大圆坯连铸凝固传热过程的数值模拟

- 格式:pdf

- 大小:276.48 KB

- 文档页数:4

第52卷第11期 2020年11月工程建设Engineering Construction7连铸坯地下运输过程中的传热过程数值模拟王业峰、刘前\周浩宇",陈小赞、李谦1陈思墨1(1.中冶长天国际工程有限责任公司,湖南长沙410205; 2.中南大学资源加工与生物工程学院,湖南长沙410083; 3.浙江大学能源工程学院,浙江杭州310027)摘要:针对初始温度为800丈的连铸坯在地下通道内运输过程中的传热过程,建立数值计算模型,重 点关注和考察地下通道混凝土、连铸坯及加装隔热罩后的温度状态。

结果表明:连铸坯进人地下通道后加热混凝土壁面使其温度迅速上升,混凝土上侧壁面温度上升最快,最高温度达到492. 85 地下通道空间内空气温度明显低于连铸坯和混凝土表面温度,连铸坯向混凝土壁面的传热主要方式为辐射传热;混凝土上侧壁面温度分布不均匀,与连铸坯正对区域的温度最高,是考察混凝土材料高温环境下安全状况时需重点关注的位置;隔热罩具有保护混凝土和对连铸坯保温的作用,能使混凝土温度维持在1〇〇 t以下,并维持连铸坯表面平均温度在700 t以上。

关键词:连铸坯运输;传热状况;温度分布;隔热罩;数值模拟中图分类号:T K124 文献标志码:A文章编号=1673-8993(2020)丨卜0007-05doi:10. 13402/j.gcjs.2020. 11. 002Numerical simulation on heat transfer in undergroundtransportation process of continuous casting billetsWang Yefeng1, Liu Qian1, Zhou Haoyu1 2, Chen Xiaozan1, Li Qian13, Chen Simo1 (X.Zhongye Changtian International Engineering Co. yLtd. f Changsha 410205,Hunan;2. School o f Minerals Processing & Bioengineering y Central South University ^ Changsha 4100S3, H unan;3.School o f Energy Engineering, Zhejiang University,Hangzhou310027, Zhejiang)Abstract: A numerical model is established against the heat transfer process with the 800 °C initial temperature of the continuous casting billets during the transportation process in the underground tunnel, and the underground passage concrete, continuous casting billets and the temperature status adding heat shield are focused on and investigated. The results show that the concrete walls are heated after the continuous casting billets enter into the underground passage. The temperature of the upper concrete wall rises the fastest with the highest temperature of 492. 85 X i. The air temperature in the underground passage space is obviously lower than that of surface of the continuous casting billets and the concrete wall, which means that radiation heat transfer is the main heat transfer mode from continuous casting billets to the concrete wall. The temperature distribution of the upper concrete wall is not uniform. The highest temperature area is the area directly opposite to the continuous casting billets. T hus,the area directly opposite to the continuous casting billets need more attention when investigating the safety situation of concrete materials at high temperatures. The heat shield has the function of heat preservation to the concrete and the continuous casting billets,the temperature of the concrete wall keeps below 100 Tl and the average temperature of the continuous casting billets surface keeps above 700 X l.Key words;transportation of continuous casting billets;heat transfer status;temperature distribution;heat shield ;numerical simulation收稿日期:2020-09-29基金项目:湖南省自然科学基金项目(2020JJ5994)作者简介:王业峰(1992 —),男,工程师,从事工业炉窑热工方向数值仿真、实验及相关装备开发的研究工作。

铸件凝固过程中热应力场及热裂的数值模拟研究分析1 铸件凝固过程数值模拟的意义及概况自1962年丹麦Fround第1个采用电子计算机模拟铸件凝固过程以来,计算机在铸造工艺研究中得到了广泛的应用,如凝固过程温度场、热应力场的数值模拟,充型过程流速场的数值模拟;组织形态及力学性能的数值模拟等。

通过这些单1或复合过程的数值模拟,可以分析铸件中存在的各种缺陷的产生原因,进而采取相应工艺措施来消除缺陷,实现工艺优化,同时可以节省大量的人力、物力和财力,缩短产品从设计到应用的周期,增强产品的市场竞争能力。

如今,在芬兰,90%以上的铸造厂在日常中应用铸造模拟软件辅助铸造工艺设计;世界上一些大型的汽车公司的铸造厂,如美国的通用、福特,德国的奔驰等,都把数值模拟软件作为1种日常工具来使用。

