC55 E. Commerce Drive, Suite B Schaumburg, IL 60173847-882-228801/07 Specifications subject to change without noticeComplete “Terms and Conditions of Sale” for product purchase and use are on Omron’s website at – under the “About Us” tab, in the Legal Matters section.ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.T o convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.。

真空设备常见英文单词transducer 传感器air cylinder气缸breaker,circuit,contactor 断路器abb contactor, power module 断路器, 电源模块ace absorber,shock 防震, 缓冲器acme transformer; contactor 变压器acopian power supply 电源供应器, 变压器aeg level transmitter, encoder 液位控制, 译码器aerquip hose, fitting 压力喉, 喉头, 喉咀agastat thermostate, thermocouple 恒温装置, 温度计airguard filter 过滤网airpel cylinder cylinder, valve 气缸、阀门airpot cylinder air cylinder 气缸、. 气阀anly counter, timer,socket 计数器, 时间制, 插座anver vacuum pad, air pump 真空吸索、真空泵appllo valve,bronze ball 球阀门asco valve valve 阀门ash worth sprocket 齿轮, 齿条atosvalve valve , pressure guage 油压阀auto guard controler,temperture 温度控制仪autotech controller, pls, encoder 角度控制器, 译码器bacber-colman temperature controller 温度装置baldor motor motor 马达电机baluff sensor sensor, switch 传感器banner sensor photo sensor; fiber, light curtain 传感器, 光织, 光帘barksdale switch,pressure 压力开关baumer sensor proximity sensor, fiber 接近开关、光织belvac machine parts 包装业零件bimba cylinder cylinder 气缸bodine motor pinch roll motor, controller, gear box 马达borns mexico sensor, micro switch 传感器brap haprison cable,joy hand held switch, 电路开关bray series valva,butterfly 蝴蝶阀brook crompton linear motor, gear box,pump motor 防爆马达browning belt,poly-v 工业皮带bussmann fuse fuse 保险丝carlo gavazzi sensor 传感器cb boiler parts, filter 锅炉配件, 过泸器chicago switch,airflow 气流开关cincinnati coupling,quick disconnet 连接器, 快速接头clarostat resistor, vr 卷烟机器用电阻crouzet counter, timer, relay 计数器, 时间制, 继电器crydom push buttom, switch 按手掣, 开关c-tek counter, timer,socket 计数器, 时间制, 插座cutler-hammer sensor, micro switch 微动开关cyklop machine parts 包装业零件datalogic sensor photo sensor, fiber sensor 红外线电眼, 光导纤维dayton motor 马达电机delta design ic manufacturing spare parts 半导体机械配件diamond chain, roller. bush 钻石牌产品dodge bearing 啤令, 轴承dolan jenner optical fiber; light sources; ringlights 光导纤维dominic anrep photo switch, fiber controller 光电开关dongag transformer 变压器durant run time meter, counter 时间制、计数器dynapar ph transmitter, gauging sys 酸碱度计, 测厚仪eagle-signal potentiometer; positioning 比例电平器eao switch push buttom, switch, lamp 按钮开关, 指示灯eaton dyna motor; speed control motor 马达控制器electromatic flow switch, level controller 流量计、液位控制emerson motor motor, speed control 调速器, 马达enots sleeve,tubing 轴承, 衬套entrelec terminal 端子器, 接头esta sequencer, tachometer 程控器, 译码器euchner sensor, positioning control 传感器, 定位装置fafnir bearing,pillow block 啤令, 轴承, 衬套fasco motor gear box, motor 马达fenner temperature controller 温控器fincor membrane keypad 膜片开关formatec machine parts 包装业零件fuji electric motor, contactor, relay 马达, 断路器, 继电器g.p.reeves machine parts 机械配件g0ldco machine parts 机械配件gast gauge,vacuum 表头, 主控制器ge fanuc motor , controller 马达, 控制器gordos pump, motor 泵, 马达gould machine parts 包装业零件guardian switch, relay 继电器hekeda ultrasonic cleaning machine 超声波清洗机heviduty transformer 变压器honeywell temp controller, sensor, sw 温控器, 开关hubble connector, socket 美国插头、连接头hyde park ultronsonic sensor 超声波传感器hydra pump, valve 泵, 阀门idec relay, lamp, push button 继电器, 指示灯, 按手旋钮ifm photo sensor, proximity sensor, encoder 近接开关, 译码器international. cam actuator, switch 凸轮驱动器, 开关intralox sprocket, belt 齿轮, 齿条, 皮带jefferson elect valve, fitting , hydraulic 液压控制系统, 阀门, 接咀jordan valae,pressure reducing 减压阀joslyn clark dc contactor, auxiliary contact 连接器kessler ellis hydraulic tube, vacuum pump 油管, 真空泵keyence sensor 传感器keystone sprockets 齿轮, 齿条, 皮带kfps proximity sensor 近接开关kitalcoppie thermocouple , temp control 热电隅, 温控器koganei penumatic valve, cylinder, fitting 气缸, 阀门, 接咀koyo cylinder 气缸, 阀门, 接咀leeson motor motor, reducer, spped control 马达, 减速箱, 控制器leuze sensor 传感器little giant vacuum pump 小巨人磁力泵litton motor motor 马达lundahl inst'mt sensor, ultrasonic, level cont 电眼、液位检测器mac solenoid valve, air fitting 电磁阀、气缸、过滤器magnetek variable speed motor; motor controller 调速马达malema flow sensor, flow switch 流量计、流量开关master pneumatic pneumatic product 气动组件maxon ignitor,spark, rod flame 火焰检测器mcgill bearing , bush 啤令, 杯士, 衬套meanwell p.sup power,supply 电源供应器, 变压器meto-fer proximity sw, sensing element 近接开关micro switch micro switch; guard switch 微动开关migatron ultronsonic sensor 超声波传感器milltronics fluidic motion control 液压控制系统minster machine parts 机械配件mitsubishi plc, contractor 编程器, 接触器moeller contactor relay, contactor 继电器, 接触器naeherung proximity switch, micro switch 微动开关namco sensor, switch 传感器national sensor, switch, relay 传感器, 微动开关new york blowe bearing, shaft 啤令, 硬轴newark potentiometer; actuator 电位器newport cylinder, valve , fitting 气缸, 阀门, 接咀norgen penumatic air cylinder, fitting, frl 气动组件ntn bearing bearing , bush 啤令, 衬套numatics calve, cylinder 阀门, 气缸ohmite resistor vr 卷烟机用可调电阻omega equipment control equipment 控制仪器omron sensor, plc 传感器opcon sensor 传感器oriental motors motor, gerabox, ac/dc control 马达, 减速箱, 控制器orion lab test equipment 实验室仪器paco detector,flame 火焰检测器palmer gauge,pressure 压力表panduit conductor, resistor 导线, 电阻parker fitting, o-ring , valve 密封圈, 接咀, 阀门partlow control meter 温控表peco sensor 传感器pepperl & fuchs sensor 传感器phoenix contact relay contactor 继电器, 接触器piab penumatic vacuum pump, suction pad 真空泵, 吸盘pittman motor mini motor 小型马达potter & brumfd time delay relay, relay 继电器, 时间延迟器prime double sheet detector 双金属片检定器protection system protection device 系统保护装置ragsdale machine parts 机械配件randolph alcoa machine parts 机械配件rechner sensor ,proximity 接近开关red lion actual stroke counter, counter timer 时间制, 温控器redicon bearing, filter, valve ,sensor 机械配件renco encoder 译码器rexnord chain & belt,sprocket 链条, 皮带, 齿轮reynolds machine parts 机械配件riese nozzle jet 喷咀rittal motor, control device 马达控制器rk electronics rocker sw, rotary 摇臂开关rkc temperature controller 温控表robroy industries bearing, bush 啤令, 杯士, 衬套rosemount valve valve 阀门ross valve valve 阀门rutherford machine parts 机械配件ryall machine parts 机械配件saftronics motor starter, motor 马达samson valve 阀门sanken frequency inverter 变频器scanner scanning device, photo sensor 光电开关schonbuch photo sensor, proximity sensor, plc 光电开关、编程器sealmaster bearings,pillow block 啤令seco motor , transformer 马达, 变压器sencon proximity sensor, managetic sensor 传感器sensortronics cable 电缆sentec sensor 传感器sick sensor sensor 传感器siemens relay, contactor 继电器, 接触器skan-o-matic pneumatic parts 气动组件smc cylinder, valve 气缸、阀门sola transformer, power supply 变压器sponsler chain ,roller, gear 链条, 滚轴, 齿轮spraying syste nozzle,floodjet 喷咀sprcher + schuit overload relay; time relay; contactor 负载电器square d contactor, sensor 接触器, 传感器ssac machine parts 机械配件stahlin switch, controller 开关, 控制器sti vision system 视像系统sumtak sensor, detector, counter, encoder 电眼、检测器、计数器sun hydraulics cartridge,relief valve 阀门sunx sensor, safety curtain 传感器super-e motor, gear box 马达、齿轮箱syrelec contractor, counter 接触器, 计数器systems control board, i/o module 控制电路板taiyo cylinder, valve 气缸, 阀门takenaka photo sensor, magnetic sw 传感器tapeswitch sensing element 传感器telemecanique sensor, relay, contactor 传感器tescor tech. i bearing,follower cam 啤令, 凸轮timken bearing, bush 啤令, 杯士, 衬套torrington bearing, bush 啤令, 杯士, 衬套toshiba inverter, motor 变频器total control inspection and measuring sys 检查及量度系统trane filter 过泸器triad auto feeding system 自动进给系统turck proximity sensor, plc, relay 接近开关、电容式开关u.s. motor motor 马达under writers power actuator 电动促动器vacuum vacuum suction pad 真空吸盘veeder-root microcontroller 微型控制器vickers valve,directional 阀门visolux sensor 传感器vorn industries thumwheel switch 姆指旋转开关warner electric dc motor speed controller, motor driver 直流马达、驱动器weed inst. thermocouple 温控器weksler thermometer 温度仪westinghouse sensor, contactor 传感器, 接触器xycom system controller device 监察系统yamatake sensor, switch 传感器, 开关yaskawa sensor, motion control 传感器, 行动控制装置。