近10年来,涌现出了许多优秀的铸造过程数值模拟软件,如美国的ProCast、德国的MAGMASoft、芬兰的CastCAE、西班牙的ForCast、日本的CASTEM、法国的SIMULOR软件等。

从功能上看,许多软件可以对砂型铸造、金属型铸造、精密铸造、压力铸造等多种工艺进行温度场、流场、应力场的数值模拟,可以预测铸件的缩孔、缩松、裂纹等缺陷和铸件各部位的组织。

国内在经历了10多年的基础研究和发展后,也出现了一些技术水平接近国外商品化的应用软件,可以进行铸钢、铸铁件砂型铸造时的三维温度场模拟及收缩缺陷的预测,以及对铸钢、铝合金件的热应力场进行模拟。

总的来说,国外软件的通用性强,能进行铸造全过程的数值模拟,并具有较强的后置处理功能及友好的用户界面。

建模方便,易于模型设计和修改,便于用户掌握和使用。

其计算精度与运算速度等方面也能满足需要。

正因为如此,国外模拟软件已经成为实际生产中的有力工具.国内不少用户趋向于采用大型通用工程软件如:COSMOS、ANSYS、ADINA等进行模拟计算。

2 数值模拟的基础性研究2.1 铸件凝固过程温度场数值模拟经过几十年的发展,铸件凝固过程温度场数值模拟技术已日臻成熟。

设计与计算!"#$TECHNOLOGY 10.3969/j.issn.l673—3355.2021.02.001超大断面圆坯垂直半连铸凝固过程模拟分析邢思深!,屈磊!,张亮&,戴广惠!摘要:采用垂直半连铸工艺制备直径超过01000mm大型圆坯的方法,是一种优化生产流程,降低材料损耗,提铸坯质量,铸的制。

和。

过01600mm大在同速下的直铸过发现在过程中的和的逐步稳定™:速对完成时的着的,速0.4m/mi*时,的V,在束时,在钢水水压力作用下的应力和都较小,漏钢事故的可能较低。

在:0.4m/mi*速下成的初始V:可保在后续中前沿的自下而上的顺序过™因此,01600mm大在垂直半铸条件下的速度应小于0.4m/min™关键词:直半连铸;超大断面圆坯;凝固过程;拉坯速度;静水压力中图分类号:TF777文献标识码:B文章编号:1673-3355(2021)02-0001-07Simulation Analysis of Solidification of Round Blooms with Super-Large Cross-Section during Vertical Semi-Continuous Casting Process Xing Sishen,Qu Lei,Zhang Liang,Dai Guanghui Abstract:The vertical semi-continuous casting technique for large round blooms in diameter equal to or beyond01000mm is a revolutionary way to optimize the production process,reduce material loss,improve the quality of blooms and break the size limit of continuous casting process.The technique allows the solidification to happen in two stages:casting and standstill cooling.The analysis by simulating the solidification of a01600mm large round bloom during vertical semi-continuous casting process at different casting speed reveals that the temperature of liquid steel in the mold and the shell thickness at the outlet become stable gradually during casting,and the casting speed of significant effect on the shape of the molten pool should be lower than0.4m/min.for vertical semi-continuous casting of01600mm large round blooms because the molten pool presents a V-shape in the longitudinal cross section when the casting speed is lower than0.4m/min.,which can reduce the risk of breakout accidents when the casting operation ends because the solidified shell suffers lower stress and deformation under hydrostatic pressure of the molten steel inside it,and can allow the solidification to occur obviously from the bottom to the top during standstill cooling.Key words:vertical semi-continuous casting;round bloom with super-large cross-section;solidification;casting speed;hydrostatic pressure随着核电、风电、水电和钢铁行业的快速发展及装备逐步大型化,市场对高质量大型铸锻件的需求量越来越大,其中由高品质特殊钢制成的、直径超过01000mm的大型轴类铸锻件是市场需求较多的一类产品,被广泛应用在大型支承辐、风机轴、核电和水电发电机组转子、船舶主轴、轴承等领域。