15/30-W ModelsCompact, Thin Power Supplies That Mount Just About Anywhere to Contribute to Control Panel Downsizing•Compact, thin size: 22.5 × 85 × 96.5 mm (W × H × D).•Three mounting directions(standard, horizontal, facing horizontal).•Mounting directly onto the panel is possible.•Safety standards:UL508/60950-1/1604, CSA C22.2 No. 14/60950-1/213,EN50178 (= VDE0160), EN60950-1 (= VDE0805).60/90/120/180/240-W ModelsNew Models with Total Run Time Monitor in Addition to Models with Maintenance Forecast Monitor•Compact size: 40 × 95 mm (W × H) (60-W Models).•Status displayed on 3-digit, 7-segment display.•Safety standards:UL508/60950, CSA C22.2 No. 14/60950,EN50178 (= VDE0160), EN60950 (= VDE0805).Features Common to All Models•Mount to DIN-rail.•Lead-free solder.Model Number Structure■Model Number LegendOrdering InformationNote:1.The output capacity of the S8VS-01505 is 10 W.2.The output capacity of the S8VS-03005 is 20 W.1.Power Ratings 015: 15 W 030: 30 W 060: 60 W 090: 90 W 120: 120 W 180: 180 W 240: 240 W2.Output voltage 05: 5 V 12: 12 V 24: 24 V3.Configuration15-W, 30-W Models None: Standard60-W Models None: Standard A:With maintenance forecast monitor B:With total run time monitor90-W, 120-W, 180-W, 240-W ModelsNone: Standard A:With maintenance forecast monitorand undervoltage alarm (transistor (sinking))B:With total run time monitor and un-dervoltage alarm(transistor (sinking))AP:With maintenance forecast monitorand undervoltage alarm (transistor (sourcing))BP:With total run time monitor and un-dervoltage alarm (transistor (sourcing))Power ratings Input VoltageOutput voltageOutput current Alarm outputModel number15 W100 to 240 VAC5 V 2.0 A ---S8VS-01505 (See note 1.)12 V 1.2 A S8VS-01512 24 V0.65 A S8VS-0152430 W5 V 4.0 A ---S8VS-03005 (See note 2.)12 V 2.5 A S8VS-0301224 V1.3 A S8VS-0302460 W24 V2.5 A---S8VS-06024S8VS-06024A S8VS-06024B90 W3.75 A---S8VS-09024Sinking S8VS-09024A Sourcing S8VS-09024AP Sinking S8VS-09024B SourcingS8VS-09024BP 120 W5 A---S8VS-12024Sinking S8VS-12024A Sourcing S8VS-12024AP Sinking S8VS-12024B SourcingS8VS-12024BP 180 W7.5 A---S8VS-18024Sinking S8VS-18024A Sourcing S8VS-18024AP Sinking S8VS-18024B SourcingS8VS-18024BP 240 W10 A---S8VS-24024Sinking S8VS-24024A Sourcing S8VS-24024AP Sinking S8VS-24024B SourcingS8VS-24024BPSpecifications■Ratings/CharacteristicsNote:1.Refer to the Engineering Data section on page B-21 for details.2.If the V .ADJ adjuster is turned, the voltage will increase by more than +15% of the voltage adjustment range. When adjusting the output voltage, confirm the actual output voltage from the Power Supply and be sure that the load is not damaged.3.The overvoltage protection of the S8VS-015@@ uses a zener diode clamp. If the internal feedback circuit is destroyed by any chance, the load may be destroyed by the clamped output voltage (approx. 140% to 190% of the rated output voltage).4.T o reset the protection, turn OFF the power supply for three minutes or longer and then turn the power supply back ON.5.The typical values indicate the values for an input condition of 230 VAC. All items are measured at a frequency of 50 Hz.6.The inrush current circuits do not differ for voltage specifications. Therefore, the typical values are the data values for 24-V models.7.The circuit forms are different, so the start up time is shorter only when using a 15-W power rating.Power ratings15 W 30 W TypeItemStandardStandardEfficiency (typical)5-V models 72% min. (76% typ.)70% min. (76% typ.)12-V models 74% min. (79% typ.)76% min. (83% typ.)24-V models77% min. (81% typ.)80% min. (85% typ.)InputVoltage 100 to 240 VAC (85 to 264 VAC)Frequency 50/60 Hz (47 to 450 Hz)Current100 V input 0.45 A max.0.9 A max.200 V input 0.25 A max.0.6 A max.230 V input 5 V: (0.14 A typ.), 12 V/24 V (0.19 A typ.) 5 V: (0.27 A typ.), 12 V/24 V (0.37 A typ.)Power factor---Harmonic current emissions Conforms to EN61000-3-2Leakage current 100 V input0.5 mA max.200 V input 1.0 mA max.230 V input5 V/12 V/24 V: (0.30 mA typ.)5 V/12 V/24 V:(0.32 mA typ.)Inrush current (See note 1.)100 V input 25 A max. (20 A typ.) (for a cold start at 25°C)200 V input50 A max. (40 A typ.) (for a cold start at 25°C)230 V input5 V/12 V/24 V: (29 A typ.) (See note 6.) 5 V/12 V/24 V: (40 A typ.) (See note 6.)OutputVoltage adjustment range (See note 2.)−10% to 15% (with V .ADJ) (guaranteed)Ripple2.0% (p-p) max. (at rated input/output voltage)f=20MHz measuring5 V: (0.70%(p-p) typ.), 12 V:(0.48%(p-p) typ.), 24 V:(0.25%(p-p) typ.) 5 V: (0.70%(p-p) typ.), 12 V:(0.52%(p-p) typ.), 24 V:(0.19%(p-p) typ.)f=100MHz measuring 5 V: (0.86%(p-p) typ.), 12 V:(0.56%(p-p) typ.), 24 V:(0.32%(p-p) typ.) 5 V: (0.80%(p-p) typ.), 12 V:(0.58%(p-p) typ.), 24 V:(0.21%(p-p)typ.)Input variation influence 0.5% max. (at 85 to 264 VAC input, 100% load)Load variation influence (rated input voltage) 2.0% max. (5 V), 1.5% max. (12 V , 24 V), (with rated input, 0 to 100% load)Temperature variation influence 0.05%/°C max.Start up time (See note 1 and 7.)100 ms max. (at rated input/output voltage)1,000 ms max. (at rated input/output voltage)5 V: (6 ms typ.), 12 V: (12 ms typ.), 24 V: (18 ms typ.) 5 V/12 V/24 V: (240 ms typ.)Hold time (See note 1.)20 ms min. (at rated input/output voltage)at 100% load 5 V: (328 ms typ.), 12V: (251 ms typ.), 24 V: (243 ms typ.) 5 V: (299 ms typ.), 12 V: (217 ms typ.), 24 V: (210 ms typ.)Additional functionsOverload protection (See note 1.)105% to 160% of rated load current, voltage drop, automatic re-set 105% to 160% of rated load current, voltage drop, intermittentoperation, automatic resetOvervoltage protection (See note 1.)Y es (a zener diode clamp) (See note 3.)Y es (See note 4.)Output voltage indication No Output current indication No Peak-hold current indication No Maintenance forecast monitor indication No Maintenance forecast monitor output No Total run time monitor indication No Total run time monitor output No Undervoltage alarm indication Y es (color: red)Undervoltage alarm output No Parallel operation No Series operation Models with 24-V output: Possible for up to 2 Power Supplies (with external diode)Models with 5- or 12-V output: Not possibleOtherOperating ambient temperature Refer to the derating curve in Engineering Data . (with no icing or condensation) Storage temperature −25 to 65°C Operating ambient humidity 25% to 85% (Storage humidity: 25% to 90%)Dielectric strength 3.0 kVAC for 1 min. (between all inputs and outputs; detection current: 20 mA)2.0 kVAC for 1 min. (between all inputs and PE terminals; detection current: 20 mA)1.0 kVAC for 1 min. (between all outputs and PE terminals; detection current: 20 mA)Insulation resistance 100 M Ω min. (between all outputs and all inputs/ PE terminals) at 500 VDC Vibration resistance 10 to 55 Hz, 0.375-mm single amplitude for 2 h each in X, Y , and Z directions10 to 150 Hz, 0.35-mm single amplitude (5 G max.) for 80 min. each in X, Y , and Z directionsShock resistance 150 m/s 2, 3 times each in ±X, ±Y , and ±Z directionsOutput indicator Y es (color: green)EMIConducted Emissions Conforms to EN61204-3 EN55011 Class B and based on FCC Class A Radiated EmissionsConforms to EN61204-3 EN55011 Class BEMSConforms to EN61204-3 high severity levelsApproved standardsUL: UL508 (Listing, Class 2: Per UL1310), UL60950-1, UL1604 (Class I /Division2)cUL: CSA C22.2 No.14 (Class 2), No.60950-1, No.213 (Class I /Division2)EN/VDE: EN50178 (=VDE0160), EN60950-1 (=VDE0805)SELV (EN60950/EN50178/UL60950-1)According to VDE0106/P100, IP20Weight 160 g max.180 g max.Specifications■Ratings/CharacteristicsNote:1.Refer to the Engineering Data section on page B-21 for details.2.If the V .ADJ adjuster is turned, the voltage will increase by more than +15% of the voltage adjustment range (by more than +10% for 240-W models). When adjusting the output voltage,confirm the actual output voltage from the Power Supply and be sure that the load is not damaged.3.T o reset the protection, turn OFF the power supply for three minutes or longer and then turn the power supply back ON.4.Displayed on 7-segment LED. (character height: 8 mm)5.Resolution of output voltage indication: 0.1 V, Precision of output voltage indication: ±2% (percentage of output voltage value, ±1 digit)6.Resolution of output current indication: 0.1 A; Precision of output current indication: ±5% F .S. ±1 digit max. (specified by rated output voltage)7.Resolution of peak-hold current indication: 0.1 