铸造凝固过程数值模拟时间:2007-4-11 9:03:441.1 概述在铸造生产中,铸件凝固过程是最重要的过程之一,大部分铸造缺陷产生于这一过程。

凝固过程的数值模拟对优化铸造工艺,预测和控制铸件质量和各种铸造缺陷以及提高生产效率都非常重要。

凝固过程数值模拟可以实现下述目的:1)预知凝固时间以便预测生产率。

2)预知开箱时间。

3)预测缩孔和缩松。

4)预知铸型的表面温度以及内部的温度分布,以便预测金属型表面熔接情况,方便金属型设计。

5)控制凝固条件。

6)为预测铸应力,微观及宏观偏析,铸件性能等提供必要的依据和分析计算的基础数据。

铸件凝固过程数值模拟开始于60年代,丹麦FORSU ND把有限差分法第一次用于铸件凝固过程的传热计算。

之后美国HEN ZEL和KE UERIAN应用瞬态传热通用程序对汽轮机内缸体铸件进行数值计算,得出了温度场,计算结果与实测结果相当接近。

这些尝试的成功,使研究者认识到用计算数值模拟技术研究铸件的凝固过程具有巨大的潜力和广阔的前景。

于是世界上许多国家都相继开展了铸件凝固过程数据模拟以及与之相关的研究工作。

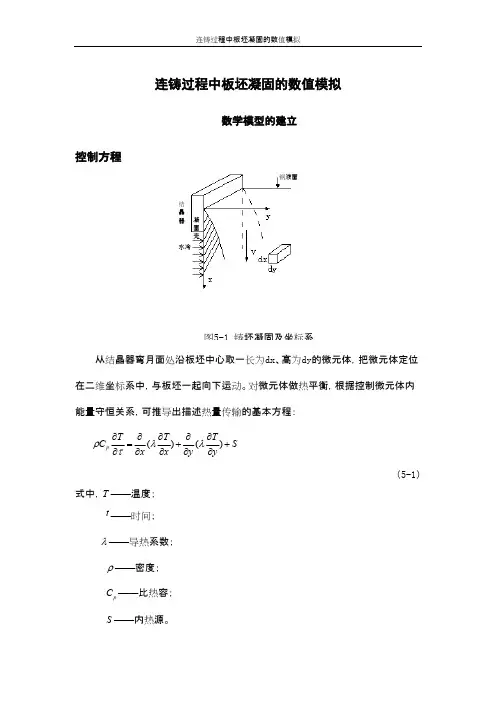

1.2 数学模型的建立和程序设计液态金属浇入铸型,它在型腔内的冷却凝固过程是一个通过铸型向环境散热的过程。

在这个过程中,铸件和铸型内部温度分布要随时间变化。

从传热方式看,这一散热过程是按导热、对流及辐射三种方式综合进行的。

显然,对流和辐射的热流主要发生在边界上。

当液态金属充满型腔后,如果不考虑铸件凝固过程中液态金属中发生的对流现象,铸件凝固过程基本上看成是一个不稳定导热过程。

因此铸件凝固过程的数学模型正是根据不稳定导热偏微分方程建立的。

但还必须考虑铸件凝固过程中的潜热释放。

基于分析和计算模型开发相应的程序,即可实现铸造凝固过程温度场的计算。

第6期 2009年12月连铸Continuous CastingNo.6December 2009关于连铸凝固传热数值模拟中钢液有效导热系数的探讨邹达基, 邹宗树(东北大学材料与冶金学院,辽宁沈阳110004)摘 要:在建立板坯连铸一维非稳态凝固传热数学模型的基础上,考虑到液相区的流动和传热状态随拉坯方向的变化,研究了有效导热系数与固相导热系数的比值m (λeff /λs )的处理方法对计算结果的影响。

结果表明,在相同的二冷条件下,m 取不同的常数对模型计算结果影响很大。

在相同的二冷条件下,将m 取为常数和取为随拉坯方向变化的变量都可以得到相同的液相穴深度,但二者的凝固壳厚度随拉坯方向的变化有一定的差别,并且出结晶器坯壳厚度差别较大。

改变二冷条件,上述二者液相穴深度不再相等。

因此,将m 取为常数的处理方法是不合理的。

关键词:板坯连铸;凝固传热;数值模拟;液相有效导热系数中图分类号:TF777.1 文献标识码:A 文章编号:100524006(2009)0620005204Discussion on E ffective Therm al Conductivity of Molten Steel inNumerical Simulation of Solidif ication in Continuous C astingZOU Da 2ji , ZOU Zo ng 2shu(School of Materials and Metallurgy ,Northeastern University ,Shenyang ,110004,Liaoning ,China )Abstract :Considering the variation of flow and heat transfer conditions in the region of slab continuous castingstrand ,the influence of m (λeff /λS )ratio of effective thermal conductivity to solid thermal conductivity on simulationresult was studied with a one 2dimensional unsteady solidification heat transfer model.The results showed that under the same secondary cooling condition ,the value of m has a great effect on the model calculating result ;the same depth of liquid core can be obtained with a constant m or a variable m along with casting direction ,but the variations of solidified shell thickness are different f rom each other ,particularly at the exit of the mold.Moreover ,if the sec 2ondary cooling condition is changed ,the depths of liquid core will no longer be equal to each other.Therefore ,the taking m as a constant is unreasonable.K ey w ords :slab continuous casting ;solidification heat transfer ;numerical simulation ;liquid effective thermal con 2ductivity作者简介:邹达基(19862),男,硕士生; E 2m ail :daji141@ 修订日期:2009206217符号表τ———时间,st p ———浇注温度,℃q w ———热流密度,W/m 2A ,B ———常数τ0———凝固时间,s α———对流给热系数,W/(m 2・℃)t w ———铸坯表面温度,℃t f 1———冷却水温度,℃t f 2———环境温度,℃W ———水流密度,L/m 2・s ε———铸坯表面黑度,一般取0.8σ———波尔兹曼常数,5.67×10-8W/(m 2・K 4)T ———温度,℃T l ,T s ———液相线、固相线温度,℃f s ———固相率C s ,C l ,C s -l ———固相区、液相区、两相区比热容,J /(kg ・℃)L f ———凝固潜热,低碳钢可取310800J /kg [2]λs ———固相导热系数,W/(m ・℃)λeff ———有效导热系数,W/(m ・℃)1 问题的提出在凝固传热的数值模拟中,对液相导热系数的处理是必须解决的问题。

连铸初始凝固过程温度波动数学模拟与解析*雷作胜,金小礼,马宁博,任忠鸣,邓康, 钟云波(上海大学,上海市现代冶金与材料制备重点实验室, 上海200072) 摘要通过独特设计的实验测量了结晶器振动过程中,连铸初始凝固点温度变化情况,发现初始凝固点温度存在与结晶器振动相对应的温度波动现象。

一个将结晶器振动考虑进来的三维非稳态传热数学模型的计算结果,也表明该温度波动现象的存在。

另外,传热数学解析表明,在结晶器内侧存在温度波动的情况下,无论有无保护渣,在钢水内部每一点都存在着与表面温度波动频率一致的温度波动,但其幅值随深度的增加而下降;在无保护渣的情况下,表面温度波动在钢水中的渗透深度约为1~2mm;保护渣的存在对温度波动有很大的衰减作用,因而能提高铸坯表面的质量;另外,采用高频率小振幅的振动,降低保护渣导热率,增加保护渣道宽度,都能有效地减小温度波动对初始凝固坯壳的影响。

这一现象可以用来解释现有的一些技术改善铸坯表面质量的原因。

关键词连铸结晶器振动振痕表面质量温度波动The Mathematical Modeling and Analyses on Temperature Fluctuation of Initial Solidified Process in Continuous Casting LEI Zuosheng, JIN Xiaoli, MA Ningbo,REN Zhongming, DENG Kang,ZHONG Yunbo (Shanghai University, Shanghai Key Laboratory of Modern Metallurgy & Material Processing, China) Abstract The Initial Solidified Point (ISP) temperature fluctuation during continuous casting caused by mold reciprocation was measured by a newly developed method. The repeated experiments results show that the ISP temperature varied periodically along with mold oscillation. The phenomena of temperature fluctuation during continuous casting were confirmed by a newly developed 3-dimension non-steady heat transfer mathematical modeling. A one-dimension heat transfer mathematic model shows that when there was a temperature fluctuation in the inner mould wall, there were corresponding temperature fluctuations at every point in the molten steel, whose frequency is the same as the boundary condition and amplitude decreased along with the increasing depth whether there was mould flux between mould and steel or not. The influence depth of surface temperature fluctuation in molten steel is about 1~2 mm when there was no mould flux. The surface temperature fluctuation attenuated rapidly when there was mould flux. Therefore mould flux was helpful to improve the billets surface quality. In addition, high frequency and low amplitude mould oscillation, decrease the thermal conductivity of mould flux and increase the mould flux channel width are all helpful to decrease the influence on early solidified shell caused by surface temperature fluctuation. Based on the phenomenon, the mechanism of how some technologies improve surface quality of continuous casting billets is analyzed. Their common mechanism was the decreasing of the temperature fluctuation of early solidification shell.Key words Continuous casting, Mold oscillation, Oscillation marks, Surface quality, temperature fluctuation.1. 前言随着技术的日益成熟,连铸朝着近终形、高速度、高质量方向发展[1],对铸坯质量的要求不断提高,铸坯表面振痕受到越来越多的关注。