A; Precision of peak-hold current indication: ±5% F .S. ±1 digit max. (specified by rated output voltage);Signal width required for peak-hold current: 20 ms8. A T ype and B T ype: Sinking, AP T ype and P T ype: Sourcing9.T o ensure the emission rating, a ferrite ring core should be used in all cabling (TDK HF60T , HF70RH or equivalent model).10.The typical values indicate the values for an input condition of 230 VAC. All items are measured at a frequency of 50 Hz.Power ratings60 W 90 WTypeItemStandardMaintenance forecast monitorTotal run time monitorStandardMaintenance forecast monitorTotal run time monitorEfficiency (typical)78% min. (86% typ.)80% min. (87% typ.)Input Voltage100 to 240 VAC (85 to 264 VAC)Frequency 50/60 Hz (47 to 450 Hz)Current100 V input 1.7 A max. 2.3 A max.200 V input 1.0 A max. 1.4 A max.230 V input (0.7 A typ.)(0.9 A typ.)Power factor ---Harmonic current emissions Conforms to EN61000-3-2Leakage current 100 V input 0.5 mA max.200 V input 1.0 mA max.230 V input (0.40 mA typ.)(0.35 mA typ.)Inrush current (See note 1.)100 V input 25 A max. (for a cold start at 25°C)200 V input 50 A max. (for a cold start at 25°C)230 V input (47 A typ.)(38 A typ.)OutputVoltage adjustment range (See note 2.)−10% to 15% (with V .ADJ) (guaranteed)Ripple 2.0% (p-p) max. (at rated input/output voltage)f=20MHz measuring (0.29% (p-p) typ.)(0.38% (p-p) typ.)f=100MHz measuring (0.32% (p-p) typ.)(0.42% (p-p) typ.)Input variation influence 0.5% max. (at 85 to 264 VAC input, 100% load)Load variation influence (rated input voltage) 1.5% max. (with rated input, 0 to 100% load)Temperature variation influence 0.05%/°C max.Start up time (See note 1.)1,000 ms max. (at rated input/output voltage)(270 ms typ.)(260 ms typ.)Hold time (See note 1.)20 ms min. (at rated input/output voltage)at 100% load (220 ms typ.)(190 ms typ.)Additional functionsOverload protection (See note 1.)105% to 160% of rated load current, voltage drop, intermittent, automatic reset Overvoltage protection (See notes 1 and 3.)Y es Output voltage indication (See note 4.)No Y es (selectable) (See note 5.)No Y es (selectable) (See note 5.)Output current indication (See note 4.)No Y es (selectable) (See note 6.)No Y es (selectable) (See note 6.)Peak-hold current indication (See note 4.)No Y es (selectable) (See note 7.)No Y es (selectable) (See note 7.)Maintenance forecast monitor indication (See note 4.)No Y es (selectable)No No Y es (selectable)NoMaintenance forecast monitor output NoY es (open collector out-put), 30 VDC max., 50 mA max. (See note 8.)No Total run time monitor indication (See note 4.)No Y es (selectable)No Y es (selectable)Total run time monitor outputNoY es (open collector out-put), 30 VDC max., 50 mA max. (See note 8.)Undervoltage alarm indication (See note 4.)No Y es (selectable)NoY es (selectable)Undervoltage alarm output terminals No Y es (open collector output)30VDC max., 50 mA max. (See note 8.)Parallel operation NoSeries operationY es for up to 2 Power Supplies (with external diode)OtherOperating ambient temperature Refer to the derating curve in Engineering Data . (with no icing or condensation)Storage temperature−25 to 65°COperating ambient humidity 25% to 85% (Storage humidity: 25% to 90%)Dielectric strength3.0 kVAC for 1 min. (between all inputs and outputs/ alarm outputs; detection current: 20 mA) 2.0 kVAC for 1 min. (between all inputs and PE terminals; detection current: 20 mA)1.0 kVAC for 1 min. (between all outputs/ alarm outputs and PE terminals; detection current: 20 mA)500 VAC for 1 min. (between all outputs and alarm outputs; detection current: 20 mA) Insulation resistance 100 M Ω min. (between all outputs/ alarm outputs and all inputs/ PE terminals) at 500 VDC Vibration resistance 10 to 55 Hz, 0.375-mm single amplitude for 2 h each in X, Y , and Z directions10 to 150Hz, 0.35-mm single amplitude (5 G max.) for 80 min each in-X, Y , and Z directionsShock resistance150 m/s 2, 3 times each in ±X, ±Y , and ±Z directionsOutput indicator Y es (color: green)EMI Conducted Emissions Conforms to EN61204-3 EN55011 Class A