收稿日期:2001201215; 修订日期:2004203214作者简介:李东辉(19682 ),女,辽宁沈阳人,讲师,博士.研究方向:连铸过程机控制系统.Em ail :annie6821@连铸凝固传热过程的数值模拟李东辉1,2,邱以清1,刘相华1,王国栋1(1.东北大学轧制技术与连轧自动化国家重点实验室,辽宁沈阳110004;2.沈阳工业学院,辽宁沈阳110045)摘要:研究和开发了连铸凝固传热过程数值模拟程序,并以生产厂的铸坯为研究对象,计算了铸坯断面温度分布和凝固壳厚度,该模型考虑了结晶器表面散热的不均匀性,处理了凝固时相变所产生的结晶潜热,将计算出的断面温度、坯壳厚度等数据与生产实验测得的数据相比较,吻合性很好。

他可用来优化连铸工艺参数,是进一步开发在线控制模型的基础。

关键词:连铸;数值模拟;热传输;数学模型中图分类号:TG249.7 文献标识码:A 文章编号:100028365(2004)0720529202Numerical Simulation of Continuous C asting during Solidif ication and H eart 2transferring ProcessL I Dong 2hui 1,2,Q IU Y i 2qing 1,L IU Xiang 2hua 1,WAN G Guo 2dong 1(1.The State K ey Laboratory of Rolling and Automation of Northeastern University ,Shenyang 110004,China ;2.Shenyang Institute of Technology ,Shenyang 110045,China )Abstract :A solidification and heat transferring process of continuous casting has researched and developed.It is applied to calculate the temperature distribution and solid shell thickness in a steel plant.Uneven elimination of heat in the mould surface is considered.The model includes variable thermal constant and freezing latent heat generated by phase changes during solidification.The thermal profile and solid shell thickness calculated by mathematical model agree with those get by experimental measurements.The model could also be used to predict the optimum process parameters in continuous casting ,and it could be a base of the development of on 2line control models.K ey w ords :Continuous casting ;Numerical simulation ;Heat 2transferring process ;Mathematical model 连铸过程中铸坯的温度分布对于产品品质、产量是非常重要的,铸坯各种缺陷的形成,通常与不合理的温度分布有关。

连铸坯凝固传热过程的数值模拟的开题报告一、选题背景连铸钢坯凝固传热过程是冶金工业中重要的工艺过程,其决定着钢坯的质量和内部组织结构。

传统的工艺方式主要依靠经验参数控制,难以解释传热过程的物理机制,难以应对复杂的生产情况,需要通过数值模拟的方法来深入研究和分析连铸钢坯凝固传热过程,为生产优化和工艺改进提供科学依据。

二、选题意义钢坯的内部组织结构和物理性能直接影响着钢材的品质和市场竞争力。

通过数值模拟连铸钢坯的传热过程,可以深入研究钢坯的内部组织结构变化规律和物理性能变化规律,为方便工艺改进和优化提供科学依据。

同时,数值模拟方法还能够实时监测生产过程中的温度场变化和组织结构演变,便于更好地控制生产并提升生产效率。

三、研究目标本研究的主要目标是建立连铸钢坯凝固传热过程的数值模拟模型,包括建立钢液流动模型、凝固模型和温度场模型等,并进行数值模拟计算,以获取钢坯的内部组织结构和物理性能变化规律,最终实现高效、稳定、高质量的钢坯生产。

四、研究方法1.建立凝固传热模型:根据钢坯凝固传热过程的物理特性和数学模型,建立凝固传热模型,并进行验证。

2.建立钢液流动模型:建立钢液流动模型,预测钢液流动的速度和力学参数。

3.数值模拟计算:通过数值计算得到钢坯的温度场、组织结构演变规律、组织性能等重要参数。

4.实验验证:通过钢坯实验,对计算结果进行验证和对比,确定数值计算的准确性和可靠性。

五、预期成果1.建立连铸钢坯凝固传热模型,预测钢坯的凝固传热过程。

2.计算预测钢坯温度场和组织结构演变规律,为生产和工艺改进提供科学依据。

3.优化工艺参数,提高钢坯的成品率和质量。

4.提升生产效率,降低生产成本。

六、论文结构安排第一章:绪论1.选题背景和意义2.研究目标和方法3.预期成果4.论文整体结构第二章:钢液流动模型1.钢液的物理特性和数学模型2.孔隙流流场的建立和验证3.钢液流动场的计算和预测第三章:钢坯的凝固传热模型1.钢坯的凝固传热特性和数学模型2.传热方程的建立和计算3.温度场的预测和验证第四章:优化和改进1.数值计算结果的分析和比对2.工艺参数的优化和改进3.生产效果的验证和检测第五章:总结和展望1.研究结论总结2.存在问题和不足3.未来研究方向参考文献。