and based on FCC Class AConforms to EN61204-3 EN55011 Class B (See note 9.)Radiated Emissions Conforms to EN61204-3 EN55011 Class A Conforms to EN61204-3 EN55011 Class B (See note 9.)EMS Conforms to EN61204-3 high severity levels Approved standards UL: UL508 (Listing, Class 2: Per UL1310), UL60950cUL: CSA C22.2 No.14 (Class 2), No.60950 EN/VDE: EN50178 (=VDE0160), EN60950 (=VDE0805)SELV (EN60950/EN50178/UL60950-1)According to VDE0106/P100, IP20UL: UL508 (Listing), UL60950cUL: CSA C22.2 No.14, No.60950EN/VDE: EN50178 (=VDE0160), EN60950 (=VDE0805)SELV (EN60950/EN50178/UL60950-1) According to VDE0106/P100, IP20Weight 330 g max.490 g max.Power ratings120 W180 W240 WType Item Standard Maintenance forecastmonitorTotal runtimemonitorStandard Maintenance forecastmonitorTotal runtimemonitorStandard Maintenance forecastmonitorTotal runtimemonitorEfficiency (typical)80% min. (87% typ.)80% min. (88% typ.)80% min. (86% typ.) Input Voltage100 to 240 VAC (85 to 264 VAC)Frequency50/60 Hz (47 to 63 Hz)Current100 V input 1.9 A max. 2.9 A max. 3.8 A max.200 V input 1.1 A max. 1.6 A max. 2.0 A max.230 V input(0.6 A typ.)(0.9 A typ.)(1.2 A typ.) Power factor0.95 min.Harmonic current emissions Conforms to EN61000-3-2Leakage current100 V input0.5 mA max.200 V input 1.0 mA max.230 V input(0.43 mA typ.)(0.45 mA typ.)(0.45 mA typ.)Inrush current (See note 1.)100 V input25 A max. (for a cold start at 25°C)200 V input50 A max. (for a cold start at 25°C)230 V input(41 mA typ.)(34 mA typ.)(39 mA typ.)Output Voltage adjustment range (See note 2.)−10% to 15% (with V.ADJ) (guaranteed)±10% (with V.ADJ) (guaranteed) Ripple 2.0% (p-p) max. (at rated input/output voltage)f=20MHz measuring(0.66%(p-p) typ.)(0.45%(p-p) typ.)(0.13%(p-p) typ.)f=100MHz measuring(0.67%(p-p) typ.)(0.52%(p-p) typ.)(0.21%(p-p) typ.) Input variation influence0.5% max. (at 85 to 264 VAC input, 100% load)Load variation influence (rated input voltage) 1.5% max. (with rated input, 0 to 100% load)Temperature variation influence0.05%/°C max.Start up time (See note 1.)1,000 ms max. (at rated input/output voltage)(380 ms typ.)(530 ms typ.)(780 ms typ.) Hold time (See note 1.)20 ms min. (at rated input/output voltage)at 100% load(60 ms typ.)(60 ms typ.)(30 ms typ.)Addition-al func-tions Overload protection (See note 1.)105% to 160% of rated load current, voltage drop, intermittent, automatic reset105% to 160% of rated loadcurrent, voltage drop, auto-matic resetOvervoltage protection (See notes 1 and 3.)Y esOutput voltage indication (See note 4.)No Y es (selectable)(See note 5.)No Y es (selectable)(See note 5.)No Y es (selectable)(See note 5.)Output current indication (See note 4.)No Y es (selectable)(See note 6.)No Y es (selectable)(See note 6.)No Y es (selectable)(See note 6.)Peak-hold current indication (See note 4.)No Y es (selectable)(See note 7.)No Y es (selectable) (See note7.)No Y es (selectable)(See note 7.) Maintenance forecast monitor indication(See note 4.)No Y es(selectable)No No Y es(selectable)No No Y es(selectable)NoMaintenance forecast monitor output No Y es(open collec-tor output),30 VDCmax., 50 mAmax.(See note 8.)No No Y es(open collec-tor output),30VDCmax., 50 mAmax.(See note 8.)No No Y es(open collec-tor output),30 VDCmax., 50 mAmax.(See note 8.)NoTotal run time monitor indication(See note 4.)No Y es(selectable)No Y es(selectable)No Y es(selectable) Total run time monitor output No Y es (opencollector out-put), 30 VDCmax., 50 mAmax.(See note 8.)No Y es (opencollector out-put), 30 VDCmax., 50 mAmax.(See note 8.)No Y es (opencollector out-put), 30 VDCmax., 50 mAmax.(See note 8.) Undervoltage alarm indication (See note 4.)No Y es (selectable)No Y es (selectable)No Y es (selectable) Undervoltage alarm output terminals No Y es (open collector output),30VDC max., 50 mA max.(See note 8.)No Y es (open collector output),30VDC max., 50 mA max.(See note 8.)No Y es (open collector output),30VDC max., 50 mA max.(See note 8.)Parallel operation NoSeries operation Y es for up to 2 Power Supplies (with external diode)Other Operating ambient temperature Refer to the derating curve in Engineering Data. (with no icing or condensation) Storage temperature−25 to 65°COperating ambient humidity25% to 85% (Storage humidity: 25% to 90%)Dielectric strength 3.0 kVAC for 1 min. (between all inputs and outputs/ alarm outputs; detection current: 20 mA)2.0 kVAC for 1 min. (between all inputs and PE terminals; detection current: 20 mA)1.0 kVAC for 1 min. (between all outputs/ alarm outputs and PE terminals; detection current: 20 mA)500 VAC for 1 min. (between all outputs and alarm outputs; detection current: 20 mA) Insulation resistance100 MΩ min. (between all outputs/ alarm outputs and all inputs/ PE terminals) at 500 VDCVibration resistance10 to 55 Hz, 0.375-mm single amplitude for 2 h each in X, Y, and Z directions10 to 150Hz, 0.35-mm single amplitude (5 G max.) for 80 min each in-X, Y, and Z directionsShock resistance150 m/s2, 3 times each in ±X, ±Y, and ±Z directionsOutput indicator Y es (color: green)EMI ConductedEmissions Conforms to EN61204-3 EN55011 Class A and based on FCC Class A Conforms to EN61204-3 EN55011 Class B (See note 9.)Radiated Emissions Conforms to EN61204-3 EN55011 Class AConforms to EN61204-3 EN55011 Class B (See note 9.)EMS Conforms to EN61204-3 high severity levelsApproved standards UL: UL508 (Listing), UL60950cUL: CSA C22.2 No.14, No.60950EN/VDE: EN50178 (=VDE0160), EN60950 (=VDE0805)SELV (EN60950/UL50178/UL60950-1)According to VDE0106/P100, IP20Weight550 g max.850 g max.1,150 g max.。

G 3V M 21U R 11I World's smallest New VSON Package with Low Output Capacitance and Low ON Resistance■Application Examples■Ordering InformationNote: When ordering tape packing, add "(TR05)" to the model number.Ask your OMRON representative for orders under 500 pcs. We can supply products with the tape already cut.Tape-cut VSONs are packaged without humidity resistance. Use manual soldering to mount them.Refer to common precautions.*The AC peak and DC value are given for the load voltage and continuous load current.■Absolute Maximum Ratings (Ta = 25°C)Note:1. The dielectric strength between the input and output was checked by applying voltage between all pins as a group on the LED sideand all pins as a group on the light-receiving side.Note: The actual product is marked differently from theimage shown here.RoHS CompliantRefer to "Common Precautions ".■Package(Unit : mm, Average)■Model Number LegendPackage type Contact formTerminalsLoad voltage (peak value) *Continuous load current (peak value) *Packing/Tape cut Packing/Tape & reel Model Minimum package quantityModelMinimum package quantity VSON41a(SPST-NO)Surface-mountingTerminals20V1,000mAG3VM-21UR11−G3VM-21UR11(TR05)500ItemSymbol G3VM-21UR11Unit Measurement conditionsI n p u tLED forward currentI F 30mALED forward current reduction rate ∆I F /°C −0.3mA/°C Ta ≥25°C LED reverse voltage V R 5 V Connection temperature T J 125 °C O u t p u tLoad voltage (AC peak/DC)V OFF 20V Continuous load current (AC peak/DC)I O 1,000mAON current reduction rate ∆I O /°C −10mA/°C Ta ≥25°C Pulse ON currentlop 3A t=100ms, Duty=1/10Connection temperatureT J 125°C Dielectric strength between I/O (See note 1.)V I-O 300Vrms AC for 1 minAmbient operating temperature Ta −40~+85°C With no icing or condensation Ambient storage temperature Tstg −40~+125°CSoldering temperature−260 °C10s•Semiconductor test equipment •Test & measurement equipment•Communication equipment •Data loggers2.451.451.3G3VM-@ @ @ @ @123451.Load Voltage 2: 20V2.Contact form 1: 1a (SPST -NO)5.Other informationsWhen specifications overlap, serial code is added in the recorded order.3.Package type U: VSON 4 pin4. Additional functions R: Low On-resistanceG3VM-21UR11MOS FET RelaysG 3V M 21U R 11I V S O N ■Electrical Characteristics (Ta = 25°C)Note:2. Turn-ON and Turn-OFF Times■Recommended Operating ConditionsFor usage with high reliability, Recommended Operation Conditions is a measure that takes into account the derating of Absolute Maximum Ratings and Electrical Characteristics.Each item on this list is an independent condition, so it is not simultaneously satisfy several