铸坯凝固传热模型的研究连铸过程是一个连续的散热过程,在这个过程中,只有建立准确的铸坯凝固传热数学模型,才能模拟铸坯的凝固过程,对不同冷却段的铸坯的表面温度进行预测,从而帮助建立更为可控和准确的二冷配水制度,提高铸坯质量。

文章从传热、钢水流动和凝固三个阶段建立起铸坯的冷却凝固传热数学模型,弥补了单纯根据传热现象建立凝固传热数学模型的不足之处,使模型更为准确地预测铸坯的表面温度。

标签:铸坯凝固传热数学模型;传热;钢水流动;凝固连铸过程是将液态钢变为固态钢的过程,在这个过程中,钢水的固态化是散发了大量的热量实现的,且连铸过程是一个连续的非线性过程,因此,建立准确的铸坯凝固过程数学模型对铸坯冷却控制,提高铸坯质量都是很重要的。

目前常用的铸坯凝固传热数学模型大多是根据铸坯的凝固传热过程建立的偏微分方程,然后根据一定的初始条件和边界条件采用有限差分法对其进行求解。

但是在实际应用中这种方法由于没有考虑钢液液芯中钢水的对流散热问题而使建立的数学模型不能准确地描述铸坯的凝固过程,也不能准确地预测铸坯的表面温度。

因此,如何补偿液相区和两相区中钢水的对流散热就成为建立铸坯凝固传热数学模型中急需解决的一个关键问题。

在本文中综合考虑了铸坯在凝固过程中存在的传热、流动和凝固三种现象,建立起能够准确描述铸坯凝固传热过程的铸坯凝固传热数学模型。

1 铸坯凝固传热数学模型为了便于分析,方坯凝固传热数学模型的假设条件进行如下设定:(1)只考虑铸坯厚度方向的传热,忽略宽度和拉坯方向的传热;(2)在沿拉坯方向上铸坯内各点温度处于非稳态;(3)钢的密度ρ和热熔C等效为常数,固定不变;(4)液相温度和固相温度固定不变;(5)铸坯在二冷区的同一个冷却段内被认为是冷却均匀的;(6)对二冷区拉辊与铸坯的接触传热和铸坯自身的辐射传热忽略不计。

基于上述假设条件,建立铸坯的凝固传热偏微分方程如下:为了简化方程,设对应于i=1,2,3,si分别表示x,y和z方向上的拉速u,v,w;Ci分别表示x,y和z坐标方向,该方程可以写为:式中,ρ表示钢液密度;C表示比热容;T表示温度;x,y和t分别表示铸坯宽度方向、厚度方向和凝固时间;S表示由凝固潜热引起的热流,其计算如下:式中,Lt为凝固潜热,δ=δ(t)为凝固壳厚度,它与铸坯温度场密切相关。

连铸热过程数学模型的建立2.1连铸热过程数学模型的建立连铸热过程为连铸坯的凝固冷却过程。

连铸坯在凝固过程中,凝固传热量不仅影响铸机生产效率和设备寿命,而且对铸坯的表面质量和内部质量都有重要影响。

因此薄板坯凝固传热规律的研究,对该工艺的生产和设计,都具有十分重要的意义。

板坯凝固冷却过程可分为三个阶段:(1)结晶器冷却。

钢液在近结晶器壁处快速冷却,形成薄的坯壳;(2)二冷区冷却。

坯壳具有足够厚度时,铸坯从结晶器中拉出,在二冷区受到强烈的喷水冷却,液芯逐渐凝固;(3)空冷区冷却。

铸坯在空气中较缓慢地冷却,铸坯断面上温度逐渐趋于均匀。

根据板坯的凝固冷却过程,连铸热过程数学模型包括结晶器、二冷区和空冷区这三部分。

结晶器中热传递主要沿水平方向进行。

传热过程包括:(1)钢水以对流和导热形式将热量传给坯壳;(2)凝固坯壳的导热;(3)凝固坯壳与结晶器壁的传热;(4)结晶器壁的导热;(5)喷淋水与结晶器壁的强制对流传热。

其中在传热过程(3)中,填充于铸坯壳与结晶器壁气隙中的渣膜控制铸坯壳向结晶器的传热量,在结晶器的传热过程中显得尤为重要。

因此,应进一步分析气隙中渣膜特性对传热的影响,建立坯壳与结晶器气隙的传热模型。

为全面分析结晶器的传热,将该模型于铸坯凝固和结晶器壁的传热祸合起来,建立统一的结晶器传热数学模型。

带有液芯的铸坯进入二冷区达到完全凝固。

在二冷区铸坯向外传热方式主要有:(1)由喷射水滴蒸发带走的热量;(2)铸坯表面与周围环境的辐射换热;(3)铸坯与支撑辊、导辊的接触换热。

喷淋水和支撑辊、导辊与铸坯的传热对铸坯内液芯长度的控制十分重要。

铸坯进入拉矫机后进入空冷区,铸坯主要以辐射换热方式和自然对流的方式进行冷却。

2.1.1 基本假设为建立连铸过程温度场数学模型,需对物理模型进行简化,作如下假设:(1)连铸生产线工况稳定;(2)由于铸坯的贝克来数很高(~ 105),忽略整个铸坯沿拉坯方向传热; (3)钢液面上保护渣具有保温作用,忽略钢液表面的散热量;(4)沿结晶器和薄板坯宽度方向传热具有对称性,只计算1/2截面的温度场; (5)注入结晶器的钢液温度恒定;(6)结晶器壁与坯壳间的气隙层厚度不随位置和时间变化; (7)不考虑结晶器内凝固壳表面的振痕对传热的影响。

第44卷 第3期 2009年3月钢铁Iron and Steel Vol.44,No.3March 2009连铸坯凝固过程热力耦合有限元模拟陈 永1,2, 罗 歆3, 沈厚发3(1.东北大学材料与冶金学院,辽宁沈阳110004; 2.攀枝花钢铁研究院材料研究所,四川攀枝花617000; 3.清华大学机械工程系,北京100084)摘 要:以铸坯和结晶器之间的间隙热阻为纽带,考虑保护渣凝固对接触热阻和渣膜热阻的影响,建立了连铸结晶器与铸坯热力耦合模型并编写了相应的有限元仿真程序。

模型预测的坯壳厚度和实验结果吻合良好,两者差值≤2mm 。

应用模型分析了大方坯连铸结晶器内的传热过程和坯壳的应力分布。

结果表明,随着拉速提高,凝固坯壳厚度减薄,铸坯产生角部裂纹的趋势增加。

关键词:大方坯连铸;结晶器;传热;热2力变形;有限元法中图分类号:TF77712 文献标识码:A 文章编号:04492749X (2009)0320036204Numerical Simulation on Thermo 2Mechanical Coupling inB loom Mold by Finite E lement MethodC H EN Y ong 1,2, L UO Xin 3, SH EN Hou 2fa 3(1.School of Materials and Metallurgy ,Northeastern University ,Shenyang 110004,Liaoning ,China ; 2.Departmentof Material Research ,Panzhihua Iron and Steel Research Institute ,Panzhihua 617000,Sichuan ,China ;3.Department of Mechanical Engineering ,Tsinghua University ,Beijing 100084,China )Abstract :A thermo 2mechanical finite element model was established to analyze the heat transfer f rom mold to strand and stress distribution in strand based on the air gap resistance between solidified shell and mold by considering the influence of the mold flux on the thermal resistance among the strand ,the flux film and the mold.The calculated strand shell thicknesses agreed well with the measured with a difference within 2mm.The heat transfer in the mold and stress distribution in the bloom at different casting speeds were obtained by using the model.It was shown that when the casting speed was increased f rom 0.7m/min to 0.9m/min ,the strand temperature became higher and the solidified shell thickness became thinner ,which increased the cracking risk near the strand corners.K ey w ords :continuous bloom casting ;mold ;heat transfer ;thermo 2mechanical deformation ;finite element method作者简介:陈 永(19692),男,博士生,教授级高级工程师; E 2m ail :chenyong880@yahoo 1com1cn ; 修订日期:2008205220 在连铸结晶器内,热2力学行为相互影响、相互作用。