conditions.ItemSymbolG3VM-21UR11Unit Measurement conditionsI np u tLED forward voltage V F Minimum1.1V I F =10mA Typical 1.27Maximum 1.4Reverse currentI R Maximum 10µA V R =5V Capacity between terminals C T Typical 30pF V=0, f=1MHz Trigger LED forward current I FT Maximum 3.0mA IO =100mA Release LED forward current I FC Minimum 0.1mA I OFF =10µA O u t p u tMaximum resistance with output ON R ON Typical 0.18ΩI F =5mA, t<1s, I O =1,000mAMaximum 0.22Current leakage when the relay is open I LEAK Maximum 1nA V OFF =20VCapacity between terminals C OFF Typical 40pF V=0, f=100MHz, t<1s Capacity between I/O terminalsC I-O Typical1pF f=1MHz, V S =0V Insulation resistance between I/O terminals R I-O Typical 108M ΩV I-O =500VDC, R O H ≤60%Turn-ON time t ON Maximum 2msI F =5mA, R L =200Ω,V DD =10V (See note 2.)Turn-OFF timet OFFMaximum1ItemSymbol G3VM-21UR11Unit Load voltage (AC peak/DC)V DD Maximum 16VOperating LED forward current I F Minimum 5mATypical 7.5Maximum 20Continuous load current (AC peak/DC)I O Maximum 1,000Ambient operating temperatureTaMinimum −20°C Maximum65V I DD OUTG3VM-21UR11MOS FET RelaysG 3V M 21U R 11I ■Engineering DataLED forward current vs.Ambient temperatureContinuous load current vs.Ambient temperatureLED forward current vs.LED forward voltageContinuous load current vs.On-state voltageOn-state resistance vs.Ambient temperatureTrigger LED forward current vs.Ambient temperatureTurn ON, Turn OFF time vs.LED forward currentTurn ON, Turn OFF time vs.Ambient temperatureCurrent leakage vs. Load voltageCurrent leakage vs. Ambient temperatureOutput terminal capacitance vs. Load voltageI F - TaAmbient temperature Ta (°C)L E D f o r w a r d c u r r e n t I F (m A )(Maximum value)05101520253035-40020-20406080100I O - Ta Ambient temperature Ta (°C)C o n t i n u o u s l o a d c u r r e n t I O (m A )(Maximum value)020040060080010001200-40-20020406080100I F - V FLED forward voltage V F (V)L E D f o r w a r d c u r r e n t I F (m A )0.11101000.81 1.2 1.4 1.6I O - V ONOn-state voltage V ON (V)C o n t i n u o u s l o a d c u r r e n t I O (A )-1.2-0.8-0.400.40.81.2-0.2-0.100.10.2R ON - Ta Ambient temperature Ta (°C)O n -s t a t e r e s i s t a n c e R O N (Ω)0.10.20.30.40.5I FT - Ta Ambient temperature Ta (°C)T r i g g e r L E D f o r w a r d c u r r e n t I F T (m A )0123-40-2020406080100t ON , t OFF - I FLED forward current I F (mA)T u r n O N , T u r n O F F t i m e t O N , t O F F (µs )101001000110100t ON , t OFF - TaAmbient temperature Ta (°C)T u r n O N , T u r n O F F t i m e t O N , t O F F (µs )101001000-40-20020406080100I LEAK - V OFFLoad voltage V OFF (V)C u r r e n t l e a k a g e I L E A K (p A )20406080I LEAK -TaAmbient temperature Ta (°C)C u r r e n t l e a k a g e I L E A K (p A )10100100010000C OFF - V OFFLoad voltage V OFF (V)O u t p u t t e r m i n a l c a p a c i t a n c e C O F F /C O F F (0V )00.20.40.60.811.205101520G 3V M 21U R 11I V S O N ■Dimensions(Unit: mm)■Approved StandardsApplying for UL recognition■Safety Precautions•Refer to "Common Precautions " for all G3VM models.Note: The actual product is marked differently from the image shown here.Actual Mounting Pad Dimensions(Recommended Value, Top View)0.8±0.1±0.1Surface-mounting TerminalsWeight: 0.01g• Application examples provided in this document are for reference only. In actual applications, confirm equipment functions and safety before using the product.OMRON CorporationElectronic and Mechanical Components CompanyContact: /ecbCat. No. K267-E1-010814(0814)(O)Note: Do not use this document to operate the Unit.• Consult your OMRON representative before using the product under conditions which are not described in the manual or applying the product to nuclear control systems, railroad systems, aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems or equipment that may have a serious influence on lives and property if used improperly. Make sure that the ratings and performance characteristics of the product provide a margin of safety for the system or equipment, and be sure to provide the system or equipment with double safety mechanism s.。