铸件凝固过程数值模拟1.铸件凝固过程数值模拟作为铸造工艺过程计算机数值模拟的基础,温度场模拟技术的发展历程最长,技术也最成熟。

温度场模拟是建立在不稳定导热偏微分方程的基础上进行的。

考虑了传热过程的热传导、对流、辐射、结晶潜热等热行为。

所采用的计算方法主要有:有限差分法、有限元法、边界元法等;所采用的边界条件处理方法有N方程法、温度函数法、点热流法、综合热阻法和动态边界条件法;潜热处理方法有:温度回升法、热函法和固相率法。

自丹麦Forsound于1962年第一次采用电子计算机模拟铸件凝固过程以来,为铸造工作者科学地掌握与分析铸造工艺过程提出了新的方法与思路,在全世界范围内产生了积极的影响,许多国家的专家与学者陆续开展此项研究工作。

在铸造工艺过程中,铸件凝固过程温度场的数值模拟计算相对简单,因此,各国的专家与学者们均以铸件凝固过程的温度场数值模拟为研究起点。

继丹麦人之后,美国在60年代中期开始进行大型铸钢件温度场的计算机数值模拟计算研究,且模拟计算的结果与实测温度场吻合良好;进入70年代后,更多的国家加入了铸件凝固过程数值模拟的研究行列中,相继开展了有关研究与应用,理论研究与实际应用各具特色。

其中有代表性的研究人员有美国芝加哥大学的R.D.Pehlke教授、佐治亚工学院的J.Berry教授、日本日立研究所的新山英辅教授、大阪大学的大中逸雄教授、德国亚探工业大学的P.Sham教授和丹麦科技大学的P.N.Hansen教授等。

我国的铸件凝固过程温度场数值模拟研究始于70年代末期,沈阳铸造研究所的张毅高级工程师与大连工学院的金俊泽教授在我国率先开展了铸造工艺过程的计算机数值模拟研究工作,虽然起步较晚,但研究工作注重与生产实践密切结合,取得了较好的应用效果,形成了我国在这一研究领域的研究特色。

1988年5月,在美国佛罗里达州召开的第四届铸造和焊接计算机数值模拟会议上,共有来自10个研究单位的从事铸造凝固过程计算机数值模拟技术研究的专家和学者参加了会议组织的模拟斧锤型铸件凝固过程的现场比赛。

铸造过程数值模拟综合实验前言一、铸造过程数值模拟的来源、内容和意义为了生产出合格的铸件,就要对影响其形成的因素进行有效的控制。

铸件的形成主要经历了充型和凝固两个阶段,宏观上主要涉及到液态金属充型流动、金属凝固和冷却收缩、高温金属冷却和收缩3种物理现象。

在充型过程中,流场、温度场和浓度场同时变化,凝固时伴随着温度场的变化的同时存在着枝晶间对流和收缩现象;收缩则导致应力场的变化。

与流动相关的主要缺陷有:浇不足、冷隔、气孔、夹渣;充型中形成的温度场分布直接关系到后续的凝固冷却过程;充型中形成的浓度场分布与后续的冷却凝固形成的偏析和组织不均匀有关。

凝固过程的温度场变化及收缩是导致缩孔缩松的主要原因,枝晶间对流和枝晶收缩是微观缩松的直接原因,热裂冷裂的形成归因于应力场的变化。

可见,客观地反映不同阶段的场的变化,并加以有效的控制,是获得合格铸件的充要条件。

传统的铸件生产因其不同于冷加工的特殊性,只能对铸件的形成过程进行粗糙的基于经验和一般理论基础上的控制,形成的控制系统——铸造工艺的局限性表现在:1)只是定性分析;2)要反复试制才能确定工艺。

铸造过程数值模拟的目的就是要对铸件形成过程各个阶段的场的变化进行数值解析以获得合理的铸件形成的控制参数,其内容主要包括温度场、流场、浓度场、应力场等的计算模拟。

二、铸造过程数值模拟原理铸造过程数值模拟技术的实质是对铸件成型系统(包括铸件—型芯—铸型等)进行几何上的有限离散,在物理模型的支持下,通过数值计算来分析铸造过程有关物理场的变化特点,并结合铸造缺陷的形成判据来预测铸件质量。

数值解法的一般步骤是:1)汇集给定问题的单值性条件,即研究对象的几何条件、物理条件、初始条件和边界条件等。

2)将物理过程所涉及的区域在空间上和时间上进行离散化处理。

3)建立内部节点(或单元)和边界节点(或单元)的数值方程。

4)选用适当的计算方法求解线性代数方程组。

5)编程计算。

其中,核心部分是数值方程的建立。